Isothermal Equation of State of Polyether Ether Ketone (PEEK) by Optical Imaging Method in Diamond Anvil Cell

Abstract

:1. Introduction

2. Experiment and Methods

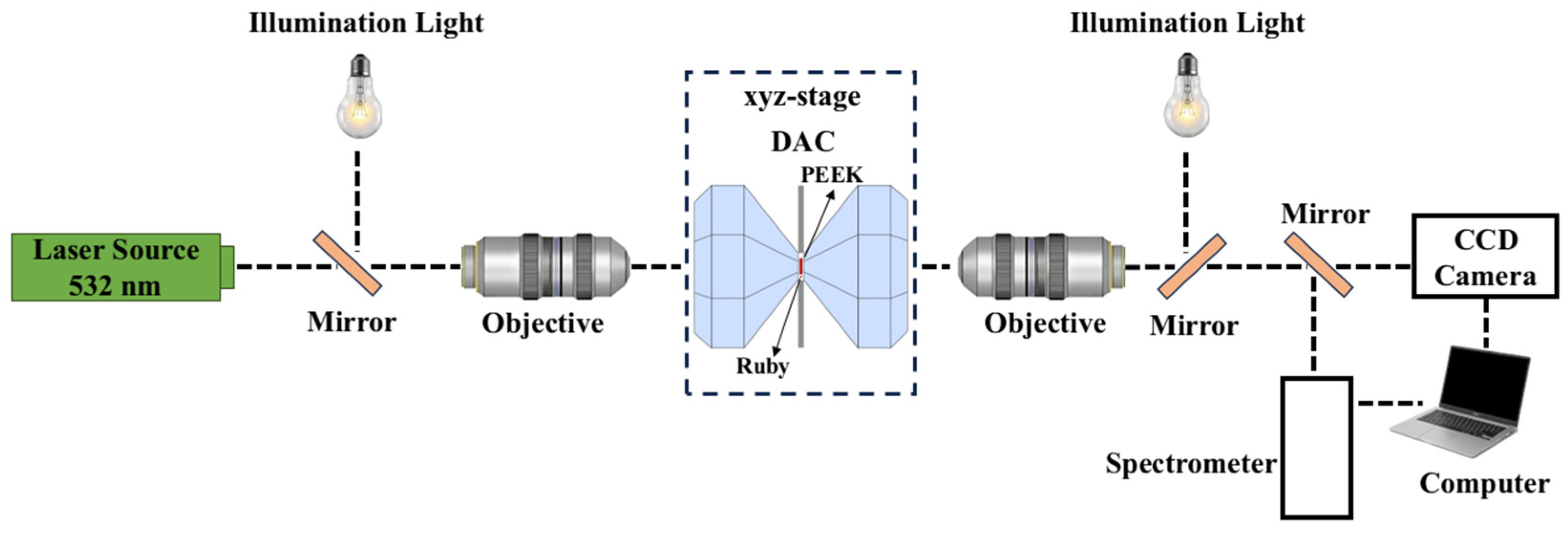

2.1. Instrumental Setup Overview

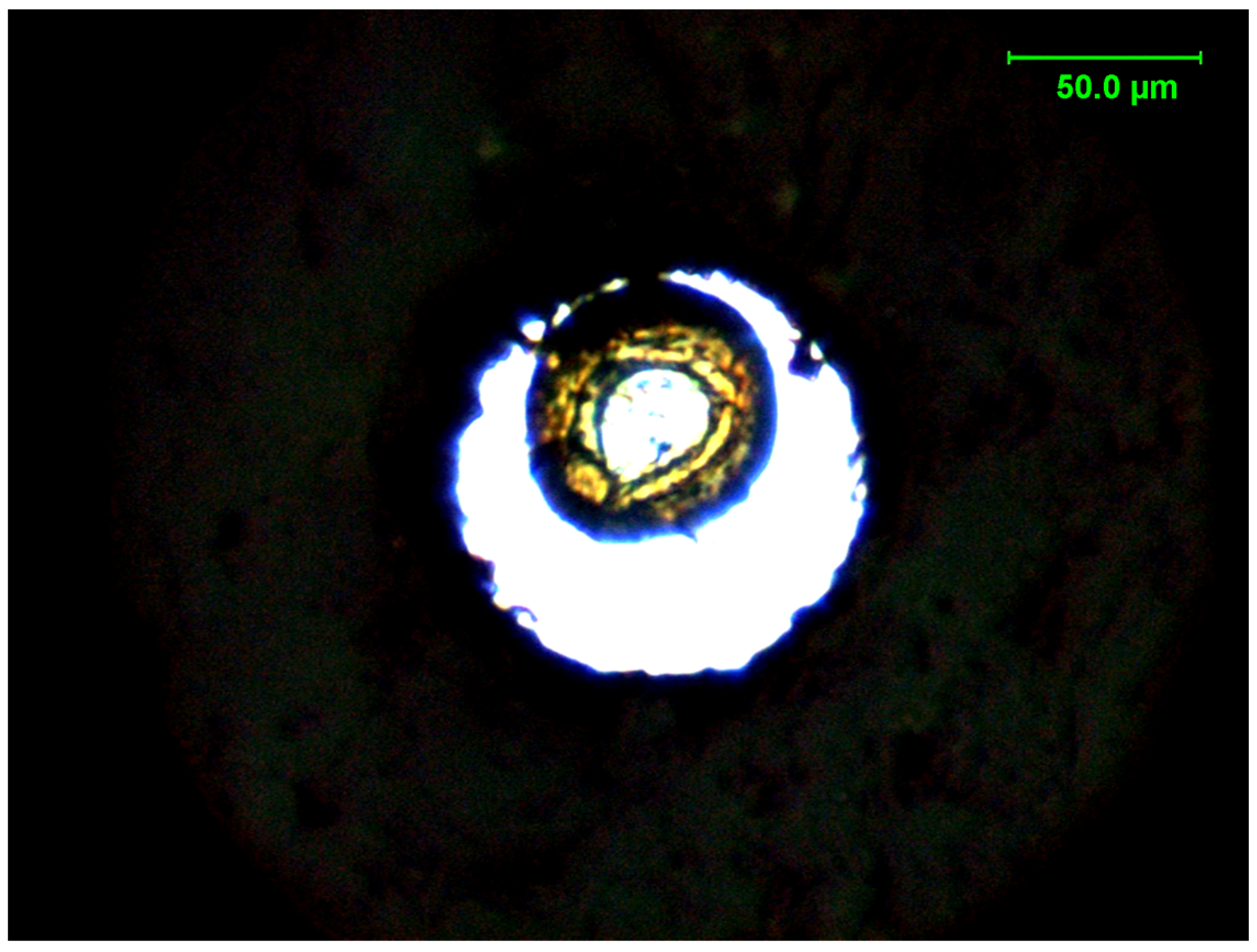

2.2. DAC and Sample Preparation

2.3. Sample Area Measurements

2.4. EOS Determination

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mishra, M. (Ed.) Encyclopedia of Polymer Applications, 1st ed.; CRC Press: Boca Raton, FL, USA, 2018; ISBN 978-1-351-01942-2. [Google Scholar]

- Balart, R.; Montanes, N.; Dominici, F.; Boronat, T.; Torres-Giner, S. Environmentally Friendly Polymers and Polymer Composites. Materials 2020, 13, 4892. [Google Scholar] [CrossRef] [PubMed]

- Schmidt, B.V.K.J. Trends in Polymers 2017/2018: Polymer Synthesis. Polymers 2019, 12, 39. [Google Scholar] [CrossRef]

- Wang, W.; Liu, D.; Lu, L.; Chen, H.; Gong, T.; Lv, J.; Zhou, S. The Improvement of the Shape Memory Function of Poly(ε-Caprolactone)/Nano-Crystalline Cellulose Nanocomposites via Recrystallization under a High-Pressure Environment. J. Mater. Chem. A 2016, 4, 5984–5992. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, H.; Zhang, D.; Chen, K. Mechanical and Wear Properties of Polyetheretherketone Composites Filled with Basalt Fibres. Sci. Eng. Compos. Mater. 2019, 26, 317–326. [Google Scholar] [CrossRef]

- Li, M.; Zhou, M.; Jiang, J.; Tian, F.; Gao, N.; Zhai, W. Microextrusion Foaming of Polyetheretherketone Fiber: Mechanical and Thermal Insulation Properties. Adv. Eng. Mater. 2022, 24, 2101110. [Google Scholar] [CrossRef]

