ABS Nanocomposites for Advanced Technical and Biomedical Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

Preparation of ABS Nanocomposites and Test Samples

2.2. Methods

2.2.1. Uniaxial Tensile Testing

2.2.2. Charpy Pendulum Impact Testing

2.2.3. Displacement Transmissibility Measurements

2.2.4. Microhardness Testing

2.2.5. Shore D Hardness Measurements

2.2.6. Statistical Analysis

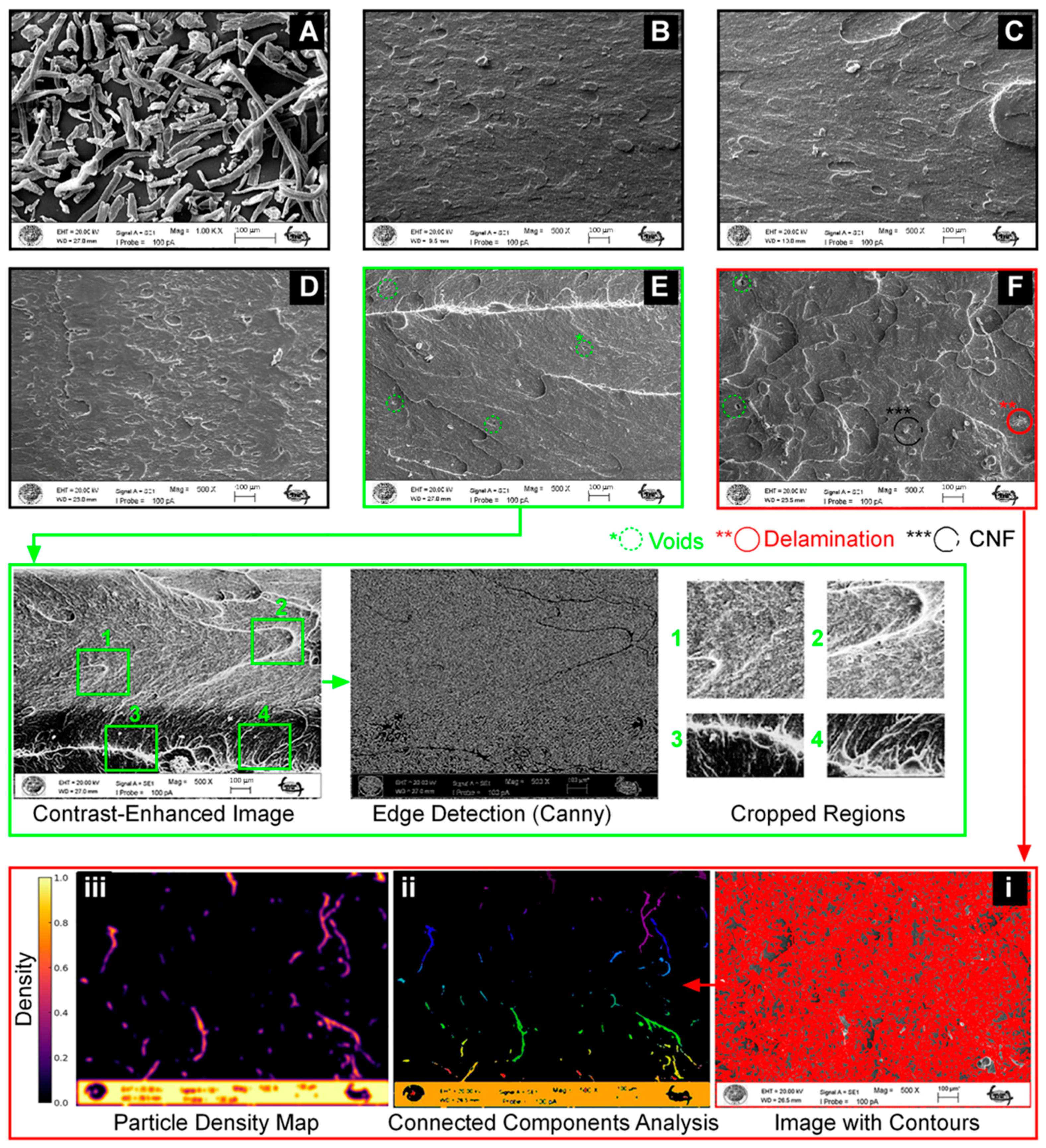

2.2.7. Particle Distribution and Agglomeration Analysis Based on SEM Images

3. Results and Discussion

3.1. Uniaxial Tensile Testing

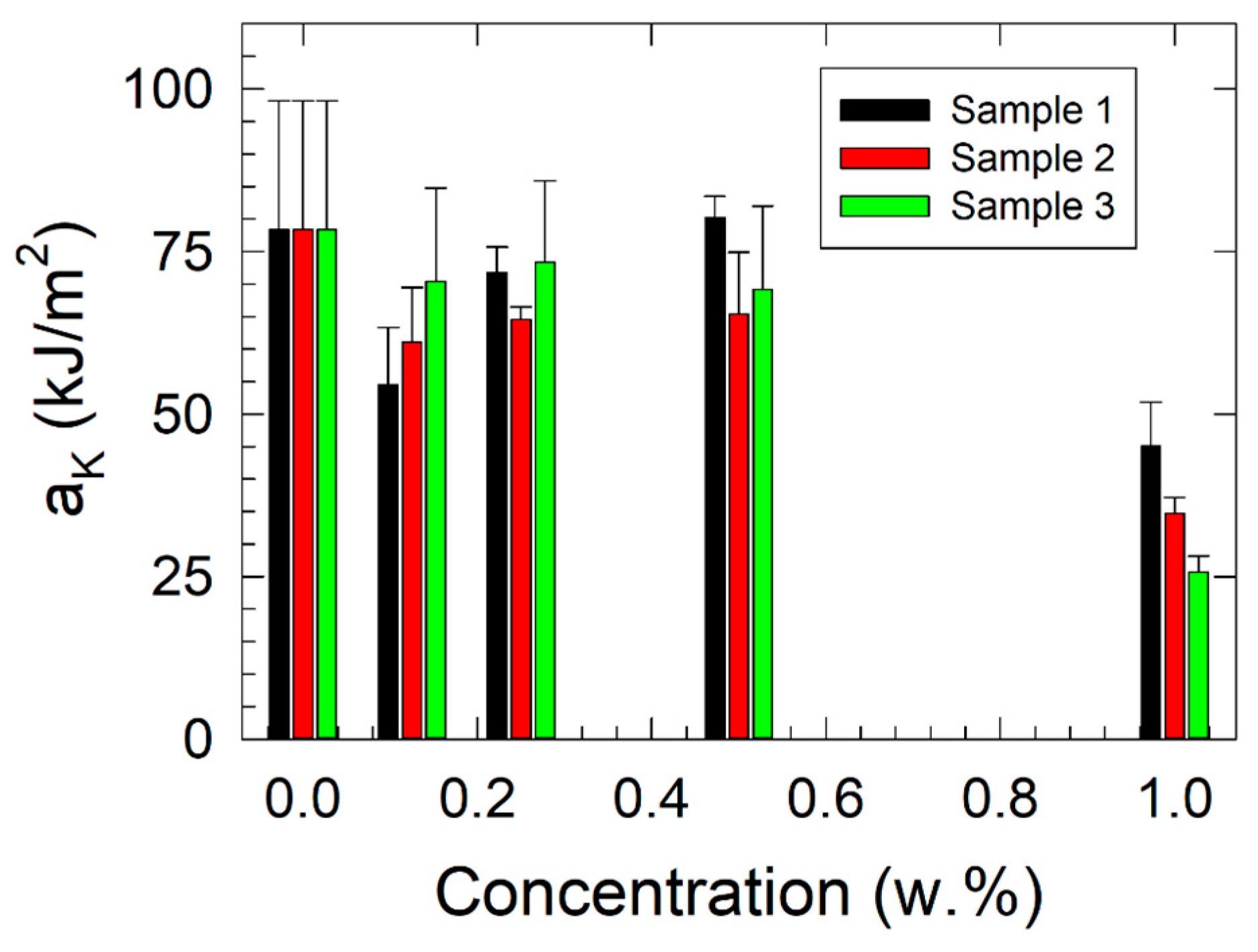

3.2. Fracture Toughness Measurements

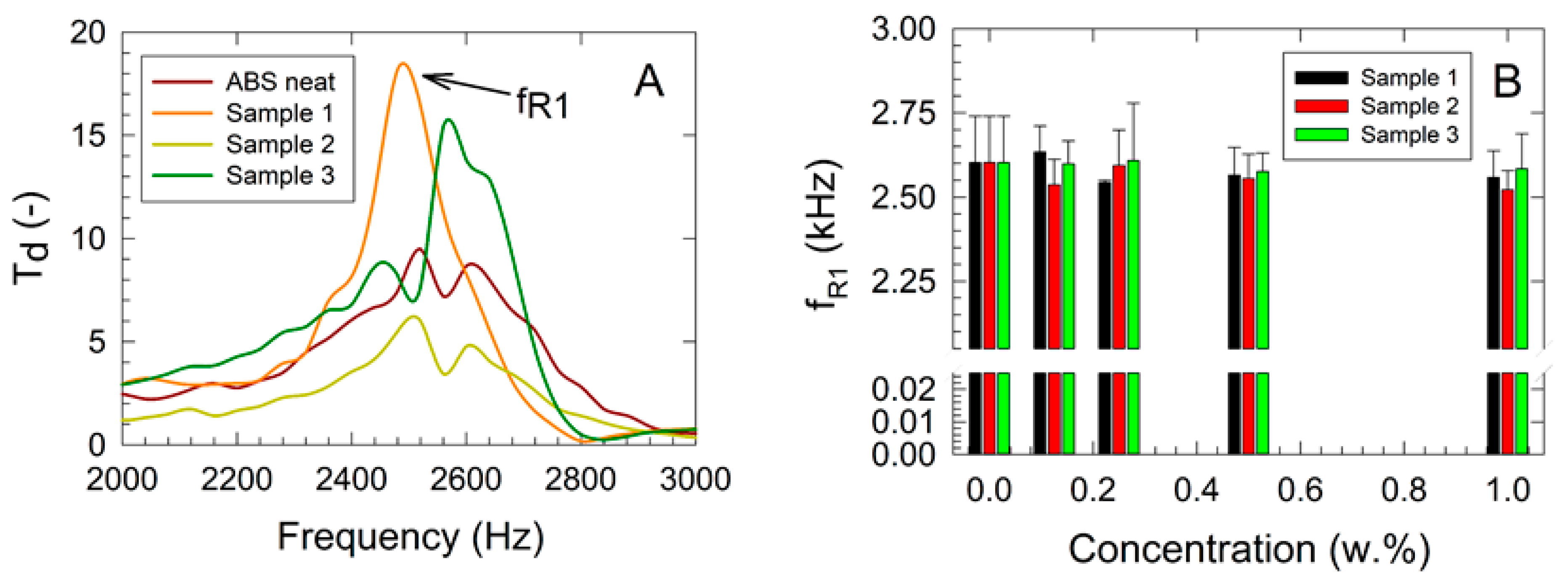

3.3. Vibration-Excited Dynamic Mechanical Testing

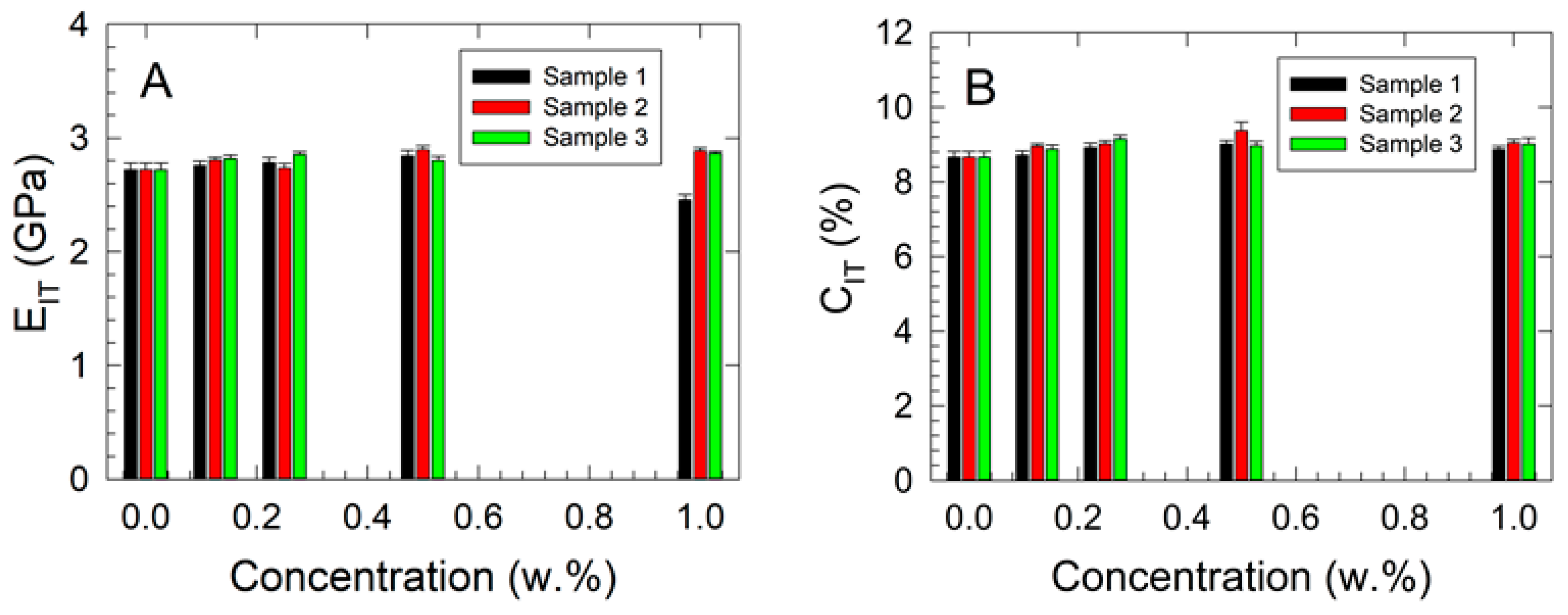

