Regulatory Frameworks and State-of-the-Art Decontamination Technologies for Recycled Polystyrene for Food Contact Applications

Abstract

:1. Introduction

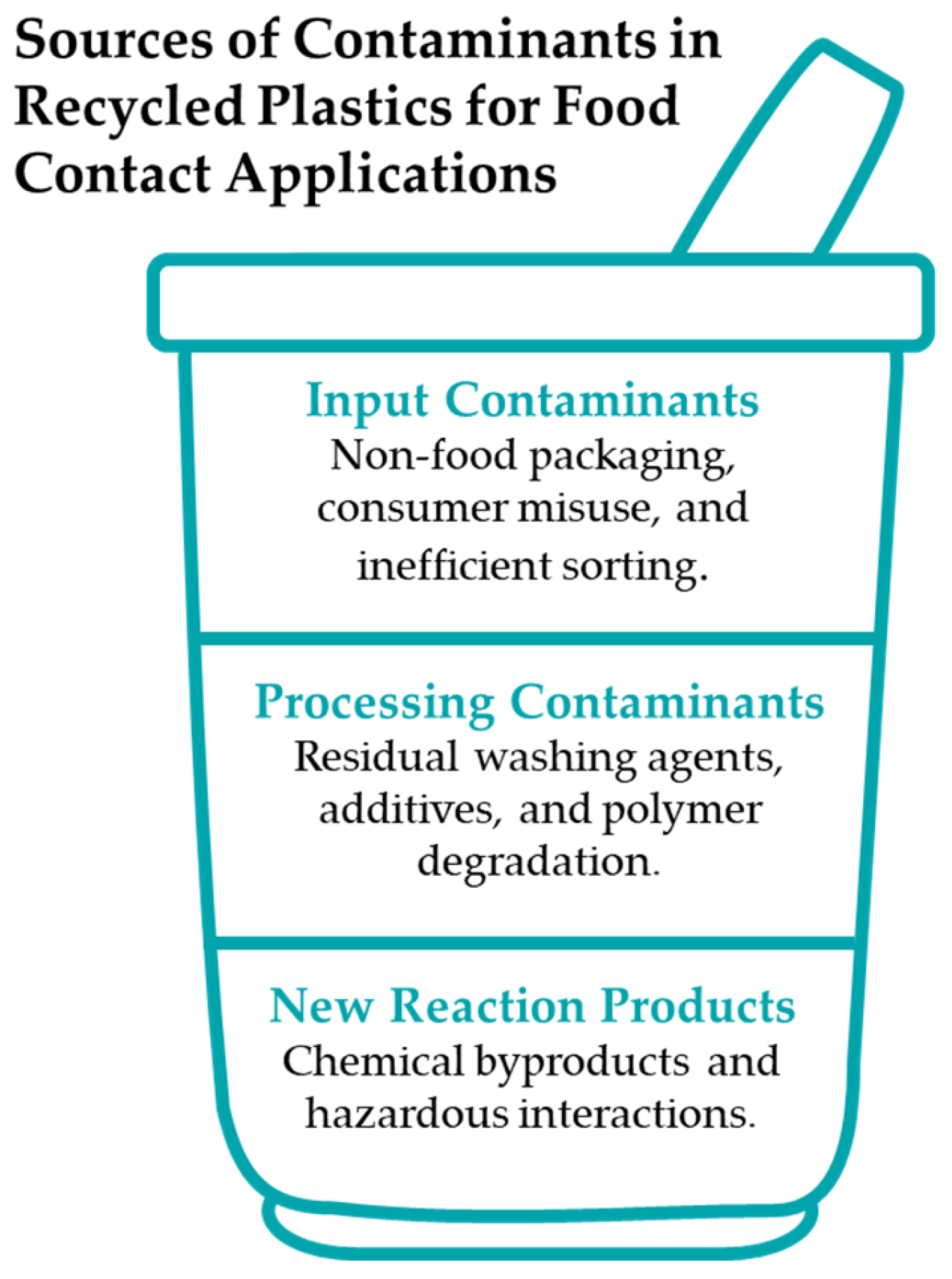

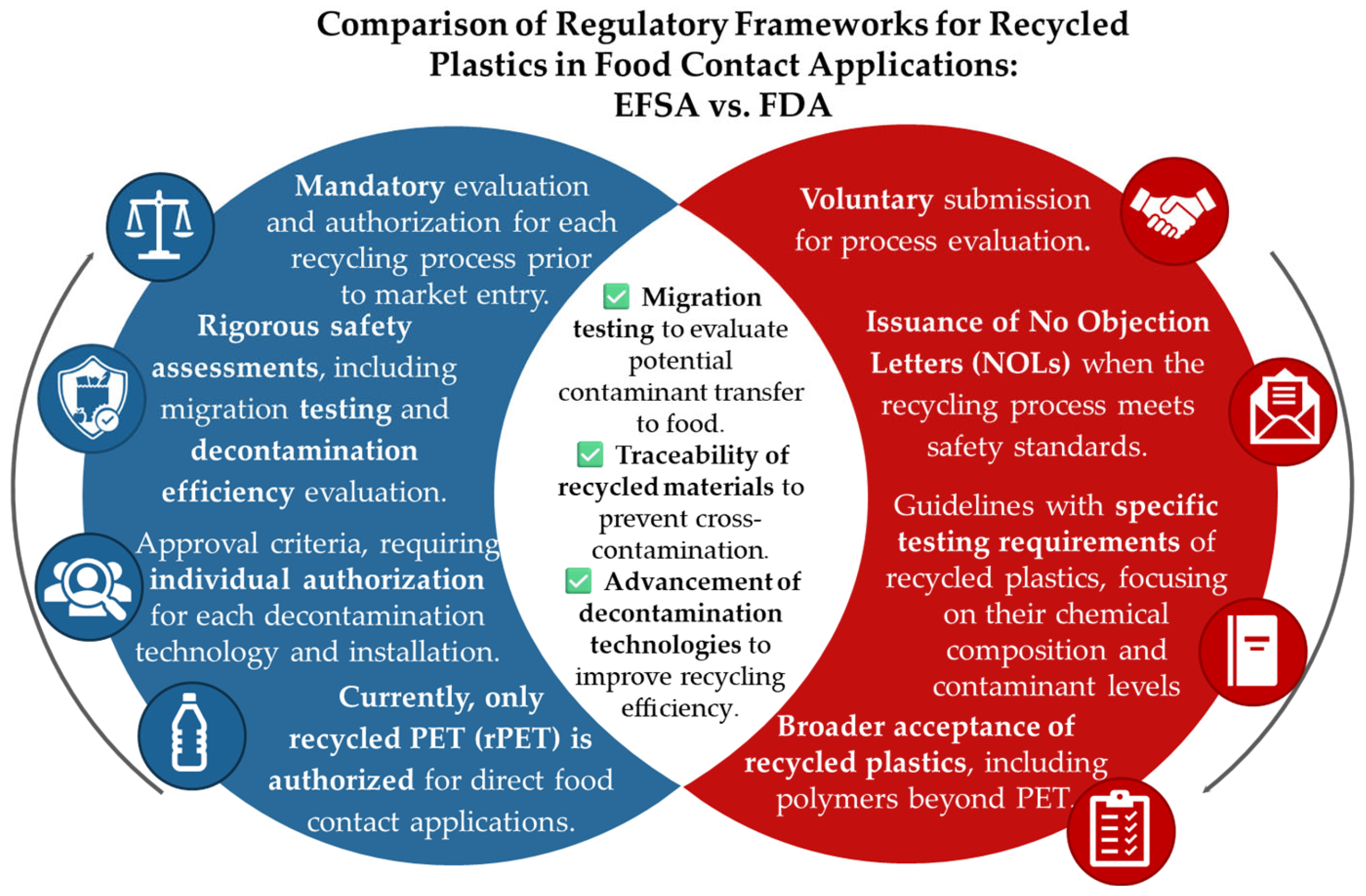

2. Legal Framework

2.1. European Legislation

Non-PET Recycling Processes Evaluation for EFSA Authorization

| Material i | ID—Process | Type ii | Status iii | Specific Conditions of Use for the Application |

Applicant iv Country | |

|---|---|---|---|---|---|---|

| Decontamination Technology | Input | Product | ||||

| PP | EFSA-Q-2009-00682—PP crate CHEP [71] | CC | A | Crates | Crates for fruits, vegetables, pre-packed meat | CHEP UK Ltd.—United Kingdom (Netherlands vi) |

| HDPE | EFSA-Q-2009-00961—Biffa Polymers EREMA advanced technology [72] | S-OL | A | Bottles, mainly from milk (from exclusive providers) | ≤30% + virgin PP for single-use trays for raw fruits, vegetables, animal products, mushrooms | Biffa Polymers Limited United Kingdom (U.K.) |

| HDPE | EFSA-Q-2010-00020—CLRrHDPE EREMA advanced technology [73] | OL | R | ≤50% + virgin HDPE for refrigerated juice and milk bottles | Closed Loop Recycling Limited—U.K. | |

| PP HDPE | EFSA-Q-2010-00021—CO.N.I.P. (National Plastic Packaging Consortium) [74] | CC | A | Crates | Crates for whole fruits and vegetables | CO.N.I.P. Italy |

| PP HDPE | EFSA-Q-2010-00068—Schoeller Arca Systems [75] | CC | A | Crates | Crates for meat, whole fruits, and vegetables | Schoeller Arca Systems B.V.—Netherlands |

| PP | EFSA-Q-2010-00104—Petra Polimeri [76] | CC * S-OL ** | A | Insert trays * or trays ** | ≤30% + virgin PP. Trays or insert trays for whole fruits and vegetables. | Petra Polimeri S.R.I.—Italy |

