Isotactic Polypropylene (iPP) Foils—Correlation of Core and Shell Crystallinity with Mechanical Properties Obtained by Nanoindentation

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

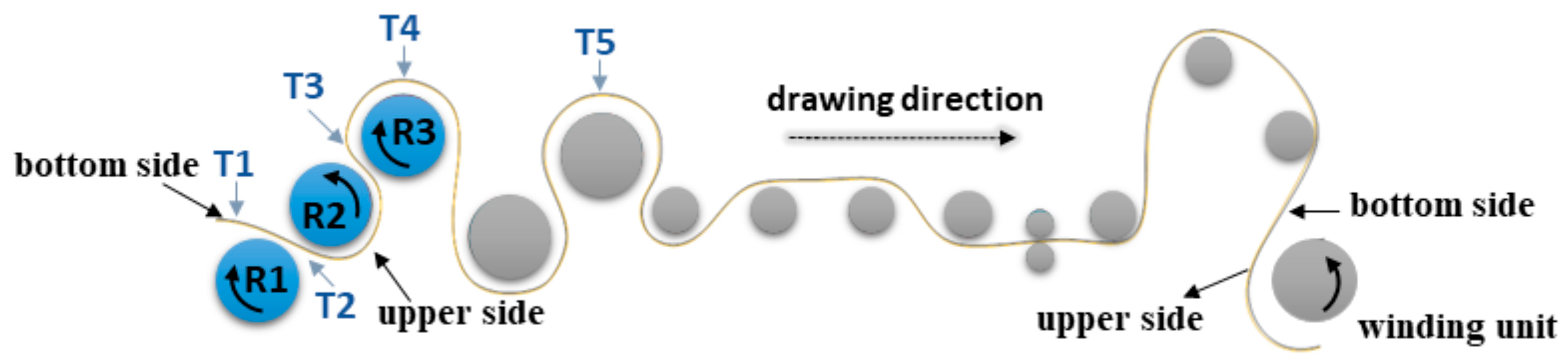

2.2. Extrusion of Foils on Industrial Calendering Line

2.3. Characterization Methods

2.3.1. Determination of Degree of Crystallinity

2.3.2. Polarized Optical Microscopy (POM)

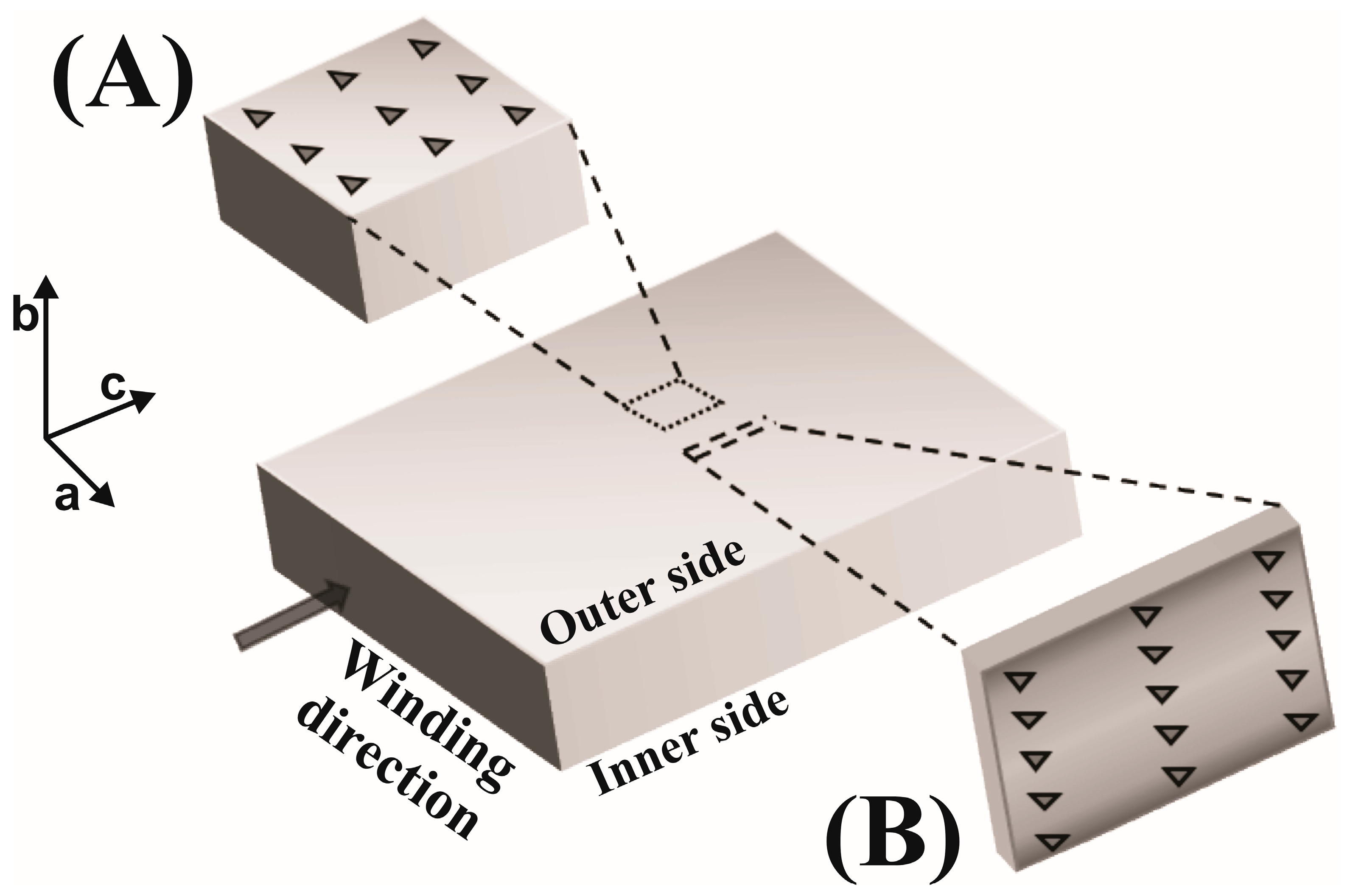

2.3.3. Nanoindentation

2.3.4. Optical Properties

3. Results and Discussion

3.1. DSC Measurements

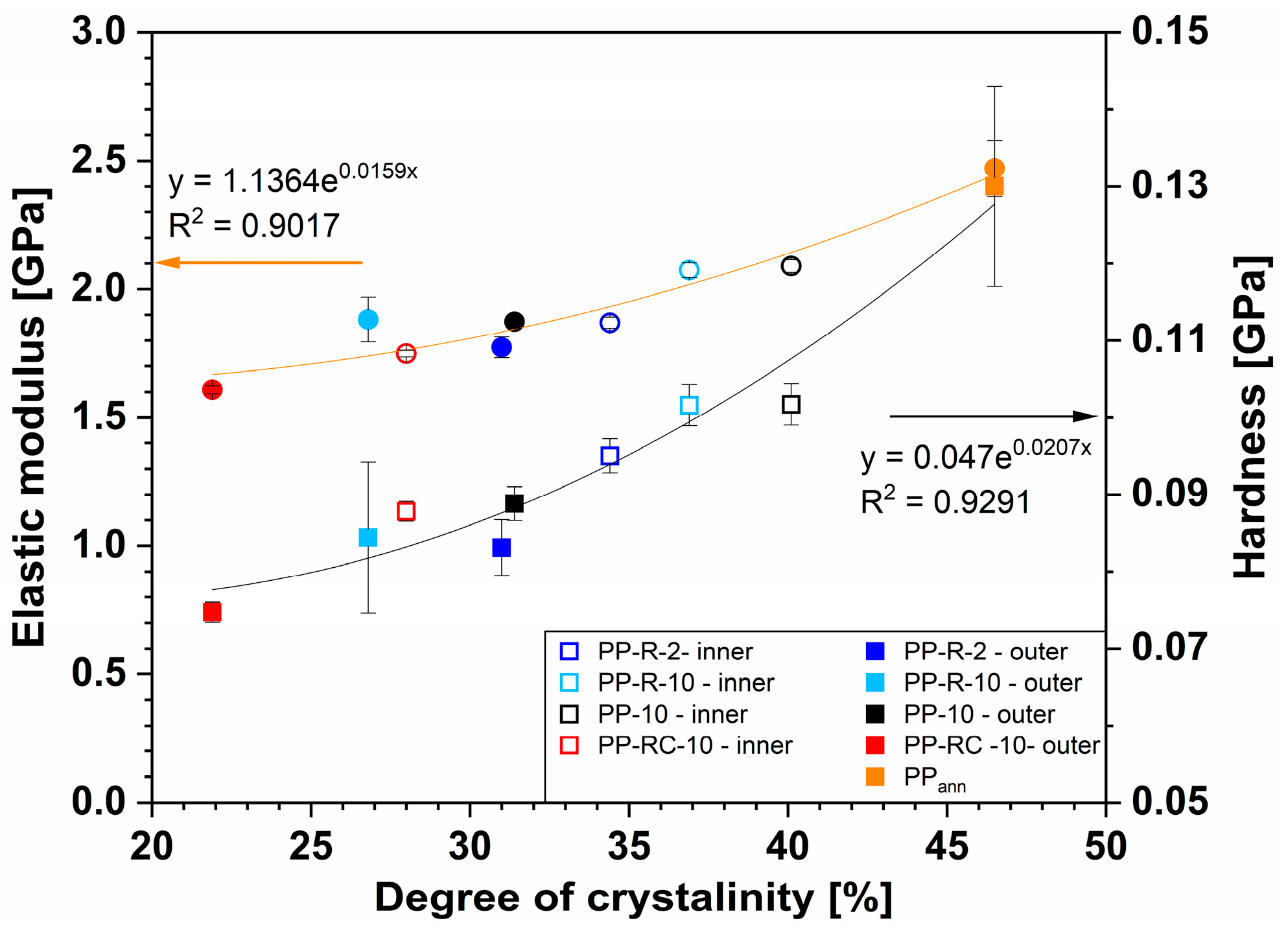

3.2. Flash DSC Measurements

3.3. Nanoindentation Measurements: Dependence of Mechanical Properties of Outer and Inner Sides of Foils

3.4. Morphology Studies: POM and Nanoindentation Measurements

