Biodegradability of PLA-Based Nonwoven Fabrics with Poultry Feathers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

- -

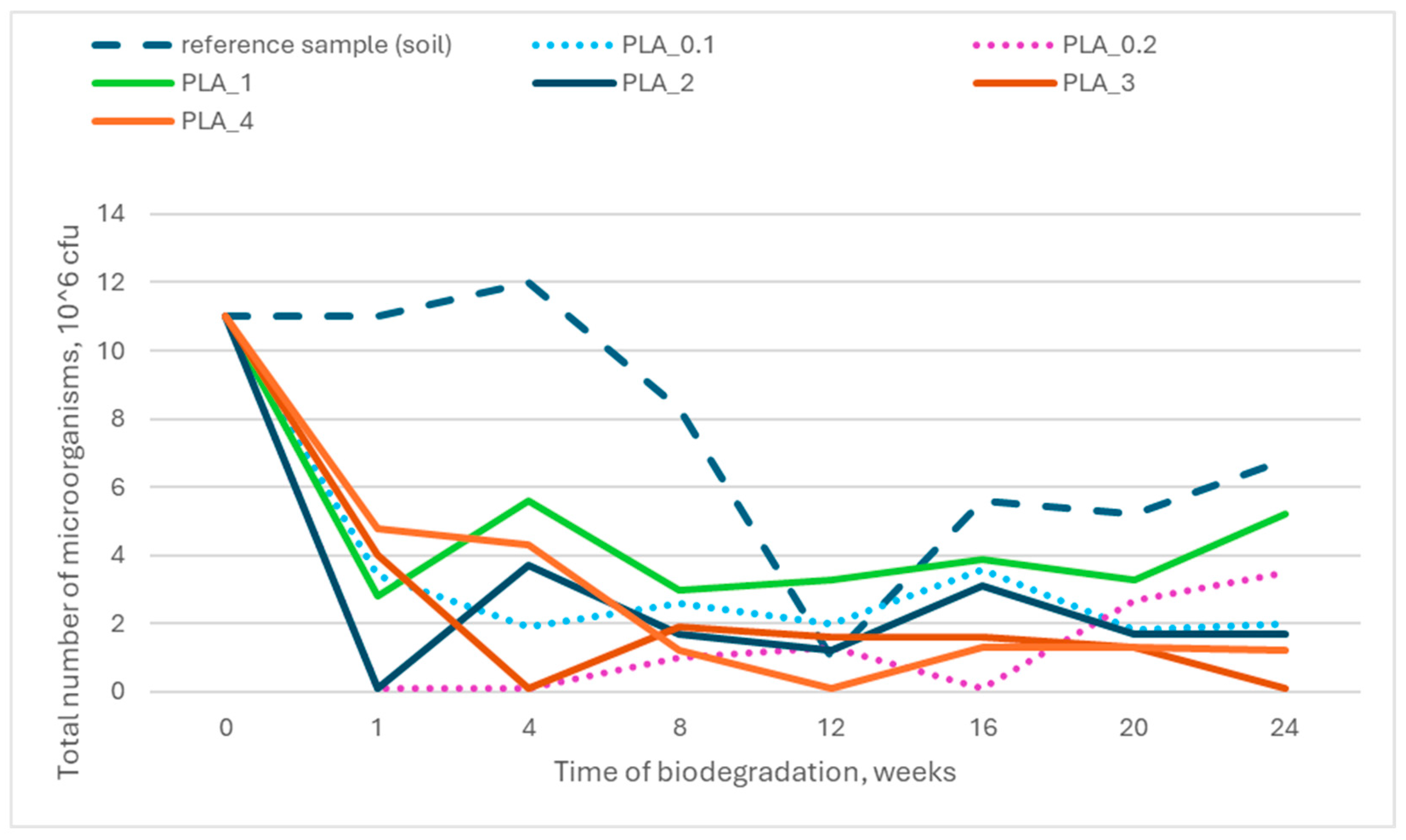

- 100% PLA—PLA_0.1, PLA_0.2—differing in basis weight,

- -

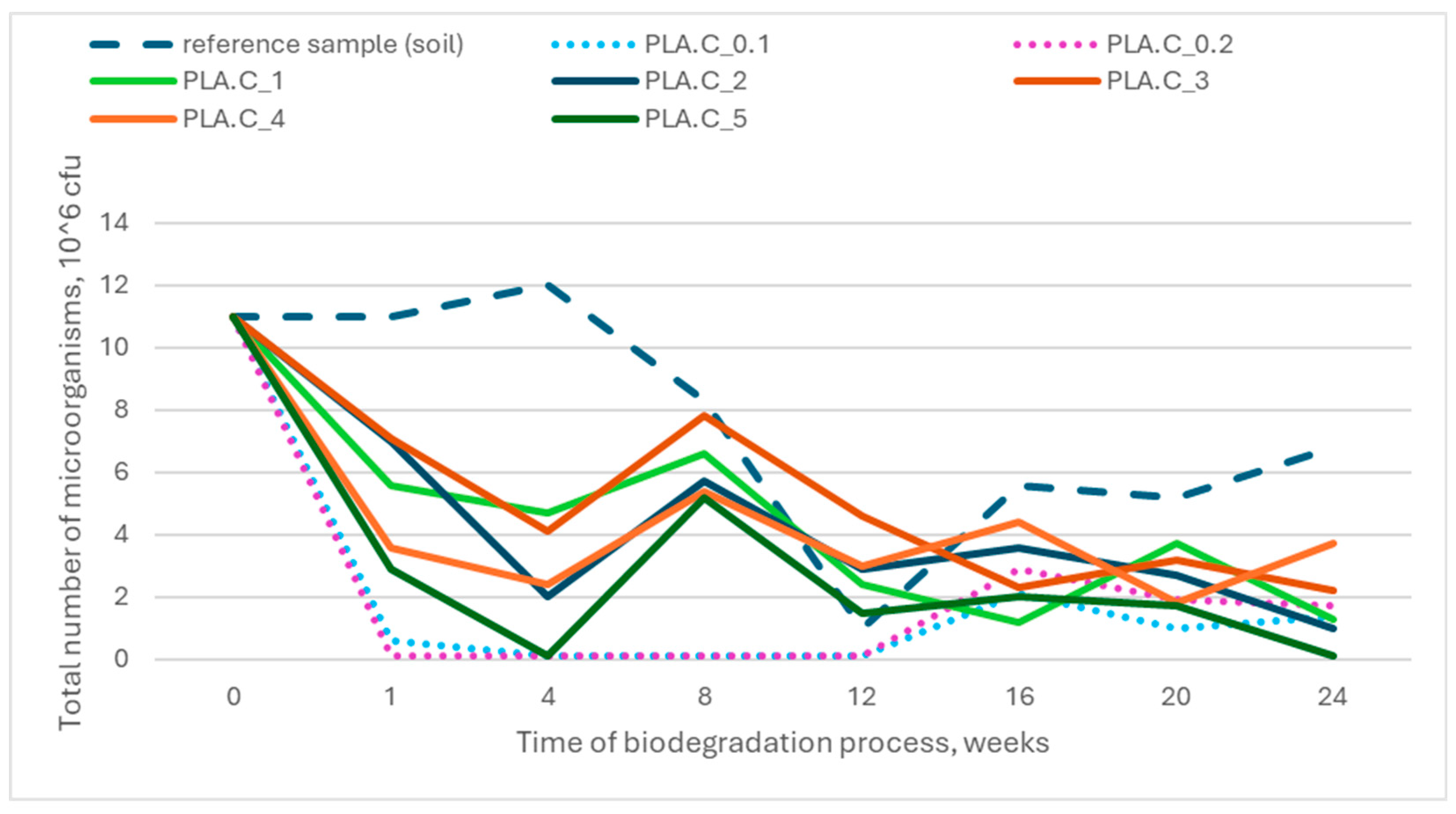

- 50% PLA/50% cotton—PLA.C_01, PLA.C_0.2—differing in basis weight,

- -

- PLA with feathers added—PLA_1—PLA_4—differing in feather content and basis weight,

- -

- PLA/cotton (1:1) with feather addition—PLA.C_1—PLA.C_5—differing in feather content and basis weight.

- -

- shredded chicken feathers (producer: CEDROB S.A. Z.D., Niepołomice, Poland),

- -

- PLA—staple fibres TREVIRA® 400 6.7 dtex bright rd 60 mm, (producer: Trevira GmbH, Bobingen, Germany)

- -

- cotton fibres, length 20–30 mm, diameter 20–30 µm (waste from the production of cosmetic pads).