3.4. Microhardness and Shore D Hardness Testing

3.5. SEM Analysis of Particle Distribution and Agglomeration

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lapčík, L.; Ruszala, M.J.A.; Vašina, M.; Lapčíková, B.; Vlček, J.; Rowson, N.A.; Grover, L.M.; Greenwood, R.W. Hollow Spheres as Nanocomposite Fillers for Aerospace and Automotive Composite Materials Applications. Compos. Part B Eng. 2016, 106, 74–80. [Google Scholar] [CrossRef]

- Lapcik, L.; Vasina, M.; Lapcikova, B.; Hui, D.; Otyepkova, E.; Greenwood, R.W.; Waters, K.E.; Vlcek, J. Materials Characterization of Advanced Fillers for Composites Engineering Applications. Nanotechnol. Rev. 2019, 8, 503–512. [Google Scholar] [CrossRef]

- Lapcík, L.; Sepetcioglu, H.; Murtaja, Y.; Lapcíková, B.; Vasina, M.; Ovsík, M.; Stanek, M.; Gautam, S. Study of Mechanical Properties of Epoxy/Graphene and Epoxy/Halloysite Nanocomposites. Nanotechnol. Rev. 2023, 12, 20220520. [Google Scholar] [CrossRef]

- Donath, E.; Sukhorukov, G.B.; Caruso, F.; Davis, S.A.; Mohwald, H. Novel Hollow Polymer Shells by Colloid-Templated Assembly of Polyelectrolytes. Angew. Chem. Int. Ed. 1998, 37, 2202–2205. [Google Scholar] [CrossRef]

- Ras, R.H.A.; Kemell, M.; de Wit, J.; Ritala, M.; ten Brinke, G.; Leskela, M.; Ikkala, O. Hollow Inorganic Nanospheres and Nanotubes with Tunable Wall Thicknesses by Atomic Layer Deposition on Self-Assembled Polymeric Templates. Adv. Mater 2007, 19, 102–106. [Google Scholar] [CrossRef]

- Ruszala, M.; Rowson, N.A.; Grover, L.M.; Choudhery, R.A. Low Carbon Footprint TiO2 Substitutes in Paint: A Review. Int. J. Chem. Eng. Appl. 2015, 6, 331. [Google Scholar] [CrossRef]

- Qi, S.J.; Kiratzis, I.; Adoni, P.; Tuekprakhon, A.; Hill, H.J.; Stamataki, Z.; Nabi, A.; Waugh, D.; Rodriguez, J.R.; Clarke, S.M.; et al. Porous Cellulose Thin Films as Sustainable and Effective Antimicrobial Surface Coatings. ACS Appl. Mater. Interfaces 2023, 15, 20638–20648. [Google Scholar] [CrossRef]

- Cai, J.; Kimura, S.; Wada, M.; Kuga, S. Nanoporous Cellulose as Metal Nanoparticles Support. Biomacromolecules 2009, 10, 87–94. [Google Scholar] [CrossRef] [PubMed]

- Klemm, D.; Kramer, F.; Moritz, S.; Lindström, T.; Ankerfors, M.; Gray, D.; Dorris, A. Nanocelluloses: A New Family of Nature-Based Materials. Angew. Chem. Int. Ed. 2011, 50, 5438–5466. [Google Scholar] [CrossRef]

