Josef Albers’ Structural Constellations: Investigating Formulations of Laminated Plastics Through Correlating the Industrial Literature with Scientific Analysis

Abstract

1. Introduction

2. Material and Methods

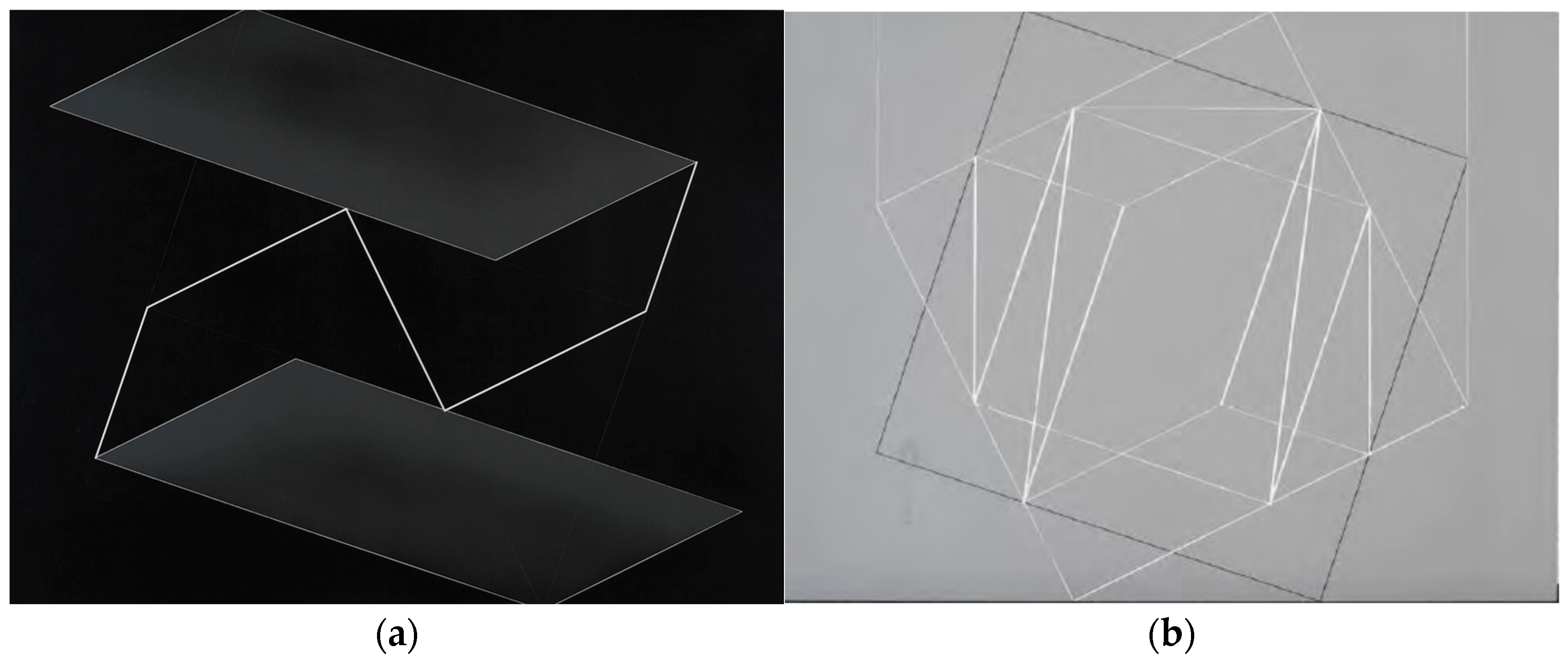

2.1. Structural Constellations

2.2. Archival Research

2.3. Data Acquisition and Processing

2.3.1. Digital Microscope Observation