2.2. Methods

3. Results

4. Discussion

- slow decomposition related to the phase of adaptation and colonisation of microorganisms on the surface; hydrolitic degradation which stars with the penetration of water into the structure of nonwoven and leads to the hydrolysis of ester bonds;

- rapid increase of decomposition which may be related to multiplication of microorganisms; metabolisation of mono- and oligomers dissolved in water into carbon dioxide and water;

- the third stage may be related with absorbtion of remnants of the polymer (dimers and monomers) by microorganisms as the source of carbon and energy.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ibrahim, A.D.; Rabah, A.B.; Ibrahim, M.L.; Magami, I.M.; Isah, J.G.; Muzoh, O.I. Bacteriological and chemical properties of soil amended with fermented poultry bird feather. Int. J. Biol. Chem. Sci. 2014, 8, 1243–1248. [Google Scholar] [CrossRef][Green Version]

- Schmidt, W.F. Innovative feather utilization strategies. In Proceedings of the National Poultry Waste Management Symposium. Auburn University Printing Services, Springdale, AR, USA, 19–21 October 1998; pp. 19–22. [Google Scholar]

- Joardar, J.C.; Rahman, M.M. Poultry feather waste management and effects on plant growth. Int. J. Recycl. Org. Waste Agric. 2018, 7, 183–188. [Google Scholar] [CrossRef]

- Lasekan, A.; Bakar, A.F.; Hashim, D. Potential of chicken by-products as sources of useful biological resources. Waste Manag. 2013, 33, 552–565. [Google Scholar] [CrossRef]

- Pal, A.; Adhikary, R.; Bera, M.; Krishiviswavidyala, B.C.; Bengal, W. Application of Different Geotextile in Soil to Improve the Soil Health in Humid and Hot Sub Humid Region of West Bengal, India. Int. J. Curr. Microbiol. App. Sci. 2020, 9, 2812–2818. [Google Scholar] [CrossRef]

- Mitchell, D.J.; Barton, A.P.; Fullen, M.A.; Hocking, T.J.; Zhi, W.B.; Zheng, Y. Field studies of the effects of jute geotextiles on runoff and erosion in Shropshire, UK. Soil. Use Manag. 2003, 19, 182–184. [Google Scholar] [CrossRef]

- Pritchard, M.; Sarsby, R.W.; Anand, S.C. Textiles in civil engineering. Part 2—Natural fibre geotextiles; Horrocks. In Handbook of Technical Textiles; Horrocks, A.R., Anand, S.C., Eds.; Woodhead Publishing: Cambridge, UK, 2000; pp. 372–405. [Google Scholar] [CrossRef]

- Sarkar, T.; Perween, T.; Datta, P. Assessing the Effect of Geotextile Mulch on Yield and Physico-Chemical Qualities of Litchi—A New Technical Approach. Int. J. Curr. Microbiol. Appl. Sci. 2019, 8, 1984–1989. [Google Scholar] [CrossRef]

- Łaba, W.; Rodziewicz, A. Biodegradation of feather keratin by Bacillus cereus in pure culture and compost. EJPAU 2008, 11, 3. [Google Scholar]

- Riffel, A.; Brandelli, A. Keratinolytic bacteria isolated from feather waste. Braz. J. Microbiol. 2006, 37, 395–399. [Google Scholar] [CrossRef]

- Bohacz, J.; Korniłłowicz-Kowalska, T. Changes in enzymatic activity in composts containing chicken feathers. Bioresour. Technol. 2009, 100, 3604–3612. [Google Scholar] [CrossRef]

- Paul, T.; Halder, S.K.; Das, A.; Bera, S.; Maity, C.; Mandal, A.; Das, P.S.; Das Mohapatra, P.K.; Pati, B.R.; Mondal, K.C. Exploitation of chicken feather waste as a plant growth promoting agent using keratinase producing novel isolate Paenibacillus woosongensis TKB2. Biocatal. Agric. Biotechnol. 2013, 2, 50–57. [Google Scholar] [CrossRef]

- Brandelli, A. Bacterial Keratinases: Useful Enzymes for Bioprocessing Agroindustrial Wastes and Beyond. Food Bioprocess Technol. 2008, 1, 105–116. [Google Scholar] [CrossRef]

- Rodziewicz, A.; Łaba, W.; Sobolczyk, J.; Grzelak, A.; Drozd, J. Compositing of keratinous waste with bacterial inoculum in a rotary bioreactor. Inż. Ap. Chem. 2009, 48, 95–97. (In Polish) [Google Scholar]