- Dufresne, A. Cellulose Nanomaterials as Green Nanoreinforcements for Polymer Nanocomposites. Philos. Trans. R. Soc. A-Math. Phys. Eng. Sci. 2018, 376, 20170040. [Google Scholar] [CrossRef]

- Dufresne, A. Nanocellulose: From Nature to High Performance Tailored Materials; Walter de Gruyter GmbH & Co. KG: Berlin, Germany, 2017. [Google Scholar]

- Bacakova, L.; Pajorova, J.; Bacakova, M.; Skogberg, A.; Kallio, P.; Kolarova, K.; Svorcik, V. Versatile Application of Nanocellulose: From Industry to Skin Tissue Engineering and Wound Healing. Nanomaterials 2019, 9, 164. [Google Scholar] [CrossRef]

- Spagnuolo, L.; D’Orsi, R.; Operamolla, A. Nanocellulose for Paper and Textile Coating: The Importance of Surface Chemistry. ChemPlusChem 2022, 87, e202200204. [Google Scholar] [CrossRef] [PubMed]

- Bishnoi, P.; Siwal, S.S.; Kumar, V.; Thakur, V.K. Cellulose-based Smart Materials: Novel Synthesis Techniques, Properties, and Applications in Energy Storage and Conversion Devices. Electron 2024, 2, e42. [Google Scholar]

- Shaghaleh, H.; Xu, X.; Wang, S.F. Current Progress in Production of Biopolymeric Materials Based on Cellulose, Cellulose Nanofibers, and Cellulose Derivatives. RSC Adv. 2018, 8, 825–842. [Google Scholar] [PubMed]

- Norizan, M.N.; Shazleen, S.S.; Alias, A.H.; Sabaruddin, F.A.; Asyraf, M.; Zainudin, E.S.; Abdullah, N.; Samsudin, M.S.; Kamarudin, S.H.; Norrrahim, M. Nanocellulose-Based Nanocomposites for Sustainable Applications: A Review. Nanomaterials 2022, 12, 3483. [Google Scholar] [CrossRef]

- Ma, L.B.; Zhang, Y.; Meng, Y.J.; Anusonti-Inthra, P.; Wang, S.Q. Preparing Cellulose Nanocrystal/Acrylonitrile-Butadiene-Styrene Nanocomposites using the Master-Batch Method. Carbohydr. Polym. 2015, 125, 352–359. [Google Scholar]

- de León, R.D.; Guzmán, E.; González, R.L.; Elizondo, A.D.; Magaña, I.; Neira, G.; Facio, A.C.; Valencia, L. Surface Modification of Cellulose Nanocrystals with Lactone Monomers Via Plasma-Induced Polymerization and their Application in ABS Nanocomposites. Polymers 2021, 13, 2699. [Google Scholar] [CrossRef]

- Feng, X.H.; Yang, Z.Z.; Rostom, S.; Dadmun, M.; Wang, S.Q.; Wang, Q.W.; Xie, Y.J. Reinforcing 3D Printed Acrylonitrile Butadiene Styrene by Impregnation of Methacrylate Resin and Cellulose Nanocrystal Mixture: Structural Effects and Homogeneous Properties. Mater. Des. 2018, 138, 62–70. [Google Scholar] [CrossRef]

- Kulich, D.M.; Gaggar, S.K.; Lowry, V.; Stepien, R. Acrylonitrile–butadiene–styrene (ABS) Polymers. In Kirk-Othmer Encyclopedia of Chemical Technology; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2000. [Google Scholar]

- Barchiki, F.; Fracaro, L.; Dominguez, A.C.; Senegaglia, A.C.; Vaz, I.M.; Soares, P.; de Moura, S.; Brofman, P. Biocompatibility of ABS and PLA Polymers with Dental Pulp Stem Cells Enhance their Potential Biomedical Applications. Polymers 2023, 15, 4629. [Google Scholar] [CrossRef]

- Rasulzade, N.S.; Abbasova, L.S.; Mamedov, B.A.; Muradov, P.Z.; Bakhshalieva, K.F. Preparation and Research of Antibacterial Composite Materials Based on ABS and Oligoethylene Ether of Salicylic Acid. Inorg. Mater. Appl. Res. 2021, 12, 393–396. [Google Scholar] [CrossRef]