2.3.2. Fourier-Transform Infra-Red (FTIR) Spectroscopy

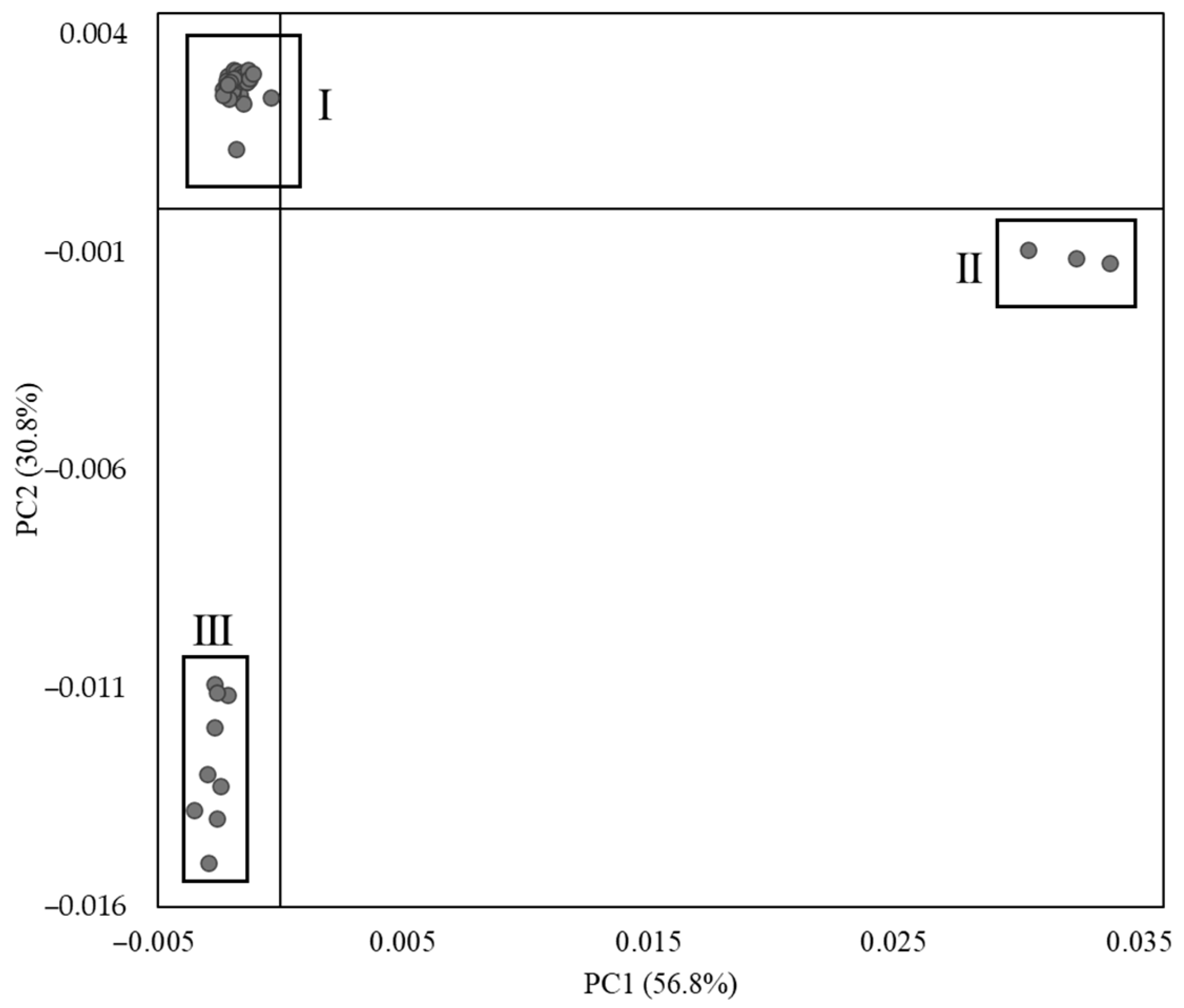

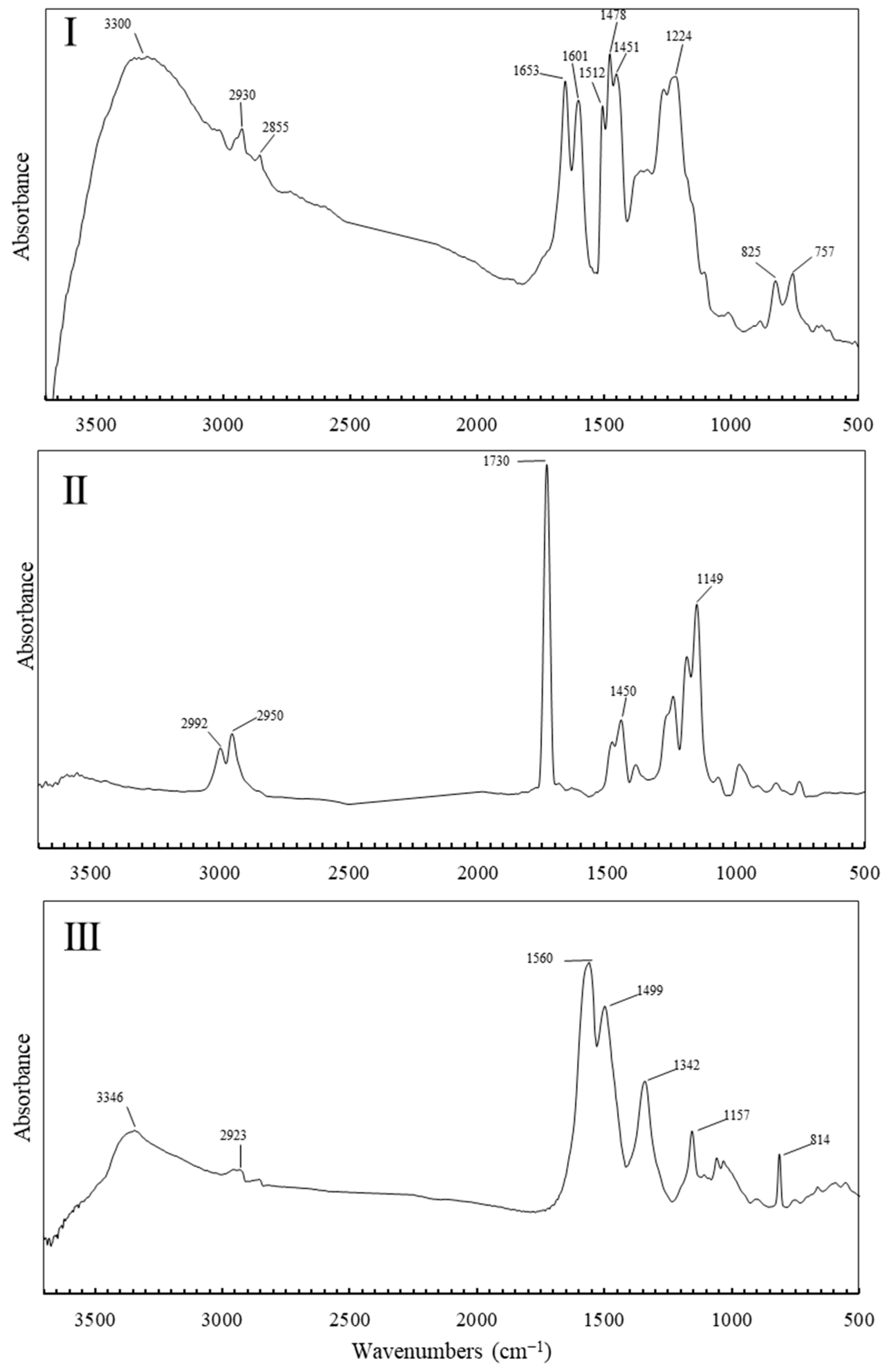

2.3.3. Principal Components Analysis (PCA)

3. Results

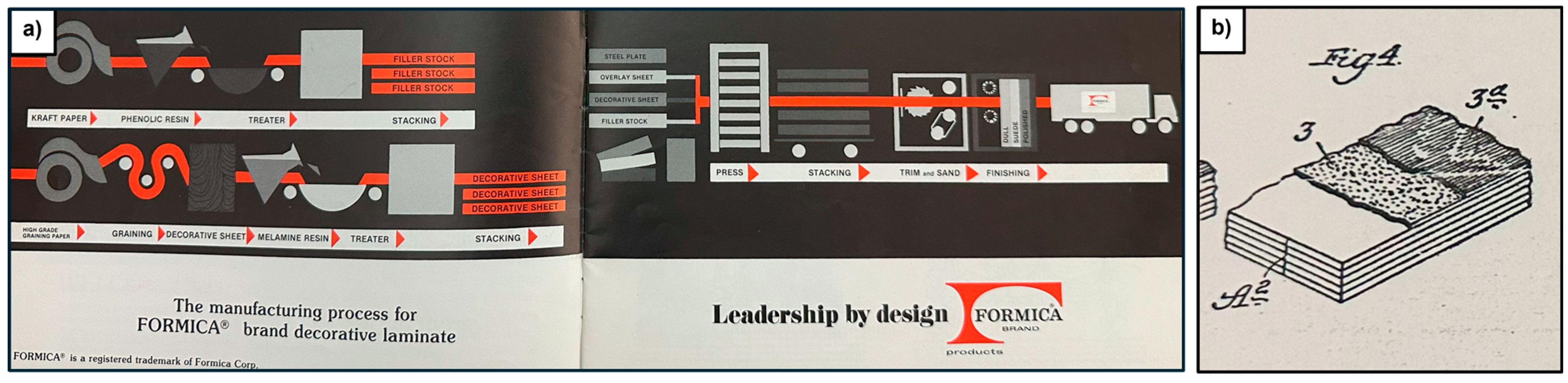

3.1. Archival Findings

3.2. Visual and Microscopic Investigations of Works

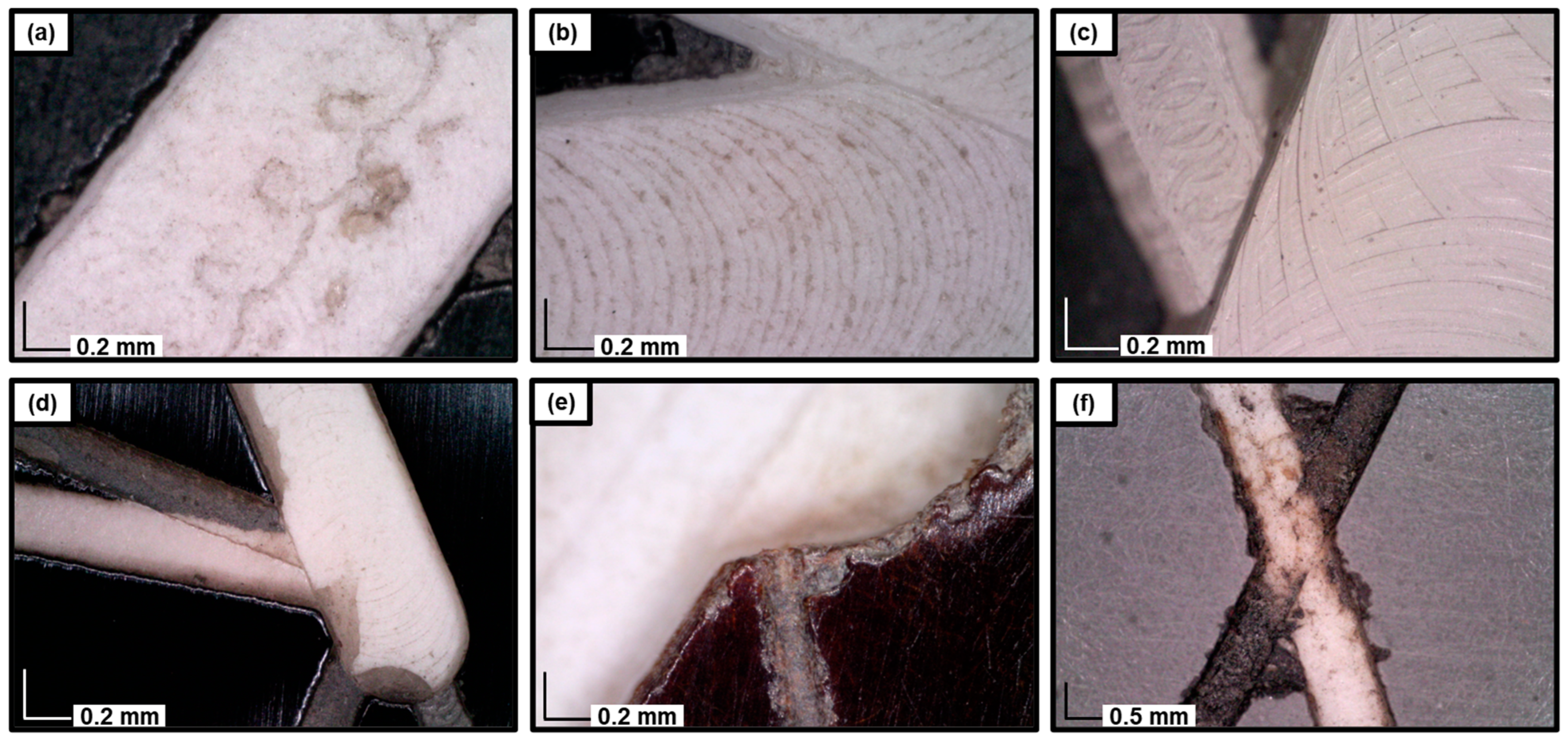

3.2.1. Topography and Engraved Lines

