Evaluation of Selected Fire Properties of Recycled Particleboards

Abstract

:1. Introduction

2. Materials and Methods

2.1. Particleboard Variants

2.2. Method of Determination of Density of Particleboards

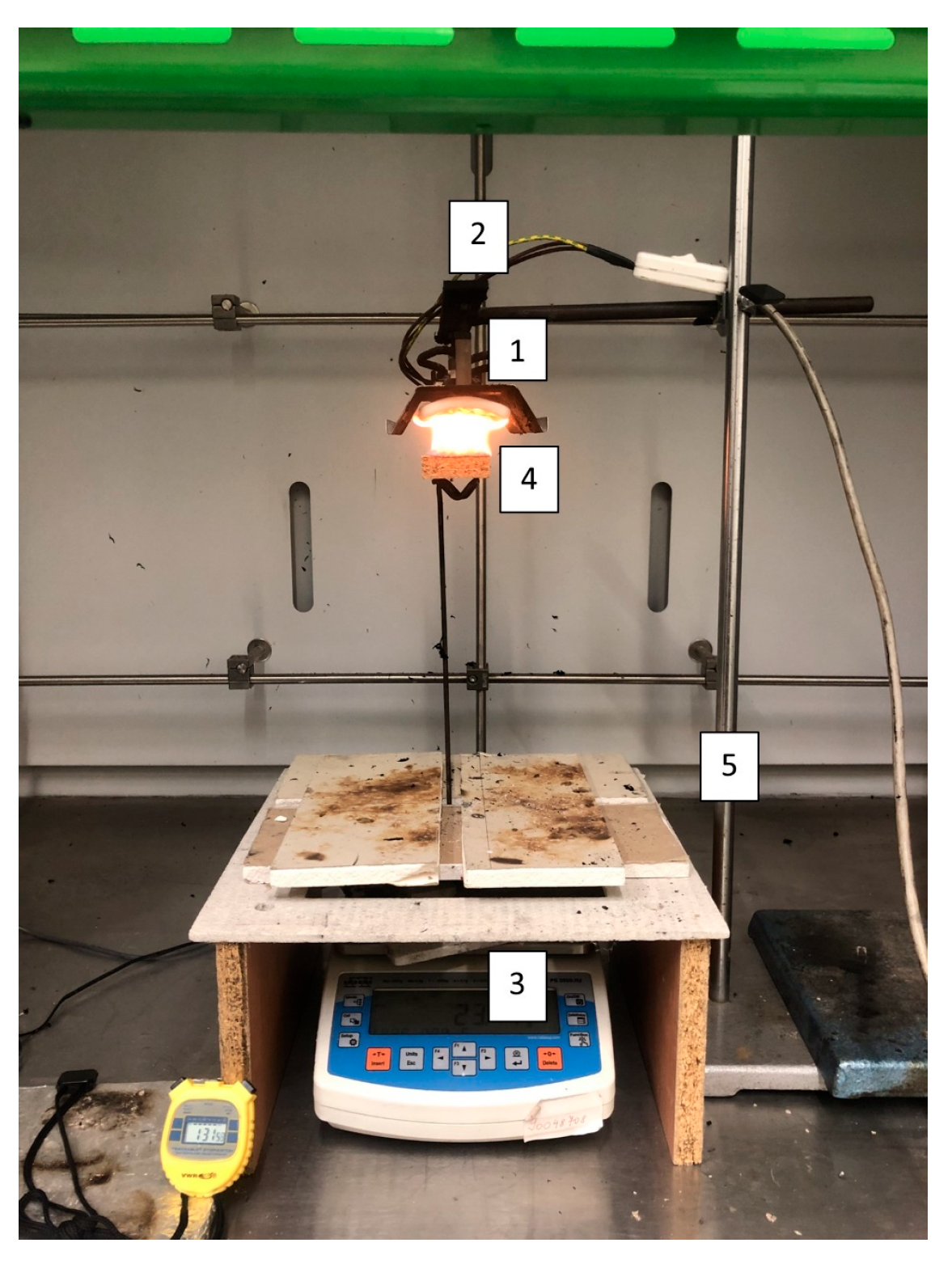

2.3. Methods of Determination of Fire Properties

- Ignition time (the time required for the test specimen to ignite);

- Burning rate—over time and maximum value (the rate at which the material combusts under thermal load);

- Mass loss—over time and at the end of test (the reduction in the sample’s mass during thermal exposure).