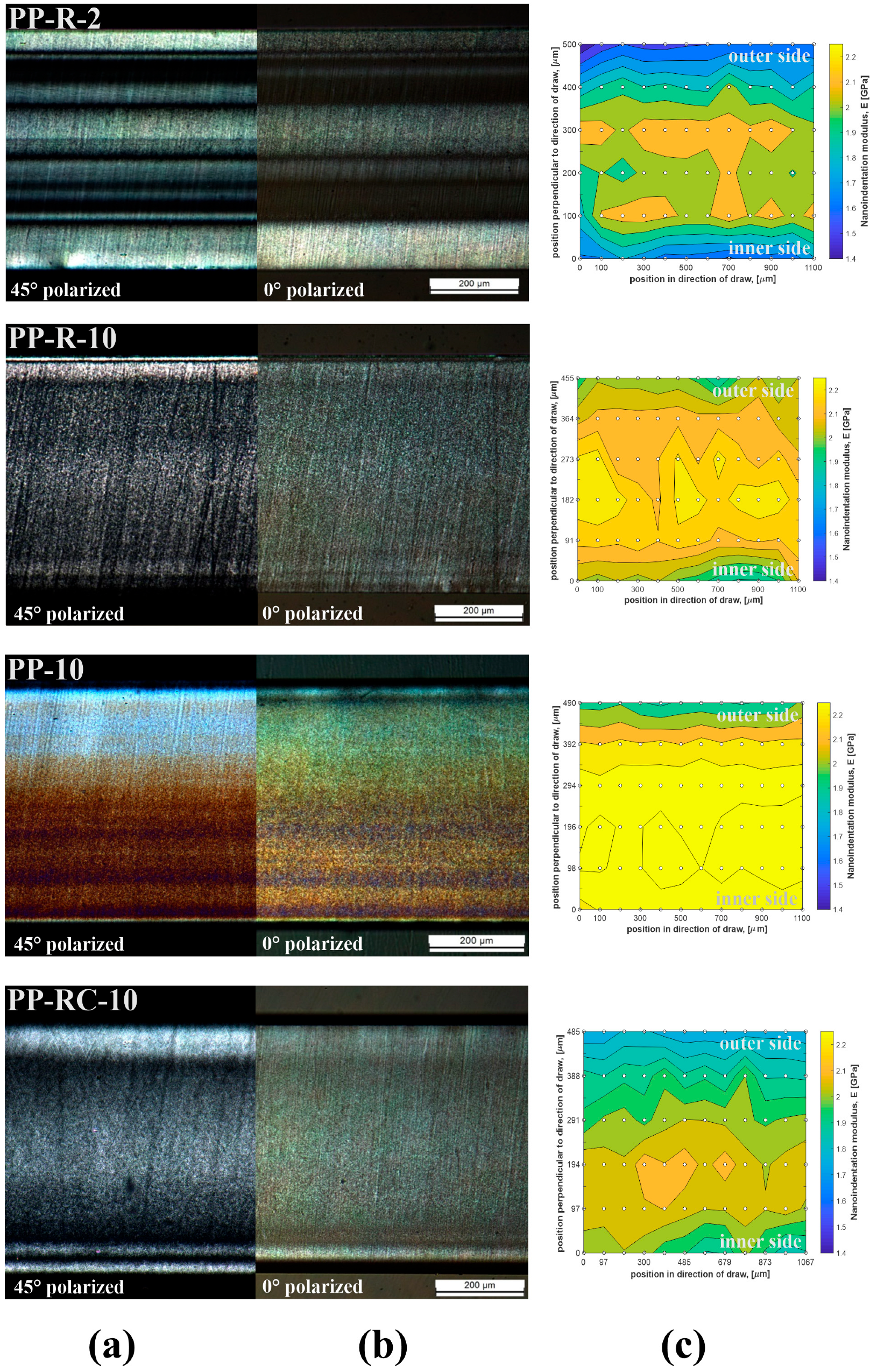

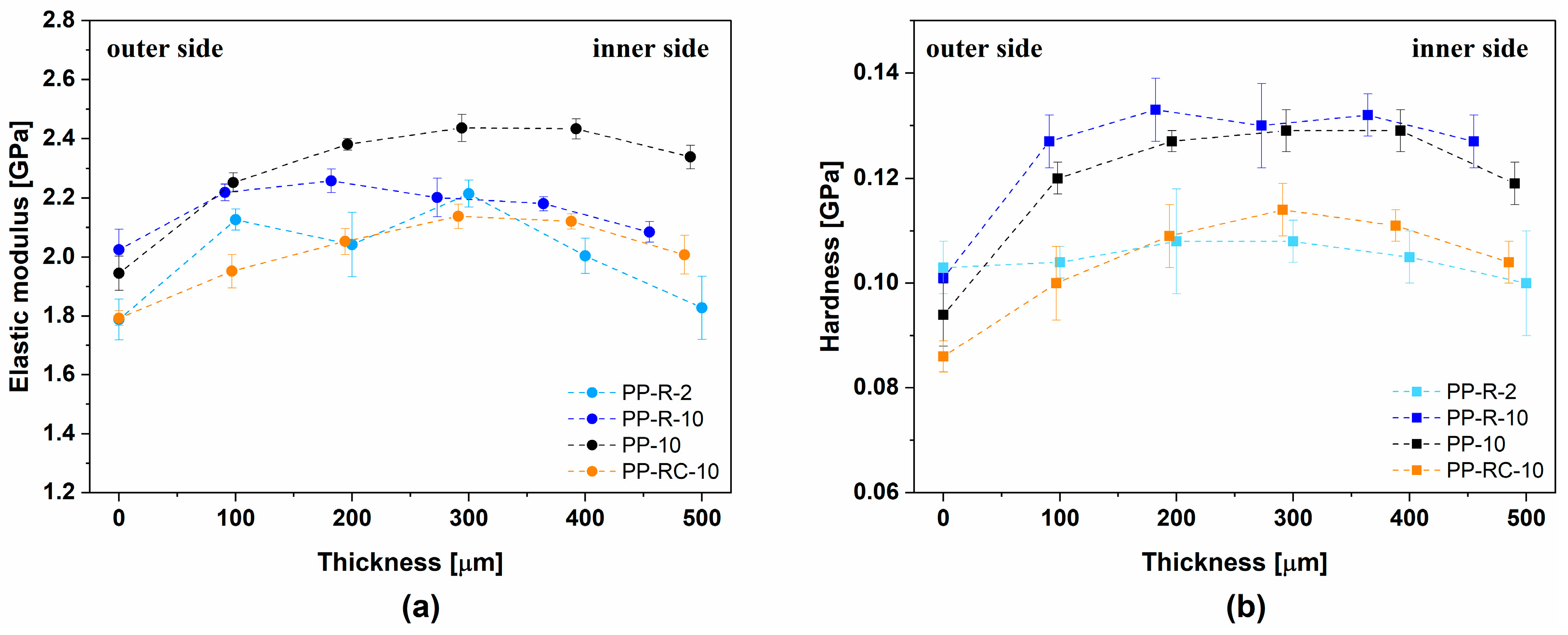

3.4.1. POM and Nanoindentation Measurements of Cross-Sections

3.4.2. Comparison of POM and Nanoindentation Measurements of PP-R-2 and PP-R-10 Foils (Different Processing Conditions)

3.4.3. Comparison of POM and Nanoindentation Measurements of PP-10, PP-R-10 and PP-RC-10 Foils (Effect of Additives)

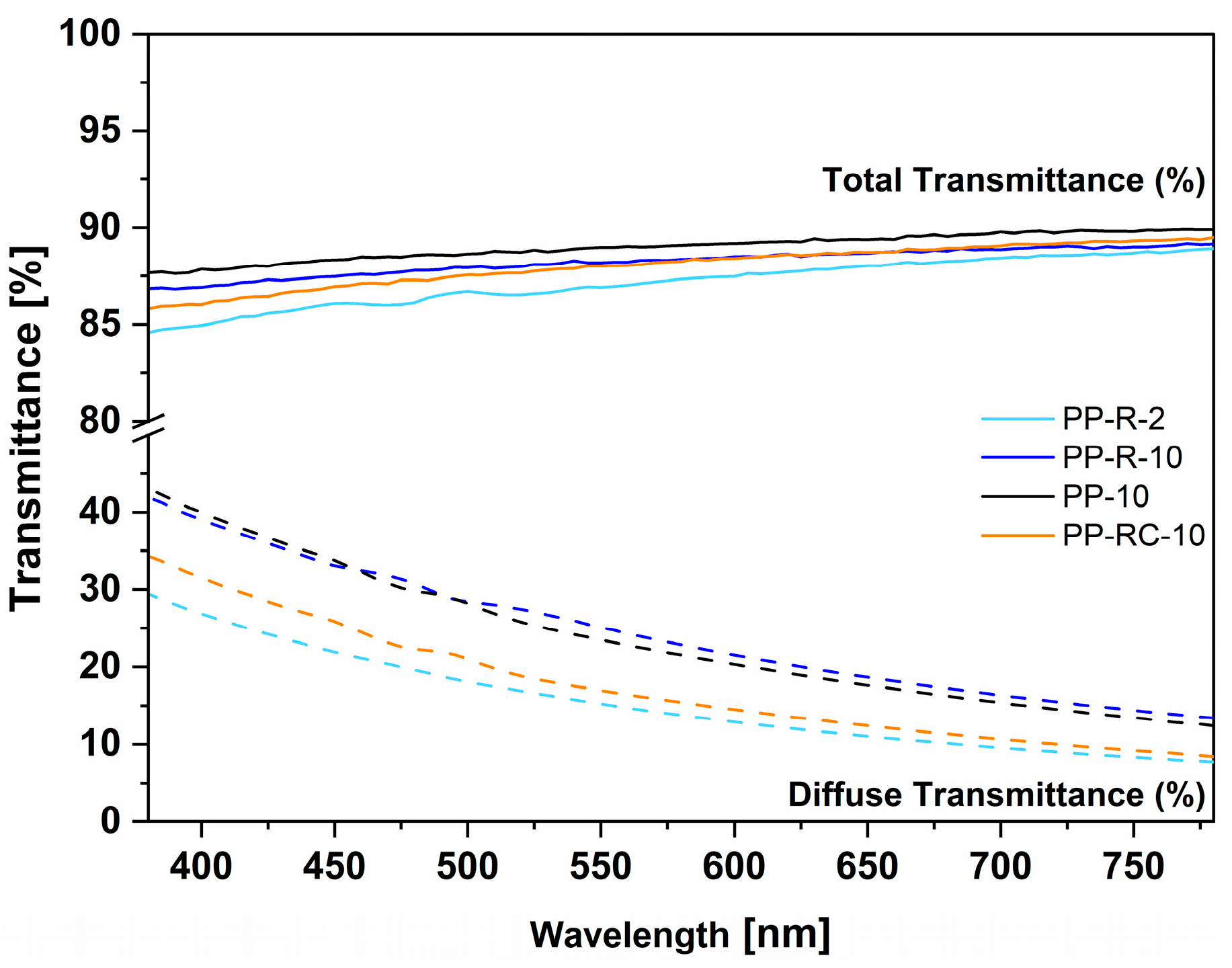

3.5. Optical Measurements of iPP Foils

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gahleitner, M.; Wolfschwenger, J.; Bachner, C.; Bernreitner, K.; Neissl, W. Crystallinity and mechanical properties of PP-homopolymers as influenced by molecular structure and nucleation. J. Appl. Polym. Sci. 1996, 61, 649–657. [Google Scholar] [CrossRef]