- Huang, B.; He, H.; Meng, S.N.; Jia, Y.C. Optimizing 3D Printing Performance of Acrylonitrile-Butadiene-Styrene Composites with Cellulose Nanocrystals/Silica Nanohybrids. Polym. Int. 2019, 68, 1351–1360. [Google Scholar]

- Sepet, H.; Tarakcioglu, N.; Misra, R. Investigation of Mechanical, Thermal and Surface Properties of Nanoclay/HDPE Nanocomposites Produced Industrially by Melt Mixing Approach. J. Compos. Mater. 2016, 50, 3105–3116. [Google Scholar]

- Sepet, H.; Aydemir, B.; Tarakcioglu, N. Evaluation of Mechanical and Thermal Properties and Creep Behavior of Micro- and Nano-CaCO3Particle-Filled HDPE Nano- and Microcomposites Produced in Large Scale. Polym. Bull. 2020, 77, 3677–3695. [Google Scholar]

- Lapcik, L.; Vasina, M.; Lapcikova, B.; Stanek, M.; Ovsik, M.; Murtaja, Y. Study of the Material Engineering Properties of High-Density Poly(Ethylene)/Perlite Nanocomposite Materials. Nanotechnol. Rev. 2020, 9, 1491–1499. [Google Scholar]

- Oliver, W.C.; Pharr, G.M. Measurement of Hardness and Elastic Modulus by Instrumented Indentation: Advances in Understanding and Refinements to Methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar]

- Manas, D.; Mizera, A.; Manas, M.; Ovsik, M.; Hylova, L.; Sehnalek, S.; Stoklasek, P. Mechanical Properties Changes of Irradiated Thermoplastic Elastomer. Polymers 2018, 10, 87. [Google Scholar] [CrossRef]

- Bonfiglio, P.; Pompoli, F.; Horoshenkov, K.V.; Rahim, M.I.B.S.A. A Simplified Transfer Matrix Approach for the Determination of the Complex Modulus of Viscoelastic Materials. Polym. Test. 2016, 53, 180–187. [Google Scholar]

- Çavdar, S.; Sepetcioglu, H.; Karagöz, I. Mechanical, Thermal, and Morphological Properties of Nanocellulose Reinforced ABS Nanocomposites. Cellulose 2024, 31, 9715–9729. [Google Scholar]

- Karagöz, I.; Tamer, L.M.; Cavusoglu, A.; Sepetcioglu, H. Investigation of Mechanical, Thermal, and Morphological Properties of Walnut Shell and Nano Clay Reinforced HDPE Composites. Mater. Today Commun. 2024, 41, 110905. [Google Scholar]

- Lapčík, L.; Vašina, M.; Murtaja, Y.; Sepetcioglu, H.; Lapčíková, B.; Ovsík, M.; Staněk, M.; Karagöz, I.; Vadanagekara, S.A. ABS nanocomposites for advanced technical and biomedical applications. Zenodo 2025. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lapčík, L.; Vašina, M.; Murtaja, Y.; Sepetcioglu, H.; Lapčíková, B.; Ovsík, M.; Staněk, M.; Karagöz, İ.; Vadanagekar, A.S. ABS Nanocomposites for Advanced Technical and Biomedical Applications. Polymers 2025, 17, 909. https://doi.org/10.3390/polym17070909

Lapčík L, Vašina M, Murtaja Y, Sepetcioglu H, Lapčíková B, Ovsík M, Staněk M, Karagöz İ, Vadanagekar AS. ABS Nanocomposites for Advanced Technical and Biomedical Applications. Polymers. 2025; 17(7):909. https://doi.org/10.3390/polym17070909

Chicago/Turabian StyleLapčík, Lubomír, Martin Vašina, Yousef Murtaja, Harun Sepetcioglu, Barbora Lapčíková, Martin Ovsík, Michal Staněk, İdris Karagöz, and Apurva Shahaji Vadanagekar. 2025. "ABS Nanocomposites for Advanced Technical and Biomedical Applications" Polymers 17, no. 7: 909. https://doi.org/10.3390/polym17070909

APA StyleLapčík, L., Vašina, M., Murtaja, Y., Sepetcioglu, H., Lapčíková, B., Ovsík, M., Staněk, M., Karagöz, İ., & Vadanagekar, A. S. (2025). ABS Nanocomposites for Advanced Technical and Biomedical Applications. Polymers, 17(7), 909. https://doi.org/10.3390/polym17070909