Research on the Tribological Behavior of Polyurethane Acrylate Coatings with Different Matrix Constituents as Well as Graphite and PTFE

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reagents

2.2. The Procedure for Paint Preparation

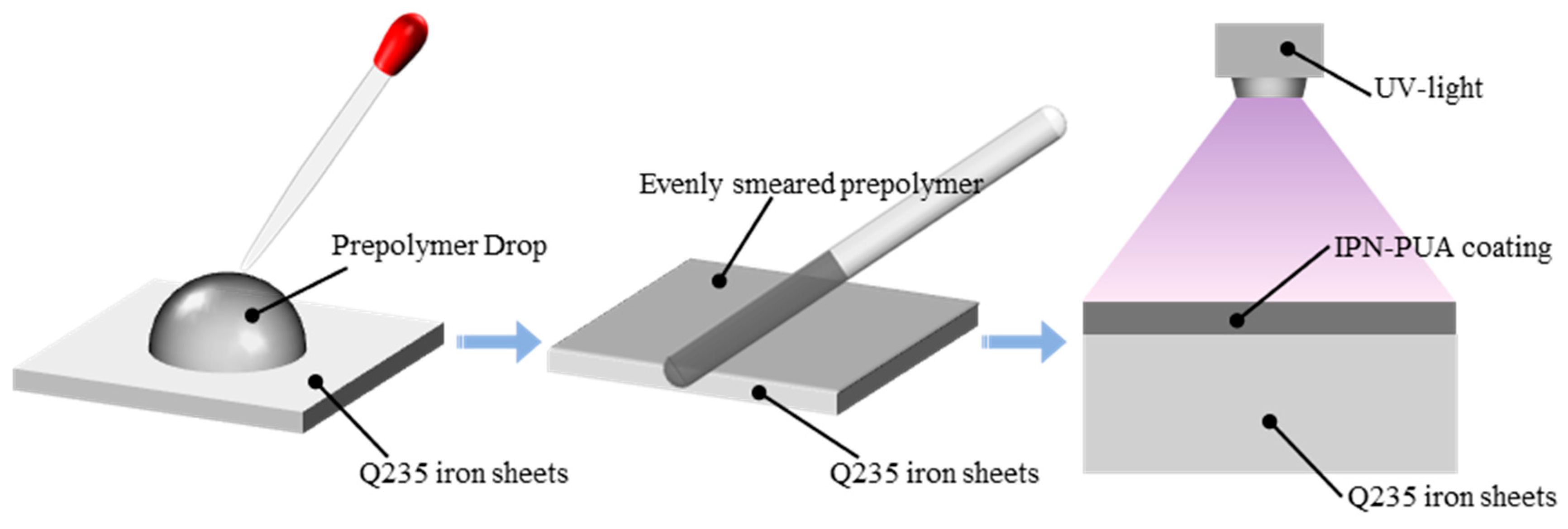

2.3. Process of Coating Curing

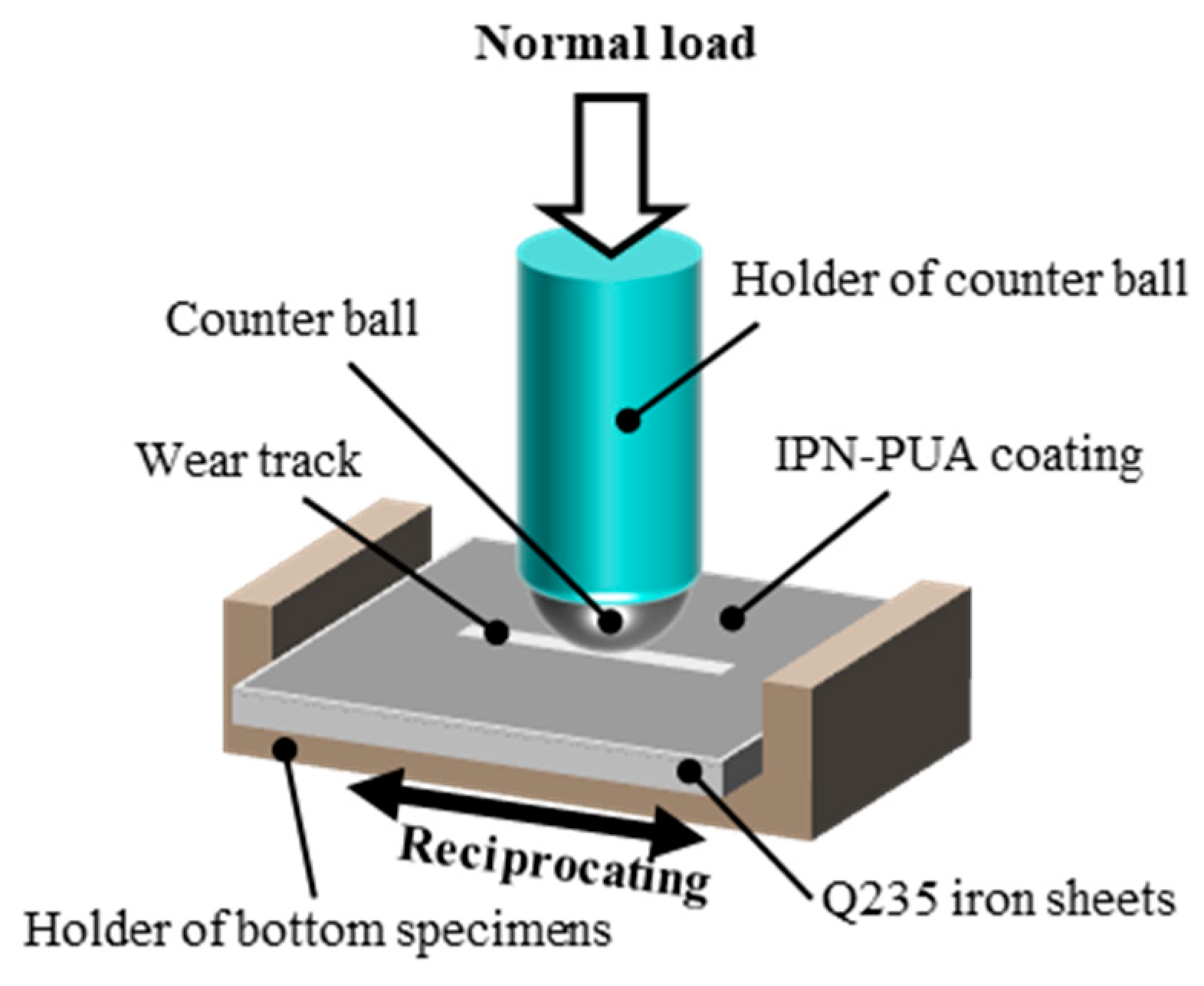

2.4. Characterization of Tribological Properties and Surface Morphologies

3. Results and Discussion

3.1. Properties of IPN-PUA Coatings with Diverse Components

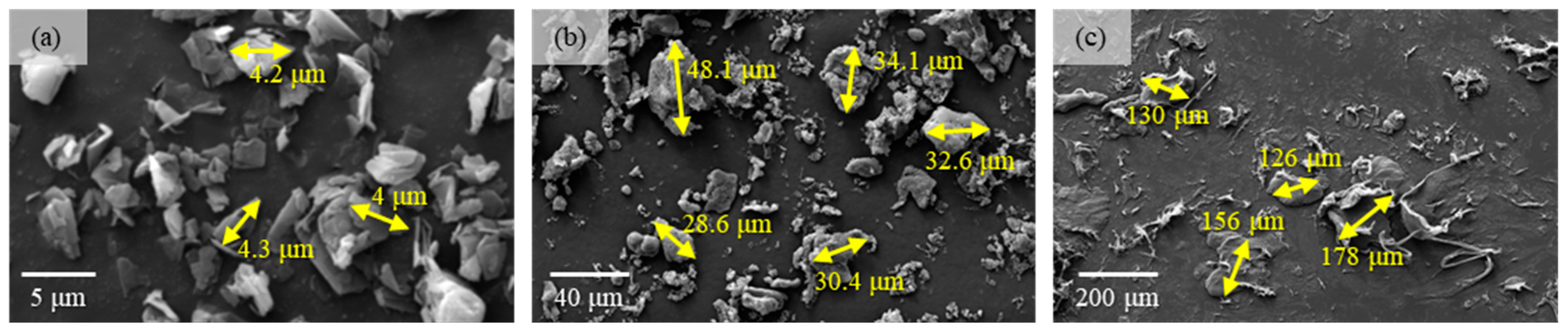

3.1.1. Surface Morphologies of IPN-PUA Coatings

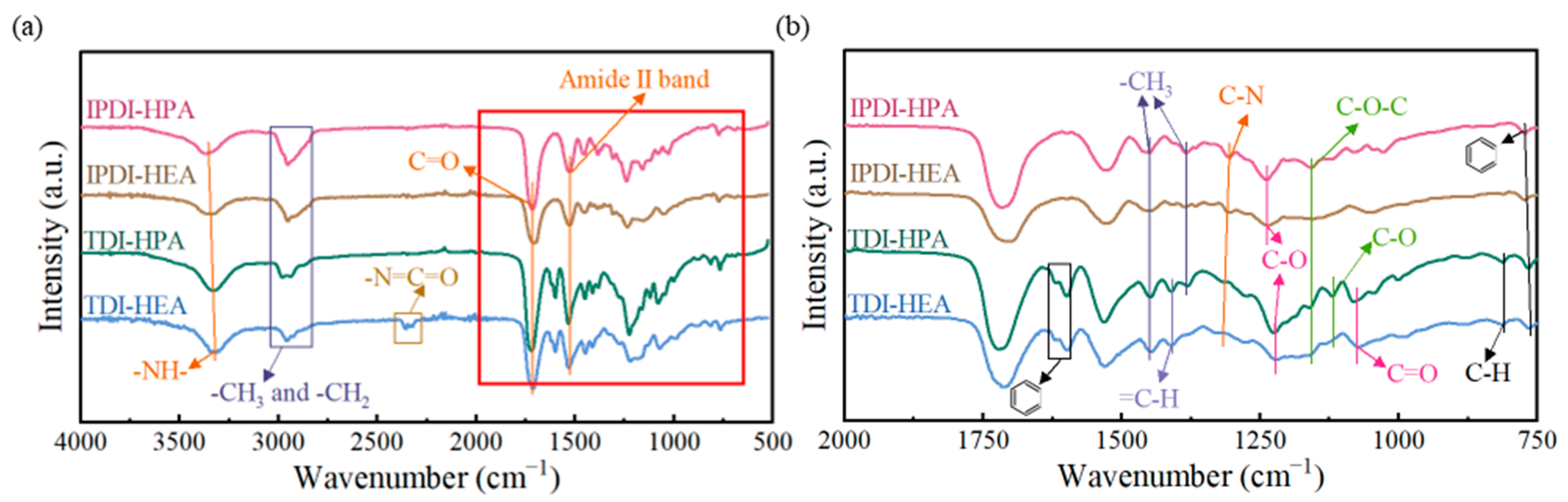

3.1.2. Components of IPN-PUA Coatings

3.1.3. Friction Properties of IPN-PUA Coatings

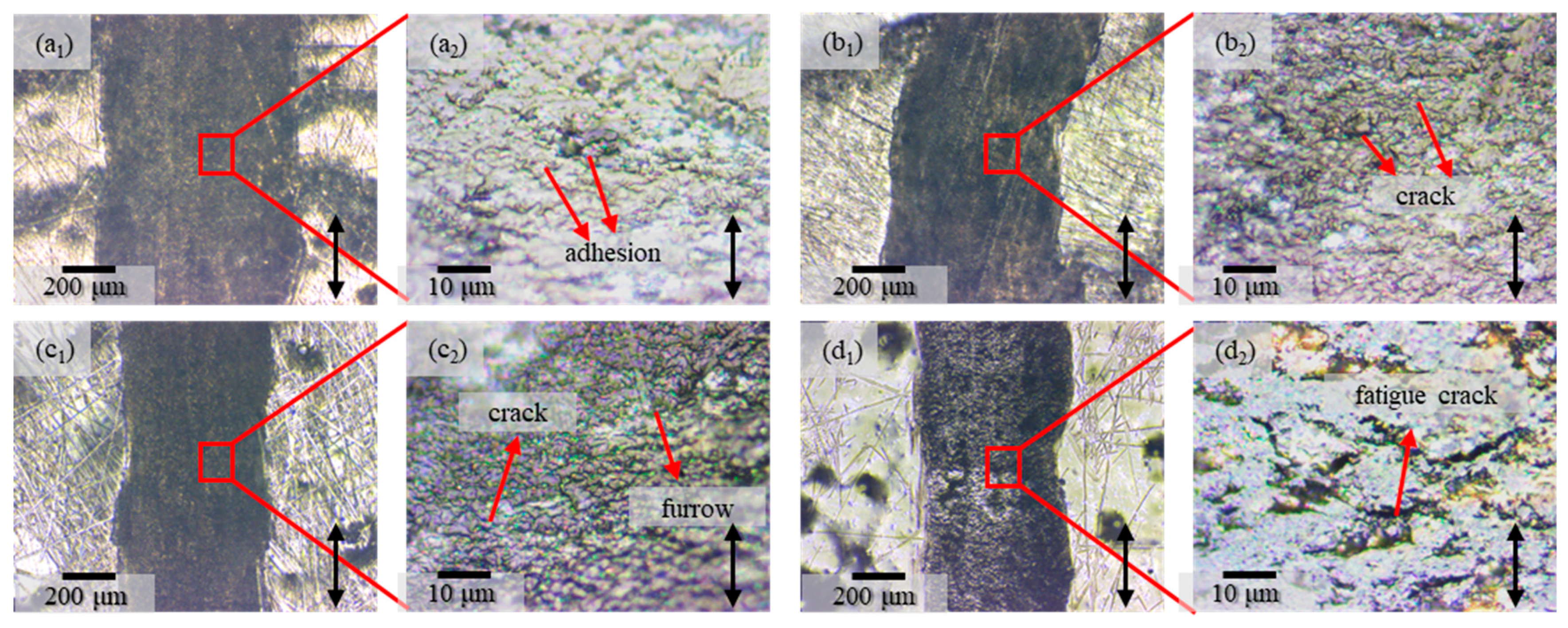

3.1.4. Wear Morphologies of IPN-PUA Coatings

3.1.5. Comprehensive Performance of IPN-PUA Coatings with Diverse Components

3.2. IPN-PUA Coatings with Different Lubricating Phases

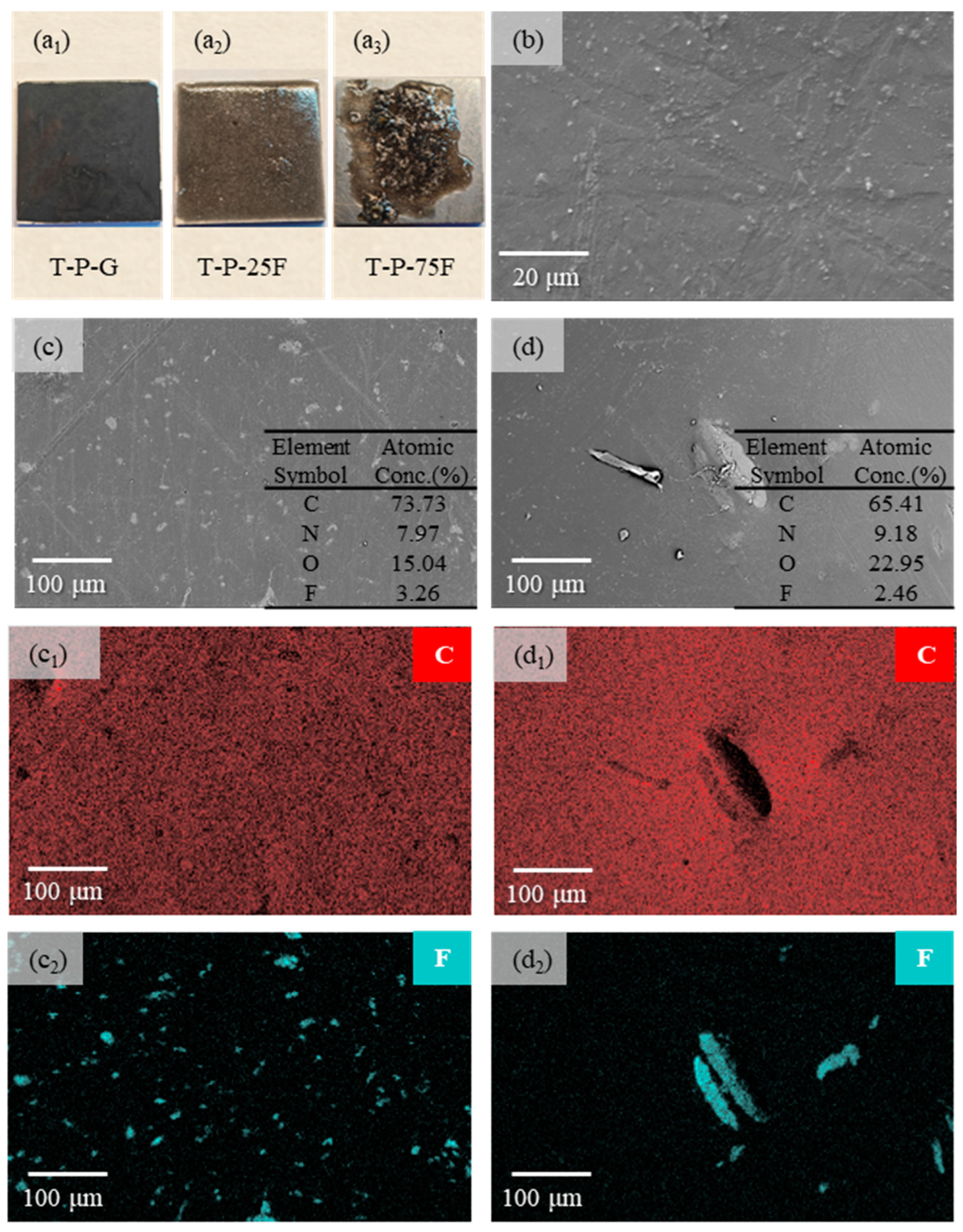