2.4. Statistical Evaluation

3. Results and Discussion

3.1. Density of Particleboards

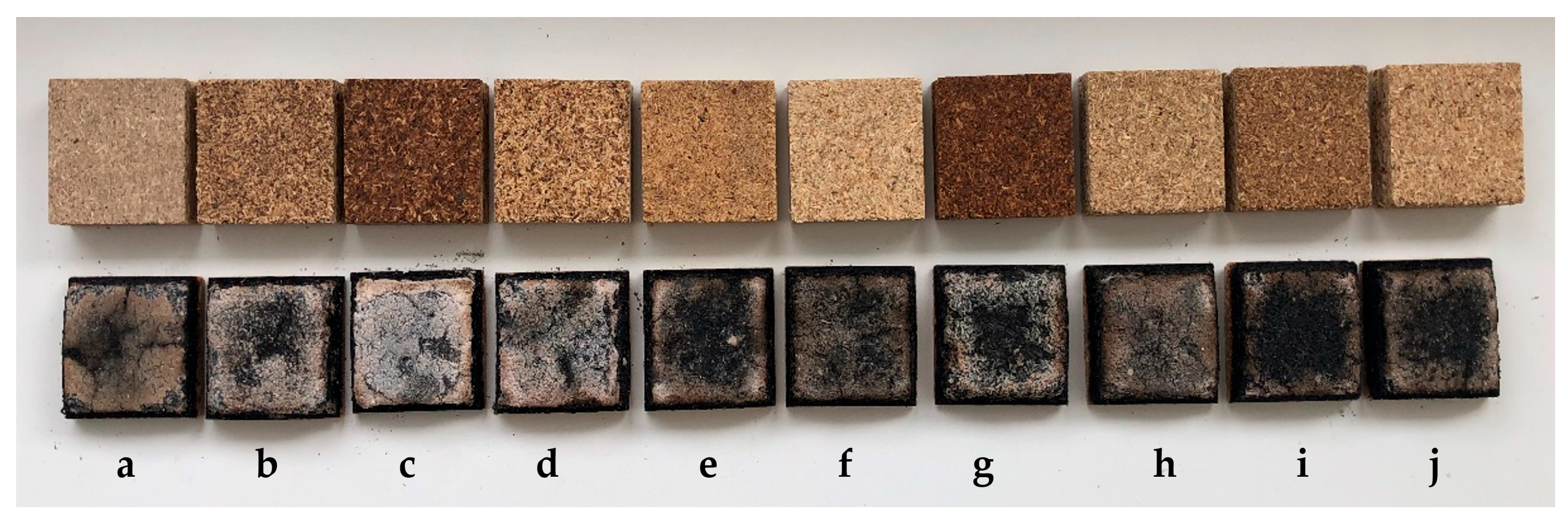

3.2. Evaluation of Fire Properties of Particleboards Under Radiant Heat

