An Overview of Potential Applications of Environmentally Friendly Hybrid Polymeric Materials

Abstract

:1. Introduction

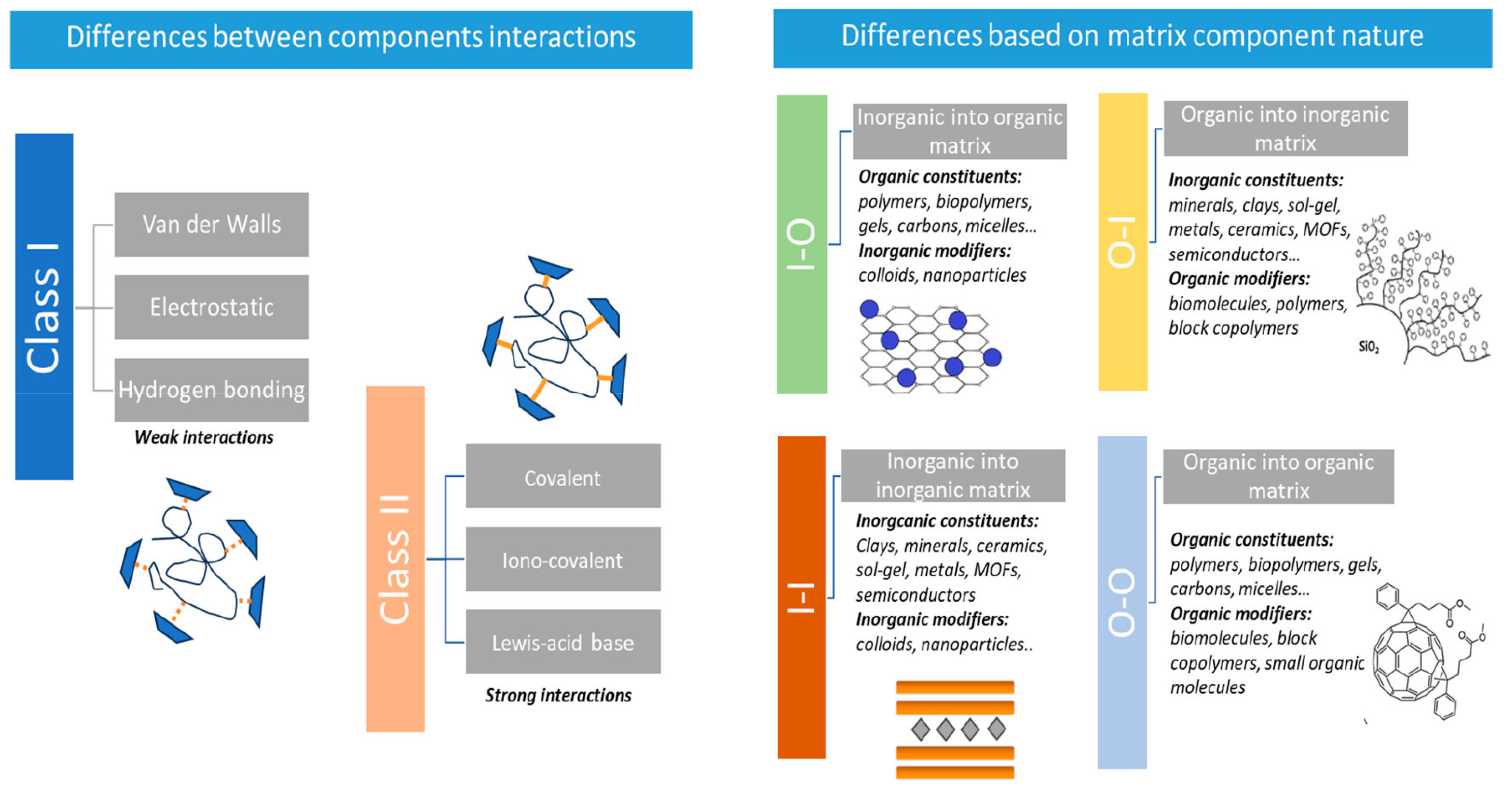

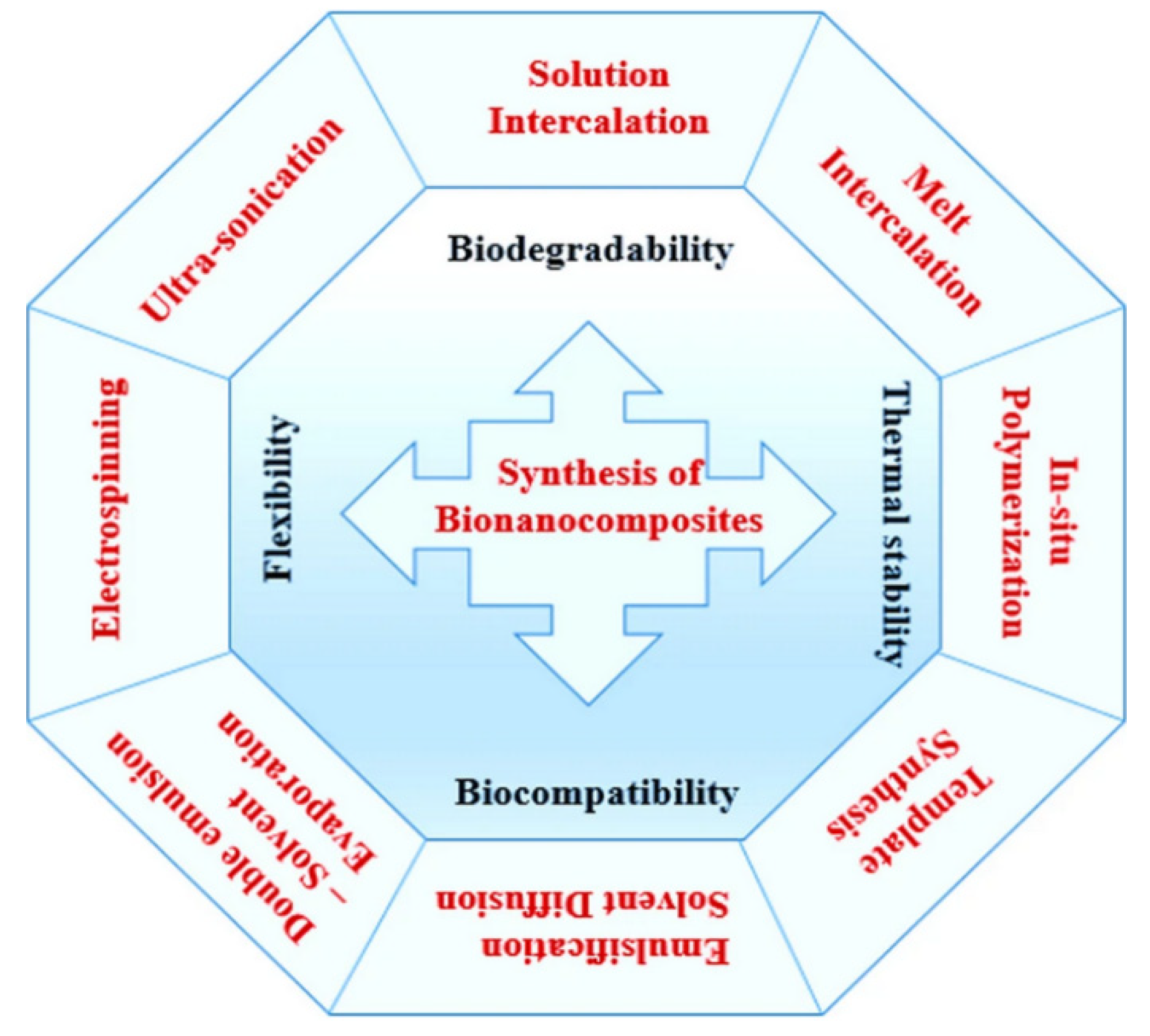

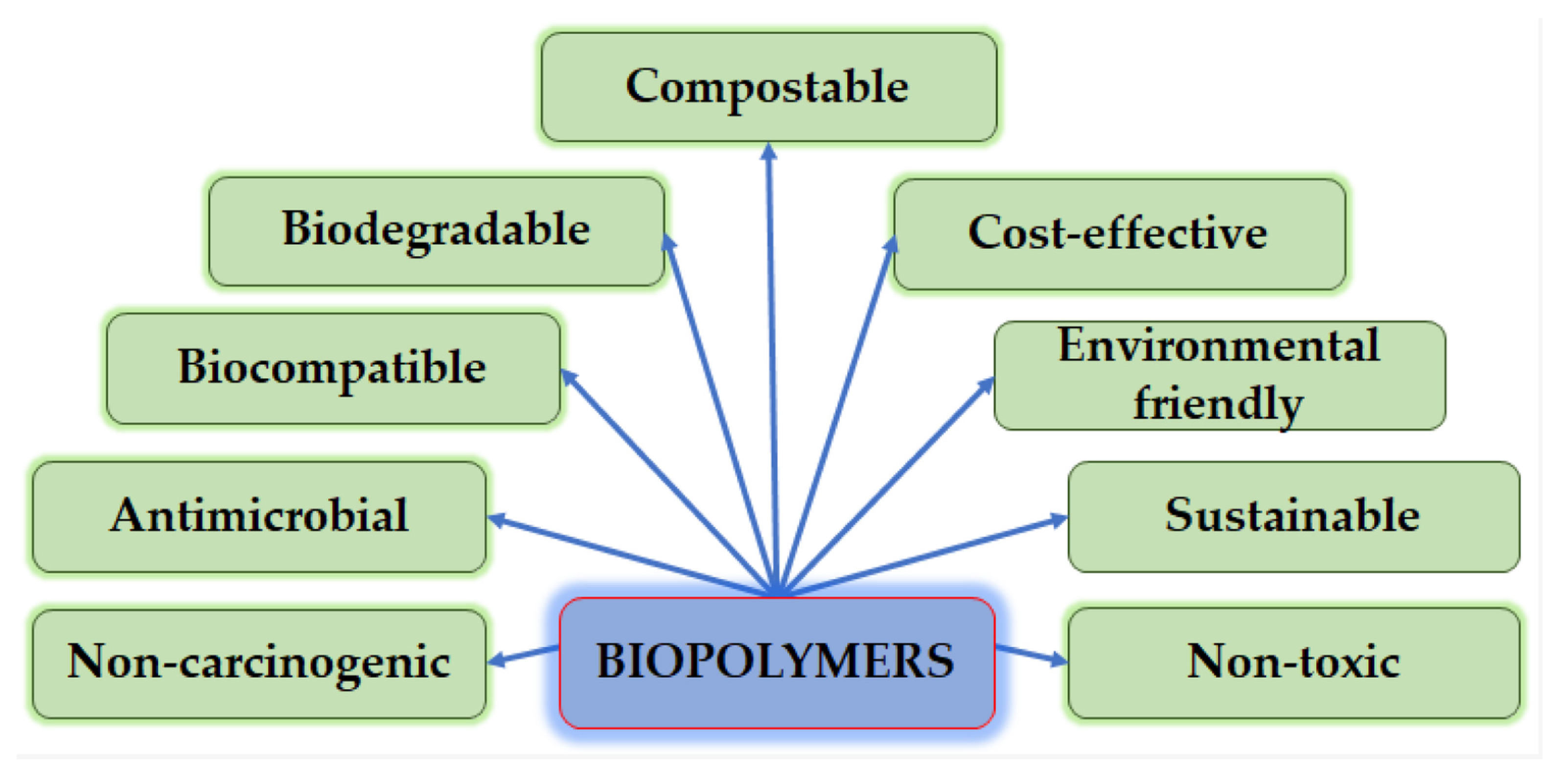

2. Definition and Types of Hybrid Polymeric Materials

- Composites: a blend of materials including matrix and micron-level dispersion.

- Nanocomposites: a sub-micron level mixture of similar kinds of materials.

- Hybrids: a sub-micron level mixture of different kinds of materials.

- Nanohybrids: an atomic or molecular level mixture of various materials with chemical bonds between their diverse materials.

