Transforming Plastic Waste into Value: A Review of Management Strategies and Innovative Applications in Sustainable Construction

Abstract

:1. Introduction

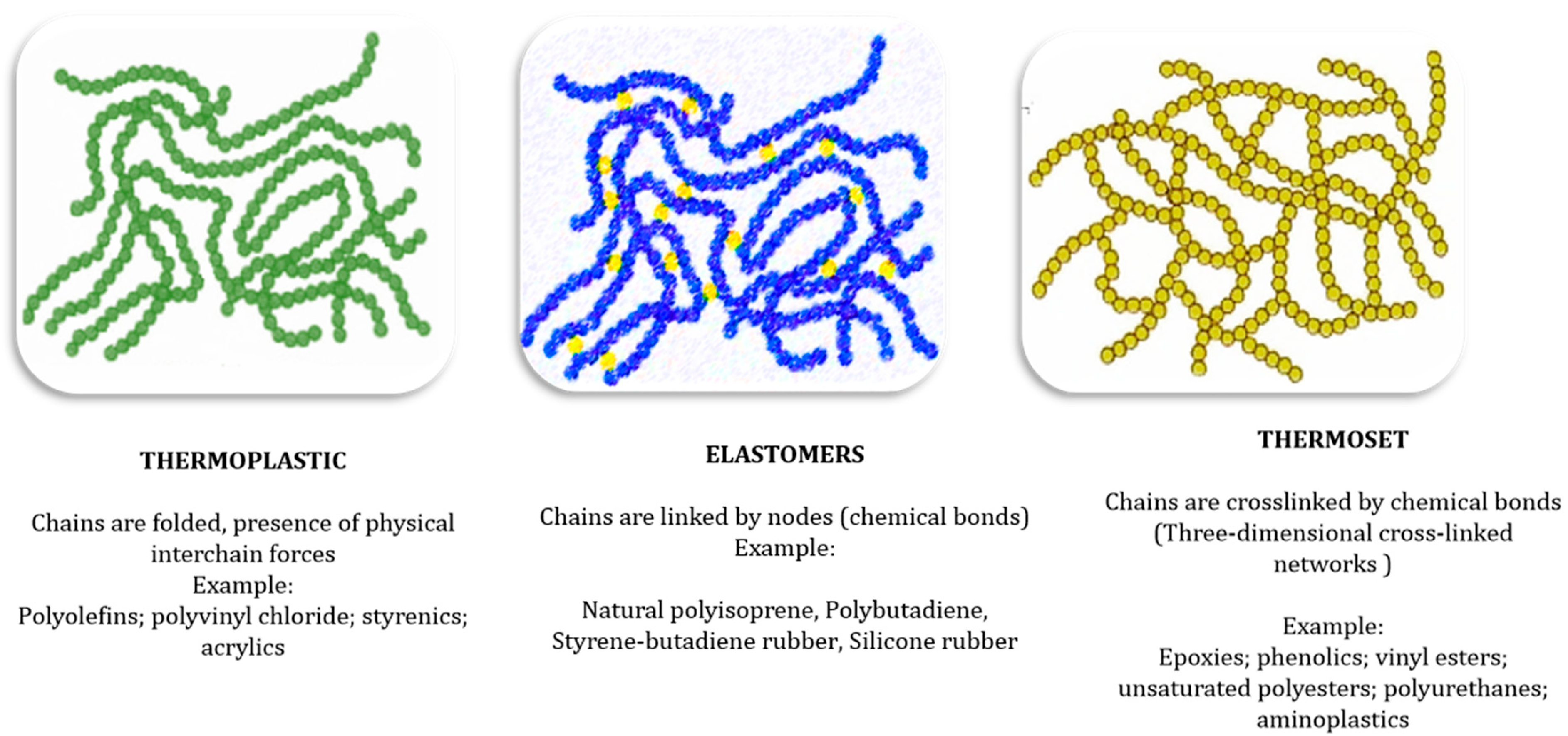

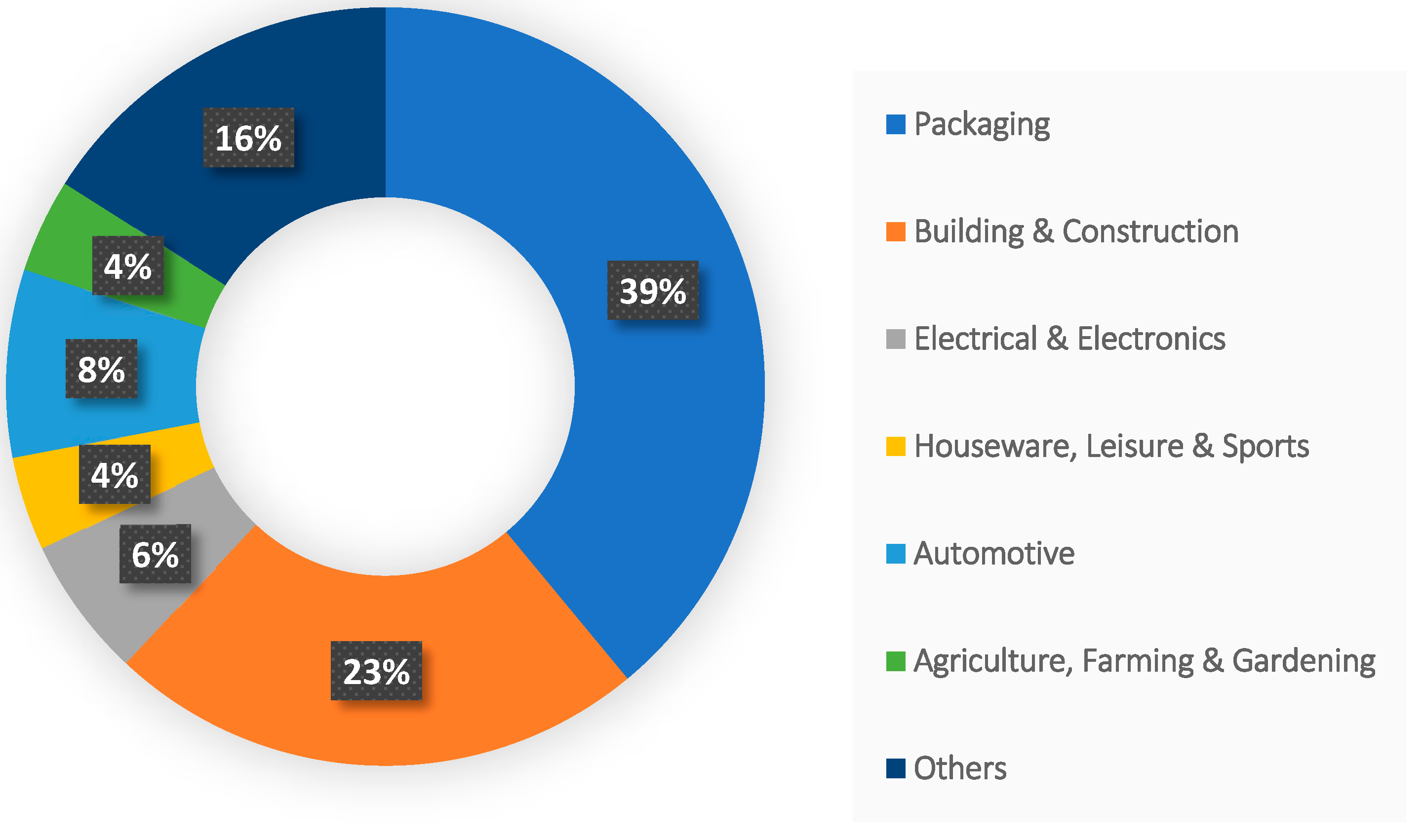

2. Classification of Plastic Waste

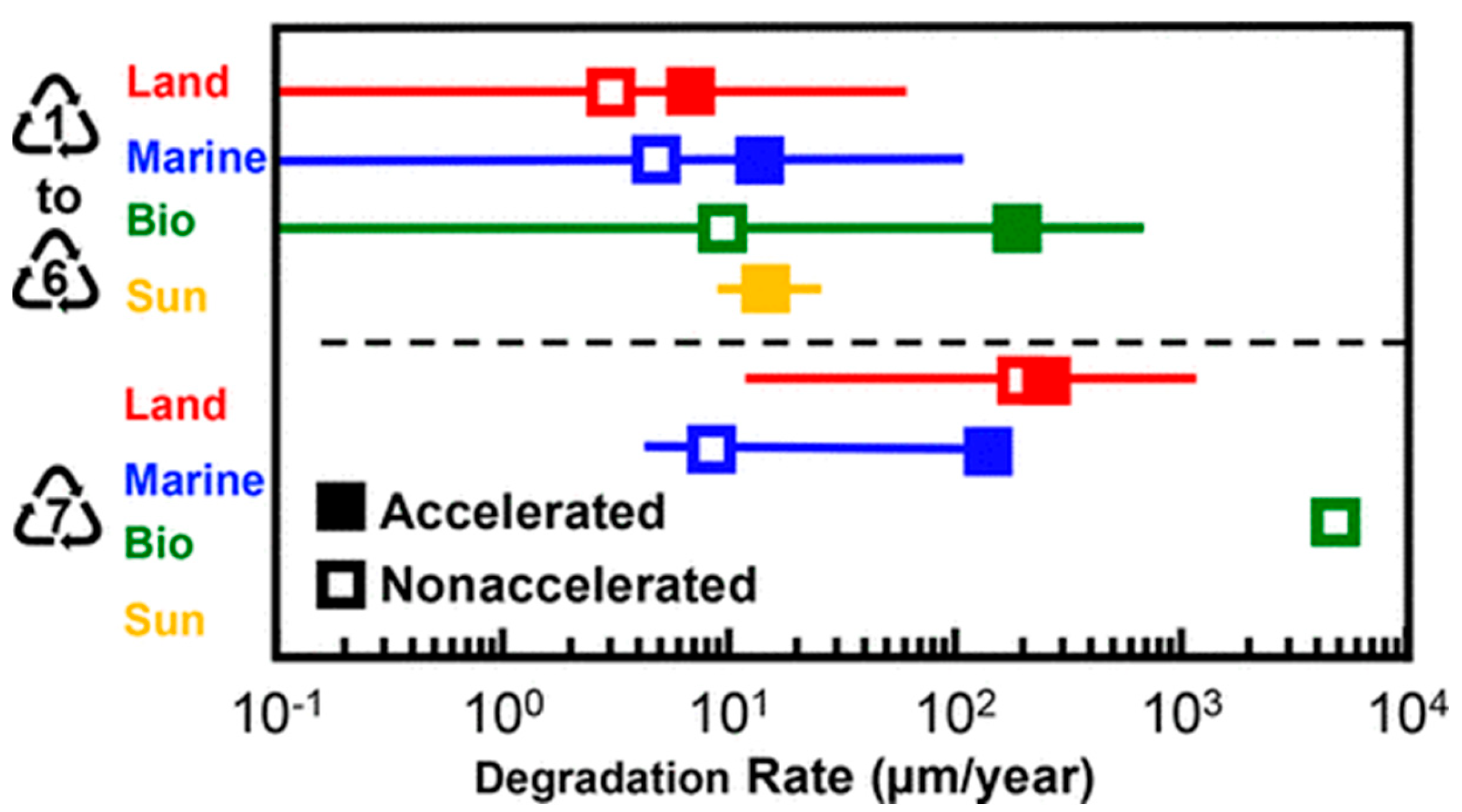

3. Environmental Impacts of Plastic Waste

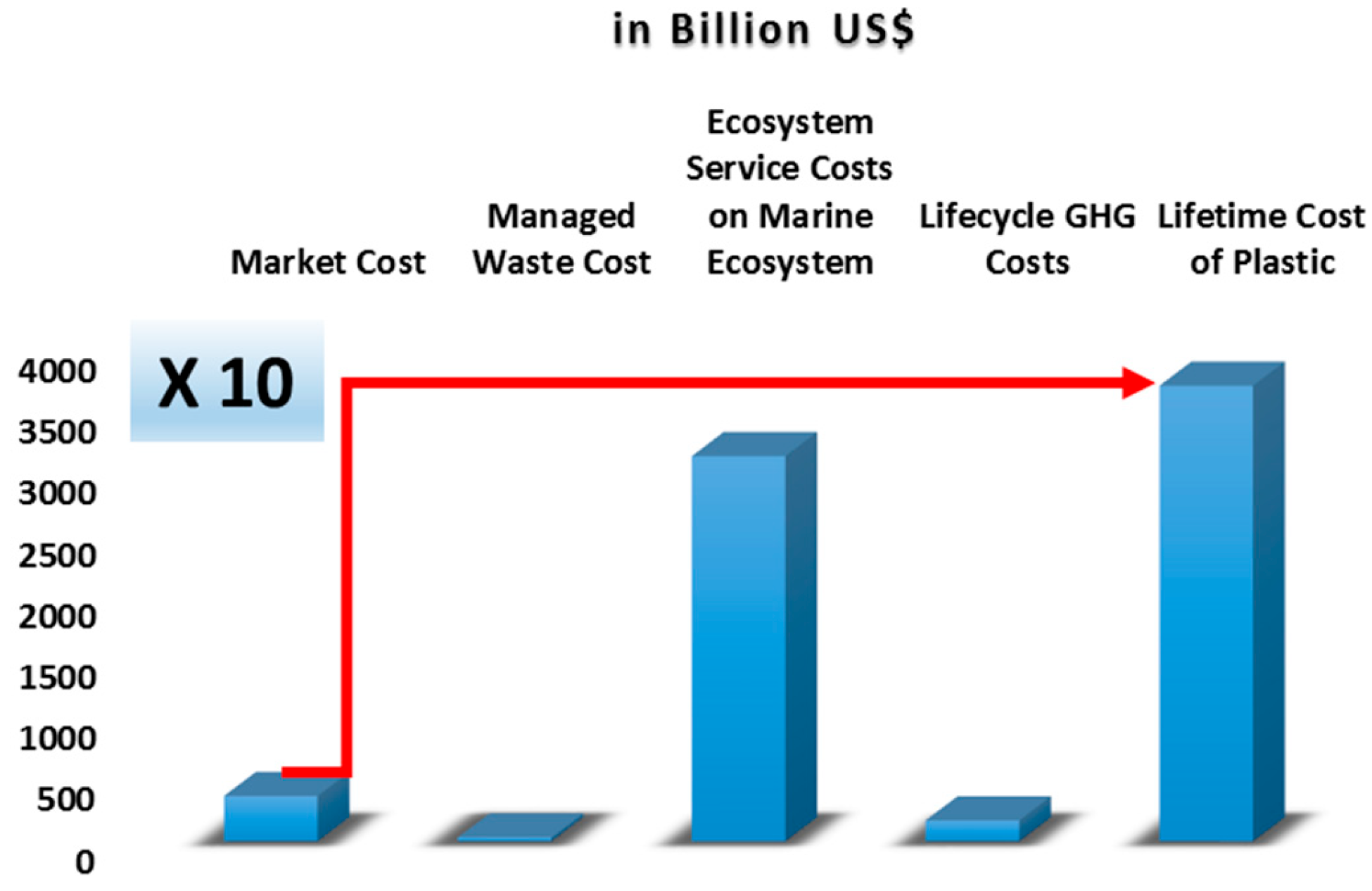

4. Socioeconomic Impacts of Plastic Waste

- The management of plastic waste entails significant financial expenditures, with annual costs surpassing USD 32 billion. These expenses encompass activities such as collection, sorting, disposal, and recycling processes.

- Clean-up efforts to remove waste incur significant costs for governments, non-governmental organizations, and concerned citizens, reaching as high as USD 15 billion annually.

- The substantial economic impact of marine plastic pollution includes a significant reduction in gross domestic product (GDP), reaching an estimated USD 7 billion in 2018 alone. This is primarily attributed to revenue losses in tourism, fishing, and aquaculture.

- Marginalized communities disproportionately bear the environmental and health burdens of the plastic lifecycle. Incineration plants and refineries are often sited in these areas, exposing residents to significant health and economic risks. Informal waste pickers face severe health risks throughout the plastic waste processing cycle. Additionally, climate change—exacerbated by plastic production and degradation—disproportionately affects disadvantaged communities, further deepening social and environmental inequities.

5. Plastic Waste Management Strategy

- Primary: Mechanical reprocessing into a product with equivalent properties (often referred to as closed-loop recycling). This technique is applicable to single-type plastics that are relatively clean or uncontaminated; for example, PET can be recycled from used bottles to create new bottles [48].

- Secondary: Mechanical reprocessing into products requiring lower properties (referred to as downgrading). Recycling and contamination with other polymers can lower the molecular weight of plastics, leading to a decline in mechanical properties. Furthermore, the reprocessing itself can cause thermo-mechanical degradation in recycled plastics. An example of secondary recycling is the production of flooring tiles from mixed polyolefins [48].

- Tertiary: Recovery of chemical constituents (it is referred to as either chemical recycling or feedstock recycling, and it occurs when the polymer is de-polymerized to its starting constituents). Pyrolysis is another example of this approach [48].

- Quaternary: Recovery of energy (described as energy from waste or valorization). This technique significantly reduces waste volume and involves energy recovery through the incineration of waste plastics. It is typically used when the waste is highly contaminated and unsuitable for conventional recycling methods [48].