| PP | EFSA-Q-2010-00892—INTERSEROH Step 1 [77] EFSA-Q-2010-00951—INTERSEROH Step 2 [78] | CC CC | A A | Crates | Crates for whole fruits and vegetables | INTERSEROH Dienstleistungs GmbH– Germany (Netherlands vi) |

| PP HDPE | EFSA-Q-2015-00444—Pokas Arcadian Recycle Ltd. Pokas Arcadian, batch process [79] | MIX | R | (1) Crates, scraps, (2) packaging from a closed collection system, or (3) approved packaging from recycling system | Crates, packaging, or as a functional barrier for whole fruits and vegetables | Pokas Arcadian Recycle Ltd. Greece |

| PP HDPE | EFSA-Q-2016-00486—Morssinkhof Plastics [80] | MIX | A * | Crates, boxes, trays, pallets, and containers (* Excluded regrind from external recyclers) | Crates for dry food, fruits, vegetables, prepacked, and unpacked meat | Morssinkhof Plastics Lichtenvoorde B.V. Netherlands |

| PCTG | EFSA-Q-2019-00016—Green Loop System [81] | CC | A | Plates | Plates for contact with aqueous, acidic, and fatty food | Mälarplast AB Switzerland |

| HDPE | EFSA-Q-2019-00296—Starlinger recoSTAR HDPE FC 1—PET2PET Starlinger recoSTAR HDPE (FC 1) [82] | OL | R | Bottles closures | Bottle closures for mineral water and beverages for long-term storage at room temperature | PET to PET Recycling Österreich GmbH Austria |

| PP HDPE | EFSA-Q-2020-00458—Loop Polymers Internal + optional EREMA refresher stage [83] | CC | R | Unused offcuts and scraps carrying print coatings, inks, or adhesives | Food contact packaging | Loop Polymers Ltd.—United Kingdom (Ireland vi) |

| PP, PET, SAN, ABS | EFSA-Q-2020-00231—deSter [84] | CC | R | Catering tableware from airline on-board services | Articles for the same on-board services | deSter BVBA Belgium |

| HDPE | Schwarz Produktion MEG Weißenfels | ND | NV | Crates, pallets, and bottles closures from PET recycling process (Drescher and Kauertz, 2023) | Crates, pallets and bottles closures (Drescher and Kauertz, 2023) | MEG Weißenfels GmbH & Co. KG Germany |

| HDPE | EFSA-Q-2020-00511—Erema HDPE regrind pro plus refresher [85] | ND | T | |||

| HDPE | EFSA-Q-2020-00772—Kunststof Recycling Nederland (KRN) [86] | CC | A | Box pallets for meat packaging. | Box pallets for refrigerated or frozen, packed, or unpacked meat. | KRN Netherlands |

| PS | Styrenics Circular Solutions EFSA-Q-2021-00151—Next Generation Recyclingmaschinen (NGR) [87] EFSA-Q-2022-00039—Gneuss 3, Multi Rotation System (MRS) [88,89] | OL | OG | Post-consumer food-packing waste from European collections systems [89,90]. | Yoghurt pots, hot and cold beverage containers, and food trays [90,91,92]. | Styrenics Circular Solutions Belgium |

| PS | OL | T | ||||

| PP HDPE | EFSA-Q-2021-00190—THEES Kunststoffverarbeitung [93] | CC | T | Crates | Not indicated | THEES GmbH Germany |

| PP HDPE | EFSA-Q-2021-00294 Cajas y Palets en una Economía Circular (CAPEC) [94] | CC | A | Crates | Crates for whole fruits and vegetables | CAPEC Spain |

| PP HDPE | EFSA-Q-2021-00336—LOGIFRUIT [95] | CC | A | Crates | Crates for fruits and vegetables | LOGIFRUIT S.L. Spain |

| HDPE | Craemer EFSA-Q-2021-00416—Leistritz extruder [96] EFSA-Q-2021-00411—Erema HDPE regrind pro plus refresher [97] | OL * CC ** | T T | Post-consumer closures *, crates, and pallets ** | Crates and pallets | Firma Craemer GmbH Germany |

| HDPE | EFSA-Q-2021-00783—AST Recycling & Rekonditionierung [98] | CC | T | Canisters [99,100] | Canisters [99,100] | AST Recycling & Reconditioning GmbH & Co. KG—Germany |

| PS | EFSA-Q-2022-00202—Ineos-styrolution Internal, twin screw degassing extrusion [101] | T | OL | Post-consumer | Yoghurt cups, food trays | INEOS Styrolution Switzerland S.A.—Switzerland (Germany vi) |

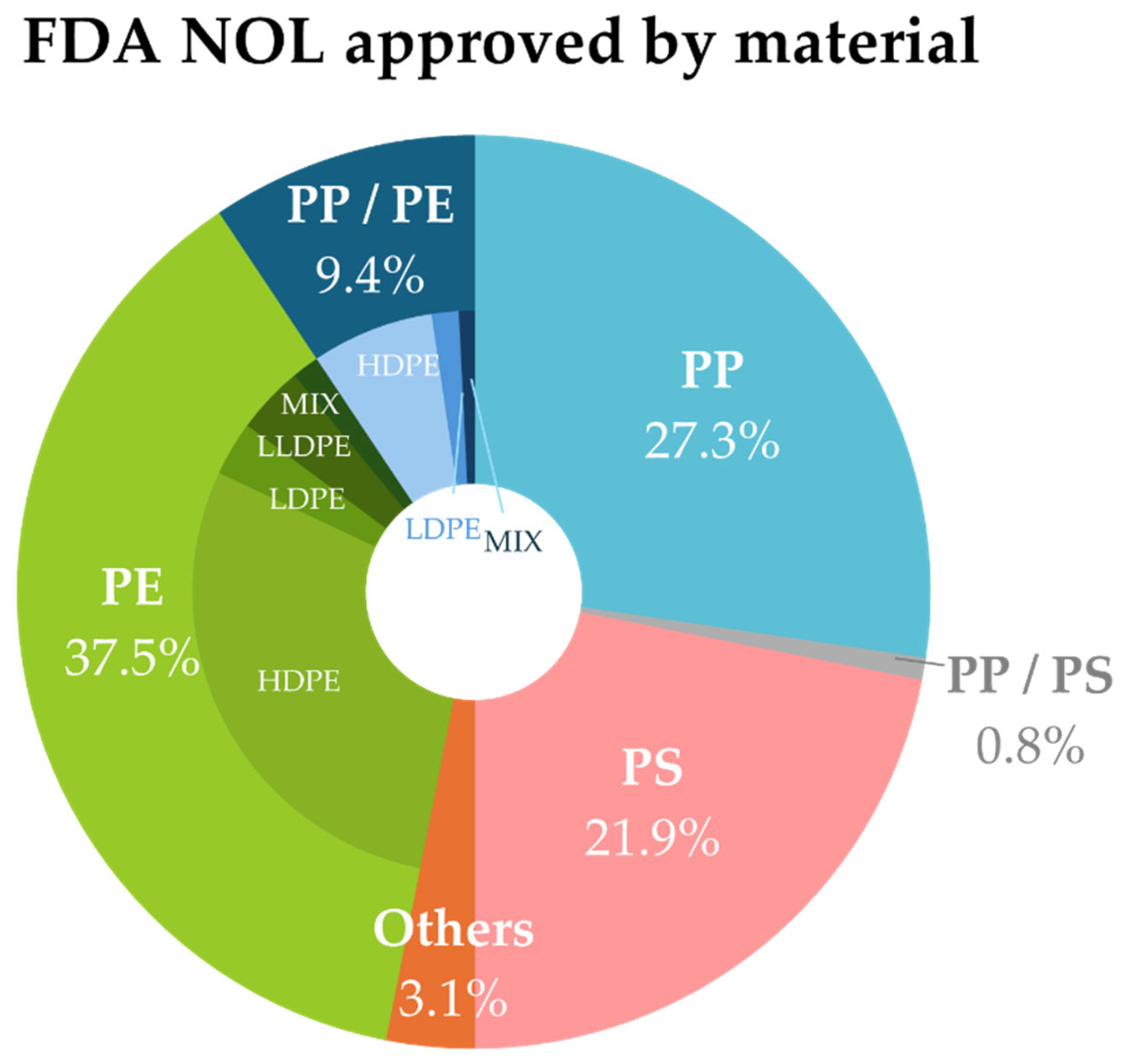

2.2. Food and Drug Administration

- -

- The component is listed in Title 21 of the U.S. Code of Federal Regulations (21 CFR), specifically the database that contains an inventory of Food Contact Substances (FCS) authorized for uses as an appropriately regulated indirect additive in contact with foods. This database includes components of materials used in the manufacturing process, packaging, transport, or food containment, but only if they are not intended to have any technical effect on the food; it is updated yearly.

- -

- Meets the criteria for ‘generally recognized as safe’ (GRAS) status, which includes, but is not limited to, a GRAS regulation (after passing a review process by the FDA) or GRAS notice (after approving a voluntary submission) [119].

- -

- Owns a prior sanction letter, granted by the FDA or USDA before 1958, expressing no opposition towards the utilization of a particular substance for a specific purpose.

- -

- The FCS manufacturer holds an effective Food Contact Substance Notification (FCN), that specifically covers the authorized uses and conditions of use. This regulation applies to manufacturers who have notified the FDA of their intention to utilize an FDA-approved FCS by submitting an FCN. The regulatory authority must conduct a thorough review of the scientific data within 120 days. If no objection is raised during this period, the FCM is considered ‘effective’ [120].