3.2.1. Surface Morphologies of the Self-Lubricating Coatings

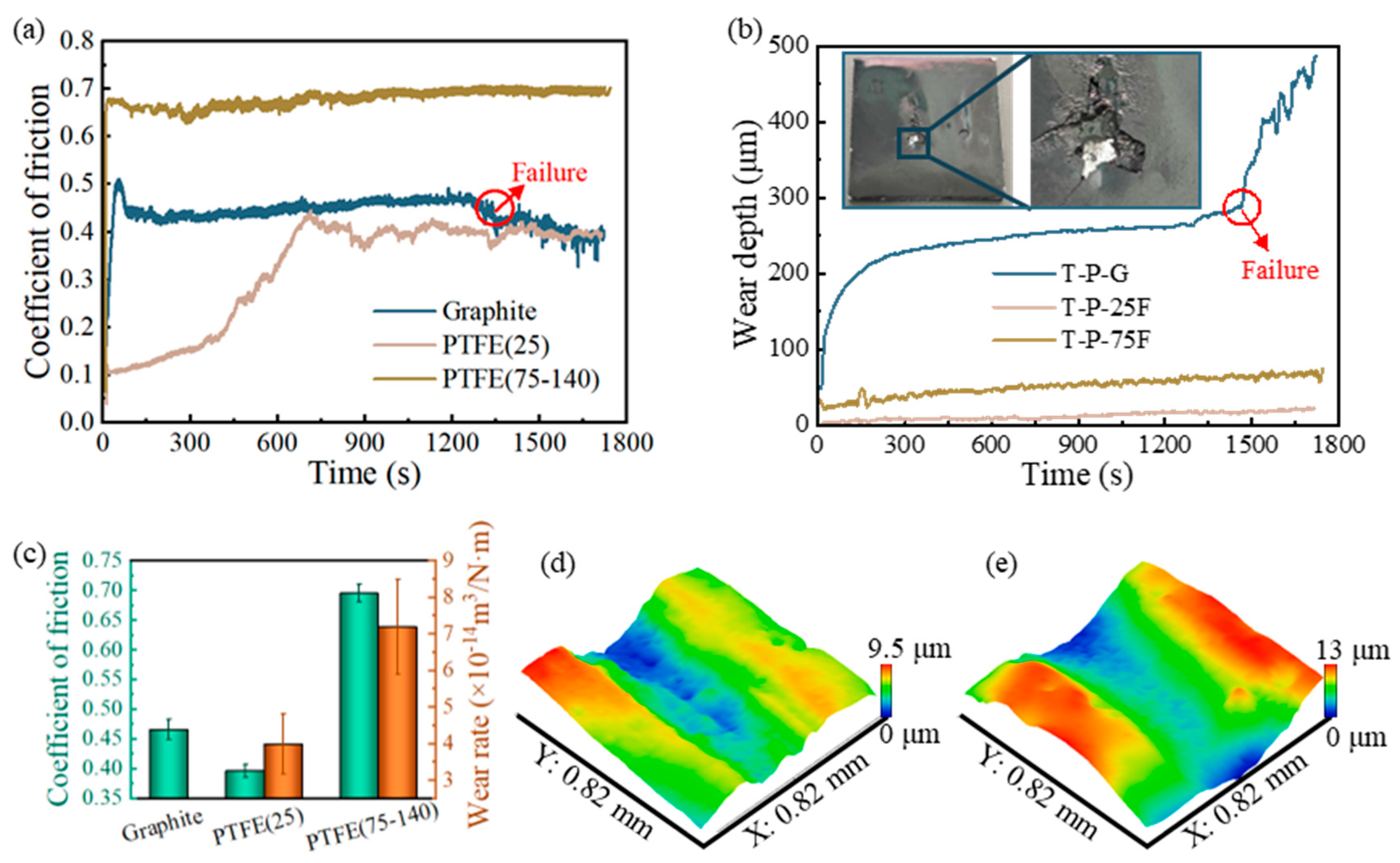

3.2.2. Friction Performance of Self-Lubricating Coatings

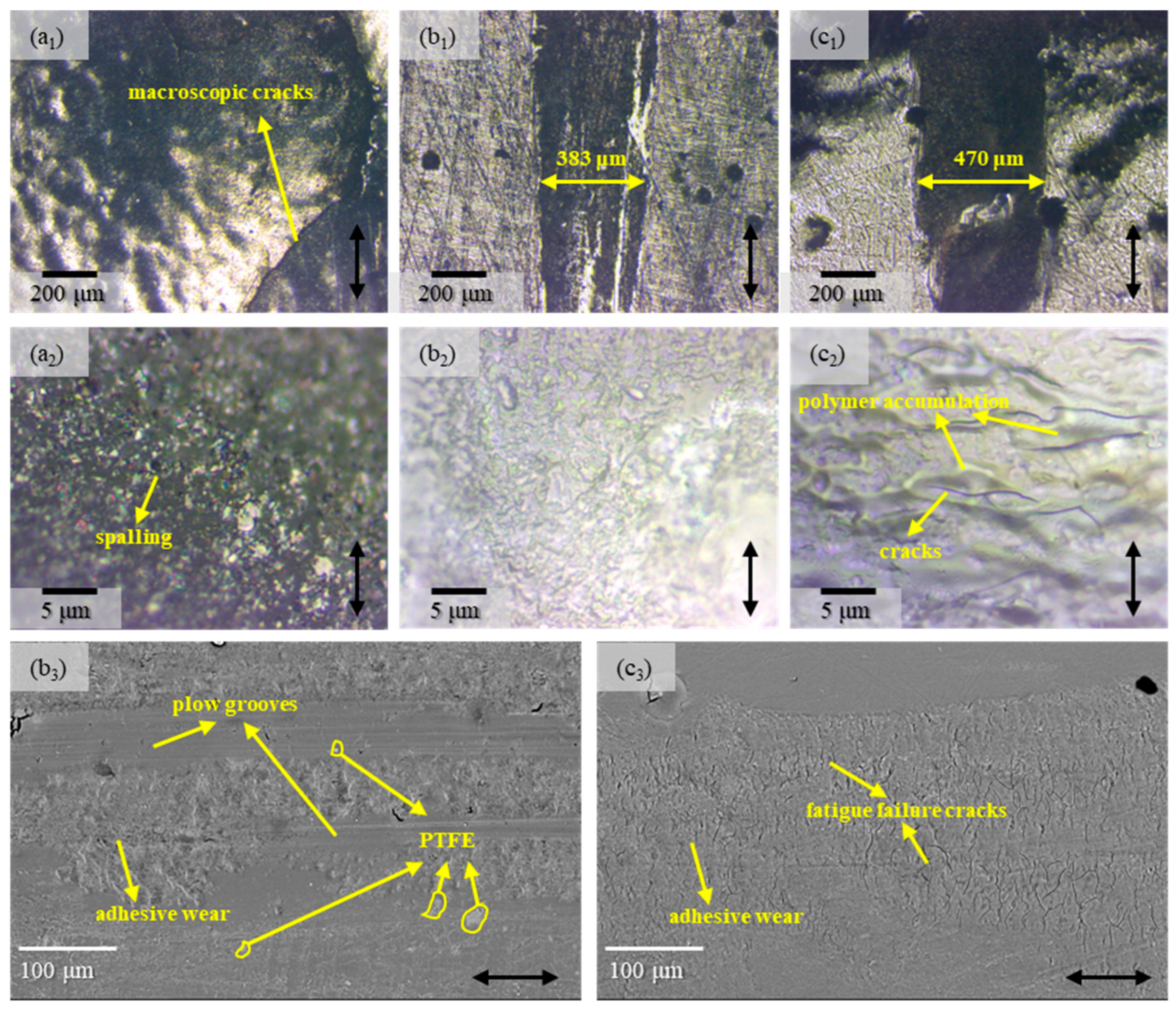

3.2.3. Wear Morphology of Self-Lubricating Coatings

4. Conclusions

- It was determined that the selection of isocyanate and hydroxyl acrylate monomers had a significant influence on the coating properties. Generally, TDI-based coatings demonstrated better wear resistance in comparison to IPDI-based ones, and coatings containing HEA had lower wear rates than those containing HPA.

- Among the four basic coatings, TDI-HPA exhibited the most favorable comprehensive performance, with its surface roughness of 1.485 μm and wear rate of 10.64 × 10−14 m3/N·m with a 56.5% reduction compared to IPDI-HPA. However, due to its high COF of 0.746, its overall performance still failed to reach a satisfactory level.