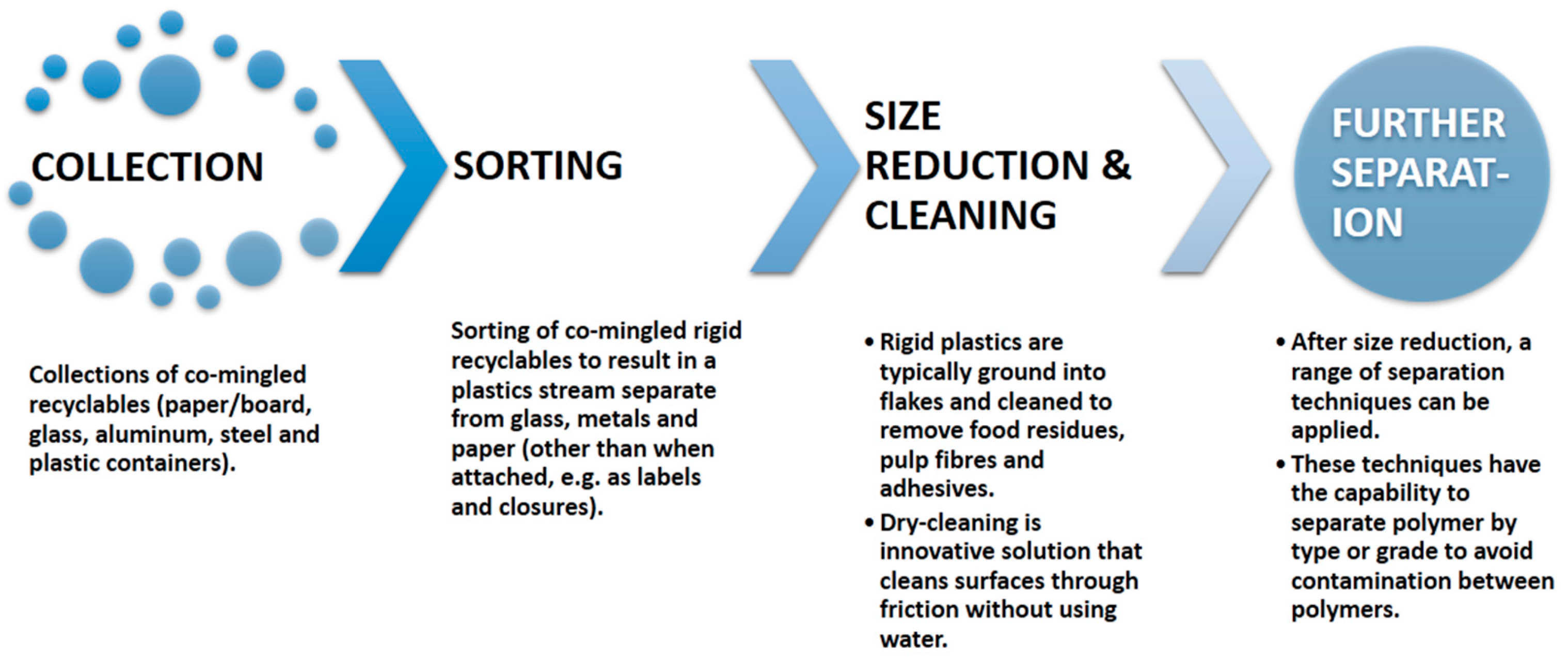

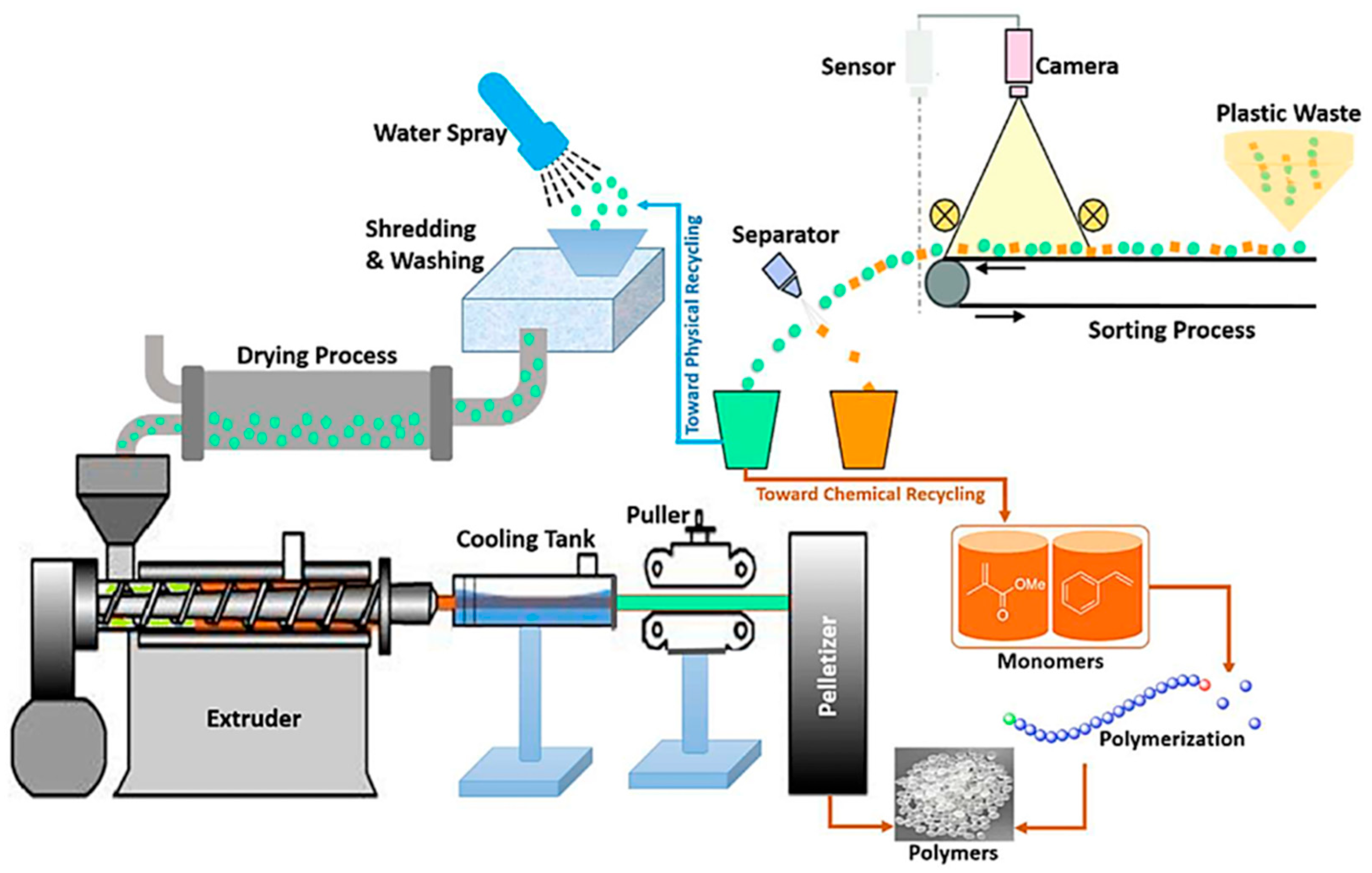

6. Plastic Waste Valorization/Recycling Methods

7. Potential Applications of Plastic Waste

7.1. Application as Soil Stabilizer

7.2. Application in Wastewater Treatment

7.3. Application in the Textile Industry

7.4. Other Potential Applications

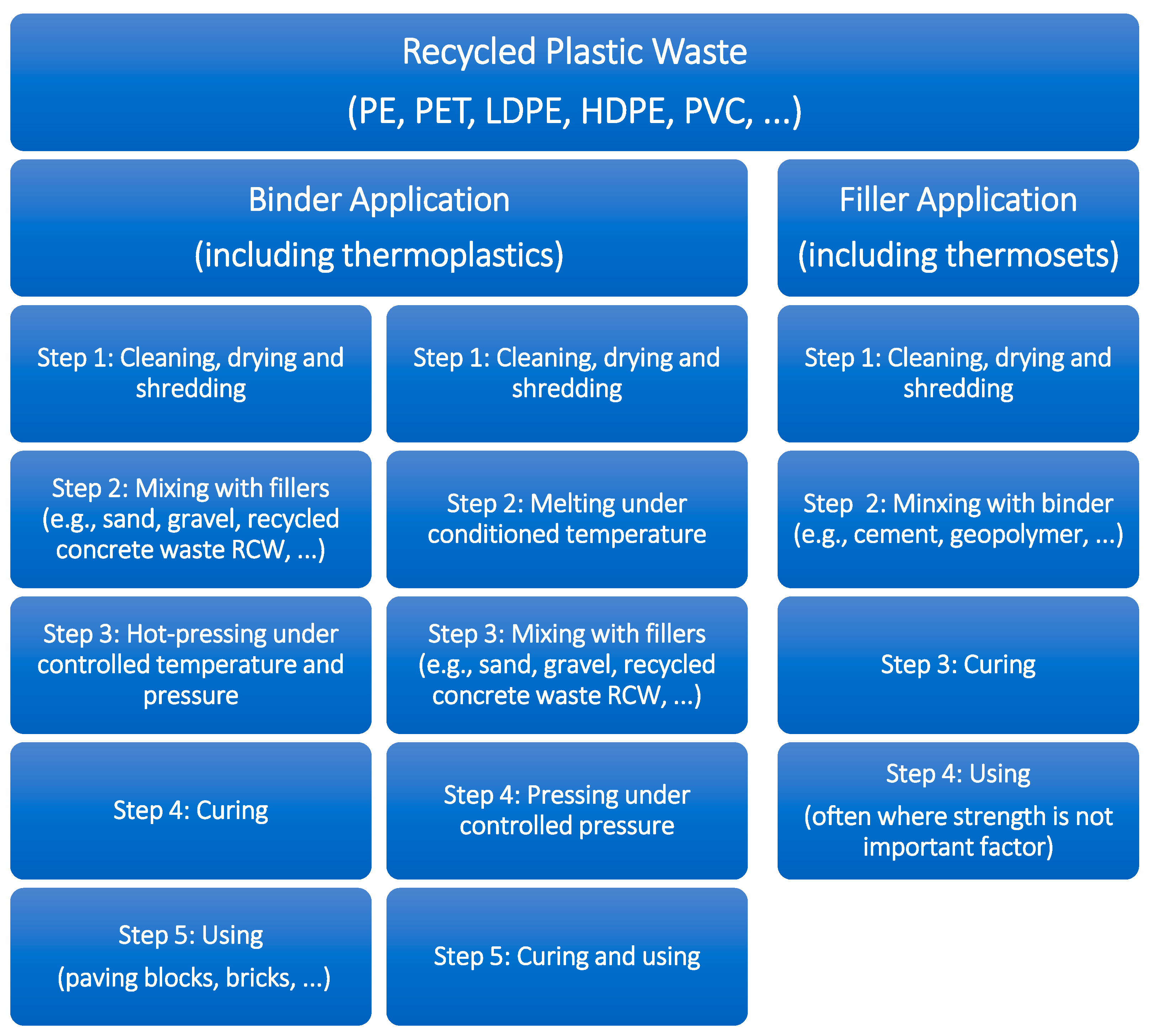

8. Application of Recycled Plastic Waste in Construction

8.1. Recycled Plastic Waste as Filler

8.2. Recycled Plastic Waste as Binder

9. Pros and Cons of Using Plastic Waste in Constructions

- (i)

- Long-term performance under different environmental conditions, including extreme weather conditions and harsh conditions (acidic or saline environment), which may accelerate the degradation over time and require frequent repairs [129].

- (ii)

- The environmental impact due to degradation: The composites may contribute to long-term environmental pollution if not properly managed at the end of their life cycle, as they may degrade slowly in natural environments and release both additives (e.g., plasticizers, stabilizers) and microplastics. Pavements and other materials undergo mechanical abrasion, leading to the release of microplastics even before they start to degrade [130].

- (iii)

- Health and safety concerns: The handling of certain types of plastic waste (especially when heated or melted) may release harmful fumes or chemicals, posing health risks to workers involved in the manufacturing process [131].

- (iv)

- Variability of plastic feedstock and presence of impurities: The properties of recycled plastic waste can vary depending on the source and type of plastic. This variability can make it difficult to maintain consistent quality and performance in construction materials [132].

- (v)

- Cost of processing and treatment: The processing of plastic waste (e.g., sorting, cleaning, melting) can be energy-intensive. Additionally, pretreatment methods, such as surface modifications, may be necessary to improve compatibilization with other common construction materials, complicating the production and further increasing the cost [133].

10. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Haba, B.; Agoudjil, B.; Boudenne, A.; Benzarti, K. Hygric properties and thermal conductivity of a new insulation material for building based on date palm concrete. Constr. Build. Mater. 2017, 154, 963–971. [Google Scholar] [CrossRef]

- Haba, B.; Benali, F.; Jawaid, M.; Leao, A.L. A Review on Gypsum-Based Composites Reinforced With Palm Fibers in Construction Applications. Int. J. Thermophys. 2022, 43, 164. [Google Scholar] [CrossRef]

- Kareche, A.; Agoudjil, B.; Haba, B.; Boudenne, A. Study on the durability of new construction materials based on mortar reinforced with date palm fibers wastes. Waste Biomass Valorization 2020, 11, 3801–3809. [Google Scholar] [CrossRef]

- Barnes, D.K.A.; Galgani, F.; Thompson, R.C.; Barlaz, M.A. Accumulation and fragmentation of plastic debris in global environments. Philos. Trans. R. Soc. Lond. B Biol. Sci. 2009, 364, 1985–1998. [Google Scholar] [CrossRef]

- Zia, K.M.; Bhatti, H.N.; Ahmad Bhatti, I. Methods for polyurethane and polyurethane composites, recycling and recovery: A review. React. Funct. Polym. 2007, 67, 675–692. [Google Scholar] [CrossRef]

- UNEP. Plastic Planet: How Tiny Plastic Particles Are Polluting Our Soil. 2021. Available online: https://www.unep.org/news-and-stories/story/plastic-planet-how-tiny-plastic-particles-are-polluting-our-soil (accessed on 10 March 2025).