- -

- A Threshold of Regulation (TOR) Exemption has been issued for the component; therefore, it does not require a Food Contact Substance Notification. This exemption addresses regulatory matters, as the substance has already been evaluated and deemed safe at exposure levels below the regulatory threshold (0.5 ppb) when migrating from packaging into food [121].

- -

- Primary recycling—Pre-consumer scraps from food contact in the industry. Product from a closed-loop chain, considered low risk; however, if more than one manufacturer is involve in the material to be treated, further evaluation is required to prove it remains non-hazardous to the consumer.

- -

- Secondary recycling—Post-consumer plastic packaging materials in mechanical recycling, maintaining the nature of the polymer. Additives, antioxidants, processing aids, and other substances involved must be reduced to levels of no concern and comply with current regulations. The assessment conducted by the FDA encompasses a range of factors, including the implementation of controls on source materials, effective sorting procedures, and limitations on the application of these materials in specific contexts and food types.

- -

- Tertiary recycling—Post-consumer plastic packaging through chemical recycling. Polymers or monomers can undergo various stages of purification in order to be repolymerized and can possibly be combined with virgin materials. The entire process may include multiple stages of purification, including washing, distillation, crystallization, and additional chemical reactions.

Non-PET Recycling Processes Evaluation for FDA Authorization

2.3. EFSA vs. FDA

2.4. Global Regulations

3. State-of-the-Art Decontamination Technologies for Post-Consuming PS

| Decontamination Method, (Author, Year) | Material | Focus | Methodology Applied |

|---|---|---|---|

| Dissolution–precipitation technique (Kol et al., 2023) [148] | HIPS | Removal of polybutadiene–polystyrene (PB-PS) particles and pigments, including TiO2 (white colour), Cr/Sb/Ti oxide (yellow colour), and carbon black (black colour). | Filtration with 0.1, 0.45 and 1 μm membranes, at 500 rpm constant stirring, pressures applied between 1.5 and 30 bar, 5 wt% polymer concentration in xylene and limonene, with centrifugation at 10, 30 and 60 min. |

| Dissolution–precipitation technique (Kara Ali et al., 2023) [168] | Recycled PS from a pilot plant | Determination of solvent content remaining in PS at various stages of a dissolution/precipitation recycling process, using p-cymene as a green solvent and heptane as an antisolvent for precipitating. | Models were made to quantify the remaining solvent content based on calibration dissolutions of 30 wt% PS in 1,2-dichloroethane (DCE) and known relative concentrations of cymene (0–16 wt%) and heptane (0–40 wt%). Samples were analyzed by Fourier Transform Infrared spectroscopy (FTIR) with ATR and deuterated L-alanine-doped tri-glycine sulphate detector. |

| Deodorization (Roosen et al., 2021) [166] | Plastic film waste (59.1% PE, 23.9% PP, 10.6% PET, 5.6% PVC, and 0.8 wt% PS). | Desorption isotherm and kinetic models for deodorization efficiencies in different washing media (distilled water, CTAB 0.92 mM, NaOH solution 1 wt%, a caustic soda mixture (NaOH 1 wt%,) with CTAB (0.92 mM), and ethyl acetate). | Shredded plastics (3, 4, 5, 6, 7, and 8 g) were stirred in 100 mL of each washing medium at 25 °C and 65 °C for desorption isotherm studies. Kinetic experiments (adding a 45 °C experiment for water and ethyl acetate), stirring in a shaker 5.0 ± 0.1 g of plastic at 200 rpm, removing at 0.5, 2, 4, 15, and 60 min. Vacuum filtration was used to separate the washing media, and the drying occurred at ambient temperature for 4 h. |

| Washing (Roosen et al., 2022 [164] | Post-consumer polystyrene (PS) trays | Deodorization in washing mediums (tap water; CTAB (9.2 mM), NaOH (2 wt%, 9.2 mM CTAB in 2 wt% NaOH solution; commercial detergent (one 18 g capsule/100 mL water) and an industrial detergent (0.5%v in 2 wt% NaOH solution), odour compounds identification, polarity chemical classes influence their removal. | Shredded 5 ± 0.1 g plastic samples were mixed with 100 mL of each medium at 25 and 65 °C and agitated using a multi-flask rotary shaker at 200 rpm for 10 min. Subsequently, they were separated by filtration, rinsed with 25 °C 100 mL distilled water and dried for 24 h in a desiccator at room temperature. |

| Washing (Demets et al., 2020) [169] | Flexible post-consumer film waste stream | Qualitative and semi-quantitatively techniques to analyze volatile contaminants before and after washing and pelletizing | The washing process involved rinsing, followed by a friction washer and a sink–float separation system, all using tap water. The materials were then dried with hot air (washed films) and subsequently pelletized using a vacuum-degassing extruder at 200 °C. |

| Dissolution–precipitation technique (Fullana et al., 2021) [176] | Mix plastic input, only tested with PE, PP, and PET. | Spanish patent technology P201931143, “Procedimiento para la descontaminación de plástico reciclado” (Procedure for the decontamination of recycled plastic). From 2019 developed at lab/pilot scale. | Separation, shredding, washing, rinsing, drying, and decontamination by means of extraction with water-soluble solvent with boiling point above 180 °C, in this case polyethylene glycol (PEG), at atmospheric pressure and subsequently rinsing. After the extraction, the plastic is rinsed at room temperature and centrifuged before and after to remove the solvent. Includes water recuperation systems by ultrafiltration or crystallization and flocculation-decantation. Meanwhile, solvent recovery by means of ultrafiltration membrane and filtering. |

| Deodorization (Ishida et al., 2020) [163] | Expanded polystyrene (EPS) fish boxes | Removal of fish-like and sea-like odours (trimethylamine and dimethyl sulphide) to improve recyclability. | Desalting and deodorization using heated vegetable oil (Oshima College Method—OCMT). EPS was immersed in heated vegetable oil (160–200 °C) for volume reduction and odour removal. The solubility of trimethylamine and dimethyl sulphide in vegetable oil was evaluated using Hansen solubility parameters, and desorption was experimentally tested by analyzing odour reduction in treated samples. |

Industrial Level Decontamination Technologies

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- European Commission. European Green Deal: Putting an End to Wasteful Packaging, Boosting Reuse and Recycling. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_22_7155 (accessed on 2 November 2023).

- United States Environmental Protection Agency. National Strategy to Prevent Plastic Pollution; United States Environmental Protection Agency: Washington, DC, USA, 2024; 64p.

- Plastics Europe. Plastics—The Fast Facts 2024. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-fast-facts-2024/ (accessed on 10 December 2024).

- Plastics Europe. The Circular Economy for Plastics: A European Analysis. Available online: https://plasticseurope.org/knowledge-hub/the-circular-economy-for-plastics-a-european-analysis-2024/ (accessed on 10 December 2024).

- Plastics Europe. Plastics—The Facts 2023. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-fast-facts-2023/ (accessed on 6 December 2023).

- European Commission. A European Strategy for Plastics in a Circular Economy. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- European Commission. Official Journal of the European Union Regulation (EU) No 2022/1616, of 15 September 2022 on Recycled Plastic Materials and Articles Intended to Come into Contact with Foods; European Commission: Brussels, Belgium, 2022; Volume 02022R1616–20220920. [Google Scholar]

- European Food Safety Authority. Administrative Guidance for the Preparation of Applications for the Authorisation of Individual Recycling Processes to Produce Recycled Plastics Materials and Articles Intended to Come into Contact with Food. EFSA Support. Publ. 2024, 21, 8968E. [Google Scholar] [CrossRef]

- Parres, F.; Balart, R.; Crespo, J.E.; López, J. Effects of the Injection-Molding Temperatures and Pyrolysis Cycles on the Butadiene Phase of High-Impact Polystyrene. J. Appl. Polym. Sci. 2007, 106, 1903–1908. [Google Scholar] [CrossRef]

- Ignatyev, I.A.; Thielemans, W.; Beke, B.V. Recycling of Polymers: A Review. ChemSusChem 2014, 7, 1579–1593. [Google Scholar] [CrossRef] [PubMed]

- Schyns, Z.O.G.; Shaver, M.P. Mechanical Recycling of Packaging Plastics: A Review. Macromol. Rapid Commun. 2020, 42, 2000415. [Google Scholar] [CrossRef]

- Geueke, B.; Groh, K.; Muncke, J. Food Packaging in the Circular Economy: Overview of Chemical Safety Aspects for Commonly Used Materials. J. Clean. Prod. 2018, 193, 491–505. [Google Scholar] [CrossRef]

- Palkopoulou, S.; Joly, C.; Feigenbaum, A.; Papaspyrides, C.D.; Dole, P. Critical Review on Challenge Tests to Demonstrate Decontamination of Polyolefins Intended for Food Contact Applications. Trends Food Sci. Technol. 2016, 49, 110–120. [Google Scholar] [CrossRef]

- Wrona, M.; Nerín, C. Analytical Approaches for Analysis of Safety of Modern Food Packaging: A Review. Molecules 2020, 25, 752. [Google Scholar] [CrossRef]

- European Food Safety Authority. Guidelines on Submission of a Dossier for Safety Evaluation by the EFSA of a Recycling Process to Produce Recycled Plastics Intended to Be Used for Manufacture of Materials and Articles in Contact with Food—Opinion of the Scientific Panel on Food Additives, Flavourings, Processing Aids and Materials in Contact with Food (AFC). EFSA J. 2008, 6, 717. [Google Scholar] [CrossRef]

- EUR-Lex. Commission Regulation (EC) No 2023/2006 of 22 December 2006 on Good Manufacturing Practice for Materials and Articles Intended to Come into Contact with Food (Text with EEA Relevance). Off. J. Eur. Union 2006, 50, 75–78. [Google Scholar]

- Francis, R. Recycling of Polymers: Methods, Characterization and Applications; Wiley-VCH: Weinheim, Germany, 2016; ISBN 978-3-527-68900-2. [Google Scholar]

- Chemical Recycling Europe. Chemical Recycling Q&A. Available online: https://chemicalrecyclingeurope.eu/questions-about-chemical-recycling/ (accessed on 7 July 2024).

