Enhancement of Partial Nitrification–Anaerobic Ammonia Oxidation in SBR Reactors via Surface-Modified Polyurethane Sponge Biofilm Carrier

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.1.1. Seed Sludge

2.1.2. Synthetic Wastewater

2.2. Methods

2.2.1. Carrier Preparation and Reactor Description

2.2.2. Reactor Operation and Control

2.2.3. Sludge Activity Detection

2.2.4. Water Quality Detection

2.2.5. Extracellular Polymeric Substances (EPS) Extraction and Speciation

2.2.6. Microbial Detection

3. Results and Discussion

3.1. Characterization of Modified Polyurethane Sponge Carrier

3.1.1. Surface Properties

3.1.2. Ammonia Nitrogen Adsorption Capacity

3.2. Reactor Performance Enhanced by Carrier Modification

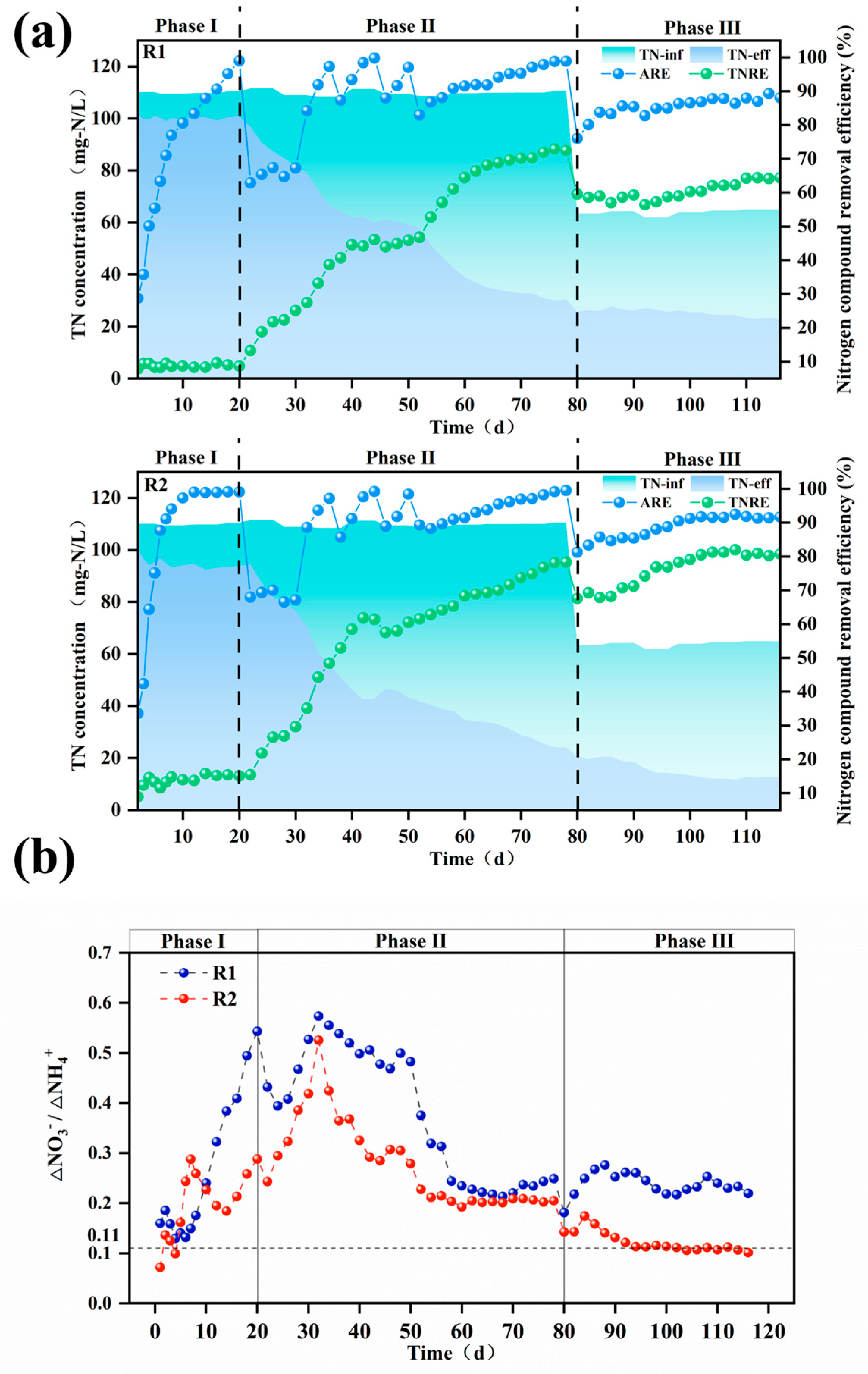

3.2.1. Nitrogen Removal

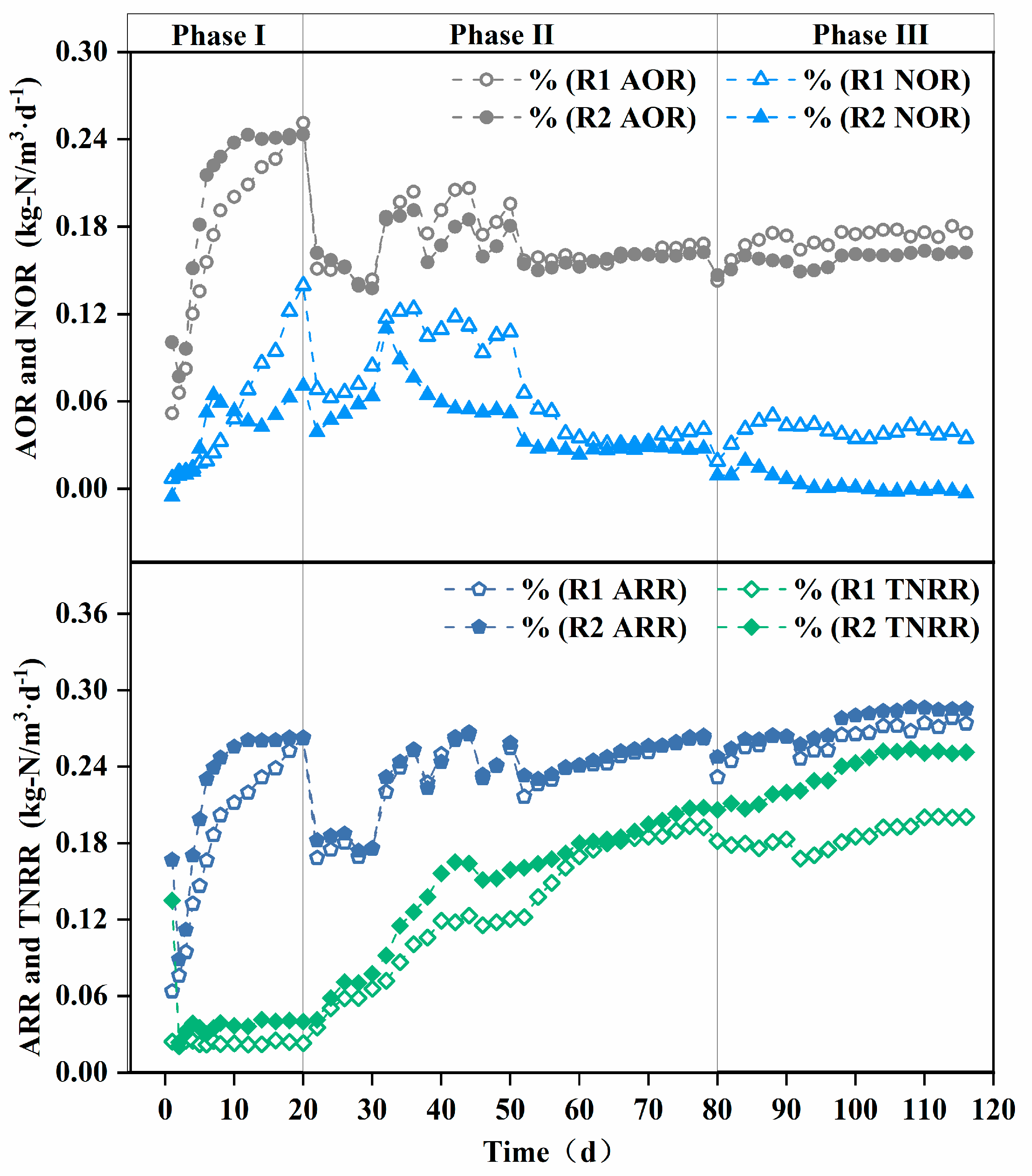

3.2.2. Start-Up of PN/A Process

3.3. Biofilm and Microbial Community

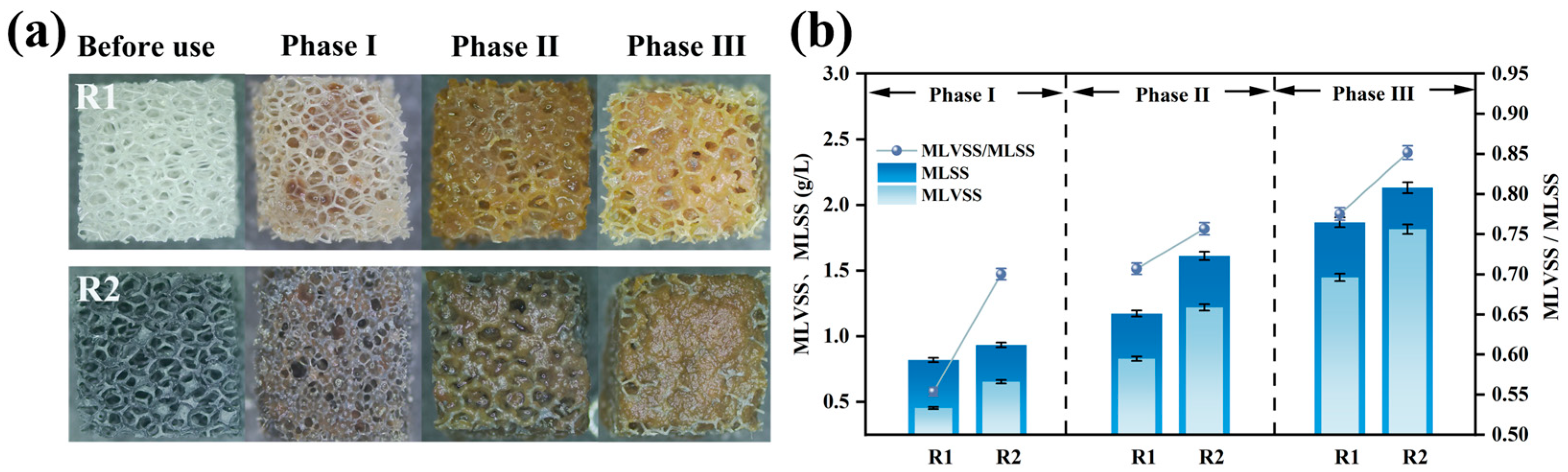

3.3.1. Biofilm and Biomass Growth on Carriers

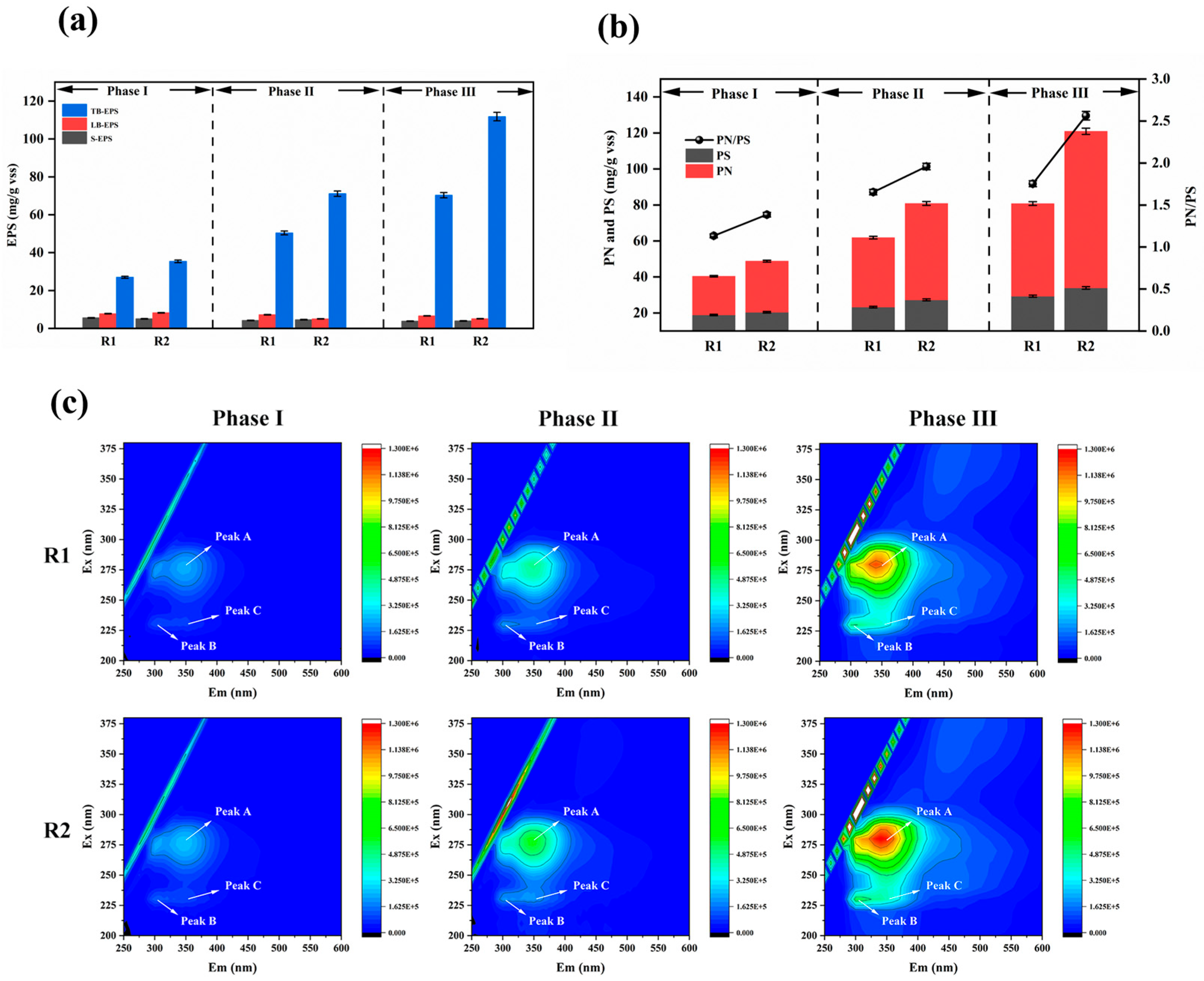

3.3.2. EPS Composition and Speciation

3.3.3. Microbial Community in Biofilm