- Yang, Y.; Jalalah, M.; Alsareii, S.A.; Harraz, F.A.; Thakur, N.; Zheng, Y.; Koutb, M.; Yoon, Y.; Salama, E.-S. Plastic wastes (PWs) and microplastics (MPs) formation: Management, migration, and environmental impact. J. Environ. Chem. Eng. 2024, 12, 112926. [Google Scholar] [CrossRef]

- Nene, A.; Sadeghzade, S.; Viaroli, S.; Yang, W.; Uchenna, U.P.; Kandwal, A.; Liu, X.; Somani, P.; Galluzzi, M. Recent advances and future technologies in nano-microplastics detection. Environ. Sci. Eur. 2025, 37, 7. [Google Scholar] [CrossRef]

- Goyal, H.; Kumar, R.; Mondal, P. Life cycle analysis of paver block production using waste plastics: Comparative assessment with concrete paver blocks. J. Clean. Prod. 2023, 402, 136857. [Google Scholar] [CrossRef]

- Kumar, R.; Verma, A.; Shome, A.; Sinha, R.; Sinha, S.; Jha, P.K.; Kumar, R.; Kumar, P.; Shubham; Das, S.; et al. Impacts of Plastic Pollution on Ecosystem Services, Sustainable Development Goals, and Need to Focus on Circular Economy and Policy Interventions. Sustainability 2021, 13, 9963. [Google Scholar] [CrossRef]

- Balu, R.; Dutta, N.K.; Roy Choudhury, N. Plastic Waste Upcycling: A Sustainable Solution for Waste Management, Product Development, and Circular Economy. Polymers 2022, 14, 4788. [Google Scholar] [CrossRef]

- Swinnerton, S.; Kurtz, K.; Neba Nforsoh, S.; Craver, V.; Tsai, C. The manufacturing process and consequent occupational health and environmental risks associated with the use of plastic waste in construction bricks in small-scale recycling plants. J. Clean. Prod. 2024, 477, 143818. [Google Scholar] [CrossRef]

- Nafiu, S.A.; Azeez, M.O.; AlAqad, K.M.; Olarewaju, T.A.; Yerima, E.A.; Tanimu, A. Waste plastic management: Recycling and the environmental health nexus. Clean. Mater. 2025, 15, 100291. [Google Scholar] [CrossRef]

- Faisal, F.; Rasul, M.G.; Jahirul, M.I.; Schaller, D. Pyrolytic conversion of waste plastics to energy products: A review on yields, properties, and production costs. Sci. Total Environ. 2023, 861, 160721. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Cui, J.; Hu, G.; Zhang, B. Recycling strategies for vitrimers. Int. J. Smart Nano Mater. 2022, 13, 367–390. [Google Scholar] [CrossRef]

- Kazemi, M.; Faisal Kabir, S.; Fini, E.H. State of the art in recycling waste thermoplastics and thermosets and their applications in construction. Resour. Conserv. Recycl. 2021, 174, 105776. [Google Scholar] [CrossRef]

- Müller, K.U. Structure-property Relationships of Homogeneous Cellulose Blends and Their Application Potential in Thermoplastic Processing; Universitätsbibliothek der TU München: Munich, Germany, 2023. [Google Scholar]

- Rezai, P.; Wu, W.I.; Selvaganapathy, P.R. 1—Microfabrication of polymers for bioMEMS. In MEMS for Biomedical Applications; Bhansali, S., Vasudev, A., Eds.; Woodhead Publishing: Sawston, UK, 2012; pp. 3–45. [Google Scholar] [CrossRef]

- Biron, M. 7—Plastics Solutions for Practical Problems. In Thermoplastics and Thermoplastic Composites, 2nd ed.; Biron, M., Ed.; William Andrew Publishing: Norwich, NY, USA, 2013; pp. 831–984. [Google Scholar]

- Nanda, S.; Berruti, F. Thermochemical conversion of plastic waste to fuels: A review. Environ. Chem. Lett. 2020, 19, 123–148. [Google Scholar] [CrossRef]

- Sastri, V.R. Chapter 3—Materials Used in Medical Devices. In Plastics in Medical Devices; Sastri, V.R., Ed.; William Andrew Publishing: Boston, MA, USA, 2010; pp. 21–32. [Google Scholar]

- Morici, E.; Dintcheva, N.T. Recycling of Thermoset Materials and Thermoset-Based Composites: Challenge and Opportunity. Polymers 2022, 14, 4153. [Google Scholar] [CrossRef]

- Global Thermoset Composites Market Size by Fiber Type, by Resin Type, by Geographic Scope and Forecast. Verified Market Research. 2024. Available online: https://www.verifiedmarketresearch.com/product/thermoset-composites-market/ (accessed on 10 March 2025).

- Commission Decision of 28 January 1997 Establishing the Identification System for Packaging Materials Pursuant to Euro-pean Parliament and Council Directive 94/62/EC on Packaging and Packaging Waste. Available online: https://eur-lex.europa.eu/legal-content/IT/TXT/PDF/?uri=CELEX:31997D0129 (accessed on 10 March 2025).

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics Recycling: Challenges and Opportunities. Philos. Trans. R. Soc. Lond. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef]

- The Circular Economy for Plastics—A European Analysis. Plastic Europe. 2024. Available online: https://plasticseurope.org/knowledge-hub/the-circular-economy-for-plastics-a-european-analysis-2024/ (accessed on 10 March 2025).

- Sogancioglu, M.; Yel, E.; Ahmetli, G. Pyrolysis of waste high density polyethylene (HDPE) and low density polyethylene (LDPE) plastics and production of epoxy composites with their pyrolysis chars. J. Clean. Prod. 2017, 165, 369–381. [Google Scholar] [CrossRef]

- Plastics—The Facts (2021): An Analysis of European Plastics Production, Demand and Waste Data; Plastics Europe: Brussels, Belgium, 2021.

- Suman, T.Y.; Li, W.-G.; Alif, S.; Faris, V.R.P.; Amarnath, D.J.; Ma, J.-G.; Pei, D.-S. Characterization of petroleum-based plastics and their absorbed trace metals from the sediments of the Marina Beach in Chennai, India. Environ. Sci. Eur. 2020, 32, 110. [Google Scholar] [CrossRef]

- Ali, N.; Khan, M.H.; Ali, M.; Sidra; Ahmad, S.; Khan, A.; Nabi, G.; Ali, F.; Bououdina, M.; Kyzas, G.Z. Insight into microplastics in the aquatic ecosystem: Properties, sources, threats and mitigation strategies. Sci. Total Environ. 2024, 913, 169489. [Google Scholar] [CrossRef] [PubMed]

- Chamas, A.; Moon, H.; Zheng, J.; Qiu, Y.; Tabassum, T.; Jang, J.H.; Abu-Omar, M.; Scott, S.L.; Suh, S. Degradation Rates of Plastics in the Environment. ACS Sustain. Chem. Eng. 2020, 8, 3494–3511. [Google Scholar] [CrossRef]

- Dimassi, S.N.; Hahladakis, J.N.; Yahia, M.N.D.; Ahmad, M.I.; Sayadi, S.; Al-Ghouti, M.A. Degradation-fragmentation of marine plastic waste and their environmental implications: A critical review. Arab. J. Chem. 2022, 15, 104262. [Google Scholar] [CrossRef]

- Wojnowska-Baryła, I.; Bernat, K.; Zaborowska, M. Plastic Waste Degradation in Landfill Conditions: The Problem with Microplastics, and Their Direct and Indirect Environmental Effects. Int. J. Environ. Res. Public Health 2022, 19, 13223. [Google Scholar] [CrossRef]

- UNEP. Plastic Pollution. Available online: https://www.unep.org/plastic-pollution (accessed on 10 March 2025).

- Fava, M. Ocean Plastic Pollution an Overview: Data and Statistics; UNESCO: Paris, France, 2022. [Google Scholar]

- Barrett, N.; Miller, J.; Orbock-Miller, S. Quantification and Categorization of Macroplastics (Plastic Debris) within a Headwaters Basin in Western North Carolina, USA: Implications to the Potential Impacts of Plastic Pollution on Biota. Environments 2024, 11, 195. [Google Scholar] [CrossRef]

- Cheng, F.; Zhang, T.; Liu, Y.; Zhang, Y.; Qu, J. Non-Negligible Effects of UV Irradiation on Transformation and Environmental Risks of Microplastics in the Water Environment. J. Xenobiot. 2022, 12, 1–12. [Google Scholar] [CrossRef]

- Kibria, M.G.; Masuk, N.I.; Safayet, R.; Nguyen, H.Q.; Mourshed, M. Plastic Waste: Challenges and Opportunities to Mitigate Pollution and Effective Management. Int. J. Environ. Res. 2023, 17, 20. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Everything You Need to Know About Plastic Pollution; UN Environment Programme: Nairobi, Kenya, 2023.

- A New Plastics Economy Is Needed to Protect the Climate; United Nations Climate Change: Bonn, Germany, 2024.

- Plastics: The Costs to Society, the Environment and the Economy. a Report for WWF by Dalberg. 2021. Available online: https://www.wwfca.org/en/plasticsthecosttosociety/ (accessed on 10 March 2025).

- The Hidden Cost of Plastic; World Wildlife Fund (WWF): Gland, Switzerland, 2021; Available online: https://www.wwfdrc.org/en/?36252%2FThe-hidden-cost-of-plastic (accessed on 10 March 2025).