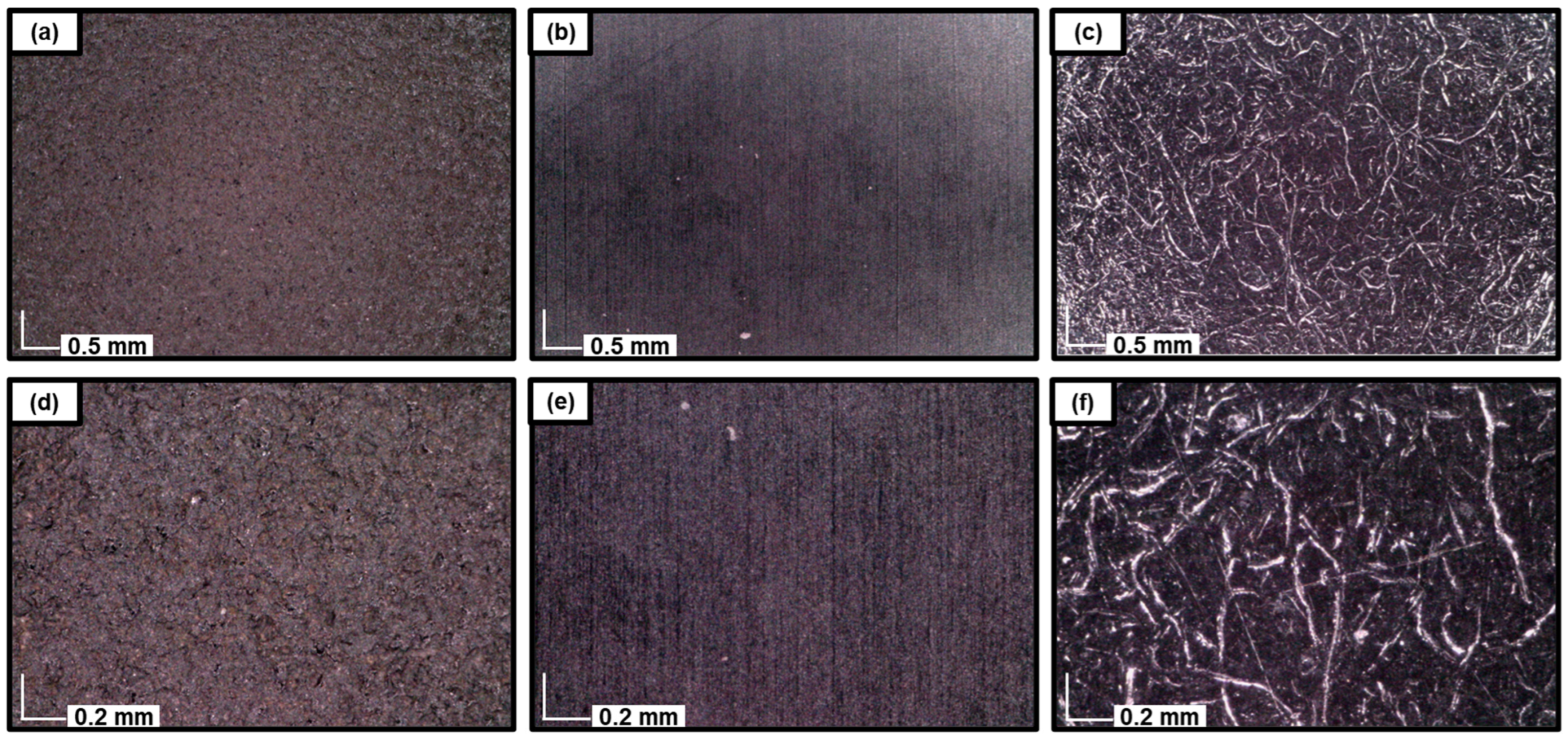

3.2.2. Surface Morphology and Patterning

3.3. Material Identification

4. Discussion and Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Redensek, J. On Josef Albers painting materials and techniques. In Josef Albers Medios Mínimos Efecto Máximo; Exh. Cat.; Fundación Juan March: Madrid, Spain, 2013. [Google Scholar]

- Redensek, J. Josef Albers, three engravings from Transformation of a Scheme. In Bauhaus und Amerika. Experimente in Licht und Bewegung; Exh. Cat.; Kerber: Bielefeld, Germany, 2018; pp. 155–164. [Google Scholar]

- Schneider, R.; Flagge, I. (Eds.) Original Resopal. Die Ästhetik der Oberfläche; Exh. Cat.; Deutsches Architekturmuseum Frankfurt a.M. Berlin; Jovis: Berlin, Germany, 2006. [Google Scholar]

- Pilato, L. (Ed.) Phenolic Resins: A Century of Progress; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar] [CrossRef]

- Bell, J.; Nel, P.; Stuart, B. Non-invasive identification of polymers in cultural heritage collections: Evaluation, optimisation and application of portable FTIR (ATR and external reflectance) spectroscopy to three-dimensional polymer-based objects. Herit. Sci. 2019, 7, 95. [Google Scholar] [CrossRef]

