Study on the Influence and Mechanism of Steel, Polyvinyl Alcohol, and Polyethylene Fibers on Slag–Yellow River Sediment Geopolymers

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material and Mixed Proportion

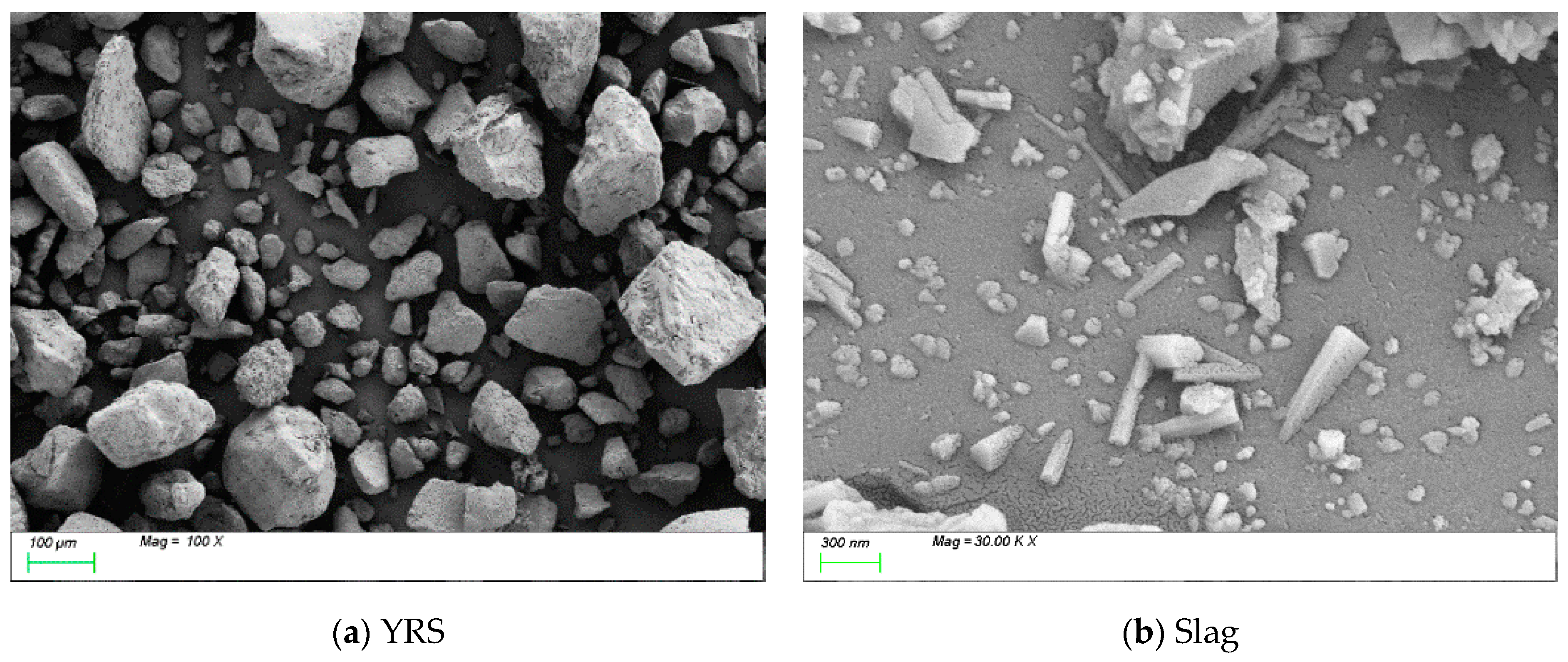

2.1.1. Raw Material

2.1.2. Mixed Proportion

2.2. Experimental Method

2.2.1. Workability Test

2.2.2. Strength Test

2.2.3. X-Ray Diffraction Analysis

2.2.4. Thermos Gravimetric Analysis

2.2.5. Scanning Electron Microscopy Test

3. Experiment Results and Analysis

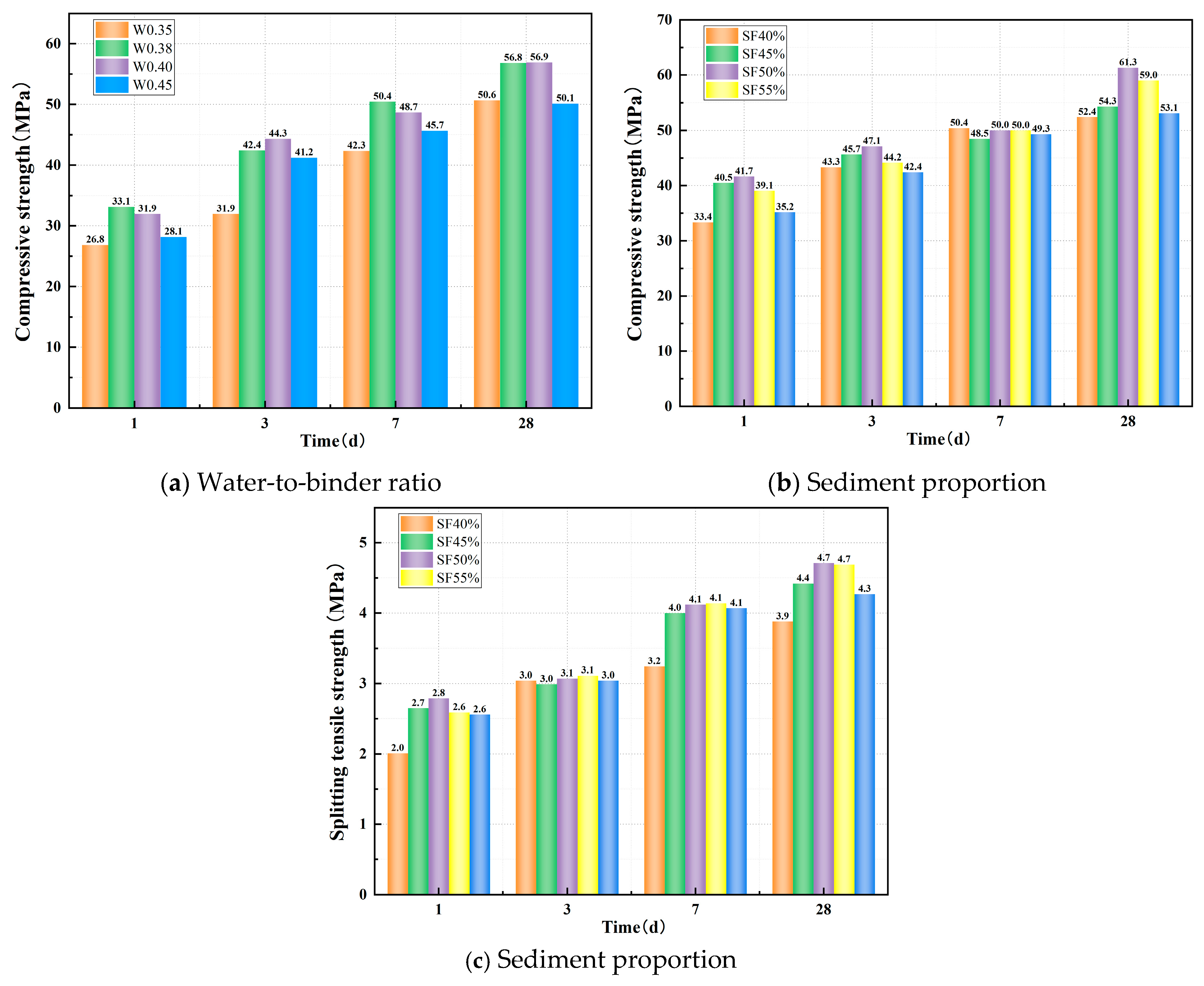

3.1. Main Mix Proportion Parameters Determination

3.2. Workability

3.3. Strength

3.3.1. Compressive Strength

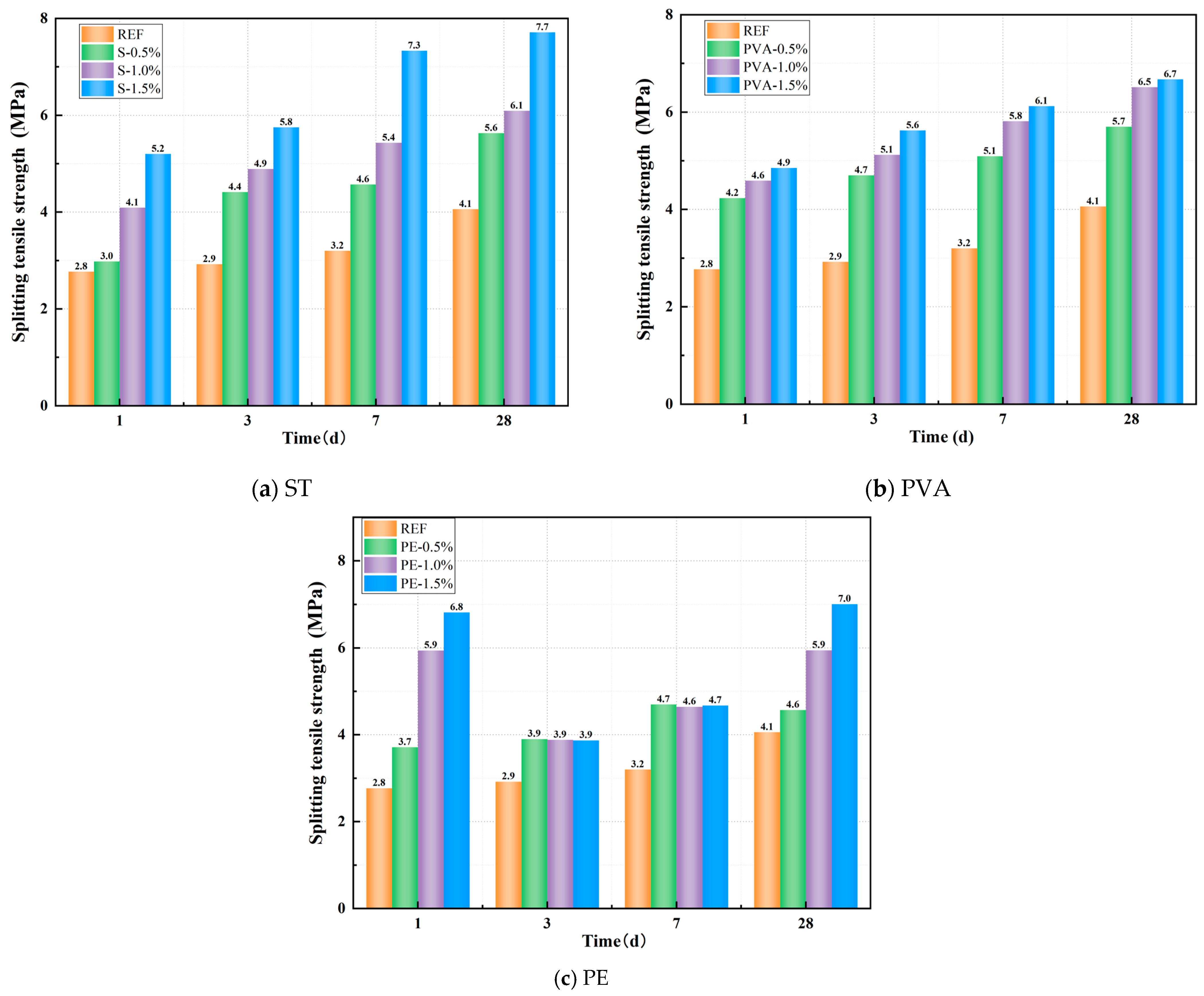

3.3.2. Splitting Tensile Strength

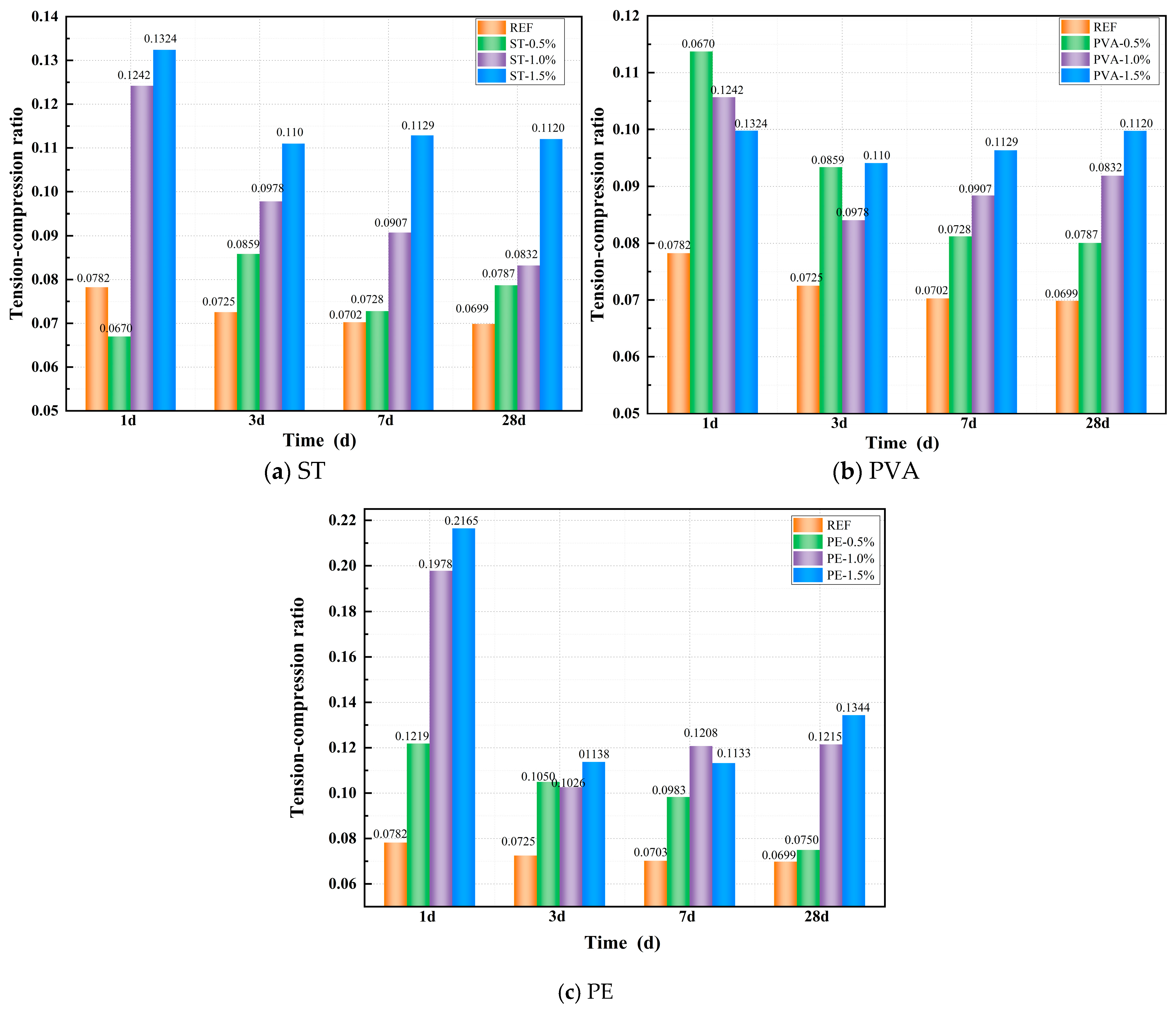

3.3.3. Tension–Compression Ratio

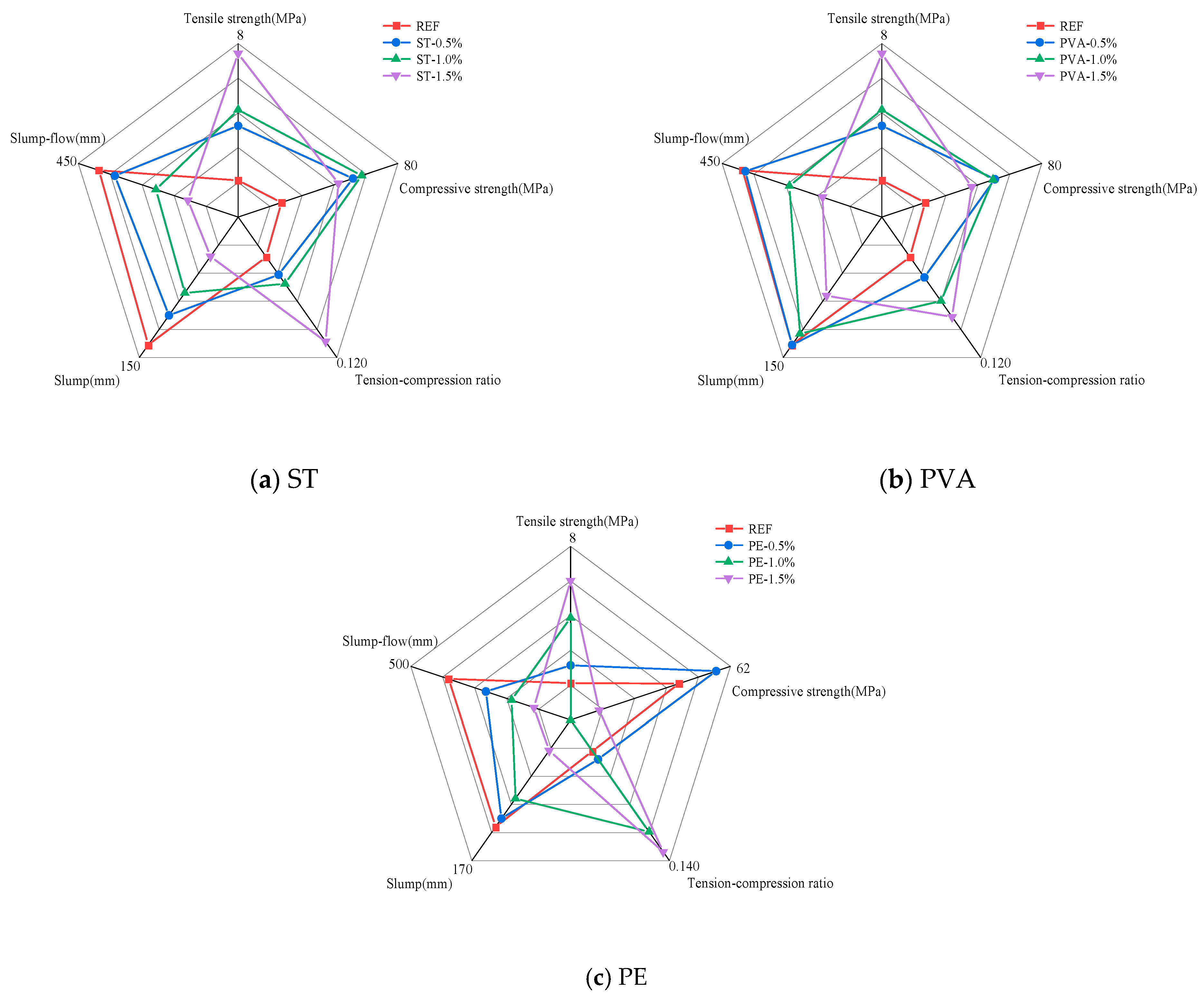

3.4. Five-Dimensional Evaluation

4. Influence Mechanism Analysis

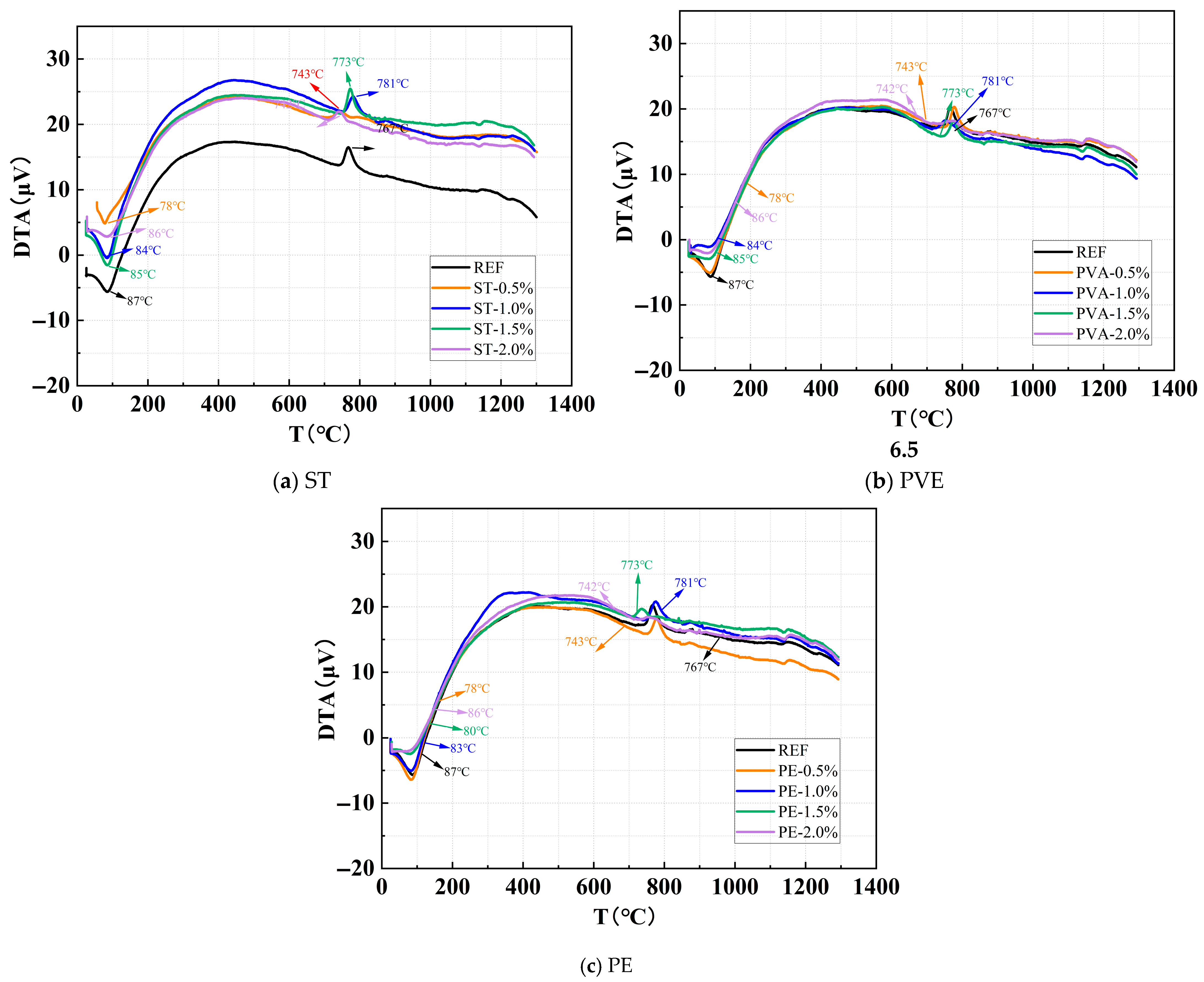

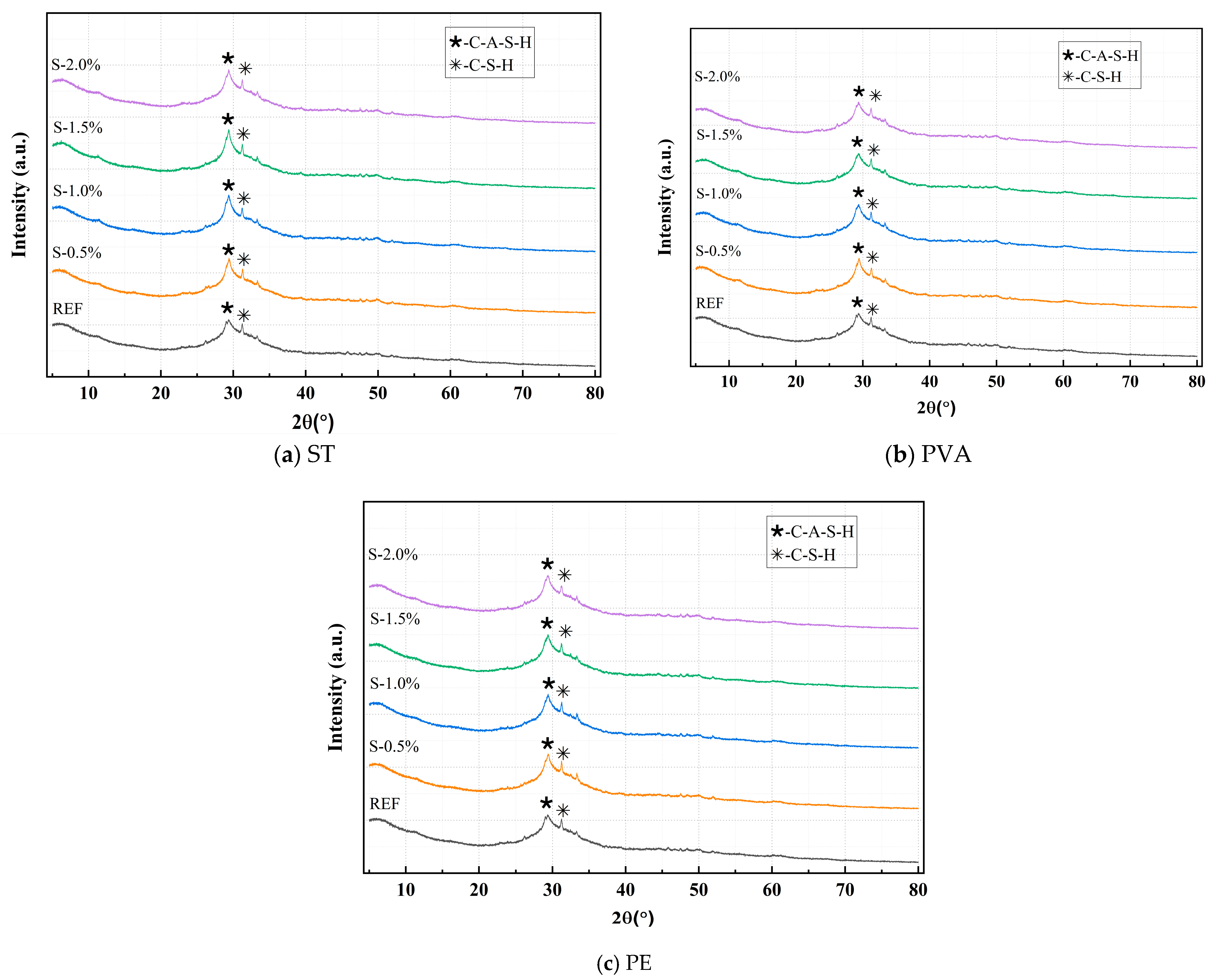

4.1. Reaction Products

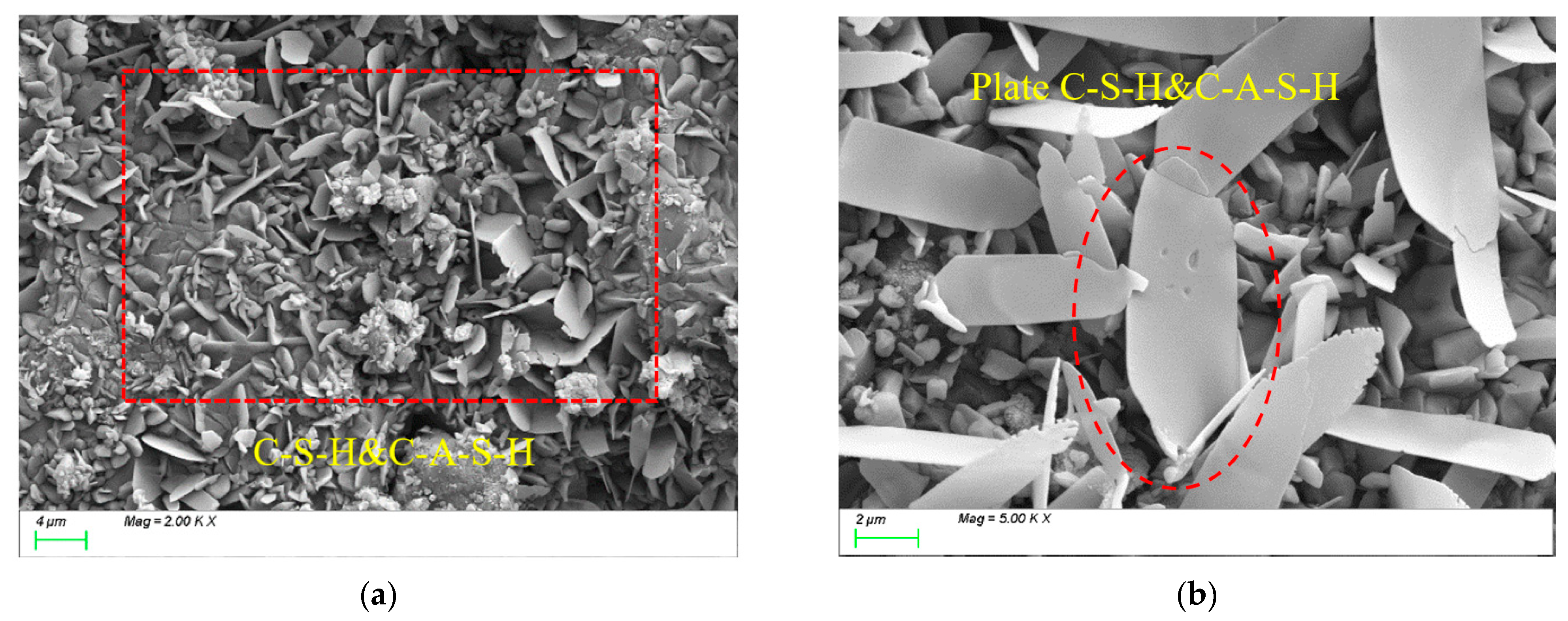

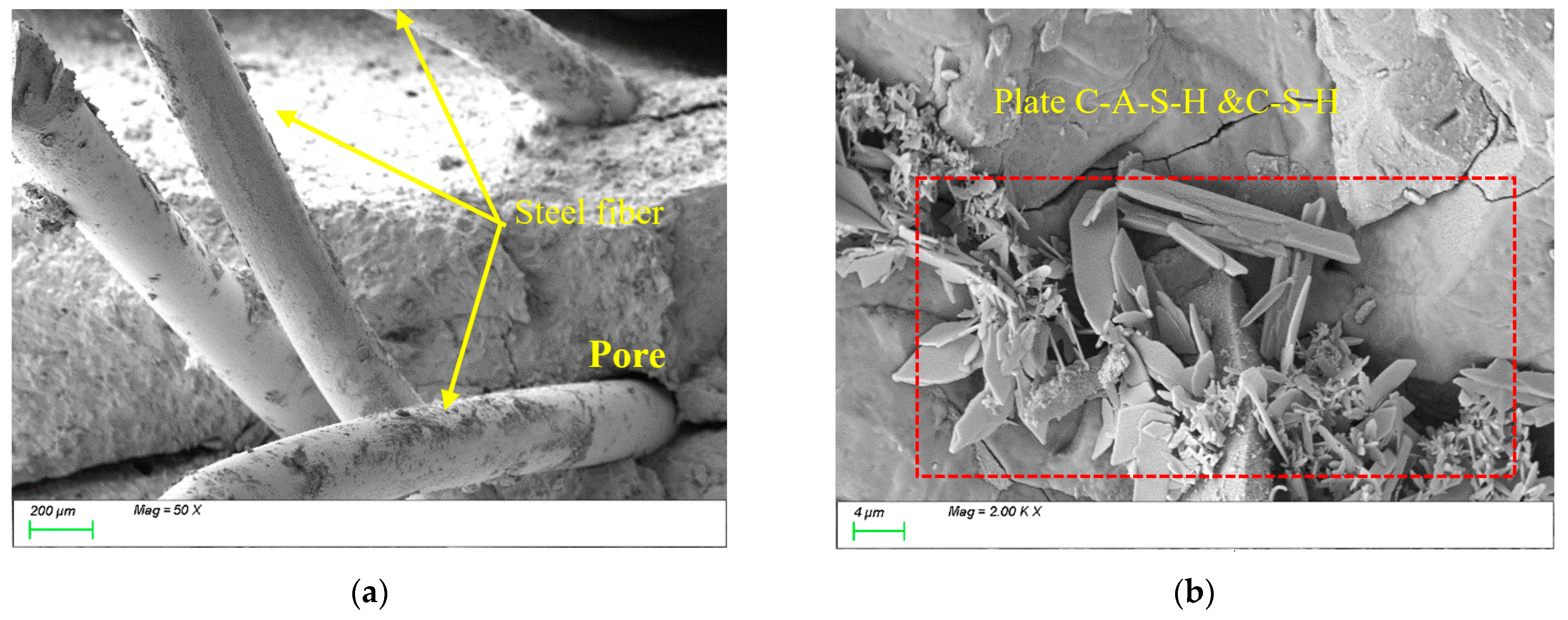

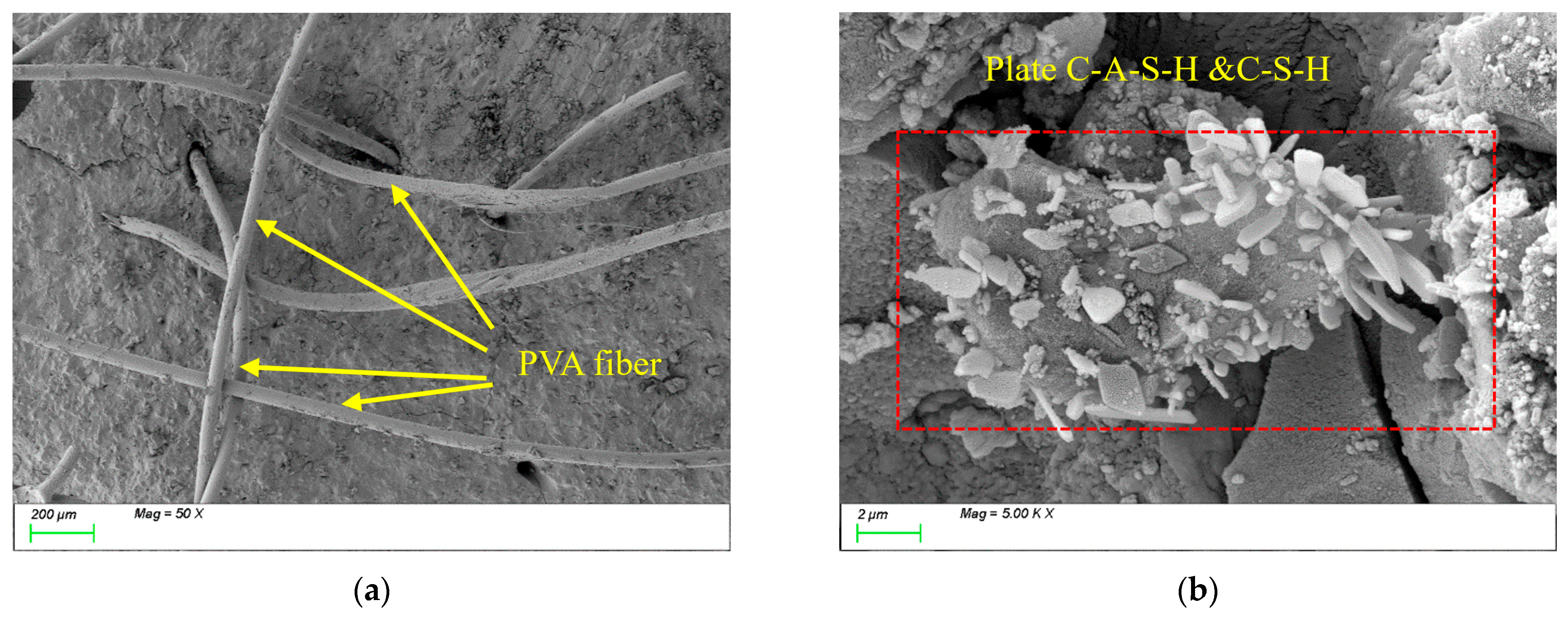

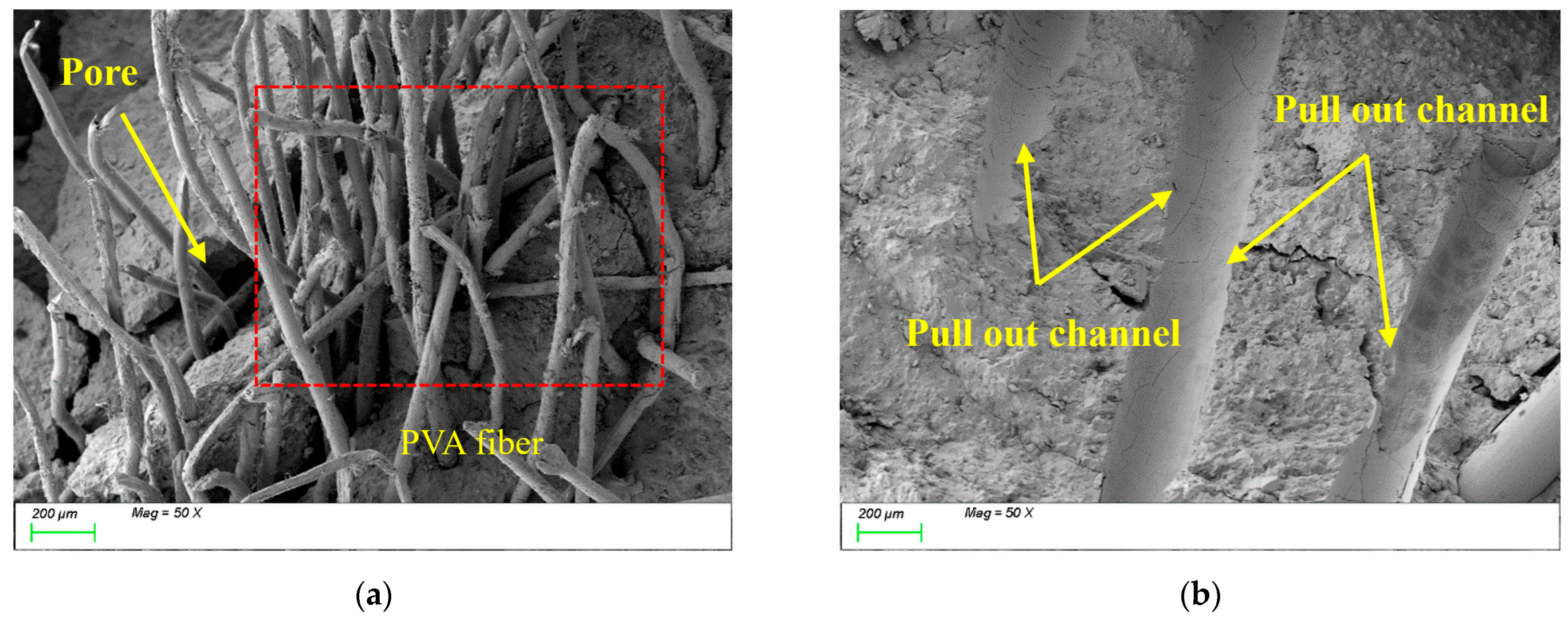