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and demolition waste management in China through the 3R principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar] [CrossRef]

- Merrington, A. 11—Recycling of Plastics. In Applied Plastics Engineering Handbook; Kutz, M., Ed.; William Andrew Publishing: Oxford, UK, 2011; pp. 177–192. [Google Scholar]

- Shen, M.; Huang, W.; Chen, M.; Song, B.; Zeng, G.; Zhang, Y. (Micro)plastic crisis: Un-ignorable contribution to global greenhouse gas emissions and climate change. J. Clean. Prod. 2020, 254, 120138. [Google Scholar] [CrossRef]

- Shrivastava, A. 7—Environmental Aspects of Plastics. In Introduction to Plastics Engineering; Shrivastava, A., Ed.; William Andrew Publishing: Norwich, NY, USA, 2018; pp. 207–232. [Google Scholar]

- Joseph, B.; James, J.; Kalarikkal, N.; Thomas, S. Recycling of medical plastics. Adv. Ind. Eng. Polym. Res. 2021, 4, 199–208. [Google Scholar] [CrossRef]

- Hasheminezhad, A.; Farina, A.; Yang, B.; Ceylan, H.; Kim, S.; Tutumluer, E.; Cetin, B. The utilization of recycled plastics in the transportation infrastructure systems: A comprehensive review. Constr. Build. Mater. 2024, 411, 134448. [Google Scholar] [CrossRef]

- Alassali, A.; Picuno, C.; Chong, Z.K.; Guo, J.; Maletz, R.; Kuchta, K. Towards Higher Quality of Recycled Plastics: Limitations from the Material’s Perspective. Sustainability 2021, 13, 13266. [Google Scholar] [CrossRef]

- Kassab, A.; Al Nabhani, D.; Mohanty, P.; Pannier, C.; Ayoub, G.Y. Advancing Plastic Recycling: Challenges and Opportunities in the Integration of 3D Printing and Distributed Recycling for a Circular Economy. Polymers 2023, 15, 3881. [Google Scholar] [CrossRef]

- Naderi Kalali, E.; Lotfian, S.; Entezar Shabestari, M.; Khayatzadeh, S.; Zhao, C.; Yazdani Nezhad, H. A critical review of the current progress of plastic waste recycling technology in structural materials. Curr. Opin. Green Sustain. Chem. 2023, 40, 100763. [Google Scholar] [CrossRef]

- Seco, A.; Ramírez, F.; Miqueleiz, L.; García, B. Stabilization of expansive soils for use in construction. Appl. Clay Sci. 2011, 51, 348–352. [Google Scholar] [CrossRef]

- Winterkorn, H.F.; Fang, H.-Y. Soil Technology and Engineering Properties of Soils. In Foundation Engineering Handbook; Fang, H.-Y., Ed.; Springer: Boston, MA, USA, 1991; pp. 88–143. [Google Scholar]

- Fauzi, A.; Djauhari, Z.; Fauzi, U. Soil Engineering Properties Improvement by Utilization of Cut Waste Plastic and Crushed Waste Glass as Additive. Int. J. Eng. Technol. 2016, 8, 15–18. [Google Scholar] [CrossRef]

- Kassa, R.B.; Workie, T.; Abdela, A.; Fekade, M.; Saleh, M.; Dejene, Y. Soil Stabilization Using Waste Plastic Materials. Open J. Civil Eng. 2020, 10, 55–68. [Google Scholar] [CrossRef]

- Gong, J.; Liu, J.; Chen, X.; Jiang, Z.; Wen, X.; Mijowska, E.; Tang, T. Converting real-world mixed waste plastics into porous carbon nanosheets with excellent performance in the adsorption of an organic dye from wastewater. J. Mater. Chem. A 2015, 3, 341–351. [Google Scholar] [CrossRef]

- Dorji, U.; Dorji, P.; Shon, H.; Badeti, U.; Dorji, C.; Wangmo, C.; Tijing, L.; Kandasamy, J.; Vigneswaran, S.; Chanan, A.; et al. On-site domestic wastewater treatment system using shredded waste plastic bottles as biofilter media: Pilot-scale study on effluent standards in Bhutan. Chemosphere 2022, 286, 131729. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Sweetser, D. Recycled PET Nanofibers for Water Filtration Applications. Materials 2016, 9, 247. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Peng, Y.; Deng, Y.; Ye, F.; Zhang, C.; Hu, X.; Liu, Y.; Zhang, D. Recycling and Reutilizing Polymer Waste via Electrospun Micro/Nanofibers: A Review. Nanomaterials 2022, 12, 1663. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Kang, S.B.; Yang, E.; Won, S.W. Preparation of adsorptive polyethyleneimine/polyvinyl chloride electrospun nanofiber membrane: Characterization and application. J. Environ. Manag. 2022, 316, 115155. [Google Scholar] [CrossRef] [PubMed]

- Bekri-Abbes, I.; Bayoudh, S.; Baklouti, M. A technique for purifying wastewater with polymeric flocculantproduced from waste plastic. Desalination 2007, 204, 198–203. [Google Scholar] [CrossRef]

- Wankasi, D.; Dikio, E.D. Polyvinyl chloride Waste as an Adsorbent for the Sorption of Pb2+ from Aqueous Solution. J. Chem. 2014, 2014, 817527. [Google Scholar] [CrossRef]

- Lee, J.H.; Lim, K.S.; Hahm, W.G.; Kim, S.H. Properties of recycled and virgin poly(ethylene terephthalate) blend fibers. J. Appl. Polym. Sci. 2013, 128, 1250–1256. [Google Scholar] [CrossRef]

- Kumartasli, S.; Avinc, O. Recycled Thermoplastics: Textile Fiber Production, Scientific and Recent Commercial Developments. In Recent Developments in Plastic Recycling; Parameswaranpillai, J., Mavinkere Rangappa, S., Gulihonnehalli Rajkumar, A., Siengchin, S., Eds.; Springer: Singapore, 2021; pp. 169–192. [Google Scholar]

- Sezgin, H.; Yalcin-Enis, I. Turning Plastic Wastes Into Textile Products. In Handbook of Solid Waste Management: Sustainability through Circular Economy; Baskar, C., Ramakrishna, S., Baskar, S., Sharma, R., Chinnappan, A., Sehrawat, R., Eds.; Springer: Singapore, 2020; pp. 1–27. [Google Scholar]

- Shukla, S.R.; Harad, A.M.; Jawale, L.S. Recycling of waste PET into useful textile auxiliaries. Waste Manag. 2008, 28, 51–56. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, Y.; Zhang, X.; Qian, J.; Xing, X.; Wang, X. Regenerated cationic dyeable polyester deriving from poly(ethylene terephthalate) waste. Polym. Degrad. Stab. 2020, 179, 109261. [Google Scholar] [CrossRef]

- Chen, Y.-H.; Ranganathan, P.; Lee, Y.-H.; Rwei, S.-P. New Strategy and Polymer Design to Synthesize Polyamide 66 (PA66) Copolymers with Aromatic Moieties from Recycled PET (rPET). ACS Sustain. Chem. Eng. 2021, 9, 3518–3528. [Google Scholar] [CrossRef]

- Guddeti, R.R.; Knight, R.; Grossmann, E.D. Depolymerization of Polypropylene in an Induction-Coupled Plasma (ICP) Reactor. Ind. Eng. Chem. Res. 2000, 39, 1171–1176. [Google Scholar] [CrossRef]

- Jia, X.; Qin, C.; Friedberger, T.; Guan, Z.; Huang, Z. Efficient and selective degradation of polyethylenes into liquid fuels and waxes under mild conditions. Sci. Adv. 2016, 2, e1501591. [Google Scholar] [CrossRef] [PubMed]

- Bajdur, W.; Pajączkowska, J.; Makarucha, B.; Sułkowska, A.; Sułkowski, W.W. Effective polyelectrolytes synthesised from expanded polystyrene wastes. Eur. Polym. J. 2002, 38, 299–304. [Google Scholar] [CrossRef]

- Gutiérrez, C.; Rodríguez, J.F.; Gracia, I.; de Lucas, A.; García, M.T. Reduction of the carbon footprint through polystyrene recycling: Economical evaluation. Process Saf. Environ. Prot. 2016, 101, 144–151. [Google Scholar] [CrossRef]

- Aji, M.P.; Wati, A.L.; Priyanto, A.; Karunawan, J.; Nuryadin, B.W.; Wibowo, E.; Marwoto, P.; Sulhadi. Polymer carbon dots from plastics waste upcycling. Environ. Nanotechnol. Monit. Manag. 2018, 9, 136–140. [Google Scholar] [CrossRef]

- Cheng, L.X.; Zhang, L.; Chen, X.Y.; Zhang, Z.J. Efficient conversion of waste polyvinyl chloride into nanoporous carbon incorporated with MnOx exhibiting superior electrochemical performance for supercapacitor application. Electrochim. Acta 2015, 176, 197–206. [Google Scholar] [CrossRef]

- Ismail, H.; Irani, M.; Ahmad, Z. Superabsorbent hydrogels prepared from waste polystyrene and linear low-density polyethylene. J. Elastomers Plast. 2012, 45, 536–550. [Google Scholar] [CrossRef]

- Lauria, A.; Lizundia, E. Luminescent carbon dots obtained from polymeric waste. J. Clean. Prod. 2020, 262, 121288. [Google Scholar] [CrossRef]

- Liu, P.-S.; Li, L.; Zhou, N.-L.; Zhang, J.; Wei, S.-H.; Shen, J. Waste polystyrene foam-graft-acrylic acid/montmorillonite superabsorbent nanocomposite. J. Appl. Polym. Sci. 2007, 104, 2341–2349. [Google Scholar] [CrossRef]

- Li, X.; Wang, J.; Yi, G.; Teong, S.P.; Chan, S.P.; Zhang, Y. From waste plastic to artificial lotus leaf: Upcycling waste polypropylene to superhydrophobic spheres with hierarchical micro/nanostructure. Appl. Catal. B Environ 2024, 342, 123378. [Google Scholar] [CrossRef]

- Altalhi, T.; Kumeria, T.; Santos, A.; Losic, D. Synthesis of well-organised carbon nanotube membranes from non-degradable plastic bags with tuneable molecular transport: Towards nanotechnological recycling. Carbon 2013, 63, 423–433. [Google Scholar] [CrossRef]

- Lee, G.; Eui Lee, M.; Kim, S.-S.; Joh, H.-I.; Lee, S. Efficient upcycling of polypropylene-based waste disposable masks into hard carbons for anodes in sodium ion batteries. J. Ind. Eng. Chem. 2022, 105, 268–277. [Google Scholar] [CrossRef]

- Yao, D.; Yang, H.; Hu, Q.; Chen, Y.; Chen, H.; Williams, P.T. Carbon nanotubes from post-consumer waste plastics: Investigations into catalyst metal and support material characteristics. Appl. Catal. B. Environ. 2021, 280, 119413. [Google Scholar] [CrossRef]

- Gong, J.; Michalkiewicz, B.; Chen, X.; Mijowska, E.; Liu, J.; Jiang, Z.; Wen, X.; Tang, T. Sustainable Conversion of Mixed Plastics into Porous Carbon Nanosheets with High Performances in Uptake of Carbon Dioxide and Storage of Hydrogen. ACS Sustain. Chem. Eng. 2014, 2, 2837–2844. [Google Scholar] [CrossRef]

- Olazabal, I.; Goujon, N.; Mantione, D.; Alvarez-Tirado, M.; Jehanno, C.; Mecerreyes, D.; Sardon, H. From Plastic Waste to New Materials for Energy Storage. Polym. Chem. 2022, 13, 4222–4229. [Google Scholar] [CrossRef]