- Saviello, D.; Toniolo, L.; Goidanich, S.; Casadio, F. Non-invasive identification of plastic materials in museum collections with portable FTIR reflectance spectroscopy: Reference database and practical applications. Microchem. J. 2016, 124, 868–877. [Google Scholar] [CrossRef]

- Angelin, E.M.; de Sá, S.F.; Soares, I.; Callapez, M.E.; Ferreira, J.L.; Melo, M.J.; Bacci, M.; Picollo, M. Application of Infrared Reflectance Spectroscopy on Plastics in Cultural Heritage Collections: A Comparative Assessment of Two Portable Mid-Fourier Transform Infrared Reflection Devices. Appl. Spectrosc. 2021, 75, 818–833. [Google Scholar] [CrossRef] [PubMed]

- Izzo, F.; Germinario, C.; Grifa, C.; Langella, A.; Mercurio, M. External reflectance FTIR dataset (4000–400 cm−1) for the identification of relevant mineralogical phases forming Cultural Heritage materials. Infrared Phys. Technol. 2020, 106, 103266. [Google Scholar] [CrossRef]

- Picollo, M.; Bartolozzi, G.; Cucci, C.; Galeotti, M.; Marchiafava, V.; Pizzo, B. Comparative Study of Fourier Transform Infrared Spectroscopy in Transmission, Attenuated Total Reflection, and Total Reflection Modes for the Analysis of Plastics in the Cultural Heritage Field. Appl. Spectrosc. 2014, 68, 389–396. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.; Wu, J.; Intisar, A.; Geng, J.; Wu, L.; Zheng, K.; Du, Y. Study on Light Aging of Silk Fabric by Fourier Transform Infrared Spectroscopy and Principal Component Analysis. Anal. Lett. 2012, 45, 1286–1296. [Google Scholar] [CrossRef]

- Geminiani, L.; Campione, F.P.; Corti, C.; Giussani, B.; Gorla, G.; Luraschi, M.; Recchia, S.; Rampazzi, L. Historical silks: A novel method to evaluate their condition with ATR-FTIR spectroscopy and Principal Component Analysis. J. Cult. Herit. 2024, 67, 9–22. [Google Scholar] [CrossRef]

- Medeghini, L.; Mignardi, S.; De Vito, C.; Conte, A.M. Evaluation of a FTIR data pretreatment method for Principal Component Analysis applied to archaeological ceramics. Microchem. J. 2016, 125, 224–229. [Google Scholar] [CrossRef]

- Conrads, U. Spiele mit den Augenmuskeln. Strukturelle Konstellationen von Josef Albers/A Play with the Eye Muscles. Structural Constellations by Josef Albers. Daidalos Archit. Kunst Kult. 1990, 35, 80–84. [Google Scholar]

- Broqua, V. Malgré la ligne droite. L’écriture américaine de Josef Albers; Les Presses du Réel: Dijon, France, 2021. [Google Scholar]

- Imdahl, M. Arbeiter Diskutieren Moderne Kunst. Seminare im Bayerwerk Leverkusen; Berlin: Edition Kunstbuch Berlin; Rembrandt: Berlin, Germany, 1982. [Google Scholar]

- Pelkonen, E.-L. Interacting with Albers. In AA Files; No. 67; Architectural Association School of Architecture: London, UK, 2013; pp. 119–128. [Google Scholar]

- Rickart, C. A Structural Analysis of Some of Albers’s Work. In Josef Albers: A Retrospective; Exh. Cat.; Solomon R. Guggenheim Museum: New York, NY, USA, 1988; pp. 58–63. [Google Scholar]

- Brachert, E. Hausrat aus Plastic. In Alltagsgegenstände aus Kunststoff in Deutschland in der Zeit von 1950–1959; Verlag und Datenbank für Geisteswissenschaften: Weimar, Germany, 2002. [Google Scholar]

- Formica Collection, Arch. Cent. Natl. Mus. Am. Hist. Available online: https://sova.si.edu/record/nmah.ac.0565 (accessed on 14 May 2024).

- Harry, J. Dubois Collection of the History of Plastics, Arch. Cent. Natl. Mus. Am. Hist. Available online: https://sova.si.edu/record/nmah.ac.0008 (accessed on 14 May 2024).