- Housmans, J.W.; Gahleitner, M.; Peters, G.W.M.; Meijer, H.E.H. Structure-property relations in molded, nucleated isotactic polypropylene. Polymer 2009, 50, 2304–2319. [Google Scholar] [CrossRef]

- Liu, X.; Zheng, G.; Dai, K.; Jia, Z.; Li, S.; Liu, C.; Chen, J.; Shen, C.; Li, Q. Morphological comparison of isotactic polypropylene molded by water-assisted and conventional injection molding. J. Mater. Sci. 2011, 46, 7830–7838. [Google Scholar] [CrossRef]

- Chandrasekaran, C. Plastics Calendering. In Handbook of Troubleshooting Plastics Processes: A Practical Guide; Scrivener Publishing LLC.: Hoboken, NJ, USA, 2012; pp. 363–382. [Google Scholar]

- Liu, X.; Dai, K.; Hao, X.; Zheng, G.; Liu, C.; Schubert, D.W.; Shen, C. Crystalline structure of injection molded β-isotactic polypropylene: Analysis of the oriented shear zone. Ind. Eng. Chem. Res. 2013, 52, 11996–12002. [Google Scholar] [CrossRef]

- Ji, C.; Xie, M.; Chang, B.; Dai, K.; Wang, B.; Zheng, G.; Liu, C.; Shen, C. β-Crystal in injection moulded poly(ethylene terephthalate) fibre/isotactic polypropylene composite. Compos. Part A Appl. Sci. Manuf. 2013, 46, 26–33. [Google Scholar] [CrossRef]

- Li, Z.M.; Li, L.B.; Shen, K.Z.; Yang, W.; Huang, R.; Yang, M.B. Transcrystalline morphology of an in situ microfibrillar poly(ethylene terephthalate)/poly(propylene) blend fabricated through a slit extrusion hot stretching-quenching process. Macromol. Rapid Commun. 2004, 25, 553–558. [Google Scholar] [CrossRef]

- Tan, V.; Kamal, M.R. Morphological zones and orientation in injection-molded polyethylene. J. Appl. Polym. Sci. 1978, 22, 2341–2355. [Google Scholar] [CrossRef]

- Kalay, G.; Bevis, M.J. Processing and physical property relationships in injection-molded isotactic polypropylene. 1. Mechanical properties. J. Polym. Sci. Part B Polym. Phys. 1997, 35, 241–263. [Google Scholar] [CrossRef]

- Wang, J.; Wang, X.; Wang, Q.; Xu, C.; Wang, Z. Effect of flowing preformed spherulites on shear-induced melt crystallization behaviors of isotactic polypropylene. Macromolecules 2018, 51, 1756–1768. [Google Scholar] [CrossRef]

- Ruan, C. “Skin-core-skin” structure of polymer crystallization investigated by multiscale simulation. Materials 2018, 11, 610. [Google Scholar] [CrossRef]