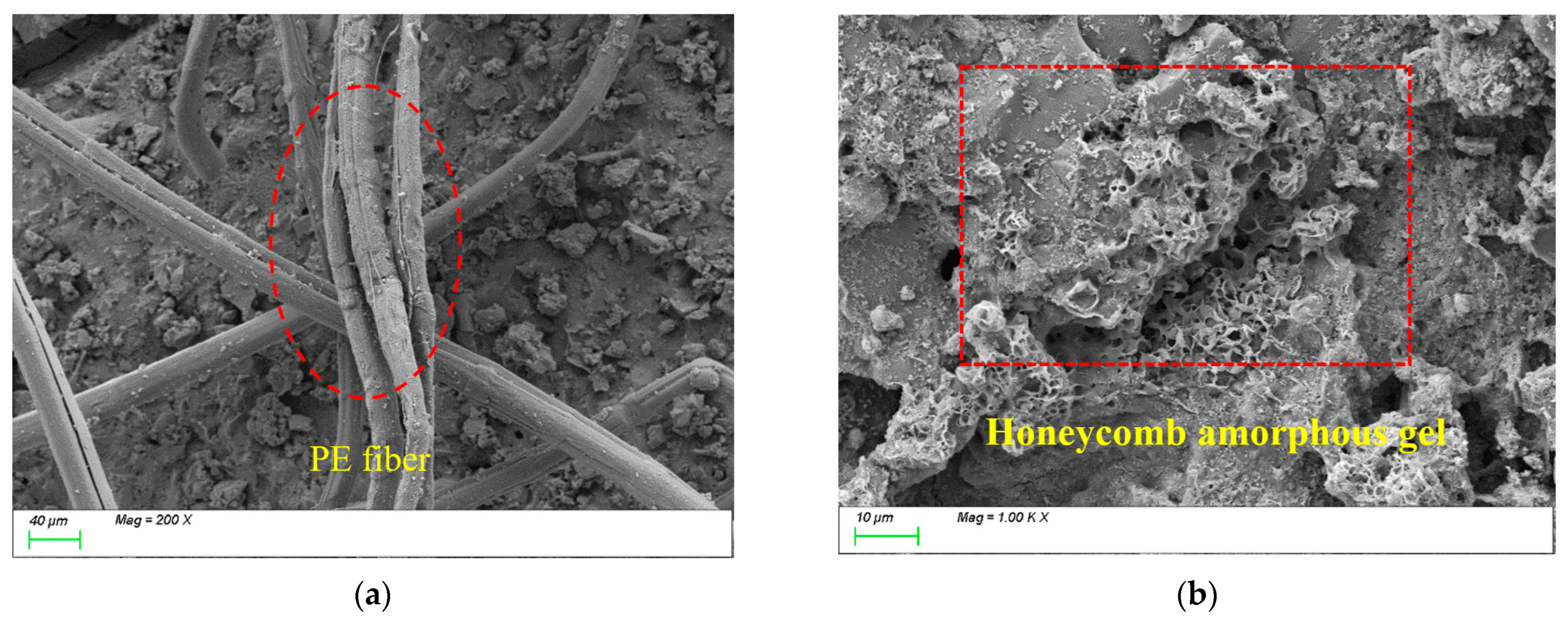

4.2. Matrix Microstructure

5. Conclusions

- (1)

- As the fiber content increases, the workability (slump and spread) of the mixture significantly decreases. STs have the most pronounced effect on workability, with ST2.0 slump and spread reduced to 29.8% and 33.1% of the initial values, respectively. PVAs and PEs have a minor impact on slump at low dosages but significantly reduce workability when the dosage exceeds 1.0%. PVA2.0 slump and spread decrease to 56.7% and 45.9% of the initial values, respectively, while PE2.0 slump and spread decrease to 38.3% and 36.0% of the initial values, respectively. The addition of fibers increases internal friction and self-weight, with the high density of STs further hindering paste fluidity.

- (2)

- An appropriate amount of STs and PVAs can significantly enhance the compressive strength and splitting tensile strength of the matrix. The 28-day compressive strength of ST1.0 and PVA1.0 increased by 25.93% and 21.96%, respectively, compared to the control group. The 28-day splitting tensile strength of ST1.5 and PVA1.5 increased by 89.90% and 64.29%, respectively, compared to the