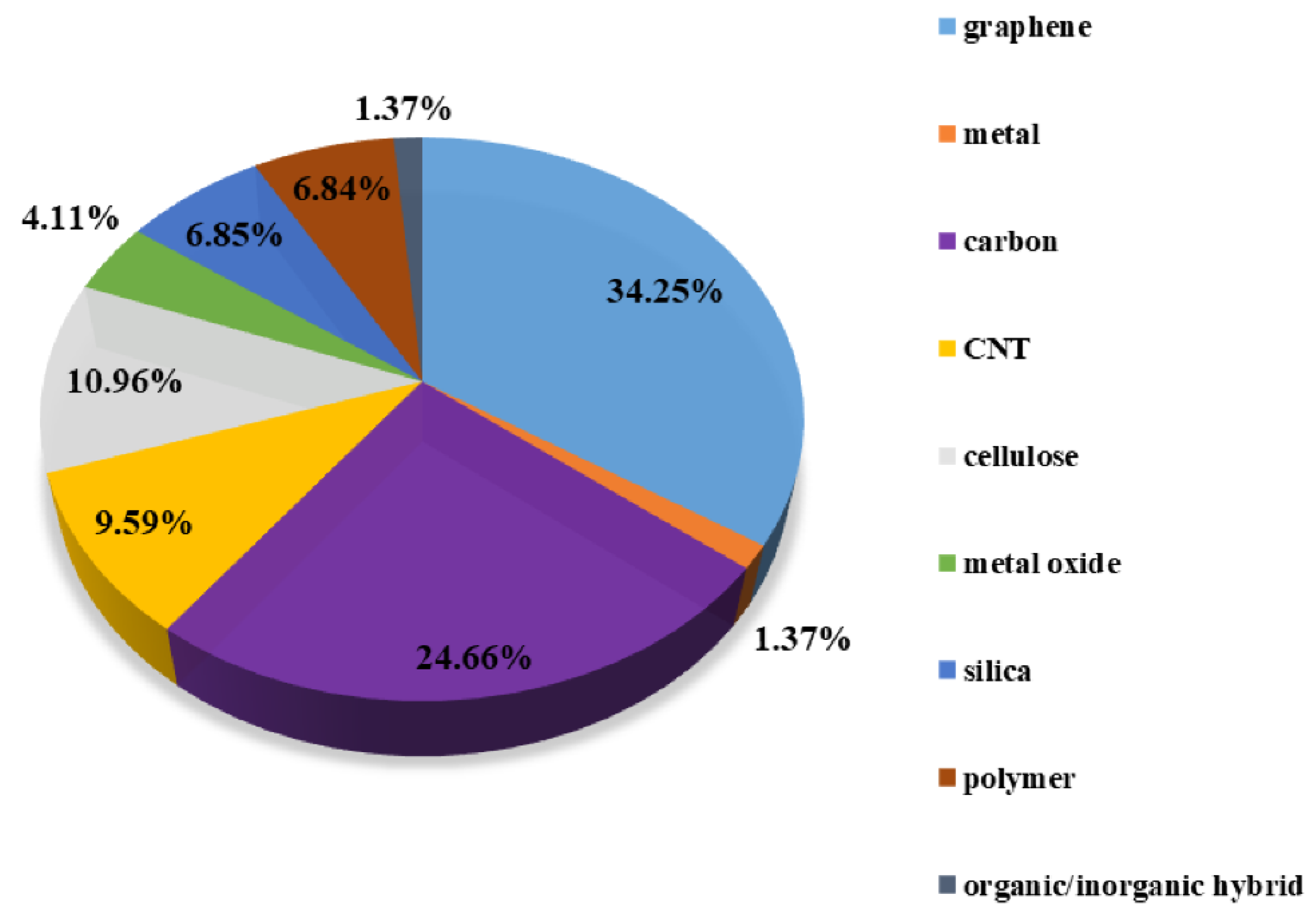

2.1. Hybrid Composites with Nano and Microparticles

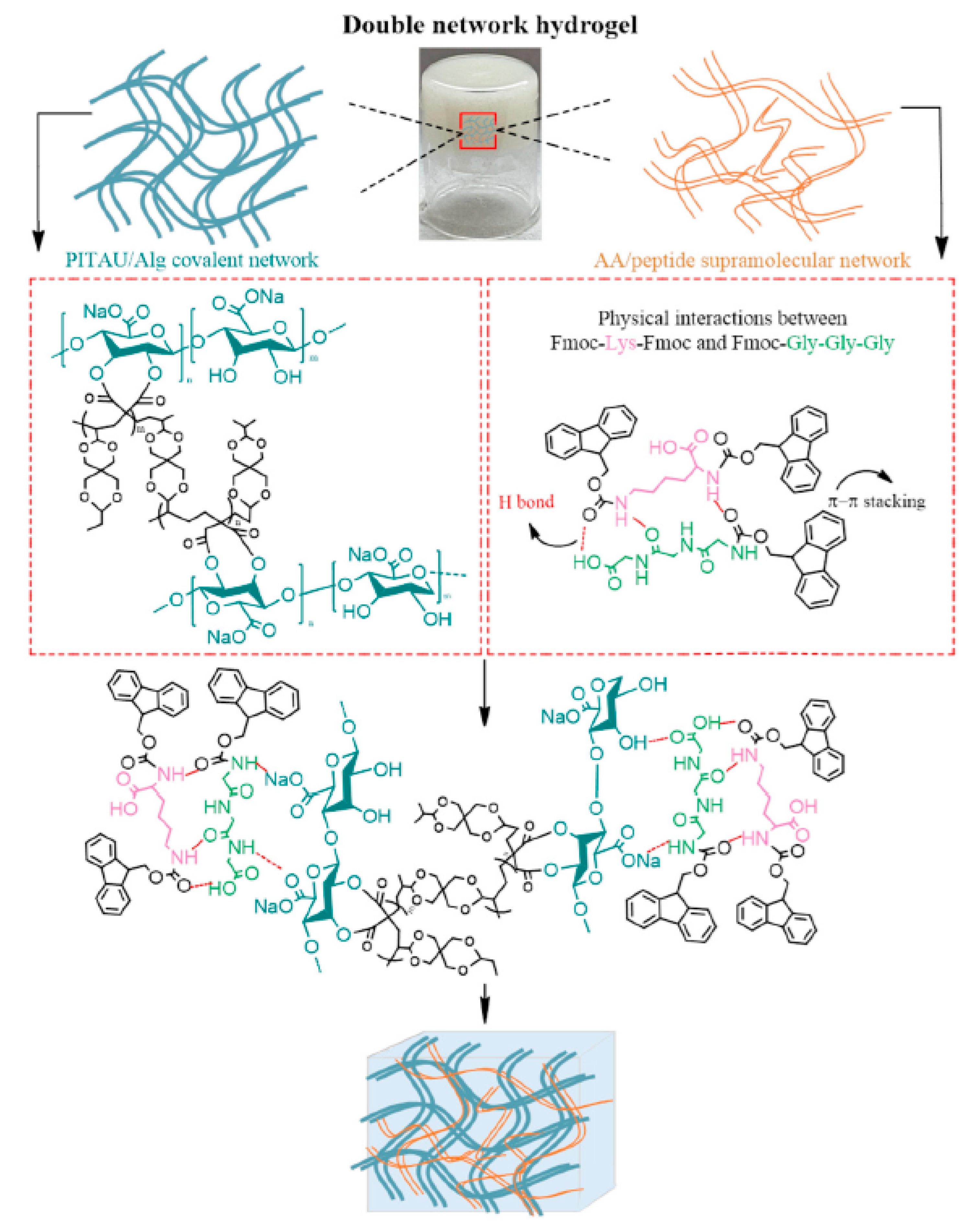

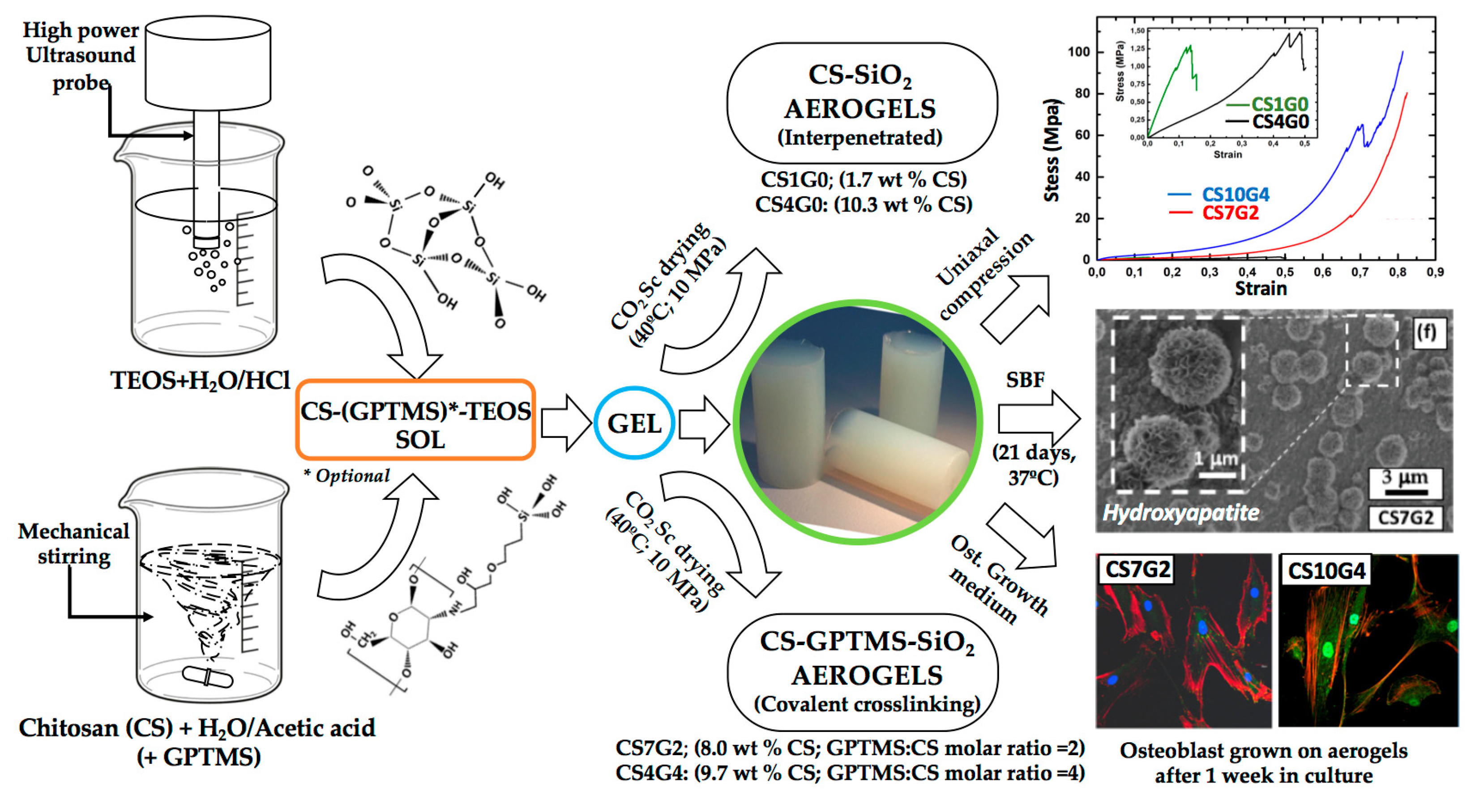

2.2. Aerogels and Hydrogels

2.3. Biohybrid Materials

2.4. Porous Structures

3. Packaging Applications

| Materials | Obtaining Method | Main Properties | Reference |

|---|---|---|---|

| Polyester-based hybrid materials | |||

| PLA/3 wt% nano-zinc oxide (ZnO NPs) and pomegranate peel extract (PEE) (0.5, 1, 1.5, and 2 wt%) | Solvent casting | higher UV barrier, water vapor permeability and elongation at break, lower tensile strength and transparency; addition of ZnO NPs and PEE hamper the development of S. aureus and E. coli. | [71] |

| PLA/(1, 2, 3, 4 wt%) Magnesium Oxide (MgO) nanoparticles (NP) bio/nanocomposites films | Solvent casting | uniform distribution of MgO NPs led to improved mechanical, antimicrobial, UV screening, and gas barrier properties | [72] |

| plasticized PLA/0.5, 1, and 1.5 wt% Cu doped ZnO functionalized with Ag NP | Melt blending | all materials showed overall migration into three food simulants < 10 mg·dm−2 (accepted value according to EU Regulation No 10/2011); PLA/ZnO:Cu/Ag 0.5 showed antibacterial activity, proper mechanical and thermal properties, good barrier properties to UV light, water vapor, oxygen, and carbon dioxide | [73] |

| PLA/thymol (6 and 8 wt%) and 1 wt% Ag-NPs | Twin screw melt Extrusion | ternary system PLA/1 wt% Ag-NPs/8 wt% thymol showed combined antioxidant and antibacterial performance, with controlled release of thymol | [74] |

| PLA/acetylated cellulose nanocrystals (ACNC) (1 wt%) and ZnO nanoparticles (1, 3, 5 and 7 wt%) | Solvent casting | surface acetylation of cellulose nanocrystals improved its dispersion in the PLA; improved UV blocking, mechanical strength, oxygen, and water vapor barrier; excellent antibacterial activity against E. coli and S. aureus; migration amounts of Zn2+ from PLA/ACNC/ZnO film to food simulants < the specific migration limit (5 mg/kg) | [75] |