- Van Krevelen, D.W.; Nijenhuis, K.T. Chapter 13—Mechanical Properties of Solid Polymers, In Properties of Polymers, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2009; pp. 383–503. [Google Scholar] [CrossRef]

- Greenhalgh, E.S. (Ed.) 4—Delamination-dominated failures in polymer composites. In Failure Analysis and Fractography of Polymer Composites; Woodhead Publishing: Sawston, UK, 2009; pp. 164–237. [Google Scholar] [CrossRef]

- Paris, C.; Coupry, C. Fourier transform Raman spectroscopic study of the first cellulose-based artificial materials in heritage. J. Raman Spectrosc. 2005, 36, 77–82. [Google Scholar] [CrossRef]

- Schilling, M.; Bouchard, M.; Khanjian, H.; Learner, T.; Phenix, A.; Rivenc, R. Application of chemical and thermal analysis methods for studying cellulose ester plastics. Acc. Chem. Res. 2010, 43, 888–896. [Google Scholar] [CrossRef] [PubMed]

- Kokkori, M.; Sutherland, K.; Daher, C. Inevitable plastic: Surveying works on plastic supports at the Art Institute of Chicago. Presented at the Future Talks 019 Conference, Pinakothek der Moderne, Munich, Germany, 11–13 November 2019. [Google Scholar]

- Mendes, A.; Filgueiras, L.; Siqueira, M.; Barbosa, G.; Holandino, C.; Moreira, D.; Pinto, J.; Nele, M. Encapsulation of Piper cabralanum (Piperaceae) nonpolar extract in poly(methyl methacrylate) by miniemulsion and evaluation of increase in the effectiveness of antileukemic activity in K562 cells. Int. J. Nanomed. 2017, 12, 8363–8373. [Google Scholar] [CrossRef] [PubMed]

- Workman, J., Jr.; Weyer, L. Practical Guide and Spectral Atlas for Interpretive Near-Infrared Spectroscopy; CRC Press: London, UK, 2012. [Google Scholar]

- van Oosten, T. Properties of Plastics: A Guide for Conservators; Getty Conservation Institute: Los Angeles, CA, USA, 2022. [Google Scholar]

- Xiong, Z.; Chen, N.; Wang, Q. Preparation and properties of melamine formaldehyde resin modified by functionalized nano-SiO2 and polyvinyl alcohol. Polym. Polym. Compos. 2020, 29, 96–106. [Google Scholar] [CrossRef]

- Feng, Y.; Qu, W.; Wu, Y.; Zhang, J.; Peng, L. Crack-resistant melamine/formaldehyde-impregnated paper-decorated panels using blocked isocyanates as a temperature-responsive crosslinker. Prog. Org. Coat. 2022, 173, 107211. [Google Scholar] [CrossRef]

