Research Progress in Electroactive Polymers for Soft Robotics and Artificial Muscle Applications

Abstract

:1. Introduction

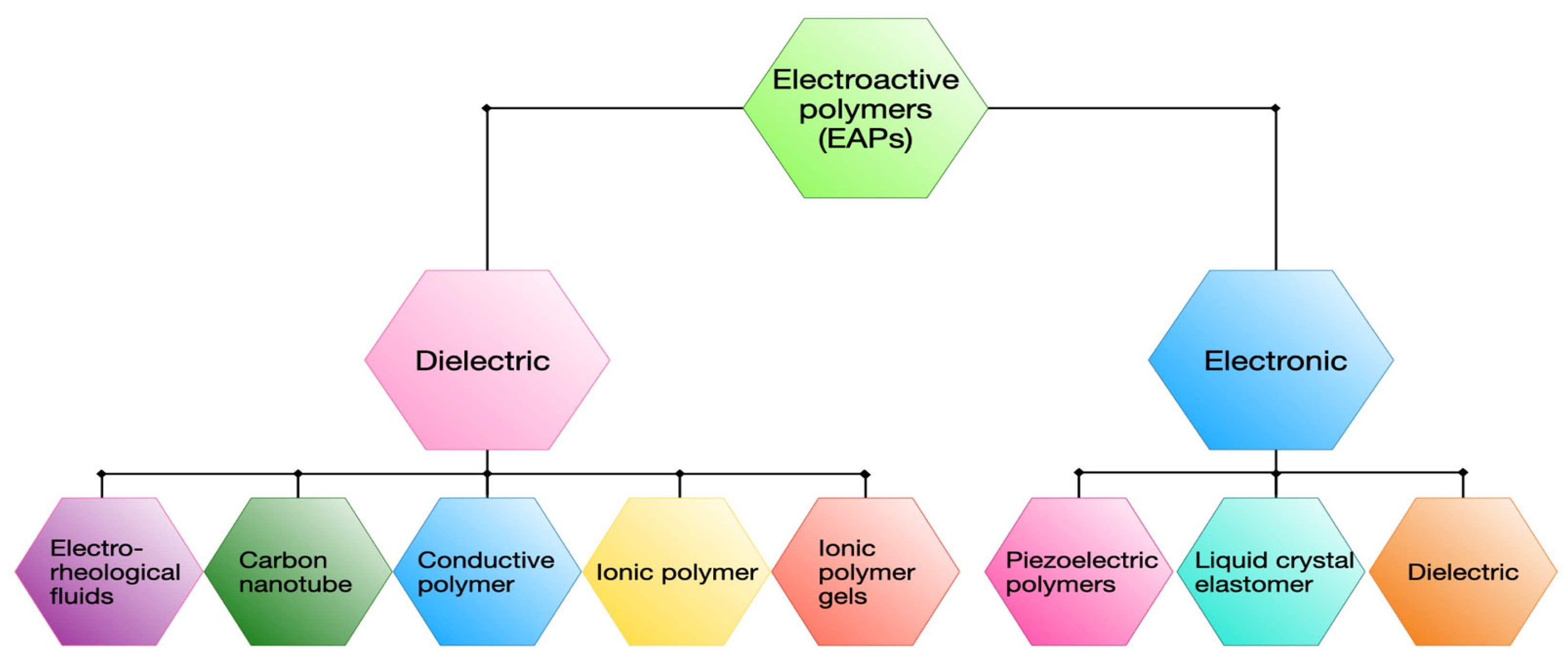

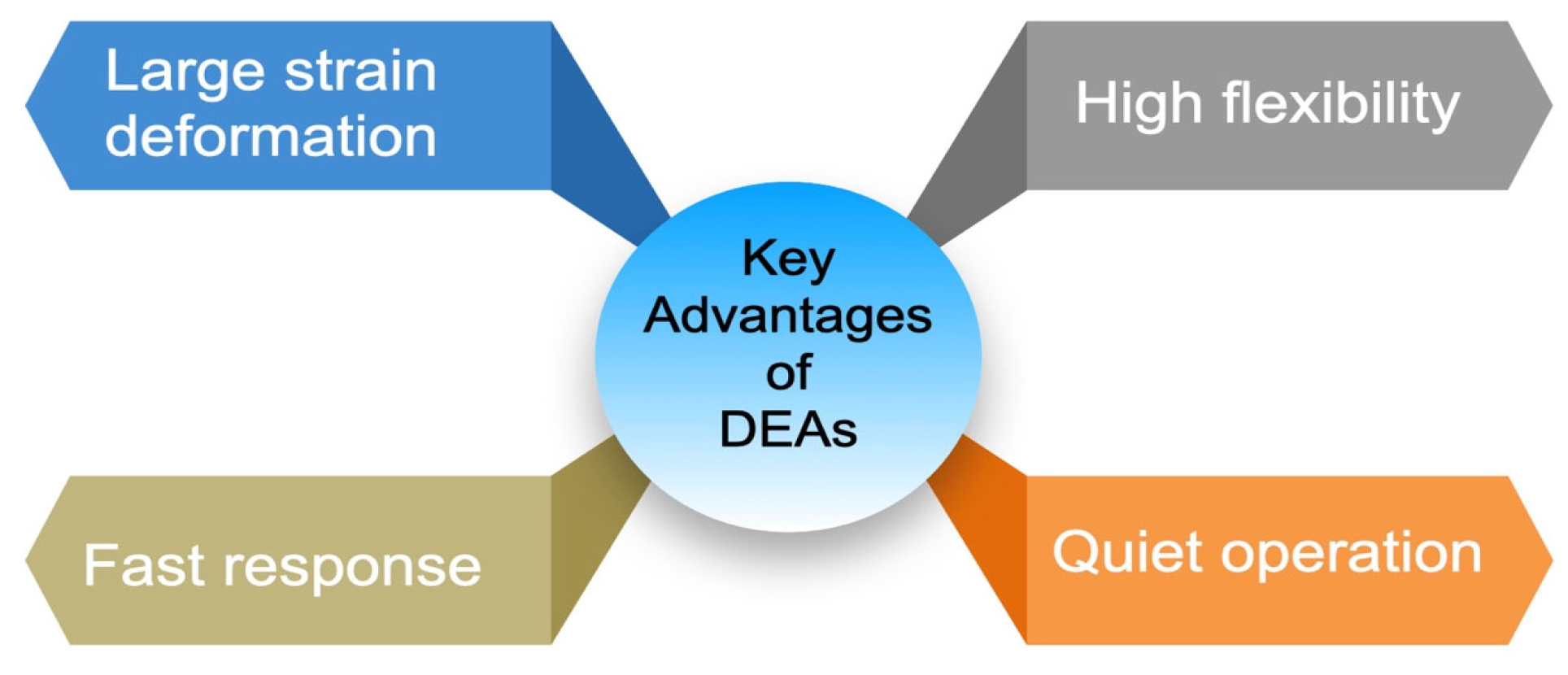

2. Classification of EAPs

3. Dielectric Elastomers Actuators

4. Liquid Crystal Elastomers Actuators

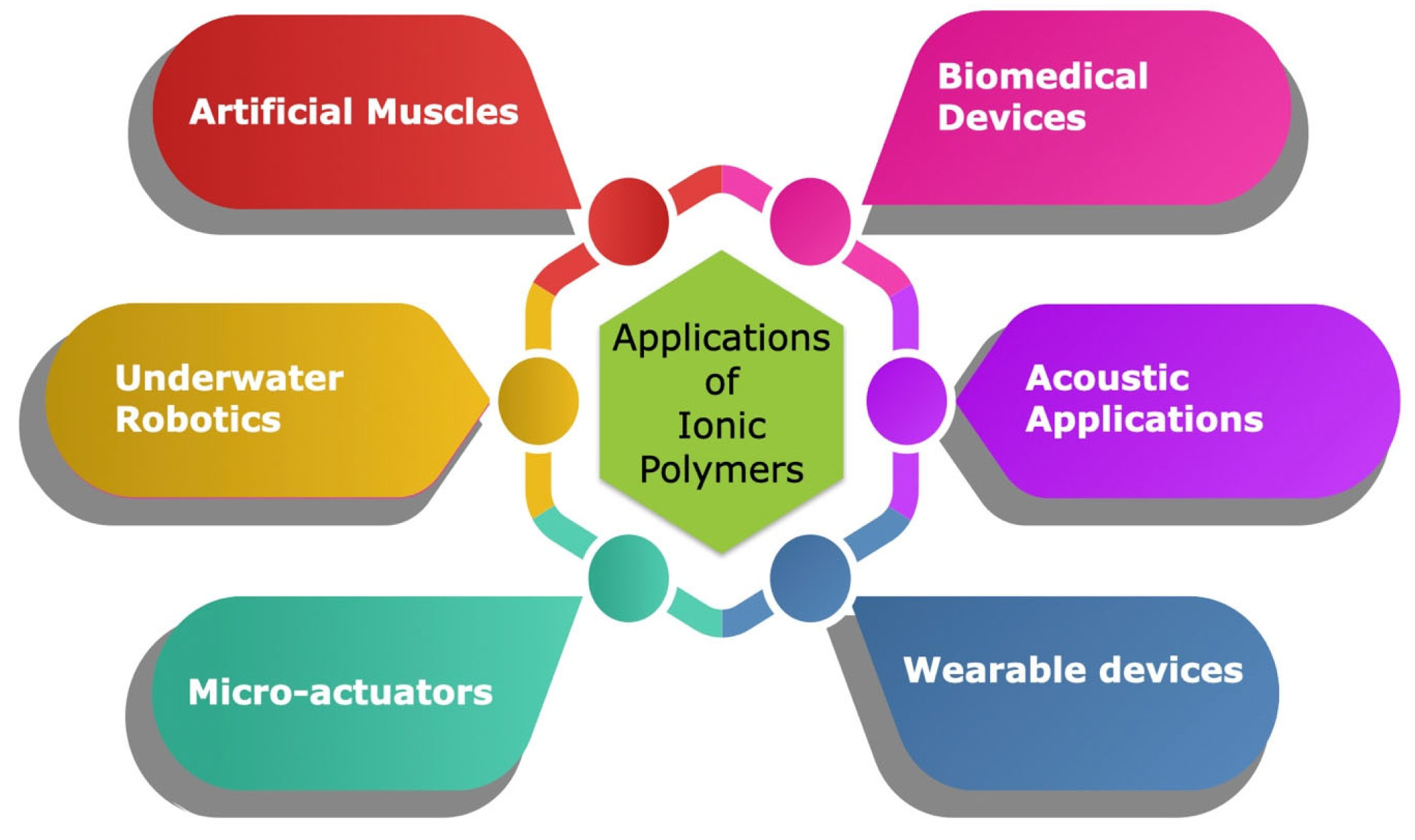

5. Ionic Polymers

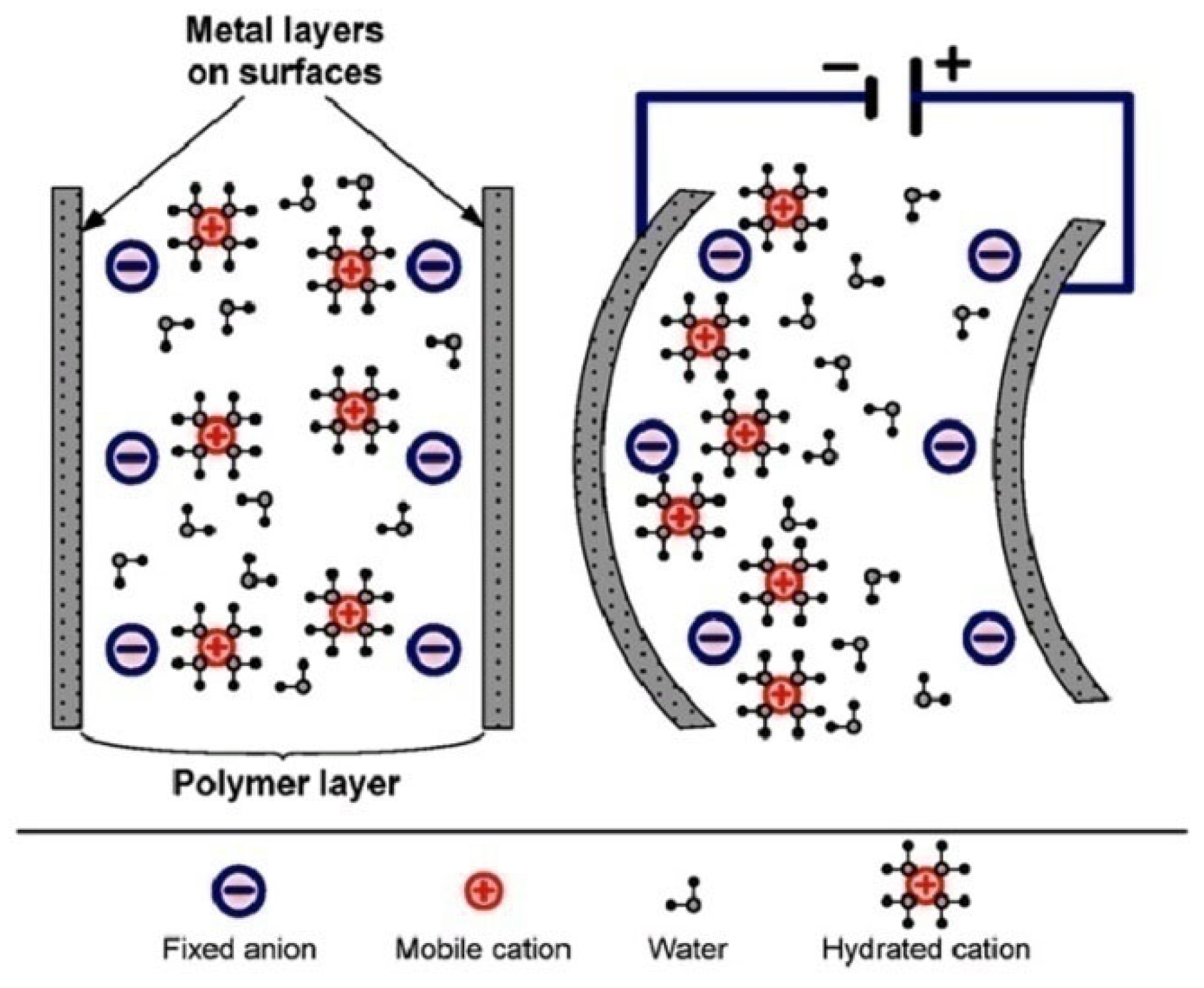

5.1. Ionic Polymer Metal Composites

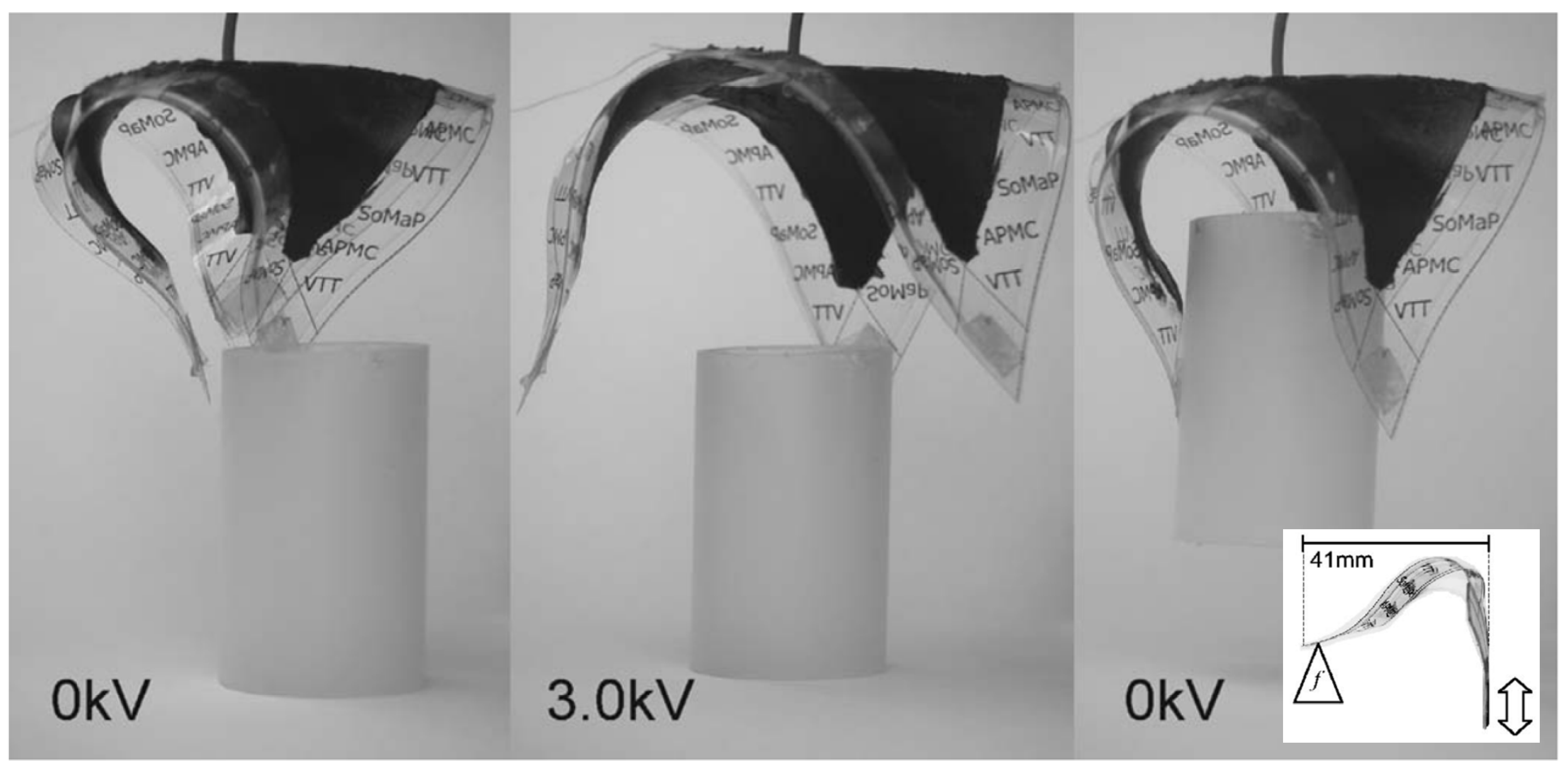

5.2. Ionic Polymer PVC Gels