- Slezak, R.; Krzystek, L.; Puchalski, M.; Krucińska, I.; Sitarski, A. Degradation of bio-based film plastics in soil under natural conditions. Sci. Total Environ. 2023, 866, 161401. [Google Scholar] [CrossRef]

- Emadian, S.M.; Onay, T.T.; Demirel, B. Biodegradation of bioplastics in natural environments. Waste Manag. 2017, 59, 576–583. [Google Scholar] [CrossRef]

- Briassoulis, D.; Mistriotis, A. Key parameters in testing biodegradation of bio-based materials in soil. Chemosphere 2018, 207, 18–26. [Google Scholar] [CrossRef] [PubMed]

- Camacho Muñoz, R.; Villada Castillo, H.S.; Hoyos Concha, J.L.; Solanilla Duque, J.F. Aerobic biodegradation of poly(lactic acid) (PLA) in thermoplastic starch (TPS) blends in soil induced by gelatin. Int. Biodeterior. Biodegrad. 2024, 193, 105831. [Google Scholar] [CrossRef]

- Smith, S.; Ozturk, M.; Frey, M. Soil biodegradation of cotton fabrics treated with common finishes. Cellulose 2021, 28, 4485–4494. [Google Scholar] [CrossRef]

- Jóźwik-Pruska, J.; Wrześniewska-Tosik, K.; Mik, T.; Wesołowska, E.; Kowalewski, T.; Pałczyńska, M.; Walisiak, D.; Szalczyńska, M. Biodegradable nonwovens with poultry feather addition as a 2 way of recycling and waste management. Polymers 2022, 14, 2370. [Google Scholar] [CrossRef]

- Rudnik, E.; Briassoulis, D. Degradation behaviour of poly(lactic acid) films and fibres in soil under Mediterranean field conditions and laboratory simulations testing. Ind. Crops Prod. 2011, 33, 648–658. [Google Scholar] [CrossRef]

- Chuensangjun, C.; Pechyen, C.; Sirisansaneeyakul, S. Degradation Behaviors of Different Blends of Polylactic Acid Buried in Soil. Energy Procedia 2013, 34, 73–82. [Google Scholar] [CrossRef]

- Tsuji, H. Poly(lactic acid). In Bio-Based Plastics: Materials and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2013; pp. 171–239. [Google Scholar] [CrossRef]

- Zaaba, N.F.; Jaafar, M. A review on degradation mechanisms of polylactic acid: Hydrolytic, photodegradative, microbial, and enzymatic degradation. Polym. Eng. Sci. 2020, 60, 2061–2075. [Google Scholar] [CrossRef]

- Tokiwa, Y.; Calabia, B.P. Biodegradability and biodegradation of poly(lactide). Appl. Microbiol. Biotechnol. 2006, 72, 244–251. [Google Scholar] [CrossRef] [PubMed]

- Khabbaz, F.; Karlsson, S.; Albertsson, A.-C. PY-GC/MS an effective technique to characterizing of degradation mechanism of poly (L-lactide) in the different environment. J. Appl. Polym. Sci. 2000, 78, 2369–2378. [Google Scholar] [CrossRef]

- Nowak, B.; Pająk, J. Biodegradacja polilaktydu (PLA). Arch. Gospod. Odpad. I Ochr. Sr. 2010, 12, 1–10. (In Polish) [Google Scholar]

- Karamanlioglu, M.; Robson, G.D. The influence of biotic and abiotic factors on the rate of degradation of poly(lactic) acid (PLA) coupons buried in compost and soil. Polym. Degrad. Stabil. 2013, 98, 2063–2071. [Google Scholar] [CrossRef]

- Jarerat, A.; Tokiwa, Y. Poly(L-lactide) degradation by Saccharothrix waywayandensis. Biotechnol. Lett. 2003, 25, 401–404. [Google Scholar] [CrossRef] [PubMed]

- Artham, T.; Doble, M. Biodegradation of aliphatic and aromatic polycarbonates. Macromol. Biosci. 2008, 8, 14–24. [Google Scholar] [CrossRef]

- Krawczyk-Walach, M.; Gzyra-Jagieła, K.; Milczarek, A.; Jóźwik-Pruska, J. Characterization of Potential Pollutants from Poly(lactic acid) after the Degradation Process in Soil under Simulated Environmental Conditions. AppliedChem 2021, 1, 156–172. [Google Scholar] [CrossRef]