- Pu, F.; Yu, Y.; Zhang, Z.; Wu, W.; Shao, Z.; Li, C.; Feng, J.; Xue, L.; Chen, F. Research and Application of Medical Polyetheretherketone as Bone Repair Material. Macromol. Biosci. 2023, 23, 2300032. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Zheng, L.; Zhuge, X.; Liu, Y.; Zhang, K.; Xu, F. Analysis of Impact Response and Damage Evolution in Multi-scale of Novel 3D Carbon Fiber-reinforced Polyetheretherketone Composites. Polym. Compos. 2024, 45, 12104–12117. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Lin, Q.; Cao, W.; Liu, C.; Shen, C. Crystallization Behavior of Partially Melted Poly (Ether Ether Ketone): Influence of Pre-Crystallization Conditions. J. Therm. Anal. Calorim. 2017, 129, 1021–1028. [Google Scholar] [CrossRef]

- Anderson, O.L. Equations of State of Solids for Geophysics and Ceramic Science; Oxford University Press: Oxford, UK, 1995; ISBN 978-0-19-505606-8. [Google Scholar]

- Birch, F. Finite Elastic Strain of Cubic Crystals. Phys. Rev. 1947, 71, 809–824. [Google Scholar] [CrossRef]

- Liu, L.; Bi, Y. How Far Away Are Accurate Equations of State Determinations? Some Issues on Pressure Scales and Non-Hydrostaticity in Diamond Anvil Cells. Matter Radiat. Extrem. 2016, 1, 224–236. [Google Scholar] [CrossRef]

- Zeng, Q.; Kono, Y.; Lin, Y.; Zeng, Z.; Wang, J.; Sinogeikin, S.V.; Park, C.; Meng, Y.; Yang, W.; Mao, H.-K.; et al. Universal Fractional Noncubic Power Law for Density of Metallic Glasses. Phys. Rev. Lett. 2014, 112, 185502. [Google Scholar] [CrossRef]

- Jacobsen, S.D.; Reichmann, H.; Spetzler, H.A.; Mackwell, S.J.; Smyth, J.R.; Angel, R.J.; McCammon, C.A. Structure and Elasticity of Single-crystal (Mg,Fe) O and a New Method of Generating Shear Waves for Gigahertz Ultrasonic Interferometry. J. Geophys. Res. Solid Earth 2002, 107, ECV 4-1–ECV 4-14. [Google Scholar] [CrossRef]

- Benjamin, A.S.; Ahart, M.; Gramsch, S.A.; Stevens, L.L.; Orler, E.B.; Dattelbaum, D.M.; Hemley, R.J. Acoustic Properties of Kel F-800 Copolymer up to 85 GPa. J. Chem. Phys. 2012, 137, 014514. [Google Scholar] [CrossRef] [PubMed]

- Scott, C.; Jeanloz, R. Optical Length Determinations in the Diamond-Anvil Cell. Rev. Sci. Instrum. 1984, 55, 558–562. [Google Scholar] [CrossRef]

- Bassett, W.A. Diamond Anvil Cell, 50th Birthday. High Press. Res. 2009, 29, 163–186. [Google Scholar] [CrossRef]

- Akella, J.; Johnson, Q.; Smith, G.S.; Ming, U.C. Diamond-Anvil Cell High Pressure X-Ray Studies on Thorium to 100 GPa. High Press. Res. 1988, 1, 91–95. [Google Scholar] [CrossRef]

- Dubrovinsky, L.; Khandarkhaeva, S.; Fedotenko, T.; Laniel, D.; Bykov, M.; Giacobbe, C.; Lawrence Bright, E.; Sedmak, P.; Chariton, S.; Prakapenka, V.; et al. Materials Synthesis at Terapascal Static Pressures. Nature 2022, 605, 274–278. [Google Scholar] [CrossRef]

- Einspruch, N.G. VLSI Electronics: Microstructure Science; Academic Press: Cambridge, MA, USA, 1981; ISBN 978-0-12-234101-4. [Google Scholar]

- Mao, H.K.; Xu, J.; Bell, P.M. Calibration of the Ruby Pressure Gauge to 800 Kbar under Quasi-hydrostatic Conditions. J. Geophys. Res. Solid Earth 1986, 91, 4673–4676. [Google Scholar] [CrossRef]

- Shen, G.; Mei, Q.; Prakapenka, V.B.; Lazor, P.; Sinogeikin, S.; Meng, Y.; Park, C. Effect of Helium on Structure and Compression Behavior of SiO2 Glass. Proc. Natl. Acad. Sci. USA 2011, 108, 6004–6007. [Google Scholar] [CrossRef] [PubMed]