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, T.; Tian, R.; Li, Q.; Wu, N.; Quan, X. Strengthened Attachment of Anammox Bacteria on Iron-Based Modified Carrier and Its Effects on Anammox Performance in Integrated Floating-Film Activated Sludge (IFFAS) Process. Sci. Total Environ. 2021, 787, 147679. [Google Scholar] [CrossRef] [PubMed]

- Huff Chester, A.L.; Eum, K.; Tsapatsis, M.; Hillmyer, M.A.; Novak, P.J. Enhanced Nitrogen Removal and Anammox Bacteria Retention with Zeolite-Coated Membrane in Simulated Mainstream Wastewater. Environ. Sci. Technol. Lett. 2021, 8, 468–473. [Google Scholar] [CrossRef]

- Adams, M.; Xie, J.; Xie, J.; Guo, M.; Chen, C. Research Advances in Anammox Granular Sludge: A Review. Crit. Rev. Environ. Sci. Technol. 2022, 52, 631–674. [Google Scholar] [CrossRef]

- Edwards, T.M. Ammonia and Aquatic Ecosystems—A Review of Global Sources, Biogeochemical Cycling, and Effects on Fish. Sci. Total Environ. 2024, 907, 167911. [Google Scholar] [CrossRef]

- Cai, X. Remote Sensing Identification of Urban Water Pollution Source Types Using Hyperspectral Data. J. Hazard. Mater. 2023, 459, 132080. [Google Scholar] [CrossRef]