| PBAT/PLA/CaCO3 70% polymer (where PBAT:PLA = 7:3), 30% CaCO3, and an additional 0.45% chain extender ADR | Twin screw melt extrusion | uniform dispersion of nano-CaCO3 in PBAT/PLA matrix through solid-state shear-milling (S3M) technology; film obtained by milling only PBAT and CaCO3 exhibited the best performance, with its longitudinal tensile strength of 22 MPa and fracture elongation of 437% | [76] |

| poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV)/0–1 wt% Fe doped ZnO nanoparticles (NPs) deposited onto PLA film | Electrospinning/electrospraying | “beads” morphology; migration in food simulants within the legislation limits; PLA/PHBV/ZnO: Fe0.3 electrospun nanosystem showed a remarkable antimicrobial effect against P. aeruginosa | [77] |

| Polysaccharide-based hybrid materials | |||

| starch/1%, 2%, and 3%, v/w cinnamon essential oil (CEO)/0%, 1%, 3%, and 5%, w/w TiO2 NPs | Solvent casting | TiO2-NPs improved functional properties of sago starch films activated by cinnamon EO; increasing TiO2-NP amount decreased barrier properties; Improved mechanical properties and antimicrobial activity against E. coli, S. typhimurium, and S. aureus; Potential active food packaging material for fresh pistachio | [78] |

| pullulan/chitin nanofibers (PCN) containing curcumin (CR) and anthocyanins (ATH) | Electrospinning | antioxidant and antimicrobial activities; color change with pH | [79] |

| pullulan/polyvinyl alcohol (PUL/PVA) nanofibers incorporated with thymol-loaded porphyrin metal-organic framework nanoparticles (THY@PCN-224 NPs) | PCN-224 synthesized via solvothermal method; encapsulation of thymol by physical adsorption method; THY@PCN/PUL/PVA nanofibers obtained by blending electrospinning | THY@PCN/PUL/PVA nanofibers showed synergistic antibacterial activities against E. coli (~99%) and S. aureus (~98%) under light irradiation. The cell viability assays and fruit preservation tests showed high film biosafety | [80] |

| bi-layer films incorporated with liposomes @anthocyanin/carrageenan/agar | Encapsulation/Layer-by-layer assembly (solution casting) | free anthocyanins and anthocyanin-loaded liposomes were added to carrageenan as the sensor layer of the bi-layer films; agar—used as the outer protective layer; the films with liposomes—a positive effect on the stability of the indicator films in high-humidity environments but slightly decreased the pH and ammonia sensitivity; the bi-layer film can be used as an indicator of meat freshness (shrimps); the encapsulation of anthocyanins by liposomes delayed the sensitivity of the film | [81] |

| Protein-based hybrid materials | |||

| hybrid biofilms flaxseed mucilage (FSM), elastin/collagen (ELN/COL) matrix, and silk sericin (SS) | Solvent casting | SS addition increased the biofilm thickness (0.14–0.30 mm), opacity (7.02–8.51 mm−1), and the tensile strength (4.90–15.55 MPa) while reducing the values of moisture content (24.15–16.66%), water solubility (84.21–41.66%) and elongation at break (177.19–46.58%); enhanced thermal; in vitro antibacterial activity against S. aureus, S. pyogen, E. coli, and P. aeruginosa | [82] |

| flaxseed mucilage/pectin impregnated with titanium dioxide and calcium chloride | Solvent casting | addition of 5 wt% TiO2 enhanced UV barrier property and increased its crystallinity (from 43.6%. to 54.1%); crosslinking agent and TiO2 resulted in a prolonged period of biodegradation of >21 days when compared to neat film; no surface cracks and agglomerates observed; the film with 1 wt% TiO2 and 5 wt% CaCl2 could be used as fully biodegradable sandwich layer in dry food or medium water activity food requiring light protection | [69] |

| soy protein/cellulose nanocrystals (CNCs) and Cedrus deodara pine needle extract (PNE) (2.5, 5, 10%, w/w, based on the dry weight of SPI) films | Solvent casting | addition of CNCs decreased the moisture content of the films by disrupting the hydrogen bonds between N-H groups of soy proteins and water molecules; decrease in elongation at break, increase in tensile strength; 5–10% PNE led to a decrease in water vapor permeability; phenolic compounds from the PNE-added films conferred strong antioxidant activities | [83] |

| whey protein isolate (WPI)/chitosan nanofiber (CSNF) (3–6% based on the dry weight of WPI)/nano-formulated cinnamon oil (CiEO) (both emulsified and Nanostructured lipid carriers (NLC) form) | CiEO-loaded NLCs prepared by the hot homogenization sonication method; Bio-nanocomposite films—solution casting | homogenous distribution of CSNF improved mechanical properties and water vapor permeability; addition of CiEO led to a decrease in the water content, water solubility, and a slight increase in the water vapor permeability of the films; plasticizing effect of emulsified and NLC form of CiEO on the WPI-chitosan nanofiber film | [84] |

| hybrid films comprised of both wheat gluten and wool keratin proteins | tyrosine-mediated photo-crosslinking method; 3D printing | neutron scattering showed the presence of both hydrophobic and hydrophilic nanodomains, gliadin nanoclusters, and interconnected micropores in the matrix; increase in keratin amount led to softer hybrid films, consistent reduction in water resistivity, increased micropore size (from 1.2 to 2.2 µm), and hydrolytic degradability; 10-layer 3D-printed film showed over 92% accuracy | [85] |

4. Medical Applications

5. Sensors

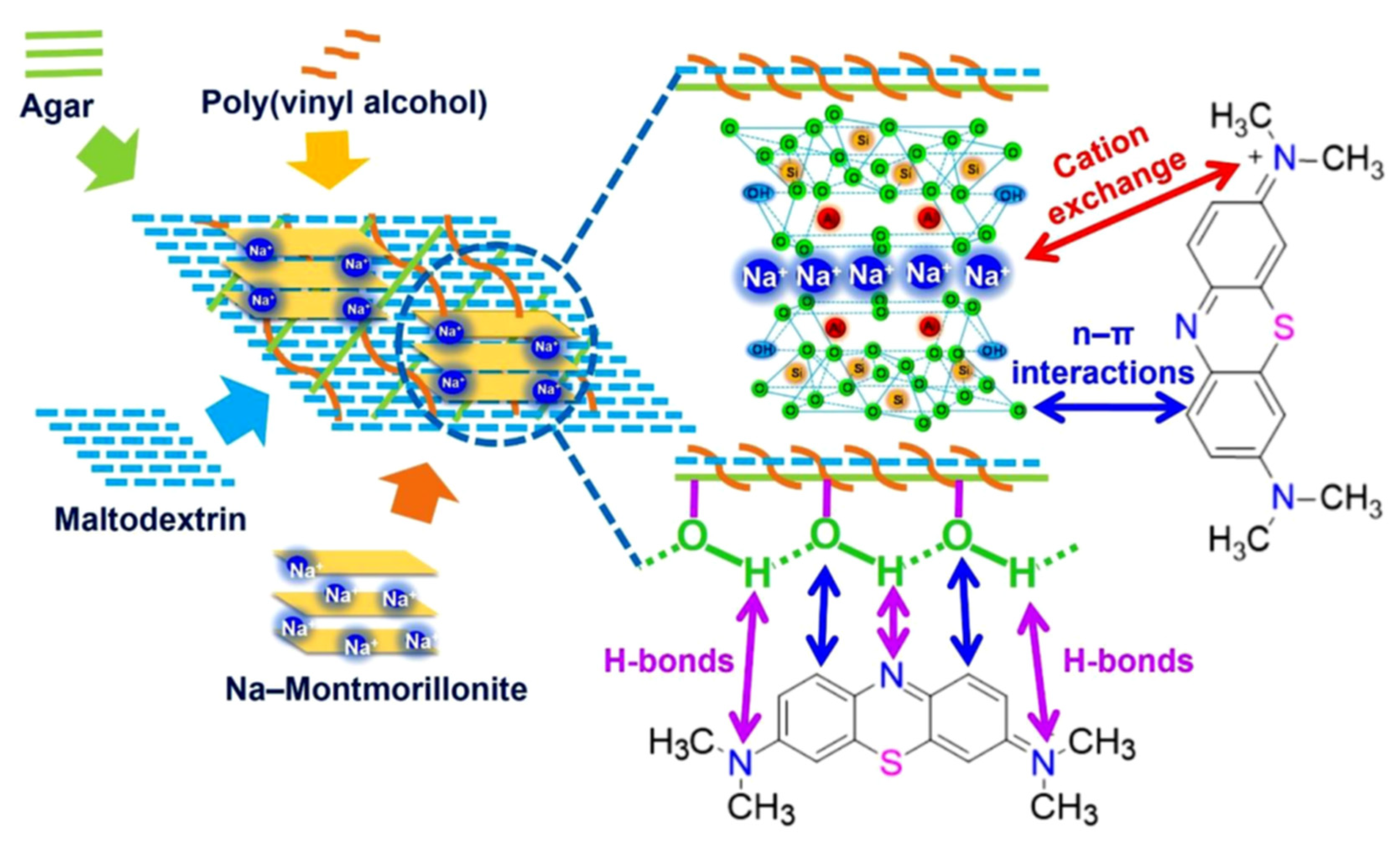

6. Water Purification

7. Electromagnetic Interference (EMI) Shielding

8. Conclusions and Future Challenges

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hybrid Polymer Market Size 2024–2032, Global Analysis Report. Available online: https://www.gminsights.com/industry-analysis/hybrid-polymer-market (accessed on 21 December 2024).

- Feroz, S.; Muhammad, N.; Ratnayake, J.; Dias, G. Keratin—Based Materials for Biomedical Applications. Bioact. Mater. 2020, 5, 496–509. [Google Scholar] [CrossRef] [PubMed]

- Talan, A.; Tiwari, B.; Yadav, B.; Tyagi, R.D.; Wong, J.W.C.; Drogui, P. Food Waste Valorization: Energy Production Using Novel Integrated Systems. Bioresour. Technol. 2021, 322, 124538. [Google Scholar] [CrossRef] [PubMed]

- Abdelhamid, M.A.A.; Khalifa, H.O.; Ki, M.-R.; Pack, S.P. Nanoengineered Silica-Based Biomaterials for Regenerative Medicine. Int. J. Mol. Sci. 2024, 25, 6125. [Google Scholar] [CrossRef] [PubMed]

- Lebeau, B.; Innocenzi, P. Hybrid Materials for Optics and Photonics. Chem. Soc. Rev. 2011, 40, 886–906. [Google Scholar] [CrossRef] [PubMed]

- Gomez-Romero, P.; Pokhriyal, A.; Rueda-García, D.; Bengoa, L.N.; González-Gil, R.M. Hybrid Materials: A Metareview. Chem. Mater. Publ. Am. Chem. Soc. 2024, 36, 8–27. [Google Scholar] [CrossRef]

- Das, P.P.; Chaudhary, V.; Singh, R.; Singh, D.; Bachchan, A.A. Advancement in Hybrid Materials, Its Applications and Future Challenges: A Review. Mater. Today Proc. 2021, 47, 3794–3801. [Google Scholar] [CrossRef]

- Shamsuyeva, M.; Hansen, O.; Endres, H.-J. Review on Hybrid Carbon/Flax Composites and Their Properties. Int. J. Polym. Sci. 2019, 2019, 9624670. [Google Scholar] [CrossRef]

- Makishima, A. Possibility of Hybrids Materials. Ceram. Jpn. 2004, 39, 90–91. [Google Scholar]

- Rejab, M.R.B.M.; Hamdan, M.H.B.M.; Quanjin, M.; Siregar, J.P.; Bachtiar, D.; Muchlis, Y. Historical Development of Hybrid Materials. In Encyclopedia of Renewable and Sustainable Materials; Hashmi, S., Choudhury, I.A., Eds.; Elsevier: Oxford, UK, 2020; pp. 445–455. ISBN 978-0-12-813196-1. [Google Scholar]

- De Oliveira Machado, V.; Leão Andrade, Â.; Fabris, J.D.; Freitas, E.T.F.; Maria da Fonte Ferreira, J.; Simon, A.; Domingues, R.Z.; Fernandez-Outon, L.E.; do Carmo, F.A.; Carlos dos Santos Souza, A.; et al. Preparation of Hybrid Nanocomposite Particles for Medical Practices. Colloids Surf. Physicochem. Eng. Asp. 2021, 624, 126706. [Google Scholar] [CrossRef]

