Palladium Membrane Applications in Hydrogen Energy and Hydrogen-Related Processes

Abstract

1. Introduction

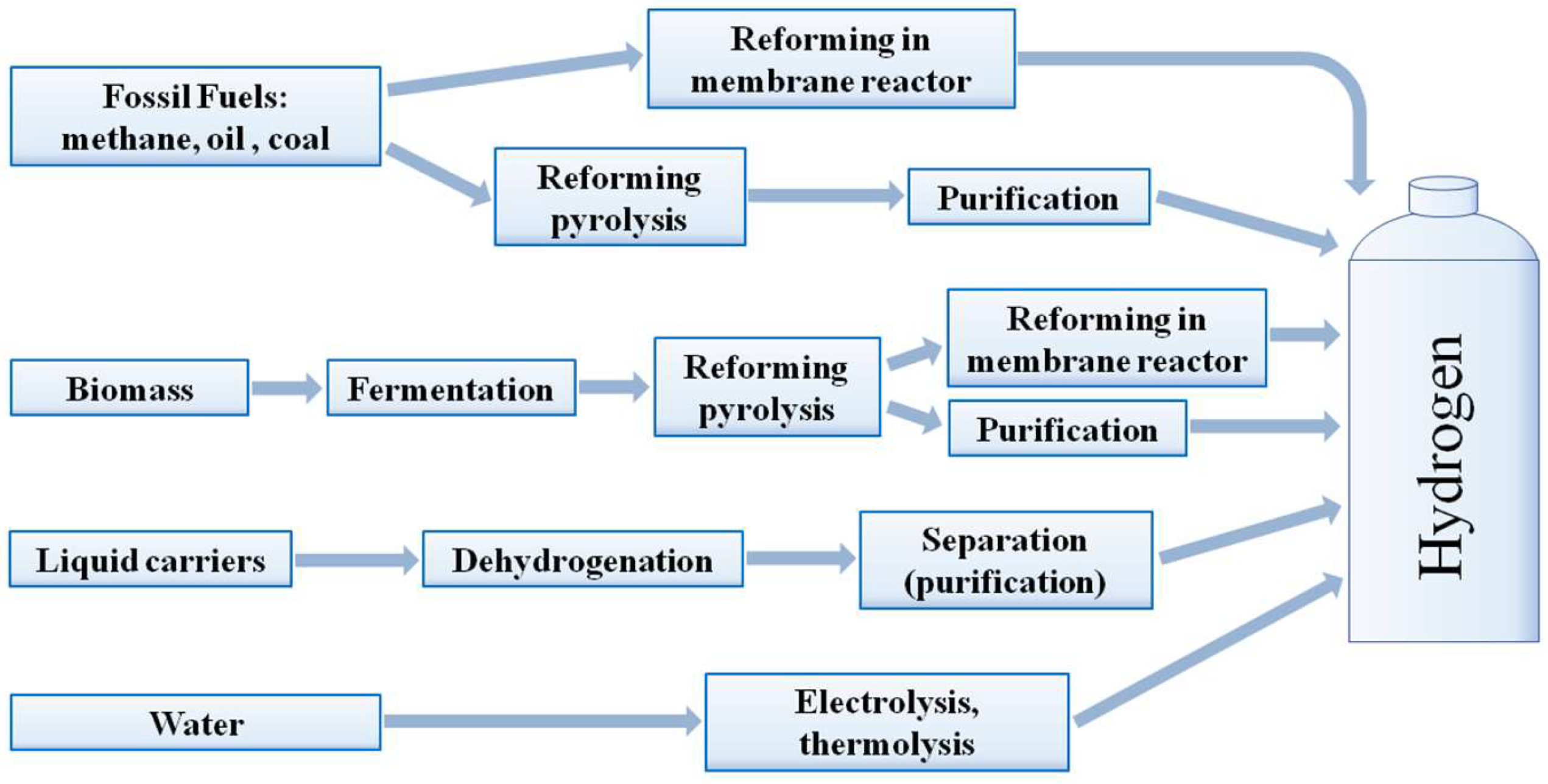

2. Key Hydrogen Production Methods

2.1. Hydrogen Production from Natural Gas

2.2. Liquid Hydrogen Carriers

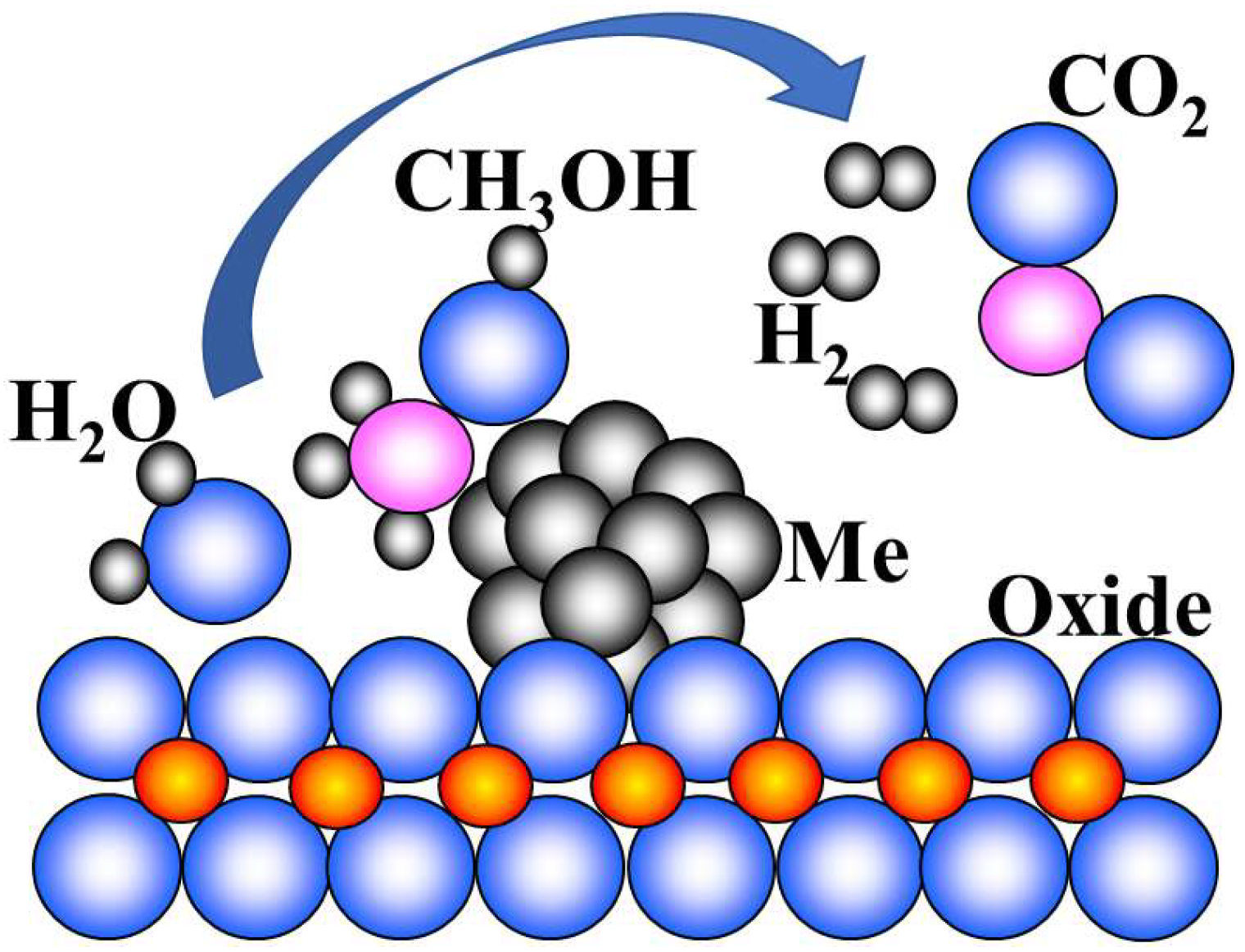

2.3. Hydrogen Production from Alcohols

2.4. Catalysts for Hydrogen Production

2.5. Water Electrolysis

3. Palladium Membranes for Hydrogen Purification

3.1. Hydrogen Purification Methods

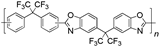

3.2. Palladium Alloy-Based Membranes

3.3. Surface Modification of Palladium Membrane

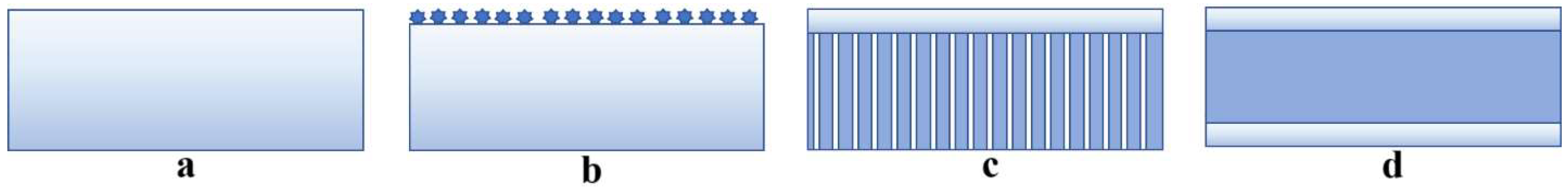

3.4. Composite Membranes

| Membrane | T, °C | Pd Layer Thickness, μm | H2 Permeability, 10−9 mol·m−1·s−1·Pa−0.5 | H2/N2 Separation Selectivity | Ref. |

|---|---|---|---|---|---|

| Pd/Al2O3 | 350 | 5 | 5.0 | 8000–37,600 | [257] |

| Pd/Al2O3 | 400 | 5 | 6.3 | – | [257] |

| Pd-Ag/PSS | 450 | 10 | 34 | 39,000 | [194] |

| Pd/PSS-CeO2 (0.07–0.1 μm) | 400 | 12.5 | 4.5 | >10,000 | [264] |

| Pd/PSS-CeO2 (3.4 μm) | 400 | 6.3 | 3.8 | >10,000 | [264] |

| Pd/PSS-CeO2 (>10 μm) | 400 | 9.0 | 3.6 | >10,000 | [264] |

| Pd/Ta/Pd (tubular) | 450 | 1 | 60–120 | – | [273] |

| Membrane | T (°C) | P(H2), 10−16 mol m−1 s−1 Pa−1 | Q(H2), GPU | Separation Selectivity | Ref. | |

|---|---|---|---|---|---|---|

| H2/N2 | H2/CO2 | |||||

| m-PBI | 150 | 150 | – | 3.4 | 1.4 | [339] |

| 200 | 260 | – | 5.0 | 4.1 | [339] | |

| m-PBI + PEG-stabilized Pd nanoparticles (2%) | 150 | 94 | – | 68 | 9.3 | [339] |

| 200 | 180 | – | 81 | 19 | [339] | |

| m-PBI + PEG-stabilized Pd nanoparticles (3%) | 150 | 210 | – | 4.1 | 3.5 | [339] |

| 200 | 320 | – | 7.3 | 5.8 | [339] | |

| m-PBI + PEG-stabilized Pd nanoparticles (4%) | 150 | 94 | – | 75 | 6.4 | [339] |

| 200 | 210 | – | 110 | 5.0 | [339] | |

| m-PBI | 100 | 43.5 | – | 4.8 | 2.5 | [340] |

| 150 | 57 | – | 2.9 | 8.1 | [340] | |

| m-PBI + PVP (1%) | 100 | 15 | – | 5.6 | 1.1 | [340] |

| 150 | 47 | – | 3.2 | 1.8 | [340] | |

| m-PBI + PVP-stabilized Pd nanoparticles (1%) | 100 | 16 | – | 5.4 | 2.4 | [340] |

| 150 | 63.5 | – | 22 | 12 | [340] | |

| 200 | 160 | – | 39 | 21 | [340] | |

| 240 | 160 | – | 43 | 21 | [340] | |

| 260 | 315 | – | 83 | 58 | [340] | |

| 300 | 510 | – | 180 | 83 | [340] | |

| m-PBI + PVP-stabilized Pd nanoparticles (3%) | 100 | 6.0 | – | 5.9 | 2.9 | [340] |