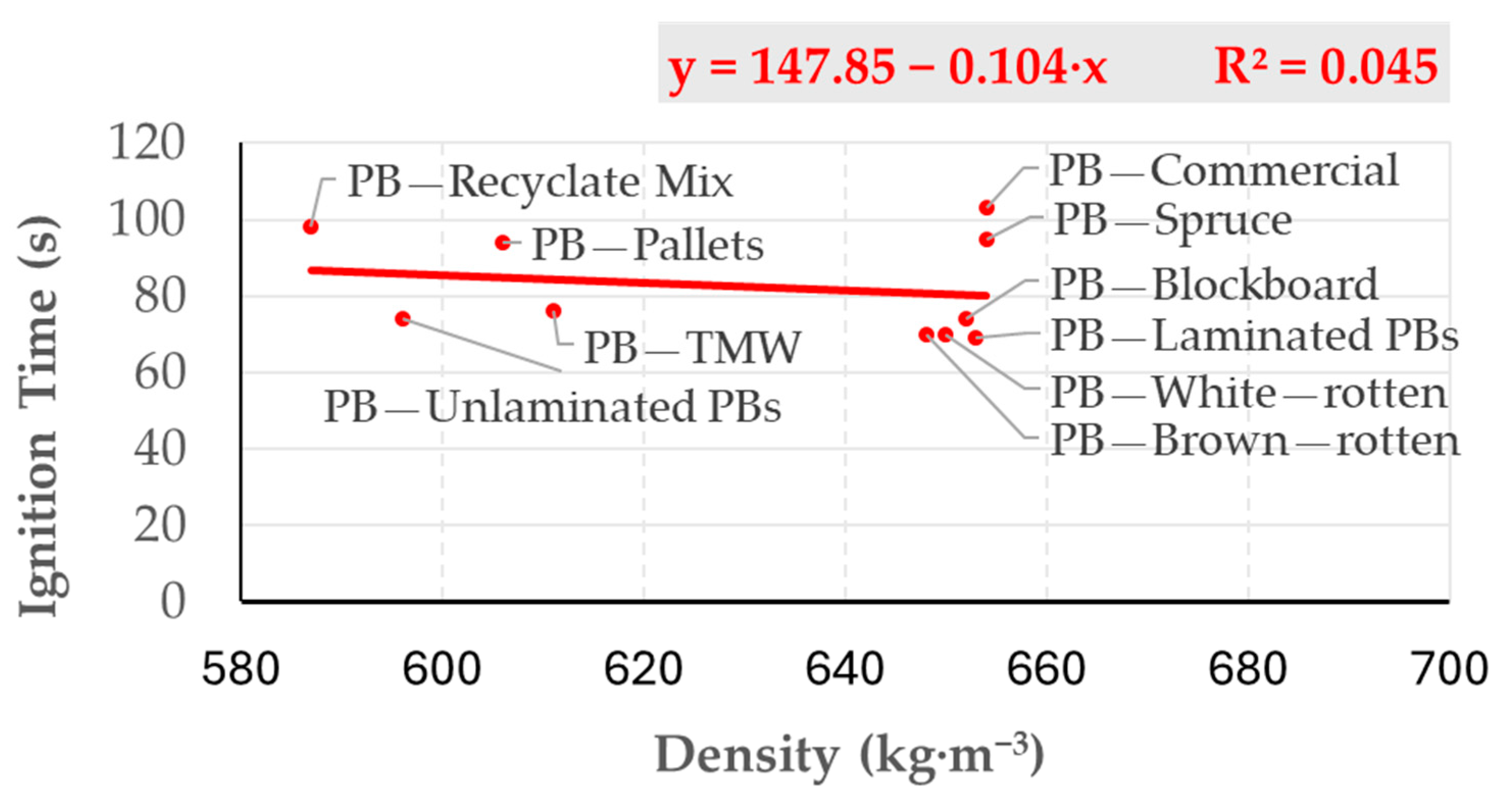

3.2.1. Influence of Density on the Ignition Time

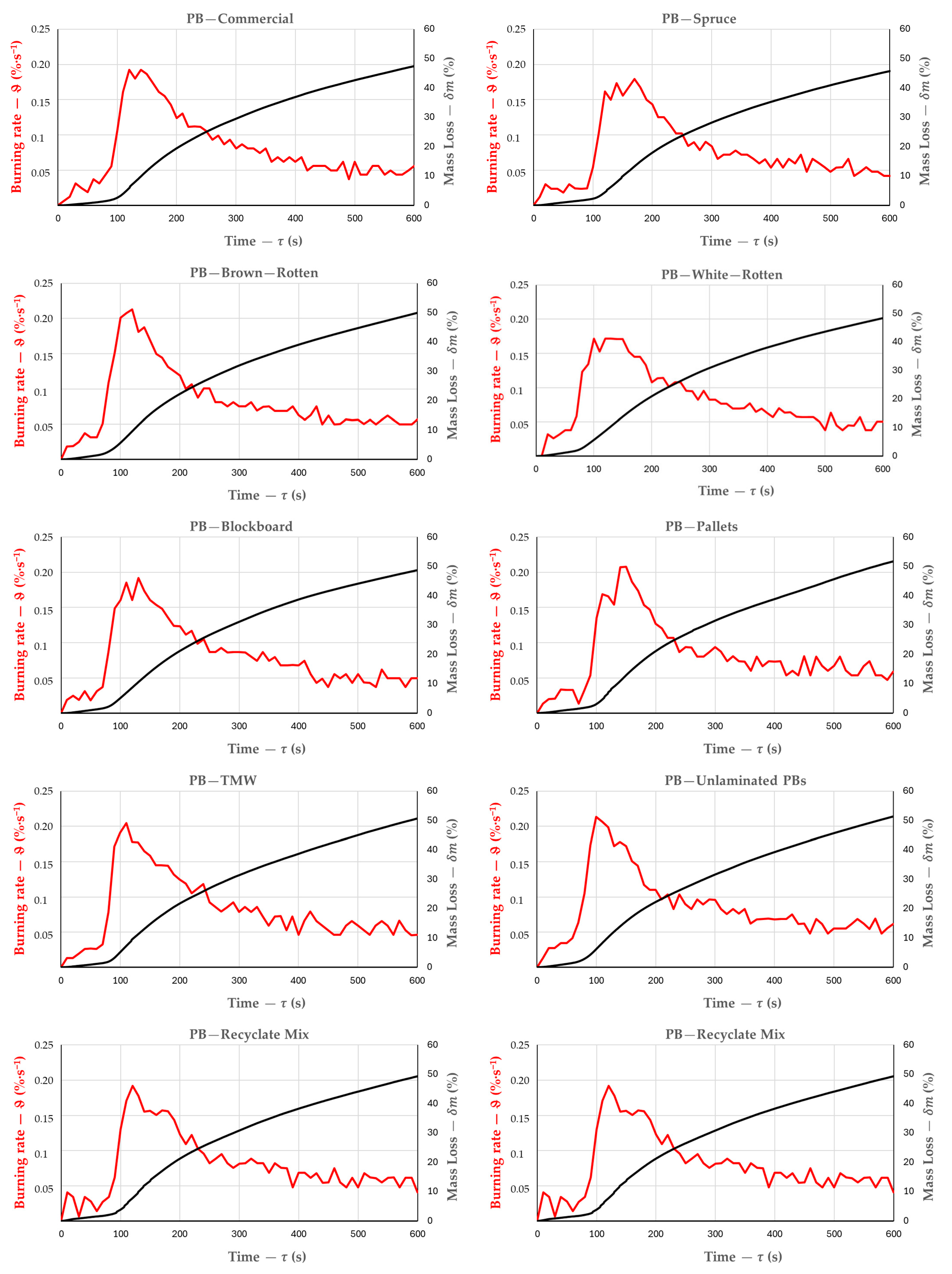

3.2.2. Influence of the Density and Material Type on the Burning Rate

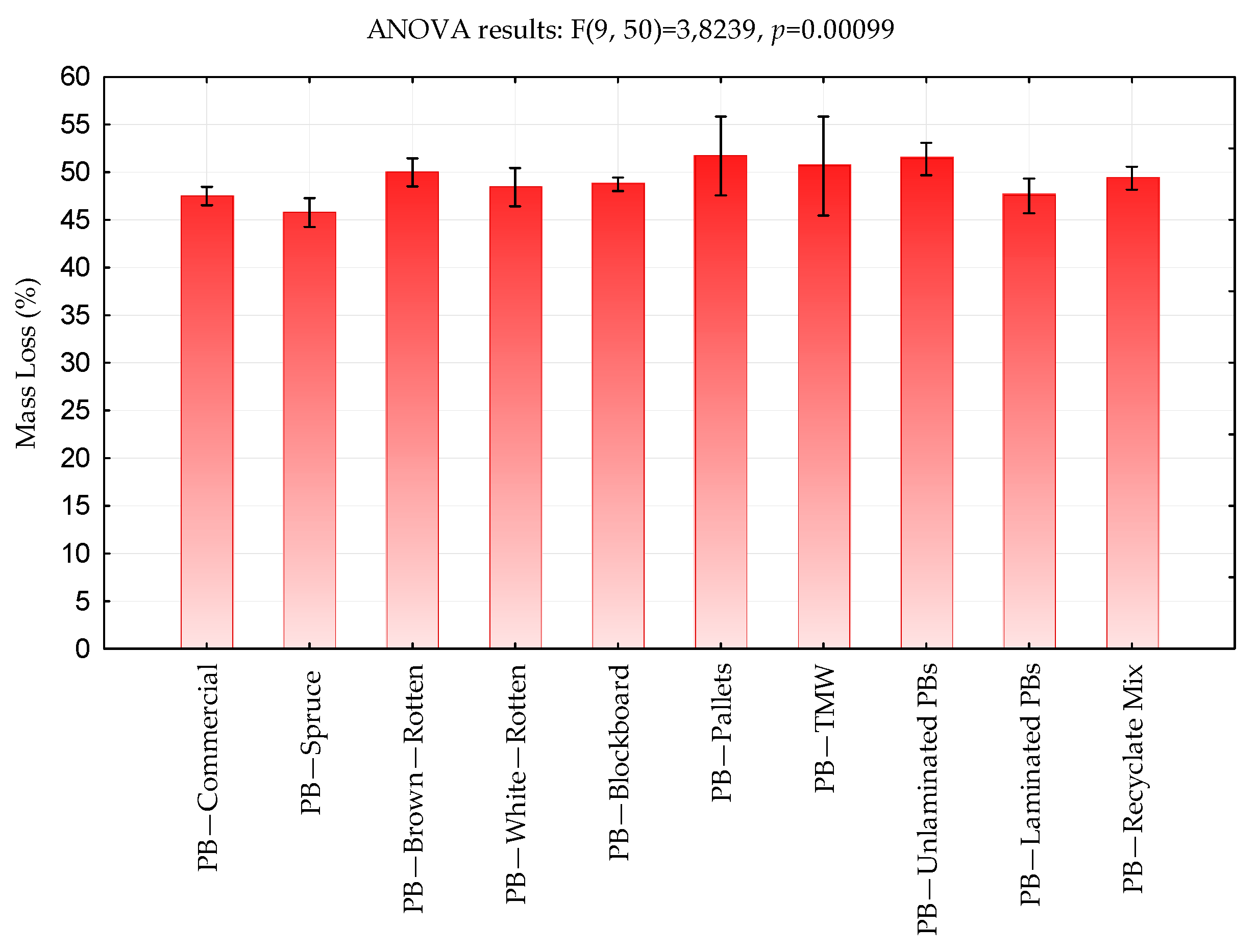