- Marchetti, R.; Vasmara, C.; Bertin, L.; Fiume, F. Conversion of Waste Cooking Oil into Biogas: Perspectives and Limits. Appl. Microbiol. Biotechnol. 2020, 104, 2833–2856. [Google Scholar] [CrossRef]

- European Bioplastics. Waste Management and Recovery Options for Bioplastics. Available online: https://www.european-bioplastics.org/bioplastics/waste-management/ (accessed on 26 June 2024).

- European Commission; Joint Research Centre. Environmental and Economic Assessment of Plastic Waste Recycling: A Comparison of Mechanical, Physical, Chemical Recycling and Energy Recovery of Plastic Waste; Publications Office: Luxembourg, 2023. [Google Scholar]

- Yang, Z.; Lü, F.; Zhang, H.; Wang, W.; Shao, L.; Ye, J.; He, P. Is Incineration the Terminator of Plastics and Microplastics? J. Hazard. Mater. 2021, 401, 123429. [Google Scholar] [CrossRef] [PubMed]

- Shen, M.; Hu, T.; Huang, W.; Song, B.; Qin, M.; Yi, H.; Zeng, G.; Zhang, Y. Can Incineration Completely Eliminate Plastic Wastes? An Investigation of Microplastics and Heavy Metals in the Bottom Ash and Fly Ash from an Incineration Plant. Sci. Total Environ. 2021, 779, 146528. [Google Scholar] [CrossRef] [PubMed]

- EFSA Panel on Food Contact Materials; Enzymes and Processing Aids (CEP); Lambré, C.; Barat Baviera, J.M.; Bolognesi, C.; Chesson, A.; Cocconcelli, P.S.; Crebelli, R.; Gott, D.M.; Grob, K.; et al. Scientific Guidance on the Criteria for the Evaluation and on the Preparation of Applications for the Safety Assessment of Post-consumer Mechanical PET Recycling Processes Intended to Be Used for Manufacture of Materials and Articles in Contact with Food. EFSA J. 2024, 22, e8879. [Google Scholar] [CrossRef] [PubMed]

- Franz, R.; Welle, F. Recycling of Post-Consumer Packaging Materials into New Food Packaging Applications—Critical Review of the European Approach and Future Perspectives. Sustainability 2022, 14, 824. [Google Scholar] [CrossRef]

- Barthélémy, E.; Spyropoulos, D.; Milana, M.-R.; Pfaff, K.; Gontard, N.; Lampi, E.; Castle, L. Safety Evaluation of Mechanical Recycling Processes Used to Produce Polyethylene Terephthalate (PET) Intended for Food Contact Applications. Food Addit. Contam. Part A 2014, 31, 490–497. [Google Scholar] [CrossRef]

- Pinter, E.; Welle, F.; Mayrhofer, E.; Pechhacker, A.; Motloch, L.; Lahme, V.; Grant, A.; Tacker, M. Circularity Study on PET Bottle-To-Bottle Recycling. Sustainability 2021, 13, 7370. [Google Scholar] [CrossRef]

- Arman Alim, A.A.; Mohammad Shirajuddin, S.S.; Anuar, F.H. A Review of Nonbiodegradable and Biodegradable Composites for Food Packaging Application. J. Chem. 2022, 2022, 7670819. [Google Scholar] [CrossRef]

- Coniglio, M.A.; Fioriglio, C.; Laganà, P. (Eds.) Polyethylene Terephthalate. In Non-Intentionally Added Substances in PET-Bottled Mineral Water; SpringerBriefs in Molecular Science; Springer International Publishing: Cham, Switzerland, 2020; p. 29. ISBN 978-3-030-39134-8. [Google Scholar]

- Welle, F. Recycling of Post-Consumer Polystyrene Packaging Waste into New Food Packaging Applications—Part 1: Direct Food Contact. Recycling 2023, 8, 26. [Google Scholar] [CrossRef]

- Welle, F. Twenty Years of PET Bottle to Bottle Recycling—An Overview. Resour. Conserv. Recycl. 2011, 55, 865–875. [Google Scholar] [CrossRef]

- Dolores, S.M.; Marina Patricia, A.; Santiago, F.; Juan, L. Influence of Biodegradable Materials in the Recycled Polystyrene. J. Appl. Polym. Sci. 2014, 131, 41161. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Samper, M.D.; Aldas, M.; López, J. On the Use of PLA-PHB Blends for Sustainable Food Packaging Applications. Materials 2017, 10, 1008. [Google Scholar] [CrossRef] [PubMed]

- Auras, R.; Harte, B.; Selke, S. An Overview of Polylactides as Packaging Materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef] [PubMed]

- Arrieta, M.P.; Peltzer, M.A.; López, J.; Peponi, L. PLA-Based Nanocomposites Reinforced with CNC for Food Packaging Applications: From Synthesis to Biodegradation. In Industrial Applications of Renewable Biomass Products; Goyanes, S.N., D’Accorso, N.B., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 265–300. ISBN 978-3-319-61287-4. [Google Scholar]

- Sid, S.; Mor, R.S.; Kishore, A.; Sharanagat, V.S. Bio-Sourced Polymers as Alternatives to Conventional Food Packaging Materials: A Review. Trends Food Sci. Technol. 2021, 115, 87–104. [Google Scholar] [CrossRef]

- Faba, S.; Arrieta, M.P.; Romero, J.; Agüero, Á.; Torres, A.; Martínez, S.; Rayón, E.; Galotto, M.J. Biodegradable Nanocomposite Poly(Lactic Acid) Foams Containing Carvacrol-Based Cocrystal Prepared by Supercritical CO2 Processing for Controlled Release in Active Food Packaging. Int. J. Biol. Macromol. 2024, 254, 127793. [Google Scholar] [CrossRef]

- O’Loughlin, J.; Doherty, D.; Herward, B.; McGleenan, C.; Mahmud, M.; Bhagabati, P.; Boland, A.N.; Freeland, B.; Rochfort, K.D.; Kelleher, S.M.; et al. The Potential of Bio-Based Polylactic Acid (PLA) as an Alternative in Reusable Food Containers: A Review. Sustainability 2023, 15, 15312. [Google Scholar] [CrossRef]

- Sousa, A.F.; Patrício, R.; Terzopoulou, Z.; Bikiaris, D.N.; Stern, T.; Wenger, J.; Loos, K.; Lotti, N.; Siracusa, V.; Szymczyk, A.; et al. Recommendations for Replacing PET on Packaging, Fiber, and Film Materials with Biobased Counterparts. Green Chem. 2021, 23, 8795–8820. [Google Scholar] [CrossRef]

- Badia, J.D.; Ribes-Greus, A. Mechanical Recycling of Polylactide, Upgrading Trends and Combination of Valorization Techniques. Eur. Polym. J. 2016, 84, 22–39. [Google Scholar] [CrossRef]

- Agüero, A.; Morcillo, M.d.C.; Quiles-Carrillo, L.; Balart, R.; Boronat, T.; Lascano, D.; Torres-Giner, S.; Fenollar, O. Study of the Influence of the Reprocessing Cycles on the Final Properties of Polylactide Pieces Obtained by Injection Molding. Polymers 2019, 11, 1908. [Google Scholar] [CrossRef]

- Agüero, Á.; Perianes, E.C.; Muelas, S.S.A.d.L.; Lascano, D.; García-Soto, M.d.M.d.l.F.; Peltzer, M.A.; Balart, R.; Arrieta, M.P. Plasticized Mechanical Recycled PLA Films Reinforced with Microbial Cellulose Particles Obtained from Kombucha Fermented in Yerba Mate Waste. Polymers 2023, 15, 285. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Beltran, F.; Abarca De Las Muelas, S.S.; Gaspar, G.; Sanchez Hernandez, R.; De La Orden, M.U.; Martinez Urreaga, J. Development of Tri-Layer Antioxidant Packaging Systems Based on Recycled PLA/Sodium Caseinate/Recycled PLA Reinforced with Lignocellulosic Nanoparticles Extracted from Yerba Mate Waste. Express Polym. Lett. 2022, 16, 881–900. [Google Scholar] [CrossRef]

- Moll, E.; Chiralt, A. Polyhydroxybutyrate-Co-Hydroxyvalerate (PHBV) with Phenolic Acids for Active Food Packaging. Polymers 2023, 15, 4222. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Garcia, D.; Quiles-Carrillo, L.; Balart, R.; Torres-Giner, S.; Arrieta, M.P. Innovative Solutions and Challenges to Increase the Use of Poly(3-Hydroxybutyrate) in Food Packaging and Disposables. Eur. Polym. J. 2022, 178, 111505. [Google Scholar] [CrossRef]

- Dhaini, A.; Hardouin-Duparc, V.; Alaaeddine, A.; Carpentier, J.-F.; Guillaume, S.M. Recent Advances in Polyhydroxyalkanoates Degradation and Chemical Recycling. Prog. Polym. Sci. 2024, 149, 101781. [Google Scholar] [CrossRef]

- Badia, J.D.; Gil-Castell, O.; Ribes-Greus, A. Long-Term Properties and End-of-Life of Polymers from Renewable Resources. Polym. Degrad. Stab. 2017, 137, 35–57. [Google Scholar] [CrossRef]

- Welle, F. Recycling of Post-Consumer Polystyrene Packaging Waste into New Food Packaging Applications—Part 2: Co-Extruded Functional Barriers. Recycling 2023, 8, 39. [Google Scholar] [CrossRef]

- Laird, K. Tomra, Ineos Styrolution and EGN Launch Pioneering PS Recycling Project. Available online: https://www.sustainableplastics.com/news/tomra-ineos-styrolution-and-egn-launch-pioneering-ps-recycling-project (accessed on 3 December 2024).