| 150 | 30.5 | – | 8.7 | 6.0 | [340] | |

| m-PBI + Pd nanorods | 150 | 190 | – | – | 34 | [344] |

| 225 | 470 | – | – | 27 | [344] | |

| m-PBI + Pd nanoparticles (58 wt%) | 200 | 220 | – | – | 33 | [341] |

| m-PBI (in hollow fibers) | 60 | – | 0.086 | – | 5.2 | [343] |

| m-PBI + Pd nanoparticles (in hollow fibers) | 60 | – | 80 | – | 10 | [343] |

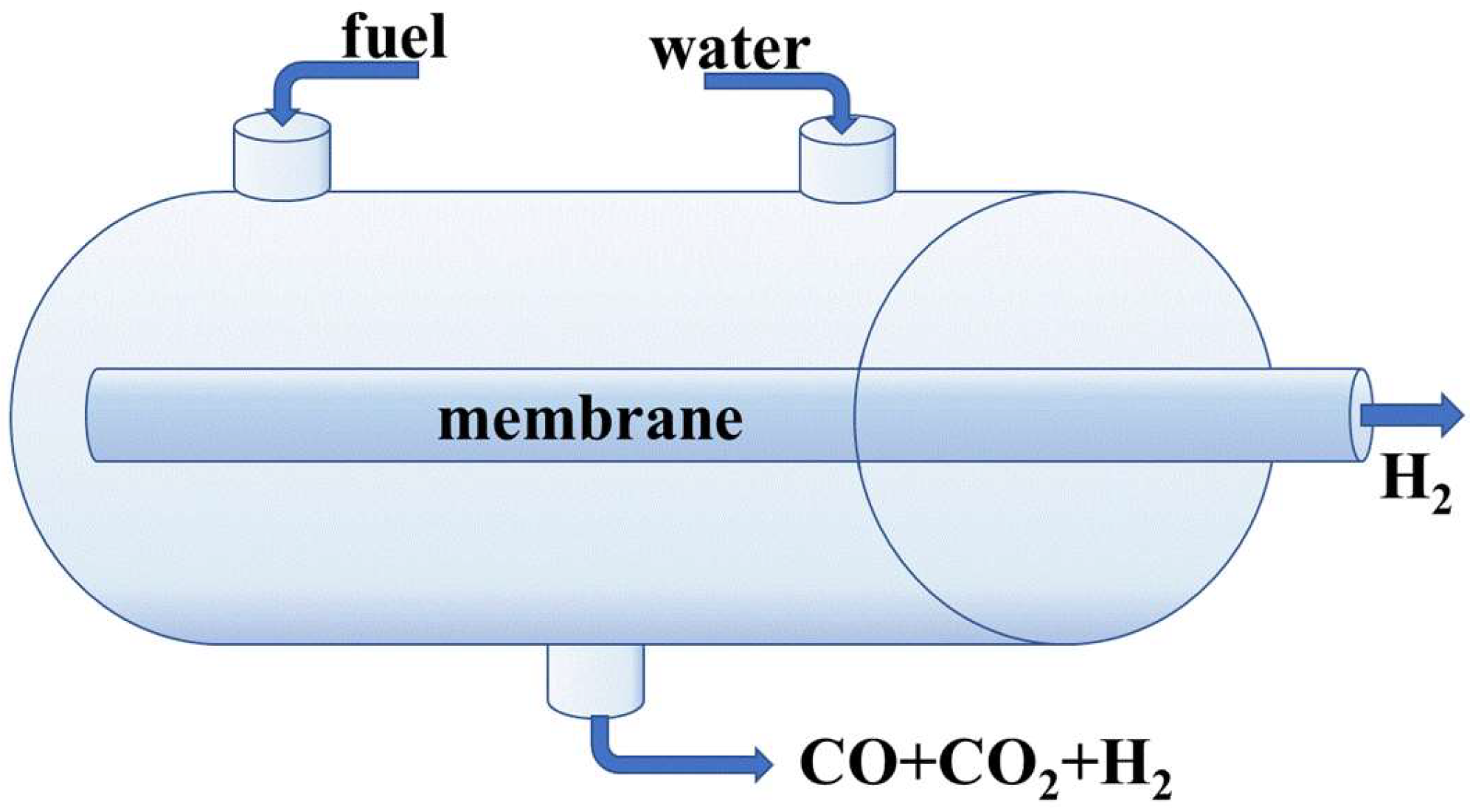

4. Membrane Reactors

4.1. Hydrogen Production Using Membrane Reactors

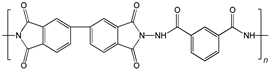

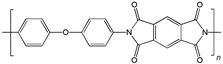

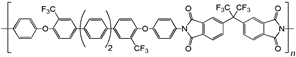

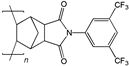

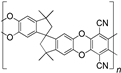

4.2. Polymer-Based Composite Membranes with Catalytically Active Palladium Particles for Hydrogenation/Dehydrogenation Processes

4.3. Polymer–Palladium Composites in Fuel Cells

4.4. Water Treatment: Hydrogenation with Palladium-Containing Membranes

4.4.1. Organo-Chlorinated Compounds’ Removal from Industrial and Waste Water

4.4.2. Dissolved Oxygen Removal

4.4.3. Nitrate and Nitrite Removal

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Angevine, P.J.; Oleck, S.M. Noble Metal-Containing Catalysts. U.S. Patent 4,683,214A, 28 July 1987. [Google Scholar]

- Liu, X.; Iocozzia, J.; Wang, Y.; Cui, X.; Chen, Y.; Zhao, S.; Li, Z.; Lin, Z. Noble metal-metal oxide nanohybrids with tailored nanostructures for efficient solar energy conversion, photocatalysis and environmental remediation. Energy Environ. Sci. 2017, 10, 402–434. [Google Scholar] [CrossRef]

- Stoffels, M.A.; Klauck, F.J.R.; Hamadi, T.; Glorius, F.; Leker, J. Technology trends of catalysts in hydrogenation reactions: A patent landscape analysis. Adv. Synth. Catal. 2020, 362, 1258–1274. [Google Scholar] [CrossRef] [PubMed]

- Han, S.J.; Gebreyohannes, T.G.; Woo lee, S.; Kim, S.K.; Kim, H.W.; Shin, J.; Kim, Y.T. Methane direct conversion to olefins, aromatics, and hydrogen over silica entrapped bimetallic MeFe-SiO2 (Me = Co, Ni, Pd, Pt) catalysts. Mol. Catal. 2023, 535, 112864. [Google Scholar] [CrossRef]

- Biffis, A.; Centomo, P.; Del Zotto, A.; Zecca, M. Pd metal catalysts for cross-couplings and related reactions in the 21st Century: A critical review. Chem. Rev. 2018, 118, 2249–2295. [Google Scholar] [CrossRef]

- McCarthy, S.; Braddock, D.C.; Wilton-Ely, J.D.E.T. Strategies for sustainable palladium catalysis. Coord. Chem. Rev. 2021, 442, 213925. [Google Scholar] [CrossRef]

- Kim, H.J.; Song, C. A refined design concept for sulfur-tolerant Pd catalyst supported on zeolite by shape-selective exclusion and hydrogen spillover for hydrogenation of aromatics. J. Catal. 2021, 403, 203–214. [Google Scholar] [CrossRef]

- Ca’, N. Della Palladium-Catalyzed Reactions. Catalysts 2021, 11, 588. [Google Scholar] [CrossRef]

- Horbaczewskyj, C.S.; Fairlamb, I.J.S. Pd-catalyzed cross-couplings: On the importance of the catalyst quantity descriptors, mol % and ppm. Org. Process Res. Dev. 2022, 26, 2240–2269. [Google Scholar] [CrossRef]

- Dong, D.-Q.; Yang, H.; Zhou, M.-Y.; Wei, Z.-H.; Wu, P.; Wang, Z.-L. Recent advances in palladium-catalyzed reactions in water. Curr. Opin. Green Sustain. Chem. 2023, 40, 100778. [Google Scholar] [CrossRef]

- Habib, M.A.; Haque, M.A.; Harale, A.; Paglieri, S.; Alrashed, F.S.; Al-Sayoud, A.; Nemitallah, M.A.; Hossain, S.; Abuelyamen, A.; Mokheimer, E.M.A.; et al. Palladium-alloy membrane reactors for fuel reforming and hydrogen production: Hydrogen production modeling. Case Stud. Therm. Eng. 2023, 49, 103359. [Google Scholar] [CrossRef]

- Gryaznov, V.M.; Smirnov, V.S. The reactions of hydrocarbons on membrane catalysts. Russ. Chem. Rev. 1974, 43, 821–834. [Google Scholar] [CrossRef]

- Gryaznov, V.M.; Mischenko, A.P.; Smirnov, V.S.; Aladyshev, S.I. Catalytic Reactor Designed for Carrying out Conjugate Chemical Reactions. U.S. Patent 3,779,711, 18 December 1973. [Google Scholar]

- Hafeez, S.; Al-Salem, S.M.; Manos, G.; Constantinou, A. Fuel production using membrane reactors: A review. Environ. Chem. Lett. 2020, 18, 1477–1490. [Google Scholar] [CrossRef]

- Vinodh, R.; Palanivel, T.; Kalanur, S.S.; Pollet, B.G. Recent advancements in catalyst coated membranes for water electrolysis: A critical review. Energy Adv. 2024, 3, 1144–1166. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, T.; Chang, Q.; Ma, C.; Yang, Y.; Wang, S.; Pan, Z.; Sun, Y.; Ding, G. Performance stability and regeneration property of catalytic membranes coupled with advanced oxidation process: A comprehensive review. Sustainability 2023, 15, 7556. [Google Scholar] [CrossRef]

- Chen, C.; Lu, L.; Fei, L.; Xu, J.; Wang, B.; Li, B.; Shen, L.; Lin, H. Membrane-catalysis integrated system for contaminants degradation and membrane fouling mitigation: A review. Sci. Total Environ. 2023, 904, 166220. [Google Scholar] [CrossRef]

- Yu, R.; Chen, W.; Zhang, J.; Liu, J.; Li, X.Y.; Lin, L. Catalytic membranes for water treatment: Perspectives and challenges. J. Hazard. Mater. Adv. 2024, 13, 100414. [Google Scholar] [CrossRef]

- Hayakawa, Y.; Miura, T.; Shizuya, K.; Wakazono, S.; Tokunaga, K.; Kambara, S. Hydrogen production system combined with a catalytic reactor and a plasma membrane reactor from ammonia. Int. J. Hydrogen Energy 2019, 44, 9987–9993. [Google Scholar] [CrossRef]

- Stenina, I.; Yaroslavtsev, A. Modern technologies of hydrogen production. Processes 2023, 11, 56. [Google Scholar] [CrossRef]

- Gapp, E.; Pfeifer, P. Membrane reactors for hydrogen production from renewable energy sources. Curr. Opin. Green Sustain. Chem. 2023, 41, 100800. [Google Scholar] [CrossRef]

- Antolini, E. Palladium in fuel cell catalysis. Energy Environ. Sci. 2009, 2, 915–931. [Google Scholar] [CrossRef]

- Zhang, L.; Chang, Q.; Chen, H.; Shao, M. Recent advances in palladium-based electrocatalysts for fuel cell reactions and hydrogen evolution reaction. Nano Energy 2016, 29, 198–219. [Google Scholar] [CrossRef]

- Che Ramli, Z.A.; Pasupuleti, J.; Tengku Saharuddin, T.S.; Yusoff, Y.N.; Isahak, W.N.R.W.; Baharudin, L.; Tak Yaw, C.; Koh, S.P.; Tiong Kiong, S. Electrocatalytic activities of platinum and palladium catalysts for enhancement of direct formic acid fuel cells: An updated progress. Alex. Eng. J. 2023, 76, 701–733. [Google Scholar] [CrossRef]

- Schwarzer, M.; Hertl, N.; Nitz, F.; Borodin, D.; Fingerhut, J.; Kitsopoulos, T.N.; Wodtke, A.M. Adsorption and absorption energies of hydrogen with palladium. J. Phys. Chem. C 2022, 126, 14500–14508. [Google Scholar] [CrossRef] [PubMed]

- Osada, W.; Tanaka, S.; Mukai, K.; Kawamura, M.; Choi, Y.; Ozaki, F.; Ozaki, T.; Yoshinobu, J. Elucidation of the atomic-scale processes of dissociative adsorption and spillover of hydrogen on the single atom alloy catalyst Pd/Cu(111). Phys. Chem. Chem. Phys. 2022, 24, 21705–21713. [Google Scholar] [CrossRef]

- Chaplin, B.P.; Reinhard, M.; Schneider, W.F.; Schüth, C.; Shapley, J.R.; Strathmann, T.J.; Werth, C.J. Critical review of Pd-based catalytic treatment of priority contaminants in water. Environ. Sci. Technol. 2012, 46, 3655–3670. [Google Scholar] [CrossRef]

- Bhat, I.U.H.; Anwar, M.N.K.; Yusoff, N.R.B.N.; Rak, A.A.L.E. Palladium catalyst for treatment of inorganic and organic pollutants in wastewater: A short review. Desalination Water Treat. 2018, 131, 132–140. [Google Scholar] [CrossRef]

- Liu, J.; Gao, J. Catalytic reduction of water pollutants: Knowledge gaps, lessons learned, and new opportunities. Front. Environ. Sci. Eng. 2023, 17, 26. [Google Scholar] [CrossRef]

- Wang, T.; Cao, X.; Jiao, L. PEM water electrolysis for hydrogen production: Fundamentals, advances, and prospects. Carbon Neutrality 2022, 1, 21. [Google Scholar] [CrossRef]

- Hu, B.; Shu, R.; Khairun, H.S.; Tian, Z.; Wang, C.; Kumar Gupta, N. Methanol steam reforming for hydrogen production over Ni-based catalysts: State-of-the-art review and future prospects. Chem. Asian J. 2024, 19, e202400217. [Google Scholar] [CrossRef]

- Abbass, K.; Qasim, M.Z.; Song, H.; Murshed, M.; Mahmood, H.; Younis, I. A review of the global climate change impacts, adaptation, and sustainable mitigation measures. Environ. Sci. Pollut. Res. 2022, 29, 42539–42559. [Google Scholar] [CrossRef]

- Bauer, C.; Treyer, K.; Antonini, C.; Bergerson, J.; Gazzani, M.; Gencer, E.; Gibbins, J.; Mazzotti, M.; McCoy, S.T.; McKenna, R.; et al. On the climate impacts of blue hydrogen production. Sustain. Energy Fuels 2022, 6, 66–75. [Google Scholar] [CrossRef]

- Scheuing, H.; Kamm, J. The EU on the road to climate neutrality—Is the ‘Fit for 55’ package fit for purpose? Renew. Energy Law Policy Rev. 2022, 10, 4–18. [Google Scholar]

- Cho, H.H.; Strezov, V.; Evans, T.J. A review on global warming potential, challenges and opportunities of renewable hydrogen production technologies. Sustain. Mater. Technol. 2023, 35, e00567. [Google Scholar] [CrossRef]

- Pearre, N.; Swan, L. Reimagining renewable electricity grid management with dispatchable generation to stabilize energy storage. Energy 2020, 203, 117917. [Google Scholar] [CrossRef]

- Alent’ev, A.Y.; Volkov, A.V.; Vorotyntsev, I.V.; Maksimov, A.L.; Yaroslavtsev, A.B. Membrane technologies for decarbonization. Membr. Membr. Technol. 2021, 3, 255–273. [Google Scholar] [CrossRef]

- Beccarello, M.; Di Foggia, G. Review and perspectives of key decarbonization drivers to 2030. Energies 2023, 16, 1345. [Google Scholar] [CrossRef]

- Johnson, M.P.; Rötzel, T.S.; Frank, B. Beyond conventional corporate responses to climate change towards deep decarbonization: A systematic literature review. Manag. Rev. Q. 2023, 73, 921–924. [Google Scholar] [CrossRef]

