UV-Assisted Material Extrusion Additive Manufacturing of Double-Base Propellant

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Preparation

2.2. Preparation of UV-Curable Paste

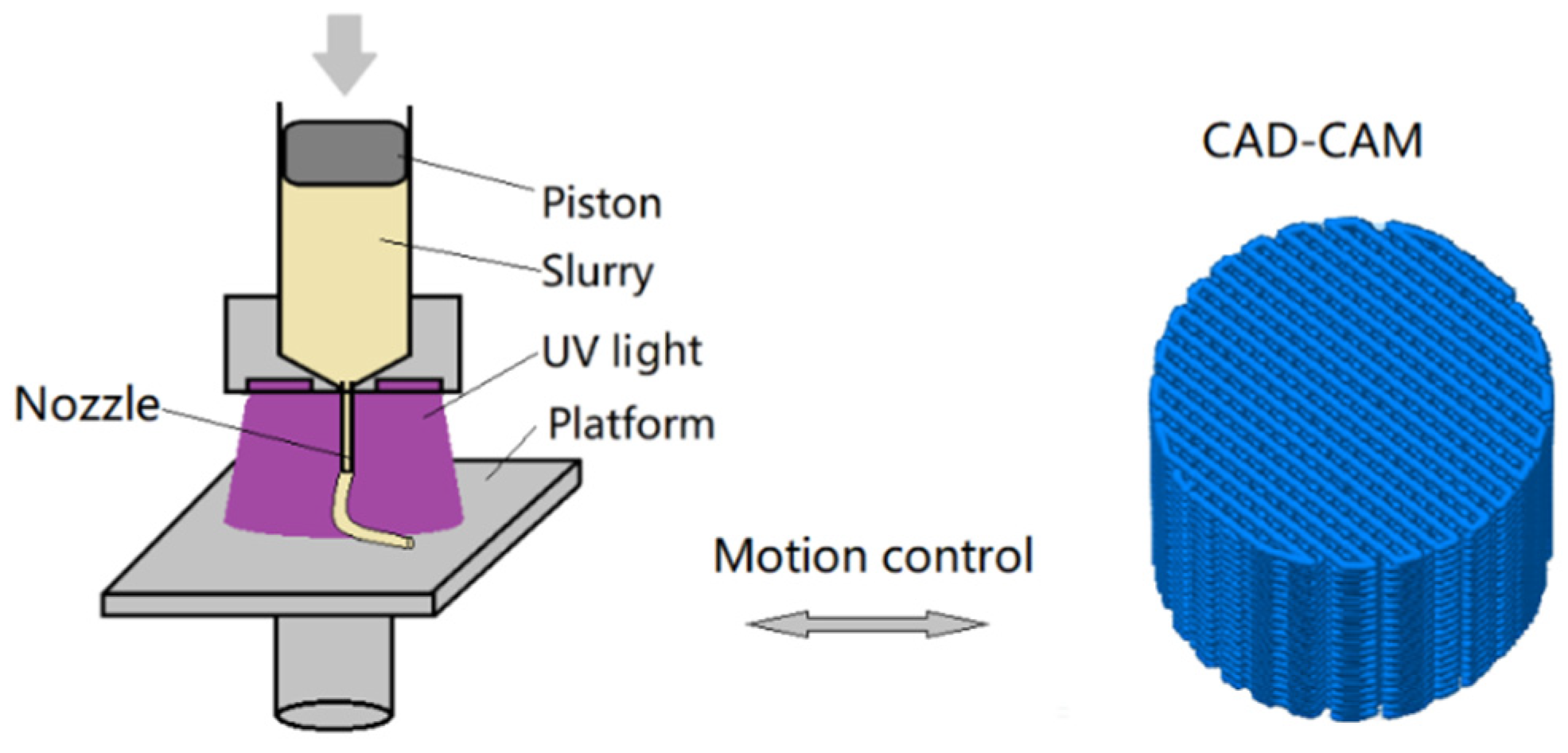

2.3. UV-Assisted DIW Printing Process

2.4. Characterization

3. Results and Discussion

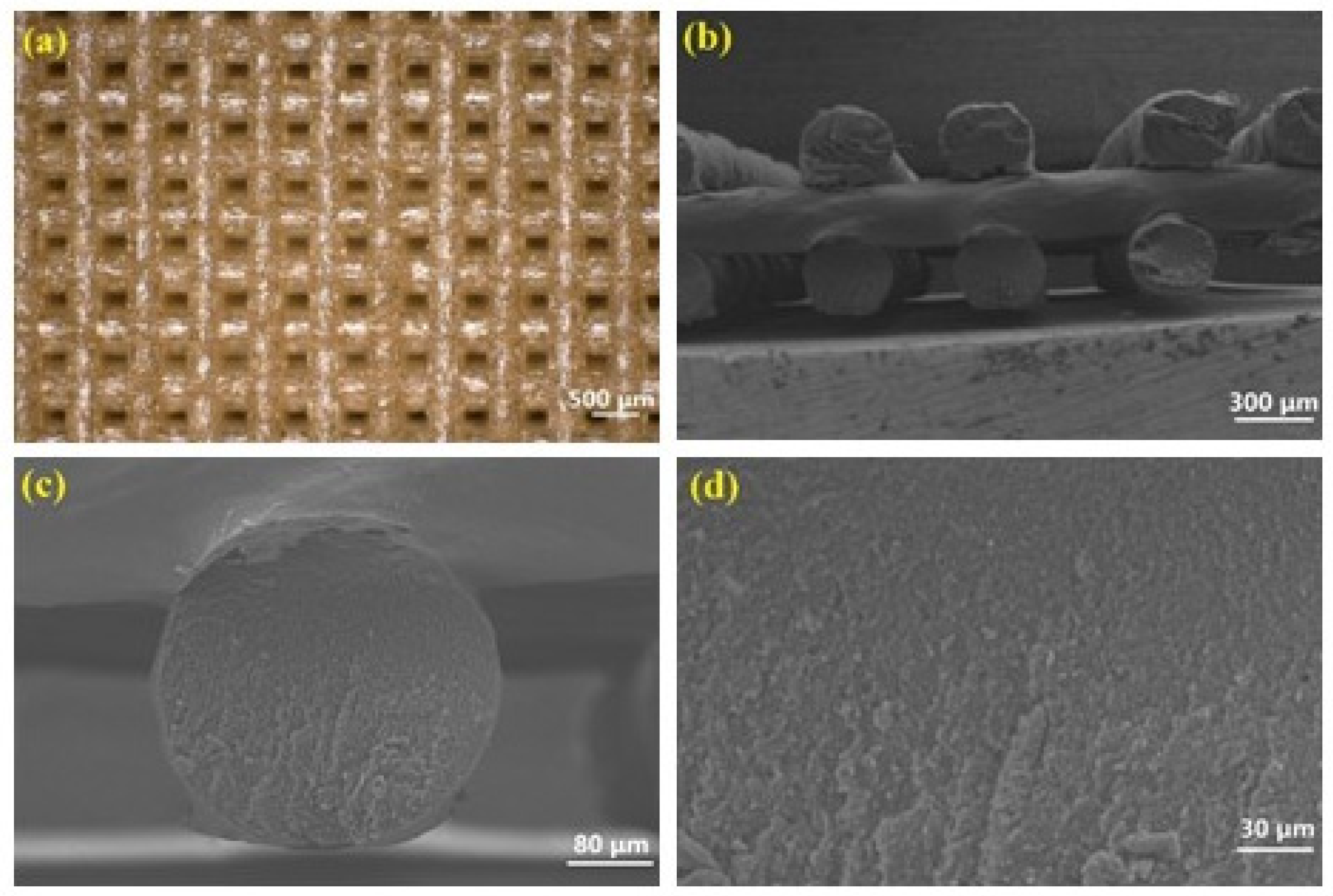

3.1. Printability and Material Characteristics

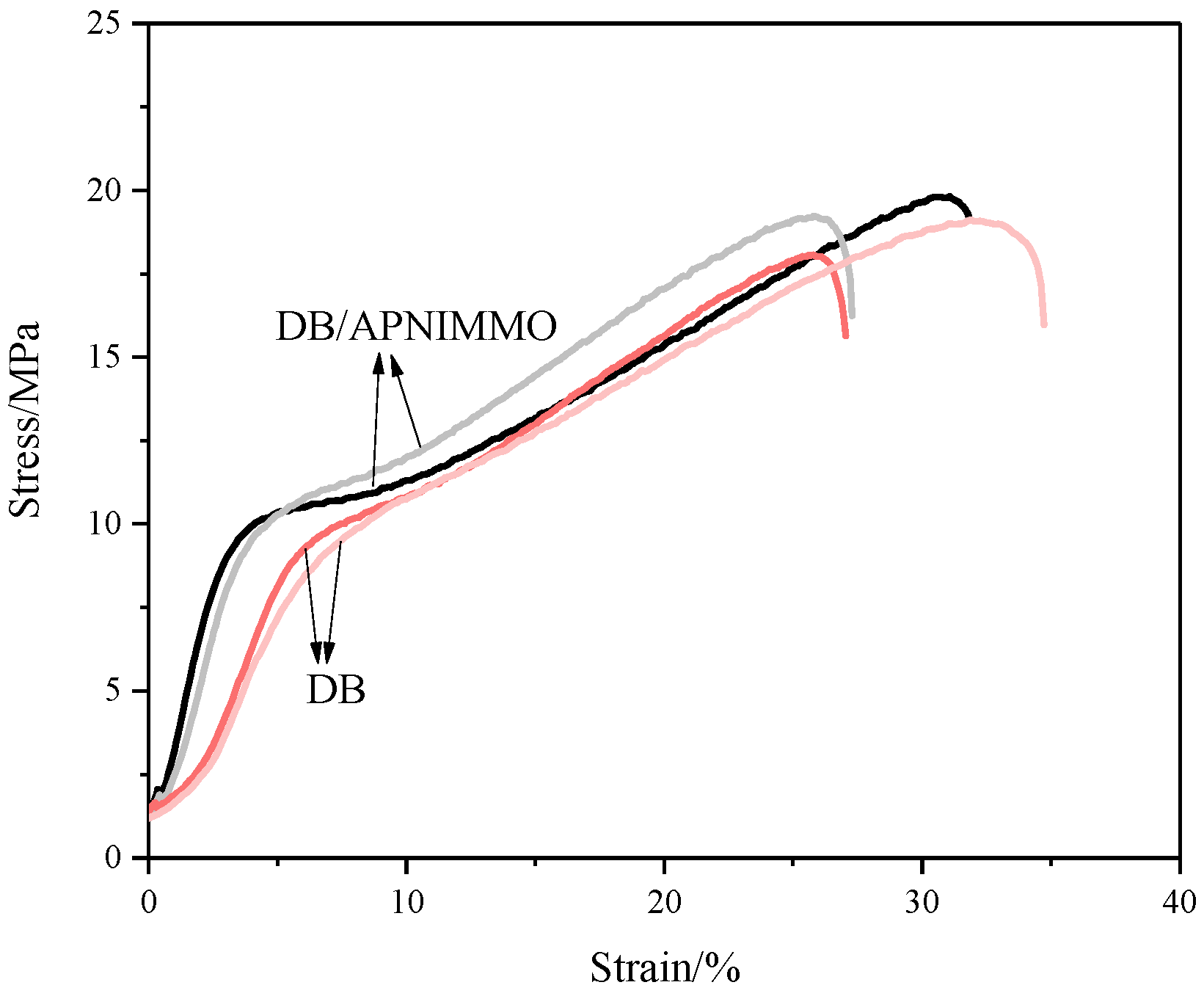

3.2. Mechanical Strength

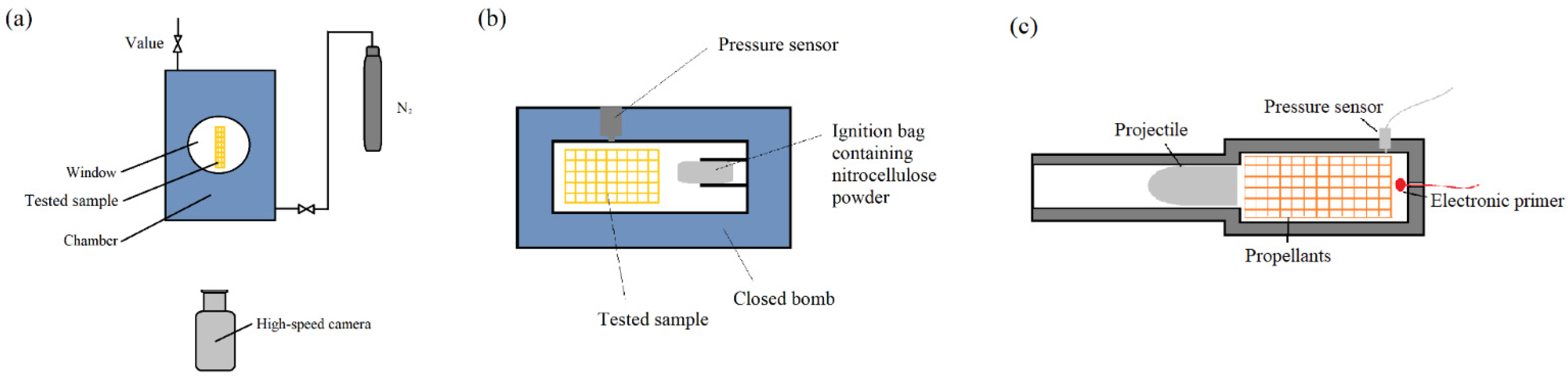