- Li, J.; Li, C.; Liao, Q.; Xu, Z. Environmentally-Friendly Technology for Rapid on-Line Recycling of Acrylonitrile-Butadiene-Styrene, Polystyrene and Polypropylene Using near-Infrared Spectroscopy. J. Clean. Prod. 2019, 213, 838–844. [Google Scholar] [CrossRef]

- Zheng, Y.; Bai, J.; Xu, J.; Li, X.; Zhang, Y. A Discrimination Model in Waste Plastics Sorting Using NIR Hyperspectral Imaging System. Waste Manag. 2018, 72, 87–98. [Google Scholar] [CrossRef]

- Lubongo, C.; Alexandridis, P. Assessment of Performance and Challenges in Use of Commercial Automated Sorting Technology for Plastic Waste. Recycling 2022, 7, 11. [Google Scholar] [CrossRef]

- Rozenstein, O.; Puckrin, E.; Adamowski, J. Development of a New Approach Based on Midwave Infrared Spectroscopy for Post-Consumer Black Plastic Waste Sorting in the Recycling Industry. Waste Manag. 2017, 68, 38–44. [Google Scholar] [CrossRef]

- European Commission. Packaging Waste. EU Rules on Packaging and Packaging Waste, Including Design and Waste Management. Available online: https://environment.ec.europa.eu/topics/waste-and-recycling/packaging-waste_en (accessed on 2 November 2023).

- European Commission. Official Journal of the European Union Regulation (EU) 2025/40 of the European Parliament and of the Council of 19 December 2024 on Packaging and Packaging Waste, Amending Regulation (EU) 2019/1020 and Directive (EU) 2019/904, and Repealing Directive 94/62/EC (Text with EEA Relevance); European Commission: Brussels, Belgium, 2025. [Google Scholar]

- European Parliament. Legislative Resolution of 24 April 2024 on the Proposal for a Regulation of the European Parliament and of the Council on Packaging and Packaging Waste, Amending Regulation (EU) 2019/1020 and Directive (EU) 2019/904, and Repealing Directive 94/62/EC; European Parliament: Luxembourg, 2024. [Google Scholar]

- EUR-Lex. Access to European Union Law Procedure 2022/0396/COD. Available online: https://eur-lex.europa.eu/procedure/ES/2022_396 (accessed on 8 December 2024).

- Council of the European Union. Council Decision (EU, Euratom) 2020/2053 of 14 December 2020 on the System of Own Resources of the European Union and Repealing Decision 2014/335/EU, Euratom; European Union: Luxembourg, 2020. [Google Scholar]

- Plastics Europe. European Plastics Producers Call for a Mandatory EU Recycled Content Target for Plastics Packaging of 30% by 2030. Available online: https://plasticseurope.org/media/european-plastics-producers-call-for-a-mandatory-eu-recycled-content-target-for-plastics-packaging-of-30-by-2030-2/ (accessed on 21 March 2023).

- Ellen MacArthur Foundation. The Global Commitment 2022 Progress Report; Ellen MacArthur Foundation: Cowes, UK, 2022. [Google Scholar]

- European Union. Official Journal Commission Regulation (EC) No 282/2008 of 27 March 2008 on Recycled Plastic Materials and Articles Intended to Come into Contact with Foods and Amending Regulation (EC) No 2023/2006 (Text with EEA Relevance); European Union: Luxembourg, 2008. [Google Scholar]

- European Food Safety Authority. Guidance of the Scientific Committee on Transparency in the Scientific Aspects of Risk Assessments Carried out by EFSA. Part 2: General Principles. EFSA J. 2009, 7, 1051. [Google Scholar] [CrossRef]

- EFSA; CEF Panel. Scientific Opinion on the Criteria to Be Used for Safety Evaluation of a Mechanical Recycling Process to Produce Recycled PET Intended to Be Used for Manufacture of Materials and Articles in Contact with Food. EFSA J. 2011, 9, 2184. [Google Scholar] [CrossRef]

- European Food Safety Authority. Administrative Guidance for the Preparation of Applications on Recycling Processes to Produce Recycled Plastics Intended to Be Used for Manufacture of Materials and Articles in Contact with Food. EFSA Support. Publ. 2021, 18, 6512E. [Google Scholar] [CrossRef]

- Strangl, M.; Ortner, E.; Buettner, A. Evaluation of the Efficiency of Odor Removal from Recycled HDPE Using a Modified Recycling Process. Resour. Conserv. Recycl. 2019, 146, 89–97. [Google Scholar] [CrossRef]

- Su, Q.-Z.; Vera, P.; Salafranca, J.; Nerín, C. Decontamination Efficiencies of Post-Consumer High-Density Polyethylene Milk Bottles and Prioritization of High Concern Volatile Migrants. Resour. Conserv. Recycl. 2021, 171, 105640. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and Chemical Recycling of Solid Plastic Waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef]

- European Parliament. Council of the European Union Regulation (EU) 2024/1781 of the European Parliament and of the Council of 13 June 2024 Establishing a Framework for the Setting of Ecodesign Requirements for Sustainable Products, Amending Directive (EU) 2020/1828 and Regulation (EU) 2023/1542 and Repealing Directive 2009/125/EC; European Parliament: Luxembourg, 2024. [Google Scholar]

- European Food Safety Authority. Open EFSA. Available online: https://open.efsa.europa.eu/questions (accessed on 6 November 2024).

- European Union. Pledge by: Styrenics Circular Solutions (SCS). Available online: https://circulareconomy.europa.eu/platform/en/commitments/pledges/styrenics-circular-solutions-scs (accessed on 22 December 2023).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2009-00682. Available online: https://open.efsa.europa.eu/questions/EFSA-Q-2009-00682 (accessed on 7 November 2024).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2009-00961. Available online: https://open.efsa.europa.eu/questions/EFSA-Q-2009-00961 (accessed on 7 November 2024).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2010-00020. Available online: https://open.efsa.europa.eu/questions/EFSA-Q-2010-00020 (accessed on 7 November 2024).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2010-00021. Available online: https://open.efsa.europa.eu/questions/EFSA-Q-2010-00021 (accessed on 7 November 2024).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2010-00068. Available online: https://open.efsa.europa.eu/questions/EFSA-Q-2010-00068 (accessed on 7 November 2024).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2010-00104. Available online: https://open.efsa.europa.eu/questions/EFSA-Q-2010-00104 (accessed on 7 November 2024).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2010-00892. Available online: https://open.efsa.europa.eu/questions/EFSA-Q-2010-00892 (accessed on 7 November 2024).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2010-00951. Available online: https://open.efsa.europa.eu/questions/EFSA-Q-2010-00951 (accessed on 7 November 2024).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2015-00444. Available online: https://open.efsa.europa.eu/questions/EFSA-Q-2015-00444 (accessed on 7 November 2024).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2016-00486. Available online: https://open.efsa.europa.eu/questions/EFSA-Q-2016-00486 (accessed on 7 November 2024).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2019-00016. Available online: https://open.efsa.europa.eu/questions/EFSA-Q-2019-00016 (accessed on 7 November 2024).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2019-00296. Available online: https://open.efsa.europa.eu/questions/EFSA-Q-2019-00296 (accessed on 7 November 2024).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2020-00458. Available online: https://open.efsa.europa.eu/questions/EFSA-Q-2020-00458 (accessed on 7 November 2024).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2020-00231. Available online: https://open.efsa.europa.eu/questions/EEFSA-Q-2020-00231 (accessed on 7 November 2024).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2020-00511. Available online: https://open.efsa.europa.eu/questions/EFSA-Q-2020-00511 (accessed on 7 November 2024).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2020-00772. Available online: https://open.efsa.europa.eu/questions/EFSA-Q-2020-00772 (accessed on 7 November 2024).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2021-00151. Available online: https://open.efsa.europa.eu/questions/EFSA-Q-2021-00151 (accessed on 7 November 2024).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2022-00039. Available online: https://open.efsa.europa.eu/questions/EFSA-Q-2022-00039 (accessed on 7 November 2024).