- In coatings, 25 μm sized PTFE particles outperform their 75 μm sized counterparts in terms of anti-friction and wear-resistance capabilities. This phenomenon is different from the impact pattern of particle size on the tribological characteristics in bulk materials. Small-sized PTFE particles are capable of achieving a more homogeneous dispersion within the coating matrix. In contrast, large-sized PTFE particles tend to induce phase separation and exert a negligible influence on enhancing the tribological properties.

- The T-P-25F coating showed a certain self-lubricating performance and remarkable wear-resistance performance. Its COF and wear rate were 0.395 and 3.97 × 10−14 m3/N·m, respectively, representing a reduction of 47% and 62.7% compared to the pure TDI-HPA coating.

- Graphite also had an impact on the friction performance of the coating. However, its light-blocking property hindered the formation of the coating during UV curing.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Donnet, C.; Erdemir, A. Solid Lubricant Coatings: Recent Developments and Future Trends. Tribol. Lett. 2004, 17, 389–397. [Google Scholar] [CrossRef]

- Ren, Y.; Zhang, L.; Xie, G.; Li, Z.; Chen, H.; Gong, H.; Xu, W.; Guo, D.; Luo, J. A Review on Tribology of Polymer Composite Coatings. Friction 2021, 9, 429–470. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, J.; Zhang, X.; Wang, X.; Long, Q.; Xu, H.; Zhu, M. The Investigation of Tribological Properties of PAI/PI-EPN Polymer Coating Filled with WS2 and SiC at Low Temperatures. J. Appl. Polym. Sci. 2024, 141, e55953. [Google Scholar] [CrossRef]

- Fernández-Álvarez, M.; Velasco, F.; Torres-Carrasco, M.; Bautista, A. Hindering the Decrease in Wear Resistance of UV-Exposed Epoxy Powder Coatings by Adding Nano-SiO2 through Ball Milling. Wear 2021, 480–481, 203935. [Google Scholar] [CrossRef]

- Chen, X.W.; Tang, S.; Xie, W.L.; Zhang, M.; Song, H.; Ran, Q.Z.; Zhang, D.F.; Zeng, D.Z. Friction and Wear Behavior of Micro-arc Oxidation-modified Graphene/Epoxy Resin Composite Coating on TC4 Titanium Alloy. Mater. Werkst. 2024, 55, 1037–1044. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, M.; Yuan, J.; Guo, F.; Men, X. Friction and Wear Behaviors of MoS2-Multi-Walled-Carbonnanotube Hybrid Reinforced Polyurethane Composite Coating. Friction 2019, 7, 316–326. [Google Scholar] [CrossRef]

- Bai, T.; Liu, Z.; Pei, Z.; Fang, W.; Ma, Y. Tribological Performance Studies of Waterborne Polyurethane Coatings with Aligned Modified Graphene Oxide@Fe3O4. ACS Omega 2021, 6, 9243–9253. [Google Scholar] [CrossRef]

- Tang, Y.; Yang, J.; Yin, L.; Chen, B.; Tang, H.; Liu, C.; Li, C. Fabrication of Superhydrophobic Polyurethane/MoS2 Nanocomposite Coatings with Wear-Resistance. Colloids Surf. A Physicochem. Eng. Asp. 2014, 459, 261–266. [Google Scholar] [CrossRef]

- Ching, Y.C.; Syamimie, N. Effect of Nanosilica Filled Polyurethane Composite Coating on Polypropylene Substrate. J. Nanomater. 2013, 2013, 567908. [Google Scholar] [CrossRef]