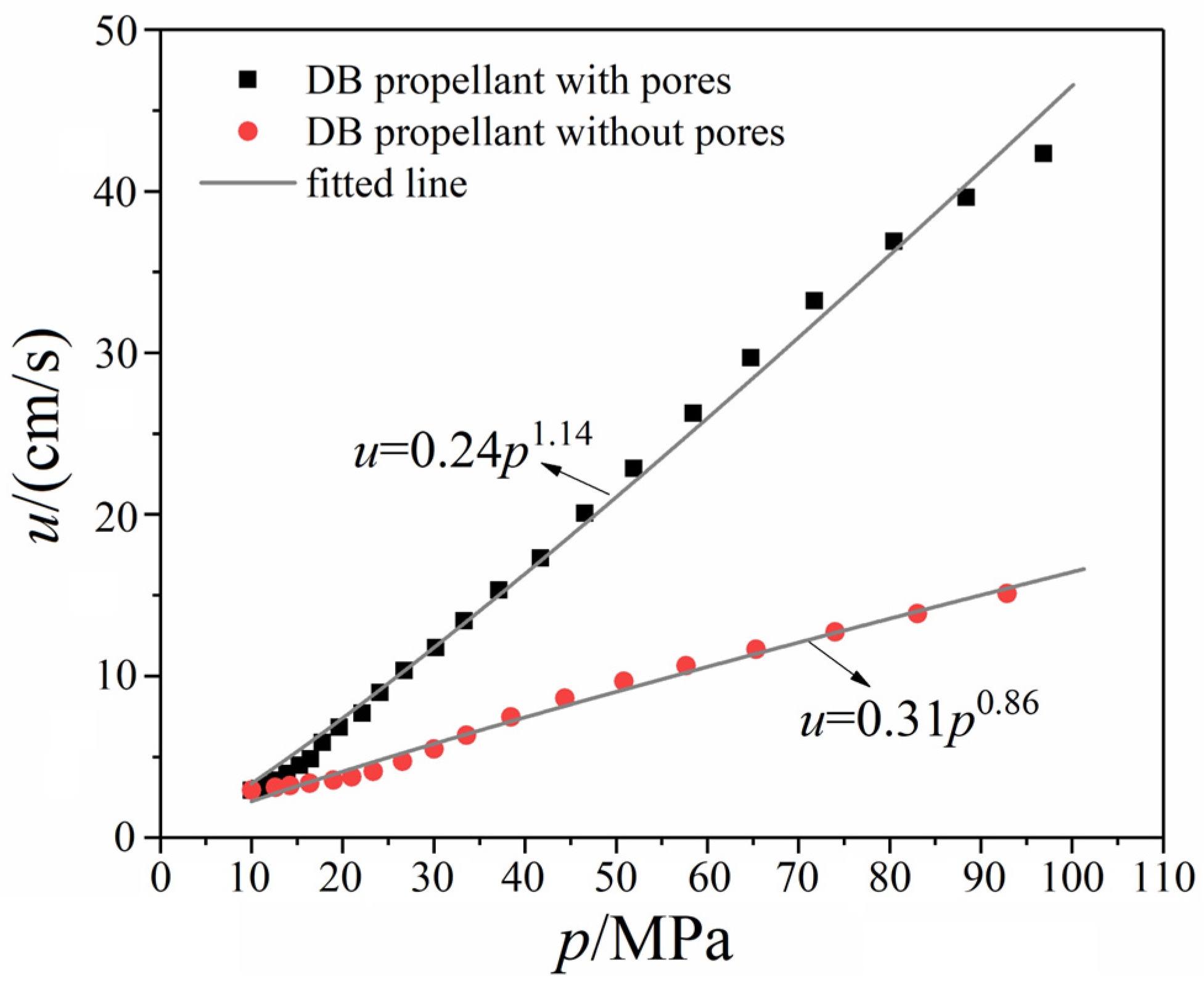

3.3. Combustion Performance

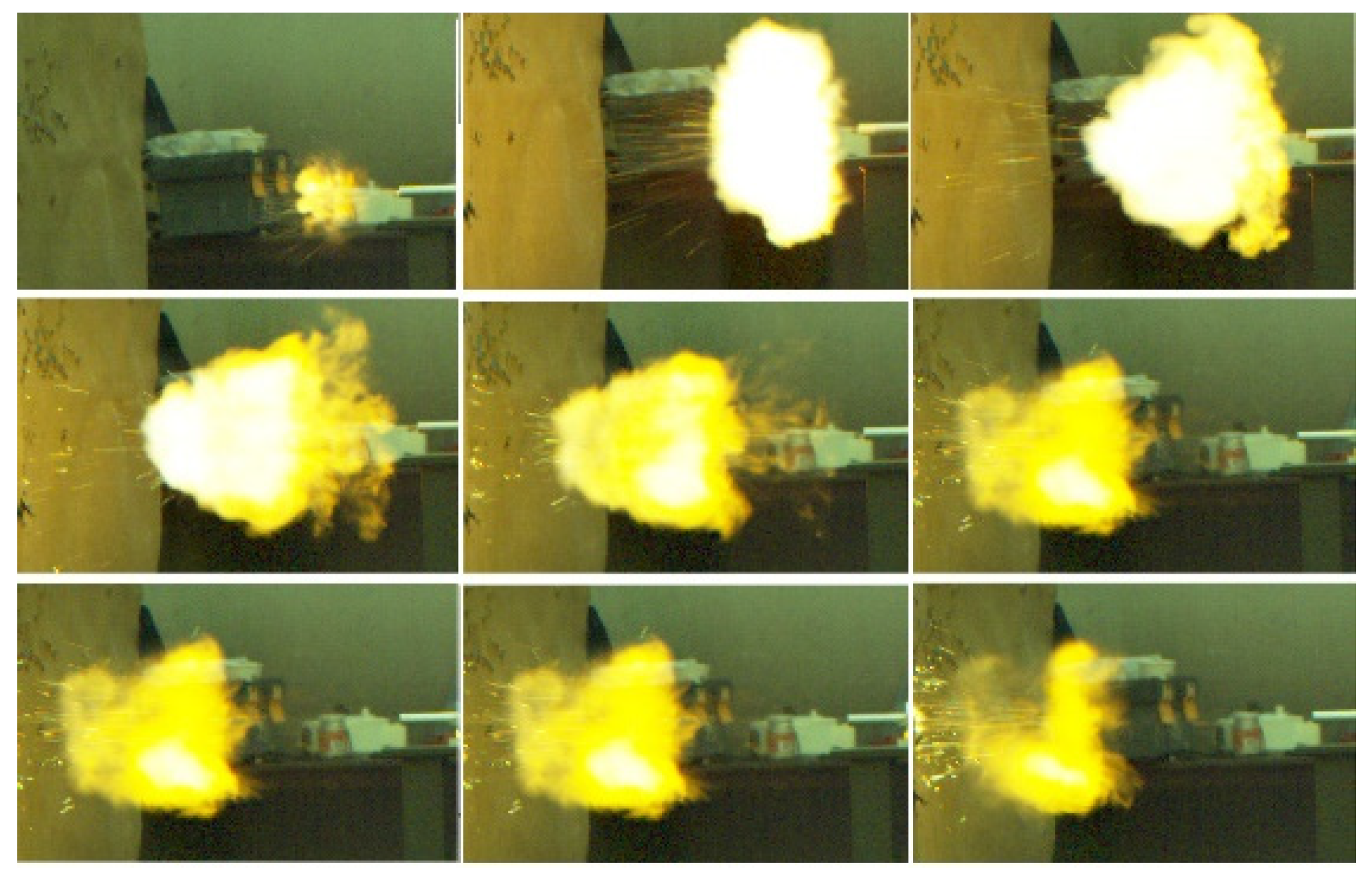

3.4. Interior Ballistic Performance Demonstration

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Böhnlein-Mauß, J.; Eberhardt, A.; Fischer, T.S. Foamed Propellants. Propellants Explos. Pyrotech. 2002, 27, 156–160. [Google Scholar] [CrossRef]

- McClain, M.S.; Gunduz, I.E.; Son, S.F. Additive manufacturing of ammonium perchlorate composite propellant with high solids loadings. Proc. Combust. Inst. 2019, 37, 3135–3142. [Google Scholar] [CrossRef]