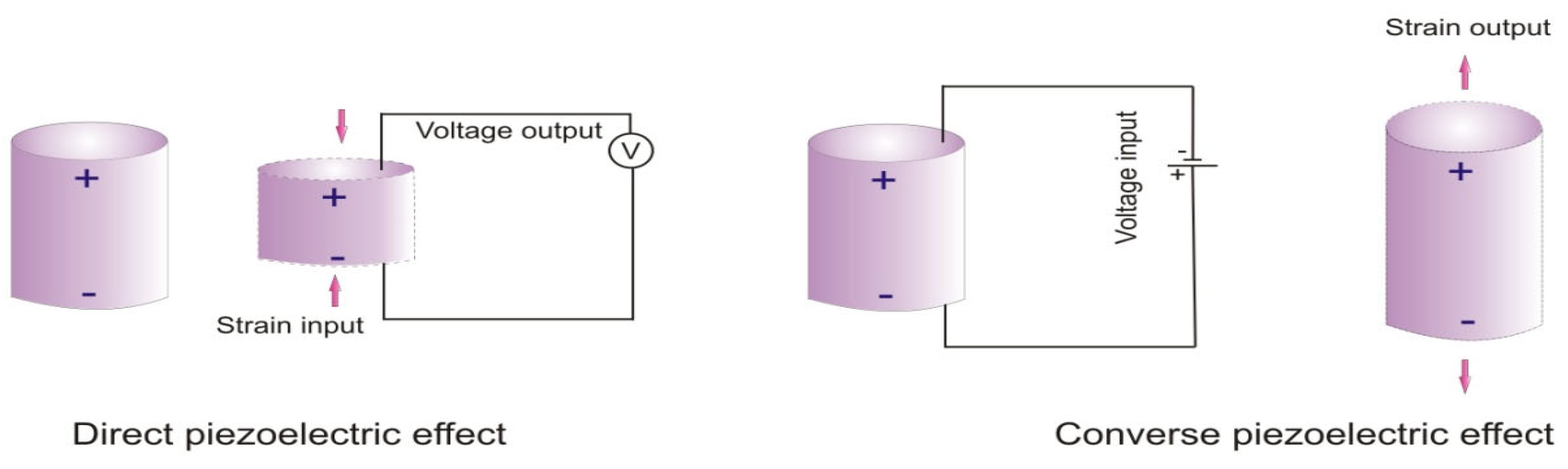

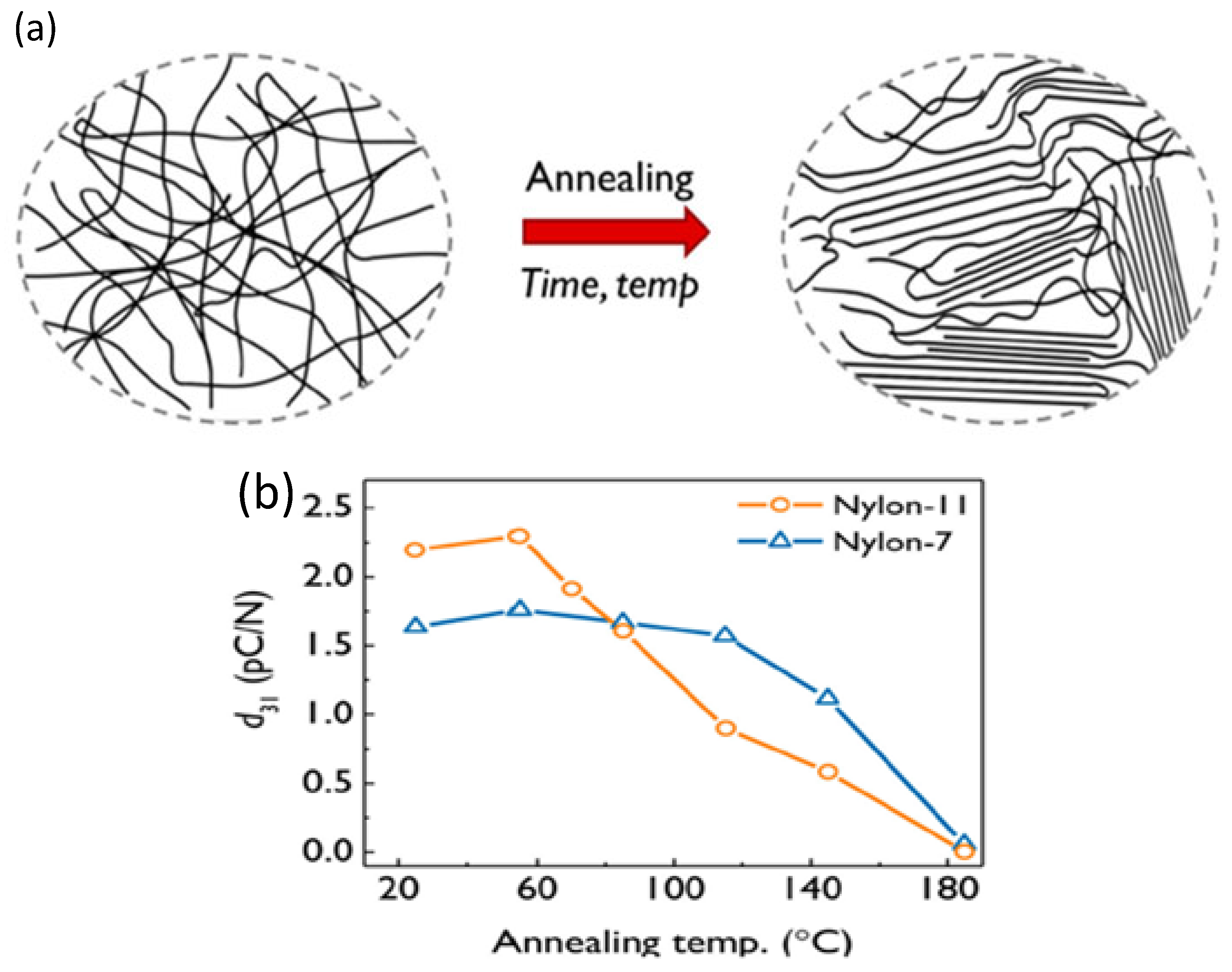

6. Piezoelectric Polymers

7. Conducting Polymers

8. Magnetic Polymer Composite

9. Recent Developments in Soft Robotics

9.1. Electro-Active Polymers

9.2. Machine Learning

9.3. Internet of Things

9.4. Comparative Study of Present Review with Existing Reviews on EAPs for Soft Robotics

10. Conclusions and Future Scope

- DEAs can achieve various actuation forms by introducing local stiffness in the elastomer or by rearranging the electrodes.