- Dehghani-Sanij, A.R.; Tharumalingam, E.; Dusseault, M.B.; Fraser, R. Study of energy storage systems and environmental challenges of batteries. Renew. Sustain. Energy Rev. 2019, 104, 192–208. [Google Scholar] [CrossRef]

- Yaroslavtsev, A.B.; Stenina, I.A.; Golubenko, D.V. Membrane materials for energy production and storage. Pure Appl. Chem. 2020, 92, 1147–1157. [Google Scholar] [CrossRef]

- Song, J.; Wei, C.; Huang, Z.-F.; Liu, C.; Zeng, L.; Wang, X.; Xu, Z.J. A review on fundamentals for designing oxygen evolution electrocatalysts. Chem. Soc. Rev. 2020, 49, 2196–2214. [Google Scholar] [CrossRef]

- Kojima, H.; Nagasawa, K.; Todoroki, N.; Ito, Y.; Matsui, T.; Nakajima, R. Influence of renewable energy power fluctuations on water electrolysis for green hydrogen production. Int. J. Hydrogen Energy 2023, 48, 4572–4593. [Google Scholar] [CrossRef]

- Fan, L.; Tu, Z.; Chan, S.H. Recent development in design a state-of-art proton exchange membrane fuel cell from stack to system: Theory, integration and prospective. Int. J. Hydrogen Energy 2023, 48, 7828–7865. [Google Scholar] [CrossRef]

- Le, P.A.; Trung, V.D.; Nguyen, P.L.; Bac Phung, T.V.; Natsuki, J.; Natsuki, T. The current status of hydrogen energy: An overview. RSC Adv. 2023, 13, 28262–28287. [Google Scholar] [CrossRef] [PubMed]

- Capurso, T.; Stefanizzi, M.; Torresi, M.; Camporeale, S.M. Perspective of the role of hydrogen in the 21st century energy transition. Energy Convers. Manag. 2022, 251, 114898. [Google Scholar] [CrossRef]

- Qazi, U.Y. Future of hydrogen as an alternative fuel for next-generation industrial applications; challenges and expected opportunities. Energies 2022, 15, 4741. [Google Scholar] [CrossRef]

- Stenina, I.A.; Yaroslavtsev, A.B. Prospects for the development of hydrogen energy. Polymer membranes for fuel cells and electrolyzers. Membr. Membr. Technol. 2024, 6, 15–26. [Google Scholar] [CrossRef]

- Bloomberg Finance. Hydrogen Economy Outlook: Key Messages, 30 March 2020. Available online: https://data.bloomberglp.com/professional/sites/24/BNEF-Hydrogen-Economy-Outlook-Key-Messages-30-Mar-2020.pdf (accessed on 30 March 2020).

- Zainal, B.S.; Ker, P.J.; Mohamed, H.; Ong, H.C.; Fattah, I.M.R.; Rahman, S.M.A.; Nghiem, L.D.; Mahlia, T.M.I. Recent advancement and assessment of green hydrogen production technologies. Renew. Sustain. Energy Rev. 2024, 189, 113941. [Google Scholar] [CrossRef]

- Yukesh Kannah, R.; Kavitha, S.; Preethi; Parthiba Karthikeyan, O.; Kumar, G.; Dai-Viet, N.V.; Rajesh Banu, J. Techno-economic assessment of various hydrogen production methods—A review. Bioresour. Technol. 2021, 319, 124175. [Google Scholar] [CrossRef]

- Agyekum, E.B.; Nutakor, C.; Agwa, A.M.; Kamel, S. A critical review of renewable hydrogen production methods: Factors affecting their scale-up and its role in future energy generation. Membranes 2022, 12, 173. [Google Scholar] [CrossRef]

- Ishaq, H.; Dincer, I.; Crawford, C. A review on hydrogen production and utilization: Challenges and opportunities. Int. J. Hydrogen Energy 2022, 47, 26238–26264. [Google Scholar] [CrossRef]

- Sarmah, M.K.; Singh, T.P.; Kalita, P.; Dewan, A. Sustainable hydrogen generation and storage—A review. RSC Adv. 2023, 13, 25253–25275. [Google Scholar] [CrossRef] [PubMed]

- Fajín, J.L.C.; Cordeiro, M.N.D.S. Renewable hydrogen production from biomass derivatives or water on trimetallic based catalysts. Renew. Sustain. Energy Rev. 2024, 189, 113909. [Google Scholar] [CrossRef]

- Iulianelli, A.; Liguori, S.; Wilcox, J.; Basile, A. Advances on methane steam reforming to produce hydrogen through membrane reactors technology: A review. Catal. Rev. 2016, 58, 1–35. [Google Scholar] [CrossRef]

- Antzaras, A.N.; Lemonidou, A.A. Recent advances on materials and processes for intensified production of blue hydrogen. Renew. Sustain. Energy Rev. 2022, 155, 111917. [Google Scholar] [CrossRef]

- Jokar, S.M.; Farokhnia, A.; Tavakolian, M.; Pejman, M.; Parvasi, P.; Javanmardi, J.; Zare, F.; Gonçalves, M.C.; Basile, A. The recent areas of applicability of palladium based membrane technologies for hydrogen production from methane and natural gas: A review. Int. J. Hydrogen Energy 2023, 48, 6451–6476. [Google Scholar] [CrossRef]

- Jeppesen, C.; Polverino, P.; Andreasen, S.J.; Araya, S.S.; Sahlin, S.L.; Pianese, C.; Kær, S.K. Impedance characterization of high temperature proton exchange membrane fuel cell stack under the influence of carbon monoxide and methanol vapor. Int. J. Hydrogen Energy 2017, 42, 21901–21912. [Google Scholar] [CrossRef]

- Sutharssan, T.; Montalvao, D.; Chen, Y.K.; Wang, W.-C.; Pisac, C.; Elemara, H. A review on prognostics and health monitoring of proton exchange membrane fuel cell. Renew. Sustain. Energy Rev. 2017, 75, 440–450. [Google Scholar] [CrossRef]

- Li, L.; Md Dostagir, N.H.; Shrotri, A.; Fukuoka, A.; Kobayashi, H. Partial oxidation of methane to syngas via formate intermediate found for a ruthenium-rhenium bimetallic catalyst. ACS Catal. 2021, 11, 3782–3789. [Google Scholar] [CrossRef]

- Alhassan, M.; Jalil, A.A.; Nabgan, W.; Hamid, M.Y.S.; Bahari, M.B.; Ikram, M. Bibliometric studies and impediments to valorization of dry reforming of methane for hydrogen production. Fuel 2022, 328, 125240. [Google Scholar] [CrossRef]

- Khatun, R.; Bhandari, S.; Poddar, M.K.; Samanta, C.; Khan, T.S.; Khurana, D.; Bal, R. Partial oxidation of methane over high coke-resistant bimetallic Pt-Ni/CeO2 catalyst: Profound influence of Pt addition on stability. Int. J. Hydrogen Energy 2022, 47, 38895–38909. [Google Scholar] [CrossRef]

- Wachter, P.; Hödl, P.; Raic, J.; Gaber, C.; Demuth, M.; Hochenauer, C. Towards thermochemical recuperation applying combined steam reforming and partial oxidation of methane: Thermodynamic and experimental considerations. Energy Convers. Manag. 2022, 251, 114927. [Google Scholar] [CrossRef]

- Dan, M.; Mihet, M.; Borodi, G.; Lazar, M.D. Combined steam and dry reforming of methane for syngas production from biogas using bimodal pore catalysts. Catal. Today 2021, 366, 87–96. [Google Scholar] [CrossRef]

- Nedolivko, V.V.; Zasypalov, G.O.; Vutolkina, A.V.; Gushchin, P.A.; Vinokurov, V.A.; Kulikov, L.A.; Egazar’yants, S.V.; Karakhanov, E.A.; Maksimov, A.L.; Glotov, A.P. Carbon dioxide reforming of methane. Russ. J. Appl. Chem. 2020, 93, 765–787. [Google Scholar] [CrossRef]

- Wittich, K.; Krämer, M.; Bottke, N.; Schunk, S.A. Catalytic dry reforming of methane: Insights from model systems. ChemCatChem 2020, 12, 2130–2147. [Google Scholar] [CrossRef]

- Qian, J.X.; Chen, T.W.; Enakonda, L.R.; Liu, D.B.; Mignani, G.; Basset, J.M.; Zhou, L. Methane decomposition to produce COx-free hydrogen and nano-carbon over metal catalysts: A review. Int. J. Hydrogen Energy 2020, 45, 7981–8001. [Google Scholar] [CrossRef]

- Naikoo, G.A.; Arshad, F.; Hassan, I.U.; Tabook, M.A.; Pedram, M.Z.; Mustaqeem, M.; Tabassum, H.; Ahmed, W.; Rezakazemi, M. Thermocatalytic hydrogen production through decomposition of methane—A review. Front. Chem. 2021, 9, 736801. [Google Scholar] [CrossRef]

- Sánchez-Bastardo, N.; Schlögl, R.; Ruland, H. Methane pyrolysis for zero-emission hydrogen production: A potential bridge technology from fossil fuels to a renewable and sustainable hydrogen economy. Ind. Eng. Chem. Res. 2021, 60, 11855–11881. [Google Scholar] [CrossRef]

- Lee, B.; Heo, J.; Kim, S.; Sung, C.; Moon, C.; Moon, S.; Lim, H. Economic feasibility studies of high pressure PEM water electrolysis for distributed H2 refueling stations. Energy Convers. Manag. 2018, 162, 139–144. [Google Scholar] [CrossRef]

- Chi, J.; Yu, H. Water electrolysis based on renewable energy for hydrogen production. Chin. J. Catal. 2018, 39, 390–394. [Google Scholar] [CrossRef]

- Pinsky, R.; Sabharwall, P.; Hartvigsen, J.; O’Brien, J. Comparative review of hydrogen production technologies for nuclear hybrid energy systems. Prog. Nucl. Energy 2020, 123, 103317. [Google Scholar] [CrossRef]

- Ji, M.; Wang, J. Review and comparison of various hydrogen production methods based on costs and life cycle impact assessment indicators. Int. J. Hydrogen Energy 2021, 46, 38612–38635. [Google Scholar] [CrossRef]

- Jiang, L.; Chen, Z.; Farouq Ali, S.M. Thermal-hydro-chemical-mechanical alteration of coal pores in underground coal gasification. Fuel 2020, 262, 116543. [Google Scholar] [CrossRef]

- Munyentwali, A.; Tan, K.C.; He, T. Advancements in the development of liquid organic hydrogen carrier systems and their applications in the hydrogen economy. Prog. Nat. Sci. Mater. Int. 2024, 34, 825–839. [Google Scholar] [CrossRef]

- Kustov, L.M.; Kalenchuk, A.N.; Bogdan, V.I. Systems for accumulation, storage and release of hydrogen. Russ. Chem. Rev. 2020, 89, 897–916. [Google Scholar] [CrossRef]

- Liu, H.; Zhou, C.; Li, W.; Li, W.; Qiu, M.; Chen, X.; Wang, H.; Sun, Y. Ultralow Rh bimetallic catalysts with high catalytic activity for the hydrogenation of N-ethylcarbazole. ACS Sustain. Chem. Eng. 2021, 9, 5260–5267. [Google Scholar] [CrossRef]

- Mollar-Cuni, A.; Ventura-Espinosa, D.; Martín, S.; García, H.; Mata, J.A. Reduced graphene oxides as carbocatalysts in acceptorless dehydrogenation of N-heterocycles. ACS Catal. 2021, 11, 14688–14693. [Google Scholar] [CrossRef]

- Mejuto, C.; Ibáñez-Ibáñez, L.; Guisado-Barrios, G.; Mata, J.A. Visible-light-promoted iridium(III)-catalyzed acceptorless dehydrogenation of N-heterocycles at room temperature. ACS Catal. 2022, 12, 6238–6245. [Google Scholar] [CrossRef]

- Song, H.; Yang, G.; Xue, P.; Li, Y.; Zou, J.; Wang, S.; Yang, H.; Chen, H. Recent development of biomass gasification for H2 rich gas production. Appl. Energy Combust. Sci. 2022, 10, 100059. [Google Scholar] [CrossRef]

- Lim, S.; Song, Y.; Jeong, K.; Park, J.H.; Na, K. Enhanced dehydrogenative H2 release from N-containing amphicyclic LOHC boosted by Pd-supported nanosheet MFI zeolites having strong acidity and large mesoporosity. ACS Sustain. Chem. Eng. 2022, 10, 3584–3594. [Google Scholar] [CrossRef]

- Itoh, N.; Kikuchi, Y.; Furusawa, T.; Sato, T. Tube-wall catalytic membrane reactor for hydrogen production by low-temperature ammonia decomposition. Int. J. Hydrogen Energy 2021, 46, 20257–20265. [Google Scholar] [CrossRef]

- Xu, X.; Liu, E.; Zhu, N.; Liu, F.; Qian, F. Review of the current status of ammonia-blended hydrogen fuel engine development. Energies 2022, 15, 1023. [Google Scholar] [CrossRef]

- Zhai, L.; Liu, S.; Xiang, Z. Ammonia as a carbon-free hydrogen carrier for fuel cells: A perspective. Ind. Chem. Mater. 2023, 1, 332–342. [Google Scholar] [CrossRef]

- Lytkina, A.A.; Orekhova, N.V.; Yaroslavtsev, A.B. Catalysts for the steam reforming and electrochemical oxidation of methanol. Inorg. Mater. 2018, 54, 1315–1329. [Google Scholar] [CrossRef]

- Kumar, A.; Daw, P.; Milstein, D. Homogeneous catalysis for sustainable energy: Hydrogen and methanol economies, fuels from biomass, and related topics. Chem. Rev. 2022, 122, 385–441. [Google Scholar] [CrossRef] [PubMed]

- Aziz, M.; Darmawan, A.; Juangsa, F.B. Hydrogen production from biomasses and wastes: A technological review. Int. J. Hydrogen Energy 2021, 46, 33756–33781. [Google Scholar] [CrossRef]