- Packaging Gateway. SCS Files Application to Authorise rPS as Food Contact Material; Packaging Gateway: London, UK, 2022. [Google Scholar]

- Plasteurope Styrenics. Circular Solutions. Application to EFSA for rPS as Food Contact Material/Successful Trials; Styrenics Circular Solutions: Brussels, Belgium, 2021. [Google Scholar]

- Brooks, B. SCS Seeks Further EFSA Approval for Food-Contact Recycled Polystyrene; S&P group: New York, NY, USA, 2022. [Google Scholar]

- FoodOnline. Styrenics Circular Solutions Seeks Further EFSA Opinion Confirming The Safety Of Mechanically Recycled Polystyrene As Food Contact Material. 7 February 2022. Available online: https://www.foodonline.com/doc/styrenics-circular-seeks-further-efsa-safety-of-mechanically-recycled-food-contact-material-0001 (accessed on 21 December 2023).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2021-00190. Available online: https://open.efsa.europa.eu/questions/EFSA-Q-2021-00190 (accessed on 7 November 2024).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2021-00294. Available online: https://open.efsa.europa.eu/questions/EFSA-Q-2021-00294 (accessed on 7 November 2024).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2021-00336. Available online: https://open.efsa.europa.eu/questions/EFSA-Q-2021-00336 (accessed on 7 November 2024).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2021-00416. Available online: https://open.efsa.europa.eu/questions/EFSA-Q-2021-00416 (accessed on 7 November 2024).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2021-00411. Available online: https://open.efsa.europa.eu/questions/EFSA-Q-2021-00411 (accessed on 7 November 2024).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2021-00783. Available online: https://open.efsa.europa.eu/questions/EFSA-Q-2021-00783 (accessed on 7 November 2024).

- Lindner Washtech. AST Group and Lindner Launch Centre of Competence. Available online: https://www.lindner-washtech.com/ast-group (accessed on 16 December 2024).

- Schopen, A. Kreislaufwirtschaft dank Kanistern aus recyceltem Granulat [Circular Economy Thanks to Canisters Made from Recycled Granules]. 2023. Available online: https://www.kunststoff-magazin.de/zerkleinerung-recycling/kreislaufwirtschaft-dank-kanistern-aus-recyceltem-granulat.htm (accessed on 21 December 2024).

- EFSA; CEP Panel. Open EFSA EFSA-Q-2022-00202. Available online: https://open.efsa.europa.eu/questions/EFSA-Q-2022-00202 (accessed on 7 November 2024).

- EFSA; CEP Panel. Scientific Opinion on the Safety Evaluation of the Process “CO.N.I.P.” Used to Recycle Polypropylene and Polyethylene Crates for Use as Food Contact Material. EFSA J. 2013, 11, 3157. [Google Scholar] [CrossRef]

- EFSA; CEP Panel. Scientific Opinion on the Safety Evaluation of the Process “INTERSEROH Step 2” Used to Recycle Polypropylene Crates for Use as Food Contact Material. EFSA J. 2013, 11, 3308. [Google Scholar] [CrossRef]

- EFSA; CEP Panel. Safety Assessment of the Process ‘Morssinkhof Plastics’, Used to Recycle High-density Polyethylene and Polypropylene Crates for Use as Food Contact Materials. EFSA J. 2018, 16, e05117. [Google Scholar] [CrossRef]

- EFSA; CEP Panel. Scientific Opinion on the Safety Evaluation of the Process “INTERSEROH Step 1” Used to Recycle Polypropylene Crates for Use as Food Contact Material. EFSA J. 2012, 10, 2912. [Google Scholar] [CrossRef]

- EFSA; CEP Panel. Safety Assessment of the Process Green Loop System, Used to Recycle Polycyclohexylene Dimethylene Terephthalate Glycol-modified (PCTG) Plates for Use as Food Contact Materials. EFSA J. 2021, 20, e07002. [Google Scholar] [CrossRef]

- EFSA; CEP Panel. Scientific Opinion on the Safety Assessment of the Processes ‘Biffa Polymers’ and ‘CLRrHDPE’ Used to Recycle High-density Polyethylene Bottles for Use as Food Contact Material. EFSA J. 2015, 13, 4016. [Google Scholar] [CrossRef]

- Vera, P.; Canellas, E.; Su, Q.-Z.; Mercado, D.; Nerín, C. Migration of Volatile Substances from Recycled High Density Polyethylene to Milk Products. Food Packag. Shelf Life 2023, 35, 101020. [Google Scholar] [CrossRef]

- EFSA; CEP Panel. Scientific Opinion on the Safety Assessment of the Process “Petra Polimeri” Used to Recycle Polypropylene Trays and Insert Trays for Use as Food Contact Material. EFSA J. 2014, 12, 3780. [Google Scholar] [CrossRef]

- EFSA; CEP Panel. Scientific Opinion on the Safety Evaluation of the Process, “PP Crates CHEP”, Used to Recycle Plastic for Use as Food Contact Materials. EFSA J. 2010, 8, 1929. [Google Scholar] [CrossRef]

- EFSA; CEP Panel. Safety Assessment of the Process Cajas y Palets En Una Economia Circular (CAPEC), Used to Recycle High-density Polyethylene and Polypropylene Crates for Use as Food Contact Materials. EFSA J. 2022, 20, e07384. [Google Scholar] [CrossRef]

- EFSA; CEP Panel. Safety Assessment of the Process LOGIFRUIT, Used to Recycle High-density Polyethylene and Polypropylene Crates for Use as Food Contact Materials. EFSA J. 2022, 20, e07477. [Google Scholar] [CrossRef]

- Anouar, B.S.; Guinot, C.; Ruiz, J.-C.; Charton, F.; Dole, P.; Joly, C.; Yvan, C. Purification of Post-Consumer Polyolefins via Supercritical CO2 Extraction for the Recycling in Food Contact Applications. J. Supercrit. Fluids 2015, 98, 25–32. [Google Scholar] [CrossRef]

- Cabanes, A.; Valdés, F.J.; Fullana, A. A Review on VOCs from Recycled Plastics. Sustain. Mater. Technol. 2020, 25, e00179. [Google Scholar] [CrossRef]

- Lam, C.; Patel, P. Food, Drug, and Cosmetic Act. Available online: https://www.ncbi.nlm.nih.gov/books/NBK585046/ (accessed on 27 December 2023).

- U.S. Food & Drug Administration. Food Packaging & Other Substances That Come in Contact with Food Information for Consumers. Available online: https://www.fda.gov/food/food-ingredients-packaging/food-packaging-other-substances-come-contact-food-information-consumers (accessed on 24 July 2024).

- U.S. Food & Drug Administration. Guidance for Industry: Use of Recycled Plastics in Food Packaging (Chemistry Considerations); U.S. Food & Drug Administration: Silver Spring, MD, USA, 2021.

- U.S. Food & Drug Administration. Determining the Regulatory Status of Components of a Food Contact Material. Available online: https://www.fda.gov/food/packaging-food-contact-substances-fcs/determining-regulatory-status-components-food-contact-material (accessed on 10 October 2024).

- U.S. Food & Drug Administration. Generally Recognized as Safe (GRAS). Available online: https://www.fda.gov/food/food-ingredients-packaging/generally-recognized-safe-gras (accessed on 9 September 2024).

- U.S. Food & Drug Administration. FDA Proposes New Rule to Revise Procedures and Update Reasons for Revoking the Authorizations for Food Contact Substances. Available online: https://www.fda.gov/food/cfsan-constituent-updates/fda-proposes-new-rule-revise-procedures-and-update-reasons-revoking-authorizations-food-contact (accessed on 27 December 2023).

- U.S. Food & Drug Administration. Guidance for Industry: Submitting Requests under 21 CFR 170.39 Threshold of Regulation for Substances Used in Food-Contact Articles. Available online: https://www.fda.gov/regulatory-information/search-fda-guidance-documents/guidance-industry-submitting-requests-under-21-cfr-17039-threshold-regulation-substances-used-food (accessed on 10 October 2024).

- U.S. Food & Drug Administration. Food Additives. In Code of Federal Regulations (21 CFR § 170). Available online: https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?CFRPart=170&showFR=1&subpartNode=21:3.0.1.1.1.4 (accessed on 30 August 2024).

- U.S. Food & Drug Administration. Food Ingredient & Packaging Terms. Available online: https://www.fda.gov/food/food-ingredients-packaging/food-ingredient-packaging-terms (accessed on 9 September 2024).

- U.S. Food & Drug Administration. Guidance for Industry: Preparation of Food Contact Substance Notifications (Administrative); U.S. Food & Drug Administration: Silver Spring, MD, USA, 2021.

- U.S. Food & Drug Administration. Ingredients, Additives, GRAS & Packaging Guidance Documents & Regulatory Information. Available online: https://www.fda.gov/food/guidance-documents-regulatory-information-topic-food-and-dietary-supplements/ingredients-additives-gras-packaging-guidance-documents-regulatory-information (accessed on 9 September 2024).

- U.S. Food & Drug Administration. Recycled Plastics in Food Packaging. Available online: https://www.fda.gov/food/packaging-food-contact-substances-fcs/recycled-plastics-food-packaging (accessed on 9 September 2024).

- U.S. Environmental Protection Agency. United States 2030 Food Loss and Waste Reduction Goal. Available online: https://www.epa.gov/sustainable-management-food/united-states-2030-food-loss-and-waste-reduction-goal (accessed on 29 November 2024).

- U.S. Environmental Protection Agency. National Recycling Strategy: Part One of a Series on Building a Circular Economy for All. Available online: https://www.epa.gov/circulareconomy/national-recycling-strategy (accessed on 29 November 2024).

- U.S. Environmental Protection Agency. Solid Waste Infrastructure for Recycling Grant Program. Available online: https://www.epa.gov/infrastructure/solid-waste-infrastructure-recycling-grant-program (accessed on 29 November 2024).

- U.S. Environmental Protection Agency. National Strategy to Prevent Plastic Pollution: Part Three of a Series on Building a Circular Economy for All. Available online: https://www.epa.gov/circulareconomy/national-strategy-prevent-plastic-pollution (accessed on 7 December 2024).

- U.S. Food & Drug Administration. Submissions on Post-Consumer Recycled (PCR) Plastics for Food-Contact Articles. Available online: https://www.cfsanappsexternal.fda.gov/scripts/fdcc/?set=RecycledPlastics (accessed on 1 November 2024).