- Recent developments in dielectric LCE actuators made from rubber polymers show an exceptional capacity to exert a load 700 times their original weight.

- Planar PVC gels are capable of stretching up to 600%, offering higher flexibility, reduced weight, and smaller size compared to multilayered PVC gel actuators.

- Inkjet printing of PVDF in piezoelectric polymers is suitable for developing large-area artificial skin.

- Conducting polymers are efficient due to their minimal electrolyte content, which allows for sufficient ionic conductivity while maintaining low weight and volume.

- The interfacial area between the electrode and polymer is crucial for influencing the actuation response and electrochemical behavior in the case of IPMC actuators.

- MPCs combining magnetic particles with polymer matrices offer a blend of flexibility and magnetic properties. These composites are valuable across industries such as biomedicine, electronics, and environmental engineering thanks to their tunable magnetic, mechanical, and thermal properties.

- EAPs, ML, and IoT are driving innovations in soft robotics. EAPs are instrumental in creating flexible actuators, while ML and IoT enhance robot control, autonomy, and adaptability.

- Machine learning techniques, such as reinforcement learning, deep learning, and supervised learning, are transforming soft robotics by optimizing design, control, and sensing. These advancements improve robot functionality, adaptability, and precision.

- IoT technologies enable advancements in soft robotics by integrating communication systems, remote control, and real-time data feedback. IoT-based platforms, such as smart gloves and self-powered robotic devices, exemplify the evolution of connected soft robotics, with significant implications for industries like automation, healthcare, and retail.

11. Future Scope of Soft Robotics

- Self-healing composites textiles present a promising solution for soft robotics, enabling remote accessibility and drug delivery applications.

- There is a significant research gap in bio-inspired soft robotics, particularly in optimizing design, manufacturing processes, and control systems.

- Future research in deep-sea diving robots will focus on integrating low-light imaging, haptics, 3D imaging, microscopy, and genomics to develop tool kits and methodologies for marine biologists.

- Sustainability in soft robots is a critical concern. Current robots often have negative environmental impacts due to their materials and power sources. Future work should prioritize the development of sustainable alternatives, such as recyclable plastics and biodegradable materials, to minimize environmental damage and promote eco-friendly manufacturing practices.

- Hydrogels, as smart actuators, can be enhanced using nanomaterials and active stiffness regulation mechanisms. However, their swelling behavior can vary with humidity, causing behavioral abnormalities. To ensure stability, nanoparticles can be integrated to prevent evaporation and enable hydrogels to function as humidity sensors in smart actuators for soft robotics.

- Systems that incorporate non-electronic information computation in soft robotics are being developed to extract materials and energy from their surroundings. These systems, capable of transforming solar energy into chemical energy for storage and consumption, represent a step towards self-sufficient, self-healing, and potentially self-replicating systems.

- IoRT systems have the potential to revolutionize industries by addressing remote labor needs and enhancing productivity through human–robot interactions. The continued development of these systems is expected to contribute significantly to the Fourth Industrial Revolution, particularly in sectors that demand advanced robotics.

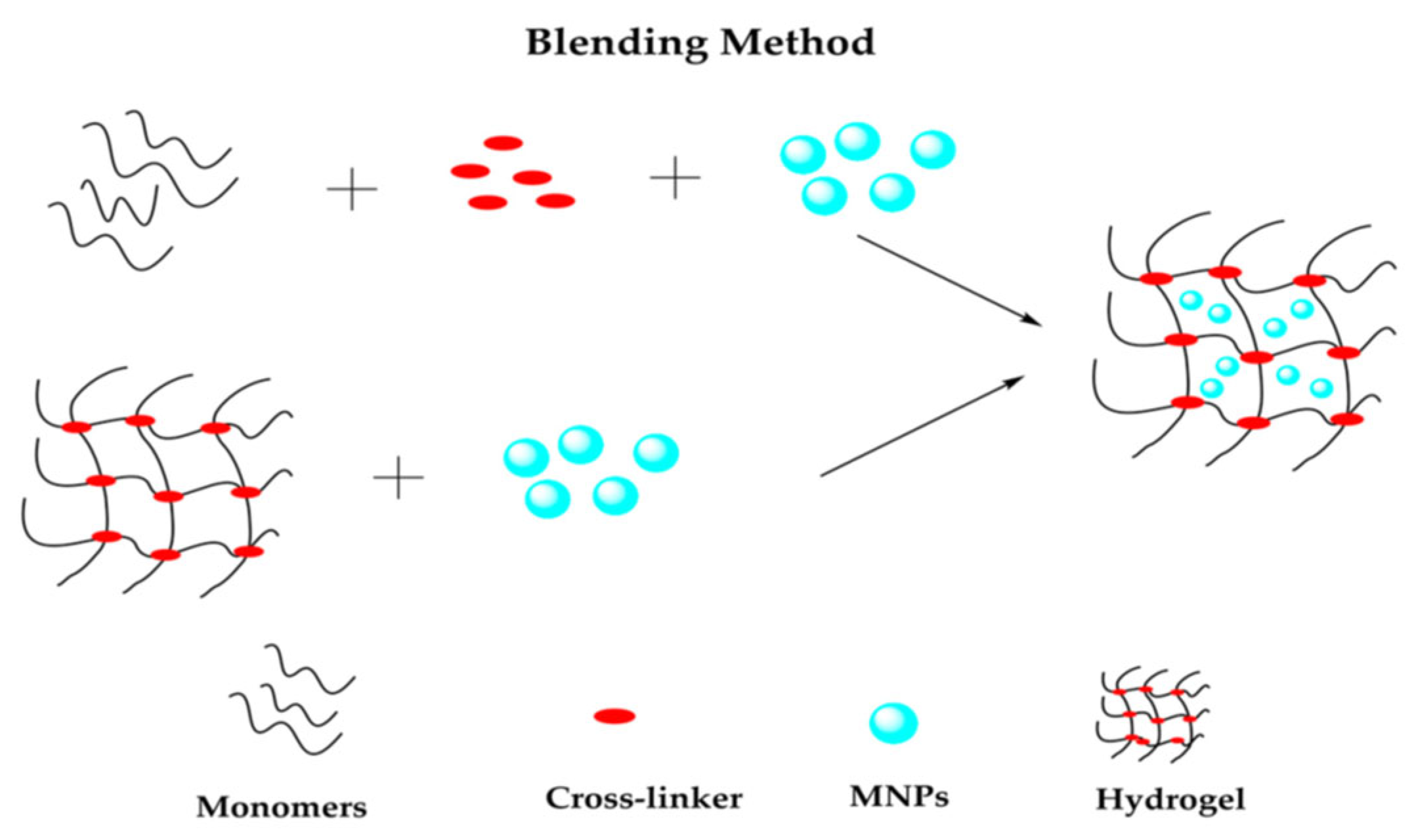

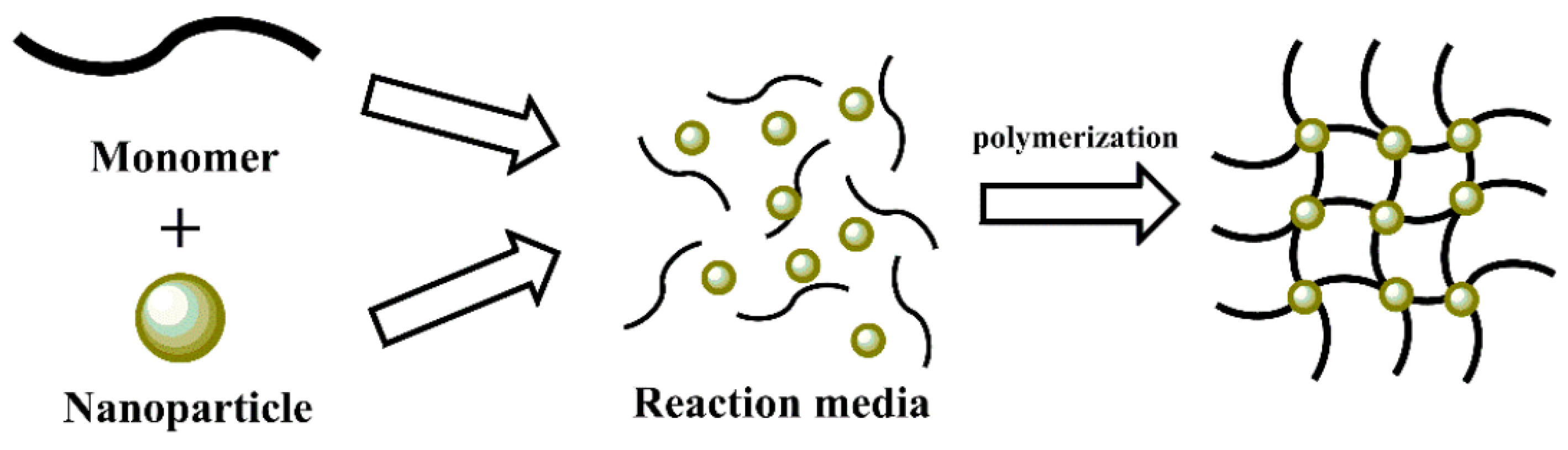

- Research can focus on combining different methods, such as blending, in situ polymerization, and molding, for the improved homogeneity and tailored properties of MPCs.

- Future studies can focus on modifying MPCs to improve their thermal stability and mechanical strength, which are crucial for applications in industries such as aerospace, automotive, and electronics.

- Eco-friendly synthesis techniques for MPCs should be explored to reduce the use of hazardous solvents and byproducts in production while promoting the development of recyclable or biodegradable materials.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qu, J.; Xu, Y.; Li, Z.; Yu, Z.; Mao, B.; Wang, Y.; Wang, Z.; Fan, Q.; Qian, X.; Zhang, M.; et al. Recent advances on underwater soft robots. Adv. Intell. Syst. 2024, 6, 2300299. [Google Scholar] [CrossRef]

- Rus, D.; Tolley, M.T. Design, fabrication and control of soft robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wang, Y.; Mushtaq, R.T.; Wei, Q. Advancements in Soft Robotics: A Comprehensive Review on Actuation Methods, Materials, and Applications. Polymers 2024, 16, 1087. [Google Scholar] [CrossRef] [PubMed]

- AboZaid, Y.A.; Aboelrayat, M.T.; Fahim, I.S.; Radwan, A.G. Soft Robotic Grippers: A Review on Technologies, Materials, and Applications. Sens. Actuators A Phys. 2024, 372, 115380. [Google Scholar] [CrossRef]

- Rodrigue, H.; Kim, J. Soft actuators in surgical robotics: A state-of-the-art review. Intell. Serv. Robot. 2023, 17, 3–17. [Google Scholar] [CrossRef]

- Yao, D.R.; Kim, I.; Yin, S.; Gao, W. Multimodal soft robotic actuation and locomotion. Adv. Mater. 2024, 36, 2308829. [Google Scholar] [CrossRef]

- Lee, C.; Kim, M.; Kim, Y.J.; Hong, N.; Ryu, S.; Kim, H.J.; Kim, S. Soft robot review. Int. J. Control. Autom. Syst. 2017, 15, 3–15. [Google Scholar] [CrossRef]

- Wang, J.; Chortos, A. Control strategies for soft robot systems. Adv. Intell. Syst. 2022, 4, 2100165. [Google Scholar] [CrossRef]