- Sülar, V.; Devrim, G. Biodegradation Behaviour of Different Textile Fibres: Visual, Morphological, Structural Properties and Soil Analyses. Fibres Text. East. Eur. 2020, 27, 100–111. [Google Scholar] [CrossRef]

- Vadillo, J.; Montes, S.; Grande, H.-J.; Verstichel, S.; Almqvist, J.; Wrześniewska-Tosik, K. Enhanced Biodegradability in Soil of Chicken Feather by Steam Explosion for Potential Application in Agricultural Biodegradable Plastics. Polymers 2023, 15, 3701. [Google Scholar] [CrossRef]

- Dharmalingam, S.; Hayes, D.G.; Wadsworth, L.C.; Dunlap, R.N. Analysis of the time course of degradation for fully biobased nonwoven agricultural mulches in compost-enriched soil. Text. Res. J. 2015, 86, 1343–1355. [Google Scholar] [CrossRef]

- Kopitar, D.; Marasovic, P. Degradation of Biodegradable Nonwoven Mulches in the Winter Period. Polymers 2024, 16, 2279. [Google Scholar] [CrossRef] [PubMed]

- Miros-Kudra, P.; Gzyra-Jagieła, K.; Kudra, M. Physicochemical Assessment of the Biodegradability of Agricultural Nonwovens Made of PLA. Fibres Text. East. Eur. 2021, 29, 26–34. [Google Scholar] [CrossRef]

- Mwasha, A. Using environmentally friendly geotextiles for soil reinforcement: A parametric study. Mater. Des. 2009, 30, 1798–1803. [Google Scholar] [CrossRef]

- Kacorzyk, P.; Strojny, J.; Białczyk, B. The Impact of Biodegradable Geotextiles on the Effect of Sodding of Difficult Terrain. Sustainability 2021, 13, 5828. [Google Scholar] [CrossRef]