| ID Number | Date | Color | Size (cm) | Sandblasted Areas | Crazing | Group |

|---|---|---|---|---|---|---|

| 1976.8.1726 | 1948 | Gray | 45.7 × 66.0 | NO | * | III |

| 1976.8.1761 | 1948 | Black | 33.8 × 62.3 | NO | NO | I |

| 1976.8.1913 | 1948 | Black | 24.1 × 48.2 | NO | NO | I |

| 1976.8.1723 | 1949 | Gray | 43.1 × 57.1 | NO | YES | III |

| 1976.8.1724 | 1949 | Gray | 43.1 × 57.1 | NO | YES | III |

| 1976.8.1892 | 1949 | Gray | 43.1 × 57.1 | NO | YES | III |

| 1976.8.1887 | 1949–1951 | Black | 43.1 × 57.1 | NO | NO | I |

| 1976.8.1704 | 1950–1951 | Black | 43.1 × 56.5 | YES | NO | I |

| 1976.8.1714 | 1950 | Black | 43.1 × 57.1 | NO | NO | I |

| 1976.8.1725 | 1950 | Wood | 43.1 × 57.1 | NO | NO | I |

| 1976.8.1885 | 1950 | Black | 43.1 × 57.1 | YES | NO | I |

| 1976.8.1891 | 1951 | Black | 43.1 × 57.1 | YES | NO | I |

| 1976.8.1750 | 1952 | Black | 43.1 × 57.1 | YES | NO | I |

| 1976.8.1756 | 1952 | Black | 43.2 × 57.1 | YES | NO | I |

| 1976.8.1763 | 1952 | Black | 43.1 × 57.1 | YES | NO | I |

| 1977.160.63 | 1952 | Black | 43.1 × 57.1 | NO | NO | I |

| 2016.8.1 | 1953 | Black | 43.1 × 57.1 | NO | * | I |

| 1976.8.1708 | 1954 | Black | 45.4 × 57.1 | YES | NO | I |

| 1976.8.1817 | 1954 | Black | 43.1 × 57.1 | YES | NO | I |

| 1976.8.1860 | 1954 | Black | 43.3 × 57.3 | YES | NO | I |

| 1976.8.1886 | 1954 | Black | 15.8 × 20.9 | NO | NO | I |

| 1977.160.64 | 1954 | Black | 15.8 × 20.9 | NO | NO | I |

| 1976.8.1904 | 1958 | Black | 16.9 × 22.8 | NO | NO | I |

| 1976.8.1908 | 1958 | Black | 49.5 × 66.0 | NO | YES | III |

| 1976.8.1905 | 1959 | Black | 50.8 × 66.6 | NO | NO | I |

| 1976.8.1893 | 1962 | Black | 49.5 × 65.4 | NO | NO | I |

| 1976.8.1703 | 1964 | Black | 12.7 × 34.9 | NO | NO | I |

| 2002.145.2 | 1964 | Black | 12.7 × 34.9 | NO | NO | I |

| 1976.8.1896 | 1966 | Black | 12.7 × 34.9 | NO | NO | I |

| 1976.8.1896a | 1966 | Black | 12.7 × 34.9 | NO | NO | I |

| 1976.8.1897 | 1966 | Black | 43.1 × 57.1 | NO | NO | I |

| 1976.8.1897a | 1966 | Black | 43.1 × 57.1 | YES | NO | I |

| 1976.8.1701 | n.d. | Black | 43.1 × 56.8 | YES | NO | I |

| 1976.8.1716 | n.d. | Black | 43.1 × 57.1 | YES | NO | I |

| 1976.8.1717 | n.d. | Black | 43.1 × 57.1 | NO | NO | I |

| 1976.8.1758 | n.d. | Black | 43.8 × 57.1 | NO | NO | I |

| 1976.8.1760 | n.d. | Black | 43.1 × 57.1 | NO | NO | I |

| 1976.8.1762 | n.d. | Black | 43.1 × 57.1 | NO | NO | I |

| 1976.8.1764 | n.d. | Black | 43.1 × 57.1 | NO | NO | I |

| 1976.8.1865 | n.d. | Black | 43.1 × 57.1 | NO | NO | I |

| 1976.8.1898 | n.d. | Black | 20.3 × 27.9 | NO | NO | I |

| 1976.8.1899 | n.d. | Black | 6.6 × 8.2 | NO | YES | III |

| 1976.8.1900 | n.d. | Black | 7.9 × 10.4 | NO | YES | III |

| 1976.8.1901 | n.d. | Black | 8.5 × 10.4 | NO | NO | II |

| 1976.8.1902 | n.d. | Black | 16.8 × 22.5 | NO | NO | I |

| 1976.8.1903 | n.d. | Black | 16.5 × 22.8 | NO | YES | III |

| 1976.8.1906 | n.d. | Black | 12.5 × 17.1 | NO | YES | III |

| 1976.8.1907 | n.d. | Black | 13.9 × 16.8 | NO | NO | I |

| 1976.8.1910 | n.d. | Transparent | 12.7 × 16.8 | NO | NO | II |

| 1976.8.1911 | n.d. | Transparent | 20.9 × 24.1 | NO | NO | II |

| 1976.8.1909 | n.d. or 1964 | Black | 17.1 × 23.1 | NO | NO | I |

| 1976.8.1759 | n.d. or 1965 | Black | 16.5 × 22.8 | NO | NO | I |

| 1976.8.1721 | n.d. | Black | 43.1 × 57.1 | NO | NO | I |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kokkori, M.; de La Codre, H.; Meier, M.C. Josef Albers’ Structural Constellations: Investigating Formulations of Laminated Plastics Through Correlating the Industrial Literature with Scientific Analysis. Polymers 2025, 17, 681. https://doi.org/10.3390/polym17050681

Kokkori M, de La Codre H, Meier MC. Josef Albers’ Structural Constellations: Investigating Formulations of Laminated Plastics Through Correlating the Industrial Literature with Scientific Analysis. Polymers. 2025; 17(5):681. https://doi.org/10.3390/polym17050681

Chicago/Turabian StyleKokkori, Maria, Hortense de La Codre, and Madeline C. Meier. 2025. "Josef Albers’ Structural Constellations: Investigating Formulations of Laminated Plastics Through Correlating the Industrial Literature with Scientific Analysis" Polymers 17, no. 5: 681. https://doi.org/10.3390/polym17050681

APA StyleKokkori, M., de La Codre, H., & Meier, M. C. (2025). Josef Albers’ Structural Constellations: Investigating Formulations of Laminated Plastics Through Correlating the Industrial Literature with Scientific Analysis. Polymers, 17(5), 681. https://doi.org/10.3390/polym17050681