- Miriyev, A.; Stack, K.; Lipson, H. Soft material for soft actuators. Nat. Commun. 2017, 8, 596. [Google Scholar] [CrossRef]

- Kim, J.; Kim, J.W.; Kim, H.C.; Zhai, L.; Ko, H.U.; Muthoka, R.M. Review of soft actuator materials. Int. J. Precis. Eng. Manuf. 2019, 20, 2221–2241. [Google Scholar] [CrossRef]

- Elango, N.; Faudzi, A.A.M. A review article: Investigations on soft materials for soft robot manipulations. Int. J. Adv. Manuf. Technol. 2015, 80, 1027–1037. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, Y.; Li, C.; Yang, X.; Chen, W. Flexible actuators for soft robotics. Adv. Intell. Syst. 2020, 2, 1900077. [Google Scholar] [CrossRef]

- Bar-Cohen, Y. Electroactive polymers as artificial muscles: A review. J. Spacecr. Rocket. 2002, 39, 822–827. [Google Scholar] [CrossRef]

- Enyan, M.; Bing, Z.; Amu-Darko, J.N.O.; Issaka, E.; Otoo, S.L.; Agyemang, M.F. Advances in smart materials soft actuators on mechanisms, fabrication, materials, and multifaceted applications: A review. J. Thermoplast. Compos. Mater. 2024, 38, 302–370. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, Y.; Ma, Y.; Wang, J. Bioinspired Stimuli-Responsive Materials for Soft Actuators. Biomimetics 2024, 9, 128. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, Y.; Tong, Q.; Shan, B.; He, L.; Zhang, Y.; Wang, D. Active electronic skin: An interface towards ambient haptic feedback on physical surfaces. Npj Flex. Electron. 2024, 8, 25. [Google Scholar] [CrossRef]

- White, B.T.; Long, T.E. Advances in polymeric materials for electromechanical devices. Macromol. Rapid Commun. 2019, 40, 1800521. [Google Scholar] [CrossRef]

- Cianchetti, M.; Laschi, C.; Menciassi, A.; Dario, P. Biomedical applications of soft robotics. Nat. Rev. Mater. 2018, 3, 143–153. [Google Scholar] [CrossRef]

- El-Atab, N.; Mishra, R.B.; Al-Modaf, F.; Joharji, L.; Alsharif, A.A.; Alamoudi, H.; Diaz, M.; Qaiser, N.; Hussain, M.M. Soft actuators for soft robotic applications: A review. Adv. Intell. Syst. 2020, 2, 2000128. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, P.; Quan, J.; Li, L.; Zhang, G.; Zhou, D. Progress, challenges, and prospects of soft robotics for space applications. Adv. Intell. Syst. 2023, 5, 2200071. [Google Scholar] [CrossRef]

- Dong, X.; Luo, X.; Zhao, H.; Qiao, C.; Li, J.; Yi, J.; Yang, L.; Oropeza, F.J.; Hu, T.S.; Xu, Q.; et al. Recent advances in biomimetic soft robotics: Fabrication approaches, driven strategies and applications. Soft Matter 2022, 18, 7699–7734. [Google Scholar] [CrossRef]

- Greco, C.; Kotak, P.; Pagnotta, L.; Lamuta, C. The evolution of mechanical actuation: From conventional actuators to artificial muscles. Int. Mater. Rev. 2022, 67, 575–619. [Google Scholar] [CrossRef]

- Lin, W.; Wei, Y.; Wang, X.; Zhai, K.; Ji, X. Study on Human Motion Energy Harvesting Devices: A Review. Machines 2023, 11, 977. [Google Scholar] [CrossRef]

- Gu, G.-Y.; Zhu, J.; Zhu, L.-M.; Zhu, X. A survey on dielectric elastomer actuators for soft robots. Bioinspiration Biomim. 2017, 12, 011003. [Google Scholar] [CrossRef] [PubMed]

- Mutlu, R.; Alici, G.; Xiang, X.; Li, W. Electro-mechanical modelling and identification of electroactive polymer actuators as smart robotic manipulators. Mechatronics 2014, 24, 241–251. [Google Scholar] [CrossRef]

- Zhao, W.; Zhang, Y.; Wang, N. Soft robotics: Research, challenges, and prospects. J. Robot. Mechatron. 2021, 33, 45–68. [Google Scholar] [CrossRef]

- Apsite, I.; Salehi, S.; Ionov, L. Materials for smart soft actuator systems. Chem. Rev. 2021, 122, 1349–1415. [Google Scholar] [CrossRef]

- Guin, T.; Settle, M.J.; Kowalski, B.A.; Auguste, A.D.; Beblo, R.V.; Reich, G.W.; White, T.J. Layered liquid crystal elastomer actuators. Nat. Commun. 2018, 9, 2531. [Google Scholar] [CrossRef]

- Shahinpoor, M. Electrically activated artificial muscles made with liquid crystal elastomers. In Proceedings of the SPIE’s 7th Annual International Symposium on Smart Structures and Materials, Newport Beach, CA, USA, 7 June 2000; Volume 3987, pp. 187–192. [Google Scholar]

- Madden, J.D.W. Conducting Polymer Actuators. Ph.D. Dissertation, Massachusetts Institute of Technology, Cambridge, MA, USA, 2000. [Google Scholar]

- Finkelmann, H.; Shahinpoor, M. Electrically controllable liquid crystal elastomer-graphite composite artifical muscles. In Proceedings of the SPIE’s 9th Annual International Symposium on Smart Structures and Materials, San Diego, CA, USA, 11 July 2002; Volume 4695, pp. 459–464. [Google Scholar]

- Davidson, Z.S.; Shahsavan, H.; Aghakhani, A.; Guo, Y.; Hines, L.; Xia, Y.; Yang, S.; Sitti, M. Monolithic shape-programmable dielectric liquid crystal elastomer actuators. Sci. Adv. 2019, 5, eaay0855. [Google Scholar] [CrossRef]

- Bar-Cohen, Y.; Zhang, Q. Electroactive polymer actuators and sensors. MRS Bull. 2008, 33, 173–181. [Google Scholar] [CrossRef]

- Carpi, F.; Kornbluh, R.; Sommer-Larsen, P.; Alici, G. Electroactive polymer actuators as artificial muscles: Are they ready for bioinspired applications? Bioinspir. Biomim. 2011, 6, 045006. [Google Scholar] [CrossRef]

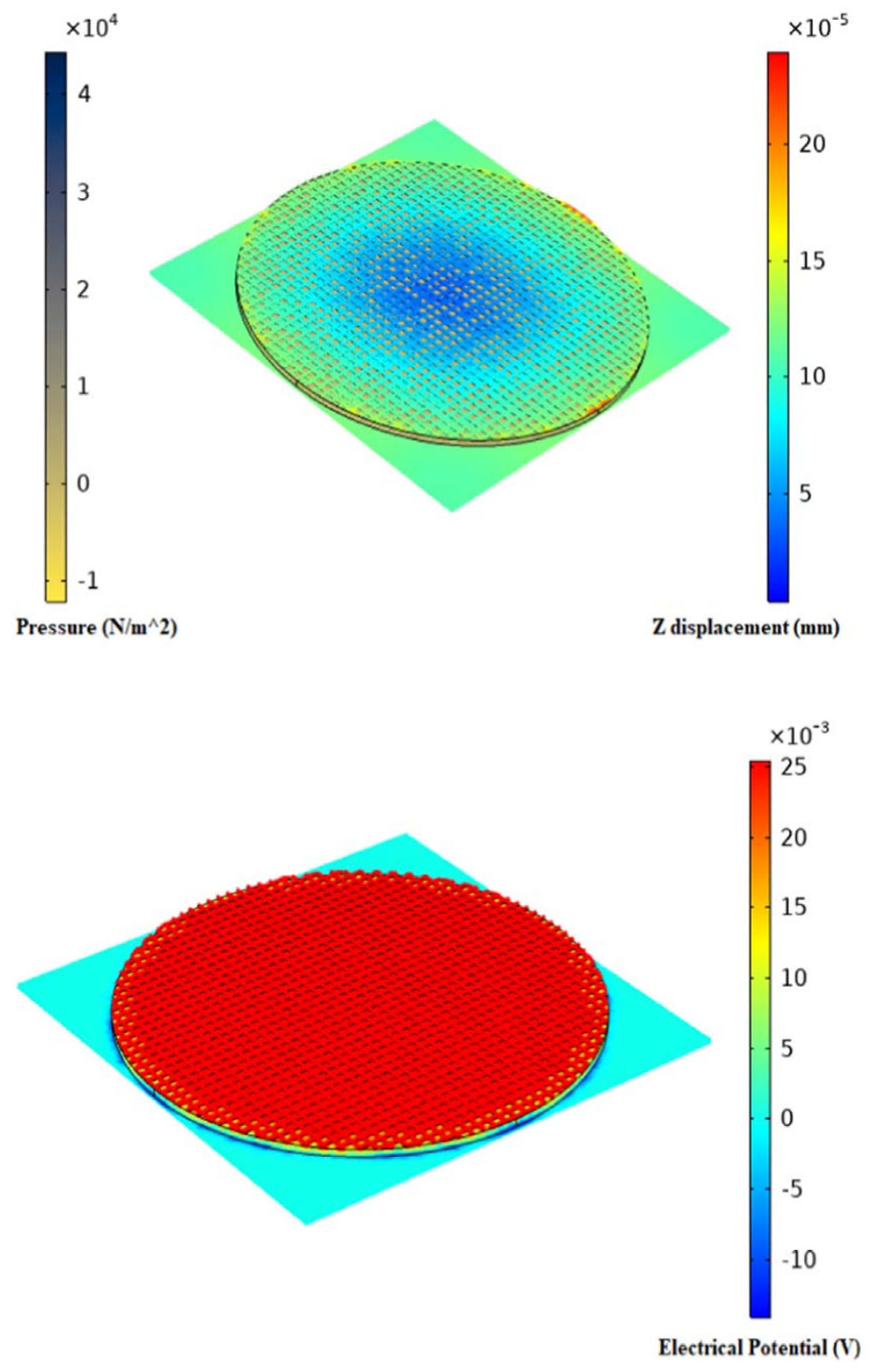

- Marín, F.; Martínez-Frutos, J.; Ortigosa, R.; Gil, A. A convex multi-variable based computational framework for multilayered electro-active polymers. Comput. Methods Appl. Mech. Eng. 2021, 374, 113567. [Google Scholar] [CrossRef]

- Kallitsis, K.; Thuau, D.; Brochon, C.; Cloutet, E.; Hadziioannou, G. Tailoring fluorinated electroactive polymers toward specific applications. Colloid Polym. Sci. 2021, 299, 457–464. [Google Scholar] [CrossRef]

- Xia, F.; Tadigadapa, S.; Zhang, Q. Electroactive polymer based microfluidic pump. Sensors Actuators A Phys. 2005, 125, 346–352. [Google Scholar] [CrossRef]

- Hartmann, F.; Penkner, L.; Danninger, D.; Arnold, N.; Kaltenbrunner, M. Soft tunable lenses based on zipping electroactive polymer actuators. Adv. Sci. 2021, 8, 2003104. [Google Scholar] [CrossRef]

- Jo, A.; Huet, C.; Naguib, H.E. Template-assisted self-assembly of conductive polymer electrodes for ionic electroactive polymers. Front. Bioeng. Biotechnol. 2020, 8, 837. [Google Scholar] [CrossRef]

- Kim, O.; Kim, S.J.; Park, M.J. Low-voltage-driven soft actuators. Chem. Commun. 2018, 54, 4895–4904. [Google Scholar] [CrossRef]

- Baughman, R.H. Conducting polymer artificial muscles. Synth. Met. 1996, 78, 339–353. [Google Scholar] [CrossRef]

- Rahman, M.H.; Werth, H.; Goldman, A.; Hida, Y.; Diesner, C.; Lane, L.; Menezes, P.L. Recent progress on electroactive polymers: Synthesis, properties and applications. Ceramics 2021, 4, 516–541. [Google Scholar] [CrossRef]