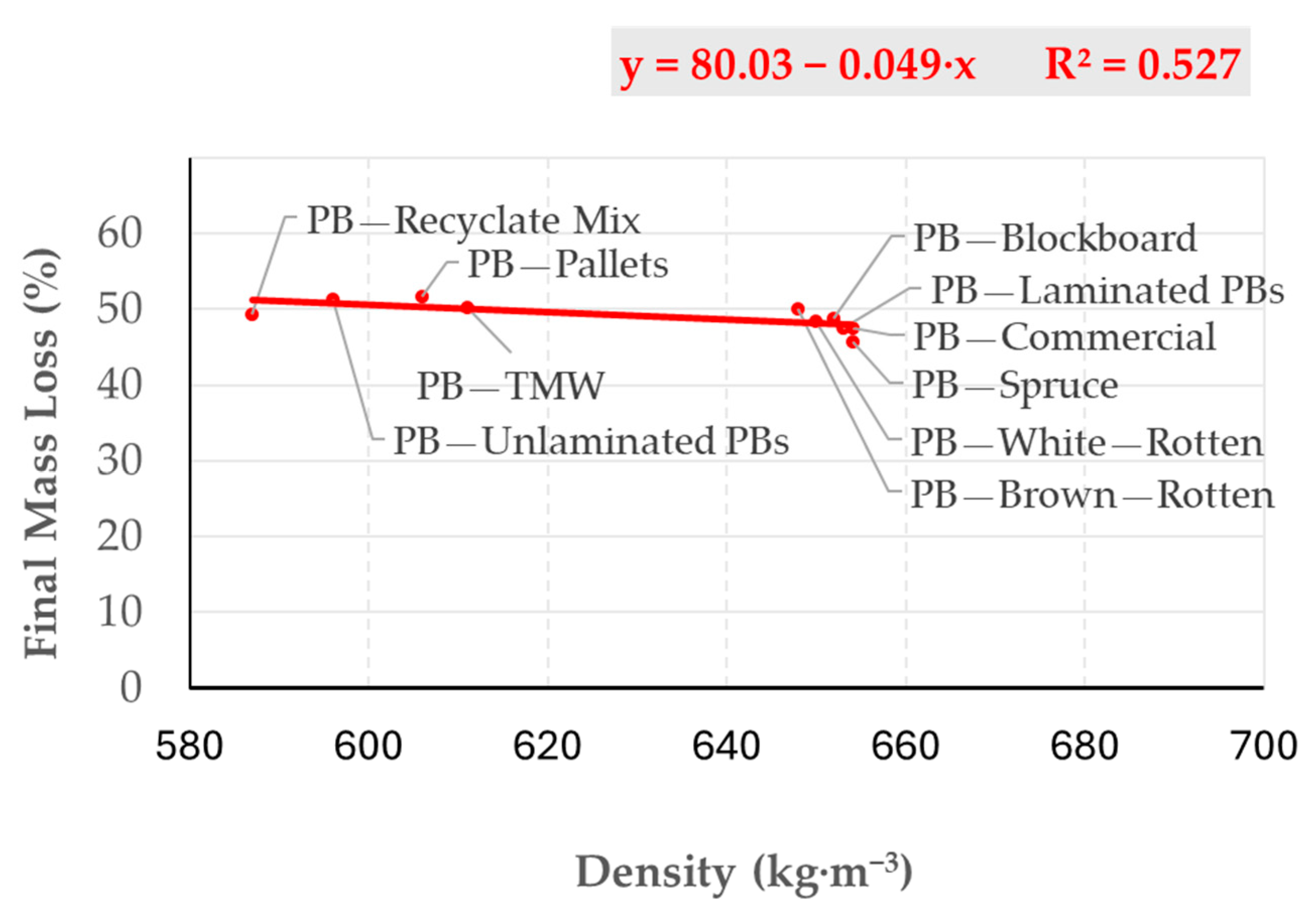

3.2.3. Influence of Particleboard Type on the Final Mass Loss

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Krug, D.; Direske, M.; Tobisch, S.; Weber, A.; Wenderdel, C. Particle-Based Materials. In Springer Handbook of Wood Science and Technology; Niemz, P., Teischinger, A., Sandberg, D., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 1409–1490. [Google Scholar]