- Mironova, E.Y.; Lytkina, A.A.; Ermilova, M.M.; Efimov, M.N.; Zemtsov, L.M.; Orekhova, N.V.; Karpacheva, G.P.; Bondarenko, G.N.; Muraviev, D.N.; Yaroslavtsev, A.B. Ethanol and methanol steam reforming on transition metal catalysts supported on detonation synthesis nanodiamonds for hydrogen production. Int. J. Hydrogen Energy 2015, 40, 3557–3565. [Google Scholar] [CrossRef]

- Yang, W.-W.; Ma, X.; Tang, X.-Y.; Dou, P.-Y.; Yang, Y.-J.; He, Y.-L. Review on developments of catalytic system for methanol steam reforming from the perspective of energy-mass conversion. Fuel 2023, 345, 128234. [Google Scholar] [CrossRef]

- Achomo, M.A.; Kumar, A.; Peela, N.R.; Muthukumar, P. Hydrogen production from steam reforming of methanol: A comprehensive review on thermodynamics, catalysts, reactors, and kinetic studies. Int. J. Hydrogen Energy 2024, 58, 1640–1672. [Google Scholar] [CrossRef]

- Cao, A.N.T.; Ng, K.H.; Ahmed, S.F.; Nguyen, H.T.; Kumar, P.S.; Tran, H.T.; Rajamohan, N.; Yusuf, M.; Show, P.L.; Balakrishnan, A.; et al. Hydrogen generation by heterogeneous catalytic steam reforming of short-chain alcohols: A review. Environ. Chem. Lett. 2024, 22, 561–583. [Google Scholar] [CrossRef]

- Jahromi, A.F.; Ruiz-López, E.; Dorado, F.; Baranova, E.A.; de Lucas-Consuegra, A. Electrochemical promotion of ethanol partial oxidation and reforming reactions for hydrogen production. Renew. Energy 2022, 183, 515–523. [Google Scholar] [CrossRef]

- Wang, Z.; Dai, H.; Wang, Z. Experimental study on improving the efficiency of hydrogen production by partial oxidation of ethanol. Int. J. Hydrogen Energy 2022, 47, 18619–18628. [Google Scholar] [CrossRef]

- François, E.; Dumas, C.; Gougeon, R.D.; Alexandre, H.; Vuilleumier, S.; Ernst, B. Unexpected high production of biohydrogen from the endogenous fermentation of grape must deposits. Bioresour. Technol. 2021, 320, 124334. [Google Scholar] [CrossRef]

- Policastro, G.; Lamboglia, R.; Fabbricino, M.; Pirozzi, F. Enhancing dark fermentative hydrogen production from problematic substrates via the co-fermentation strategy. Fermentation 2022, 8, 706. [Google Scholar] [CrossRef]

- Cao, W.; Wei, X.; Jiang, Y.; Feng, J.; Gao, Z.; Tang, C. Furfural influences hydrogen evolution and energy conversion in photo-fermentation by Rhodobacter capsulatus. Catalysts 2022, 12, 979. [Google Scholar] [CrossRef]

- Guilhaume, N.; Bianchi, D.; Wandawa, R.A.; Yin, W.; Schuurman, Y. Study of CO2 and H2O adsorption competition in the combined dry/steam reforming of biogas. Catal. Today 2021, 375, 282–289. [Google Scholar] [CrossRef]

- Siang, T.J.; Jalil, A.A.; Liew, S.Y.; Owgi, A.H.K.; Rahman, A.F.A. A review on state-of-the-art catalysts for methane partial oxidation to syngas production. Catal. Rev. 2024, 66, 343–399. [Google Scholar] [CrossRef]

- Zhang, J.; Men, Y.; Wang, Y.; Liao, L.; Liu, S.; Wang, J.; An, W. Morphology effect of Pd/In2O3/CeO2 catalysts on methanol steam reforming for hydrogen production. Int. J. Hydrogen Energy 2024, 51, 1185–1199. [Google Scholar] [CrossRef]

- Vogt, C.; Kranenborg, J.; Monai, M.; Weckhuysen, B.M. Structure sensitivity in steam and dry methane reforming over nickel: Activity and carbon formation. ACS Catal. 2020, 10, 1428–1438. [Google Scholar] [CrossRef]

- Wu, Y.; Pei, C.; Tian, H.; Liu, T.; Zhang, X.; Chen, S.; Xiao, Q.; Wang, X.; Gong, J. Role of Fe species of Ni-based catalysts for efficient low-temperature ethanol steam reforming. JACS Au 2021, 1, 1459–1470. [Google Scholar] [CrossRef]

- Ye, R.; Xiao, S.; Lai, Q.; Wang, D.; Huang, Y.; Feng, G.; Zhang, R.; Wang, T. Advances in enhancing the stability of Cu-based catalysts for methanol reforming. Catalysts 2022, 12, 747. [Google Scholar] [CrossRef]

- Chernyshev, V.M.; Ananikov, V.P. Nickel and palladium catalysis: Stronger demand than ever. ACS Catal. 2022, 12, 1180–1200. [Google Scholar] [CrossRef]

- Kappis, K.; Papavasiliou, J.; Kuśmierz, M.; Słowik, G.; Li, Y.; Li, H.; Gac, W.; Avgouropoulos, G. Steam reforming of methanol over combustion synthesized CuZnOx-based catalysts for fuel cell applications. Chem. Eng. J. 2023, 461, 142098. [Google Scholar] [CrossRef]

- Mao, Q.; Gao, Z.; Liu, X.; Guo, Y.; Wang, Y.; Ma, D. The Cu–Al2O3 interface: An unignorable active site for methanol steam reforming hydrogen production. Catal. Sci. Technol. 2024, 14, 3448–3458. [Google Scholar] [CrossRef]

- Guo, C.; Li, M.; Guo, W.; Xie, J.; Qin, H.; Liao, M.; Zhang, Y.; Gao, P.; Xiao, H. Quench-induced Cu-ZnO catalyst for hydrogen production from methanol steam reforming. Chem. Eng. J. 2024, 486, 150331. [Google Scholar] [CrossRef]

- Shu, Q.; Zhang, Q.; Zhu, X. Enhancing activation and stability of core-shell CuZn catalyst by ZnOx oxygen vacancies for methanol steam reforming. Appl. Catal. A Gen. 2024, 678, 119652. [Google Scholar] [CrossRef]

- Jiang, W.; Ma, X.; Zhang, D.; Li, Z.; Fu, P. Highly efficient catalysts for hydrogen generation through methanol steam reforming: A critical analysis of modification strategies, deactivation, mechanisms and kinetics. J. Ind. Eng. Chem. 2024, 130, 54–72. [Google Scholar] [CrossRef]

- Huang, J.; Ning, S.; Luo, B.; Wang, Z.; Deng, W.; Zhao, B.; Su, Y. Copper-based catalysts supported on novel Metal-Organic Framework MIL-125(Ti) for selective catalytic reduction of NO with CO. Fuel 2024, 364, 131167. [Google Scholar] [CrossRef]

- Lytkina-Payen, A.; Tabachkova, N.; Yaroslavtsev, A. Methanol steam reforming on bimetallic catalysts based on in and nb doped titania or zirconia: A support effect. Processes 2022, 10, 19. [Google Scholar] [CrossRef]

- Mitchell, S.; Pérez-Ramírez, J. Single atom catalysis: A decade of stunning progress and the promise for a bright future. Nat. Commun. 2020, 11, 10–12. [Google Scholar] [CrossRef]

- Hannagan, R.T.; Giannakakis, G.; Flytzani-Stephanopoulos, M.; Sykes, E.C.H. Single-atom alloy catalysis. Chem. Rev. 2020, 120, 12044–12088. [Google Scholar] [CrossRef]

- Abiso, A.M.; Fasanya, O.O.; Suleiman, M.Y.; Atta, A.Y.; Dutta, J.; Jibril, B.E.Y. Advances in copper-based catalysts for sustainable hydrogen production via methanol steam reforming. Chem. Eng. J. Adv. 2024, 19, 100625. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, R.; Zhang, X.; Zhao, H. Recent advances in single-atom alloys: Preparation methods and applications in heterogeneous catalysis. RSC Adv. 2024, 14, 3936–3951. [Google Scholar] [CrossRef] [PubMed]

- Lytkina, A.A.; Orekhova, N.V.; Ermilova, M.M.; Yaroslavtsev, A.B. The influence of the support composition and structure (MXZr1-XO2-δ) of bimetallic catalysts on the activity in methanol steam reforming. Int. J. Hydrogen Energy 2018, 43, 198–207. [Google Scholar] [CrossRef]

- Taherian, Z.; Khataee, A.; Han, N.; Orooji, Y. Hydrogen production through methane reforming processes using promoted-Ni/mesoporous silica: A review. J. Ind. Eng. Chem. 2022, 107, 20–30. [Google Scholar] [CrossRef]

- Zhou, F.; Zhang, R.; Li, H.; Liu, J.; Wu, Y.; Toan, S.; Sun, Z. The critical role of Ga doped Cu/Al2O3 aerogels in carbon monoxide suppression during steam reforming of methanol. Fuel Process. Technol. 2023, 249, 107792. [Google Scholar] [CrossRef]

- De Maron, J.; Mafessanti, R.; Gramazio, P.; Orfei, E.; Fasolini, A.; Basile, F. H2 production by methane oxy-reforming: Effect of catalyst pretreatment on the properties and activity of Rh-Ce0.5Zr0.5O2 synthetized by microemulsion. Nanomaterials 2023, 13, 53. [Google Scholar] [CrossRef]

- Zhang, J.; Su, D.S.; Blume, R.; Schlögl, R.; Wang, R.; Yang, X.; Gajović, A. Surface chemistry and catalytic reactivity of a nanodiamond in the steam-free dehydrogenation of ethylbenzene. Angew. Chem. Int. Ed. 2010, 49, 8640–8644. [Google Scholar] [CrossRef]

- Bepari, S.; Khan, M.; Li, X.; Mohammad, N.; Kuila, D. Effect of Ce and Zn on Cu-based mesoporous carbon catalyst for methanol steam reforming. Top. Catal. 2023, 66, 375–392. [Google Scholar] [CrossRef]

- Lytkina, A.A.; Orekhova, N.V.; Ermilova, M.M.; Belenov, S.V.; Guterman, V.E.; Efimov, M.N.; Yaroslavtsev, A.B. Bimetallic carbon nanocatalysts for methanol steam reforming in conventional and membrane reactors. Catal. Today 2016, 268, 60–67. [Google Scholar] [CrossRef]

- Hu, G.; Wang, J.; Liu, D.; Zhang, X.; Yu, B.; Huang, T.; Zhu, M.; Yu, H. A Joule-heated carbon nanofiber aerogel-supported catalyst for hydrogen production via methanol steam reforming. Carbon 2023, 214, 118311. [Google Scholar] [CrossRef]

- Lytkina, A.A.; Orekhova, N.V.; Ermilova, M.M.; Petriev, I.S.; Baryshev, M.G.; Yaroslavtsev, A.B. Ru-Rh based catalysts for hydrogen production via methanol steam reforming in conventional and membrane reactors. Int. J. Hydrogen Energy 2019, 44, 13310–13322. [Google Scholar] [CrossRef]

- Shiva Kumar, S.; Lim, H. An overview of water electrolysis technologies for green hydrogen production. Energy Rep. 2022, 8, 13793–13813. [Google Scholar] [CrossRef]

- Teng, T.; Zhang, X.; Xue, Q.; Zhang, B. Research of proton exchange membrane fuel cell modeling on concentration polarization under variable-temperature operating conditions. Energies 2024, 17, 730. [Google Scholar] [CrossRef]

- AlZohbi, G. An overview of hydrogen energy generation. ChemEngineering 2024, 8, 17. [Google Scholar] [CrossRef]

- Apel, P.Y.; Biesheuvel, P.M.; Bobreshova, O.V.; Borisov, I.L.; Vasil’eva, V.I.; Volkov, V.V.; Grushevenko, E.A.; Nikonenko, V.V.; Parshina, A.V.; Pismenskaya, N.D.; et al. Concentration polarization in membrane systems. Membr. Membr. Technol. 2024, 6, 133–161. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, Y.; Xu, L.; Hu, Z.; Zhao, G.; Sun, H.; Li, J.; Ouyang, M. Polarization decomposing of proton exchange membrane fuel cell considering liquid water accumulation. J. Electrochem. Soc. 2022, 169, 124517. [Google Scholar] [CrossRef]

- El-Shafie, M.; Kambara, S.; Hayakawa, Y. Hydrogen production technologies overview. J. Power Energy Eng. 2019, 7, 107–154. [Google Scholar] [CrossRef]

- Shiva Kumar, S.; Himabindu, V. Hydrogen production by PEM water electrolysis—A review. Mater. Sci. Energy Technol. 2019, 2, 442–454. [Google Scholar] [CrossRef]

- Hauch, A.; Küngas, R.; Blennow, P.; Hansen, A.B.; Hansen, J.B.; Mathiesen, B.V.; Mogensen, M.B. Recent advances in solid oxide cell technology for electrolysis. Science 2020, 370, eaba6118. [Google Scholar] [CrossRef]

- Ahmad Kamaroddin, M.F.; Sabli, N.; Tuan Abdullah, T.A.; Siajam, S.I.; Abdullah, L.C.; Abdul Jalil, A.; Ahmad, A. Membrane-based electrolysis for hydrogen production: A review. Membranes 2021, 11, 810. [Google Scholar] [CrossRef]

- Mehanovic, D.; Al-Haiek, A.; Leclerc, P.; Rancourt, D.; Fréchette, L.; Picard, M. Energetic, GHG, and economic analyses of electrified steam methane reforming using conventional reformer tubes. Energy Convers. Manag. 2023, 276, 116549. [Google Scholar] [CrossRef]

- Das, G.; Choi, J.H.; Nguyen, P.K.T.; Kim, D.J.; Yoon, Y.S. Anion exchange membranes for fuel cell application: A review. Polymers 2022, 14, 1197. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Weber, A.Z. Ionomer optimization for hydroxide-exchange-membrane water electrolyzers operated with distilled water: A modeling study. J. Electrochem. Soc. 2022, 169, 054506. [Google Scholar] [CrossRef]