- Maksimkin, A.V.; Dayyoub, T.; Telyshev, D.V.; Gerasimenko, A.Y. Electroactive polymer-based composites for artificial muscle-like actuators: A review. Nanomaterials 2022, 12, 2272. [Google Scholar] [CrossRef]

- Bashir, M.; Rajendran, P. A review on electroactive polymers development for aerospace applications. J. Intell. Mater. Syst. Struct. 2018, 29, 3681–3695. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, L.; Liu, Y.; Leng, J. Review of dielectric elastomer actuators and their applications in soft robots. Adv. Intell. Syst. 2021, 3, 2000282. [Google Scholar] [CrossRef]

- Qiu, Y.; Zhang, E.; Plamthottam, R.; Pei, Q. Dielectric elastomer artificial muscle: Materials innovations and device explorations. Accounts Chem. Res. 2019, 52, 316–325. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Liu, Y.D.; Shi, Q.; Liang, Y. Electroactive dielectric polymer gels as new-generation soft actuators: A review. J. Mater. Sci. 2021, 56, 14943–14963. [Google Scholar] [CrossRef]

- Shankar, R.; Ghosh, T.K.; Spontak, R.J. Dielectric elastomers as next-generation polymeric actuators. Soft Matter 2007, 3, 1116–1129. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, J.; Luo, M.; Chen, H.; Yang, Z.; Li, D.; Li, P. A bio-inspired soft-rigid hybrid actuator made of electroactive dielectric elastomers. Appl. Mater. Today 2020, 21, 100814. [Google Scholar] [CrossRef]

- Wang, J.; Gao, D.; Lee, P.S. Recent progress in artificial muscles for interactive soft robotics. Adv. Mater. 2021, 33, 2003088. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, X.; Jiang, Y.; Zang, W.; Cao, P.; Tian, M.; Ning, N.; Zhang, L. Dielectric elastomer actuators for artificial muscles: A comprehensive review of soft robot explorations. Resour. Chem. Mater. 2022, 1, 308–324. [Google Scholar] [CrossRef]

- Li, J.; Liu, L.; Liu, Y.; Leng, J. Dielectric elastomer spring-roll bending actuators: Applications in soft robotics and design. Soft Robot. 2019, 6, 69–81. [Google Scholar] [CrossRef]

- Adachi, M.; Hamazawa, K.; Mimuro, Y. Vibration transport system for lunar and Martian regolith using dielectric elastomer actuator. J. Electrost. 2017, 89, 88–98. [Google Scholar] [CrossRef]

- Chen, F.; Wang, M.Y.; Zhu, J.; Zhang, Y.F. Interactions between dielectric elastomer actuators and soft bodies. Soft Robot. 2016, 3, 161–169. [Google Scholar] [CrossRef]

- Thongking, W.; Wiranata, A.; Minaminosono, A.; Mao, Z.; Maeda, S. Soft robotic gripper based on multi-layers of dielectric elastomer actuators. J. Robot. Mechatronics 2021, 33, 968–974. [Google Scholar] [CrossRef]

- Kofod, G.; Wirges, W.; Paajanen, M.; Bauer, S. Energy minimization for self-organized structure formation and actuation. Appl. Phys. Lett. 2007, 90, 081916. [Google Scholar] [CrossRef]

- Schadt, M. Liquid crystal materials and liquid crystal displays. Annu. Rev. Mater. Sci. 1997, 27, 305–379. [Google Scholar] [CrossRef]

- Marrucci, G.; Greco, F. Flow behavior of liquid crystalline polymers. Adv. Chem. Phys. 1993, 86, 331–404. [Google Scholar]

- Cao, S.; Aimi, J.; Yoshio, M. Electroactive soft actuators based on columnar ionic liquid crystal/polymer composite membrane electrolytes forming 3D continuous ionic channels. ACS Appl. Mater. Interfaces 2022, 14, 43701–43710. [Google Scholar] [CrossRef]

- Liu, G.; Deng, Y.; Ni, B.; Nguyen, G.T.M.; Vancaeyzeele, C.; Brûlet, A.; Vidal, F.; Plesse, C.; Li, M. Electroactive Bi-Functional Liquid Crystal Elastomer Actuators. Small 2024, 20, 2307565. [Google Scholar] [CrossRef]

- Xiao, Y.Y.; Jiang, Z.C.; Zhao, Y. Liquid crystal polymer-based soft robots. Adv. Intell. Syst. 2020, 2, 2000148. [Google Scholar] [CrossRef]

- Lehmann, W.; Skupin, H.; Tolksdorf, C.; Gebhard, E.; Zentel, R.; Krüger, P.; Lösche, M.; Kremer, F. Giant lateral electrostriction in ferroelectric liquid-crystalline elastomers. Nature 2001, 410, 447–450. [Google Scholar] [CrossRef]

- Madden, J.; Vandesteeg, N.; Anquetil, P.; Madden, P.; Takshi, A.; Pytel, R.; Lafontaine, S.; Wieringa, P.; Hunter, I. Artificial muscle technology: Physical principles and naval prospects. IEEE J. Ocean. Eng. 2004, 29, 706–728. [Google Scholar] [CrossRef]

- Palffy-Muhoray, P. Printed actuators in a flap. Nat. Mater. 2009, 8, 614–615. [Google Scholar] [CrossRef]

- Nemat-Nasser, S.; Wu, Y. Comparative experimental study of ionic polymer–metal composites with different backbone ionomers and in various cation forms. J. Appl. Phys. 2003, 93, 5255–5267. [Google Scholar] [CrossRef]

- Noh, T.-G.; Tak, Y.; Nam, J.-D.; Choi, H. Electrochemical characterization of polymer actuator with large interfacial area. Electrochimica Acta 2002, 47, 2341–2346. [Google Scholar] [CrossRef]

- Kim, K.J.; Shahinpoor, M. Ionic polymer–metal composites: II. Manufacturing techniques. Smart Mater. Struct. 2003, 12, 65. [Google Scholar] [CrossRef]

- Luqman, M.; Anis, A.; Shaikh, H.M.; Al-Zahrani, S.M.; Alam, M.A. Development of a Soft Robotic Bending Actuator Based on a Novel Sulfonated Polyvinyl Chloride–Phosphotungstic Acid Ionic Polymer–Metal Composite (IPMC) Membrane. Membranes 2022, 12, 651. [Google Scholar] [CrossRef] [PubMed]

- Mirvakili, S.M.; Hunter, I.W. Artificial muscles: Mechanisms, applications, and challenges. Adv. Mater. 2018, 30, 1704407. [Google Scholar] [CrossRef]

- Ahn, K.K.; Truong, D.Q.; Nam, D.N.C.; Yoon, J.I.; Yokota, S. Position control of ionic polymer metal composite actuator using quantitative feedback theory. Sens. Actuators A Phys. 2010, 159, 204–212. [Google Scholar] [CrossRef]

- Li, Y.; Hashimoto, M. PVC gel based artificial muscles: Characterizations and actuation modular constructions. Sens. Actuators A Phys. 2015, 233, 246–258. [Google Scholar] [CrossRef]

- Xia, H.; Takasaki, M.; Hirai, T. Actuation mechanism of plasticized PVC by electric field. Sens. Actuators A Phys. 2010, 157, 307–312. [Google Scholar] [CrossRef]

- Basinski, Z.S.; Christian, J. Crystallography of deformation by twin boundary movements in indium-thallium alloys. Acta Met. 1954, 2, 101–116. [Google Scholar] [CrossRef]

- Li, Y.; Li, Y.; Hashimoto, M. Low-voltage planar PVC gel actuator with high performances. Sens. Actuators B Chem. 2019, 282, 482–489. [Google Scholar] [CrossRef]

- Sharif, M.A. PVC gel smart sensor for robotics sensing applications: An experimental and finite element simulation study. Eng. Res. Express 2022, 4, 035029. [Google Scholar] [CrossRef]

- Xie, M.; Hisano, K.; Zhu, M.; Toyoshi, T.; Pan, M.; Okada, S.; Tsutsumi, O.; Kawamura, S.; Bowen, C. Flexible multifunctional sensors for wearable and robotic applications. Adv. Mater. Technol. 2019, 4, 1800626. [Google Scholar] [CrossRef]

- Sohn, J.W.; Choi, S.B. Various robots made from piezoelectric materials and electroactive polymers: A review. Int. J. Mech. Syst. Eng. 2017, 3, 2. [Google Scholar] [CrossRef]

- Guo, J.; Nie, M.; Wang, Q. A piezoelectric poly (vinylidene fluoride) tube featuring highly-sensitive and isotropic piezoelectric output for compression. RSC Adv. 2021, 11, 1182–1186. [Google Scholar] [CrossRef]

- Xin, Y.; Tian, H.; Guo, C.; Li, X.; Sun, H.; Wang, P.; Lin, J.; Wang, S.; Wang, C. PVDF tactile sensors for detecting contact force and slip: A review. Ferroelectrics 2016, 504, 31–45. [Google Scholar] [CrossRef]

- Mishra, S.; Unnikrishnan, L.; Nayak, S.K.; Mohanty, S. Advances in piezoelectric polymer composites for energy harvesting applications: A systematic review. Macromol. Mater. Eng. 2018, 304, 1800463. [Google Scholar] [CrossRef]

- Kim, D.H.; Kim, B.; Kang, H. Development of a piezoelectric polymer-based sensorized microgripper for microassembly and micromanipulation. Microsyst. Technol. 2004, 10, 275–280. [Google Scholar] [CrossRef]

- Tian, H. A robot attached the soft sensor using PVDF film for objects discrimination. Integr. Ferroelectr. 2018, 192, 94–102. [Google Scholar] [CrossRef]

- Seminara, L.; Pinna, L.; Valle, M.; Basirico, L.; Loi, A.; Cosseddu, P.; Bonfiglio, A.; Ascia, A.; Biso, M.; Ansaldo, A.; et al. Piezoelectric polymer transducer arrays for flexible tactile sensors. IEEE Sens. J. 2013, 13, 4022–4029. [Google Scholar] [CrossRef]

- Kimoto, A.; Sugitani, N.; Fujisaki, S. A multifunctional tactile sensor based on PVDF films for identification of materials. IEEE Sens. J. 2010, 10, 1508–1513. [Google Scholar] [CrossRef]

- Hosoda, K.; Tada, Y.; Asada, M. Anthropomorphic robotic soft fingertip with randomly distributed receptors. Robot. Auton. Syst. 2006, 54, 104–109. [Google Scholar] [CrossRef]

- Namvarrechi, S. Fabrication, Characterization and Modelling of Piezoelectric PVDF-TrFE Polymer as a Force Sensor Using Spin Coating Method. Ph.D. Dissertation, Concordia University, Monreal, QC, Canada, 2021. [Google Scholar]

- Gupta, S.; Shakthivel, D.; Lorenzelli, L.; Dahiya, R. Temperature compensated tactile sensing using MOSFET with P (VDF-TrFE)/BaTiO3 capacitor as extended gate. IEEE Sens. J. 2018, 19, 435–442. [Google Scholar] [CrossRef]

- Smith, M.; Kar-Narayan, S. Piezoelectric polymers: Theory, challenges and opportunities. Int. Mater. Rev. 2022, 67, 65–88. [Google Scholar] [CrossRef]

- Melling, D.; Martinez, J.G.; Jager, E.W.H. Conjugated polymer actuators and devices: Progress and opportunities. Adv. Mater. 2019, 31, 1808210. [Google Scholar] [CrossRef]

- Das, T.K.; Prusty, S. Review on conducting polymers and their applications. Polym. Technol. Eng. 2012, 51, 1487–1500. [Google Scholar] [CrossRef]

- Martins, P.; Correia, D.M.; Correia, V.; Lanceros-Mendez, S. Polymer-based actuators: Back to the future. Phys. Chem. Chem. Phys. 2020, 22, 15163–15182. [Google Scholar] [CrossRef]

- Otero, T.F. Biomimetic conducting polymers: Synthesis, materials, properties, functions, and devices. Polym. Rev. 2013, 53, 311–351. [Google Scholar] [CrossRef]

- Namsheer, K.; Rout, C.S. Conducting polymers: A comprehensive review on recent advances in synthesis, properties and applications. RSC Adv. 2021, 11, 5659–5697. [Google Scholar]