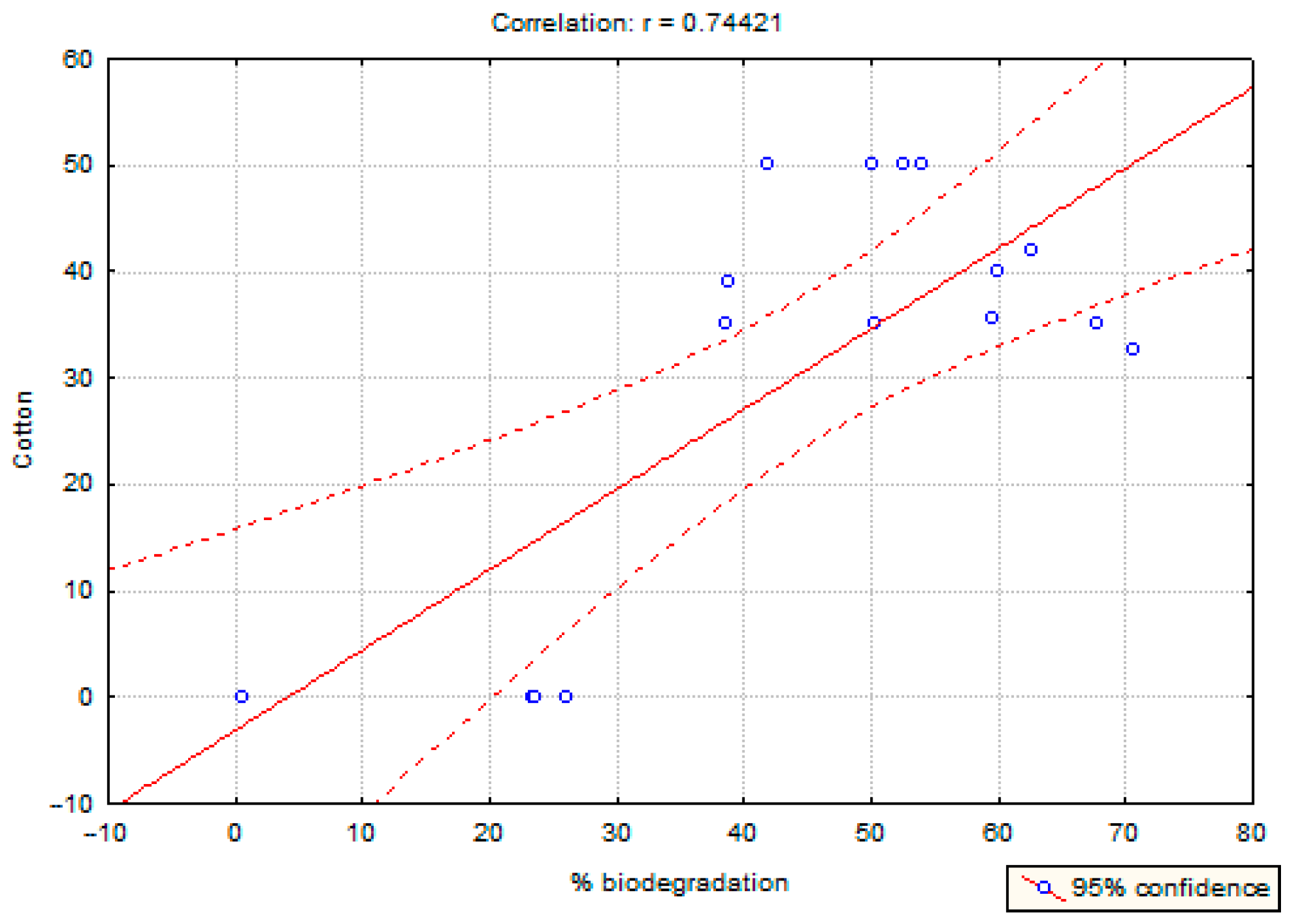

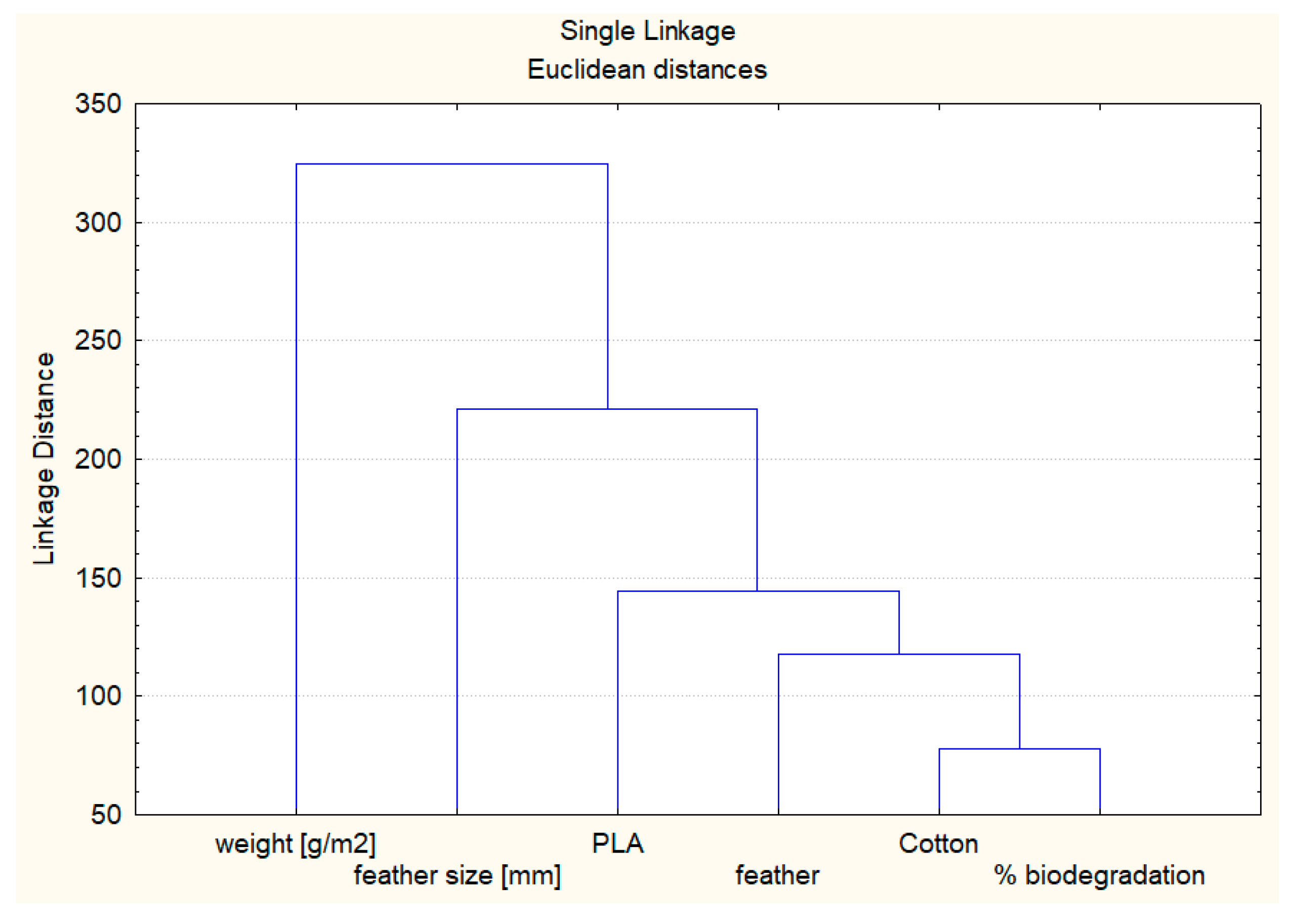

| Nonwoven | Biodegradation Degree, % ± SD | Composition, % | Basic Weight, g/m2 | ||

|---|---|---|---|---|---|

| Cotton | PLA | Feather | |||

| PLA_0.1 | 1.51 ± 0.46 | 0 | 100 | 0 | 106 |

| PLA_0.2 | 0.622 ± 0.325 | 0 | 100 | 0 | 140 |

| PLA_1 | 40.30 ± 2.73 | 0 | 63 | 37 | 169 |

| PLA_2 | 26.0 ± 1.93 | 0 | 69 | 31 | 202 |

| PLA_3 | 23.6 ± 5.8 | 0 | 71 | 29 | 197 |

| PLA_4 | 23.4 ± 1.74 | 0 | 75 | 25 | 186 |

| PLA.C_0.1 | 54.0 ± 1.40 | 50 | 50 | 0 | 106 |

| PLA.C_0.2 | 41.8 ± 1.16 | 50 | 50 | 0 | 122 |

| PLA.C_1 | 70.8 ± 6.37 | 32.5 | 32.5 | 35 | 153 |

| PLA.C_2 | 67.6 ± 2.57 | 35 | 35 | 30 | 147 |

| PLA.C_3 | 59.6 ± 2.84 | 35.5 | 35.5 | 29 | 141 |

| PLA.C_4 | 59.9 ± 1.23 | 40 | 40 | 20 | 152 |

| PLA.C_5 | 62.7 ± 1.21 | 42 | 42 | 16 | 146 |

| Element Number | Element Symbol | Element Name | PLA.C_1, 1 Week | PLA.C_1 24 Weeks | |

|---|---|---|---|---|---|

| Weight Conc., % | |||||

| 6 | C | Carbon | 38.900 | 41.466 | |

| 7 | N | Nitrogen | 3.800 | 2.711 | |

| 8 | O | Oxygen | 56.500 | 55.823 | |