- Du, N.; Roy, C.; Peach, R.; Turnbull, M.; Thiele, S.; Bock, C. Anion-exchange membrane water electrolyzers. Chem. Rev. 2022, 122, 11830–11895. [Google Scholar] [CrossRef] [PubMed]

- Ďurovič, M.; Hnát, J.; Strečková, M.; Bouzek, K. Efficient cathode for the hydrogen evolution reaction in alkaline membrane water electrolysis based on NiCoP embedded in carbon fibres. J. Power Sources 2023, 556, 232506. [Google Scholar] [CrossRef]

- Fallah Vostakola, M.; Ozcan, H.; El-Emam, R.S.; Amini Horri, B. Recent advances in high-temperature steam electrolysis with solid oxide electrolysers for green hydrogen production. Energies 2023, 16, 3327. [Google Scholar] [CrossRef]

- Hammi, Z.; Labjar, N.; Lotfi, E.M.; El Hajjaji, S. Production of green hydrogen employing proton exchange membrane water electrolyzer: Characterization of electrolyte membrane. A critical review. J. Membr. Sci. Res. 2023, 9, 1978109. [Google Scholar] [CrossRef]

- Kadier, A.; Kalil, M.S.; Abdeshahian, P.; Chandrasekhar, K.; Mohamed, A.; Azman, N.F.; Logroño, W.; Simayi, Y.; Hamid, A.A. Recent advances and emerging challenges in microbial electrolysis cells (MECs) for microbial production of hydrogen and value-added chemicals. Renew. Sustain. Energy Rev. 2016, 61, 501–525. [Google Scholar] [CrossRef]

- Rousseau, R.; Etcheverry, L.; Roubaud, E.; Basséguy, R.; Délia, M.-L.; Bergel, A. Microbial electrolysis cell (MEC): Strengths, weaknesses and research needs from electrochemical engineering standpoint. Appl. Energy 2020, 257, 113938. [Google Scholar] [CrossRef]

- Durakovic, G.; del Granado, P.C.; Tomasgard, A. Are green and blue hydrogen competitive or complementary? Insights from a decarbonized European power system analysis. Energy 2023, 282, 128282. [Google Scholar] [CrossRef]

- Arcos, J.M.M.; Santos, D.M.F. The hydrogen color spectrum: Techno-economic analysis of the available technologies for hydrogen production. Gases 2023, 3, 25–46. [Google Scholar] [CrossRef]

- Filippov, S.P.; Keiko, A.V. Coal gasification: At the crossroad. technological factors. Therm. Eng. 2021, 68, 209–220. [Google Scholar] [CrossRef]

- Ustolin, F.; Paltrinieri, N.; Berto, F. Loss of integrity of hydrogen technologies: A critical review. Int. J. Hydrogen Energy 2020, 45, 23809–23840. [Google Scholar] [CrossRef]

- Osman, A.I.; Mehta, N.; Elgarahy, A.M.; Hefny, M.; Al-Hinai, A.; Al-Muhtaseb, A.H.; Rooney, D.W. Hydrogen production, storage, utilisation and environmental impacts: A review. Environ. Chem. Lett. 2022, 20, 153–188. [Google Scholar] [CrossRef]

- Katebah, M.; Al-Rawashdeh, M.; Linke, P. Analysis of hydrogen production costs in Steam-Methane Reforming considering integration with electrolysis and CO2 capture. Clean. Eng. Technol. 2022, 10, 100552. [Google Scholar] [CrossRef]

- Jiang, L.; Xue, D.; Wei, Z.; Chen, Z.; Mirzayev, M.; Chen, Y.; Chen, S. Coal decarbonization: A state-of-the-art review of enhanced hydrogen production in underground coal gasification. Energy Rev. 2022, 1, 100004. [Google Scholar] [CrossRef]

- Dash, S.K.; Chakraborty, S.; Elangovan, D. A brief review of hydrogen production methods and their challenges. Energies 2023, 16, 1141. [Google Scholar] [CrossRef]

- Martínez de León, C.; Ríos, C.; Brey, J.J. Cost of green hydrogen: Limitations of production from a stand-alone photovoltaic system. Int. J. Hydrogen Energy 2023, 48, 11885–11898. [Google Scholar] [CrossRef]

- IEA. Global Hydrogen Review 2023; OECD Publishing: Paris, France, 2023. [Google Scholar] [CrossRef]

- Du, Z.; Liu, C.; Zhai, J.; Guo, X.; Xiong, Y.; Su, W.; He, G. A review of hydrogen purification technologies for fuel cell vehicles. Catalysts 2021, 11, 393. [Google Scholar] [CrossRef]

- Markowski, J.; Wojtasik, M. Piroliza metanu na tle wybranych metod otrzymywania wodoru. Nafta-Gaz 2023, 79, 428–435. [Google Scholar] [CrossRef]

- Kim, T.; Song, Y.; Kang, J.; Kim, S.K.; Kim, S. A review of recent advances in hydrogen purification for selective removal of oxygen: Deoxo catalysts and reactor systems. Int. J. Hydrogen Energy 2022, 47, 24817–24834. [Google Scholar] [CrossRef]

- Risco-Bravo, A.; Varela, C.; Bartels, J.; Zondervan, E. From green hydrogen to electricity: A review on recent advances, challenges, and opportunities on power-to-hydrogen-to-power systems. Renew. Sustain. Energy Rev. 2024, 189, 113930. [Google Scholar] [CrossRef]

- Li, H.; Liao, Z.; Sun, J.; Jiang, B.; Wang, J.; Yang, Y. Modelling and simulation of two-bed PSA process for separating H2 from methane steam reforming. Chin. J. Chem. Eng. 2019, 27, 1870–1878. [Google Scholar] [CrossRef]

- Yáñez, M.; Relvas, F.; Ortiz, A.; Gorri, D.; Mendes, A.; Ortiz, I. PSA purification of waste hydrogen from ammonia plants to fuel cell grade. Sep. Purif. Technol. 2020, 240, 116334. [Google Scholar] [CrossRef]

- Vermaak, L.; Neomagus, H.W.J.P.; Bessarabov, D.G. Recent advances in membrane-based electrochemical hydrogen separation: A review. Membranes 2021, 11, 127. [Google Scholar] [CrossRef]

- Panda, P.K.; Sahoo, B.; Ramakrishna, S. Hydrogen production, purification, storage, transportation, and their applications: A review. Energy Technol. 2023, 11, 2201434. [Google Scholar] [CrossRef]

- Sidhikku Kandath Valappil, R.; Ghasem, N.; Al-Marzouqi, M. Current and future trends in polymer membrane-based gas separation technology: A comprehensive review. J. Ind. Eng. Chem. 2021, 98, 103–129. [Google Scholar] [CrossRef]

- Alentiev, A.Y.; Ryzhikh, V.E.; Syrtsova, D.A.; Belov, N.A. Polymer materials for solving actual problems of membrane gas. Russ. Chem. Rev. 2023, 92, RCR5083. [Google Scholar] [CrossRef]

- Gao, J.; Song, Y.; Jia, C.; Sun, L.; Wang, Y.; Wang, Y.; Kipper, M.J.; Huang, L.; Tang, J. A comprehensive review of recent developments and challenges for gas separation membranes based on two-dimensional materials. FlatChem 2024, 43, 100594. [Google Scholar] [CrossRef]

- Li, P.; Wang, Z.; Qiao, Z.; Liu, Y.; Cao, X.; Li, W.; Wang, J.; Wang, S. Recent developments in membranes for efficient hydrogen purification. J. Membr. Sci. 2015, 495, 130–168. [Google Scholar] [CrossRef]

- Sazali, N.; Mohamed, M.A.; Salleh, W.N.W. Membranes for hydrogen separation: A significant review. Int. J. Adv. Manuf. Technol. 2020, 107, 1859–1881. [Google Scholar] [CrossRef]

- Lu, H.T.; Li, W.; Miandoab, E.S.; Kanehashi, S.; Hu, G. The opportunity of membrane technology for hydrogen purification in the power to hydrogen (P2H) roadmap: A review. Front. Chem. Sci. Eng. 2021, 15, 464–482. [Google Scholar] [CrossRef]

- Al- Janabi, S.K.; Barron, A.R.; Shabbani, H.J.K.; Othman, M.R.; Kim, J. Advances in hydrogen production from sustainable resources through biological and thermochemical pathways: Review and bibliometric analysis. Int. J. Hydrogen Energy 2024, 60, 28–45. [Google Scholar] [CrossRef]

- Bernardo, P.; Drioli, E.; Golemme, G. Membrane gas separation: A review/state of the art. Ind. Eng. Chem. Res. 2009, 48, 4638–4663. [Google Scholar] [CrossRef]

- Robeson, L.M.; Smith, Z.P.; Freeman, B.D.; Paul, D.R. Contributions of diffusion and solubility selectivity to the upper bound analysis for glassy gas separation membranes. J. Membr. Sci. 2014, 453, 71–83. [Google Scholar] [CrossRef]

- Yaroslavtsev, A.B.; Yampolskii, Y.P. Hybrid membranes containing inorganic nanoparticles. Mendeleev Commun. 2014, 24, 319–326. [Google Scholar] [CrossRef]

- Moral, G.; Ortiz, A.; Gorri, D.; Ortiz, I. Hydrogen recovery from industrial waste streams using Matrimid®/ZIF mixed matrix membranes. Int. J. Hydrogen Energy 2024, 51, 210–224. [Google Scholar] [CrossRef]

- Mao, D.; Griffin, J.M.; Dawson, R.; Fairhurst, A.; Bimbo, N. Metal organic frameworks for hydrogen purification. Int. J. Hydrogen Energy 2021, 46, 23380–23405. [Google Scholar] [CrossRef]

- Chen, S.; Wahiduzzaman, M.; Ji, T.; Liu, Y.; Li, Y.; Wang, C.; Sun, Y.; He, G.; Maurin, G.; Wang, S.; et al. Oriented titanium-MOF membrane for hydrogen purification. Angew. Chem. Int. Ed. 2025, 64, e202413701. [Google Scholar] [CrossRef]

- Fan, H.; Peng, M.; Strauss, I.; Mundstock, A.; Meng, H.; Caro, J. MOF-in-COF molecular sieving membrane for selective hydrogen separation. Nat. Commun. 2021, 12, 38. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, J.; Zhang, N.; Li, Z.; Bao, J.; Zhang, X.; He, G.; Chen, C.; Song, Y. Tunable nano-wrinked channels of reduced graphene oxide membranes for molecular sieving gas separation. Carbon 2024, 216, 118524. [Google Scholar] [CrossRef]

- Guo, Q.; Ghalei, B.; Qin, D.; Mizutani, D.; Joko, I.; Al-Aziz, H.; Higashino, T.; Ito, M.M.; Imahori, H.; Sivaniah, E. Graphene oxide-fullerene nanocomposite laminates for efficient hydrogen purification. Chem. Commun. 2023, 59, 10012–10015. [Google Scholar] [CrossRef] [PubMed]

- Lim, D.-W.; Ha, J.; Oruganti, Y.; Moon, H.R. Hydrogen separation and purification with MOF-based materials. Mater. Chem. Front. 2021, 5, 4022–4041. [Google Scholar] [CrossRef]

- Al-Mufachi, N.A.; Rees, N.V.; Steinberger-Wilkens, R. Hydrogen selective membranes: A review of palladium-based dense metal membranes. Renew. Sustain. Energy Rev. 2015, 47, 540–551. [Google Scholar] [CrossRef]

- Król, A.; Gajec, M.; Holewa-Rataj, J.; Kukulska-Zając, E.; Rataj, M. Hydrogen purification technologies in the context of its utilization. Energies 2024, 17, 3794. [Google Scholar] [CrossRef]

- Fernandez, E.; Helmi, A.; Medrano, J.A.; Coenen, K.; Arratibel, A.; Melendez, J.; de Nooijer, N.C.A.; Spallina, V.; Viviente, J.L.; Zuñiga, J.; et al. Palladium based membranes and membrane reactors for hydrogen production and purification: An overview of research activities at Tecnalia and TU/e. Int. J. Hydrogen Energy 2017, 42, 13763–13776. [Google Scholar] [CrossRef]

- Iulianelli, A.; Jansen, J.C.; Esposito, E.; Longo, M.; Dalena, F.; Basile, A. Hydrogen permeation and separation characteristics of a thin Pd-Au/Al2O3 membrane: The effect of the intermediate layer absence. Catal. Today 2019, 330, 32–38. [Google Scholar] [CrossRef]

- Suzuki, A.; Yukawa, H. A review for consistent analysis of hydrogen permeability through dense metallic membranes. Membranes 2020, 10, 120. [Google Scholar] [CrossRef]

- Chen, W.-H.; Escalante, J.; Chi, Y.-H.; Lin, Y.-L. Hydrogen permeation enhancement in a Pd membrane tube system under various vacuum degrees. Int. J. Hydrogen Energy 2020, 45, 7401–7411. [Google Scholar] [CrossRef]

- Bosko, M.L.; Dalla Fontana, A.; Tarditi, A.; Cornaglia, L. Advances in hydrogen selective membranes based on palladium ternary alloys. Int. J. Hydrogen Energy 2021, 46, 15572–15594. [Google Scholar] [CrossRef]

- Girotto, C.P.; Nippes, R.P.; Macruz, P.D.; Gomes, A.D.; de Souza, M.; Rodriguez, M.T. Effect of physicochemical properties on the performance of palladium-based composite membranes: A review. J. Mater. Res. 2023, 38, 4868–4891. [Google Scholar] [CrossRef]

- Cardoso, S.P.; Azenha, I.S.; Lin, Z.; Portugal, I.; Rodrigues, A.E.; Silva, C.M. Inorganic membranes for hydrogen separation. Sep. Purif. Rev. 2018, 47, 229–266. [Google Scholar] [CrossRef]

- Hadjixenophontos, E.; Mahmoudizadeh, M.; Rubin, M.; Ullmer, D.; Razmjooei, F.; Hanf, A.C.; Brien, J.; Dittmeyer, R.; Ansar, A. Palladium membrane with high density of large-angle grain boundaries to promote hydrogen diffusivity. Membranes 2022, 12, 617. [Google Scholar] [CrossRef] [PubMed]