- Amarasinghe, I.T.; Qian, Y.; Gunawardena, T.; Mendis, P.; Belleville, B. Composite panels from wood waste: A detailed review of processes, standards, and applications. J. Compos. Sci. 2024, 8, 417. [Google Scholar] [CrossRef]

- Tureková, I.; Ivanovičová, M.; Harangózo, J.; Gašpercová, S.; Marková, I. Experimental Study of the Influence of Selected Factors on the Particle Board Ignition by Radiant Heat Flux. Polymers 2022, 14, 1648. [Google Scholar] [CrossRef] [PubMed]

- Food and Agriculture Organization of the United Nations, FAO Stats. Available online: https://www.fao.org/faostat/en/#data/FO (accessed on 7 February 2025).

- Kawalerczyk, J.; Kuliński, M.; Majlingová, A.; Dukarska, D.; Mirski, R. The effect of wood particles polyesterification with sorbitol and citric acid on the properties of particleboard produced with the use of PF/pMDI adhesive. Eur. J. Wood Prod. 2024, 82, 1725–1737. [Google Scholar] [CrossRef]

- Laskowska, A.; Mamiński, M. Properties of particleboard produced from post-industrial UF- and PF-bonded plywood. Eur. J. Wood Prod. 2018, 76, 427–435. [Google Scholar] [CrossRef]

- Irle, M.; Barbu, M.C. Wood-based panel technology. In Wood-Based Panels—An Introduction for Specialists, 1st ed.; Thoemen, H., Irle, M., Sernek, M., Eds.; Brunel University Press: London, UK, 2010; Volume 1, pp. 1–90. [Google Scholar]

- Yang, S.; Galih, N.M.; Kim, J.; Lee, H.; Kang, S. Physical and mechanical properties of particleboard mixed with waste ACQ-treated wood. J. Mater Cycles Waste Manag. 2024, 26, 410–420. [Google Scholar] [CrossRef]

- Besserer, A.; Troilo, S.; Girods, P.; Rogaume, Y.; Brosse, N. Cascading Recycling of Wood Waste: A Review. Polymers 2021, 13, 1752. [Google Scholar] [CrossRef]

- Vis, M.; Mantau, U.; Allen, B. (Eds.) Study on the Optimised Cascading Use of Wood; Publications Office: Brussels, Belgium, 2016. [Google Scholar]

- Grexa, O.; Lübke, H. Flammability parameters of wood tested on a cone calorimeter. Polym. Degrad. Stab. 2001, 74, 427–432. [Google Scholar] [CrossRef]

- Fojutowski, A.; Wroblewska, H.; Cichy, W. Investigation on the rate of combustibility, ignitibility and fire toxicity of wood and wood based materials. Ann. Warsaw Agric. Univ. Wood Technol. 2004, 55, 205–215. [Google Scholar]

- Lee, B.H.; Kim, H.S.; Kim, S.; Kim, H.J.; Lee, B.; Deng, Y.; Feng, Q.; Luo, J. Evaluating the flammability of wood-based panels and gypsum particleboard using a cone calorimeter. Konstr. Build. Mater. 2011, 25, 3044–3050. [Google Scholar] [CrossRef]

- Tudor, E.M.; Scheriau, C.; Barbu, M.C.; Réh, R.; Krišťák, Ľ.; Schnabel, T. Enhanced resistance to fire of the bark-based panels bonded with clay. Appl. Sci. 2020, 10, 5594. [Google Scholar] [CrossRef]

- Najahi, A.; Aguado, R.J.; Tarrés, Q.; Boufi, S.; Delgado-Aguilar, M. Harvesting value from agricultural waste: Dimensionally stable fiberboards and particleboards with enhanced mechanical performance and fire retardancy through the use of lignocellulosic nanofibers. Ind. Crop. Prod. 2023, 204, 117336. [Google Scholar] [CrossRef]

- Cintura, E.; Faria, P.; Molari, L.; Mazzocchetti, L.; Dalle Donne, M.; Giorgini, L.; Nunes, L. Bio-based boards made of hazelnut shell and A. donax for indoor applications-A solution with good performance in case of fire. J. Build. Eng. 2024, 95, 110274. [Google Scholar] [CrossRef]