control group. The 28-day tensile-to-compressive ratio of ST1.5 and PVA1.5 increased by 60.35% and 42.79%, respectively, compared to the control group. In contrast, PEs primarily contribute to toughness, with PE1.5′s 28-day splitting tensile strength increasing by 72.61% and the 28-day tensile-to-compressive ratio increasing by 92.32% compared to the control group.

- (3)

- With an increase in age, all fiber-reinforced specimens (containing STs, PVAs or PEs) exhibited significantly higher increasing rates in the tensile-to-compressive strength ratio compared to the reference group, and the ratio enhancement became more pronounced with higher fiber content; after 28 days of standard curing the ST-0.5, ST-1.0, and ST-1.5 mixtures showed 12.64%, 19.11%, and 60.35% improvements in the ratio, respectively, while the PVA-0.5, PVA-1.0, and PVA-1.5 mixtures achieved 14.58%, 31.48%, and 42.79% enhancements, respectively, and the PE-0.5, PE-1.0, and PE-1.5 mixtures attained 7.41%, 73.91%, and 92.32% increases, respectively, which conclusively verified the effective development of fiber bridging effects in the cementitious composites.

- (4)

- STs, PVAs, and PEs do not alter the types of characteristic products in geopolymer cementitious materials, but they affect the generation of gel-like products and the distribution of free water to varying degrees. PVAs and PEs have a more significant impact than STs, and excessive fiber content can affect the generation of characteristic gel products and their thermal decomposition behavior.

- (5)

- STs enhance the compressive performance of the matrix through their high modulus and stiffness and inhibit crack propagation through fiber bridging. PVAs suppress crack propagation through their flexibility and good bonding properties, while PEs improve the tensile performance of the matrix through their high tensile strength and elastic modulus. Although their reinforcing effect on the matrix at the microscopic scale is relatively weak, the interfacial properties between PEs and the cement matrix could be optimized through surface treatments (e.g., chemical modification or coating applications) in future studies, thereby enhancing fiber–matrix interactions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| STs | Steel fibers | nm | Nanometer |

| YRS | Yellow river sediment | # | Number |

| C-S-H | Calcium silicate hydrate | P | Pressure |