- Wang, D.; Guo, C.; Wang, R.; Zheng, B.; Gao, B.; Nie, F. Additive manufacturing and combustion performance of CL-20 composites. J. Mater. Sci. 2020, 55, 2836–2845. [Google Scholar] [CrossRef]

- Bird, D.T.; Ravindra, N.M. A review: Advances and modernization in U.S army gun propellants. JOM 2021, 73, 1144–1164. [Google Scholar] [CrossRef]

- Xiao, L.; Wang, Q.; Li, W.; Liu, Q.; Hao, G.; Gao, X.; Ke, X.; Liu, J.; Jiang, W.; Qiao, Y.; et al. Preparation and performances of nano-HMX and TNT melt-cast explosives based on 3D printing technology. Acta Armamentarii 2018, 39, 1291–1298. [Google Scholar]

- Zhakeyev, A.; Wang, P.; Zhang, L.; Shu, W.; Wang, H.; Xuan, J. Additive manufacturing: Unlocking the evolution of energy materials. Adv. Sci. 2017, 4, 2198–3844. [Google Scholar] [CrossRef] [PubMed]

- Bencomo, J.A.; Iacono, S.T.; McCollum, J. 3D printing multifunctional fluorinated nanocomposites: Tuning electroactivity, rheology and chemical reactivity. J. Mater. Chem. A 2018, 6, 12308–12315. [Google Scholar] [CrossRef]