- Qi, G. Ammonium Sulfite Pretreatment of Wheat Straw for Efficient Enzymatic Saccharification. Sustain. Energy Technol. Assess. 2018, 29, 12–18. [Google Scholar] [CrossRef]

- Durán, U. Enhanced Ammonia Removal at Room Temperature by pH Controlled Partial Nitrification and Subsequent anaerobic ammonium oxidation. Environ. Technol. 2013, 35, 383–390. [Google Scholar] [CrossRef]

- Bagchi, S.; Biswas, R.; Nandy, T. Alkalinity and Dissolved Oxygen as Controlling Parameters for Ammonia Removal through Partial Nitritation and ANAMMOX in a Single-Stage Bioreactor. J. Ind. Microbiol. Biotechnol. 2010, 37, 871–876. [Google Scholar] [CrossRef]

- Tsushima, I.; Ogasawara, Y.; Kindaichi, T.; Satoh, H.; Okabe, S. Development of High-Rate Anaerobic Ammonium-Oxidizing (Anammox) Biofilm Reactors. Water Res. 2007, 41, 1623–1634. [Google Scholar] [CrossRef]

- Wang, Z.; Zheng, M.; Duan, H.; Yuan, Z.; Hu, S. A 20-Year Journey of Partial Nitritation and Anammox (PN/A): From Sidestream toward Mainstream. Environ. Sci. Technol. 2022, 56, 7522–7531. [Google Scholar] [CrossRef]

- Miao, Y.; Peng, Y.; Zhang, L.; Li, B.; Li, X.; Wu, L.; Wang, S. Partial Nitrification-Anammox (PNA) Treating Sewage with Intermittent Aeration Mode: Effect of Influent C/N Ratios. Chem. Eng. J. 2018, 334, 664–672. [Google Scholar] [CrossRef]

- Si, Y. Rapid Pathogen Discovery in Diseased Turbot (Scophthalmus Maximus) Using 16S rRNA High Throughput Sequencing. Aquac. Rep. 2021, 21, 100835. [Google Scholar] [CrossRef]

- Fang, A.; Feng, K.; Mei, X.; Liu, B.; Xie, G.; Ren, N.; Xing, D. The Simultaneous Recruitment of Anammox Granules and Biofilm by a Sequential Immobilization and Granulation Approach. Chem. Eng. J. 2021, 417, 128041. [Google Scholar] [CrossRef]

- Qian, Y.; Guo, Y.; Shen, J.; Qin, Y.; Li, Y.-Y. Biofilm Growth Characterization and Treatment Performance in a Single Stage Partial Nitritation/Anammox Process with a Biofilm Carrier. Water Res. 2022, 217, 118437. [Google Scholar] [CrossRef]

- Peng, Z.; Zhang, L.; Zhang, Q.; Li, X.; Peng, Y. Establishing a Two-Stage System to Efficiently Treat Real Domestic Sewage by Partial Nitrification-SBR and Air-Lift Anammox-UASB: Reactivating and Enhancing Anammox Bacteria to Optimize the Nitrogen Removal Performance. Chem. Eng. J. 2025, 506, 160333. [Google Scholar] [CrossRef]

- Cui, H.; Zhang, L.; Peng, Y.; Zhang, Q.; Li, X. Achieving Stable Nitritation for Mainstream Anammox by Combining Nitrite Exposure Inhibition with High DO Reactivation. J. Water Process Eng. 2022, 46, 102589. [Google Scholar] [CrossRef]

- Kent, T.R.; Sun, Y.; An, Z.; Bott, C.B.; Wang, Z.-W. Mechanistic Understanding of the NOB Suppression by Free Ammonia Inhibition in Continuous Flow Aerobic Granulation Bioreactors. Environ. Int. 2019, 131, 105005. [Google Scholar] [CrossRef]

- Li, Z.; Li, D.; Zhang, J.; Wang, W.; Li, M.; Wang, S.; Zeng, H.; Zhang, J. Unravelling the Optimal Strategy on the Stable Mineralized Anammox Granular Systems in Treating Low-Strength Wastewater. J. Water Process Eng. 2024, 59, 105083. [Google Scholar] [CrossRef]