| C-A-S-H | Calcium aluminum silicate hydrate | XRD | X-ray Diffraction |

| ITZs | Interfacial Transition Zones | m | Meter |

| N | Newton | SiO2 | Silicon Dioxide |

| PVAs | Polyvinyl Alcohol fibers | g | Gram |

| PEs | Polyethylene fibers | g cm−3 | Grams per Cubic Centimeter |

| MPa | Megapascal | Sulfate lon | |

| OPC | Ordinary Portland cement | N | Newton |

| TGA | Thermogravimetric Analysis | SiO2 | Silicon dioxide |

| SEM | Scanning electron microscope | SG | Specific gravity |

| mm | Millimeter | SS | Sodium Silicate |

| m2 | Square meters | μW | Microwatt |

| m2 kg−1 | Square meters per kilogram | NaOH | Sodium Hydroxide |

| min | Minute | % | Percentage |

References

- Yang, Z.X.; Zeng, L.Y. Research on the Current Situation of Mining Management of National Sandy and Stony soil Mines. Nat. Resour. Econ. China 2020, 33, 44–50. [Google Scholar] [CrossRef]

- Wei, J.; Cen, K. Empirical assessing cement CO2 emissions based on China’s economic and social development during 2001–2030. Sci. Total Environ. 2019, 653, 200–211. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Liu, C.Y.; Hao, Y.F.; Zhang, Y.; Chen, L.; Li, Z. Experimental investigation of engineered geopolymer composite for structural strengthening against blast loads. Def. Technol. 2024, 32, 496–509. [Google Scholar] [CrossRef]