- Gabitto, J.; Tsouris, C. Modeling sulfur poisoning of palladium membranes used for hydrogen separation. Int. J. Chem. Eng. 2019, 2019, 9825280. [Google Scholar] [CrossRef]

- Easa, J.; Yan, C.; Schneider, W.F.; O’Brien, C.P. CO and C3H6 poisoning of hydrogen permeation across Pd77Ag23 alloy membranes: A comparative study with pure palladium. Chem. Eng. J. 2022, 430, 133080. [Google Scholar] [CrossRef]

- Chen, W.-H.; Chen, Z.-Y.; Lim, S.; Park, Y.-K.; Show, P.-L. Hydrogen permeation in a palladium membrane tube: Impacts of outlet and vacuum degree. Int. J. Hydrogen Energy 2022, 47, 40787–40802. [Google Scholar] [CrossRef]

- Peters, T.; Caravella, A. Pd-based membranes: Overview and perspectives. Membranes 2019, 9, 25. [Google Scholar] [CrossRef]

- Chen, C.-H.; Ma, Y.H. The effect of H2S on the performance of Pd and Pd/Au composite membrane. J. Membr. Sci. 2010, 362, 535–544. [Google Scholar] [CrossRef]

- Bosko, M.L.; Lombardo, E.A.; Cornaglia, L.M. The effect of electroless plating time on the morphology, alloy formation and H2 transport properties of Pd–Ag composite membranes. Int. J. Hydrogen Energy 2011, 36, 4068–4078. [Google Scholar] [CrossRef]

- Peters, T.A.; Carvalho, P.A.; Stange, M.; Bredesen, R. Formation of hydrogen bubbles in Pd-Ag membranes during H2 permeation. Int. J. Hydrogen Energy 2020, 45, 7488–7496. [Google Scholar] [CrossRef]

- Nemitallah, M.A. Characteristics of hydrogen separation and methane steam reforming in a Pd-based membrane reactor of shell and tube design. Case Stud. Therm. Eng. 2023, 45, 102939. [Google Scholar] [CrossRef]

- Shi, L.; Goldbach, A.; Xu, H. High-flux H2 separation membranes from (Pd/Au)n nanolayers. Int. J. Hydrogen Energy 2011, 36, 2281–2284. [Google Scholar] [CrossRef]

- Jia, H.; Wu, P.; Zeng, G.; Salas-Colera, E.; Serrano, A.; Castro, G.R.; Xu, H.; Sun, C.; Goldbach, A. High-temperature stability of Pd alloy membranes containing Cu and Au. J. Membr. Sci. 2017, 544, 151–160. [Google Scholar] [CrossRef]

- Anzelmo, B.; Wilcox, J.; Liguori, S. Hydrogen production via natural gas steam reforming in a Pd-Au membrane reactor. Comparison between methane and natural gas steam reforming reactions. J. Membr. Sci. 2018, 568, 113–120. [Google Scholar] [CrossRef]

- Dalla Fontana, A.; Sirini, N.; Cornaglia, L.M.; Tarditi, A.M. Hydrogen permeation and surface properties of PdAu and PdAgAu membranes in the presence of CO, CO2 and H2S. J. Membr. Sci. 2018, 563, 351–359. [Google Scholar] [CrossRef]

- Iulianelli, A.; Manisco, M.; Bion, N.; Le Valant, A.; Epron, F.; Colpan, C.O.; Esposito, E.; Jansen, J.C.; Gensini, M.; Caravella, A. Sustainable H2 generation via steam reforming of biogas in membrane reactors: H2S effects on membrane performance and catalytic activity. Int. J. Hydrogen Energy 2021, 46, 29183–29197. [Google Scholar] [CrossRef]

- Pomerantz, N.; Ma, Y.H. Effect of H2S on the performance and long-term stability of Pd/Cu membranes. Ind. Eng. Chem. Res. 2009, 48, 4030–4039. [Google Scholar] [CrossRef]

- Burkhanov, B.G.S.; Gorina, N.B.; Kolchugina, N.B.; Roshan, N.R.; Slovetsky, D.I.; Chistov, E.M. Palladium-based alloy membranes for separation of high purity hydrogen from hydrogen-containing gas mixtures. Platin. Met. Rev. 2011, 55, 3–12. [Google Scholar] [CrossRef]

- Peters, T.A.; Kaleta, T.; Stange, M.; Bredesen, R. Hydrogen transport through a selection of thin Pd-alloy membranes: Membrane stability, H2S inhibition, and flux recovery in hydrogen and simulated WGS mixtures. Catal. Today 2012, 193, 8–19. [Google Scholar] [CrossRef]

- Acha, E.; van Delft, Y.C.; Cambra, J.F.; Arias, P.L. Thin PdCu membrane for hydrogen purification from in-situ produced methane reforming complex mixtures containing H2S. Chem. Eng. Sci. 2018, 176, 429–438. [Google Scholar] [CrossRef]

- Pati, S.; Ashok, J.; Dewangan, N.; Chen, T.; Kawi, S. Ultra-thin (~1 μm) Pd–Cu membrane reactor for coupling CO2 hydrogenation and propane dehydrogenation applications. J. Membr. Sci. 2020, 595, 117496. [Google Scholar] [CrossRef]

- Cerone, N.; Zito, G.D.; Florio, C.; Fabbiano, L.; Zimbardi, F. Recent advancements in Pd-based membranes for hydrogen separation. Energies 2024, 17, 4095. [Google Scholar] [CrossRef]

- Gade, S.K.; Keeling, M.K.; Davidson, A.P.; Hatlevik, O.; Way, J.D. Palladium–ruthenium membranes for hydrogen separation fabricated by electroless co-deposition. Int. J. Hydrogen Energy 2009, 34, 6484–6491. [Google Scholar] [CrossRef]

- Abu El Hawa, H.W.; Paglieri, S.N.; Morris, C.C.; Harale, A.; Douglas Way, J. Application of a Pd–Ru composite membrane to hydrogen production in a high temperature membrane reactor. Sep. Purif. Technol. 2015, 147, 388–397. [Google Scholar] [CrossRef]

- Lee, S.M.; Xu, N.; Kim, S.S.; Li, A.; Grace, J.R.; Lim, C.J.; Boyd, T.; Ryi, S.-K.; Susdorf, A.; Schaadt, A. Palladium/ruthenium composite membrane for hydrogen separation from the off-gas of solar cell production via chemical vapor deposition. J. Membr. Sci. 2017, 541, 1–8. [Google Scholar] [CrossRef]

- Liu, J.; Bellini, S.; de Nooijer, N.C.A.; Sun, Y.; Pacheco Tanaka, D.A.; Tang, C.; Li, H.; Gallucci, F.; Caravella, A. Hydrogen permeation and stability in ultra-thin Pd Ru supported membranes. Int. J. Hydrogen Energy 2020, 45, 7455–7467. [Google Scholar] [CrossRef]

- Yin, Z.; Yang, Z.; Tong, Y.; Du, M.; Mi, J.; Yu, Q.; Li, S. Improved sulfur tolerance of Pd–Ru membranes: Influence of H2S concentration and exposure time on the hydrogen flux. Int. J. Hydrogen Energy 2023, 48, 38335–38343. [Google Scholar] [CrossRef]

- Sheu, W.-J.; Hsu, Z.-W.; Chen, W.-H.; Chen, Y.-C. Investigation of steam methane reforming in a Pd–Ru membrane reactor with a counter-current configuration. Int. J. Hydrogen Energy 2024, 52, 938–952. [Google Scholar] [CrossRef]

- Peng, L.; Rao, Y.; Luo, L.; Chen, C. The poisoning of Pd–Y alloy membranes by carbon monoxide. J. Alloys Compd. 2009, 486, 74–77. [Google Scholar] [CrossRef]

- Conde, J.J.; Maroño, M.; Sánchez-Hervás, J.M. Pd-based membranes for hydrogen separation: Review of alloying elements and their influence on membrane properties. Sep. Purif. Rev. 2017, 46, 152–177. [Google Scholar] [CrossRef]

- Tropin, E.S.; Shubnikova, E.V.; Bragina, O.A.; Nemudry, A.P. Production of ultra-pure hydrogen for fuel cells using a module based on nickel capillaries. Russ. J. Electrochem. 2024, 60, 30–35. [Google Scholar] [CrossRef]

- Omidifar, M.; Babaluo, A.A. Fabrication of thin (~2 μm) pure Ni and Pd–Ni alloy composite membranes by the organic-inorganic activation method for hydrogen separation. Int. J. Hydrogen Energy 2024, 53, 1025–1036. [Google Scholar] [CrossRef]

- Omidifar, M.; Akbar Babaluo, A.; Jamshidi, S. H2 permeance and surface characterization of a thin (2 μm) Pd-Ni composite membrane prepared by electroless plating. Chem. Eng. Sci. 2024, 283, 119370. [Google Scholar] [CrossRef]

- Amer, J.; Benguerba, Y.; Elboughdiri, N.; Albrahim, M.; Burgard, M.; Ernst, B. Enhancing hydrogen separation efficiency: Insights from the permeability study of nickel-based composite membranes. Int. J. Hydrogen Energy 2024, 66, 703–718. [Google Scholar] [CrossRef]

- Escalante, Y.; Tarditi, A.M. Thermally stable membranes based on PdNiAu systems with high nickel content for hydrogen separation. J. Membr. Sci. 2023, 676, 121581. [Google Scholar] [CrossRef]

- de Nooijer, N.; Sanchez, J.D.; Melendez, J.; Fernandez, E.; Pacheco Tanaka, D.A.; van Sint Annaland, M.; Gallucci, F. Influence of H2S on the hydrogen flux of thin-film PdAgAu membranes. Int. J. Hydrogen Energy 2020, 45, 7303–7312. [Google Scholar] [CrossRef]

- Chen, Z.; Yang, Z.; Tong, Y.; Yin, Z.; Li, S. High hydrogen permeability of Pd-Ru-In membranes prepared by electroless co-deposition. Sep. Purif. Technol. 2024, 343, 127073. [Google Scholar] [CrossRef]

- Jazani, O.; Bennett, J.; Liguori, S. Effect of temperature, air exposure and gas mixture on Pd82–Ag15–Y3 membrane for hydrogen separation. Int. J. Hydrogen Energy 2024, 51, 624–636. [Google Scholar] [CrossRef]

- Ievlev, V.M.; Dontsov, A.I.; Gorbunov, S.V.; Il’inova, T.N.; Kannykin, S.V.; Prizhimov, A.S.; Roshan, N.R.; Solntsev, K.A. Structure, texture, and substructure of foil in sequential rolling steps of Cu–36.4 at % Pd alloy. Inorg. Mater. 2021, 57, 1194–1200. [Google Scholar] [CrossRef]

- Yun, S.; Ted Oyama, S. Correlations in palladium membranes for hydrogen separation: A review. J. Membr. Sci. 2011, 375, 28–45. [Google Scholar] [CrossRef]

- Wang, M.; Ding, Y.; Hu, J.; Xu, L.; Yang, X. Numerical simulation of water and heat transport in the cathode channel of a PEM fuel cell. Int. J. Hydrogen Energy 2022, 47, 11007–11027. [Google Scholar] [CrossRef]

- Zhang, K.; Gade, S.K.; Way, J.D. Effects of heat treatment in air on hydrogen sorption over Pd–Ag and Pd–Au membrane surfaces. J. Membr. Sci. 2012, 403–404, 78–83. [Google Scholar] [CrossRef]

- Zhang, K.; Gade, S.K.; Hatlevik, Ø.; Way, J.D. A sorption rate hypothesis for the increase in H2 permeability of palladium-silver (Pd–Ag) membranes caused by air oxidation. Int. J. Hydrogen Energy 2012, 37, 583–593. [Google Scholar] [CrossRef]

- Mironova, E.Y.; Lytkina, A.A.; Ermilova, M.M.; Orekhova, N.V.; Zhilyaeva, N.A.; Roshan, N.R.; Ievlev, V.M.; Yaroslavtsev, A.B. Methanol steam reforming in a reactor with a palladium–copper membrane in the presence of a nickel-copper catalyst. Pet. Chem. 2020, 60, 1232–1238. [Google Scholar] [CrossRef]

- Ievlev, V.M.; Dontsov, A.I.; Morozova, N.B.; Roshan, N.R.; Serbin, O.V.; Prizhimov, A.S.; Solntsev, K.A. Techniques for surface cleaning of membrane foil from palladium-based solid solutions. Inorg. Mater. 2020, 56, 1059–1064. [Google Scholar] [CrossRef]

- Mironova, E.Y.; Dontsov, A.I.; Morozova, N.B.; Gorbunov, S.V.; Ievlev, V.M.; Yaroslavtsev, A.B. Lamp processing of the surface of PdCu membrane foil: Hydrogen permeability and membrane catalysis. Inorg. Mater. 2021, 57, 781–789. [Google Scholar] [CrossRef]

- Ievlev, V.M.; Solntsev, K.A.; Gorbunov, S.V.; Roshan, N.R.; Kas’yanov, V.S.; Morozova, N.B.; Dontsov, A.I. Effect of ultrasonic treatment of Pd–4 at % In–1 at % Ru membrane foil: Sorption and hydrogen permeability. Inorg. Mater. 2023, 59, 1275–1282. [Google Scholar] [CrossRef]

- Loza, S.A.; Zabolotsky, V.I.; Loza, N.V.; Fomenko, M.A. Structure, morphology, and transport characteristics of profiled bilayer membranes. Pet. Chem. 2016, 56, 1027–1033. [Google Scholar] [CrossRef]

- Pushankina, P.; Baryshev, M.; Petriev, I. Synthesis and study of palladium mono- and bimetallic (with Ag and Pt) nanoparticles in catalytic and membrane hydrogen processes. Nanomaterials 2022, 12, 4178. [Google Scholar] [CrossRef]