- Chandru, R.A.; Balasubramanian, N.; Oommen, C.; Raghunandan, B.N. Additive manufacturing of solid rocket. J. Propul. Power 2018, 34, 1090–1093. [Google Scholar] [CrossRef]

- Guo, H.; Xu, S.; Gao, H.H.; Geng, X.H.; An, C.W.; Xu, C.H.; Li, Q.B.; Wang, S.; Ye, B.Y.; Wang, J.Y. CL-20 based ultraviolet curing explosive composite with high performance. Propellants Explos. Pyrotech. 2019, 44, 935–940. [Google Scholar] [CrossRef]

- Ye, B.Y.; Song, C.K.; Huang, H.; Li, Q.B.; An, C.W.; Wang, J.Y. Direct ink writing of 3D-honeycombed CL-20 structures with low critical size. Def. Technol. 2020, 16, 588–595. [Google Scholar] [CrossRef]

- Straathof, M.H.; van Driel, C.A.; van Lingen, J.N.J.; Ingenhut, B.L.J.; Cate, A.T.T.; Maalderink, H.H. Development of propellant compositions for vat photopolymerization additive manufacturing. Propellants Explos. Pyrotech. 2020, 45, 36–52. [Google Scholar] [CrossRef]

- Rijnders, B. 3D Gradient Printing of Energetic Multi-Materials. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2019. [Google Scholar]