- Yang, S.; Peng, Y.; Zhang, S.; Han, X.; Li, J.; Zhang, L. Carrier Type Induces Anammox Biofilm Structure and the Nitrogen Removal Pathway: Demonstration in a Full-Scale Partial Nitritation/Anammox Process. Bioresour. Technol. 2021, 334, 125249. [Google Scholar] [CrossRef]

- Huang, T. Fast Start-up and Enhancement of Partial Nitritation and Anammox Process for Treating Synthetic Wastewater in a Sequencing Bath Biofilm Reactor: Strategy and Function of Nitric Oxide. Bioresour. Technol. 2021, 335, 125225. [Google Scholar] [CrossRef]

- Wang, W. Dissolved Oxygen Microelectrode Measurements to Develop a More Sophisticated Intermittent Aeration Regime Control Strategy for Biofilm-Based CANON Systems. Chem. Eng. J. 2019, 365, 165–174. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, Y.; Xu, Z.; Lei, J.; Lian, H.; Zhang, J.; Wang, Z. Surface Modification of Polyurethane Sponge with Zeolite and Zero-Valent Iron Promotes Short-Cut Nitrification. Polymers 2024, 16, 1506. [Google Scholar] [CrossRef] [PubMed]

- Sheng, X.; Ting, Y.P.; Pehkonen, S.O. Force Measurements of Bacterial Adhesion on Metals Using a Cell Probe Atomic Force Microscope. J. Colloid Interface Sci. 2007, 310, 661–669. [Google Scholar] [CrossRef] [PubMed]

- Huang, J. Intermittent Aeration Improving Activated Granular Sludge Granulation for Nitrogen and Phosphorus Removal from Domestic Wastewater. Bioresour. Technol. Rep. 2021, 15, 100739. [Google Scholar] [CrossRef]

- Zhang, S. Anammox Activity Improved Significantly by the Cross-Fed NO from Ammonia-Oxidizing Bacteria and Denitrifying Bacteria to Anammox Bacteria. Water Res. 2024, 249, 120986. [Google Scholar] [CrossRef]

- Liu, T.; Xu, J.; Tian, R.; Quan, X. Enhanced Simultaneous Nitrification and Denitrification via Adding N-Acyl-Homoserine Lactones (AHLs) in Integrated Floating Fixed-Film Activated Sludge Process. Biochem. Eng. J. 2021, 166, 107884. [Google Scholar] [CrossRef]

- Lei, J.; Xu, Z.; Chen, Y.; Yu, G.; Liu, Z.; Wang, S.; Zhang, J.; Li, K.; Xie, L. Methane Production Reduced by Lignin Derivatives in Pulping Wastewater: Inhibition of Free Hydrolase. Fermentation 2024, 10, 247. [Google Scholar] [CrossRef]

- Yu, J. Spectroscopic Fingerprints Profiling the Polysaccharide/Protein/Humic Architecture of Stratified Extracellular Polymeric Substances (EPS) in Activated Sludge. Water Res. 2023, 235, 119866. [Google Scholar] [CrossRef]

- Boleij, M. Solubilization and Characterization of Extracellular Proteins from Anammox Granular Sludge. Water Res. 2019, 164, 114952. [Google Scholar] [CrossRef]

- Jiang, H. Modification of Polyurethane Sponge Filler Using Medical Stones and Application in a Moving Bed Biofilm Reactor for Ex Situ Remediation of Polluted Rivers. J. Water Process Eng. 2021, 42, 102189. [Google Scholar] [CrossRef]

- Chen, R.; Takemura, Y.; Liu, Y.; Ji, J.; Sakuma, S.; Kubota, K.; Ma, H.; Li, Y.-Y. Using Partial Nitrification and Anammox To Remove Nitrogen from Low-Strength Wastewater by Co-Immobilizing Biofilm inside a Moving Bed Bioreactor. ACS Sustain. Chem. Eng. 2019, 7, 1353–1361. [Google Scholar] [CrossRef]

- Chen, Z. Nitrite Accumulation Stability Evaluation for Low-Strength Ammonium Wastewater by Adsorption and Biological Desorption of Zeolite under Different Operational Temperature. Sci. Total Environ. 2020, 704, 135260. [Google Scholar] [CrossRef] [PubMed]