- Yang, J.; Wang, Z.Q.; He, X.Y.; Su, Y.; Tang, Y.Z.; Qi, H.H.; Yang, C.; Xiong, G.Q. Using superabsorbent polymer to mitigate the fast setting and high autogenous shrinkage of carbide slag and sodium silicate activated ultrafine GGBS based composites. Sustain. Chem. Pharm. 2024, 39, 101550. [Google Scholar] [CrossRef]

- Cao, B.S.; Li, Y.; Li, P.P. Synergistic Effect of Blended Precursors and Silica Fume on Strength and High Temperature Resistance of Geopolymer. Materials 2024, 17, 2975. [Google Scholar] [CrossRef]

- Yang, N.; Xuan, Q.D.; Fu, Y.; Ma, X.; Lei, D.Y.; Niu, J.L.; Dai, J.G. Phosphate activated geopolymer-based coating with high temperature resistance for sub-ambient radiative cooling. Sustain. Cities Soc. 2024, 100, 104992. [Google Scholar] [CrossRef]

- Wang, Z.K.; Fu, C.H.; Wang, K.; Zhao, J.; Shumuye, E.D.; Yang, Z.H. Effect of geopolymer concrete cover on improving tensile and transverse shear behaviors of BFRP bars after exposure to high temperature. Case Stud. Constr. Mater. 2024, 20, e02862. [Google Scholar] [CrossRef]