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. Fiji: An Open-Source Platform for Biological-Image Analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef]

- Vinet, P.; Ferrante, J.; Smith, J.R.; Rose, J.H. A Universal Equation of State for Solids. J. Phys. C Solid State Phys. 1986, 19, L467. [Google Scholar] [CrossRef]

- Millett, J.C.F.; Bourne, N.K.; GrayIII, G.T. The Response of Polyether Ether Ketone to One-Dimensional Shock Loading. J. Phys. D Appl. Phys. 2004, 37, 942–947. [Google Scholar] [CrossRef]

- Roberts, A.; Appleby-Thomas, G.J.; Hazell, P. Experimental Determination of Grüneisen Gamma for Polyether Ether Ketone (PEEK) Using the Shock-Reverberation Technique. AIP Conf. Proc. 2012, 1426, 824–827. [Google Scholar] [CrossRef]

- Dattelbaum, D.M.; Jensen, J.D.; Schwendt, A.M.; Kober, E.M.; Lewis, M.W.; Menikoff, R. A Novel Method for Static Equation-of State-Development: Equation of State of a Cross-Linked Poly (Dimethylsiloxane) (PDMS) Network to 10 GPa. J. Chem. Phys. 2005, 122, 144903. [Google Scholar] [CrossRef]

- Haill, T.A.; Mattsson, T.R.; Root, S.; Schroen, D.G.; Flicker, D.G. Mesoscale Simulation of Shocked Poly-(4-Methyl-1-Pentene) (PMP) Foams. AIP Conf. Proc. 2012, 1426, 913–916. [Google Scholar] [CrossRef]

- Jankovič, L.; Végsö, K.; Šiffalovič, P.; Šauša, O.; Čaplovič, L.; Čaplovičová, M.; Medlín, R.; Uhlík, P.; Nógellová, Z. XRD, SAXS, and PALS Investigations of Three Different Polymers Reinforced with Tetraoctylammonium Exchanged Montmorillonite. Int. J. Polym. Anal. Charact. 2016, 21, 524–536. [Google Scholar] [CrossRef]

- Tashiro, K.; Kusaka, K.; Yamamoto, H.; Hosoya, T.; Okada, S.; Ohhara, T. Hybridization of Wide-Angle X-Ray and Neutron Diffraction Techniques in the Crystal Structure Analyses of Synthetic Polymers. Polymers 2023, 15, 465. [Google Scholar] [CrossRef] [PubMed]

- Ivan’kova, E.; Kasatkin, I.; Vaganov, G.; Elokhovskiy, V.; Bugrov, A.; Yudin, V.; Pavlova, E.; Slouf, M. Morphological Transformation in Polymer Composite Materials Filled with Carbon Nanoparticles: Part 1—SEM and XRD Investigations. Materials 2022, 15, 3531. [Google Scholar] [CrossRef] [PubMed]

- Lappas, A.; Brown, C.M.; Kordatos, K.; Suard, E.; Tanigaki, K.; Prassides, K. Neutron Diffraction Study of the Polymeric Structure of Na2RbC60. J. Phys. Condens. Matter 1999, 11, 371–381. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Yang, N.; Zhang, Y.; Liu, L. Isothermal Equation of State of Polyether Ether Ketone (PEEK) by Optical Imaging Method in Diamond Anvil Cell. Polymers 2025, 17, 655. https://doi.org/10.3390/polym17050655

Chen Y, Yang N, Zhang Y, Liu L. Isothermal Equation of State of Polyether Ether Ketone (PEEK) by Optical Imaging Method in Diamond Anvil Cell. Polymers. 2025; 17(5):655. https://doi.org/10.3390/polym17050655

Chicago/Turabian StyleChen, Ying, Ning Yang, Yi Zhang, and Lei Liu. 2025. "Isothermal Equation of State of Polyether Ether Ketone (PEEK) by Optical Imaging Method in Diamond Anvil Cell" Polymers 17, no. 5: 655. https://doi.org/10.3390/polym17050655

APA StyleChen, Y., Yang, N., Zhang, Y., & Liu, L. (2025). Isothermal Equation of State of Polyether Ether Ketone (PEEK) by Optical Imaging Method in Diamond Anvil Cell. Polymers, 17(5), 655. https://doi.org/10.3390/polym17050655