- Um, M.S.; Ham, D.S.; Cho, S.K.; Lee, S.-J.; Kim, K.J.; Lee, J.H.; Choa, S.-H.; Jung, H.W.; Choi, W.J. Surface Mechanical Properties of Poly(Urethane Acrylate)/Silica Hybrid Interpenetrating Polymer Network (IPN) Coatings. Prog. Org. Coat. 2016, 97, 166–174. [Google Scholar] [CrossRef]

- Athawale, V.D.; Kulkarni, M.A. Core-shell and Interpenetrating-network PU/AC Hybrids: Synthesis and Comparison—Waterborne Polyurethane/Polyacrylate Hybrid Dispersions. Pigment Resin Technol. 2010, 39, 141–148. [Google Scholar] [CrossRef]

- Liu, J.; Miao, P.; Zhang, W.; Song, G.; Feng, J.; Leng, X.; Li, Y. Synthesis and Characterization of Interpenetrating Polymer Networks (IPNs) Based on UV Curable Resin and Blocked Isocyanate/Polyols. Polymer 2022, 256, 125254. [Google Scholar] [CrossRef]

- Ma, C.; Gao, X.; Yang, Y.; Bian, X.; Wang, B.; Liu, X.; Wang, Y.; Su, D.; Zhang, G.; Qu, L.; et al. The Three-Dimensional Culture of L929 and C2C12 Cells Based on SPI-SA Interpenetrating Network Hydrogel Scaffold with Excellent Mechanical Properties. Front. Bioeng. Biotechnol. 2024, 11, 1329183. [Google Scholar] [CrossRef]

- Ding, X.; Wang, M.; Wei, L.; Wang, L.; Yuan, M.; Yu, F.; Yang, H. Mechanical Properties of Three N-Isopropylacrylamide-Based Semi-Interpenetrating Network Bilayer Hydrogels and Their Effects on Multi-Stimuli Responsiveness. Iran Polym. J. 2024, 33, 273–287. [Google Scholar] [CrossRef]

- Xu, Z.; Liu, Y.; Lv, M.; Qiao, X.; Fan, G.-C.; Luo, X. An Anti-Fouling Wearable Molecular Imprinting Sensor Based on Semi-Interpenetrating Network Hydrogel for the Detection of Tryptophan in Sweat. Anal. Chim. Acta 2023, 1283, 341948. [Google Scholar] [CrossRef] [PubMed]

- Yi, L.; Zhou, L.; Yan, L.; Xu, Z. Preparation of Polyethylene Glycol/Polyacrylamide Interpenetrating Network Hydrogel for Simultaneously Enhancing the Fire Protection and Aging Resistance of Fireproof Glass. J. Appl. Polym. Sci. 2023, 140, e54644. [Google Scholar] [CrossRef]

- Moradi, G.; Monazzam, M.; Ershad-Langroudi, A.; Parsimehr, H.; Keshavarz, S.T. Organoclay Nanoparticles Interaction in PU:PMMA IPN Foams: Relationship between the Cellular Structure and Damping-Acoustical Properties. Appl. Acoust. 2020, 164, 107295. [Google Scholar] [CrossRef]

- Li, Y.Q.; Zhu, X.; Luo, Z.; Sun, W.H. Research for Damping Behavior and Microstructure of Interpenetrating Polymer Networks Based on Multi-Components. Adv. Mater. Res. 2011, 328–330, 1177–1181. [Google Scholar] [CrossRef]

- Zahedi, F.; Amraei, I.A.; Fathizade, M.A. Investigation of Dynamic-Mechanical Properties of Multilayer Latex IPNs (MLIPNs) with Core/Shell Morphology: Synthesis and Characterization. Polymer 2016, 83, 162–171. [Google Scholar] [CrossRef]

- Li, X.; Niu, Y.; Ai, T.; Li, X.; Yang, P.; Wang, X.; Zhang, Z. Preparation and Performance Study of Polyurethane/Epoxy Resin Interpenetrating Networks with Self-healing, Shape Memory, and High Damping Properties. Macro Chem. Phys. 2024, 225, 2300311. [Google Scholar] [CrossRef]

- Xu, J.; Wang, H.; Wen, X.; Wang, S.; Wang, H. Mechanically Strong, Wet Adhesive, and Self-Healing Polyurethane Ionogel Enhanced with a Semi-Interpenetrating Network for Underwater Motion Detection. ACS Appl. Mater. Interfaces 2022, 14, 54203–54214. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, S.; Chakrabarty, D.; Mukherjee, S.; Bhowmik, S. Characteristics of Simultaneous Epoxy-Novolac Full Interpenetrating Polymer Network (IPN) Adhesive. J. Adhes. Sci. Technol. 2018, 32, 705–720. [Google Scholar] [CrossRef]

- Ahmed, S.; Chakrabarty, D.; Bhowmik, S.; Mukherjee, S.; Rane, R. Epoxy-Novolac Interpenetrating Network Adhesive for Bonding of Plasma-Nitrided Titanium. J. Adhes. Sci. Technol. 2015, 29, 1446–1464. [Google Scholar] [CrossRef]

- Cai, M.; Lin, Q.; Li, W.; Fan, X.; Zhu, M. Phen@TiO2 Modified Epoxy Resin/Polyacrylate IPN Composite Coating towards Wear/Corrosion Resistance and Intelligent Self-Repairing/Diagnosis. Prog. Org. Coat. 2022, 173, 107207. [Google Scholar] [CrossRef]

- Fabre-Francke, I.; Berrebi, M.; Lavédrine, B.; Fichet, O. Hybrid PMMA Combined with Polycarbonate inside Interpenetrating Polymer Network Architecture for Development of New Anti-Scratch Glass. Mater. Today Commun. 2019, 21, 100582. [Google Scholar] [CrossRef]

- Wu, C.; Hou, D.; Yin, B.; Chen, B.; Li, Z. A Polystyrene Acrylate-Polysiloxane Multicomponent Protective Coating with Interpenetrating Polymer Network Structure for Cementitious Materials. Prog. Org. Coat. 2024, 195, 108640. [Google Scholar] [CrossRef]