- Zuidema, H. Flow Induced Crystallization of Polymers Application to Injection Moulding; Technische Universiteit Eindhoven: Eindhoven, The Netherlands, 2000. [Google Scholar]

- Speranza, V.; Liparoti, S.; Pantani, R.; Titomanlio, G. Hierarchical structure of iPP during injection molding process with fast mold temperature evolution. Materials 2019, 12, 424. [Google Scholar] [CrossRef]

- Yarysheva, A.Y.; Bagrov, D.V.; Bakirov, A.V.; Yarysheva, L.M.; Chvalun, S.N.; Volynskii, A.L. Effect of initial polypropylene structure on its deformation via crazing mechanism in a liquid medium. Eur. Polym. J. 2018, 100, 233–240. [Google Scholar] [CrossRef]

- Liparoti, S.; Speranza, V.; Sorrentino, A.; Titomanlio, G. Mechanical properties distribution within polypropylene injection molded samples: Effect of mold temperature under uneven thermal conditions. Polymers 2017, 9, 585. [Google Scholar] [CrossRef]

- Adamovsky, S.A.; Minakov, A.A.; Schick, C. Scanning microcalorimetry at high cooling rate. Thermochim. Acta 2003, 403, 55–63. [Google Scholar] [CrossRef]

- De Santis, F.; Adamovsky, S.; Titomanlio, G.; Schick, C. Scanning nanocalorimetry at high cooling rate of isotactic polypropylene. Macromolecules 2006, 39, 2562–2567. [Google Scholar] [CrossRef]

- Wunderlich, B. Termination of crystallization or ordering of flexible, linear macromolecules. J. Therm. Anal. Calorim. 2012, 109, 1117–1132. [Google Scholar] [CrossRef]

- Toda, A.; Taguchi, K.; Sato, K.; Nozaki, K.; Maruyama, M.; Tagashira, K.; Konishi, M. Melting kinetics of it-polypropylene crystals over wide heating rates. J. Therm. Anal. Calorim. 2013, 113, 1231–1237. [Google Scholar] [CrossRef]

- Schawe, J.E.K. Cooling rate dependence of the crystallinity at nonisothermal crystallization of polymers: A phenomenological model. J. Appl. Polym. Sci. 2016, 133, 42977. [Google Scholar] [CrossRef]

- Fischer-Cripps, A.C. Nanoindentation, 3rd ed.; Springer: New York, NY, USA, 2011; ISBN 978-1-4419-9871-2. [Google Scholar]

- Jiang, J.; Wang, S.; Sun, B.; Ma, S.; Zhang, J.; Li, Q.; Hu, G.H. Effect of mold temperature on the structures and mechanical properties of micro-injection molded polypropylene. Mater. Des. 2015, 88, 245–251. [Google Scholar] [CrossRef]

- Jariyavidyanont, K.; Wüstefeld, C.; Chudoba, T.; Androsch, R. Combining fast scanning chip calorimetry and nanoindentation: Young’s modulus and hardness of poly (l-lactic acid) containing α′- and α-crystals. Polym. Test. 2024, 137, 108524. [Google Scholar] [CrossRef]

- Christöfl, P.; Czibula, C.; Seidlhofer, T.; Berer, M.; Macher, A.; Helfer, E.; Schrank, T.; Oreski, G.; Teichert, C.; Pinter, G. Morphological characterization of semi-crystalline POM using nanoindentation. Int. J. Polym. Anal. Charact. 2021, 26, 692–706. [Google Scholar] [CrossRef]

- Parenteau, T.; Ausias, G.; Grohens, Y.; Pilvin, P. Structure, mechanical properties and modelling of polypropylene for different degrees of crystallinity. Polymer 2012, 53, 5873–5884. [Google Scholar] [CrossRef]

- Parambil, N.K.; Chen, B.R.; Deitzel, J.M.; Gillespie, J.W. A methodology for predicting processing induced thermal residual stress in thermoplastic composite at the microscale. Compos. Part B Eng. 2022, 231, 109562. [Google Scholar] [CrossRef]

- Di Sacco, F.; Gahleitner, M.; Wang, J.; Portale, G. Systematic Investigation on the Structure-Property Relationship in Isotactic Polypropylene Films Processed via Cast Film Extrusion. Polymers 2020, 12, 1636. [Google Scholar] [CrossRef] [PubMed]

- Samadi-Dooki, A.; Lamontia, M.A.; Londoño, J.D.; Williamson, C.; Burch, H.E.; Yahyazadehfar, M.; Carbajal, L.A.; Kourtakis, K. Effect of Chain Orientation on Coupling of Optical and Mechanical Anisotropies of Polymer Films. Coatings 2024, 14, 764. [Google Scholar] [CrossRef]

- Mileva, D.; Gahleitner, M.; Gloger, D.; Tranchida, D. Crystal structure: A way to control properties in cast films of polypropylene. Polym. Bull. 2018, 75, 5587–5598. [Google Scholar] [CrossRef]