- Sharma, S.; Sudhakara, P.; Omran, A.A.B.; Singh, J.; Ilyas, R.A. Recent trends and developments in conducting polymer nanocomposites for multifunctional applications. Polymers 2021, 13, 2898. [Google Scholar] [CrossRef]

- Ma, Z.; Shi, W.; Yan, K.; Pan, L.; Yu, G. Doping engineering of conductive polymer hydrogels and their application in advanced sensor technologies. Chem. Sci. 2019, 10, 6232–6244. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Wang, J.-Y.; Pei, J. Achieving efficient n-doping of conjugated polymers by molecular dopants. Acc. Chem. Res. 2021, 54, 2871–2883. [Google Scholar] [CrossRef] [PubMed]

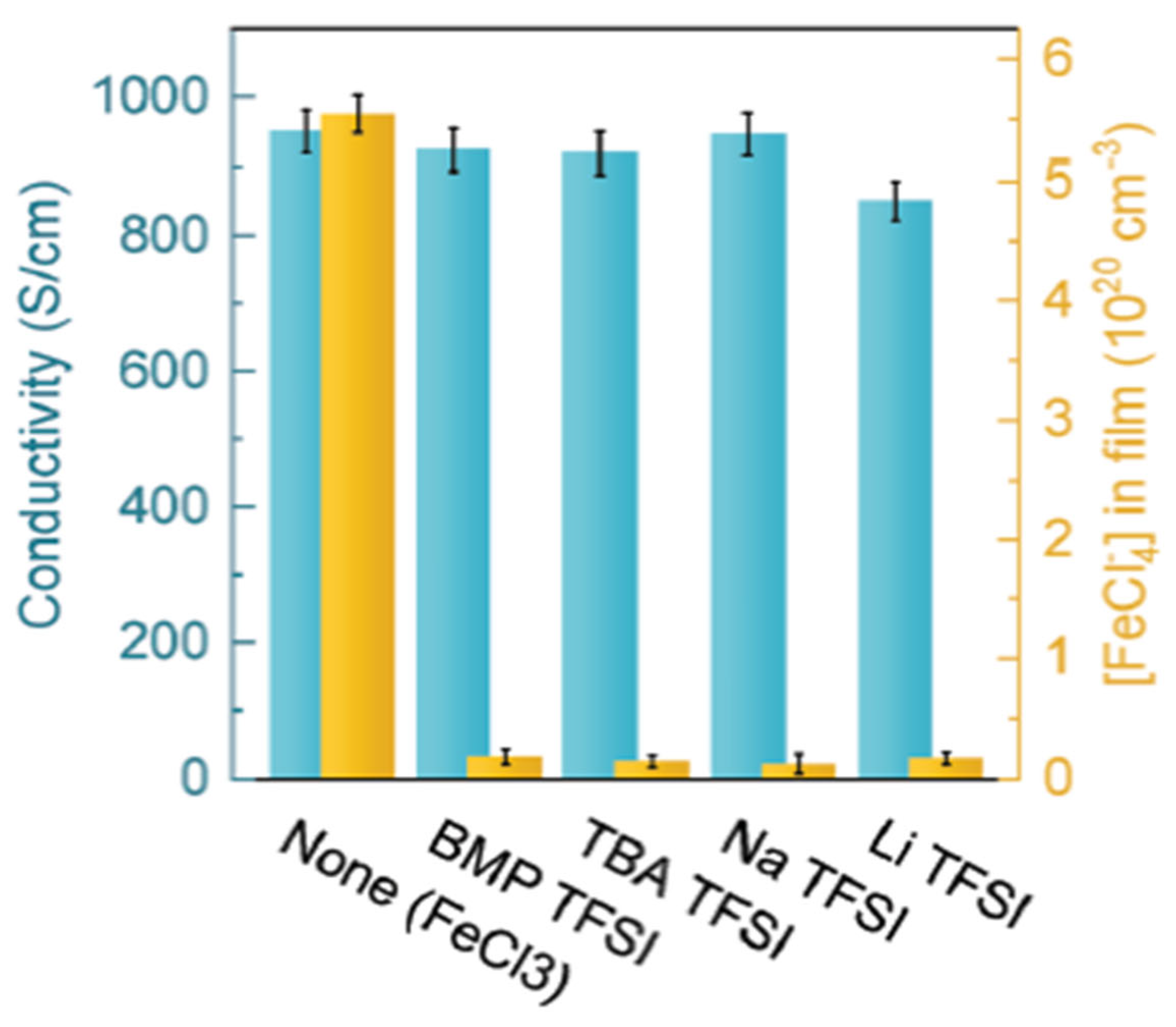

- Jacobs, I.E.; Lin, Y.; Huang, Y.; Ren, X.; Simatos, D.; Chen, C.; Tjhe, D.; Statz, M.; Lai, L.; Finn, P.A.; et al. High-Efficiency Ion-Exchange Doping of Conducting Polymers. Adv. Mater. 2022, 34, 2102988. [Google Scholar] [CrossRef] [PubMed]

- Ma, S.; Xue, P.; Valenzuela, C.; Zhang, X.; Chen, Y.; Liu, Y.; Yang, L.; Xu, X.; Wang, L. Highly Stretchable and Conductive MXene-Encapsulated Liquid Metal Hydrogels for Bioinspired Self-Sensing Soft Actuators. Adv. Funct. Mater. 2024, 34, 2309899. [Google Scholar] [CrossRef]

- Hu, H.; Zhang, S.; Xu, J.; Salim, T.; Li, Y.; Hu, X.; Zhang, Z.; Cheng, G.; Yuan, N.; Lam, Y.M.; et al. Thermal-sensing actuator based on conductive polymer ionogel for autonomous human-machine interaction. Sens. Actuators B Truongchem. 2024, 398, 134756. [Google Scholar] [CrossRef]

- Liu, L.; Li, Y.; Lu, Z.; Miao, R.; Zhang, N. Thermal and light-driven soft actuators based on a conductive polypyrrole nanofibers integrated poly (N-isopropylacrylamide) hydrogel with intelligent response. J. Colloid Interface Sci. 2024, 675, 336–346. [Google Scholar] [CrossRef]

- Hu, H.; Zhang, S.; Zhang, M.; Xu, J.; Salim, T.; Li, Y.; Hu, X.; Zhang, Z.; Cheng, G.; Yuan, N.; et al. Artificial Muscles Based on Coiled Conductive Polymer Yarns. Adv. Funct. Mater. 2024, 34, 2401685. [Google Scholar] [CrossRef]

- Périgo, E.A.; Weidenfeller, B.; Kollár, P.; Füzer, J. Past, present, and future of soft magnetic composites. Appl. Phys. Rev. 2018, 5, 031301. [Google Scholar] [CrossRef]

- Parveen, S.; Misra, R.; Sahoo, S.K. Nanoparticles: A boon to drug delivery, therapeutics, diagnostics and imaging. Nanomed. Nanotechnol. Biol. Med. 2012, 8, 147–166. [Google Scholar] [CrossRef]

- Shubayev, V.I.; Pisanic, T.R.; Jin, S. Magnetic nanoparticles for theragnostics. Adv. Drug Deliv. Rev. 2009, 61, 467–477. [Google Scholar] [CrossRef]

- Cole, A.J.; Yang, V.C.; David, A.E. Cancer theranostics: The rise of targeted magnetic nanoparticles. Trends Biotechnol. 2011, 29, 323–332. [Google Scholar] [CrossRef] [PubMed]

- Sharma, R.; Sharma, A.; Chen, C. State of art on bioimaging by nanoparticles in hyperthermia and thermometry: Visualization of tissue protein targeting. Open Nanomed. J. 2011, 3, 10–23. [Google Scholar] [CrossRef]

- Audonnet, V.; Malaquin, L.; Viovy, J.-L. Polymeric coatings on micro- and nanometric particles for bioapplications. Bioanal. Rev. 2011, 3, 41–66. [Google Scholar] [CrossRef]

- Gijs, M.A.M.; Lacharme, F.; Lehmann, U. Microfluidic Applications of Magnetic Particles for Biological Analysis and Catalysis. Chem. Rev. 2009, 110, 1518–1563. [Google Scholar] [CrossRef]

- Lu, Q.; Choi, K.; Nam, J.-D.; Choi, H.J. Magnetic Polymer Composite Particles: Design and Magnetorheology. Polymers 2021, 13, 512. [Google Scholar] [CrossRef]

- Keçili, R.; Büyüktiryaki, S.; Dolak, I.; Hussain, C.M. The use of magnetic nanoparticles in sample preparation devices and tools. In Handbook of Nanomaterials in Analytical Chemistry; Elsevier: Amsterdam, The Netherlands, 2020; pp. 75–95. [Google Scholar]

- Haldorai, Y.; Shim, J.-J.; Lim, K.T. Synthesis of polymer–inorganic filler nanocomposites in supercritical CO2. J. Supercrit. Fluids 2012, 71, 45–63. [Google Scholar] [CrossRef]

- Chung, Y.-C.; Choi, J.W.; Choi, M.W.; Chun, B.C. Characterization of flexibly linked shape memory polyurethane composite with magnetic property. J. Thermoplast. Compos. Mater. 2012, 25, 283–303. [Google Scholar] [CrossRef]

- Rajput, A.B.; Rahaman, S.J.; Sarkhel, G.; Patra, M.K.; Vadera, S.R.; Singru, P.M.; Yagci, Y.; Ghosh, N. Synthesis, characterization, and properties of flexible magnetic nanocomposites of cobalt ferrite–polybenzoxazine–linear low-density polyethylene. J. Appl. Polym. Sci. 2012, 128, 3726–3733. [Google Scholar] [CrossRef]

- Noor, A.; Ibreheim, H.S. Effect of ZrO2 on Mechanical Strength, Antibacterial, and Anti Fungal of Epoxy Adhesive. Indian J. Nat. Sci. 2019, 9, 17005–17012. [Google Scholar]

- Arias, A.; Heuzey, M.-C.; Huneault, M.A.; Ausias, G.; Bendahou, A. Enhanced dispersion of cellulose nanocrystals in melt-processed polylactide-based nanocomposites. Cellulose 2015, 22, 483–498. [Google Scholar] [CrossRef]

- Cherifi, Z.; Zaoui, A.; Boukoussa, B.; Derdar, H.; El Abed, O.Z.; Zeggai, F.Z.; Meghabar, R.; Chebout, R. Ultrasound-promoted preparation of cellulose acetate/organophilic clay bio-nanocomposites films by solvent casting method. Polym. Bull. 2022, 80, 1831–1843. [Google Scholar] [CrossRef]

- Bustamante-Torres, M.; Romero-Fierro, D.; Estrella-Nuñez, J.; Arcentales-Vera, B.; Chichande-Proaño, E.; Bucio, E. Polymeric Composite of Magnetite Iron Oxide Nanoparticles and Their Application in Biomedicine: A Review. Polymers 2022, 14, 752. [Google Scholar] [CrossRef] [PubMed]

- Soykan, C.; Akbay, M. In-Situ synthesis of polymer–clay nanocomposites: Exfoliation of organophilic montmorillonite nanolayers in poly 2-thiozylmethacrylamide. J. Mater. Sci. Technol. Res. 2019, 6, 22–33. [Google Scholar] [CrossRef]

- Guo, F.; Aryana, S.; Han, Y.; Jiao, Y. A Review of the Synthesis and Applications of Polymer–Nanoclay Composites. Appl. Sci. 2018, 8, 1696. [Google Scholar] [CrossRef]

- Shabzendedar, S.; Modarresi-Alam, A.R.; Noroozifar, M.; Kerman, K. Core-shell nanocomposite of superparamagnetic Fe3O4 nanoparticles with poly(m-aminobenzenesulfonic acid) for polymer solar cells. Org. Electron. 2020, 77, 105462. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, Y.; Xue, Y.; Wang, J.; Li, X.; Wu, X.; Qin, Y.; Chen, W. Sequential in-situ route to synthesize novel composite hydrogels with excellent mechanical, conductive, and magnetic responsive properties. Mater. Des. 2020, 193, 108759. [Google Scholar] [CrossRef]