- Kuperkar, K.; Atanase, L.I.; Bahadur, A.; Crivei, I.C.; Bahadur, P. Degradable Polymeric Bio(Nano)Materials and Their Biomedical Applications: A Comprehensive Overview and Recent Updates. Polymers 2024, 16, 206. [Google Scholar] [CrossRef]

- Rehman, M.; Yanen, W.; Mushtaq, R.T.; Ishfaq, K.; Zahoor, S.; Ahmed, A.; Kumar, M.S.; Gueyee, T.; Rahman, M.M.; Sultana, J. Additive Manufacturing for Biomedical Applications: A Review on Classification, Energy Consumption, and Its Appreciable Role since COVID-19 Pandemic. Prog. Addit. Manuf. 2023, 8, 1007–1041. [Google Scholar] [CrossRef] [PubMed]

- Abadi, B.; Goshtasbi, N.; Bolourian, S.; Tahsili, J.; Adeli-Sardou, M.; Forootanfar, H. Electrospun Hybrid Nanofibers: Fabrication, Characterization, and Biomedical Applications. Front. Bioeng. Biotechnol. 2022, 10, 986975. [Google Scholar] [CrossRef] [PubMed]

- Salehipour, M.; Rezaei, S.; Haddad, R.; Mogharabi-Manzari, M. Preparation of Electrospun Hybrid Polyacrylonitrile Nanofibers Containing TiO/FeO and Their Capsaicinoids Adsorption Applications. Vietnam J. Chem. 2022, 60, 267–280. [Google Scholar] [CrossRef]

- Zhang, Y.; Yin, C.; Cheng, Y.; Huang, X.; Liu, K.; Cheng, G.; Li, Z. Electrospinning Nanofiber-Reinforced Aerogels for the Treatment of Bone Defects. Adv. Wound Care 2020, 9, 441–452. [Google Scholar] [CrossRef] [PubMed]

- Nandhini, J.; Karthikeyan, E.; Rajeshkumar, S. Eco-Friendly Bio-Nanocomposites: Pioneering Sustainable Biomedical Advancements in Engineering. Discov. Nano 2024, 19, 86. [Google Scholar] [CrossRef]

- Sarıipek, F.B.; Sevgi, F.; Dursun, S. Preparation of Poly(ε-Caprolactone) Nanofibrous Mats Incorporating Graphene Oxide-Silver Nanoparticle Hybrid Composite by Electrospinning Method for Potential Antibacterial Applications. Colloids Surf. Physicochem. Eng. Asp. 2022, 653, 129969. [Google Scholar] [CrossRef]

- Kazemzadeh, G.; Jirofti, N.; Mohebbi-Kalhori, D.; Sarhaddi, F.; Taheri, R. Pathological Examination of Blended and Co-Electrospinning Hybrid Polycaprolactone/Polyurethane Nanofibers for Soft Tissue Engineering Applications. J. Ind. Text. 2022, 51, 6816S–6837S. [Google Scholar] [CrossRef]

- Neto, J.C.d.M.; Nascimento, N.R.D.; Bello, R.H.; de Verçosa, L.A.; Neto, J.E.; da Costa, J.C.M.; Diaz, F.R.V.; Rol, F.; Diaz, o.V. Kaolinite Review: Intercalation and Production of Polymer Nanocomposites. Eng. Sci. 2021, 17, 28–44. [Google Scholar] [CrossRef]

- Stephen, C.; Shivamurthy, B.; Mohan, M.; Mourad, A.-H.I.; Selvam, R.; Thimmappa, B.H.S. Low Velocity Impact Behavior of Fabric Reinforced Polymer Composites—A Review. Eng. Sci. 2022, 18, 75–97. [Google Scholar] [CrossRef]

- Scaffaro, R.; Gammino, M.; Maio, A. Wet Electrospinning-Aided Self-Assembly of Multifunctional GO-CNT@PCL Core-Shell Nanocomposites with Spider Leg Bioinspired Hierarchical Architectures. Compos. Sci. Technol. 2022, 221, 109363. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A. Integrated Ternary Bionanocomposites with Superior Mechanical Performance via the Synergistic Role of Graphene and Plasma Treated Carbon Nanotubes. Compos. Part B Eng. 2019, 168, 550–559. [Google Scholar] [CrossRef]

- Priyadarshi, R.; Kim, S.-M.; Rhim, J.-W. Pectin/Pullulan Blend Films for Food Packaging: Effect of Blending Ratio. Food Chem. 2021, 347, 129022. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.; Rhim, J.-W. Preparation of Pectin/Agar-Based Functional Films Integrated with Zinc Sulfide Nano Petals for Active Packaging Applications. Colloids Surf. B Biointerfaces 2021, 207, 111999. [Google Scholar] [CrossRef] [PubMed]

- Dash, K.K.; Ali, N.A.; Das, D.; Mohanta, D. Thorough Evaluation of Sweet Potato Starch and Lemon-Waste Pectin Based-Edible Films with Nano-Titania Inclusions for Food Packaging Applications. Int. J. Biol. Macromol. 2019, 139, 449–458. [Google Scholar] [CrossRef]

- Jawaid, M.; Qaiss, A.E.K.; Bouhfid, R. (Eds.) Nanoclay Reinforced Polymer Composites: Nanocomposites and Bionanocomposites; Engineering Materials; Springer: Singapore, 2016; ISBN 978-981-10-1952-4. [Google Scholar]

- Wang, J.; Sun, K.; Hao, W.; Du, Y.; Pan, C. Structure and Properties Research on Montmorillonite Modified by Flame-Retardant Dendrimer. Appl. Clay Sci. 2014, 90, 109–121. [Google Scholar] [CrossRef]

- Zauro, S.A.; Vishalakshi, B. Amphoteric Gellan Gum-Based Terpolymer-Montmorillonite Composite: Synthesis, Swelling, and Dye Adsorption Studies. Int. J. Ind. Chem. 2017, 8, 345–362. [Google Scholar] [CrossRef]

- De Menezes, L.R.; da Silva, E.O. The Use of Montmorillonite Clays as Reinforcing Fillers for Dental Adhesives. Mater. Res. 2016, 19, 236–242. [Google Scholar] [CrossRef]

- Fang, X.; Zhang, Z.; Chen, Z. Study on Preparation of Montmorillonite-Based Composite Phase Change Materials and Their Applications in Thermal Storage Building Materials. Energy Convers. Manag. 2008, 49, 718–723. [Google Scholar] [CrossRef]

- Ul-Islam, M.; Khan, T.; Park, J.K. Nanoreinforced Bacterial Cellulose-Montmorillonite Composites for Biomedical Applications. Carbohydr. Polym. 2012, 89, 1189–1197. [Google Scholar] [CrossRef]

- Ogunsola, S.S.; Oladipo, M.E.; Oladoye, P.O.; Kadhom, M. Carbon Nanotubes for Sustainable Environmental Remediation: A Critical and Comprehensive Review. Nano-Struct. Nano-Objects 2024, 37, 101099. [Google Scholar] [CrossRef]

- Kistler, S.S. Coherent Expanded Aerogels and Jellies. Nature 1931, 127, 741. [Google Scholar] [CrossRef]

- Xia, Y.; Gao, C.; Gao, W. A Review on Elastic Graphene Aerogels: Design, Preparation, and Applications. J. Polym. Sci. 2022, 60, 2239–2261. [Google Scholar] [CrossRef]

- Jing, J.; Qian, X.; Si, Y.; Liu, G.; Shi, C. Recent Advances in the Synthesis and Application of Three-Dimensional Graphene-Based Aerogels. Molecules 2022, 27, 924. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Zhou, L.; Chen, L.; Duan, G.; Mei, C.; Huang, C.; Han, J.; Jiang, S. Anisotropic Nanocellulose Aerogels with Ordered Structures Fabricated by Directional Freeze-Drying for Fast Liquid Transport. Cellulose 2019, 26, 6653–6667. [Google Scholar] [CrossRef]

- Członka, S.; Bertino, M.F.; Kośny, J.; Shukla, N. Freeze-Drying Method as a New Approach to the Synthesis of Polyurea Aerogels from Isocyanate and Water. J. Sol-Gel Sci. Technol. 2018, 87, 685–695. [Google Scholar] [CrossRef]

- Xiao, H.; Zhao, X.; Lv, J.; He, X.; Chen, M.; Tan, W.; Yang, W.; Zeng, K.; Hu, J.; Yang, G. Ultrasound-Assisted Freeze-Drying Strategy to Enhance Nanoparticle Dispersion in Aerogels: A Case Study on Polyimide/Silica Nanocomposite Aerogel. Polym. Eng. Sci. 2023, 63, 3819–3830. [Google Scholar] [CrossRef]

- Cheng, G.; Xie, C.; Cheng, Y.; Gong, C.; Li, Z.; Dong, X.; Deng, H.; Li, Z. Enhanced Mineralization of the Nanofibers-Incorporated Aerogels Increases Mechanical Properties of Scaffold and Promotes Bone Formation. Mater. Today Adv. 2022, 16, 100318. [Google Scholar] [CrossRef]

- Pantić, M.; Nowak, M.; Lavrič, G.; Knez, Ž.; Novak, Z.; Zizovic, I. Enhancing the Properties and Morphology of Starch Aerogels with Nanocellulose. Food Hydrocoll. 2024, 156, 110345. [Google Scholar] [CrossRef]

- Nita, L.E.; Ghilan, A.; Rusu, A.G.; Neamtu, I.; Chiriac, A.P. New Trends in Bio-Based Aerogels. Pharmaceutics 2020, 12, 449. [Google Scholar] [CrossRef]

- Bao, Y.; He, J.; Song, K.; Guo, J.; Zhou, X.; Liu, S. Functionalization and Antibacterial Applications of Cellulose-Based Composite Hydrogels. Polymers 2022, 14, 769. [Google Scholar] [CrossRef]

- Mehta, P.; Sharma, M.; Devi, M. Hydrogels: An Overview of Its Classifications, Properties, and Applications. J. Mech. Behav. Biomed. Mater. 2023, 147, 106145. [Google Scholar] [CrossRef] [PubMed]

- Muhammad, G.; Iqbal, M.M.; Shahid, M.; Ashraf, R.S.; Altaf, M.; Hussain, M.A.; Raza, M.A. Chapter 3—Purification of Water by the Use of Hydrogels. In Green Sustainable Process for Chemical and Environmental Engineering and Science; Inamuddin, Altalhi, T., Mazumder, M.A.J., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 69–112. ISBN 978-0-443-18746-9. [Google Scholar]

- Luca, A.; Nacu, I.; Tanasache, S.; Peptu, C.A.; Butnaru, M.; Verestiuc, L. New Methacrylated Biopolymer-Based Hydrogels as Localized Drug Delivery Systems in Skin Cancer Therapy. Gels 2023, 9, 371. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, L.; Armstrong, J.P.K.; Salmeron-Sanchez, M.; Stevens, M.M. Assembling Living Building Blocks to Engineer Complex Tissues. Adv. Funct. Mater. 2020, 30, 1909009. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Zhang, Z.; Wang, J.; Wang, Q.; Shang, L. Biohybrid Materials: Structure Design and Biomedical Applications. Mater. Today Bio 2022, 16, 100352. [Google Scholar] [CrossRef]

- González, A.; Sabio, L.; Hurtado, C.; Ramírez-Rodríguez, G.B.; Bansal, V.; Delgado-López, J.M.; Dominguez-Vera, J.M. Entrapping Living Probiotics into Collagen Scaffolds: A New Class of Biomaterials for Antibiotic-Free Therapy of Bacterial Vaginosis. Adv. Mater. Technol. 2020, 5, 2000137. [Google Scholar] [CrossRef]

- Jacques, E.; Hosoyama, K.; Biniam, B.; Eren Cimenci, C.; Sedlakova, V.; Steeves, A.J.; Variola, F.; Davis, D.R.; Stewart, D.J.; Suuronen, E.J.; et al. Collagen-Based Microcapsules As Therapeutic Materials for Stem Cell Therapies in Infarcted Myocardium. ACS Biomater. Sci. Eng. 2020, 6, 4614–4622. [Google Scholar] [CrossRef]

- Wang, X.; Yu, Y.; Yang, C.; Shao, C.; Shi, K.; Shang, L.; Ye, F.; Zhao, Y. Microfluidic 3D Printing Responsive Scaffolds with Biomimetic Enrichment Channels for Bone Regeneration. Adv. Funct. Mater. 2022, 32, 2111909. [Google Scholar] [CrossRef]