- Menyhárd, A.; Suba, P.; Laszlo, Z.; Fekete, H.M.; Mester, Á.; Horváth, Z.; Vörös, G.; Varga, J.; Móczó, J. Direct correlation between modulus and the crystalline structure in isotactic polypropylene. Express Polym. Lett. 2015, 9, 308–320. [Google Scholar] [CrossRef]

- Adamovsky, S.; Schick, C. Ultra-fast isothermal calorimetry using thin film sensors. Thermochim. Acta 2004, 415, 1–7. [Google Scholar] [CrossRef]

- Minakov, A.A.; Adamovsky, S.A.; Schick, C. Non-adiabatic thin-film (chip) nanocalorimetry. Thermochim. Acta 2005, 432, 177–185. [Google Scholar] [CrossRef]

- Gee, D.R.; Melia, T.P. Thermal properties of melt and solution crystallized isotactic polypropylene. Die Makromol. Chem. 1970, 132, 195–201. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- D’Errico, J. Surface Fitting Using Gridfit. MATLAB Central File Exchange. Available online: https://www.mathworks.com/matlabcentral/fileexchange/8998-surface-fitting-using-gridfit (accessed on 18 June 2019).

- ASTM D1003-21; Standard Test Method for Haze and Luminous Transmittance of Transparent Plastics. ASTM: West Conshohocken, PA, USA, 2021.

- Altepeter, M.; Schöppner, V.; Wanke, S.; Austermeier, L.; Meinheit, P.; Schmidt, L. Polypropylene Degradation on Co-Rotating Twin-Screw Extruders. Polymers 2023, 15, 2181. [Google Scholar] [CrossRef]

- Fischer, C.; Drummer, D. Crystallization and Mechanical Properties of Polypropylene under Processing-Relevant Cooling Conditions with respect to Isothermal Holding Time. Int. J. Polym. Sci. 2016, 2016, 5450708. [Google Scholar] [CrossRef]

- Oseli, A.; Tomković, T.; Hatzikiriakos, S.G.; Vesel, A.; Arzenšek, M.; Rojac, T.; Mihelčič, M.; Slemenik Perše, L. Carbon nanotube network formation and configuration/morphology on reinforcing and conductive performance of polymer-based nanocomposites. Compos. Sci. Technol. 2023, 237, 110010. [Google Scholar] [CrossRef]

- Gradišar Centa, U.; Mihelčič, M.; Bobnar, V.; Remškar, M.; Slemenik Perše, L. The Effect of PVP on Thermal, Mechanical, and Dielectric Properties in PVDF-HFP/PVP Thin Film. Coatings 2022, 12, 1241. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Y.; Jiang, L.; Yang, X.; Zhou, Y.; Wang, X.; Li, Q.; Shen, C.; Turng, L.S. Effect of injection speed on the mechanical properties of isotactic polypropylene micro injection molded parts based on a nanoindentation test. J. Appl. Polym. Sci. 2019, 136, 47329. [Google Scholar] [CrossRef]

- Molnár, J.; Hertner-Horváth, A.; Menyhárd, A. Prediction of tensile modulus from calorimetric melting curves of polylactic acid with pronounced cold crystallization ability. Polym. Test. 2021, 95, 107112. [Google Scholar] [CrossRef]

- Popli, R.K.; Mandelkern, L. Influence of structural and morphological factors on the mechanical properties of the polyethylenes. J. Polym. Sci. Part B 1987, 25, 441–483. [Google Scholar] [CrossRef]

- Larsson, P.-L. Principal Stress Ratio Effect at Residual Stress Determination Utilizing the Variation of Indentation Hardness. Lubricants 2019, 7, 50. [Google Scholar] [CrossRef]

- Lai, S.L.; Ramanath, G.; Allen, L.H.; Infante, P.; Ma, Z. High-speed (104 °C/s) scanning microcalorimetry with monolayer sensitivity (J/m2). Appl. Phys. Lett. 1995, 67, 1229. [Google Scholar] [CrossRef]

- Hill, M.J.; Keller, A. Further studies on polyethylene crystallized under stress: Morphology, calorimetry, and stress relaxation. J. Macromol. Sci. Part B 1971, 5, 591–615. [Google Scholar] [CrossRef]

- Kantz, M.R.; Newman, H.D.; Stigale, F.H. The skin-core morphology and structure–property relationships in injection-molded polypropylene. J. Appl. Polym. Sci. 1972, 16, 1249–1260. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, J.; Qian, X.; Deng, P.; Shen, K. Morphology evolution including formation of cylindrulite in isotactic polypropylene derived from periodical shear field. Polymer 2012, 53, 4318–4327. [Google Scholar] [CrossRef]

- Liedauer, S.; Eder, G.; Janeschitz-Kriegl, H.; Jerschow, P.; Geymayer, W.; Ingolic, E. On the Kinetics of Shear Induced Crystallization in Polypropylene. Int. Polym. Process. 1993, 8, 236–244. [Google Scholar] [CrossRef]