- Luong, H.M.; Pham, M.T.; Guin, T.; Madhogaria, R.P.; Phan, M.-H.; Larsen, G.K.; Nguyen, T.D. Sub-second and ppm-level optical sensing of hydrogen using templated control of nano-hydride geometry and composition. Nat. Commun. 2021, 12, 2414. [Google Scholar] [CrossRef]

- Petriev, I.S.; Pushankina, P.D.; Andreev, G.A. Investigation of low-temperature hydrogen permeability of surface modified Pd–Cu membranes. Membr. Membr. Technol. 2023, 5, 360–369. [Google Scholar] [CrossRef]

- Hanifah, M.F.R.; Jaafar, J.; Othman, M.H.D.; Ismail, A.F.; Rahman, M.A.; Yusof, N.; Aziz, F.; Rahman, N.A. One-pot synthesis of efficient reduced graphene oxide supported binary Pt-Pd alloy nanoparticles as superior electro-catalyst and its electro-catalytic performance toward methanol electro-oxidation reaction in direct methanol fuel cell. J. Alloys Compd. 2019, 793, 232–246. [Google Scholar] [CrossRef]

- Chowdhury, S.R.; Kanti Bera, K.; Ray, A.; Bera, P.; Maiyalagan, T.; Bhattacharya, S.K. Synergistic catalytic activity of palladium–silver alloy nanoparticle for anodic oxidation of ethanol in alkali. Int. J. Hydrogen Energy 2021, 46, 14212–14224. [Google Scholar] [CrossRef]

- Karaman, C. Engineering of N,P,S-Triple doped 3-dimensional graphene architecture: Catalyst-support for “surface-clean” Pd nanoparticles to boost the electrocatalysis of ethanol oxidation reaction. Int. J. Hydrogen Energy 2023, 48, 6691–6701. [Google Scholar] [CrossRef]

- Jung, H.; King, M.E.; Personick, M.L. Strategic synergy: Advances in the shape control of bimetallic nanoparticles with dilute alloyed surfaces. Curr. Opin. Colloid Interface Sci. 2019, 40, 104–117. [Google Scholar] [CrossRef]

- Chen, Y.; Dai, Q.; Zhang, Q.; Huang, Y. Precisely deposited Pd on ZnO (002) facets derived from complex reduction strategy for methanol steam reforming. Int. J. Hydrogen Energy 2022, 47, 14869–14883. [Google Scholar] [CrossRef]

- Wu, H.-L.; Chen, C.-H.; Huang, M.H. Seed-mediated synthesis of branched gold nanocrystals derived from the side growth of pentagonal bipyramids and the formation of gold nanostars. Chem. Mater. 2009, 21, 110–114. [Google Scholar] [CrossRef]

- Zhang, L.; Zhong, S.; Xu, A. Highly branched concave Au/Pd bimetallic nanocrystals with superior electrocatalytic activity and highly efficient SERS enhancement. Angew. Chem. Int. Ed. 2013, 52, 645–649. [Google Scholar] [CrossRef]

- Shao, Z.; Zhu, W.; Wang, H.; Yang, Q.; Yang, S.; Liu, X.; Wang, G. Controllable synthesis of concave nanocubes, right bipyramids, and 5-fold twinned nanorods of palladium and their enhanced electrocatalytic performance. J. Phys. Chem. C 2013, 117, 14289–14294. [Google Scholar] [CrossRef]

- Petriev, I.; Pushankina, P.; Bolotin, S.; Lutsenko, I.; Kukueva, E.; Baryshev, M. The influence of modifying nanoflower and nanostar type Pd coatings on low temperature hydrogen permeability through Pd-containing membranes. J. Membr. Sci. 2021, 620, 118894. [Google Scholar] [CrossRef]

- Xia, Y.; Xiong, Y.; Lim, B.; Skrabalak, S.E. Shape-controlled synthesis of metal nanocrystals: Simple chemistry meets complex physics? Angew. Chem. Int. Ed. 2009, 48, 60–103. [Google Scholar] [CrossRef] [PubMed]

- Petriev, I.S.; Pushankina, P.D.; Andreev, G.A.; Yaroslavtsev, A.B. Mechanisms of formation and shape control of pentagonal Pd-nanostars and their unique properties in electrocatalytic methanol oxidation and membrane separation of high-purity hydrogen. Int. J. Hydrogen Energy 2024, 70, 404–413. [Google Scholar] [CrossRef]

- Vicinanza, N.; Svenum, I.-H.; Peters, T.; Bredesen, R.; Venvik, H. New insight to the effects of heat treatment in air on the permeation properties of thin Pd77%Ag23% membranes. Membranes 2018, 8, 92. [Google Scholar] [CrossRef] [PubMed]

- Jayaraman, V.; Lin, Y.S.; Pakala, M.; Lin, R.Y. Fabrication of ultrathin metallic membranes on ceramic supports by sputter deposition. J. Membr. Sci. 1995, 99, 89–100. [Google Scholar] [CrossRef]

- Qiao, A.; Zhang, K.; Tian, Y.; Xie, L.; Luo, H.; Lin, Y.S.; Li, Y. Hydrogen separation through palladium–copper membranes on porous stainless steel with sol–gel derived ceria as diffusion barrier. Fuel 2010, 89, 1274–1279. [Google Scholar] [CrossRef]

- Toro, L.; Moscardini, E.; Baldassari, L.M.; Forte, F.; Coletta, J.; Palo, E.; Cosentino, V.; Angelini, F.; Arratibel Plazaola, A.; Pagnanelli, F.; et al. Regeneration of exhausted palladium-based membranes: Recycling process and economics. Membranes 2022, 12, 723. [Google Scholar] [CrossRef]

- Arratibel Plazaola, A.; Pacheco Tanaka, D.A.; Van Sint Annaland, M.; Gallucci, F. Recent advances in Pd-based membranes for membrane reactors. Molecules 2017, 22, 51. [Google Scholar] [CrossRef]

- Melendez, J.; Fernandez, E.; Gallucci, F.; van Sint Annaland, M.; Arias, P.L.; Pacheco Tanaka, D.A. Preparation and characterization of ceramic supported ultra-thin (~1 µm) Pd-Ag membranes. J. Membr. Sci. 2017, 528, 12–23. [Google Scholar] [CrossRef]

- Zhao, C.; Xu, H.; Goldbach, A. Duplex Pd/ceramic/Pd composite membrane for sweep gas-enhanced CO2 capture. J. Membr. Sci. 2018, 563, 388–397. [Google Scholar] [CrossRef]

- Orakwe, I.; Shehu, H.; Gobina, E. Preparation and characterization of palladium ceramic alumina membrane for hydrogen permeation. Int. J. Hydrogen Energy 2019, 44, 9914–9921. [Google Scholar] [CrossRef]

- Alkali, A. Electroless plating of palladium membranes on porous substrates for hydrogen separation and the effects of process factors on plating rate and efficiency: A review. J. Power Energy Eng. 2020, 8, 1–19. [Google Scholar] [CrossRef]

- Magnone, E.; Lee, S.H.; Park, J.H. Relationships between electroless plating temperature, Pd film thickness and hydrogen separation performance of Pd-coated Al2O3 hollow fibers. Mater. Lett. 2020, 272, 127811. [Google Scholar] [CrossRef]

- Yue, L.; Chen, C.; Li, J.; Xiao, C.; Xia, X.; Ran, G.; Fu, X.; Hou, J.; Gong, Y.; Wang, H. Inhibition effect of CO on hydrogen permeation through a Pd/Al2O3 composite membrane: A comprehensive study on concentration polarization and competitive adsorption effect. Fusion Sci. Technol. 2020, 76, 680–689. [Google Scholar] [CrossRef]

- Lundin, S.-T.B.; Patki, N.S.; Zhang, Z.; Fuerst, T.F.; Wolden, C.A.; Way, J.D. PdAu/YSZ composite hydrogen separation membranes with enhanced stability in the presence of CO. J. Membr. Sci. 2020, 611, 118371. [Google Scholar] [CrossRef]

- Chen, W.-H.; Escalante, J. Influence of vacuum degree on hydrogen permeation through a Pd membrane in different H2/N2 gas mixtures. Renew. Energy 2020, 155, 1245–1263. [Google Scholar] [CrossRef]

- Tosto, E.; Martinez-Diaz, D.; Sanz, R.; Azzato, G.; Calles, J.A.; Medrano, J.A.; Fernandez, E.; Pacheco Tanaka, D.A.; Gallucci, F.; Alique, D.; et al. Systematic experimental assessment of concentration polarization and inhibition in Pd-based membranes for hydrogen purification. Fuel Process. Technol. 2021, 213, 106661. [Google Scholar] [CrossRef]

- Kong, S.Y.; Kim, D.H.; Henkensmeier, D.; Kim, H.J.; Ham, H.C.; Han, J.; Yoon, S.P.; Yoon, C.W.; Choi, S.H. Ultrathin layered Pd/PBI–HFA composite membranes for hydrogen separation. Sep. Purif. Technol. 2017, 179, 486–493. [Google Scholar] [CrossRef]

- Delima, R.S.; Sherbo, R.S.; Dvorak, D.J.; Kurimoto, A.; Berlinguette, C.P. Supported palladium membrane reactor architecture for electrocatalytic hydrogenation. J. Mater. Chem. A 2019, 7, 26586–26595. [Google Scholar] [CrossRef]

- Alique, D.; Martinez-Diaz, D.; Sanz, R.; Calles, J. Review of supported Pd-based membranes preparation by electroless plating for ultra-pure hydrogen production. Membranes 2018, 8, 5. [Google Scholar] [CrossRef]

- Salomé Macedo, M.; Acha Uriarte, N.; Soria, M.A.; Madeira, L.M.; Calles, J.A.; Sanz, R.; Alique, D. Effect of ceria particle size as intermediate layer for preparation of composite Pd-membranes by electroless pore-plating onto porous stainless-steel supports. Sep. Purif. Technol. 2023, 327, 124932. [Google Scholar] [CrossRef]

- Martinez-Diaz, D.; Alique, D.; Calles, J.A.; Sanz, R. Pd-thickness reduction in electroless pore-plated membranes by using doped-ceria as interlayer. Int. J. Hydrogen Energy 2020, 45, 7278–7289. [Google Scholar] [CrossRef]

- Martinez-Diaz, D.; Martínez del Monte, D.; García-Rojas, E.; Alique, D.; Calles, J.A.; Sanz, R. Comprehensive permeation analysis and mechanical resistance of electroless pore-plated Pd-membranes with ordered mesoporous ceria as intermediate layer. Sep. Purif. Technol. 2021, 258, 118066. [Google Scholar] [CrossRef]

- Martinez-Diaz, D.; Sanz, R.; Carrero, A.; Calles, J.A.; Alique, D. Effective H2 separation through electroless pore-plated Pd membranes containing graphite lead barriers. Membranes 2020, 10, 410. [Google Scholar] [CrossRef] [PubMed]

- de Moura Silva, C.L.; Ribeiro, S.R.F.L.; Terra, N.M.; Cardoso, V.L.; Reis, M.H.M. Improved hydrogen permeation through thin Pd/Al2O3 composite membranes with graphene oxide as intermediate layer. Int. J. Hydrogen Energy 2020, 45, 22990–23005. [Google Scholar] [CrossRef]

- Dehghani Kiadehi, A.; Taghizadeh, M.; Rami, M.D. Preparation of Pd/SAPO-34/PSS composite membranes for hydrogen separation: Effect of crystallization time on the zeolite growth on PSS support. J. Ind. Eng. Chem. 2020, 81, 206–218. [Google Scholar] [CrossRef]

- Huang, Y.; Liu, Q.; Jin, X.; Ding, W.; Hu, X.; Li, H. Coating the porous Al2O3 substrate with a natural mineral of Nontronite-15A for fabrication of hydrogen-permeable palladium membranes. Int. J. Hydrogen Energy 2020, 45, 7412–7422. [Google Scholar] [CrossRef]

- Sanz-Villanueva, D.; Alique, D.; Vizcaíno, A.J.; Sanz, R.; Calles, J.A. Pre-activation of SBA-15 intermediate barriers with Pd nuclei to increase thermal and mechanical resistances of pore-plated Pd-membranes. Int. J. Hydrogen Energy 2021, 46, 20198–20212. [Google Scholar] [CrossRef]

- Zito, P.F.; Brunetti, A.; Barbieri, G. Hydrogen concentration and purification by membrane process: A multistage analysis. Renew. Energy 2023, 218, 119243. [Google Scholar] [CrossRef]

- Park, Y.; Kwak, Y.; Yu, S.; Badakhsh, A.; Lee, Y.-J.; Jeong, H.; Kim, Y.; Sohn, H.; Nam, S.W.; Yoon, C.W.; et al. Degradation mechanism of a Pd/Ta composite membrane: Catalytic surface fouling with inter-diffusion. J. Alloys Compd. 2021, 854, 157196. [Google Scholar] [CrossRef]

- Ryu, S.; Badakhsh, A.; Oh, J.G.; Ham, H.C.; Sohn, H.; Yoon, S.P.; Choi, S.H. Experimental and numerical study of Pd/Ta and PdCu/Ta composites for thermocatalytic hydrogen permeation. Membranes 2022, 13, 23. [Google Scholar] [CrossRef]

- Alimov, V.N.; Bobylev, I.V.; Busnyuk, A.O.; Notkin, M.E.; Peredistov, E.Y.; Livshits, A.I. Hydrogen transport through the tubular membranes of V-Pd alloys: Permeation, diffusion, surface processes and WGS mixture test of membrane assembly. J. Membr. Sci. 2018, 549, 428–437. [Google Scholar] [CrossRef]

- Alimov, V.N.; Bobylev, I.V.; Busnyuk, A.O.; Kolgatin, S.N.; Kuzenov, S.R.; Peredistov, E.Y.; Livshits, A.I. Extraction of ultrapure hydrogen with V-alloy membranes: From laboratory studies to practical applications. Int. J. Hydrogen Energy 2018, 43, 13318–13327. [Google Scholar] [CrossRef]