- Gao, Y.; Yang, W.; Hu, R.; Zhou, J.; Zhang, Y. Validation of CL-20-based propellant formulations for photopolymerization 3D printing. Propellants Explos. Pyrotech. 2021, 46, 1844–1848. [Google Scholar] [CrossRef]

- Li, M.; Yang, W.; Xu, M.; Hu, R.; Zheng, L. Study of photocurable energetic resin based propellants fabricated by 3D printing. Mater. Des. 2021, 207, 109891. [Google Scholar] [CrossRef]

- Zhou, M.; Nan, F.; He, W.; Wang, M. Design and preparation of propellant 3D printer based on extrusion deposition technology. Chin. J. Energetic Mater. (Hanneng Cailiao) 2021, 29, 530–534. [Google Scholar]

- Wang, M.; Zhou, Y.; Jin, G.; Yuan, J.; Lin, X.; Nan, F.; He, W. Extrusion 3D printing technology of double base gun propellants. Chin. J. Energetic Mater. (Hanneng Cailiao) 2022, 30, 897–902. [Google Scholar]

- Afriat, A. Combustion Characteristics of Additively Manufactured Gun Propellants. Master’s Thesis, Purdue University, West Lafayette, IN, USA, 2021. [Google Scholar]

- Xiao, Z.G.; Ying, S.J.; He, W.D.; Xu, F.M. A novel interior ballistic prediction of gun propellants based on experimental pressure-apparent burning rate model in closed vessel. Adv. Mater. Res. 2013, 668, 584–588. [Google Scholar] [CrossRef]

- Tucker, J. A Whole Life Assessment of Extruded Double Base Rocket Propellants. Ph.D. Thesis, School of Mechanical Engineering West Lafayette, West Lafayette, IN, USA, 2021. [Google Scholar]

- Steinberger, R. The Chemistry of Propellants; Pergamon Press: Oxford, UK, 1959. [Google Scholar]

- Hu, S.; Ju, Y.; Meng, H.; Zhou, C.S. Effects of strain rate on mechanical properties of DBP under uniaxial compression condition. J. Ballist. (Dandao Xuebao) 2011, 23, 75–79. [Google Scholar]

| Formula | f/(kJ/kg) | Qv/(kJ/kg) | Tv/K | Average Molecular Weight of Combustion Gas/(g/mol) |

|---|---|---|---|---|

| DB-APNIMMO | 973 | 2861 | 2334 | 20.41 |

| DB | 1134 | 3853 | 3060 | 22.43 |

| Filament Type | Initial Modulus/MPa | Yield Strength/MPa | Yield Strain/% | Breaking Strength/MPa | Elongation at Break/% |

|---|---|---|---|---|---|

| DB/APNIMMO | 310 | 8.75 | 3.41 | 19.8 | 30.7 |

| 280 | 9.21 | 3.75 | 19.2 | 25.9 | |

| DB | 170 | 9.26 | 6.02 | 18.1 | 25.7 |

| 160 | 8.40 | 6.93 | 19.1 | 33.1 |

| Propellant Mass/g | p/MPa | V/(cm/s) |

|---|---|---|

| 1.02 | 98 | 31,400 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Gao, Y.; Wang, Q.; Yang, W.; Gao, G.-L.; Jiang, Z. UV-Assisted Material Extrusion Additive Manufacturing of Double-Base Propellant. Polymers 2025, 17, 808. https://doi.org/10.3390/polym17060808

Li M, Gao Y, Wang Q, Yang W, Gao G-L, Jiang Z. UV-Assisted Material Extrusion Additive Manufacturing of Double-Base Propellant. Polymers. 2025; 17(6):808. https://doi.org/10.3390/polym17060808

Chicago/Turabian StyleLi, Manman, Yuchen Gao, Qionglin Wang, Weitao Yang, Guo-Lin Gao, and Zaixing Jiang. 2025. "UV-Assisted Material Extrusion Additive Manufacturing of Double-Base Propellant" Polymers 17, no. 6: 808. https://doi.org/10.3390/polym17060808

APA StyleLi, M., Gao, Y., Wang, Q., Yang, W., Gao, G.-L., & Jiang, Z. (2025). UV-Assisted Material Extrusion Additive Manufacturing of Double-Base Propellant. Polymers, 17(6), 808. https://doi.org/10.3390/polym17060808