- Popescu, C.M.; Pfriem, A. Treatments and modification to improve the reaction to fire of wood and wood based products. An overview. Fire Mater. 2020, 44, 100–111. [Google Scholar] [CrossRef]

- Ferrandez-Garcia, B.E.; Garcia-Ortuño, T.; Ferrandez-Villena, M.; Ferrandez-Garcia, M.T. Evaluation of the Properties and Reaction-to-Fire Performance of Binderless Particleboards Made from Canary Island Palm Trunks. Fire 2024, 7, 193. [Google Scholar] [CrossRef]

- Taghiyari, H.R.; Militz, H.; Antov, P.; Papadopoulos, A.N. Effects of Wollastonite on Fire Properties of Particleboard Made from Wood and Chicken Feather Fibers. Coatings 2021, 11, 518. [Google Scholar] [CrossRef]

- Selamat, M.E.; Hui, T.Y.; Hashim, R.; Sulaiman, O.; Kassim, M.H.M.; Stalin, N.J. Properties of Particleboard Made from Oil Palm Trunks Added Magnesium Oxide as Fire Retardant. J. Phys. Sci. 2018, 29, 59–75. [Google Scholar] [CrossRef]

- Lee, C.H.; Sapuan, S.M.; Hassan, M.R. A Review of the Flammability Factors of Kenaf and Allied Fibre Reinforced Polymer Composites. Adv. Mater. Sci. Eng. 2014, 2014, 514036. [Google Scholar] [CrossRef]

- Lazko, J.; Landercy, N.; Laoutid, F.; Dangreau, L.; Huguet, M.; Talon, O. Flame retardant treatments of insulating agro-materials from flax short fibres. Polym. Degrad. Stab. 2013, 98, 1043–1051. [Google Scholar] [CrossRef]

- Antoun, K.; Besserer, A.; El Hage, R.; Segovia, C.; Sonnier, R.; Brosse, N. Environmentally-Friendly, Binder-Free, Non-Flammable Particleboard with Enhanced Properties. Ind. Crops Prod. 2024, 222, 119578. [Google Scholar] [CrossRef]

- Ferrández-Garcia, C.C.; Garcia-Ortuño, T.; Ferrández-Garcia, M.T.; Ferrández-Villena, M.; Ferrández-García, C.E. Fire-resistance, Physical, and Mechanical Characterization of Binderless Rice Straw Particleboards. BioResources 2017, 12, 8539–8549. [Google Scholar] [CrossRef]

- Bhatnagar, S.K. Fire and rice husk particleboard. Fire Mater. 1994, 18, 51–55. [Google Scholar] [CrossRef]

- Suh, J.S.; Han, T.H.; Park, J.S.; Park, J.Y. Physical and mechanical properties and fire-endurance characteristics of recycled particleboards. J. Korea Furn. Soc. 2008, 19, 475–486. [Google Scholar]

- Harada, T.; Uesugi, S.; Masuda, H. Fire resistance of thick wood-based boards. J. Wood Sci. 2006, 52, 544–551. [Google Scholar] [CrossRef]

- Satinová, V.; Hlaváč, P.; Iždinský, J.; Reinprecht, L. Rot evaluation in spruce logs and rot reflection into dimensions of chips for particleboards. Acta Fac. Xylologiae Zvolen 2022, 64, 5–16. [Google Scholar]

- Iždinský, J.; Vidholdová, Z.; Reinprecht, L. Particleboards from recycled wood. Forests 2020, 11, 1166. [Google Scholar] [CrossRef]

- Iždinský, J.; Reinprecht, L.; Vidholdová, Z. Particleboards from recycled pallets. Forests 2021, 12, 1597. [Google Scholar] [CrossRef]

- Iždinský, J.; Vidholdová, Z.; Reinprecht, L. Particleboards from recycled thermally modified wood. Forests 2021, 12, 1462. [Google Scholar] [CrossRef]

- Satinová, V.; Jánošíková, S.; Langová, N.; Vidholdová, Z.; Iždinský, J. The effect of type of wood-based recyclate and low-quality timber in particleboard on mechanical properties of furniture joints. Acta Fac. Xylologiae Zvolen 2024, 66, 17–32. [Google Scholar]

- EN 323; Wood-Based Panels—Determination of Density. European Committee for Standardization: Brussels, Belgium, 1993.