- Juthi, A.Z.; Li, F.; Wang, B.; Alam, M.M.; Talukder, M.E.; Qiu, B. pH-Responsive Super-Porous Hybrid Hydrogels for Gastroretentive Controlled-Release Drug Delivery. Pharmaceutics 2023, 15, 816. [Google Scholar] [CrossRef]

- Shin, Y.; Chang, J.H.; Liu, J.; Williford, R.; Shin, Y.-K.; Exarhos, G.J. Hybrid Nanogels for Sustainable Positive Thermosensitive Drug Release. J. Control. Release 2001, 73, 1–6. [Google Scholar] [CrossRef]

- Voicu, A.I.; Gȃrea, S.A.; Vasile, E.; Ghebaur, A.; Iovu, H. Hybrid Hosts Based on Sodium Alginate and Porous Clay Heterostructures for Drug Encapsulation. Polymers 2021, 13, 2803. [Google Scholar] [CrossRef]

- Chlanda, A.; Oberbek, P.; Heljak, M.; Kijeńska-Gawrońska, E.; Bolek, T.; Gloc, M.; John, Ł.; Janeta, M.; Woźniak, M.J. Fabrication, Multi-Scale Characterization and in-Vitro Evaluation of Porous Hybrid Bioactive Glass Polymer-Coated Scaffolds for Bone Tissue Engineering. Mater. Sci. Eng. C 2019, 94, 516–523. [Google Scholar] [CrossRef] [PubMed]

- El-Bahrawy, N.R.; Elgharbawy, H.; Elmekawy, A.; Salem, M.; Morsy, R. Development of Porous Hydroxyapatite/PVA/Gelatin/Alginate Hybrid Flexible Scaffolds with Improved Mechanical Properties for Bone Tissue Engineering. Mater. Chem. Phys. 2024, 319, 129332. [Google Scholar] [CrossRef]

- Eviana Putri, N.R.; Wang, X.; Chen, Y.; Li, X.; Kawazoe, N.; Chen, G. Preparation of PLGA-Collagen Hybrid Scaffolds with Controlled Pore Structures for Cartilage Tissue Engineering. Prog. Nat. Sci. Mater. Int. 2020, 30, 642–650. [Google Scholar] [CrossRef]

- Shirosaki, Y.; Furuse, M.; Asano, T.; Kinoshita, Y.; Kuroiwa, T. Skull Bone Regeneration Using Chitosan-Siloxane Porous Hybrids—Long-Term Implantation. Pharmaceutics 2018, 10, 70. [Google Scholar] [CrossRef]

- Allijn, I.; du Preez, N.; Tasior, M.; Bansal, R.; Stamatialis, D. One-Step Fabrication of Porous Membrane-Based Scaffolds by Air-Water Interfacial Phase Separation: Opportunities for Engineered Tissues. Membranes 2022, 12, 453. [Google Scholar] [CrossRef]

- Zeinali, R.; del Valle, L.J.; Torras, J.; Puiggalí, J. Recent Progress on Biodegradable Tissue Engineering Scaffolds Prepared by Thermally-Induced Phase Separation (TIPS). Int. J. Mol. Sci. 2021, 22, 3504. [Google Scholar] [CrossRef]

- Bianchi, E.; Ruggeri, M.; Vigani, B.; Totaro Fila, C.; Icaro Cornaglia, A.; Boselli, C.; Viseras, C.; Rossi, S.; Sandri, G. Gas Foamed Scaffolds as Smart 3D Structures in Skin Tissue Engineering. J. Drug Deliv. Sci. Technol. 2024, 95, 105541. [Google Scholar] [CrossRef]

- Ranganathan, N.; Mugeshwaran, A.; Joseph Bensingh, R.; Abdul Kader, M.; Nayak, S.K. Biopolymeric Scaffolds for Tissue Engineering Application. In Biomedical Engineering and Its Applications in Healthcare; Paul, S., Ed.; Springer: Singapore, 2019; pp. 249–274. ISBN 9789811337055. [Google Scholar]

- Reys, L.L.; Silva, S.S.; Pirraco, R.P.; Marques, A.P.; Mano, J.F.; Silva, T.H.; Reis, R.L. Influence of Freezing Temperature and Deacetylation Degree on the Performance of Freeze-Dried Chitosan Scaffolds towards Cartilage Tissue Engineering. Eur. Polym. J. 2017, 95, 232–240. [Google Scholar] [CrossRef]

- Calore, A.R.; Mota, C.; Bernaerts, K.; Harings, J.; Moroni, L. Melt-Extrusion Additive Manufacturing for Tissue Engineering: Applications and Limitations. 3D Print. Addit. Manuf. 2024, 11. [Google Scholar] [CrossRef]

- Lai, J.; Wang, M. Developments of Additive Manufacturing and 5D Printing in Tissue Engineering. J. Mater. Res. 2023, 38, 4692–4725. [Google Scholar] [CrossRef]

- Sodupe Ortega, E.; Sanz-Garcia, A.; Pernia-Espinoza, A.; Escobedo-Lucea, C. Efficient Fabrication of Polycaprolactone Scaffolds for Printing Hybrid Tissue-Engineered Constructs. Materials 2019, 12, 613. [Google Scholar] [CrossRef]

- Kankala, R.K.; Xu, X.-M.; Liu, C.-G.; Chen, A.-Z.; Wang, S.-B. 3D-Printing of Microfibrous Porous Scaffolds Based on Hybrid Approaches for Bone Tissue Engineering. Polymers 2018, 10, 807. [Google Scholar] [CrossRef] [PubMed]

- Horvat, G.; Žvab, K.; Knez, Ž.; Novak, Z. Hybrid Polylactic-Acid-Pectin Aerogels: Synthesis, Structural Properties, and Drug Release. Polymers 2023, 15, 407. [Google Scholar] [CrossRef] [PubMed]

- Akhila, K.; Ramakanth, D.; Rao, L.L.; Gaikwad, K.K. UV-Blocking Biodegradable Film Based on Flaxseed Mucilage/Pectin Impregnated with Titanium Dioxide and Calcium Chloride for Food Packaging Applications. Int. J. Biol. Macromol. 2023, 239, 124335. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Liu, R.; Han, J.; Ren, L.; Jiang, L. Protein-Based Packaging Films in Food: Developments, Applications, and Challenges. Gels 2024, 10, 418. [Google Scholar] [CrossRef] [PubMed]

- Dai, L.; Li, R.; Liang, Y.; Liu, Y.; Zhang, W.; Shi, S. Development of Pomegranate Peel Extract and Nano ZnO Co-Reinforced Polylactic Acid Film for Active Food Packaging. Membranes 2022, 12, 1108. [Google Scholar] [CrossRef]

- Swaroop, C.; Shukla, M. Nano-Magnesium Oxide Reinforced Polylactic Acid Biofilms for Food Packaging Applications. Int. J. Biol. Macromol. 2018, 113, 729–736. [Google Scholar] [CrossRef]

- Vasile, C.; Rapa, M.; Stefan, M.; Stan, M.; Macavei, S.; Darie-Nita, R.N.; Barbu-Tudoran, L.; Vodnar, D.C.; Popa, E.E.; Stefan, R.; et al. New PLA/ZnO:Cu/Ag Bionanocomposites for Food Packaging. Express Polym. Lett. 2017, 11, 531–544. [Google Scholar] [CrossRef]

- Ramos, M.; Beltran, A.; Fortunati, E.; Peltzer, M.A.; Cristofaro, F.; Visai, L.; Valente, A.J.M.; Jiménez, A.; Kenny, J.M.; Garrigós, M.C. Controlled Release of Thymol from Poly(Lactic Acid)-Based Silver Nanocomposite Films with Antibacterial and Antioxidant Activity. Antioxidants 2020, 9, 395. [Google Scholar] [CrossRef]

- Yu, F.; Fei, X.; He, Y.; Li, H. Poly(Lactic Acid)-Based Composite Film Reinforced with Acetylated Cellulose Nanocrystals and ZnO Nanoparticles for Active Food Packaging. Int. J. Biol. Macromol. 2021, 186, 770–779. [Google Scholar] [CrossRef]

- Jia, X.; Wen, Q.; Sun, Y.; Chen, Y.; Gao, D.; Ru, Y.; Chen, N. Preparation and Performance of PBAT/PLA/CaCO3 Composites via Solid-State Shear Milling Technology. Polymers 2024, 16, 2942. [Google Scholar] [CrossRef] [PubMed]

- Râpă, M.; Stefan, M.; Popa, P.A.; Toloman, D.; Leostean, C.; Borodi, G.; Vodnar, D.C.; Wrona, M.; Salafranca, J.; Nerín, C.; et al. Electrospun Nanosystems Based on PHBV and ZnO for Ecological Food Packaging. Polymers 2021, 13, 2123. [Google Scholar] [CrossRef] [PubMed]

- Arezoo, E.; Mohammadreza, E.; Maryam, M.; Abdorreza, M.N. The Synergistic Effects of Cinnamon Essential Oil and Nano TiO2 on Antimicrobial and Functional Properties of Sago Starch Films. Int. J. Biol. Macromol. 2020, 157, 743–751. [Google Scholar] [CrossRef] [PubMed]

- Duan, M.; Yu, S.; Sun, J.; Jiang, H.; Zhao, J.; Tong, C.; Hu, Y.; Pang, J.; Wu, C. Development and Characterization of Electrospun Nanofibers Based on Pullulan/Chitin Nanofibers Containing Curcumin and Anthocyanins for Active-Intelligent Food Packaging. Int. J. Biol. Macromol. 2021, 187, 332–340. [Google Scholar] [CrossRef] [PubMed]

- Min, T.; Sun, X.; Zhou, L.; Du, H.; Zhu, Z.; Wen, Y. Electrospun Pullulan/PVA Nanofibers Integrated with Thymol-Loaded Porphyrin Metal-Organic Framework for Antibacterial Food Packaging. Carbohydr. Polym. 2021, 270, 118391. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, Y.; Zhang, J.; Shi, J.; Liu, L.; Huang, X.; Song, W.; Li, Z.; Zou, X.; Povey, M. High-Stability Bi-Layer Films Incorporated with Liposomes @Anthocyanin/Carrageenan/Agar for Shrimp Freshness Monitoring. Foods 2023, 12, 732. [Google Scholar] [CrossRef]

- Hailu, G.T.; Alemea, M.T.; Lemessa, F. Development of Silk Sericin-Based Polysaccharide-Protein Hybrid Biofilms: Mechanical, Thermal, and Antibacterial Properties. Next Res. 2025, 2, 100097. [Google Scholar] [CrossRef]

- Yu, Z.; Sun, L.; Wang, W.; Zeng, W.; Mustapha, A.; Lin, M. Soy Protein-Based Films Incorporated with Cellulose Nanocrystals and Pine Needle Extract for Active Packaging. Ind. Crop. Prod. 2018, 112, 412–419. [Google Scholar] [CrossRef]

- Mohammadi, M.; Mirabzadeh, S.; Shahvalizadeh, R.; Hamishehkar, H. Development of Novel Active Packaging Films Based on Whey Protein Isolate Incorporated with Chitosan Nanofiber and Nano-Formulated Cinnamon Oil. Int. J. Biol. Macromol. 2020, 149, 11–20. [Google Scholar] [CrossRef]

- Alshehhi, J.R.M.H.; Wanasingha, N.; Balu, R.; Mata, J.; Shah, K.; Dutta, N.K.; Choudhury, N.R. 3D-Printable Sustainable Bioplastics from Gluten and Keratin. Gels 2024, 10, 136. [Google Scholar] [CrossRef]

- Darie-Niţă, R.N.; Vasile, C. Halloysite Containing Composites for Food Packaging Applications. In Composite Materials for Food Packaging; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2018; p. 462. [Google Scholar]

- Bumbudsanpharoke, N.; Ko, S. Nanoclays in Food and Beverage Packaging. J. Nanomater. 2019, 2019, 8927167. [Google Scholar] [CrossRef]

- Darie, R.N.; Pâslaru, E.; Sdrobis, A.; Pricope, G.M.; Hitruc, G.E.; Poiată, A.; Baklavaridis, A.; Vasile, C. Effect of Nanoclay Hydrophilicity on the Poly(Lactic Acid)/Clay Nanocomposites Properties. Ind. Eng. Chem. Res. 2014, 53, 7877–7890. [Google Scholar] [CrossRef]

- Kumar, L.; Deshmukh, R.K.; Hakim, L.; Gaikwad, K.K. Halloysite Nanotube as a Functional Material for Active Food Packaging Application: A Review. Food Bioprocess Technol. 2024, 17, 33–46. [Google Scholar] [CrossRef] [PubMed]