- Chen, Z.M.; Liu, H.; Zhu, P.H.; Li, H.C.; Ge, T.Z.; Yang, L.; Chen, C.H.; Dong, Y.L. Effect of Curing Mechanism on Sulfuric Acid Corrosion Resistance of Geopolymer Recycled Aggregate Concrete. Ksce J. Civ. Eng. 2024, 28, 1173–1182. [Google Scholar] [CrossRef]

- Zhou, Y.W.; Yu, Y.; Guo, W.H.; Xing, F.; Guo, M.H. Development of inorganic anticorrosive coatings for steel bars: Corrosion resistance testing and design. Cem. Concr. Compos. 2024, 152, 105612. [Google Scholar] [CrossRef]

- Cui, L.; Xiang, T.; Hu, B.; Lv, Y.; Rong, H.; Liu, D.E.; Zhang, S.; Guo, M.; Lv, Z.; Chen, D. Design of monolithic super hydrophobic concrete with excellent anti-corrosion and self-cleaning properties. Colloids Surf. A Physicochem. Eng. Asp. 2024, 685, 133345. [Google Scholar] [CrossRef]

- Gopalakrishnan, R.; Chinnaraju, K. Durability of ambient cured alumina silicate concrete based on slag/fly ash blends against sulfate environment. Constr. Build. Mater. 2019, 204, 70–83. [Google Scholar] [CrossRef]

- Ahmad, M.R.; Chen, B.; Shah, S.F.A. Influence of different admixtures on the mechanical and durability properties of one-part alkali-activated mortars. Constr. Build. Mater. 2020, 265, 120320. [Google Scholar] [CrossRef]

- Alzeer, M.I.M.; MacKenzie, K.J.D. Chapter 5—Fiber composites of inorganic polymers (geopolymers) reinforced with natural fibers. In Composite Materials; Low, I.-M., Dong, Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 117–147. [Google Scholar] [CrossRef]

- Krishna, R.S.; Shaikh, F.; Mishra, J.; Lazorenko, G.; Kasprzhitskii, A. Mine tailings-based geopolymers: Properties, applications and industrial prospects. Ceram. Int. 2021, 47, 17826–17843. [Google Scholar] [CrossRef]

- Nuaklong, P.; Worawatnalunart, P.; Jongvivatsakul, P.; Tangaramvong, S.; Pothisiri, T.; Likitlersuang, S. Pre- and post-fire mechanical performances of high calcium fly ash geopolymer concrete containing granite waste. J. Build. Eng. 2021, 44, 103265. [Google Scholar] [CrossRef]

- Figiela, B.; Bąk, A.; Hebda, M.; Korniejenko, K. Eco-friendly production of foamed geopolymers based on mine waste. J. Achiev. Mater. Manuf. Eng. 2023, 121, 341–349. [Google Scholar] [CrossRef]

- Dong, C.H.; Li, T.; Zhang, Y.M.; Liu, J. Damage process and performance of PVA fiber-reinforced alkali-activated slag mortar plate under bending. J. Southeast Univ. (Engl. Ed.) 2018, 34, 229–236. [Google Scholar] [CrossRef]

- Zhang, S.Z.; He, S.; Ghiassi, B.; Breugel, K.V.; Ye, G. Interface bonding properties of polyvinyl alcohol (PVA) fiber in alkali-activated slag/fly ash. Cem. Concr. Res. 2023, 173, 107308. [Google Scholar] [CrossRef]

- Sarker, P.K.; Haque, R.; Ramgolam, K.V. Fracture behaviour of heat cured fly ash based geopolymer concrete. Mater. Des. 2013, 44, 580–586. [Google Scholar] [CrossRef]

- Pan, Z.; Sanjayan, J.G.; Rangan, B.V. Fracture properties of geopolymer paste and concrete. Mag. Concr. 2011, 63, 763–771. [Google Scholar] [CrossRef]

- Thomas, R.J.; Peethamparan, S. Alkali-activated concrete: Engineering propertie sand stress strain behavior. Constr. Build. Mater. 2015, 93, 49–56. [Google Scholar] [CrossRef]

- Atis, C.D.; Bilim, C.; Celik, O.; Karahan, O. Influence of activator on the strength and drying shrinkage of alkali-activated slag mortar. Constr. Build. Mater. 2009, 23, 548–555. [Google Scholar] [CrossRef]

- Rashad, A.M. A comprehensive overview about the influence of different additives on the properties of alkali-activated slag-A guide for civil engineer. Constr. Build. Mater. 2013, 47, 29–55. [Google Scholar] [CrossRef]

- Rashad, A.M. A comprehensive overview about the influence of different admixtures and additives on the properties of alkali-activated fly ash. Mater. Des. 2014, 53, 1005–1025. [Google Scholar] [CrossRef]

- Qian, H.; Umar, M.; Khan, M.N.A.; Shi, Y.; Manan, A.; Raza, A.; Chen, G. A State-of-the-Art Review on Shape Memory Alloys (SMA) in Concrete: Mechanical Properties, Self-Healing Capabilities, and Hybrid Composite Fabrication. Mater. Today Commun. 2024, 40, 109738. [Google Scholar] [CrossRef]

- Emdadi, A.; Mehdipour, I.; Libre, N.A.; Shekarchi, M. Optimized workability and mechanical properties of FRCM by using fiber factor approach: Theoretical and experimental study. Mater. Struct. 2015, 48, 149–1161. [Google Scholar] [CrossRef]

- Mehdipour, I.; Vahdani, M.; Libre, N.A.; Shekarchi, M. Relationship between workability and mechanical properties of fibre-reinforced self-consolidating mortar. Mag. Concr. Res. 2013, 65, 1011–1022. [Google Scholar] [CrossRef]

- Si, W.; Cao, M.; Li, L. Establishment of fiber factor for rheological and mechanical performance of polyvinyl alcohol (PVA) fiber reinforced mortar. Constr. Build. Mater. 2020, 265, 120347. [Google Scholar] [CrossRef]

- Ohno, M.; Li, V.C. An integrated design method of engineered geopolymer composite. Cem. Coner. Compos. 2018, 88, 73–85. [Google Scholar] [CrossRef]

- Nematollahi, B.; Qiu, J.; Yang, E.H.; Sanjayan, J. Microscale investigation of fiber-matrix interface properties of strain-hardening geopolymer composite. Ceram. Int. 2017, 43, 15616–15625. [Google Scholar] [CrossRef]

- Shah, I.; Li, J.; Khan, N.; Almujibah, H.R.; Rehman, M.M.; Raza, A.; Peng, Y. Bond-Slip Behavior of Steel Bar and Recycled Steel Fibre-Reinforced Concrete. J. Renew. Mater. 2024, 12, 167–186. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, C.; Zhang, Z.; Li, N.; Shi, D. Mechanical and fracture properties of ultra-high performance geopolymer concrete: Effects of steel fiber and silica fume. Cemt Concr. Compos. 2020, 112, 103665. [Google Scholar] [CrossRef]

- Martinie, L.; Rossi, P.; Roussel, N. Rheology of fiber reinforced cementitious materials: Classification and prediction. Cem. Concr. Res. 2010, 40, 226–234. [Google Scholar] [CrossRef]

- Cui, S.; Fu, F.; Zeng, G.; Chen, Z.; Li, G. Analysis on mechanical property and pore structure of concrete for spraying use in hot-dry environment fiber. J. Southeast Univ. (Nat. Sci. Ed.) 2022, 52, 43–49. [Google Scholar]

- Wang, W.; Huo, J.; Zeng, L.; Liu, W.; Wang, Y. Interlayer Mechanical Characteristics and Anti-penetrability Performance of Combined Shotcrete in Single-shell Lining. Mater. Rep. 2023, 37, 90–96. [Google Scholar]

- Lee, B.Y.; Cho, C.G.; Lim, H.J.; Song, J.K.; Yang, K.H.; Li, V.C. Strain hardening fiber-reinforced alkali-activated mortar—A feasibility study. Constr. Build. Mater. 2012, 37, 15–20. [Google Scholar] [CrossRef]