- Romero-Fierro, D.; Bustamante-Torres, M.; Bravo-Plascencia, F.; Magaña, H.; Bucio, E. Polymer-Magnetic Semiconductor Nanocomposites for Industrial Electronic Applications. Polymers 2022, 14, 2467. [Google Scholar] [CrossRef]

- Chen, A.; Wang, Q.; Li, M.; Peng, Z.; Lai, J.; Zhang, J.; Xu, J.; Huang, H. Combined approach of compression molding and magnetic attraction to micropatterning of magnetic polydimethylsiloxane composite surfaces with excellent anti-icing/deicing performance. ACS Appl. Mater. Interfaces 2021, 13, 48153–48162. [Google Scholar] [CrossRef]

- Gautam, R.K.; Chattopadhyaya, M.C. Functionalized Magnetic Nanoparticles: Adsorbents and Applications. In Nanomaterials for Wastewater Remediation; Elsevier: Amsterdam, The Netherlands, 2016; pp. 139–159. [Google Scholar] [CrossRef]

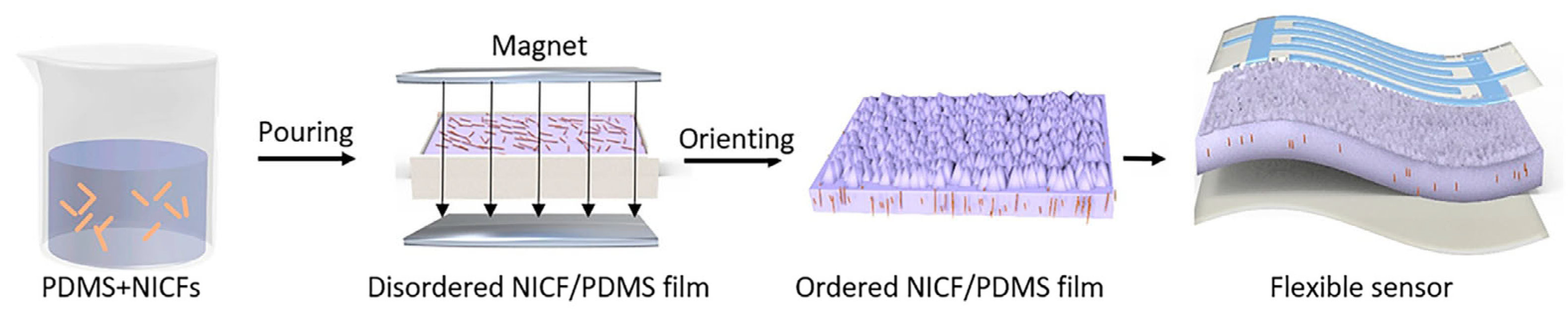

- Jiang, Y.; Liang, F.; Li, H.Y.; Li, X.; Fan, Y.J.; Cao, J.W.; Yin, Y.M.; Wang, Y.; Wang, Z.L.; Zhu, G. A flexible and ultra-highly sensitive tactile sensor through a parallel circuit by a magnetic aligned conductive composite. ACS Nano 2022, 16, 746–754. [Google Scholar] [CrossRef]

- Jiles, D.; Lo, C. The role of new materials in the development of magnetic sensors and actuators. Sens. Actuators A Phys. 2003, 106, 3–7. [Google Scholar] [CrossRef]

- Varga, Z.; Filipcsei, G.; Zrínyi, M. Magnetic field sensitive functional elastomers with tuneable elastic modulus. Polymer 2006, 47, 227–233. [Google Scholar] [CrossRef]

- Urso, M.; Ussia, M.; Novotný, F.; Pumera, M. Trapping and detecting nanoplastics by MXene-derived oxide microrobots. Nat. Commun. 2022, 13, 3573. [Google Scholar] [CrossRef] [PubMed]

- Mamatha, G.M.; Pradipkumar, D.R.; Hari, K.; Girish, K.S. Polymer based composites for electromagnetic interference (EMI) shielding: The role of magnetic fillers in effective attenuation of microwaves, a review. Hybrid Adv. 2024, 6, 100200. [Google Scholar]

- Ganguly, S.; Margel, S. Fabrication and Applications of Magnetic Polymer Composites for Soft Robotics. Micromachines 2023, 14, 2173. [Google Scholar] [CrossRef]

- Ganguly, S.; Margel, S. Magnetic Polymeric Conduits in Biomedical Applications. Micromachines 2025, 16, 174. [Google Scholar] [CrossRef]

- Sasmal, A.; Sen, S.; Arout Chelvane, J.; Arockiarajan, A. PVDF based flexible magnetoelectric composites for capacitive energy storage, hybrid mechanical energy harvesting and self-powered magnetic field detection. Polymer 2023, 281, 126141. [Google Scholar] [CrossRef]

- Lu, F.; Chen, T.; Xiang, K.; Wang, Y. Ionic electro-active polymer actuator based on cobalt-containing nitrogen-doped carbon/conducting polymer soft electrode. Polym. Test. 2020, 84, 106413. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Arif, Z.U.; Tariq, A.; Hossain, M.; Khan, K.A.; Umer, R. 3D printing of magneto-active smart materials for advanced actuators and soft robotics applications. Eur. Polym. J. 2024, 205, 112718. [Google Scholar] [CrossRef]

- Hassan, H.; Hallez, H.; Thielemans, W.; Vandeginste, V. A review of electro-active shape memory polymer composites: Materials engineering strategies for shape memory enhancement. Eur. Polym. J. 2024, 208, 112861. [Google Scholar] [CrossRef]

- Yang, L.; Wang, H. High-performance electrically responsive artificial muscle materials for soft robot actuation. Acta Biomater. 2024, 185, 24–40. [Google Scholar] [CrossRef]

- Reghunadhan, A.; Krishna, A.; Jose, A.J. Polymers in robotics. In Polymer Science and Innovative Applications; Elsevier: Amsterdam, The Netherlands, 2020; pp. 393–421. [Google Scholar]

- Trümpler, N.; Kanno, R.; David, N.; Huch, A.; Nguyen, P.H.; Jurinovs, M.; Nyström, G.; Gaidukovs, S.; Kovac, M. Low-Cost 3D printed, Biocompatible Ionic Polymer Membranes for Soft Actuators. arXiv 2025, arXiv:2501.12025. [Google Scholar]

- Jumet, B.; Bell, M.D.; Sanchez, V.; Preston, D.J. A data-driven review of soft robotics. Adv. Intell. Syst. 2020, 4, 2100163. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, F.; Cheng, G.; Jiao, J.; Zhang, Z. Advances in electroactive polymer-based haptic actuators for human-machine interfaces: From principles to applications. Nanomaterials 2021, 11, 2975. [Google Scholar] [CrossRef]

- Bernat, J.; Gajewski, P.; Kołota, J.; Marcinkowska, A. Review of soft actuators controlled with electrical stimuli: IPMC, DEAP, and MRE. Appl. Sci. 2023, 13, 1651. [Google Scholar] [CrossRef]

- Biswal, D.K. Application of Electroactive Polymer Actuator: A Brief Review. In Biomimicry Materials and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2023; pp. 127–146. [Google Scholar]

- Fernandes, L.; Correia, D.; Costa, C.; Lanceros-Mendez, S. Recent Advances in Ionic Liquid-Based Hybrid Materials for Electroactive Soft Actuator Applications. Macromol. Mater. Eng. 2024, 310, 2400279. [Google Scholar] [CrossRef]

- Kanaan, A.F.; Pinho, A.C.; Piedade, A.P. Electroactive polymers obtained by conventional and non-conventional technologies. Polymers 2021, 13, 2713. [Google Scholar] [CrossRef]

- Jo, S.J.; Kim, G.M.; Kim, J. Recent Advances in Electric Stimulus-Responsive Soft Actuators. Compos. Res. 2024, 37, 247–264. [Google Scholar]

- Deng, C.; Li, Z. Advanced Drive Technologies for Bionic Soft Robots. J. Bionic Eng. 2025, 22, 1–39. [Google Scholar] [CrossRef]

- Beregoi, M.; Beaumont, S.; Evanghelidis, A.; Otero, T.F.; Enculescu, I. Bioinspired polypyrrole based fibrillary artificial muscle with actuation and intrinsic sensing capabilities. Sci. Rep. 2022, 12, 15019. [Google Scholar] [CrossRef]

- Bruns, M.; Mehraeen, S.; Martinez, J.G.; Cherif, C.; Jager, E.W.H. PEDOT/Polypyrrole Core–Sheath Fibers for Use as Conducting Polymer Artificial Muscles. ACS Appl. Mater. Interfaces 2025, 17, 6901–6912. [Google Scholar] [CrossRef]

- Brochu, P.; Pei, Q. Dielectric elastomers for actuators and artificial muscles. In Electroactivity in Polymeric Materials; Springer: New York, NY, USA, 2012; pp. 1–56. [Google Scholar]

- Guo, Y.; Qin, Q.; Han, Z.; Plamthottam, R.; Possinger, M.; Pei, Q. Dielectric elastomer artificial muscle materials advancement and soft robotic applications. SmartMat 2023, 4, e1203. [Google Scholar] [CrossRef]

- Jiang, H.; Li, C.; Huang, X. Actuators based on liquid crystalline elastomer materials. Nanoscale 2013, 5, 5225–5240. [Google Scholar] [CrossRef] [PubMed]

- Shahinpoor, M.; Bar-Cohen, Y.; Simpson, J.O.; Smith, J. Ionic polymer-metal composites (IPMCs) as biomimetic sensors, actuators and artificial muscles-a review. Smart Mater. Struct. 1998, 7, R15. [Google Scholar] [CrossRef]

- Ariano, P.; Accardo, D.; Lombardi, M.; Bocchini, S.; Draghi, L.; De Nardo, L.; Fino, P. Polymeric materials as artificial muscles: An overview. J. Appl. Biomater. Funct. Mater. 2015, 13, 1–9. [Google Scholar] [CrossRef]

- Le, T.-H.; Kim, Y.; Yoon, H. Electrical and electrochemical properties of conducting polymers. Polymers 2017, 9, 150. [Google Scholar] [CrossRef]

- Yin, S.; Jia, Z.; Li, X.; Zhu, J.; Xu, Y.; Li, T. Machine-learning-accelerated design of functional structural components in deep-sea soft robots. Extreme Mech. Lett. 2022, 52, 101635. [Google Scholar] [CrossRef]

- Chin, K.; Hellebrekers, T.; Majidi, C. Machine learning for soft robotic sensing and control. Adv. Intell. Syst. 2020, 2, 1900171. [Google Scholar] [CrossRef]

- Yao, J.; Cao, Q.; Ju, Y.; Sun, Y.; Liu, R.; Han, X.; Li, L. Adaptive actuation of magnetic soft robots using deep reinforcement learning. Adv. Intell. Syst. 2023, 5, 2200339. [Google Scholar] [CrossRef]

- Čakurda, T.; Trojanová, M.; Pomin, P.; Hošovský, A. Deep Learning Methods in Soft Robotics: Architectures and Applications. Adv. Intell. Syst. 2024, 2400576. [Google Scholar] [CrossRef]

- Yasa, O.; Toshimitsu, Y.; Michelis, M.Y.; Jones, L.S.; Filippi, M.; Buchner, T.; Katzschmann, R.K. An overview of soft robotics. Annu. Rev. Control. Robot. Auton. Syst. 2023, 6, 1–29. [Google Scholar] [CrossRef]

- Terrile, S.; López, A.; Barrientos, A. Use of Finite Elements in the Training of a Neural Network for the Modeling of a Soft Robot. Biomimetics 2023, 8, 56. [Google Scholar] [CrossRef] [PubMed]

- Tsompanas, M.-A.; You, J.; Philamore, H.; Rossiter, J.; Ieropoulos, I. Neural networks predicting microbial fuel cells output for soft robotics applications. Front. Robot. AI 2021, 8, 633414. [Google Scholar] [CrossRef]

- Raeisinezhad, M.; Pagliocca, N.; Koohbor, B.; Trkov, M. Design optimization of a pneumatic soft robotic actuator using model-based optimization and deep reinforcement learning. Front. Robot. AI 2021, 8, 639102. [Google Scholar] [CrossRef]