- Abbas, A.; Yi, Y.M.; Saleem, F.; Jin, Z.; Veksha, A.; Yan, Q.; Lisak, G.; Lim, T.M. Multiwall carbon nanotubes derived from plastic packaging waste as a high-performance electrode material for supercapacitors. Int. J. Energy Res. 2021, 45, 19611–19622. [Google Scholar] [CrossRef]

- Dědek, I.; Bartusek, S.; Dvořáček, J.J.; Nečas, J.; Petruš, J.; Jakubec, P.; Kupka, V.; Otyepka, M. Maximizing the electrochemical performance of supercapacitor electrodes from plastic waste. J. Energy Storage 2023, 72, 108660. [Google Scholar] [CrossRef]

- Ma, C.; Min, J.; Gong, J.; Liu, X.; Mu, X.; Chen, X.; Tang, T. Transforming polystyrene waste into 3D hierarchically porous carbon for high-performance supercapacitors. Chemosphere 2020, 253, 126755. [Google Scholar] [CrossRef]

- Min, J.; Zhang, S.; Li, J.; Klingeler, R.; Wen, X.; Chen, X.; Zhao, X.; Tang, T.; Mijowska, E. From polystyrene waste to porous carbon flake and potential application in supercapacitor. Waste Manag. 2019, 85, 333–340. [Google Scholar] [CrossRef]

- Zhi, M.; Yang, F.; Meng, F.; Li, M.; Manivannan, A.; Wu, N. Effects of Pore Structure on Performance of An Activated-Carbon Supercapacitor Electrode Recycled from Scrap Waste Tires. ACS Sustain. Chem. Eng. 2014, 2, 1592–1598. [Google Scholar] [CrossRef]

- Nyika, J.; Dinka, M. Recycling plastic waste materials for building and construction Materials: A minireview. Mater. Today Proc. 2022, 62, 3257–3262. [Google Scholar] [CrossRef]

- Maitlo, G.; Ali, I.; Maitlo, H.A.; Ali, S.; Unar, I.N.; Ahmad, M.B.; Bhutto, D.K.; Karmani, R.K.; Naich, S.U.; Sajjad, R.U.; et al. Plastic Waste Recycling, Applications, and Future Prospects for a Sustainable Environment. Sustainability 2022, 14, 11637. [Google Scholar] [CrossRef]

- González-Torres, M.; Pérez-Lombard, L.; Coronel, J.F.; Maestre, I.R.; Yan, D. A review on buildings energy information: Trends, end-uses, fuels and drivers. Energy Rep. 2022, 8, 626–637. [Google Scholar] [CrossRef]

- Wang, C.; Liu, Y.; Chen, W.-Q.; Zhu, B.; Qu, S.; Xu, M. Critical review of global plastics stock and flow data. J. Ind. Ecol. 2021, 25, 1300–1317. [Google Scholar] [CrossRef]

- Miller, S.A.; John, V.M.; Pacca, S.A.; Horvath, A. Carbon dioxide reduction potential in the global cement industry by 2050. Cem. Concr. Res. 2018, 114, 115–124. [Google Scholar] [CrossRef]

- Hausfather, Z.; Friedlingstein, P. Analysis: Growth of Chinese Fossil CO2 Emissions Drives New Global Record in 2023. Available online: https://www.carbonbrief.org/analysis-growth-of-chinese-fossil-co2-emissions-drives-new-global-record-in-2023/ (accessed on 10 March 2025).

- Wei, R.; Sakai, Y. Experimental investigation on bending strength of compacted plastic-concrete. Resour. Conserv. Recycl. 2021, 169, 105521. [Google Scholar] [CrossRef]

- Hamada, H.M.; Al-Attar, A.; Abed, F.; Beddu, S.; Humada, A.M.; Majdi, A.; Yousif, S.T.; Thomas, B.S. Enhancing sustainability in concrete construction: A comprehensive review of plastic waste as an aggregate material. Sustain. Mater. Technol. 2024, 40, e00877. [Google Scholar] [CrossRef]

- Filho, W.; Hunt, J.; Lingos, A.; Platje, J.; Vieira, L.; Will, M.; Gavriletea, M. The Unsustainable Use of Sand: Reporting on a Global Problem. Sustainability 2021, 13, 3356. [Google Scholar] [CrossRef]

- The Problem with Our Dwindling Sand Reserves; UN Environment Programme: Nairobi, Kenya, 2023.

- Belmokaddem, M.; Mahi, A.; Senhadji, Y.; Pekmezci, B.Y. Mechanical and physical properties and morphology of concrete containing plastic waste as aggregate. Constr. Build. Mater. 2020, 257, 119559. [Google Scholar] [CrossRef]

- Almeshal, I.; Tayeh, B.A.; Alyousef, R.; Alabduljabbar, H.; Mohamed, A.M. Eco-friendly concrete containing recycled plastic as partial replacement for sand. J. Mater. Res. Technol. 2020, 9, 4631–4643. [Google Scholar] [CrossRef]

- Thorneycroft, J.; Orr, J.; Savoikar, P.; Ball, R.J. Performance of structural concrete with recycled plastic waste as a partial replacement for sand. Constr. Build. Mater. 2018, 161, 63–69. [Google Scholar] [CrossRef]

- Akinwumi, I.; Soladoye, O.; Ajayi, V.; Epelle, P. Experimental Insight into the Containment of Plastic Waste in Cement-Stabilised Soil as a Road Pavement Layer Material. Infrastructures 2022, 7, 172. [Google Scholar] [CrossRef]

- Ahmad, F.; Jamal, A.; Mazher, K.M.; Umer, W.; Iqbal, M. Performance Evaluation of Plastic Concrete Modified with E-Waste Plastic as a Partial Replacement of Coarse Aggregate. Materials 2022, 15, 175. [Google Scholar] [CrossRef] [PubMed]

- Babafemi, A.J.; Šavija, B.; Paul, S.C.; Anggraini, V. Engineering Properties of Concrete with Waste Recycled Plastic: A Review. Sustainability 2018, 10, 3875. [Google Scholar] [CrossRef]

- Albano, C.; Camacho, N.; Hernández, M.; Matheus, A.; Gutiérrez, A. Influence of content and particle size of waste pet bottles on concrete behavior at different w/c ratios. Waste Manag. 2009, 29, 2707–2716. [Google Scholar] [CrossRef]

- Kashani, A.; Ngo, T.D.; Mendis, P.; Black, J.R.; Hajimohammadi, A. A sustainable application of recycled tyre crumbs as insulator in lightweight cellular concrete. J. Clean. Prod. 2017, 149, 925–935. [Google Scholar] [CrossRef]

- Basha, S.I.; Ali, M.R.; Al-Dulaijan, S.U.; Maslehuddin, M. Mechanical and thermal properties of lightweight recycled plastic aggregate concrete. J. Build. Eng. 2020, 32, 101710. [Google Scholar] [CrossRef]

- Jacob-Vaillancourt, C.; Sorelli, L. Characterization of concrete composites with recycled plastic aggregates from postconsumer material streams. Constr. Build. Mater. 2018, 182, 561–572. [Google Scholar] [CrossRef]

- Senhadji, Y.; Siad, H.; Escadeillas, G.; Benosman, A.S.; Chihaoui, R.; Mouli, M.; Lachemi, M. Physical, mechanical and thermal properties of lightweight composite mortars containing recycled polyvinyl chloride. Constr. Build. Mater. 2019, 195, 198–207. [Google Scholar] [CrossRef]

- Almohana, A.I.; Abdulwahid, M.Y.; Galobardes, I.; Mushtaq, J.; Almojil, S.F. Producing sustainable concrete with plastic waste: A review. Environ. Chall. 2022, 9, 100626. [Google Scholar] [CrossRef]

- Aciu, C.; Iluţiu-Varvara, D.-A.; Manea, D.; Orban, Y.; Babota, F. Recycling of plastic waste materials in the composition of ecological mortars. In Proceedings of the 11th International Conference Interdisciplinarity in Engineering, INTER-ENG 2017, Tirgu-Mures, Romania, 5–6 October 2017; pp. 274–279. [Google Scholar]

- Mendes, J.C.; Barreto, R.R.; Costa, L.C.B.; Brigolini, G.J.; Peixoto, R.A.F. Correlation Between Ultrasonic Pulse Velocity and Thermal Conductivity of Cement-Based Composites. J. Nondestruct. Eval. 2020, 39, 36. [Google Scholar] [CrossRef]

- Bodnárová, L.; Valek, J.; Novosad, P. Testing of Action of Direct Flame on Concrete. Sci. World J. 2015, 2015, 371913. [Google Scholar] [CrossRef]

- Steyn, Z.C.; Babafemi, A.J.; Fataar, H.; Combrinck, R. Concrete containing waste recycled glass, plastic and rubber as sand replacement. Constr. Build. Mater. 2021, 269, 121242. [Google Scholar] [CrossRef]

- Saikia, N.; de Brito, J. Use of plastic waste as aggregate in cement mortar and concrete preparation: A review. Constr. Build. Mater. 2012, 34, 385–401. [Google Scholar] [CrossRef]

- Thiam, M.; Fall, M. Mechanical, physical and microstructural properties of a mortar with melted plastic waste binder. Constr. Build. Mater. 2021, 302, 124190. [Google Scholar] [CrossRef]

- Thiam, M.; Fall, M. Engineering properties of a building material with melted plastic waste as the only binder. J. Build. Eng. 2021, 44, 102684. [Google Scholar] [CrossRef]

- Thiam, M.; Fall, M.; Diarra, M.S. Mechanical properties of a mortar with melted plastic waste as the only binder: Influence of material composition and curing regime, and application in Bamako. Case Stud. Constr. Mater. 2021, 15, e00634. [Google Scholar] [CrossRef]

- Sakai, Y.; Tarekegne, B.; Kishi, T. Recycling of Hardened Cementitious Material by Pressure and Control of Volumetric Change. J. Adv. Concr. Technol. 2016, 14, 47–54. [Google Scholar] [CrossRef]

- Howes, R.; Hadi, M.N.S.; South, W. Concrete strength reduction due to over compaction. Constr. Build. Mater. 2019, 197, 725–733. [Google Scholar] [CrossRef]

- Jo, B.-W.; Park, S.-K.; Park, J.-C. Mechanical properties of polymer concrete made with recycled PET and recycled concrete aggregates. Constr. Build. Mater. 2008, 22, 2281–2291. [Google Scholar] [CrossRef]

- Agyeman, S.; Obeng-Ahenkora, N.K.; Assiamah, S.; Twumasi, G. Exploiting recycled plastic waste as an alternative binder for paving blocks production. Case Stud. Constr. Mater. 2019, 11, e00246. [Google Scholar] [CrossRef]

