Qualification of the Vitrimeric Matrices in Industrial-Scale Wet Filament Winding Processes for Type-4 Pressure Vessels

Abstract

1. Introduction

2. Determination of Thermal Behaviour

2.1. Material Formulation and Curing Process

2.2. Determination of Topological Freezing, Glass Transition and Decomposition Temperatures

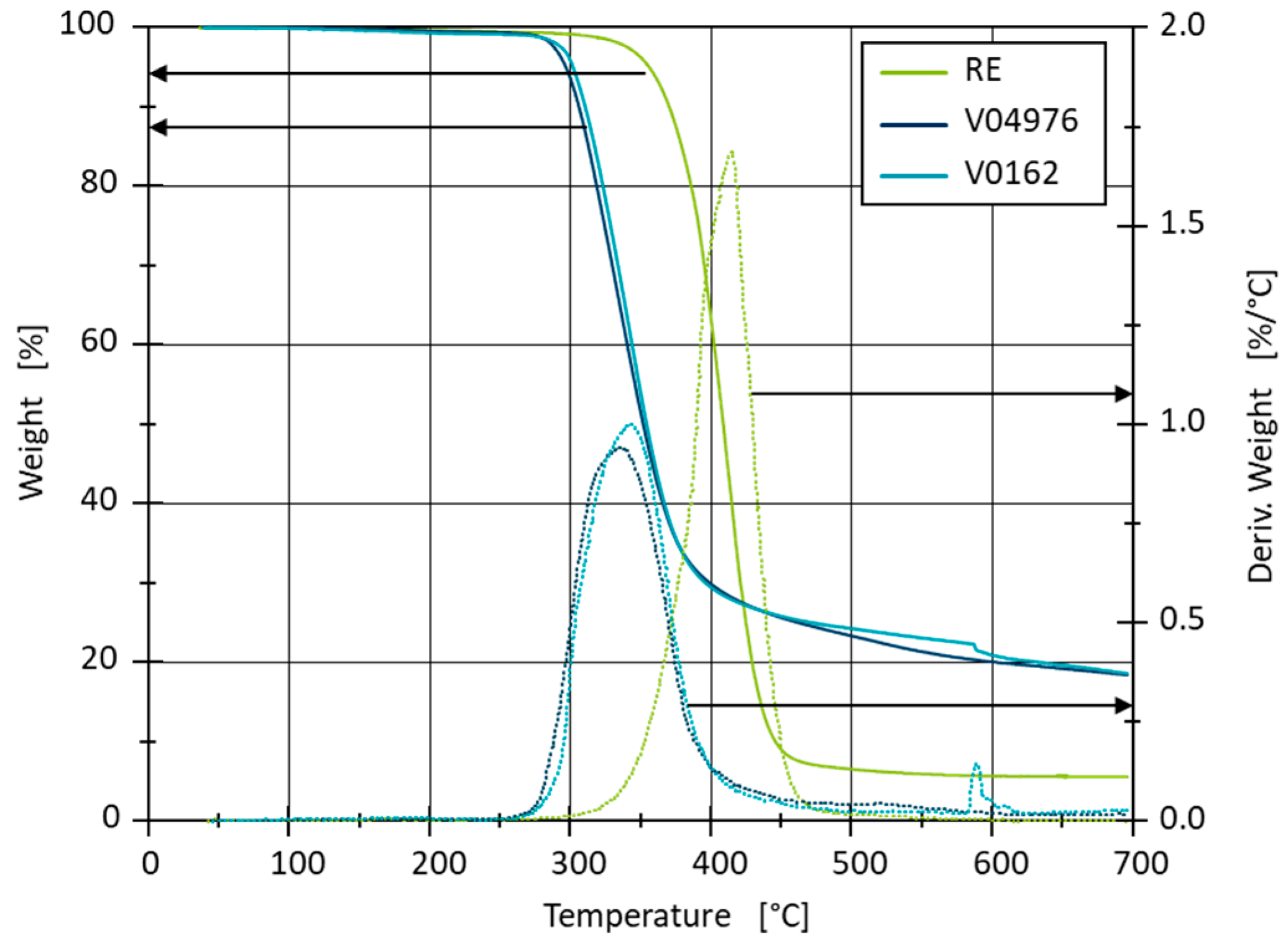

2.2.1. Determination of Decomposition Temperatures

2.2.2. Estimation of Transition Temperatures

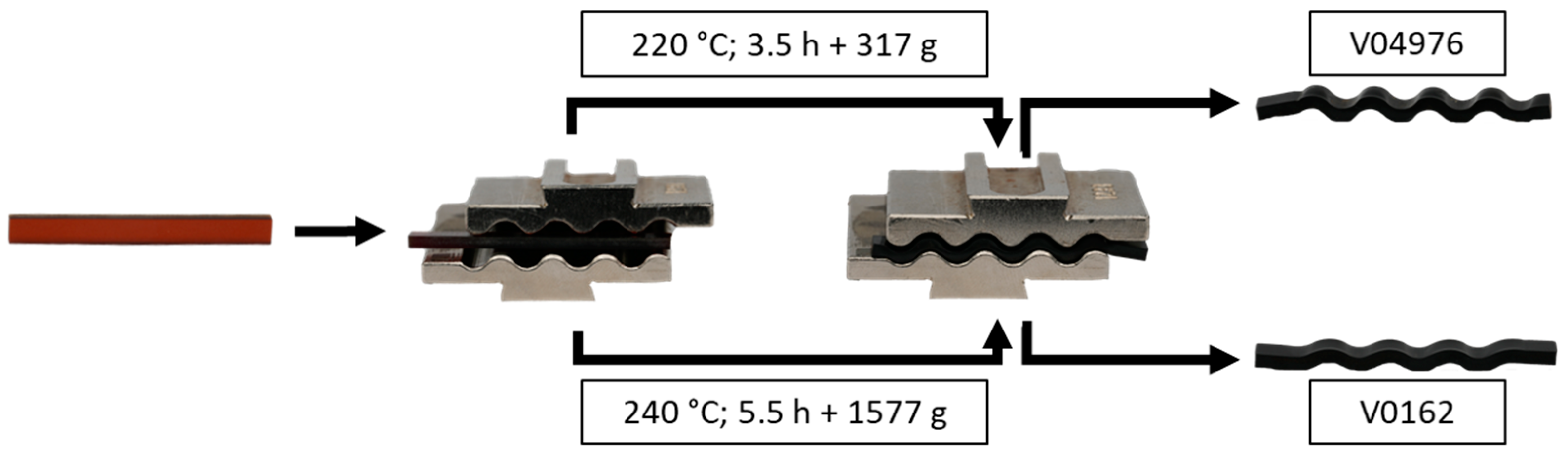