- Giannakas, A.E.; Salmas, C.E.; Moschovas, D.; Baikousi, M.; Kollia, E.; Tsigkou, V.; Karakassides, A.; Leontiou, A.; Kehayias, G.; Avgeropoulos, A.; et al. Nanocomposite Film Development Based on Chitosan/Polyvinyl Alcohol Using ZnO@Montmorillonite and ZnO@Halloysite Hybrid Nanostructures for Active Food Packaging Applications. Nanomaterials 2022, 12, 1843. [Google Scholar] [CrossRef]

- Abdullah, Z.W.; Dong, Y. Biodegradable and Water Resistant Poly(Vinyl) Alcohol (PVA)/Starch (ST)/Glycerol (GL)/Halloysite Nanotube (HNT) Nanocomposite Films for Sustainable Food Packaging. Front. Mater. 2019, 6, 58. [Google Scholar] [CrossRef]

- Stanley, J.; John, A.; Pušnik Črešnar, K.; Fras Zemljič, L.; Lambropoulou, D.A.; Bikiaris, D.N. Active Agents Incorporated in Polymeric Substrates to Enhance Antibacterial and Antioxidant Properties in Food Packaging Applications. Macromol 2023, 3, 1–27. [Google Scholar] [CrossRef]

- Li, Y.; Ying, Y.; Zhou, Y.; Ge, Y.; Yuan, C.; Wu, C.; Hu, Y. A pH-Indicating Intelligent Packaging Composed of Chitosan-Purple Potato Extractions Strength by Surface-Deacetylated Chitin Nanofibers. Int. J. Biol. Macromol. 2019, 127, 376–384. [Google Scholar] [CrossRef]

- Râpă, M.; Darie-Niță, R.N.; Coman, G. Valorization of Fruit and Vegetable Waste into Sustainable and Value-Added Materials. Waste 2024, 2, 258–278. [Google Scholar] [CrossRef]

- Samaniego-Aguilar, K.; Sánchez-Safont, E.; Rodríguez, A.; Marín, A.; Candal, M.V.; Cabedo, L.; Gamez-Perez, J. Valorization of Agricultural Waste Lignocellulosic Fibers for Poly(3-Hydroxybutyrate-Co-Valerate)-Based Composites in Short Shelf-Life Applications. Polymers 2023, 15, 4507. [Google Scholar] [CrossRef]

- Ezati, P.; Rhim, J.W.; Molaei, R.; Priyadarshi, R.; Roy, S.; Min, S.; Kim, Y.H.; Lee, S.G.; Han, S. Preparation and Characterization of B, S, and N-Doped Glucose Carbon Dots: Antibacterial, Antifungal, and Antioxidant Activity. Sustain. Mater. Technol. 2022, 32, e00397. [Google Scholar] [CrossRef]

- Li, Y.; Yang, J.; Sun, L.; Liu, B.; Li, H.; Peng, L. Crosslinked Fish Scale Gelatin/Alginate Dialdehyde Functional Films Incorporated with Carbon Dots Derived from Pomelo Peel Waste for Active Food Packaging. Int. J. Biol. Macromol. 2023, 253, 127290. [Google Scholar] [CrossRef] [PubMed]

- Kalendova, A.; Kupkova, J.; Urbaskova, M.; Merinska, D. Applications of Clays in Nanocomposites and Ceramics. Minerals 2024, 14, 93. [Google Scholar] [CrossRef]

- Madej-Kiełbik, L.; Gzyra-Jagieła, K.; Jóźwik-Pruska, J.; Dziuba, R.; Bednarowicz, A. Biopolymer Composites with Sensors for Environmental and Medical Applications. Materials 2022, 15, 7493. [Google Scholar] [CrossRef] [PubMed]

- Thadepalli, S. Review of Multifarious Applications of Polymers in Medical and Health Care Textiles. Mater. Today Proc. 2022, 55, 330–336. [Google Scholar] [CrossRef]

- Pratiwi, R.D.; Muttaqien, S.E.; Gustini, N.; Difa, N.S.; Syahputra, G.; Rosyidah, A. Eco-Friendly Synthesis of Chitosan and Its Medical Application: From Chitin Extraction to Nanoparticle Preparation. ADMET DMPK 2023, 11, 435–455. [Google Scholar] [CrossRef]

- Sayyed, M.I.; Al-Ghamdi, H.; Almuqrin, A.H.; Yasmin, S.; Elsafi, M. A Study on the Gamma Radiation Protection Effectiveness of Nano/Micro-MgO-Reinforced Novel Silicon Rubber for Medical Applications. Polymers 2022, 14, 2867. [Google Scholar] [CrossRef]

- Tang, S.; Shen, Y.; Jiang, L.; Zhang, Y. Surface Modification of Nano-Hydroxyapatite/Polymer Composite for Bone Tissue Repair Applications: A Review. Polymers 2024, 16, 1263. [Google Scholar] [CrossRef]

- Ahmed, K.K.; Tamer, M.A.; Ghareeb, M.M.; Salem, A.K. Recent Advances in Polymeric Implants. AAPS PharmSciTech 2019, 20, 300. [Google Scholar] [CrossRef]

- Jain, C.; Surabhi, P.; Marathe, K. Critical Review on the Developments in Polymer Composite Materials for Biomedical Implants. J. Biomater. Sci. Polym. Ed. 2023, 34, 893–917. [Google Scholar] [CrossRef]

- Pandey, A.; Sahoo, S. Progress on Medical Implant: A Review and Prospects. J. Bionic Eng. 2023, 20, 470–494. [Google Scholar] [CrossRef]

- Ranakoti, L.; Gangil, B.; Bhandari, P.; Singh, T.; Sharma, S.; Singh, J.; Singh, S. Promising Role of Polylactic Acid as an Ingenious Biomaterial in Scaffolds, Drug Delivery, Tissue Engineering, and Medical Implants: Research Developments, and Prospective Applications. Molecules 2023, 28, 485. [Google Scholar] [CrossRef] [PubMed]

- Opriș, O.; Mormile, C.; Lung, I.; Stegarescu, A.; Soran, M.-L.; Soran, A. An Overview of Biopolymers for Drug Delivery Applications. Appl. Sci. 2024, 14, 1383. [Google Scholar] [CrossRef]

- Dwivedi, R.; Kumar, S.; Pandey, R.; Mahajan, A.; Nandana, D.; Katti, D.S.; Mehrotra, D. Polycaprolactone as Biomaterial for Bone Scaffolds: Review of Literature. J. Oral Biol. Craniofacial Res. 2020, 10, 381–388. [Google Scholar] [CrossRef] [PubMed]

- Pantić, M.; Horvat, G.; Berk Bevc, M.; Knez, Ž.; Novak, Z. Design and Synthesis of Novel Polycaprolactone-Chitosan Based Scaffolds Using Supercritical Carbon Dioxide. J. CO2 Util. 2024, 80, 102697. [Google Scholar] [CrossRef]

- Deuber, F.; Mousavi, S.; Federer, L.; Adlhart, C. Amphiphilic Nanofiber-Based Aerogels for Selective Liquid Absorption from Electrospun Biopolymers. Adv. Mater. Interfaces 2017, 4, 1700065. [Google Scholar] [CrossRef]

- Merk, M.; Chirikian, O.; Adlhart, C. 3D PCL/Gelatin/Genipin Nanofiber Sponge as Scaffold for Regenerative Medicine. Materials 2021, 14, 2006. [Google Scholar] [CrossRef]

- Batista, M.P.; Gonçalves, V.S.S.; Gaspar, F.B.; Nogueira, I.D.; Matias, A.A.; Gurikov, P. Novel Alginate-Chitosan Aerogel Fibres for Potential Wound Healing Applications. Int. J. Biol. Macromol. 2020, 156, 773–782. [Google Scholar] [CrossRef]

- Chyzy, A.; Plonska-Brzezinska, M.E. Hydrogel Properties and Their Impact on Regenerative Medicine and Tissue Engineering. Molecules 2020, 25, 5795. [Google Scholar] [CrossRef]

- Meng, Y.; Lu, J.; Cheng, Y.; Li, Q.; Wang, H. Lignin-Based Hydrogels: A Review of Preparation, Properties, and Application. Int. J. Biol. Macromol. 2019, 135, 1006–1019. [Google Scholar] [CrossRef]

- Ciolacu, D.; Cazacu, G. New Green Hydrogels Based on Lignin. J. Nanosci. Nanotechnol. 2018, 18, 2811–2822. [Google Scholar] [CrossRef]

- Jaiswal, L.; Shankar, S.; Rhim, J.-W.; Hahm, D.-H. Lignin-Mediated Green Synthesis of AgNPs in Carrageenan Matrix for Wound Dressing Applications. Int. J. Biol. Macromol. 2020, 159, 859–869. [Google Scholar] [CrossRef] [PubMed]

- Eivazzadeh-Keihan, R.; Aliabadi, H.A.M.; Radinekiyan, F.; Sobhani, M.; Khalili, F.; Maleki, A.; Madanchi, H.; Mahdavi, M.; Shalan, A.E. Investigation of the Biological Activity, Mechanical Properties and Wound Healing Application of a Novel Scaffold Based on Lignin-Agarose Hydrogel and Silk Fibroin Embedded Zinc Chromite Nanoparticles. RSC Adv. 2021, 11, 17914–17923. [Google Scholar] [CrossRef] [PubMed]

- Nan, N.; Hu, W.; Wang, J. Lignin-Based Porous Biomaterials for Medical and Pharmaceutical Applications. Biomedicines 2022, 10, 747. [Google Scholar] [CrossRef] [PubMed]

- Ciolacu, D.E.; Nicu, R.; Suflet, D.M.; Rusu, D.; Darie-Nita, R.N.; Simionescu, N.; Cazacu, G.; Ciolacu, F. Multifunctional Hydrogels Based on Cellulose and Modified Lignin for Advanced Wounds Management. Pharmaceutics 2023, 15, 2588. [Google Scholar] [CrossRef]

- Ghilan, A.; Croitoriu, A.; Chiriac, A.P.; Nita, L.E.; Bercea, M.; Rusu, A.G. Injectable Networks Based on a Hybrid Synthetic/Natural Polymer Gel and Self-Assembling Peptides Functioning as Reinforcing Fillers. Polymers 2023, 15, 636. [Google Scholar] [CrossRef]

- Diaconu, A.; Chiriac, A.P.; Nita, L.E.; Tudorachi, N.; Neamtu, I.; Vasile, C.; Pinteala, M. Design and Synthesis of a New Polymer Network Containing Pendant Spiroacetal Moieties. Des. Monomers Polym. 2015, 18, 780–788. [Google Scholar] [CrossRef]

- Platon, I.-V.; Ghiorghita, C.-A.; Lazar, M.M.; Aprotosoaie, A.C.; Gradinaru, A.C.; Nacu, I.; Verestiuc, L.; Nicolescu, A.; Ciocarlan, N.; Dinu, M.V. Highly Compressible, Superabsorbent, and Biocompatible Hybrid Cryogel Constructs Comprising Functionalized Chitosan and St. John’s Wort Extract. Biomacromolecules 2024, 25, 5081–5097. [Google Scholar] [CrossRef]

- Mathew, S.A.; Arumainathan, S. Crosslinked Chitosan-Gelatin Biocompatible Nanocomposite as a Neuro Drug Carrier. ACS Omega 2022, 7, 18732–18744. [Google Scholar] [CrossRef]

- Filip, D.; Macocinschi, D.; Nica, S.L.; Asandulesa, M.; Condurache, B.; Stoleru, E.; Rata, D.M.; Bargan, A.; Zaltariov, M.-F. Hybrid Green Bionanocomposites Based on Chitosan/Starch/Gelatin and Metallic Nanoparticles for Biological Applications. Int. J. Biol. Macromol. 2023, 253, 127571. [Google Scholar] [CrossRef]

- Jarquin-Yáñez, K.; Rubio-Rosas, E.; Piñón-Zárate, G.; Castell-Rodríguez, A.; Poisot, M. Cellulose-Chitosan-Nanohydroxyapatite Hybrid Composites by One-Pot Synthesis for Biomedical Applications. Polymers 2021, 13, 1655. [Google Scholar] [CrossRef]

- Shuai, C.; Peng, B.; Liu, M.; Peng, S.; Feng, P. A Self-Assembled Montmorillonite-Carbon Nanotube Hybrid Nanoreinforcement for Poly-l-Lactic Acid Bone Scaffold. Mater. Today Adv. 2021, 11, 100158. [Google Scholar] [CrossRef]