- Tavsanli, B.; Bilici, C.; Sungur, P.; Ide, S.; Okay, O. Butyl Rubber as a Macro-Cross-Linker in the Preparation of a Shape-Memory and Self-Healing Polymer. J. Rheol. 2022, 66, 1367–1378. [Google Scholar] [CrossRef]

- Carbajo-Gordillo, A.I.; Benito, E.; Galbis, E.; Grosso, R.; Iglesias, N.; Valencia, C.; Lucas, R.; García-Martín, M.-G.; de-Paz, M.-V. Simultaneous Formation of Polyhydroxyurethanes and Multicomponent Semi-IPN Hydrogels. Polymers 2024, 16, 880. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Wang, Q.; Wang, T. Friction and Wear Behaviors of Two Kinds of Hydroxyl-Terminated Polydimethylsiloxane-Modified PU/EP IPN Composites under Dry Sliding Conditions. Tribol. Lett. 2011, 43, 319–327. [Google Scholar] [CrossRef]

- Yu, P.; Li, G.; Zhang, L.; Zhao, F.; Guo, Y.; Pei, X.-Q.; Zhang, G. Role of SiC Submicron-Particles on Tribofilm Growth at Water-Lubricated Interface of Polyurethane/Epoxy Interpenetrating Network (PU/EP IPN) Composites and Steel. Tribol. Int. 2021, 153, 106611. [Google Scholar] [CrossRef]

- Xia, S.; Liu, Y.; Pei, F.; Zhang, L.; Gao, Q.; Zou, W.; Peng, J.; Cao, S. Identical Steady Tribological Performance of Graphene-Oxide-Strengthened Polyurethane/Epoxy Interpenetrating Polymer Networks Derived from Graphene Nanosheet. Polymer 2015, 64, 62–68. [Google Scholar] [CrossRef]

- Xia, S.; Liu, Y.; Zhang, L.; Wang, D.; Zou, W.; Peng, J.; Cao, S. Tribological Mechanism Improving the Wear Resistance of Polyurethane/Epoxy Interpenetrating Polymer Network via Nanodiamond Hybridization. J. Appl. Polym. Sci. 2014, 131, 40244. [Google Scholar] [CrossRef]

- Yu, P.; Li, G.; Zhang, L.; Zhao, F.; Chen, S.; Dmitriev, A.I.; Zhang, G. Regulating Microstructures of Interpenetrating Polyurethane-Epoxy Networks towards High-Performance Water-Lubricated Bearing Materials. Tribol. Int. 2019, 131, 454–464. [Google Scholar] [CrossRef]

- Lin, Q.; Wang, X.; Cai, M.; Yan, H.; Zhao, Z.; Fan, X.; Zhu, M. Enhancement of Si3N4@MoS2 Core-Shell Structure on Wear/Corrosion Resistance of Epoxy Resin/Polyacrylate IPN Composite Coating. Appl. Surf. Sci. 2021, 568, 150938. [Google Scholar] [CrossRef]

- Li, Z.; Qi, X.; Liu, C.; Fan, B.; Yang, X. Particle Size Effect of PTFE on Friction and Wear Properties of Glass Fiber Reinforced Epoxy Resin Composites. Wear 2023, 532–533, 205104. [Google Scholar] [CrossRef]

- Ceylan, R.; Ozun, E.; Özzaim Toker, P.; Korkusuz, O.B.; Yarar, E.; Fidan, S.; Bora, M.Ö.; Sınmazçelik, T. Understanding the Effect of Solid Lubricants on Scratch Behavior in Epoxy Resins: An Experimental and Statistical Approach. Polym. Compos. 2024, 45, 7346–7363. [Google Scholar] [CrossRef]

- Wu, X.; Wyman, I.; Zhang, G.; Lin, J.; Liu, Z.; Wang, Y.; Hu, H. Preparation of Superamphiphobic Polymer-Based Coatings via Spray- and Dip-Coating Strategies. Prog. Org. Coat. 2016, 90, 463–471. [Google Scholar] [CrossRef]

- Moridi, A.; Hassani-Gangaraj, S.M.; Guagliano, M.; Dao, M. Cold Spray Coating: Review of Material Systems and Future Perspectives. Surf. Eng. 2014, 30, 369–395. [Google Scholar] [CrossRef]

- Petrovicova, E.; Schadler, L.S. Thermal Spraying of Polymers. Int. Mater. Rev. 2002, 47, 169–190. [Google Scholar] [CrossRef]

- Pathania, A.; Arya, R.K.; Ahuja, S. Crosslinked Polymeric Coatings: Preparation, Characterization, and Diffusion Studies. Prog. Org. Coat. 2017, 105, 149–162. [Google Scholar] [CrossRef]

- Zhou, J.; Zhu, C.; Liang, H.; Wang, Z.; Wang, H. Preparation of UV-Curable Low Surface Energy Polyurethane Acrylate/Fluorinated Siloxane Resin Hybrid Coating with Enhanced Surface and Abrasion Resistance Properties. Materials 2020, 13, 1388. [Google Scholar] [CrossRef] [PubMed]

- Cao, W.; Yan, W.; Yang, X.; Li, Z.; Geng, J.; Dong, Y.; Zhang, Y.; Qi, X. Multiscale Study on the Solid-Liquid Synergistic Lubrication Mechanism of Graphite and Liquid Lubricant in Polymer Composites. Carbon 2024, 230, 119605. [Google Scholar] [CrossRef]

- Cao, W.; Yang, X.; Wang, H.; Dong, Y.; Liu, C.; Fan, B.; Qi, X. IPN-PUA: An Ultra-Low Density Self-Lubricating Composites with IPN Structure-Liquid Lubricant Coupling Mechanism. Friction 2025, 13, 9440997. [Google Scholar] [CrossRef]

- GB/T265-1988; Petroleum Products—Determination of Kinematic Viscosity and Calculation of Dynamic Viscosity. Standardization Administration of the People’s Pepublic of China: Beijing, China, 1988.