- Street, S. Revolution FDA NOL Press Release; Revolution: Chicago, IL, USA, 2022. [Google Scholar]

- Hochegger, A.; Panto, S.; Jones, N.; Leitner, E. One-Dimensional and Comprehensive Two-Dimensional Gas Chromatographic Approaches for the Characterization of Post-Consumer Recycled Plastic Materials. Anal. Bioanal. Chem. 2023, 415, 2447–2457. [Google Scholar] [CrossRef]

- EFSA; CEP Panel. Safety Assessment of the Process PCR Ambalaj, Based on the Starlinger iV+ Technology, Used to Recycle Post-consumer PET into Food Contact Materials. EFSA J. 2023, 21, e08130. [Google Scholar] [CrossRef]

- EFSA; CEP Panel. Safety Assessment of the Process Umincorp, Based on the NGR Technology, Used to Recycle Post-consumer PET into Food Contact Materials. EFSA J. 2023, 21, e08263. [Google Scholar] [CrossRef]

- Lawrence, K.; Cooper, V.; Kissoon, P. Sustaining Voluntary Recycling Programmes in a Country Transitioning to an Integrated Solid Waste Management System. J. Environ. Manag. 2020, 257, 109966. [Google Scholar] [CrossRef] [PubMed]

- Packaginglaw China Announces New Food Safety Standards, Including Ones for Food-Contact Materials 2023. Available online: https://www.packaginglaw.com/news/china-announces-new-food-safety-standards-including-ones-food-contact-materials (accessed on 20 February 2025).

- GB/T 45090-2024; Plastics—Identification and Marking of Recycled Plastic. China Standard Press: Beijing, China, 2024.

- Tsang, H. South Korea Issues New Food Contact Material and Article Standards. Available online: https://www.sgs.com/en/news/2021/11/safeguards-15421-south-korea-issues-new-food-contact-material-and-articles-standards (accessed on 18 February 2025).

- British Plastics Federation. Plastic in Food Contact Applications. Available online: https://www.bpf.co.uk/press/food-contact-position-statement.aspx (accessed on 19 February 2025).

- HM Revenue & Customs Policy Paper: Introduction of Plastic Packaging Tax from April 2022. Available online: https://www.gov.uk/government/publications/introduction-of-plastic-packaging-tax-from-april-2022/introduction-of-plastic-packaging-tax-2021?utm_source=chatgpt.com (accessed on 19 February 2025).

- Mason, D. Packaging Waste Regulations Quick Guide (2025 Update). Available online: https://www.gwp.co.uk/guides/packaging-waste-regulations/ (accessed on 19 February 2025).

- Grupo Mercado Común (MERCOSUR). Reglamento Técnico MERCOSUR Sobre Envases de Polietilentereftalato (PET) Postconsumo Reciclado Grado Alimentario (PET-PCR Grado Alimentario) Destinados a Estar En Contacto Con Alimentos; MERCOSUR/GMC/RES. No 30/07; Universidad de Chile: Santiago, Chile, 2008. [Google Scholar]

- Grob, K.; Biedermann, M.; Scherbaum, E.; Roth, M.; Rieger, K. Food Contamination with Organic Materials in Perspective: Packaging Materials as the Largest and Least Controlled Source? A View Focusing on the European Situation. Crit. Rev. Food Sci. Nutr. 2006, 46, 529–535. [Google Scholar] [CrossRef] [PubMed]

- Groh, K.J.; Geueke, B.; Martin, O.; Maffini, M.; Muncke, J. Overview of Intentionally Used Food Contact Chemicals and Their Hazards. Environ. Int. 2021, 150, 106225. [Google Scholar] [CrossRef]

- MacCombie, G. Enforcement’s Perspective. Presented at the Introductory Workshop to Support the Evaluation on Food Contact Materials (FCMs) Legislation, Brussels, Belgium, 24 September 2018. [Google Scholar]

- Capricho, J.C.; Prasad, K.; Hameed, N.; Nikzad, M.; Salim, N. Upcycling Polystyrene. Polymers 2022, 14, 5010. [Google Scholar] [CrossRef]

- Kol, R.; Carrieri, E.; Gusev, S.; Verswyvel, M.; Niessner, N.; Lemonidou, A.; Achilias, D.S.; De Meester, S. Removal of Undissolved Substances in the Dissolution-Based Recycling of Polystyrene Waste by Applying Filtration and Centrifugation. Sep. Purif. Technol. 2023, 325, 124682. [Google Scholar] [CrossRef]

- Sánchez-Rivera, K.L.; Zhou, P.; Radkevich, E.; Sharma, A.; Bar-Ziv, E.; Van Lehn, R.C.; Huber, G.W. A Solvent-Targeted Recovery and Precipitation Scheme for the Recycling of up to Ten Polymers from Post-Industrial Mixed Plastic Waste. Waste Manag. 2025, 194, 290–297. [Google Scholar] [CrossRef]

- Rodríguez-Liébana, J.A.; Martín-Lara, M.A.; Navas-Martos, F.J.; Peñas-Sanjuan, A.; Godoy, V.; Arjandas, S.; Calero, M. Morpho-Structural and Thermo-Mechanical Characterization of Recycled Polypropylene and Polystyrene from Mixed Post-Consumer Plastic Waste. J. Environ. Chem. Eng. 2022, 10, 108332. [Google Scholar] [CrossRef]

- Arvanitoyannis, I.S.; Kotsanopoulos, K.V. Migration Phenomenon in Food Packaging. Food-Package Interactions, Mechanisms, Types of Migrants, Testing and Relative Legislation-A Review. Food Bioprocess Technol. 2014, 7, 21–36. [Google Scholar] [CrossRef]

- Abolghasemi-Fakhri, L.; Ghanbarzadeh, B.; Dehghannya, J.; Abbasi, F.; Adun, P. Styrene Monomer Migration from Polystyrene Based Food Packaging Nanocomposite: Effect of Clay and ZnO Nanoparticles. Food Chem. Toxicol. 2019, 129, 77–86. [Google Scholar] [CrossRef]

- Gelbke, H.-P.; Banton, M.; Block, C.; Dawkins, G.; Eisert, R.; Leibold, E.; Pemberton, M.; Puijk, I.M.; Sakoda, A.; Yasukawa, A. Risk Assessment for Migration of Styrene Oligomers into Food from Polystyrene Food Containers. Food Chem. Toxicol. 2019, 124, 151–167. [Google Scholar] [CrossRef]

- Guazzotti, V.; Hendrich, V.; Gruner, A.; Fiedler, D.; Störmer, A.; Welle, F. Migration of Styrene in Yogurt and Dairy Products Packaged in Polystyrene: Results from Market Samples. Foods 2022, 11, 2120. [Google Scholar] [CrossRef] [PubMed]

- Lin, Q.-B.; Song, X.-C.; Fang, H.; Wu, Y.-M.; Wang, Z.-W. Migration of Styrene and Ethylbenzene from Virgin and Recycled Expanded Polystyrene Containers and Discrimination of These Two Kinds of Polystyrene by Principal Component Analysis. Food Addit. Contam. Part A 2017, 34, 126–132. [Google Scholar] [CrossRef] [PubMed]

- Pilevar, Z.; Bahrami, A.; Beikzadeh, S.; Hosseini, H.; Jafari, S.M. Migration of Styrene Monomer from Polystyrene Packaging Materials into Foods: Characterization and Safety Evaluation. Trends Food Sci. Technol. 2019, 91, 248–261. [Google Scholar] [CrossRef]

- Kusch, P.; Knupp, G. Headspace-SPME-GC-MS Identification of Volatile Organic Compounds Released from Expanded Polystyrene. J. Polym. Environ. 2004, 12, 83–87. [Google Scholar] [CrossRef]

- Song, X.-C.; Wrona, M.; Nerin, C.; Lin, Q.-B.; Zhong, H.-N. Volatile Non-Intentionally Added Substances (NIAS) Identified in Recycled Expanded Polystyrene Containers and Their Migration into Food Simulants. Food Packag. Shelf Life 2019, 20, 100318. [Google Scholar] [CrossRef]

- de Sousa Cunha, R.; Mumbach, G.D.; Machado, R.A.F.; Bolzan, A. A Comprehensive Investigation of Waste Expanded Polystyrene Recycling by Dissolution Technique Combined with Nanoprecipitation. Environ. Nanotechnol. Monit. Manag. 2021, 16, 100470. [Google Scholar] [CrossRef]

- Gil-Jasso, N.D.; Giles-Mazón, E.A.; Soriano-Giles, G.; Reinheimer, E.W.; Varela-Guerrero, V.; Ballesteros-Rivas, M.F. A Methodology for Recycling Waste Expanded Polystyrene Using Flower Essential Oils. Fuel 2022, 307, 121835. [Google Scholar] [CrossRef]

- Mumbach, G.D.; Bolzan, A.; Machado, R.A.F. A Closed-Loop Process Design for Recycling Expanded Polystyrene Waste by Dissolution and Polymerization. Polymer 2020, 209, 122940. [Google Scholar] [CrossRef]

- Noguchi, T.; Miyashita, M.; Inagaki, Y.; Watanabe, H. A New Recycling System for Expanded Polystyrene Using a Natural Solvent. Part 1. A New Recycling Technique. Packag. Technol. Sci. 1998, 11, 19–27. [Google Scholar] [CrossRef]

- Ishida, T. Removal of Fish Odors Form Styrofoam Packaging to Improve Recycling Potential Using Hansen Solubility Parameters. Recycling 2020, 5, 30. [Google Scholar] [CrossRef]