- Park, J.S.; Lee, J.J. Ignition and heat release rate of wood-based materials in cone calorimeter tests. J. Korean Wood Sci. Technol. 2008, 36, 1–8. [Google Scholar]

- Mancel, V.; Čabalová, I.; Krilek, J.; Réh, R.; Zachar, M.; Jurczyková, T. Fire resistance evaluation of new wooden composites containing waste rubber from automobiles. Polymers 2022, 14, 4465. [Google Scholar] [CrossRef]

- Marková, I.; Ivaničová, M.; Osvaldová, L.M.; Harangózo, J.; Tureková, I. Ignition of Wood-Based Boards by Radiant Heat. Forests 2022, 13, 738. [Google Scholar] [CrossRef]

- Martinka, J.; Hroncová, E.; Chrebet, T.; Balog, K. The influence of spruce wood heat treatment on its thermal stability and burning process. Eur. J. Wood Wood Prod. 2014, 72, 477–486. [Google Scholar] [CrossRef]

- Lin, H.C.; Ohuchi, T.; Murase, Y. Estimating thermal behavior and analyzing evolved species of adhesives through thermogravimetric analysis combined with spectrometric techniques. J. Fac. Agric. Kyushu Univ. 2004, 49, 449–459. [Google Scholar] [CrossRef] [PubMed]

- Quintiere, J.G. A Semi-Quantitative Model for the Burning Rate of Solid Materials; National Institute of Standards and Technology, Building and Fire Research Laboratory: Gaithersburg, MD, USA, 1992; pp. 1–48. [Google Scholar]

- Mitterová, I. The comparison of flame retardants efficiency applied on spruce and particle samples exposed to the radiant and flame source. Delta 2011, 5, 34–39. [Google Scholar]

- Owodunni, A.; Hashim, R.; Taiwo, O.; Hussin, M.; Kassim, M.; Bustami, Y.; Sulaiman, O.; Amini, M.; Hiziroglu, S. Flame-retardant Properties of Particleboard Made from Coconut Fibre Using Modified Potato Starch as a Binder. J. Phys. Sci. 2020, 31, 129–143. [Google Scholar] [CrossRef]

- Singh, J. Nature and extent of deterioration in buildings due to fungi. Build. Mycol. 2006, 30–52. [Google Scholar]

| Type of PBs | Density | Ignition Time | Mass Loss | Maximum Burning Rate | ||||

|---|---|---|---|---|---|---|---|---|

| SD | SD | SD | Time | Burning Rate | ||||

| PB—Commercial | 654 | 9 | 95 | 7.17 | 47.48 | 0.91 | 140 | 0.192 |

| PB—Sound Spruce Wood | 654 | 22 | 103 | 4.89 | 45.76 | 1.63 | 180 | 0.180 |

| PB—Wood Degraded by Brown Rot | 648 | 29 | 70 | 6.05 | 50.00 | 1.41 | 120 | 0.213 |

| PB—Wood Degraded by White Rot | 650 | 35 | 70 | 7.17 | 48.44 | 1.91 | 130 | 0.172 |

| PB—Blockboard | 652 | 25 | 74 | 5.85 | 48.74 | 0.67 | 130 | 0.192 |

| PB—Aged Spruce Pallets | 606 | 17 | 94 | 6.11 | 51.71 | 3.95 | 150 | 0.208 |

| PB—Thermally Modified Wood | 611 | 13 | 76 | 4.68 | 50.26 | 5.24 | 110 | 0.205 |

| PB—Unlaminated PBs | 596 | 30 | 74 | 9.32 | 51.39 | 1.62 | 100 | 0.214 |

| PB—Laminated PBs | 653 | 29 | 69 | 4.55 | 47.52 | 1.74 | 90 | 0.182 |

| PB—Mixture of Recycled Wood Materials | 587 | 22 | 98 | 3.14 | 49.38 | 1.15 | 120 | 0.192 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vidholdová, Z.; Zachar, M.; Iždinský, J.; Satinová, V. Evaluation of Selected Fire Properties of Recycled Particleboards. Polymers 2025, 17, 805. https://doi.org/10.3390/polym17060805

Vidholdová Z, Zachar M, Iždinský J, Satinová V. Evaluation of Selected Fire Properties of Recycled Particleboards. Polymers. 2025; 17(6):805. https://doi.org/10.3390/polym17060805

Chicago/Turabian StyleVidholdová, Zuzana, Martin Zachar, Ján Iždinský, and Viktória Satinová. 2025. "Evaluation of Selected Fire Properties of Recycled Particleboards" Polymers 17, no. 6: 805. https://doi.org/10.3390/polym17060805

APA StyleVidholdová, Z., Zachar, M., Iždinský, J., & Satinová, V. (2025). Evaluation of Selected Fire Properties of Recycled Particleboards. Polymers, 17(6), 805. https://doi.org/10.3390/polym17060805