- Yue, X.; Yu, G.; Lu, Y.; Liu, Z.; Li, Q.; Tang, J.; Liu, J. Community of the Completely Autotrophic Nitrogen Removal over Nitrite Process in a Submerged Aerated Biological FIlter. Bioresour. Technol. 2018, 254, 67–74. [Google Scholar] [CrossRef] [PubMed]

- Chen, G. Optimizing of Operation Strategies of the Single-Stage Partial Nitrification-Anammox Process. J. Clean. Prod. 2020, 256, 120667. [Google Scholar] [CrossRef]

- Mokete, R. Exploration of the Reactivity of Nanoscale Zero-Valent Iron (NZVI) Associated Nanoparticles in Diverse Experimental Conditions. Chem. Eng. 2020, 150, 107879. [Google Scholar] [CrossRef]

- Liu, W.; Zhou, H.; Zhao, W.; Wang, C.; Wang, Q.; Wang, J.; Wu, P.; Shen, Y.; Ji, X.; Yang, D. Rapid Initiation of a Single-Stage Partial Nitritation-Anammox Process Treating Low-Strength Ammonia Wastewater: Novel Insights into Biofilm Development on Porous Polyurethane Hydrogel Carrier. Bioresour. Technol. 2022, 357, 127344. [Google Scholar] [CrossRef]

- Sanchez-Huerta, C. Influence of Biofilm Thickness on the Removal of Thirteen Different Organic Micropollutants via a Membrane Aerated Biofilm Reactor (MABR). J. Hazard. Mater. 2022, 432, 128698. [Google Scholar] [CrossRef]

- Guo, K. Potential Directions for Future Development of Mainstream Partial Nitrification-Anammox Processes: Ammonia-Oxidizing Archaea as Novel Functional Microorganisms Providing Nitrite. Bioresour. Technol. 2024, 399, 130605. [Google Scholar] [CrossRef]

- Wang, B. Recovering Partial Nitritation in a PN/A System during Mainstream Wastewater Treatment by Reviving AOB Activity after Thoroughly Inhibiting AOB and NOB with Free Nitrous Acid. Environ. Int. 2020, 139, 105684. [Google Scholar] [CrossRef]

- Sheng, G.-P.; Xu, J.; Li, W.-H.; Yu, H.-Q. Quantification of the Interactions between Ca2+, Hg2+ and Extracellular Polymeric Substances (EPS) of Sludge. Chemosphere 2013, 93, 1436–1441. [Google Scholar] [CrossRef]

- Hu, Y.-Q. Effect of Pure Oxygen Aeration on Extracellular Polymeric Substances (EPS) of Activated Sludge Treating Saline Wastewater. Process Saf. Environ. Prot. 2019, 123, 344–350. [Google Scholar] [CrossRef]

- Vandana; Priyadarshanee, M.; Das, S. Bacterial Extracellular Polymeric Substances: Biosynthesis and Interaction with Environmental Pollutants. Chemosphere 2023, 332, 138876. [Google Scholar] [CrossRef] [PubMed]

- Crovadore, J. Metatranscriptomic and Metagenomic Description of the Bacterial Nitrogen Metabolism in Waste Water Wet Oxidation Effluents. Heliyon 2017, 3, e00427. [Google Scholar] [CrossRef]

- Benselfelt, T.; Cranston, E.D.; Ondaral, S.; Johansson, E.; Brumer, H.; Rutland, M.W.; Wag, L. Adsorption of Xyloglucan onto Cellulose Surfaces of Different Morphologies: An Entropy-Driven Process. Biomacromolecules 2016, 17, 2801–2811. [Google Scholar] [CrossRef]

- Hudson, J.; Egan, S. Opportunistic Diseases in Marine Eukaryotes: Could Bacteroidota Be the next Threat to Ocean Life? Environ. Microbiol. 2022, 24, 4505–4518. [Google Scholar] [CrossRef]

- Sheng, G.-P.; Yu, H.-Q. Characterization of Extracellular Polymeric Substances of Aerobic and Anaerobic Sludge Using Three-Dimensional Excitation and Emission Matrix Fluorescence Spectroscopy. Water Res. 2006, 40, 1233–1239. [Google Scholar] [CrossRef]