2.2.3. Demonstration of the Vitrimeric Properties via Compression Moulding

3. Comparison of Thermo-Mechanical Properties of Vitrimers and Conventional Thermosetting Epoxy Resin

4. Comparison of Wet Filament Winding Process Using Vitrimer and Thermoset Matrices

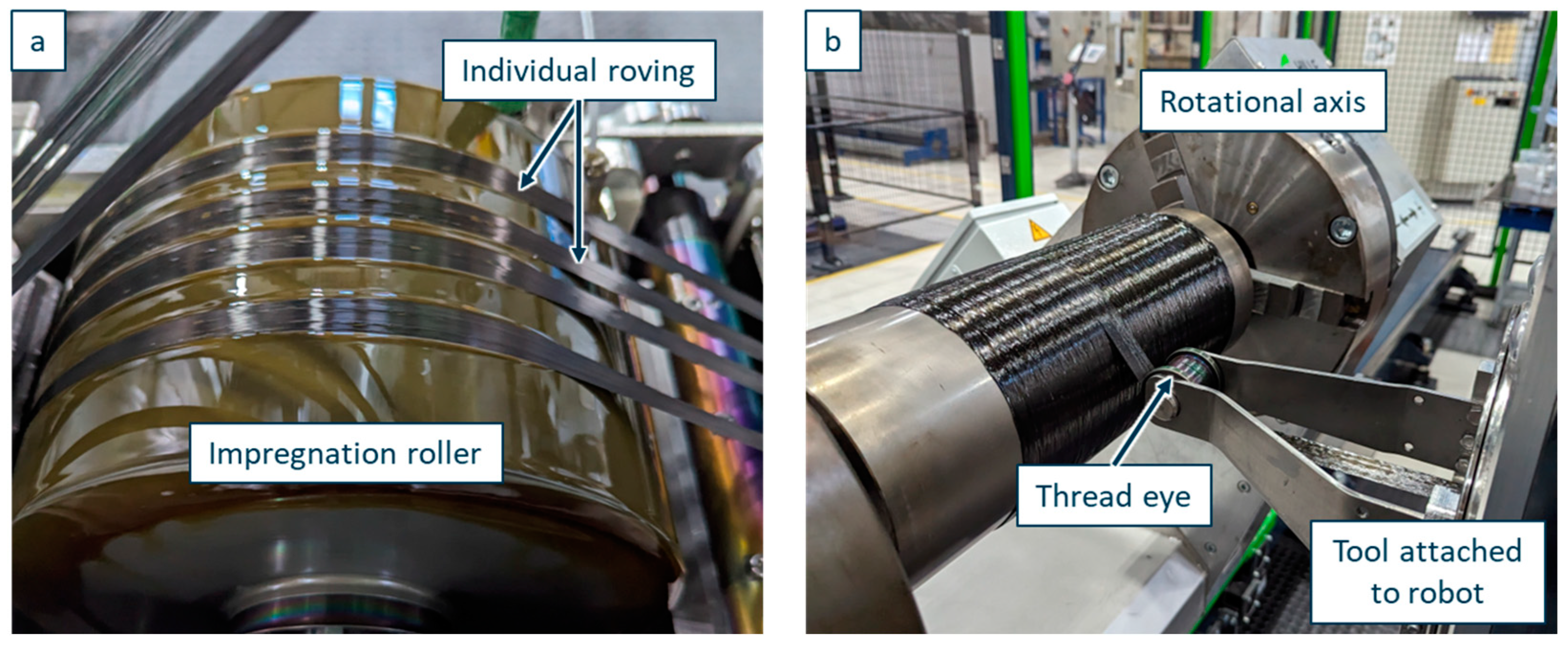