| 16 | S | Sulfur | 0.800 | - | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jóźwik-Pruska, J.; Wrześniewska-Tosik, K.; Kowalewski, T.; Wietecha, J.; Pałczyńska, M.; Szalczyńska, M. Biodegradability of PLA-Based Nonwoven Fabrics with Poultry Feathers. Polymers 2025, 17, 957. https://doi.org/10.3390/polym17070957

Jóźwik-Pruska J, Wrześniewska-Tosik K, Kowalewski T, Wietecha J, Pałczyńska M, Szalczyńska M. Biodegradability of PLA-Based Nonwoven Fabrics with Poultry Feathers. Polymers. 2025; 17(7):957. https://doi.org/10.3390/polym17070957

Chicago/Turabian StyleJóźwik-Pruska, Jagoda, Krystyna Wrześniewska-Tosik, Tomasz Kowalewski, Justyna Wietecha, Michalina Pałczyńska, and Magdalena Szalczyńska. 2025. "Biodegradability of PLA-Based Nonwoven Fabrics with Poultry Feathers" Polymers 17, no. 7: 957. https://doi.org/10.3390/polym17070957

APA StyleJóźwik-Pruska, J., Wrześniewska-Tosik, K., Kowalewski, T., Wietecha, J., Pałczyńska, M., & Szalczyńska, M. (2025). Biodegradability of PLA-Based Nonwoven Fabrics with Poultry Feathers. Polymers, 17(7), 957. https://doi.org/10.3390/polym17070957