- Boitout, H. Influence of the Temperature on Flow-Induced Crystallization of Isotactic Polypropylene and Propylene-Ethylene Random Copolymer; University of Nebraska-Lincoln: Lincoln, NE, USA, 2014. [Google Scholar]

- Fernandez-Ballester, L.; Thurman, D.W.; Zhou, W.; Kornfield, J.A. Effect of long chains on the threshold stresses for flow-induced crystallization in iPP: Shish kebabs vs. sausages. Macromolecules 2012, 45, 6557–6570. [Google Scholar] [CrossRef]

- Woodward, A.E. Understanding Polymer Morphology; Hanser Pub Inc.: Munich, Germany, 1996; Volume 33, ISBN 1569901414. [Google Scholar]

- Aurrekoetxea, J.; Sarrionandia, M.A.; Urrutibeascoa, I.; Maspoch, M.L. Effects of recycling on the microstructure and the mechanical properties of isotactic polypropylene. J. Mater. Sci. 2001, 36, 2607–2613. [Google Scholar] [CrossRef]

) indicates the indents of the measurements.

) indicates the indents of the measurements.

) indicates the indents of the measurements.

) indicates the indents of the measurements.

| Sample | Haul-Off Speed [m/min] | Material | Average Thickness (μm) |

|---|---|---|---|

| PP-R-2 | 2 | PPH + R | 780 ± 10 |

| PP-R-10 | 10 | PPH + R | 720 ± 20 |

| PP-10 | 10 | PPH | 750 ± 15 |

| PP-RC-10 | 10 | PPH + RC | 785 ± 10 |

| Sample | 1st Heating | 2nd Heating | ||||

|---|---|---|---|---|---|---|

| ∆Hm [J/g] | Tm [°C] | Xc [%] | ∆Hm [J/g] | Tm [°C] | Xc [%] | |

| PP-R-2 | 81.3 | 164.5 | 39.3 | 90.4 | 162.3 | 43.7 |

| PP-R-10 | 86.3 | 170.9 | 41.7 | 93.6 | 165.6 | 45.2 |

| PP-10 | 89.8 | 169.5 | 43.4 | 97.8 | 166.8 | 47.6 |

| PP-RC-10 | 81.8 | 170.4 | 39.5 | 90.1 | 164.7 | 43.5 |

| PPann | 100.4 | 167.2 | 48.5 | 93.4 | 161.7 | 45.1 |

| Sample | Inner Side | Outer Side | ∆cryst. [Inner − Outer] | |

|---|---|---|---|---|

| PP-R-2 | ∆Hm [J/g] | 71.3 | 64.2 | |

| Tm [°C] | 147.2 | 141.0 | ||

| Xc [%] | 34.4 | 31.0 | 3.4 | |

| PP-R-10 | ∆Hm [J/g] | 76.4 | 55.5 | |

| Tm [°C] | 147.5 | 142.8 | ||

| Xc [%] | 36.9 | 26.8 | 10.1 | |

| PP-10 | ∆Hm [J/g] | 83.0 | 65.0 | |

| Tm [°C] | 147.0 | 140.5 | ||

| Xc [%] | 40.1 | 31.4 | 8.7 | |

| PP-RC-10 | ∆Hm [J/g] | 58.0 | 45.3 | |

| Tm [°C] | 147.1 | 148.4 | ||

| Xc [%] | 28.0 | 21.9 | 8.7 |

| Sample | Total Transmittance [%] | Diffuse Transmittance [%] | Haze [%] |

|---|---|---|---|

| PP-R-2 | 87.2 | 14.3 | 15.8 |

| PP-R-10 | 88.3 | 23.6 | 26.1 |

| PP-10 | 89.0 | 22.3 | 24.4 |

| PP-RC-10 | 88.2 | 16.0 | 17.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huskić, M.; Slemenik Perše, L.; Orel, B.; Mihelčič, M. Isotactic Polypropylene (iPP) Foils—Correlation of Core and Shell Crystallinity with Mechanical Properties Obtained by Nanoindentation. Polymers 2025, 17, 736. https://doi.org/10.3390/polym17060736

Huskić M, Slemenik Perše L, Orel B, Mihelčič M. Isotactic Polypropylene (iPP) Foils—Correlation of Core and Shell Crystallinity with Mechanical Properties Obtained by Nanoindentation. Polymers. 2025; 17(6):736. https://doi.org/10.3390/polym17060736

Chicago/Turabian StyleHuskić, Miroslav, Lidija Slemenik Perše, Boris Orel, and Mohor Mihelčič. 2025. "Isotactic Polypropylene (iPP) Foils—Correlation of Core and Shell Crystallinity with Mechanical Properties Obtained by Nanoindentation" Polymers 17, no. 6: 736. https://doi.org/10.3390/polym17060736

APA StyleHuskić, M., Slemenik Perše, L., Orel, B., & Mihelčič, M. (2025). Isotactic Polypropylene (iPP) Foils—Correlation of Core and Shell Crystallinity with Mechanical Properties Obtained by Nanoindentation. Polymers, 17(6), 736. https://doi.org/10.3390/polym17060736