- Darie-Niță, R.N.; Irimia, A.; Doroftei, F.; Stefan, L.M.; Iwanczuk, A.; Trusz, A. Bioactive and Physico-Chemical Assessment of Innovative Poly(Lactic Acid)-Based Biocomposites Containing Sage, Coconut Oil, and Modified Nanoclay. Int. J. Mol. Sci. 2023, 24, 3646. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Hsieh, M.-H.; Li, S.-H.; Wu, J.; Weisel, R.D.; Chang, Y.; Sung, H.-W.; Li, R.-K. A Conductive Cell-Delivery Construct as a Bioengineered Patch That Can Improve Electrical Propagation and Synchronize Cardiomyocyte Contraction for Heart Repair. J. Control. Release 2020, 320, 73–82. [Google Scholar] [CrossRef] [PubMed]

- Raman, R.; Bhaduri, B.; Mir, M.; Shkumatov, A.; Lee, M.K.; Popescu, G.; Kong, H.; Bashir, R. High-Resolution Projection Microstereolithography for Patterning of Neovasculature. Adv. Healthc. Mater. 2016, 5, 610–619. [Google Scholar] [CrossRef]

- Paltanea, G.; Manescu (Paltanea), V.; Antoniac, I.; Antoniac, A.; Nemoianu, I.V.; Robu, A.; Dura, H. A Review of Biomimetic and Biodegradable Magnetic Scaffolds for Bone Tissue Engineering and Oncology. Int. J. Mol. Sci. 2023, 24, 4312. [Google Scholar] [CrossRef]

- Tampieri, A.; Landi, E.; Valentini, F.; Sandri, M.; D’Alessandro, T.; Dediu, V.; Marcacci, M. A Conceptually New Type of Bio-Hybrid Scaffold for Bone Regeneration. Nanotechnology 2011, 22, 015104. [Google Scholar] [CrossRef]

- Bagheri, E.; Ansari, L.; Abnous, K.; Taghdisi, S.M.; Charbgoo, F.; Ramezani, M.; Alibolandi, M. Silica Based Hybrid Materials for Drug Delivery and Bioimaging. J. Control. Release 2018, 277, 57–76. [Google Scholar] [CrossRef]

- Vallet-Regí, M.; Colilla, M.; González, B. Medical Applications of Organic-Inorganic Hybrid Materials within the Field of Silica-Based Bioceramics. Chem. Soc. Rev. 2011, 40, 596–607. [Google Scholar] [CrossRef]

- Lázár, I.; Čelko, L.; Menelaou, M. Aerogel-Based Materials in Bone and Cartilage Tissue Engineering—A Review with Future Implications. Gels 2023, 9, 746. [Google Scholar] [CrossRef]

- Maleki, H.; Shahbazi, M.-A.; Montes, S.; Hosseini, S.H.; Eskandari, M.R.; Zaunschirm, S.; Verwanger, T.; Mathur, S.; Milow, B.; Krammer, B.; et al. Mechanically Strong Silica-Silk Fibroin Bioaerogel: A Hybrid Scaffold with Ordered Honeycomb Micromorphology and Multiscale Porosity for Bone Regeneration. ACS Appl. Mater. Interfaces 2019, 11, 17256–17269. [Google Scholar] [CrossRef]

- Pérez-Moreno, A.; Reyes-Peces, M.V.; Vilches-Pérez, J.I.; Fernández-Montesinos, R.; Pinaglia-Tobaruela, G.; Salido, M.; de la Rosa-Fox, N.; Piñero, M. Effect of Washing Treatment on the Textural Properties and Bioactivity of Silica/Chitosan/TCP Xerogels for Bone Regeneration. Int. J. Mol. Sci. 2021, 22, 8321. [Google Scholar] [CrossRef] [PubMed]

- Reyes-Peces, M.V.; Pérez-Moreno, A.; De-Los-Santos, D.M.; Mesa-Díaz, M.d.M.; Pinaglia-Tobaruela, G.; Vilches-Pérez, J.I.; Fernández-Montesinos, R.; Salido, M.; de la Rosa-Fox, N.; Piñero, M. Chitosan-GPTMS-Silica Hybrid Mesoporous Aerogels for Bone Tissue Engineering. Polymers 2020, 12, 2723. [Google Scholar] [CrossRef] [PubMed]

- Demeyer, S.; Athipornchai, A.; Pabunrueang, P.; Trakulsujaritchok, T. Development of Mangiferin Loaded Chitosan-Silica Hybrid Scaffolds: Physicochemical and Bioactivity Characterization. Carbohydr. Polym. 2021, 261, 117905. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Yang, S.; Ren, J.; Ling, S. Flame-Retardant and Sustainable Silk Ionotronic Skin for Fire Alarm Systems. ACS Mater. Lett. 2020, 2, 712–720. [Google Scholar] [CrossRef]

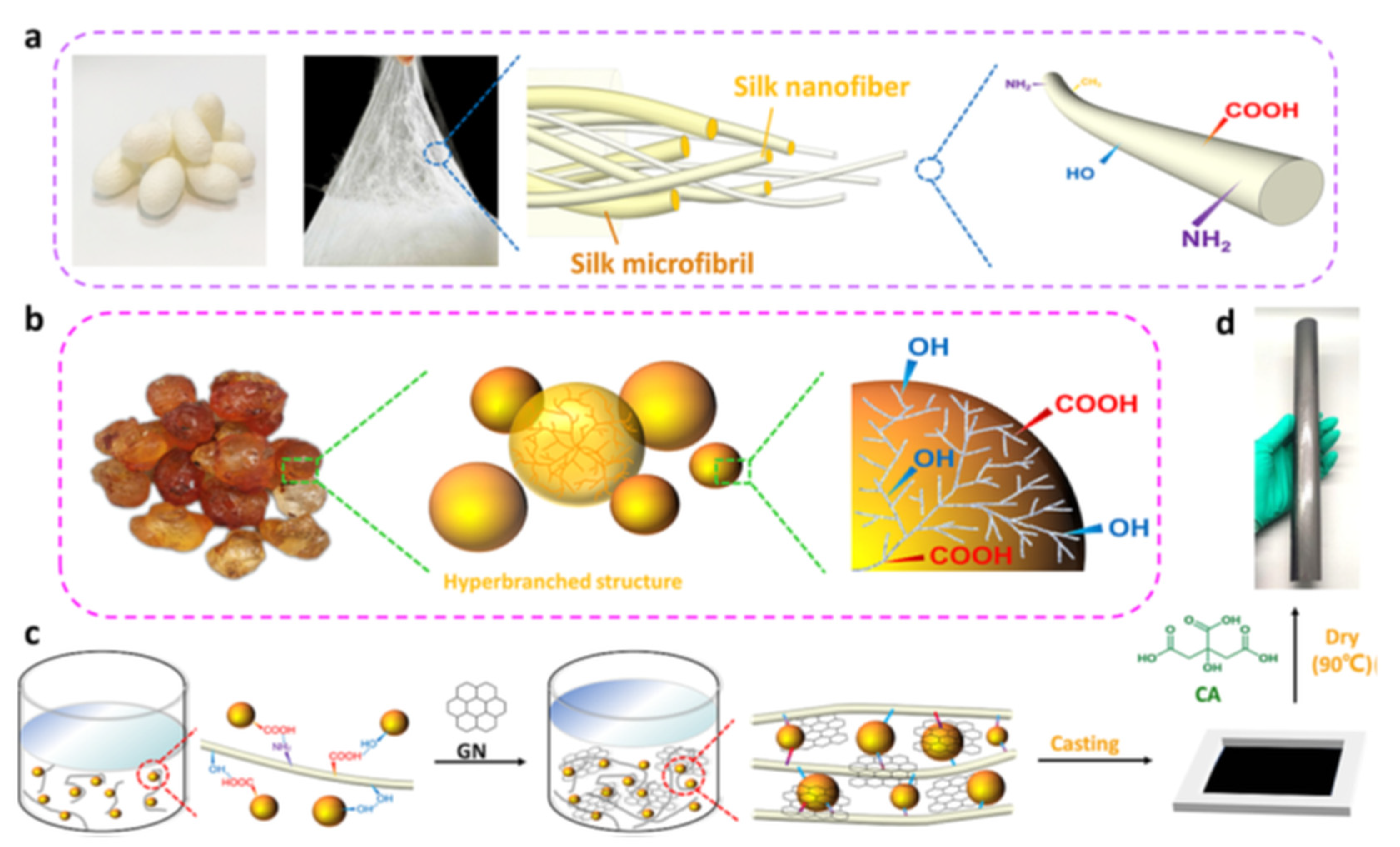

- Lu, T.; Han, X.; Chen, D.; Li, J.; Zhang, Z.; Lu, S.; Wang, H. Multifunctional Bio-Films Based on Silk Nanofibres/Peach Gum Polysaccharide for Highly Sensitive Temperature, Flame, and Water Detection. Int. J. Biol. Macromol. 2023, 231, 123472. [Google Scholar] [CrossRef]

- Cao, M.; Su, J.; Fan, S.; Qiu, H.; Su, D.; Li, L. Wearable Piezoresistive Pressure Sensors Based on 3D Graphene. Chem. Eng. J. 2021, 406, 126777. [Google Scholar] [CrossRef]

- Fan, L.; Chen, L.; He, Y.; Liu, H. Flexible Pressure/Strain Sensors Based on 3D Conductive Materials. Prog. Chem. 2021, 33, 767–778. [Google Scholar] [CrossRef]

- Lee, J.-H.; Park, S.-J. Recent advances in preparations and applications of carbon aerogels: A review. Carbon 2020, 163, 1–18. [Google Scholar] [CrossRef]

- Qin, Z.; Chen, X.; Lv, Y.; Zhao, B.; Fang, X.; Pan, K. Wearable and High-Performance Piezoresistive Sensor Based on Nanofiber/Sodium Alginate Synergistically Enhanced MXene Composite Aerogel. Chem. Eng. J. 2023, 451, 138586. [Google Scholar] [CrossRef]

- Chen, Z.; Hu, Y.; Zhuo, H.; Liu, L.; Jing, S.; Zhong, L.; Peng, X.; Sun, R. Compressible, Elastic, and Pressure-Sensitive Carbon Aerogels Derived from 2D Titanium Carbide Nanosheets and Bacterial Cellulose for Wearable Sensors. Chem. Mater. 2019, 31, 3301–3312. [Google Scholar] [CrossRef]

- Wang, B.; Yin, X.; Cheng, R.; Li, J.; Ying, G.; Chen, K. Compressible, Superelastic and Fatigue Resistant Carbon Nanofiber Aerogels Derived from Bacterial Cellulose for Multifunctional Piezoresistive Sensors. Carbon 2022, 199, 318–328. [Google Scholar] [CrossRef]

- Wang, G.; Liu, X.; Song, Z.; Yu, D.; Li, G.; Wang, H.; Ge, S.; Liu, W. Multifunctional Flexible Pressure Sensor Based on a Cellulose Fiber-Derived Hierarchical Carbon Aerogel. ACS Appl. Electron. Mater. 2023, 5, 1581–1591. [Google Scholar] [CrossRef]

- Li, C.; Li, G.; Li, G.; Yu, D.; Song, Z.; Liu, X.; Wang, H.; Liu, W. Cellulose Fiber-Derived Carbon Fiber Networks for Durable Piezoresistive Pressure Sensing. ACS Appl. Electron. Mater. 2021, 3, 2389–2397. [Google Scholar] [CrossRef]

- Muthuraj, R.; Sachan, A.; Castro, M.; Feller, J.-F.; Seantier, B.; Grohens, Y. Vapor and Pressure Sensors Based on Cellulose Nanofibers and Carbon Nanotubes Aerogel with Thermoelectric Properties. J. Renew. Mater. 2017, 6, 277–287. [Google Scholar] [CrossRef]

- Xiong, Z.-M.; O’Donovan, M.; Sun, L.; Choi, J.Y.; Ren, M.; Cao, K. Anti-Aging Potentials of Methylene Blue for Human Skin Longevity. Sci. Rep. 2017, 7, 2475. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Hoang, B.N.; Tran, T.V.; Nguyen, D.V.; Nguyen, T.D.; Vo, D.-V.N. Agar/Maltodextrin/Poly(Vinyl Alcohol) Walled Montmorillonite Composites for Removal of Methylene Blue from Aqueous Solutions. Surf. Interfaces 2021, 26, 101410. [Google Scholar] [CrossRef]

- Minisy, I.M.; Salahuddin, N.A.; Ayad, M.M. Adsorption of Methylene Blue onto Chitosan-Montmorillonite/Polyaniline Nanocomposite. Appl. Clay Sci. 2021, 203, 105993. [Google Scholar] [CrossRef]

- Roufegari-Nejhad, E.; Sirousazar, M.; Abbasi-Chiyaneh, V.; Kheiri, F. Removal of Methylene Blue from Aqueous Solutions Using Poly(Vinyl Alcohol)/Montmorillonite Nanocomposite Hydrogels: Taguchi Optimization. J. Polym. Environ. 2019, 27, 2239–2249. [Google Scholar] [CrossRef]