- Natali, A.; Manzi, S.; Bignozzi, M.C. Novel fiber-reinforced composite materials based on sustainable geopolymer matrix. Procedia Eng. 2011, 21, 1124–1131. [Google Scholar] [CrossRef]

- Zhang, Y.; Wei, S.; Li, Z.; Zhou, X.; Eddie; Chau, C. Impact properties of geopolymer based extrudates incorporated with fly ash and PVA short fiber. Constr. Build. Mater. 2008, 22, 370–383. [Google Scholar] [CrossRef]

- Zhang, Y.; Wei, S.; Li, Z.; Zhou, X. Geopolymer extruded composites with incorporated fly ash and polyvinyl alcohol short fiber. ACI Mater. J. 2009, 106, 3–10. [Google Scholar]

- Hu, F.; Xin, X.; Guo, A.; Yu, Z.Y.; Shao, Q.; Sheikh, M.N.; Sun, Z.H. Effect of mix proportion parameters on chloride erosion resistance of fly ash/slag-based engineered geopolymer composites. J. Clean. Prod. 2024, 438, 140785. [Google Scholar] [CrossRef]

- Yuan, C.F.; Raza, A.; Manan, A.; Manan, A.; Ahmad, S.; Chao, W.; Umar, M. Numerical and experimental study of Yellow River sand in engineered cementitious composite. Proc. Inst. Civil. Eng.-Eng. Sustain. 2025, 178, 3–20. [Google Scholar] [CrossRef]

- Akturk, B.; Akca, A.H.; Kizilkanat, A.B. Fracture response of fiber-reinforced sodium carbonate activated slag mortar. Constr. Build. Mater. 2020, 241, 118128. [Google Scholar] [CrossRef]

- Zhou, X.; Zeng, Y.; Chen, P.; Jiao, Z.; Zheng, W. Mechanical properties of basalt and polypropylene fibre-reinforced alkali-activated slag concrete. Constr. Build. Mater. 2020, 269, 121284. [Google Scholar] [CrossRef]

- Abdollahnejad, Z.; Mastali, M.; Falah, M.; Shaad, K.M.; Luukkonen, T.; Illikainen, M. Durability of the reinforced one-part alkali-activated slag mortar with different fibers. Waste Biomass 2020, 12, 487–501. [Google Scholar] [CrossRef]

- Yuan, C.F.; Xu, S.W.; Raza, A.; Wang, C.; Wang, D. Influence and Mechanism of Curing Methods on Mechanical Properties of Manufactured Sand UHPC. Materials 2022, 15, 6183. [Google Scholar] [CrossRef] [PubMed]

- Raza, A.; Memon, B.A.; Oad, M. Effect of Curing Types on Compressive Strength of Recycled Aggregates Concrete. Quaid-E-Awam Univ. Res. J. Eng. 2019, 17, 7–12. [Google Scholar] [CrossRef]

- GB/T50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Architecture & Building Press: Beijing, China, 2019.

- Huang, B.T.; Wu, J.; Yu, J.; Dai, J.G.; Leung, C.K.; Li, V.C. Seawater sea-sand engineered/strain-hardening cementitious composites (ECC/SHCC): Assessment and modeling of crack characteristics. Cem. Concr. Res. 2021, 140, 106292. [Google Scholar] [CrossRef]

- Cheng, T.W.; Chiu, J.P. Fire-resistant geopolymer produced by granulated blast furnace slag. Miner. Eng. 2003, 16, 205–210. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Jaturapitakkul, C.; Chalee, W.; Rattanasak, U. Comparative study on thecharacteristics of fly ash and bottom ash geopolymers. Waste Manag. 2009, 29, 539–543. [Google Scholar] [CrossRef]

| Minerals | SiO2 | CaO | Al2O3 | Fe2O3 | K2O | TiO2 | MgO | Other |

|---|---|---|---|---|---|---|---|---|

| YRS | 68.64 | 8.40 | 12.33 | 3.25 | 2.55 | 0.74 | 2.05 | 2.04 |

| slag | 32.47 | 41.06 | 14.52 | 0.28 | 0.44 | 1.25 | 7.08 | 2.9 |

| Fiber Type | Diameter (mm) | Density (g.cm−3) | Length (mm) | Tensile Strength (MPa) | Elasticity (GPa) | Elongation (%) |

|---|---|---|---|---|---|---|

| ST | 0.22 | 7.9 | 13 | 2800 | 210 | 5 |

| PVA | 0.04 | 1.3 | 12 | 1560 | 41 | 6.5 |

| PE | 0.02~0.03 | 0.9 | 12 | 3378 | 125 | 3 |

| SiO2/(%) | Na2O/(%) | H2O/(%) | Density/(g/cm3) | Modulus | Beaume |

|---|---|---|---|---|---|

| 30 | 13.5 | 56.5 | 1.51 | 2.3 | 50 |

| No. | Sand | NaOH | SS | Slag | ST | PVA | PE | Water |

|---|---|---|---|---|---|---|---|---|

| REF | 1.000 | 0.020 | 0.128 | 0.660 | — | — | — | 0.192 |

| ST-0.5% | 1.000 | 0.020 | 0.128 | 0.660 | 0.032 | — | — | 0.192 |

| ST-1.0% | 1.000 | 0.020 | 0.128 | 0.660 | 0.065 | — | — | 0.192 |

| ST-1.5% | 1.000 | 0.020 | 0.128 | 0.660 | 0.097 | — | — | 0.192 |

| PVA-0.5% | 1.000 | 0.020 | 0.128 | 0.660 | — | 0.006 | — | 0.192 |

| PVA-1.0% | 1.000 | 0.020 | 0.128 | 0.660 | — | 0.011 | — | 0.192 |

| PVA-1.5% | 1.000 | 0.020 | 0.128 | 0.660 | — | 0.017 | — | 0.192 |

| PE-0.5% | 1.000 | 0.020 | 0.128 | 0.660 | — | — | 0.004 | 0.192 |

| PE-1.0% | 1.000 | 0.020 | 0.128 | 0.660 | — | — | 0.007 | 0.192 |

| PE-1.5% | 1.000 | 0.020 | 0.128 | 0.660 | — | — | 0.011 | 0.192 |

| Properties | Performance Index | Specimen Size | Quantity |

|---|---|---|---|

| Workability | Slump | — | — |

| Slump flow | — | — | |

| Strength | Compressive strength | 100 mm × 100 mm × 100 mm | 120 |

| Splitting tensile strength | 100 mm × 100 mm × 100 mm | 120 | |

| Characteristic products | Thermos gravimetric analysis | 40 mm × 40 mm × 40 mm | 30 |

| X-ray diffraction analysis | 40 mm × 40 mm × 40 mm | 30 | |

| Microstructural properties | Scanning electron microscopy | 40 mm × 40 mm × 40 mm | 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Jiang, E.; Li, K.; Shi, H.; Chen, C.; Yuan, C. Study on the Influence and Mechanism of Steel, Polyvinyl Alcohol, and Polyethylene Fibers on Slag–Yellow River Sediment Geopolymers. Polymers 2025, 17, 1072. https://doi.org/10.3390/polym17081072

Zhang G, Jiang E, Li K, Shi H, Chen C, Yuan C. Study on the Influence and Mechanism of Steel, Polyvinyl Alcohol, and Polyethylene Fibers on Slag–Yellow River Sediment Geopolymers. Polymers. 2025; 17(8):1072. https://doi.org/10.3390/polym17081072

Chicago/Turabian StyleZhang, Ge, Enhui Jiang, Kunpeng Li, Huawei Shi, Chen Chen, and Chengfang Yuan. 2025. "Study on the Influence and Mechanism of Steel, Polyvinyl Alcohol, and Polyethylene Fibers on Slag–Yellow River Sediment Geopolymers" Polymers 17, no. 8: 1072. https://doi.org/10.3390/polym17081072

APA StyleZhang, G., Jiang, E., Li, K., Shi, H., Chen, C., & Yuan, C. (2025). Study on the Influence and Mechanism of Steel, Polyvinyl Alcohol, and Polyethylene Fibers on Slag–Yellow River Sediment Geopolymers. Polymers, 17(8), 1072. https://doi.org/10.3390/polym17081072