4.1. Production of CFRP Pipes

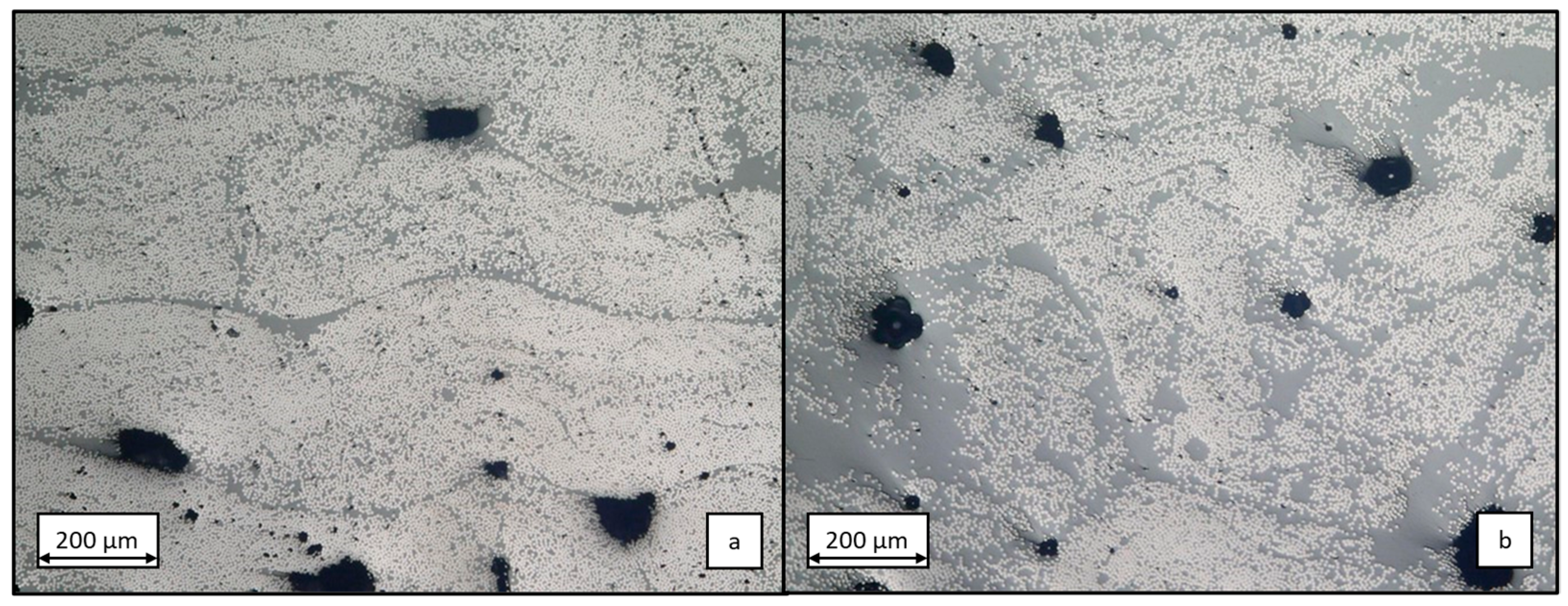

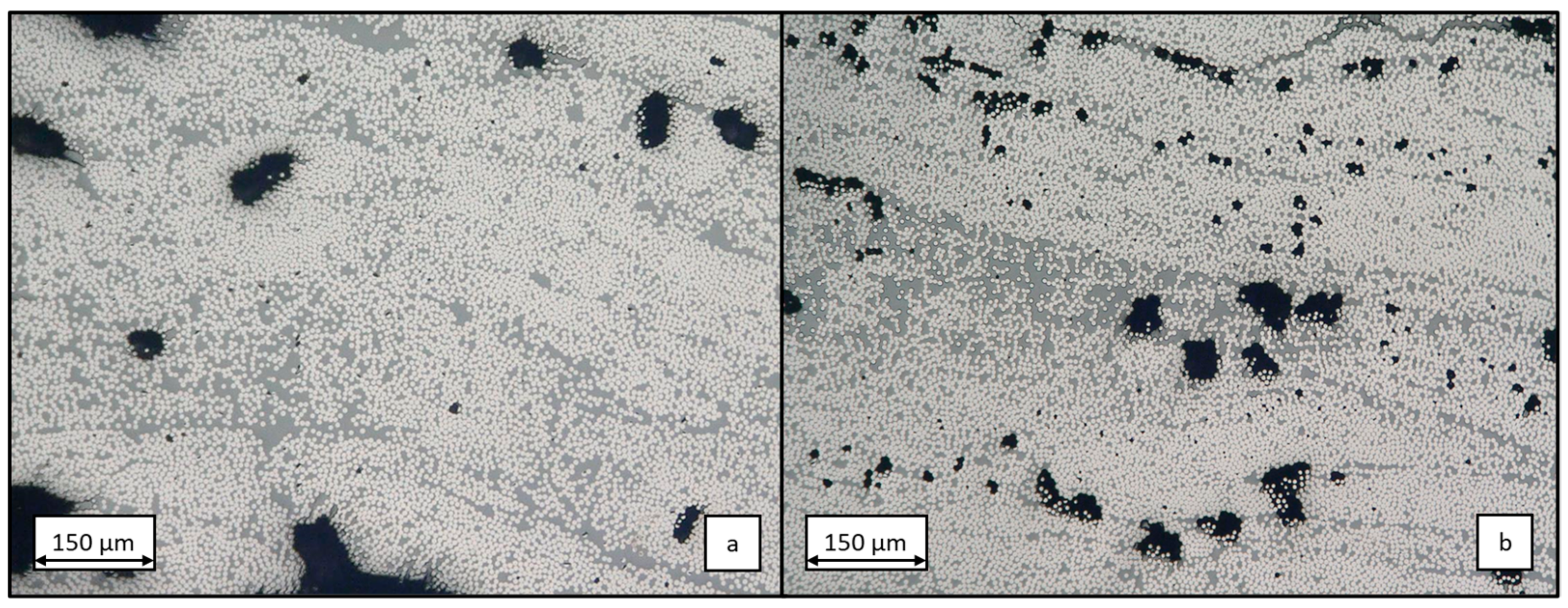

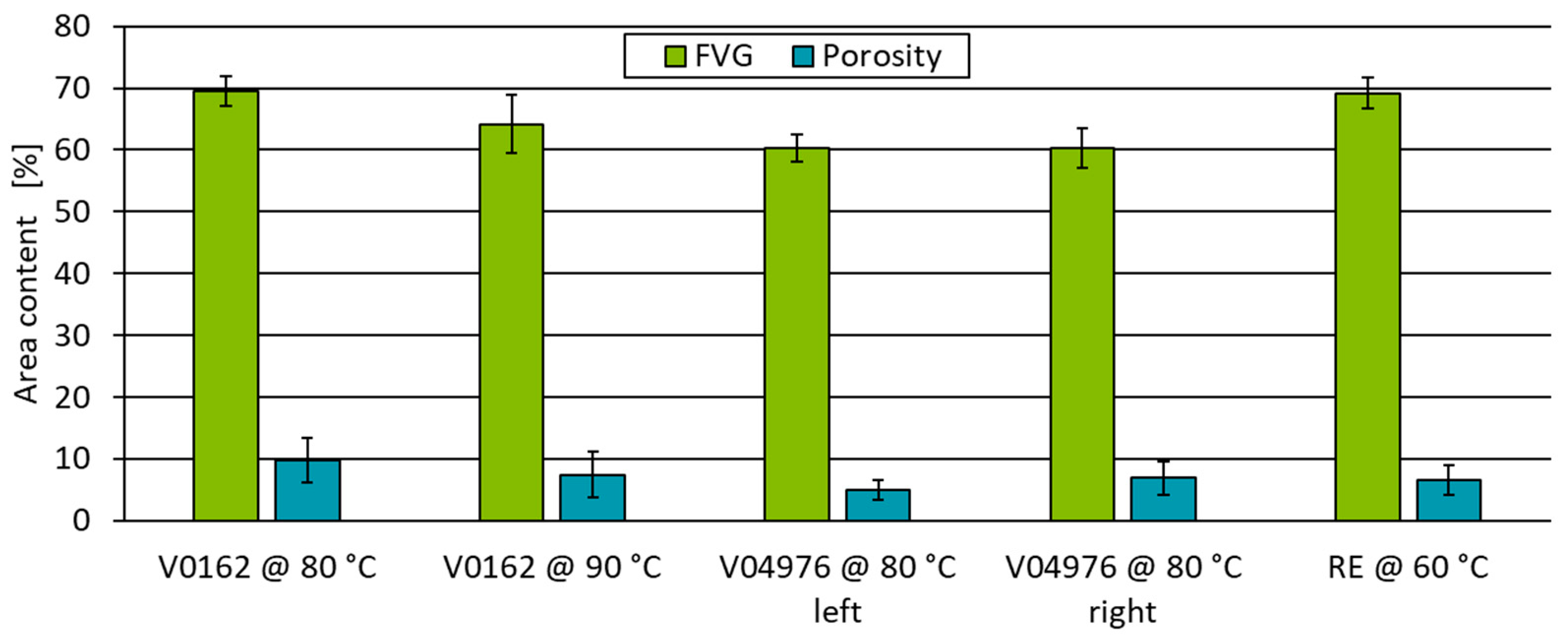