- Alimov, V.N.; Busnyuk, A.O.; Kuzenov, S.R.; Peredistov, E.U.; Livshits, A.I. Bcc V–Fe alloys for the hydrogen separation membranes: Hydrogen solubility and global character of alloying effect. J. Membr. Sci. 2022, 644, 120159. [Google Scholar] [CrossRef]

- Kuzenov, S.R.; Alimov, V.N.; Busnyuk, A.O.; Peredistov, E.U.; Livshits, A.I. Hydrogen transport through V–Fe alloy membranes: Permeation, diffusion, effects of deviation from Sieverts’ law. J. Membr. Sci. 2023, 674, 121504. [Google Scholar] [CrossRef]

- Guo, Y.; Guo, Y.; Zou, D.; Pan, Q.; Jiang, C.; Li, Y.; Chen, C. Effect of single atomic layer graphene film on the thermal stability and hydrogen permeation of Pd-coated Nb composite membrane. Int. J. Hydrogen Energy 2022, 47, 8359–8371. [Google Scholar] [CrossRef]

- Liang, X.; Li, X.; Chen, R.; Nagaumi, H.; Guo, J.; Liu, D. Enhancement of hydrogen permeation stability at high temperatures for Pd/Nb30Ti35Co35/Pd composite membranes by HfN intermediate layer. J. Membr. Sci. 2022, 643, 120062. [Google Scholar] [CrossRef]

- Mercea, P.; Mureşan, L.; Mecea, V.; Silipaş, D.; Ursu, I. Permeation of gases through poly (ethylene terephthalate) membranes metallized with palladium. J. Membr. Sci. 1988, 35, 291–300. [Google Scholar] [CrossRef]

- Mercea, P.V.; Silipas, D.; Mecea, V.; Ursu, I. The separation of a gas mixture through a metallized polymer membrane. Gas Sep. Purif. 1990, 4, 137–140. [Google Scholar] [CrossRef]

- Mercea, P.V.; Mecea, V. Gas separation through a high-flux asymmetric polymer membrane metallized with palladium. Gas Sep. Purif. 1991, 5, 267–272. [Google Scholar] [CrossRef]

- Gryaznov, V.M.; Serebryannikova, O.S.; Serov, Y.M.; Ermilova, M.M.; Karavanov, A.N.; Mischenko, A.P.; Orekhova, N.V. Preparation and catalysis over palladium composite membranes. J. Membr. Sci. 1993, 77, 284. [Google Scholar] [CrossRef]

- Gryaznov, V.M.; Yermilova, M.M.; Zavodchenko, S.I.; Orekhova, N.V. Hydrogen permeability of some metal-polymer membranes. Vysokomol. Soedininiya 1993, 35, 325–329. (In Russian) [Google Scholar]

- Patel, A.K.; Acharya, N.K. Metal coated and nanofiller doped polycarbonate membrane for hydrogen transport. Int. J. Hydrogen Energy 2018, 43, 21675–21682. [Google Scholar] [CrossRef]

- Kamakshi; Kumar, R.; Saraswat, V.K.; Kumar, M.; Awasthi, K. Palladium nanoparticle binding in functionalized track etched PET membrane for hydrogen gas separation. Int. J. Hydrogen Energy 2017, 42, 16186–16194. [Google Scholar] [CrossRef]

- Saini, N.; Agarwal, S.; Awasthi, K. Bimetallic PdPt alloy nanoparticle-decorated track-etched polyethylene terephthalate membranes for efficient H2 separation. Mater. Adv. 2024, 5, 2906–2916. [Google Scholar] [CrossRef]

- Kumar, R.; Kamakshi; Shisodia, S.; Kumar, M.; Awasthi, K. Effect of UV irradiation on PC membrane and use of Pd nanoparticles with/without PVP for H2 selectivity enhancement over CO2 and N2 gases. Int. J. Hydrogen Energy 2018, 43, 21690–21698. [Google Scholar] [CrossRef]

- Lin, Z.; Yuan, Z.; Dai, Z.; Shao, L.; Eisen, M.S.; He, X. A review from material functionalization to process feasibility on advanced mixed matrix membranes for gas separations. Chem. Eng. J. 2023, 475, 146075. [Google Scholar] [CrossRef]

- Sun, S.; Li, S.; Wang, S.; Chen, Y. Design and development of highly selective and permeable membranes for H2/CO2 separation—A review. Chem. Eng. J. 2024, 494, 152972. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, X.; Zhai, J.; Li, X.; Guo, X.; He, G. Research progress and prospects on hydrogen separation membranes. Clean Energy 2023, 7, 217–241. [Google Scholar] [CrossRef]

- Rezakazemi, M.; Sadrzadeh, M.; Matsuura, T. Thermally stable polymers for advanced high-performance gas separation membranes. Prog. Energy Combust. Sci. 2018, 66, 1–41. [Google Scholar] [CrossRef]

- Rusanov, A.L.; Komarova, L.G. 5.21—High-Performance Heterocyclic Polymers; Elsevier B.V.: Amsterdam, The Netherlands, 2012; pp. 537–596. ISBN 9780080878621. [Google Scholar] [CrossRef]

- Yampolskii, Y.; Belov, N.; Alentiev, A. Perfluorinated polymers as materials of membranes for gas and vapor separation. J. Membr. Sci. 2020, 598, 117779. [Google Scholar] [CrossRef]

- Karpov, G.O.; Bermeshev, M.V.; Borisov, I.L.; Sterlin, S.R.; Tyutyunov, A.A.; Yevlampieva, N.P.; Bulgakov, B.A.; Volkov, V.V.; Finkelshtein, E.S. Metathesis-type poly-exo-tricyclononenes with fluoroorganic side substituents: Synthesis and gas-transport properties. Polymer 2018, 153, 626–636. [Google Scholar] [CrossRef]

- Borisov, I.L.; Grushevenko, E.A.; Anokhina, T.S.; Bakhtin, D.S.; Levin, I.S.; Bondarenko, G.N.; Volkov, V.V.; Volkov, A.V. Influence of side chains assembly on the structure and transport properties of comb-like polysiloxanes in hydrocarbon separation. Mater. Today Chem. 2021, 22, 100598. [Google Scholar] [CrossRef]

- Ershova, T.; Anisimov, A.; Krylov, F.; Polshchikova, N.; Temnikov, M.; Shchegolikhina, O.; Muzafarov, A. A new highly efficient method for the preparation of phenyl-containing siloxanes by condensation of phenylsilanols in liquid ammonia. Chem. Eng. Sci. 2022, 247, 116916. [Google Scholar] [CrossRef]

- Anokhina, T.S.; Ershova, T.O.; Anisimov, A.A.; Temnikov, M.N.; Grushevenko, E.A.; Borisov, I.L.; Volkov, A.V.; Muzafarov, A.M. Pervaporation and Gas Separation Properties of High-Molecular Ladder-like Polyphenylsilsesquioxanes. Polymers 2023, 15, 3277. [Google Scholar] [CrossRef] [PubMed]

- Kryzhanovskii, I.N.; Temnikov, M.N.; Anisimov, A.A.; Ratnikov, A.K.; Frank, I.V.; Naumkin, A.V.; Chistovalova, S.M.; Muzafarov, A.M. From silicon to silicones without dimethyldichlorosilane: Direct green mechanochemical synthesis of methylmethoxysilanes from silicon and dimethyl ether. Green Chem. 2024, 26, 6656–6665. [Google Scholar] [CrossRef]

- Han, Y.; Ho, W.S.W. Polymeric membranes for CO2 separation and capture. J. Membr. Sci. 2021, 628, 119244. [Google Scholar] [CrossRef]

- Bera, D.; Chatterjee, R.; Banerjee, S. Aromatic polyamide nonporous membranes for gas separation application. e-Polymers 2021, 21, 108–130. [Google Scholar] [CrossRef]

- Suhail, F.; Batool, M.; Anjum, T.; Shah, A.T.; Tabassum, S.; Khan, A.L.; AlMohamadi, H.; Najam, M.; Gilani, M.A. Enhanced CO2 separation performance of polysulfone membranes via incorporation of pyrazole modified MCM-41 mesoporous silica as a nano-filler. Fuel 2023, 350, 128840. [Google Scholar] [CrossRef]

- Singh, S.; Varghese, A.M.; Reddy, K.S.K.; Romanos, G.E.; Karanikolos, G.N. Polysulfone mixed-matrix membranes comprising poly(ethylene glycol)-grafted carbon nanotubes: Mechanical properties and CO2 separation performance. Ind. Eng. Chem. Res. 2021, 60, 11289–11308. [Google Scholar] [CrossRef]

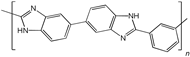

- Patdiya, J.; Gavane, G.B.; Kandasubramanian, B. A review on polybenzimidazoles blends and nanocomposites for engineering applications. Polym. Technol. Mater. 2022, 61, 1411–1438. [Google Scholar] [CrossRef]

- Aili, D.; Yang, J.; Jankova, K.; Henkensmeier, D.; Li, Q. From polybenzimidazoles to polybenzimidazoliums and polybenzimidazolides. J. Mater. Chem. A 2020, 8, 12854–12886. [Google Scholar] [CrossRef]

- Bitter, J.H.; Tashvigh, A.A.; Asadi Tashvigh, A. Recent advances in polybenzimidazole membranes for hydrogen purification. Ind. Eng. Chem. Res. 2022, 61, 6125–6134. [Google Scholar] [CrossRef]

- Xu, Z.; Croft, Z.L.; Guo, D.; Cao, K.; Liu, G. Recent development of polyimides: Synthesis, processing, and application in gas separation. J. Polym. Sci. 2021, 59, 943–962. [Google Scholar] [CrossRef]

- Wang, X.; Wilson, T.J.; Alentiev, D.; Gringolts, M.; Finkelshtein, E.; Bermeshev, M.; Long, B.K. Substituted polynorbornene membranes: A modular template for targeted gas separations. Polym. Chem. 2021, 12, 2947–2977. [Google Scholar] [CrossRef]

- Wozniak, A.I.; Bermesheva, E.V.; Petukhov, D.I.; Lunin, A.O.; Borisov, I.L.; Shantarovich, V.P.; Bekeshev, V.G.; Alentiev, D.A.; Bermeshev, M.V. The magic of spiro-epoxy moiety: An easy way to improve CO2-separation performance of polymer membrane. Adv. Funct. Mater. 2024, 34, 2405461. [Google Scholar] [CrossRef]

- Sen, S.K.; Dasgupta, B.; Banerjee, S. Effect of introduction of heterocyclic moieties into polymer backbone on gas transport properties of fluorinated poly(ether imide) membranes. J. Membr. Sci. 2009, 343, 97–103. [Google Scholar] [CrossRef]

- Chatfield, D.A.; Einhorn, I.N. Stepwise Thermal Degradation of a Polybenzimidazole Foam. J. Polym. Sci. 1981, 19, 601–618. [Google Scholar] [CrossRef]

- Kumbharkar, S.C.; Karadkar, P.B.; Kharul, U.K. Enhancement of gas permeation properties of polybenzimidazoles by systematic structure architecture. J. Membr. Sci. 2006, 286, 161–169. [Google Scholar] [CrossRef]

- Tanaka, K.; Okano, M.; Toshino, H.; Kita, H.; Okamoto, K.-I. Effect of methyl substituents on permeability and permselectivity of gases in polyimides prepared from methyl-substituted phenylenediamines. J. Polym. Sci. Part B Polym. Phys. 1992, 30, 907–914. [Google Scholar] [CrossRef]

- Frazer, A.H.; Sweeny, W.; Wallenberger, F.T. Poly(1,3,4-oxadiazoles): A new class of polymers by cyclodehydration of polyhydrazides. J. Polym. Sci. Part A Gen. Pap. 1964, 2, 1157–1169. [Google Scholar] [CrossRef]

- Alentiev, A.Y.; Syrtsova, D.A.; Nikiforov, R.Y.; Ryzhikh, V.E.; Belov, N.A.; Skupov, K.M.; Volkova, Y.A.; Ponomarev, I.I. Polynaphthoylenebenzimidazoles as polymer materials for high-temperature membrane gas separation. Polymer 2024, 308, 127394. [Google Scholar] [CrossRef]

- Nazarov, I.V.; Khrychikova, A.P.; Medentseva, E.I.; Bermesheva, E.V.; Borisov, I.L.; Yushkin, A.A.; Volkov, A.V.; Wozniak, A.I.; Petukhov, D.I.; Topchiy, M.A.; et al. CO2-selective vinyl-addition polymers from nadimides: Synthesis and performance for membrane gas separation. J. Membr. Sci. 2023, 677, 121624. [Google Scholar] [CrossRef]

- Alentiev, A.Y.; Yampolskii, Y.P.; Shantarovich, V.P.; Nemser, S.M.; Platé, N.A. High transport parameters and free volume of perfluorodioxole copolymers. J. Membr. Sci. 1997, 126, 123–132. [Google Scholar] [CrossRef]

- Guo, L.; Shi, Y.; Wu, S.; Jin, J.; Wang, Z. Poly(hydrazide-imide) membranes with enhanced interchain interaction for highly selective H2/CO2 separation. Macromolecules 2023, 56, 3430–3439. [Google Scholar] [CrossRef]

- Park, H.B.; Han, S.H.; Jung, C.H.; Lee, Y.M.; Hill, A.J. Thermally rearranged (TR) polymer membranes for CO2 separation. J. Membr. Sci. 2010, 359, 11–24. [Google Scholar] [CrossRef]

- Ramimoghadam, D.; Boyd, S.E.; Brown, C.L.; Mac, A.; Gray, E.; Webb, C.J. The Effect of Thermal Treatment on the Hydrogen-Storage Properties of PIM-1. ChemPhysChem 2019, 20, 1613–1623. [Google Scholar] [CrossRef]

- Alentiev, A.Y.; Chirkov, S.V.; Nikiforov, R.Y.; Levin, I.A.; Kechekyan, A.S.; Kechekyan, P.A.; Belov, N.A. Poly(2,6-Dimethyl-1,4-Phenylene Oxide) as a Polymer-Polymer Nanocomposite: Mechanical and Gas Transport Characteristics. Membr. Membr. Technol. 2022, 4, 3–14. [Google Scholar] [CrossRef]