- Guo, M.; Chen, H.; Maia, J.M. Effects of Structure and Processing on the Surface Roughness of Extruded Co-Continuous Poly(Ethylene) Oxide/Ethylene-Vinyl Acetate Blends. J. Polym. Eng. 2020, 40, 763–770. [Google Scholar] [CrossRef]

- Sultan, M.; Zia, K.M.; Bhatti, H.N.; Jamil, T.; Hussain, R.; Zuber, M. Modification of Cellulosic Fiber with Polyurethane Acrylate Copolymers. Part I: Physicochemical Properties. Carbohydr. Polym. 2012, 87, 397–404. [Google Scholar] [CrossRef]

- Bakhshandeh, E.; Sobhani, S.; Croutxé-Barghorn, C.; Allonas, X.; Bastani, S. Siloxane-Modified Waterborne UV-Curable Polyurethane Acrylate Coatings: Chemorheology and Viscoelastic Analyses. Prog. Org. Coat. 2021, 158, 106323. [Google Scholar] [CrossRef]

- Zhang, Y.; Feng, R.; Chen, Z.; Zhao, T.; Ju, Y.; Yan, S.; Song, S.; Zhao, G.; Dong, L. Significantly Enhancing Energy Storage Performances of Flexible Dielectric Film by Introducing Poly(1,4-Anthraquinone). Eur. Polym. J. 2021, 152, 110486. [Google Scholar] [CrossRef]

- Peng, C.; Zeng, F.; Yuan, B.; Wang, Y. An MD Simulation Study to the Indentation Size Effect of Polystyrene and Polyethylene with Various Indenter Shapes and Loading Rates. Appl. Surf. Sci. 2019, 492, 579–590. [Google Scholar] [CrossRef]

- Yan, Y.; Zhang, B.; Wang, J.; Cao, C.; Yan, F. MWCNT–Polyimide Fiber-Reinforced Composite for High-Temperature Tribological Applications. Coatings 2024, 14, 181. [Google Scholar] [CrossRef]

- Ma, Y.; Ye, Y.; Wan, H.; Chen, L.; Zhou, H.; Chen, J. Tribological Behaviors of the UV Curing Polyurethane Acrylate Resin-Polytetrafluoroethylene Bonded Solid Lubricating Coatings Filled with LaF3. Prog. Org. Coat. 2018, 121, 218–225. [Google Scholar] [CrossRef]

- Zhang, H.; Feng, X.; Wu, Y.; Wu, Z. Effect of Photoinitiator Concentration and Film Thickness on the Properties of UV-Curable Self-Matting Coating for Wood-Based Panels. Forests 2023, 14, 1189. [Google Scholar] [CrossRef]

- Lee, S.-J.; Kim, G.-M.; Kim, C.-L. Self-Lubrication and Tribological Properties of Polymer Composites Containing Lubricant. RSC Adv. 2023, 13, 3541–3551. [Google Scholar] [CrossRef] [PubMed]

- He, H.; Liu, Y.; Xu, Y.; Yu, S.; Wang, W.; Liang, F. Self-Lubrication Waterborne Epoxy Composite Coating with Amphiphilic Janus Nanoparticles. Prog. Org. Coat. 2024, 189, 108303. [Google Scholar] [CrossRef]

- Zhang, D.; Ho, J.K.L.; Dong, G.; Zhang, H.; Hua, M. Tribological Properties of Tin-Based Babbitt Bearing Alloy with Polyurethane Coating under Dry and Starved Lubrication Conditions. Tribol. Int. 2015, 90, 22–31. [Google Scholar] [CrossRef]

- Wang, S.; Han, X.; Jiang, S.; Huang, Y.; Yin, X.; Chai, C. A Review of Solid Lubrication Based on Polyurethane Composites. Polym. Compos. 2023, 44, 4420–4432. [Google Scholar] [CrossRef]

- Edman Jonsson, G.; Fredriksson, H.; Sellappan, R.; Chakarov, D. Nanostructures for Enhanced Light Absorption in Solar Energy Devices. Int. J. Photoenergy 2011, 2011, 1–11. [Google Scholar] [CrossRef]

- Zhu, J.; Yan, S.; Feng, N.; Ye, L.; Ou, J.-Y.; Liu, Q.H. Near Unity Ultraviolet Absorption in Graphene without Patterning. Appl. Phys. Lett. 2018, 112, 153106. [Google Scholar] [CrossRef]

- Karimi, S.; Helal, E.; Gutierrez, G.; Moghimian, N.; Madinehei, M.; David, E.; Samara, M.; Demarquette, N. A Review on Graphene’s Light Stabilizing Effects for Reduced Photodegradation of Polymers. Crystals 2020, 11, 3. [Google Scholar] [CrossRef]

| Paint | IPDI-HPA | IPDI-HEA | TDI-HPA | TDI-HEA |

|---|---|---|---|---|

| Viscosity (mm2/s) | 22.02 22.73 | 24.31 25.08 | 106.03 94.79 | 1127.87 1176.06 |

| Viscometer capillary diameter | 1.2 mm | 1.2 mm | 2 mm | 2 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, W.; Yang, X.; Song, Z.; Geng, J.; Liu, C.; Zhang, N.; Qi, X. Research on the Tribological Behavior of Polyurethane Acrylate Coatings with Different Matrix Constituents as Well as Graphite and PTFE. Polymers 2025, 17, 1121. https://doi.org/10.3390/polym17081121

Cao W, Yang X, Song Z, Geng J, Liu C, Zhang N, Qi X. Research on the Tribological Behavior of Polyurethane Acrylate Coatings with Different Matrix Constituents as Well as Graphite and PTFE. Polymers. 2025; 17(8):1121. https://doi.org/10.3390/polym17081121

Chicago/Turabian StyleCao, Weihua, Xiao Yang, Zhenjie Song, Jia Geng, Changxin Liu, Ning Zhang, and Xiaowen Qi. 2025. "Research on the Tribological Behavior of Polyurethane Acrylate Coatings with Different Matrix Constituents as Well as Graphite and PTFE" Polymers 17, no. 8: 1121. https://doi.org/10.3390/polym17081121

APA StyleCao, W., Yang, X., Song, Z., Geng, J., Liu, C., Zhang, N., & Qi, X. (2025). Research on the Tribological Behavior of Polyurethane Acrylate Coatings with Different Matrix Constituents as Well as Graphite and PTFE. Polymers, 17(8), 1121. https://doi.org/10.3390/polym17081121