- Guo, J. Comparative Study on the Treatment of Swine Wastewater by VFCW-MFC and VFCW: Pollutants Removal, Electricity Generation, Microorganism Community. J. Environ. Manag. 2023, 342, 118299. [Google Scholar] [CrossRef]

- Brewer, T.E.; Albertsen, M.; Edwards, A.; Kirkegaard, R.H.; Rocha, E.P.C.; Fierer, N. Unlinked rRNA Genes Are Widespread among Bacteria and Archaea. ISME J. 2020, 14, 597–608. [Google Scholar] [CrossRef]

- Luo, J.; Yang, J.; Li, S.; Li, X.; Chang, G.; Yang, Y. Initiating an Anaerobic Ammonium Oxidation Reactor by Inoculation with Starved Anaerobic Ammonium Oxidation Sludge and Modified Carriers. Bioresour. Technol. 2022, 359, 127438. [Google Scholar] [CrossRef]

| Trace Element I | Concentration (g/L) | Trace Element II | Concentration (g/L) |

|---|---|---|---|

| 2Na·EDTA·2H2O | 15 | 2Na·EDTA·2H2O | 5 |

| Na2SeO3 | 0.156 | FeSO4·7H2O | 5 |

| Na2MoO4·2H2O | 0.22 | ||

| NiCl2·6H2O | 0.19 | ||

| MnCl2·4H2O | 0.99 | ||

| CuSO4·5H2O | 0.25 | ||

| ZnSO4·7H2O | 0.43 | ||

| CoCl2·6H2O | 0.24 | ||

| H3BO3 | 0.014 |

| Stage | Time (d) | NH4+-N (mg N/L) | Air (L/min) | HRT (h) | NLR (kg-N/m3·d−1) |

|---|---|---|---|---|---|

| I Start-up period | 1~20 | 110 | 0.15 | 10 | 0.264 |

| II Transition period | 21~78 | 110 | 0.04~0.1 | 10 | 0.264 |

| III Stable period | 79~116 | 60 | 0.04 | 5 | 0.288 |

| MLSS (g/L) | MLVSS (g/L) | AGBS (mg/Carrier) | VAGBS (mg/Carrier) | |

|---|---|---|---|---|

| R1 | 0.82 ± 0.02 | 0.66 ± 0.05 | 6.83 ± 0.01 | 5.45 ± 0.01 |

| R2 | 1.12 ± 0.06 | 0.95 ± 0.03 | 9.37 ± 0.01 | 7.92 ± 0.01 |

| Growth | 0.30 ± 0.04 | 0.29 ± 0.03 | 2.54 ± 0.01 | 2.47 ± 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Xu, Z.; Li, K.; Xie, L.; Han, B.; Wang, Q.; Song, H.; Zhang, J. Enhancement of Partial Nitrification–Anaerobic Ammonia Oxidation in SBR Reactors via Surface-Modified Polyurethane Sponge Biofilm Carrier. Polymers 2025, 17, 1145. https://doi.org/10.3390/polym17091145

Liu Z, Xu Z, Li K, Xie L, Han B, Wang Q, Song H, Zhang J. Enhancement of Partial Nitrification–Anaerobic Ammonia Oxidation in SBR Reactors via Surface-Modified Polyurethane Sponge Biofilm Carrier. Polymers. 2025; 17(9):1145. https://doi.org/10.3390/polym17091145

Chicago/Turabian StyleLiu, Zexiang, Zhihong Xu, Kelin Li, Li Xie, Biao Han, Qiming Wang, Hainong Song, and Jian Zhang. 2025. "Enhancement of Partial Nitrification–Anaerobic Ammonia Oxidation in SBR Reactors via Surface-Modified Polyurethane Sponge Biofilm Carrier" Polymers 17, no. 9: 1145. https://doi.org/10.3390/polym17091145

APA StyleLiu, Z., Xu, Z., Li, K., Xie, L., Han, B., Wang, Q., Song, H., & Zhang, J. (2025). Enhancement of Partial Nitrification–Anaerobic Ammonia Oxidation in SBR Reactors via Surface-Modified Polyurethane Sponge Biofilm Carrier. Polymers, 17(9), 1145. https://doi.org/10.3390/polym17091145