- Abou Taleb, M.F.; Hegazy, D.E.; Ismail, S.A. Radiation Synthesis, Characterization and Dye Adsorption of Alginate-Organophilic Montmorillonite Nanocomposite. Carbohydr. Polym. 2012, 87, 2263–2269. [Google Scholar] [CrossRef]

- Mi, X.; Shang, Z.; Du, C.; Li, G.; Su, T.; Chang, X.; Li, R.; Zheng, Z.; Tie, J. Adsorption of an Anionic Azo Dye Using Moringa Oleifera Seed Protein-Montmorillonite Composite. J. Chem. 2019, 2019, 8464815. [Google Scholar] [CrossRef]

- Hosseinzadeh, H.; Zoroufi, S.; Mahdavinia, G.R. Study on Adsorption of Cationic Dye on Novel Kappa-Carrageenan/Poly(Vinyl Alcohol)/Montmorillonite Nanocomposite Hydrogels. Polym. Bull. 2015, 72, 1339–1363. [Google Scholar] [CrossRef]

- Yadav, A.; Bagotia, N.; Yadav, S.; Sharma, A.K.; Kumar, S. Adsorptive Studies on the Removal of Dyes from Single and Binary Systems Using Saccharum munja Plant-Based Novel Functionalized CNT Composites. Environ. Technol. Innov. 2021, 24, 102015. [Google Scholar] [CrossRef]

- EL-Saeid, M.H.; BaQais, A.; Alshabanat, M. Study of the Photocatalytic Degradation of Highly Abundant Pesticides in Agricultural Soils. Molecules 2022, 27, 634. [Google Scholar] [CrossRef] [PubMed]

- Sukthavorn, K.; Nootsuwan, N.; Rajendran, R.; Rojviroon, T.; Veranitisagul, C.; Laobuthee, A. Polylactic Acid Composite Nonwoven Fabric Incorporating Nano-Silver Coated Titanium Dioxide for Photocatalytic Degradation of Carbaryl in Water. J. Polym. Environ. 2024, 32, 4901–4911. [Google Scholar] [CrossRef]

- Naddafiun, F.; Zohoori, S.; Yamin, F.; Torabi, N.; Chadorkafoor, F.; Nasiripoor, R.; Jalalian, Y. Doping Cork Fibers with Nanomaterials for the Removal of Organo-Phosphorous Pesticide. J. Text. Inst. 2024, 115, 1954–1961. [Google Scholar] [CrossRef]

- Apostol, I.; Anghel, N.; Doroftei, F.; Bele, A.; Spiridon, I. Xanthan or Esterified Xanthan/Cobalt Ferrite-Lignin Hybrid Materials for Methyl Blue and Basic Fuchsine Dyes Removal: Equilibrium, Kinetic and Thermodynamic Studies. Mater. Today Chem. 2023, 27, 101299. [Google Scholar] [CrossRef]

- Jiao, G.-J.; Ma, J.; Li, Y.; Jin, D.; Guo, Y.; Zhou, J.; Sun, R. Enhanced Adsorption Activity for Phosphate Removal by Functional Lignin-Derived Carbon-Based Adsorbent: Optimization, Performance and Evaluation. Sci. Total Environ. 2021, 761, 143217. [Google Scholar] [CrossRef]

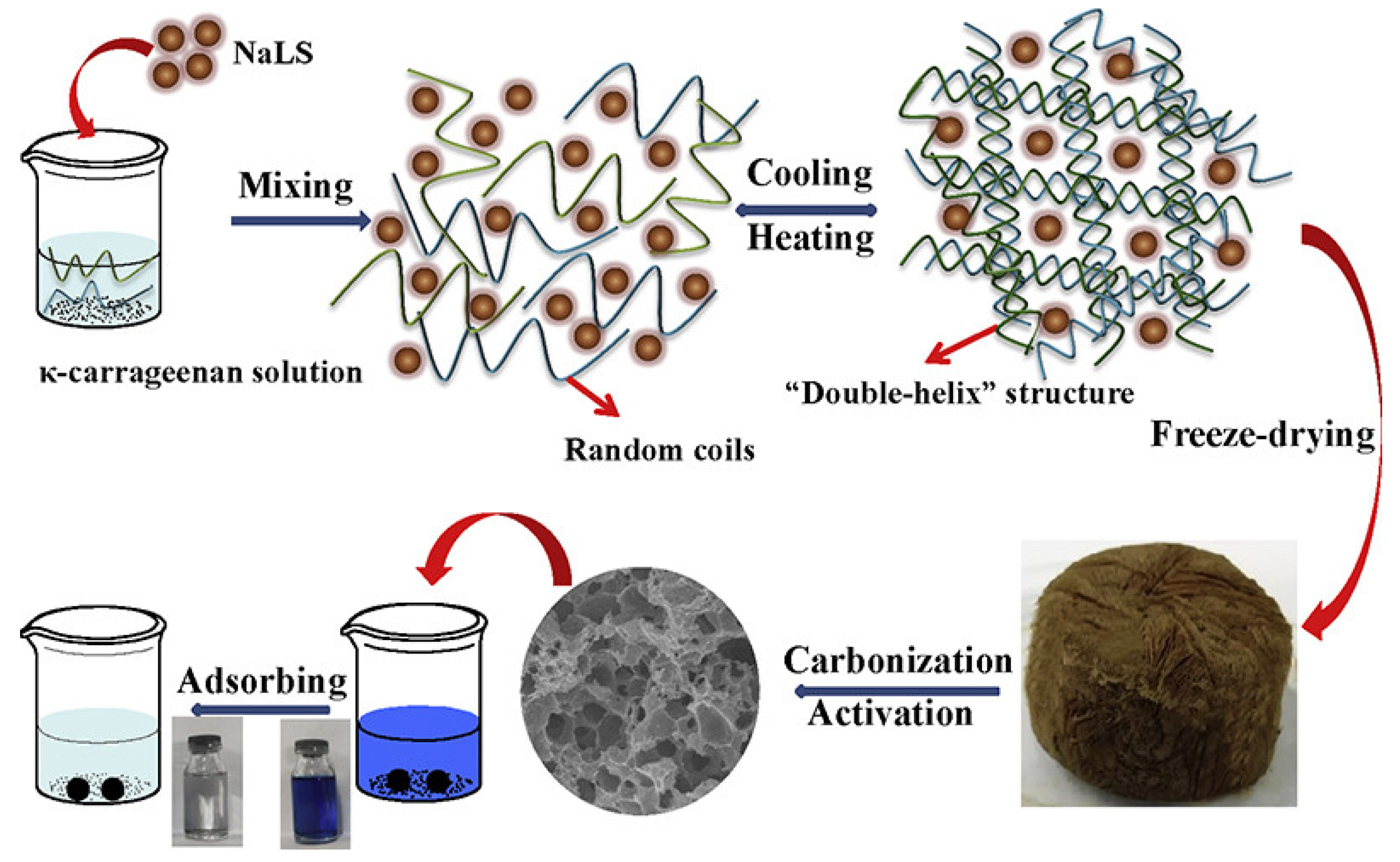

- Lv, D.; Li, Y.; Wang, L. Carbon Aerogels Derived from Sodium Lignin Sulfonate Embedded in Carrageenan Skeleton for Methylene-Blue Removal. Int. J. Biol. Macromol. 2020, 148, 979–987. [Google Scholar] [CrossRef]

- Lai, H.; Levitt, B.B. The Roles of Intensity, Exposure Duration, and Modulation on the Biological Effects of Radiofrequency Radiation and Exposure Guidelines. Electromagn. Biol. Med. 2022, 41, 230–255. [Google Scholar] [CrossRef]

- Velayudhan, P.; M S, K.; Kalarikkal, N.; Thomas, S. Exploring the Potential of Sustainable Biopolymers as a Shield against Electromagnetic Radiations. ACS Appl. Bio Mater. 2024, 7, 3568–3586. [Google Scholar] [CrossRef]

- Hassan, M.W.; Elshazly, T.M.; Ponnamma, D. Cellulose-Inspired Approaches to Sustainable EMI Shielding Materials: A Comprehensive Review. Int. J. Biol. Macromol. 2024, 273, 132920. [Google Scholar] [CrossRef] [PubMed]

- Xie, Y.; Ye, L.; Chen, W.; Liu, P.; Liu, Y. Electrically Conductive and All-Weather Materials from Waste Cross-Linked Polyethylene Cables for Electromagnetic Interference Shielding. Ind. Eng. Chem. Res. 2022, 61, 3610–3619. [Google Scholar] [CrossRef]

- Wyss, K.M.; De Kleine, R.D.; Couvreur, R.L.; Kiziltas, A.; Mielewski, D.F.; Tour, J.M. Upcycling End-of-Life Vehicle Waste Plastic into Flash Graphene. Commun. Eng. 2022, 1, 3. [Google Scholar] [CrossRef]

- Moaref, R.; Shajari, S.; Sundararaj, U. From Waste to Value Added Products: Manufacturing High Electromagnetic Interference Shielding Composite from End-of-Life Vehicle (ELV) Waste. Polymers 2024, 16, 120. [Google Scholar] [CrossRef]

- Louie, S.M.; Ma, R.; Lowry, G.V. Chapter 2—Transformations of Nanomaterials in the Environment. In Frontiers of Nanoscience; Lead, J.R., Valsami-Jones, E., Eds.; Nanoscience and the Environment; Elsevier: Amsterdam, The Netherlands, 2014; Volume 7, pp. 55–87. [Google Scholar]

- Uddin, A.; Khatoon, R.; Estevez, D.; Salem, M.; Ali, A.; Attique, S.; Lu, J.; Qin, F.X. Waste Paper Cellulose Based-MoS2 Hybrid Composites: Towards Sustainable Green Shielding. Mater. Today Commun. 2022, 31, 103858. [Google Scholar] [CrossRef]

- Long, A.; Zhao, P.; Liao, L.; Wang, R.; Tao, J.; Liao, J.; Liao, X.; Zhao, Y. Sustainable Kapok Fiber-Derived Carbon Microtube as Broadband Microwave Absorbing Material. Materials 2022, 15, 4845. [Google Scholar] [CrossRef]

- Gu, W.; Sheng, J.; Huang, Q.; Wang, G.; Chen, J.; Ji, G. Environmentally Friendly and Multifunctional Shaddock Peel-Based Carbon Aerogel for Thermal-Insulation and Microwave Absorption. Nano-Micro Lett. 2021, 13, 102. [Google Scholar] [CrossRef]

- Lee, Y.S.; Malek, M.F.B.A.; Cheng, E.M.; Liu, W.W.; You, K.Y.; Iqbal, M.N.; Wee, F.H.; Khor, S.F.; Zahid, L.; Haji Abd Malek, M.F.B. Experimental Determination of the Performance of Rice Husk-Carbon Nanotube Composites for Absorbing Microwave Signals in the Frequency Range of 12.4–18 GHZ. Prog. Electromagn. Res. 2013, 140, 795–812. [Google Scholar] [CrossRef]

- Tolvanen, J.; Hannu, J.; Hietala, M.; Kordas, K.; Jantunen, H. Biodegradable Multiphase Poly(Lactic Acid)/Biochar/Graphite Composites for Electromagnetic Interference Shielding. Compos. Sci. Technol. 2019, 181, 107704. [Google Scholar] [CrossRef]

- Han, M.; Zhang, R.; Wu, Q.; Wu, N.; Liu, J. Biopolymer-Based Aerogels for Electromagnetic Wave Shielding and Absorbing. Chin. J. Chem. 2023, 41, 322–334. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Darie-Niță, R.N.; Frąckowiak, S. An Overview of Potential Applications of Environmentally Friendly Hybrid Polymeric Materials. Polymers 2025, 17, 252. https://doi.org/10.3390/polym17020252

Darie-Niță RN, Frąckowiak S. An Overview of Potential Applications of Environmentally Friendly Hybrid Polymeric Materials. Polymers. 2025; 17(2):252. https://doi.org/10.3390/polym17020252

Chicago/Turabian StyleDarie-Niță, Raluca Nicoleta, and Stanisław Frąckowiak. 2025. "An Overview of Potential Applications of Environmentally Friendly Hybrid Polymeric Materials" Polymers 17, no. 2: 252. https://doi.org/10.3390/polym17020252

APA StyleDarie-Niță, R. N., & Frąckowiak, S. (2025). An Overview of Potential Applications of Environmentally Friendly Hybrid Polymeric Materials. Polymers, 17(2), 252. https://doi.org/10.3390/polym17020252