- Johnson, C.C.; Quackenbush, T.; Sorensen, T.; Wingate, D.; Killpack, M.D. Using first principles for deep learning and model-based control of soft robots. Front. Robot. AI 2021, 8, 654398. [Google Scholar] [CrossRef] [PubMed]

- Shih, B.; Shah, D.; Li, J.; Thuruthel, T.G.; Park, Y.-L.; Iida, F.; Bao, Z.; Kramer-Bottiglio, R.; Tolley, M.T. Electronic skins and machine learning for intelligent soft robots. Sci. Robot. 2020, 5, eaaz9239. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.; Kim, S.H.; Kim, T.; Kang, B.B.; Lee, M.; Park, W.; Ku, S.; Kim, D.; Kwon, J.; Lee, H. Review of machine learning methods in soft robotics. PLoS ONE 2021, 16, e0246102. [Google Scholar] [CrossRef]

- Mirza, N.M. Machine learning and soft robotics. In Proceedings of the 2020 21st International Arab Conference on Information Technology (ACIT), Giza, Egypt, 28–30 November 2021; IEEE Access: New York, NY, USA; pp. 1–5. [Google Scholar]

- Truby, R.L.; Della Santina, C.; Rus, D. Distributed proprioception of 3D configuration in soft, sensorized robots via deep learning. IEEE Robot. Autom. Lett. 2020, 5, 3299–3306. [Google Scholar] [CrossRef]

- Lou, G.; Wang, C.; Xu, Z.; Liang, J.; Zhou, Y. Controlling soft robotic arms using hybrid modelling and reinforcement learning. IEEE Robot. Autom. Lett. 2024, 9, 7070–7077. [Google Scholar] [CrossRef]

- Huang, H.; Lin, J.; Wu, L.; Fang, B.; Wen, Z.; Sun, F. Machine learning-based multi-modal information perception for soft robotic hands. Tsinghua Sci. Technol. 2020, 25, 255–269. [Google Scholar] [CrossRef]

- Ding, Z.Y.; Loo, J.Y.; Baskaran, V.M.; Nurzaman, S.G.; Tan, C.P. Predictive uncertainty estimation using deep learning for soft robot multimodal sensing. IEEE Robot. Autom. Lett. 2021, 6, 951–957. [Google Scholar] [CrossRef]

- Bhagat, S.; Banerjee, H.; Ho Tse, Z.T.; Ren, H. Deep reinforcement learning for soft, flexible robots: Brief review with impending challenges. Robotics 2019, 8, 4. [Google Scholar] [CrossRef]

- Thuruthel, T.G.; Falotico, E.; Renda, F.; Laschi, C. Model-based reinforcement learning for closed-loop dynamic control of soft robotic manipulators. IEEE Trans. Robot. 2018, 35, 124–134. [Google Scholar] [CrossRef]

- Wang, S.; Sun, Z. Hydrogel and machine learning for soft robots’ sensing and signal processing: A review. J. Bionic Eng. 2023, 20, 845–857. [Google Scholar] [CrossRef]

- Wang, L.; Sun, X.; Wang, D.; Cui, P.; Wang, J.; Li, Q. High-precision, programmable soft wireless robotics for cooling tower cleaning based on Internet of Things technology. Chem. Eng. J. 2024, 495, 153268. [Google Scholar] [CrossRef]

- Zhang, Z.; Wen, F.; Sun, Z.; Guo, X.; He, T.; Lee, C. Artificial intelligence-enabled sensing technologies in the 5G/internet of things era: From virtual reality/augmented reality to the digital twin. Adv. Intell. Syst. 2022, 4, 2100228. [Google Scholar] [CrossRef]

- Sun, Z.; Zhu, M.; Zhang, Z.; Chen, Z.; Shi, Q.; Shan, X.; Yeow, R.C.H.; Lee, C. Artificial Intelligence of Things (AIoT) enabled virtual shop applications using self-powered sensor enhanced soft robotic manipulator. Adv. Sci. 2021, 8, 2100230. [Google Scholar] [CrossRef]

- Sayeed, A.; Verma, C.; Kumar, N.; Koul, N.; Illés, Z. Approaches and challenges in Internet of robotic things. Future Internet 2022, 14, 265. [Google Scholar] [CrossRef]

- Börner, K.; Scrivner, O.; Cross, L.E.; Gallant, M.; Ma, S.; Martin, A.S.; Record, L.; Yang, H.; Dilger, J.M. Mapping the co-evolution of artificial intelligence, robotics, and the internet of things over 20 years (1998–2017). PLoS ONE 2020, 15, e0242984. [Google Scholar] [CrossRef]

- Sundaravadivel, P.; Ghosh, P.K.; Suwal, B. IoT-enabled Soft Robotics for Electrical Engineers. In Proceedings of the Great Lakes Symposium on VLSI 2022, New York, NY, USA, 6–8 June 2022; pp. 329–332. [Google Scholar]

- Yang, Y.; Guo, X.; Zhu, M.; Sun, Z.; Zhang, Z.; He, T.; Lee, C. Triboelectric nanogenerator enabled wearable sensors and electronics for sustainable internet of things integrated green earth. Adv. Energy Mater. 2022, 13, 2203040. [Google Scholar] [CrossRef]

- Romeo, L.; Petitti, A.; Marani, R.; Milella, A. Internet of robotic things in smart domains: Applications and challenges. Sensors 2020, 20, 3355. [Google Scholar] [CrossRef]

- Kua, J.; Loke, S.W.; Arora, C.; Fernando, N.; Ranaweera, C. Internet of things in space: A review of opportunities and challenges from satellite-aided computing to digitally-enhanced space living. Sensors 2021, 21, 8117. [Google Scholar] [CrossRef] [PubMed]

- Ye, L.; Zheng, Y. The Image Processing Using Soft Robot Technology in Fitness Motion Detection Under the Internet of Things. IEEE Access 2022, 10, 115815–115822. [Google Scholar] [CrossRef]

- Alkahtani, M.E.; Elbadawi, M.; Chapman, C.A.; Green, R.A.; Gaisford, S.; Orlu, M.; Basit, A.W. Electroactive Polymers for On-Demand Drug Release. Adv. Healthc. Mater. 2024, 13, 2301759. [Google Scholar] [CrossRef] [PubMed]

- Ghevondyan, M.; Davtyan, M.; Aghayan, M. Dielectric elastomer actuators: Medical applications review. Discov. Mater. 2025, 5, 43. [Google Scholar] [CrossRef]

- Fattah-Alhosseini, A.; Chaharmahali, R.; Alizad, S.; Kaseem, M.; Dikici, B. A review of smart polymeric materials: Recent developments and prospects for medicine applications. Hybrid Adv. 2024, 5, 100178. [Google Scholar] [CrossRef]

- Sarker, A.; Islam, T.U.; Islam, R. A Review on Recent Trends of Bioinspired Soft Robotics: Actuators, Control Methods, Materials Selection, Sensors, Challenges, and Future Prospects. Adv. Intell. Syst. 2024, 2400414. [Google Scholar] [CrossRef]

- Kim, S.; Lee, S.-N.; Melvin, A.A.; Choi, J.-W. Stimuli-Responsive Polymer Actuator for Soft Robotics. Polymers 2024, 16, 2660. [Google Scholar] [CrossRef]

- Garofalo, S.; Morano, C.; Perrelli, M.; Pagnotta, L.; Carbone, G.; Mundo, D.; Bruno, L. A critical review of transitioning from conventional actuators to artificial muscles in upper-limb rehabilitation devices. J. Intell. Mater. Syst. Struct. 2024, 35, 1263–1290. [Google Scholar] [CrossRef]

- Mohammed, M.; Al-Ibadi, A. Types and Applications of Soft Robot Arms and End-Effectors: A Review. J. Robot. Res. 2024, 1, 40–52. [Google Scholar]

| Serial Number | Applications/Applied Areas of LCE’s Actuators | Reference |

|---|---|---|

| 1. |

| [19] |

| 2. |

| [1] |

| Serial Number | Applications/Applied Areas of IPMC Actuators | Reference |

|---|---|---|

| 1. |

| [5] |

| 2. |

| [3] |

| 3. |

| [11] |

| Serial Number | Applications/Applied Areas of Conducting Polymer Actuators | Reference |

|---|---|---|

| 1. |

| [5] |

| 2. |

| [3] |

| 3. |

| [7] |

| Type of EAPs | Highlights | Challenges | Operating Voltage | Actuation Strain | Response Time | References |

|---|---|---|---|---|---|---|

| Dielectric Elastomers |

|

| High (in the range of kV) | Up to 300% | Milliseconds | [43,149,150] |

| Liquid Crystal Elastomers |

|

| ~100 V | 10–300% | Seconds-Minutes | [43,151] |

| Ionic EAPs |

|

| 1–5 V | 1–10% | Milliseconds-Seconds | [43,152] |

| Piezoelectric Polymers |

|

| >0.5–1 kV | 0.1–1% | Microseconds-milliseconds | [43,153] |

| Conducting Polymers |

|

| 1–5 V | 2–12% | Seconds-Minutes | [43,92,154] |

| Major Theme of Existing Review | Novelty of Present Review with Respect to Existing Review | Difference Between Present and Existing Review/Work | Ref. |

|---|---|---|---|

| Electric Stimulus-Responsive Soft Actuators | machine learning and IoT in robotics | Description of machine learning and IoT are totally absent in this existing review | [145] |

| Conducting polymers as drug delivery carrier or medium indicated its presence towards application in health-care IoT | recent developments in EAP and machine learning | Description of machine learning is totally absent in this existing review | [184] |

| Dielectric elastomer actuators for medical applications | recent developments in EAP and machine learning and IoT in robotics | Description of machine learning and IoT are totally absent in this existing review | [185] |

| Smart polymeric materials | recent developments in EAP and machine learning and IoT in robotics | Description of machine learning and IoT are totally absent in this existing review | [186] |

| EAP’s for soft robotics and artificial muscle | machine learning and IoT in robotics | Description of machine learning and IoT are totally absent in this existing review | [136] |

| Bio-inspired soft robotics sensors and actuators | IoT in robotics | Machine learning is partially discussed in existing review but machine learning and IoT both are thoroughly discussed for soft robotics in present review | [187] |

| Stimuli-Responsive Polymer Actuator for Soft Robotics | machine learning and IoT in robotics | Description of machine learning and IoT are totally absent in this existing review | [188] |

| Conventional actuators and artificial muscles in upper-limb rehabilitation devices | machine learning and IoT in robotics | Description of machine learning and IoT are totally absent in this existing review | [189] |

| Ionic Liquid-Based Hybrid Materials for electroactive Soft Actuator Applications | recent developments in EAP and machine learning and IoT in robotics | Description of machine learning and IoT are totally absent in this existing review | [143] |

| Types and Applications of Soft Robot Arms | machine learning and IoT in robotics | Description of machine learning and IoT are totally absent in this existing review | [190] |

| Recent advances in soft robotics | machine learning and IoT in robotics | Description of machine learning and IoT are totally absent in this existing review | [3] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dewang, Y.; Sharma, V.; Baliyan, V.K.; Soundappan, T.; Singla, Y.K. Research Progress in Electroactive Polymers for Soft Robotics and Artificial Muscle Applications. Polymers 2025, 17, 746. https://doi.org/10.3390/polym17060746

Dewang Y, Sharma V, Baliyan VK, Soundappan T, Singla YK. Research Progress in Electroactive Polymers for Soft Robotics and Artificial Muscle Applications. Polymers. 2025; 17(6):746. https://doi.org/10.3390/polym17060746

Chicago/Turabian StyleDewang, Yogesh, Vipin Sharma, Vijay Kumar Baliyan, Thiagarajan Soundappan, and Yogesh Kumar Singla. 2025. "Research Progress in Electroactive Polymers for Soft Robotics and Artificial Muscle Applications" Polymers 17, no. 6: 746. https://doi.org/10.3390/polym17060746

APA StyleDewang, Y., Sharma, V., Baliyan, V. K., Soundappan, T., & Singla, Y. K. (2025). Research Progress in Electroactive Polymers for Soft Robotics and Artificial Muscle Applications. Polymers, 17(6), 746. https://doi.org/10.3390/polym17060746