- Jassim, A.K. Recycling of Polyethylene Waste to Produce Plastic Cement. Procedia Manuf. 2017, 8, 635–642. [Google Scholar] [CrossRef]

- Zhuang, S.; Wang, Q.; Zhang, M. Water absorption behaviour of concrete: Novel experimental findings and model characterization. J. Build. Eng. 2022, 53, 104602. [Google Scholar] [CrossRef]

- De Schutter, G.; Audenaert, K. Evaluation of water absorption of concrete as a measure for resistance against carbonation and chloride migration. Mater. Struct. 2004, 37, 591–596. [Google Scholar] [CrossRef]

- Youssef, A.M.; El-Gendy, A.; Kamel, S. Evaluation of corn husk fibers reinforced recycled low density polyethylene composites. Mater. Chem. Phys. 2015, 152, 26–33. [Google Scholar] [CrossRef]

- Kim, J.; Kim, N. Recycling Waste Paver Blocks in the Manufacture of New Concrete Paver Blocks and Building Bricks. Appl. Sci. 2022, 12, 10970. [Google Scholar] [CrossRef]

- Conlon, K. Plastic roads: Not all they’re paved up to be. Int. J. Sustain. Dev. World Ecol. 2022, 29, 80–83. [Google Scholar] [CrossRef]

- Enfrin, M.; Myszka, R.; Giustozzi, F. Paving roads with recycled plastics: Microplastic pollution or eco-friendly solution? J. Hazard. Mater. 2022, 437, 129334. [Google Scholar] [CrossRef]

- Evode, N.; Qamar, S.A.; Bilal, M.; Barceló, D.; Iqbal, H.M.N. Plastic waste and its management strategies for environmental sustainability. Case Stud. Chem. Environ. Eng. 2021, 4, 100142. [Google Scholar] [CrossRef]

- Alaghemandi, M. Sustainable Solutions Through Innovative Plastic Waste Recycling Technologies. Sustainability 2024, 16, 10401. [Google Scholar] [CrossRef]

- Wu, S.; Montalvo, L. Repurposing waste plastics into cleaner asphalt pavement materials: A critical literature review. J. Clean. Prod. 2021, 280, 124355. [Google Scholar] [CrossRef]

| Polymer Symbol | Polymer Chemical Structure and Applications | Recycling Code | Production by Polymer Type (EU-2022) [26] |

|---|---|---|---|

| Polyethylene Terephthalate (PET) | Fibers, 3D printing filaments, bottles for beverage, electrical appliance components, etc. |  Easy production process; recyclable and reusable; high calorific value; inexpensive | 5.0% |

| High-Density Polyethylene (HDPE) | Flexible and rigid pipes, fibers, milk jug, ballistic plates, etc. -[CH2-CH2-]n- |  Durable; withstands most solvents; can be recycled multiple times | 8.7% |

| Polyvinyl Chloride (PVC) | Electric cables, pipes, weather-resistant coats, sheets, etc. -[CH2-CHCl-]n- |  Durable and resistant to harsh conditions; leaches chemicals over time; recycled PVC has lower market value; challenges in waste collection | 9.1% |

| Low-Density Polyethylene (LDPE) | Bags, houseware, trays, containers, etc. -[CH2-CH2-]n- |  Soft, lightweight, and less toxic; difficult to fully recycle; challenges in waste collection | 13.4% |

| Polypropylene (PP) | Containers, electrical cables, medicals devices, nonwoven fabrics |  Tough and lightweight; heat-resistant; durable; easily recycled in semi-rigid form but more difficult to recycle in film form. | 15.4% |

| Polystyrene (PS) | Packaging, containers, rigid panels, etc.  |  Hard to recycle; leaches chemicals when heated; requires separation from other waste streams; inexpensive | 5.4% |

| Polyamide (PA) Polycarbonate (PC) Polyacrylonitrile (PAN) Polyurethane (PU) | Compact disks, medical devices, baby bottles, foams, etc. |  Almost never recycled; require separation from other waste streams | Other fossil-based plastics 23.3% |

| Properties | Natural Sand | PVC Sand | PP Sand | HDPE Sand |

|---|---|---|---|---|

| Density (g/cm3) | 2.68 | 1.40 | 0.88 | 0.96 |

| Grain size (mm) | 0–3 | 0–3 | 0–3 | 0–3 |

| Shape | Angular | Angular | Angular | Angular |

| Composite Material | Main Features | Advantages | Disadvantages |

|---|---|---|---|

| Concrete with plastic particles as filler—sand substitution | - Optimal range: up to 10% with few impacts on strength and durability - PET, LDPE, HDPE, PVC investigated | - Reduction in sand consumption - Reduction in unit weight - Reduction in thermal conductivity - Reduction in costs and impacts. | - Reduction in workability (if flaky particles are used) - Reduction in mechanical strength (irrespective of the type and amount of plastic) - Increased porosity - Reduction in ITZ strength - Reduction in durability-related performances |

| Example Lightweight recycled plastic aggregate concrete [108]. | - Mostly mixed PE. - Recycled plastic waste produced in the shape of granules, fibers, and flakes - Small size of plastics (5–10 mm). - Fiber plastic about 0.5 mm and the length in the range of 3–10 mm. | - Lightweight: decrease in unit weight with plastic content. - Thermal insulation: decrease in thermal conductivity by 35–65% compared to the control concrete. - Results: using 100% recycled plastics led to unit weight of 1500 kg/m3 and a compressive strength of 17 MPa. - Results: using 25% recycled plastics led to unit weight of 2000 kg/m3, and a compressive strength of 35 MPa. - Thermal conductivity of the control concrete is 1.7 W/mK while it is around 1.1–0.5 W/mK for the plastic–concrete. | - Decrease in compressive and flexural strength, modulus of elasticity, and bond strength with an increase in the quantity of recycled plastics. - Granule-type exhibited better compressive strength followed by flake- and fiber-type. - Flake-type exhibited better flexural strength than granule- and fiber-type. |

| Polymer concrete with recycled plastic—melting process | - Optimal range: 45–65% of the total mass - HDPE, LDPE investigated - Melting temperature: 100 °C - Dependent on curing method | - No cement or virgin polymers - Ductile behavior - Reduction in costs and impacts | - Possible impacts on workability and aggregates segregation (out of the optimal range) - Relatively low mechanical strength - High porosity |