- Roosen, M.; Harinck, L.; Ügdüler, S.; De Somer, T.; Hucks, A.-G.; Belé, T.G.A.; Buettner, A.; Ragaert, K.; Van Geem, K.M.; Dumoulin, A.; et al. Deodorization of Post-Consumer Plastic Waste Fractions: A Comparison of Different Washing Media. Sci. Total Environ. 2022, 812, 152467. [Google Scholar] [CrossRef] [PubMed]

- Rung, C.; Welle, F.; Gruner, A.; Springer, A.; Steinmetz, Z.; Munoz, K. Identification and Evaluation of (Non-)Intentionally Added Substances in Post-Consumer Recyclates and Their Toxicological Classification. Recycling 2023, 8, 24. [Google Scholar] [CrossRef]

- Roosen, M.; De Somer, T.; Demets, R.; Ügdüler, S.; Meesseman, V.; Van Gorp, B.; Ragaert, K.; Van Geem, K.M.; Walgraeve, C.; Dumoulin, A.; et al. Towards a Better Understanding of Odor Removal from Post-Consumer Plastic Film Waste: A Kinetic Study on Deodorization Efficiencies with Different Washing Media. Waste Manag. 2021, 120, 564–575. [Google Scholar] [CrossRef]

- Strangl, M.; Ortner, E.; Fell, T.; Ginzinger, T.; Buettner, A. Odor Characterization along the Recycling Process of Post-Consumer Plastic Film Fractions. J. Clean. Prod. 2020, 260, 121104. [Google Scholar] [CrossRef]

- Kara Ali, Z.; Pin, J.-M.; Pellerin, C. Quantification of P-Cymene and Heptane in a Solvent-Based Green Process of Polystyrene Recycling. Appl. Spectrosc. Pract. 2023, 1, 27551857231179982. [Google Scholar] [CrossRef]

- Demets, R.; Roosen, M.; Vandermeersch, L.; Ragaert, K.; Walgraeve, C.; De Meester, S. Development and Application of an Analytical Method to Quantify Odour Removal in Plastic Waste Recycling Processes. Resour. Conserv. Recycl. 2020, 161, 104907. [Google Scholar] [CrossRef]

- Ügdüler, S.; Van Geem, K.M.; Roosen, M.; Delbeke, E.I.P.; De Meester, S. Challenges and Opportunities of Solvent-Based Additive Extraction Methods for Plastic Recycling. Waste Manag. 2020, 104, 148–182. [Google Scholar] [CrossRef]

- Zhao, Y.-B.; Lv, X.-D.; Ni, H.-G. Solvent-Based Separation and Recycling of Waste Plastics: A Review. Chemosphere 2018, 209, 707–720. [Google Scholar] [CrossRef]

- van Velzen, E.T.; Jansen, M. Solvent Extraction as Additional Purification Method for Postconsumer Plastic Packaging Waste; No 1261; Wageningen UR-Food & Biobased Research: Wageningen, The Netherlands, 2011. [Google Scholar]

- Mayrhofer, E.; Prielinger, L.; Sharp, V.; Rainer, B.; Kirchnawy, C.; Rung, C.; Gruner, A.; Juric, M.; Springer, A. Safety Assessment of Recycled Plastics from Post-Consumer Waste with a Combination of a Miniaturized Ames Test and Chromatographic Analysis. Recycling 2023, 8, 87. [Google Scholar] [CrossRef]

- Kanwal, F.; Waraich, S.M.; Jamil, T. FT-IR Analysis of Recycled Polystyrene for Food Packaging. J. Chem. Soc. Pakistan 2007, 29, 1275–1281. [Google Scholar]

- Vilaplana, F.; Karlsson, S.; Ribes-Greus, A. Changes in the Microstructure and Morphology of High-Impact Polystyrene Subjected to Multiple Processing and Thermo-Oxidative Degradation. Eur. Polym. J. 2007, 43, 4371–4381. [Google Scholar] [CrossRef]

- Fullana, A.; Cabanes, A.; Horodytska, O. Procedimiento Para La Descontaminación de Plástico Reciclado; University of Alicante: San Vicente del Raspeig, Spain, 2021. [Google Scholar]

- Packaging Europe. The Next Steps for Recycled Polystyrene; Packaging Europe: Norwich, UK, 2024. [Google Scholar]

- Appel, B. Gneuss—Plastic Recycling—We Could Do More and Faster—Meeting with Gneuss Kunststofftechnik on Innovations and Investments in a Challenging Time and Environment. Available online: https://www.petnology.com/magazine/article/gneuss-plastic-recycling-we-could-do-more-and-faster-meeting-with-gneuss-kunststofftechnik-on-innovations-and-investments-in-a-challenging-time-and-environment (accessed on 6 November 2024).

- Gneuss. MRS EXTRUDER. Available online: https://www.gneuss.com/en/polymer-technologies/extrusion/mrs-extruder/ (accessed on 22 January 2024).

- Gneuss, D. Arrangement for Filtering Plastic Melts. WO/2001/043847, 21 June 2001. [Google Scholar]

- Gneuss, D.; Walach, W. Extruder for Producing Molten Plastic Material. WO/2003/033240, 24 April 2003. [Google Scholar]

- Gneuss Company. Available online: https://www.gneuss.com/en/company/ (accessed on 24 February 2025).

- Gneuss, D.; Gneuss, D.; Gneuss, S. Method of Processing Solid Polymer Particles of a Polycondensate by Means of a Multi-Rotation System. WO/2020/108705A1, 4 June 2020. [Google Scholar]

- Gneuss, S.; Gneuss, D.; Gneuss, D. Extruder for the Viscosity-Increasing Preparation of Meltable Polymers. WO/2021/008659A1, 21 January 2021. [Google Scholar]

- Castellanos, P. Recycled Polystyrene Plastic in Food Packaging (Plástico Reciclado de Poliestireno En Envases de Alimentos). Available online: https://www.plastico.com/es/noticias/plastico-reciclado-de-poliestireno-en-envases-de-alimentos (accessed on 1 November 2024).

- Packaging Europe. Insights into the Circularity Potential of Polystyrene—Mechanical Recycling. Available online: https://packagingeurope.com/insights-into-the-circularity-potential-of-polystyrene-mechanical-recycling/5047.article (accessed on 1 November 2024).

- Next Generation Recycling (NGR). NGR Applications & Solutions; NGR: Kuala Lumpur, Malaysia, 2024. [Google Scholar]

- Fraunhofer Institute for Process Engineering and Packaging (IVV). Styrenics Circular Solutions AISBL Technical Dossier: Recycled Polystyrene for Direct Food Contact Application—SCS Petition (NGR); Fraunhofer Institute for Process Engineering and Packaging IV: Freising, Germany, 2021. [Google Scholar]

- Stache, K. INEOS Styrolution Announces First Yoghurt Cup in Supermarket Containing Mechanical Recycling of Polystyrene at Food Contact Quality. Available online: https://www.ineos-styrolution.com/news/ineos-styrolution-announces-first-yoghurt-cup-in-supermarket-containing-mechanical-recycling-of-polystyrene-at-food-contact-quality (accessed on 17 January 2025).

- INEOS Styrolution Mechanical Recycling: Converting Waste into Value. Available online: https://styrolution-eco.com/mechanical-recycling-of-styrenics.html (accessed on 29 November 2024).

- Lang, S. EGN, Ineos and Tomra Plan 40,000 Tpy Recycling Plant for PS in Germany. Available online: https://www.euwid-recycling.com/news/business/egn-ineos-and-tomra-plan-40000-tpy-recycling-plant-for-ps-in-germany-050723/ (accessed on 3 December 2024).

- TOMRA. INEOS Styrolution Offers Mechanically Recycled Polystyrene Developed in Close Collaboration with TOMRA. Available online: https://www.tomra.com/en/news-and-media/news/2021/ineos-styrolution-offers-mechanically-recycled-polystyrene (accessed on 5 December 2024).

- Packaging Europe Polystyrene Mechanically Recycled into Yoghurt Cups in Supermarket ‘First’. Available online: https://packagingeurope.com/news/polystyrene-mechanically-recycled-into-yoghurt-cups-in-supermarket-first/12307.article (accessed on 17 January 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sepúlveda-Carter, J.; Moreno de Castro, J.L.; Marín, L.; Baños, P.; Rodríguez, M.S.; Arrieta, M.P. Regulatory Frameworks and State-of-the-Art Decontamination Technologies for Recycled Polystyrene for Food Contact Applications. Polymers 2025, 17, 658. https://doi.org/10.3390/polym17050658

Sepúlveda-Carter J, Moreno de Castro JL, Marín L, Baños P, Rodríguez MS, Arrieta MP. Regulatory Frameworks and State-of-the-Art Decontamination Technologies for Recycled Polystyrene for Food Contact Applications. Polymers. 2025; 17(5):658. https://doi.org/10.3390/polym17050658

Chicago/Turabian StyleSepúlveda-Carter, Javiera, José L. Moreno de Castro, Laura Marín, Paula Baños, Marcos Sánchez Rodríguez, and Marina P. Arrieta. 2025. "Regulatory Frameworks and State-of-the-Art Decontamination Technologies for Recycled Polystyrene for Food Contact Applications" Polymers 17, no. 5: 658. https://doi.org/10.3390/polym17050658

APA StyleSepúlveda-Carter, J., Moreno de Castro, J. L., Marín, L., Baños, P., Rodríguez, M. S., & Arrieta, M. P. (2025). Regulatory Frameworks and State-of-the-Art Decontamination Technologies for Recycled Polystyrene for Food Contact Applications. Polymers, 17(5), 658. https://doi.org/10.3390/polym17050658