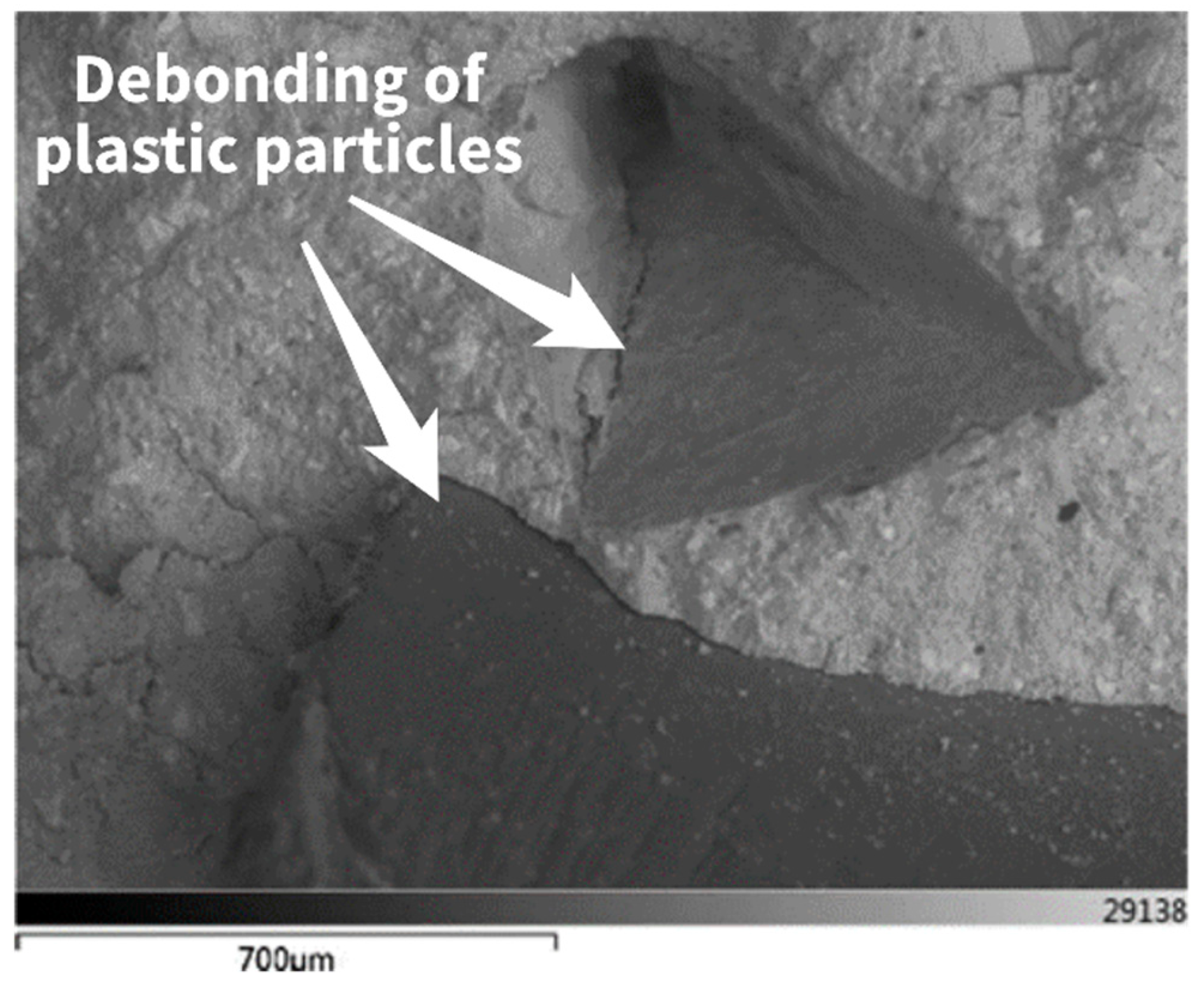

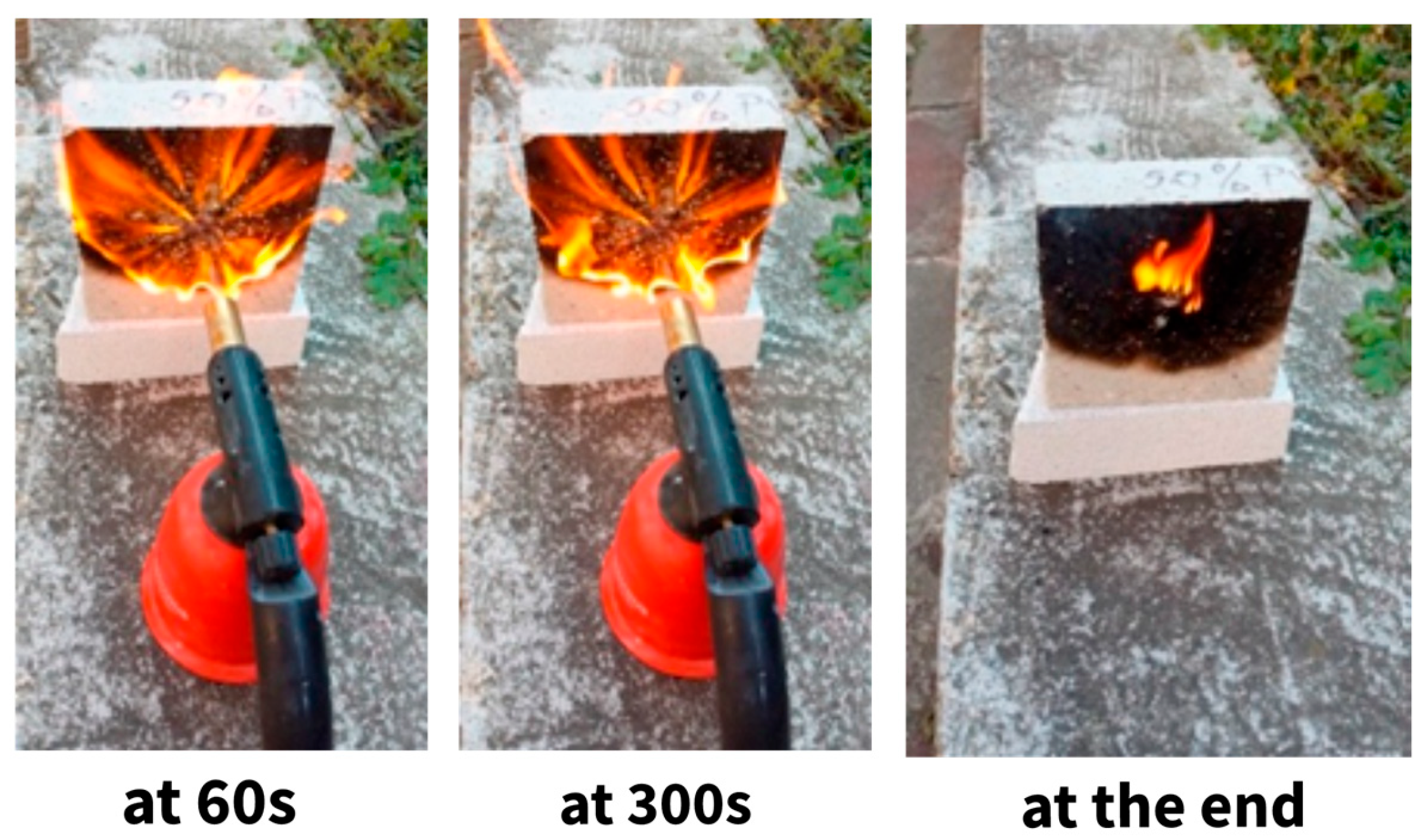

| Example Plastic waste as the only binder to develop cemented construction material– PlasticWasteCrete (PWC) [118]. | - Binding phase: two types of plastics (HDPE and LDPE) are blended, and melted at 250 °C. - PWC: binding phase mixed with mineral aggregates (sand and gravel). - No water is needed. | - Delay in thermal degradation. Inorganic materials (sand and gravel) as well as melting process contribute to the reinforcement and thermal stability of PWC. - Melted plastic binds granular materials with the presence of voids (the number of pores is less compared to conventional concrete due to the effect of water in Portland cement—SEM and MIP analysis). - Compressive strength: 10–15 MPa. Splitting tensile strength: 2–4 MPa. - Average density: 2.09–2.27 g/cm3. - 48 h immersion absorptions: 0.35% and 0.37%, very low compared to conventional cement concrete (4.58%). | - Melting process risks. - Long-term behavior and durability not fully understood. |

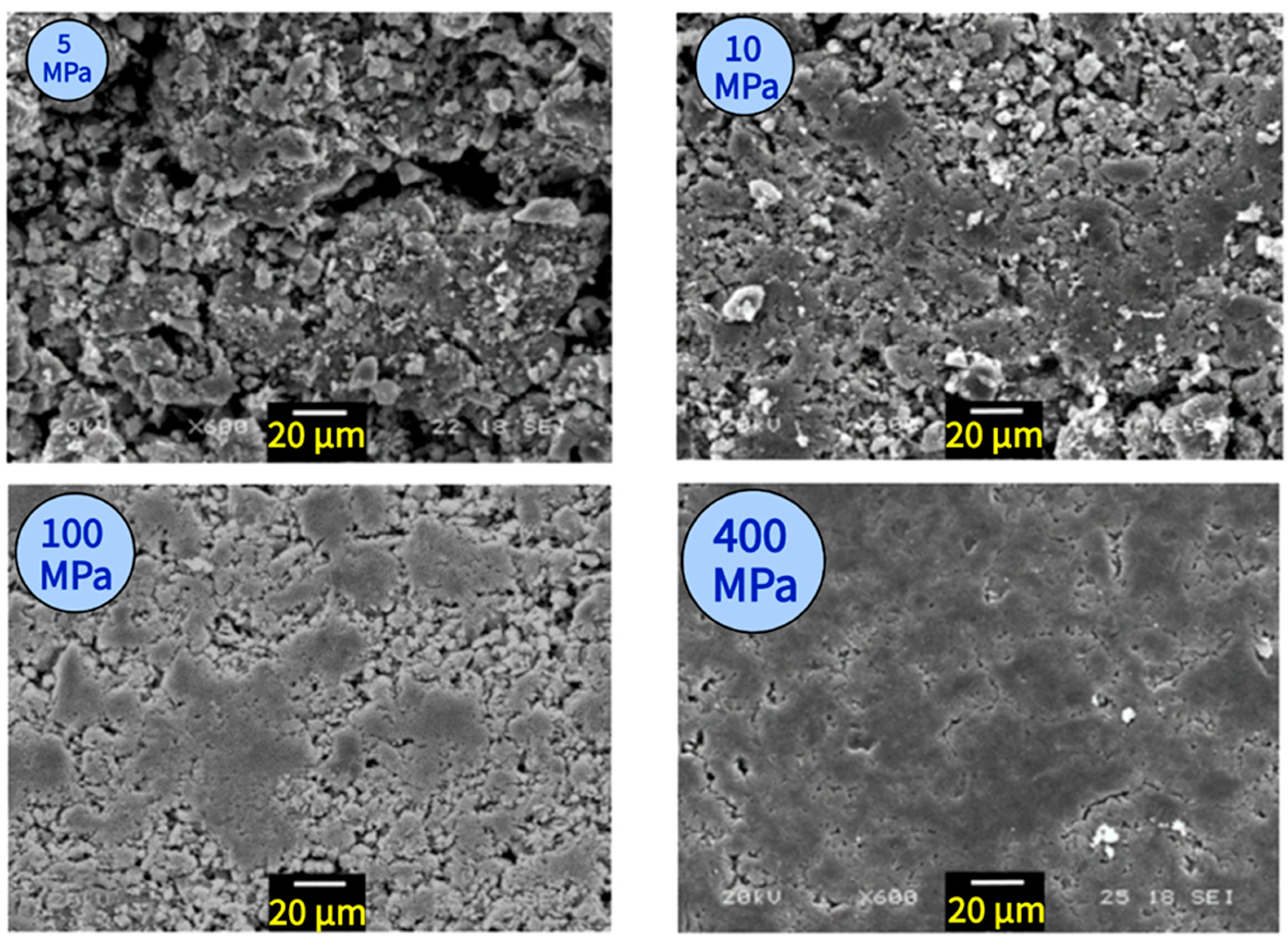

| Polymer concrete with recycled plastic—high pressure process | - Compaction process varying from 5 to 400 MPa investigated - Can be coupled with a thermal process | - Relatively good mechanical strength - Vibration-compacted concrete application - Low porosity | - Limitations in the practice - High impacts of the process |

| Example Compacted plastic concrete (CPC) alternative to traditional concrete [96]. | - Recycled ordinary Portland cement concrete waste. - Recycled plastic waste PE. - Hot-pressing of recycled concrete powder (105–300 µm) with recycled plastic powder (65–150 °C and 10–50 MPa). | - Closed loop: recycling of concrete and a high-volume plastic waste. - Hot-pressing ensures a good fusion between concrete and plastic particles (SEM). - Superior bending strength than traditional concrete (5.5 MPa with 15% plastics—11 MPa with 25–75% plastic). - Less water is needed compared to traditional concrete. - Low porosity (SEM) confirms high durability and high frost-damage resistance. | - The effect of many factors like the type of plastic and the morphology of plastic are not fully understood. - Effects of recycling and hot-pressing of plastic. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haba, B.; Djellali, S.; Abdelouahed, Y.; Boudjelida, S.; Faleschini, F.; Carraro, M. Transforming Plastic Waste into Value: A Review of Management Strategies and Innovative Applications in Sustainable Construction. Polymers 2025, 17, 881. https://doi.org/10.3390/polym17070881

Haba B, Djellali S, Abdelouahed Y, Boudjelida S, Faleschini F, Carraro M. Transforming Plastic Waste into Value: A Review of Management Strategies and Innovative Applications in Sustainable Construction. Polymers. 2025; 17(7):881. https://doi.org/10.3390/polym17070881

Chicago/Turabian StyleHaba, Bourhaneddine, Souad Djellali, Yasmine Abdelouahed, Soufiane Boudjelida, Flora Faleschini, and Mauro Carraro. 2025. "Transforming Plastic Waste into Value: A Review of Management Strategies and Innovative Applications in Sustainable Construction" Polymers 17, no. 7: 881. https://doi.org/10.3390/polym17070881

APA StyleHaba, B., Djellali, S., Abdelouahed, Y., Boudjelida, S., Faleschini, F., & Carraro, M. (2025). Transforming Plastic Waste into Value: A Review of Management Strategies and Innovative Applications in Sustainable Construction. Polymers, 17(7), 881. https://doi.org/10.3390/polym17070881