4.2. Visual Comparison of Fibre Impregnation Quality

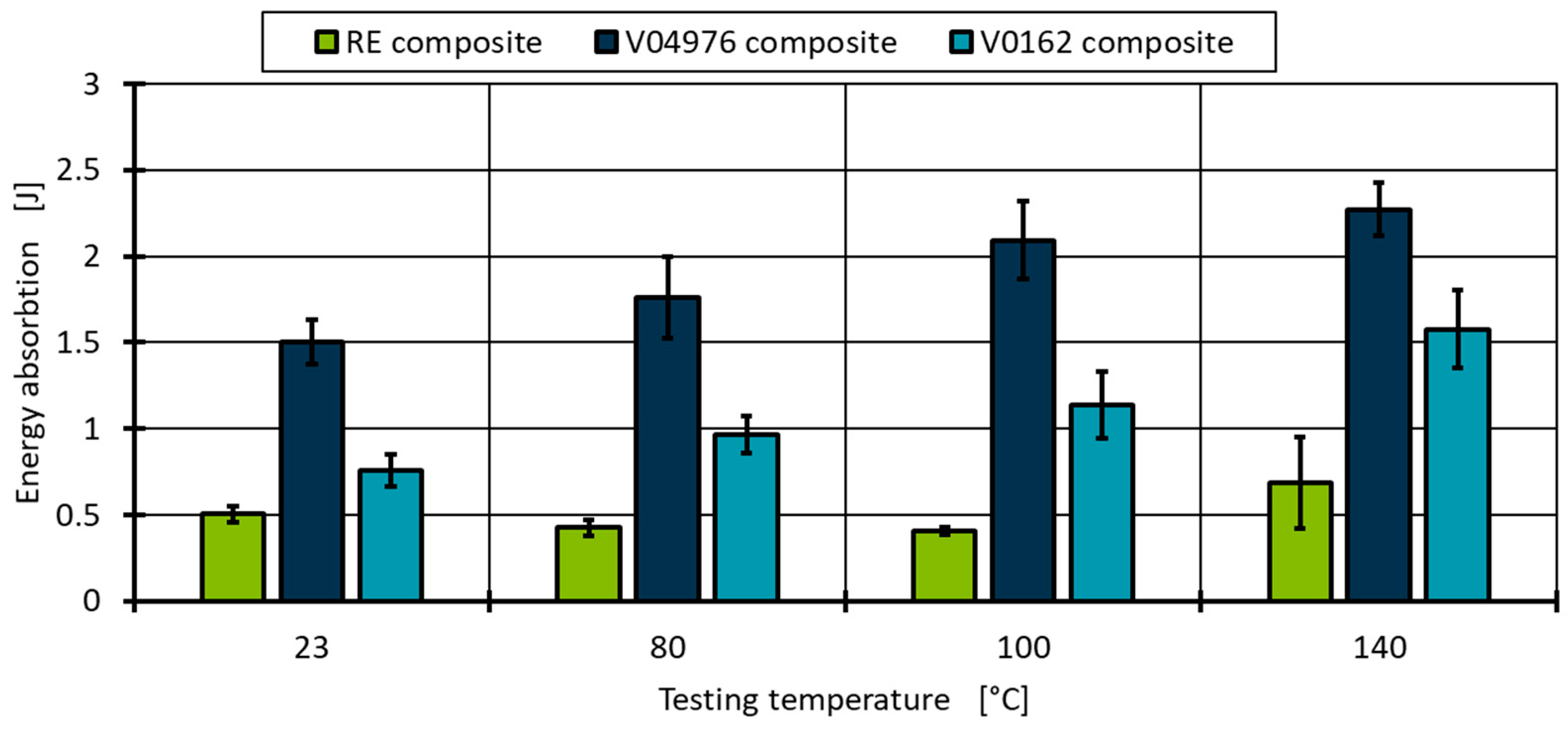

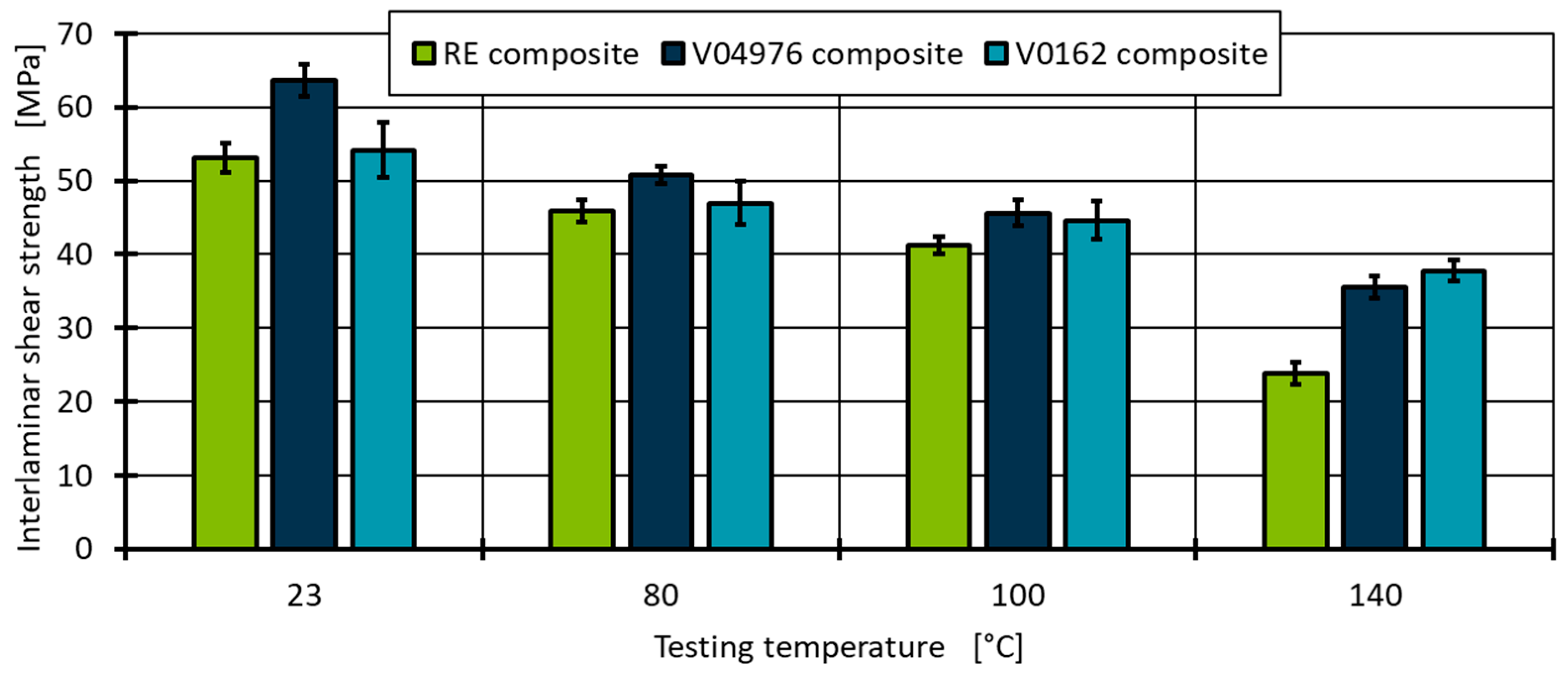

5. Mechanical Comparison of the CRFP Pipe Segments

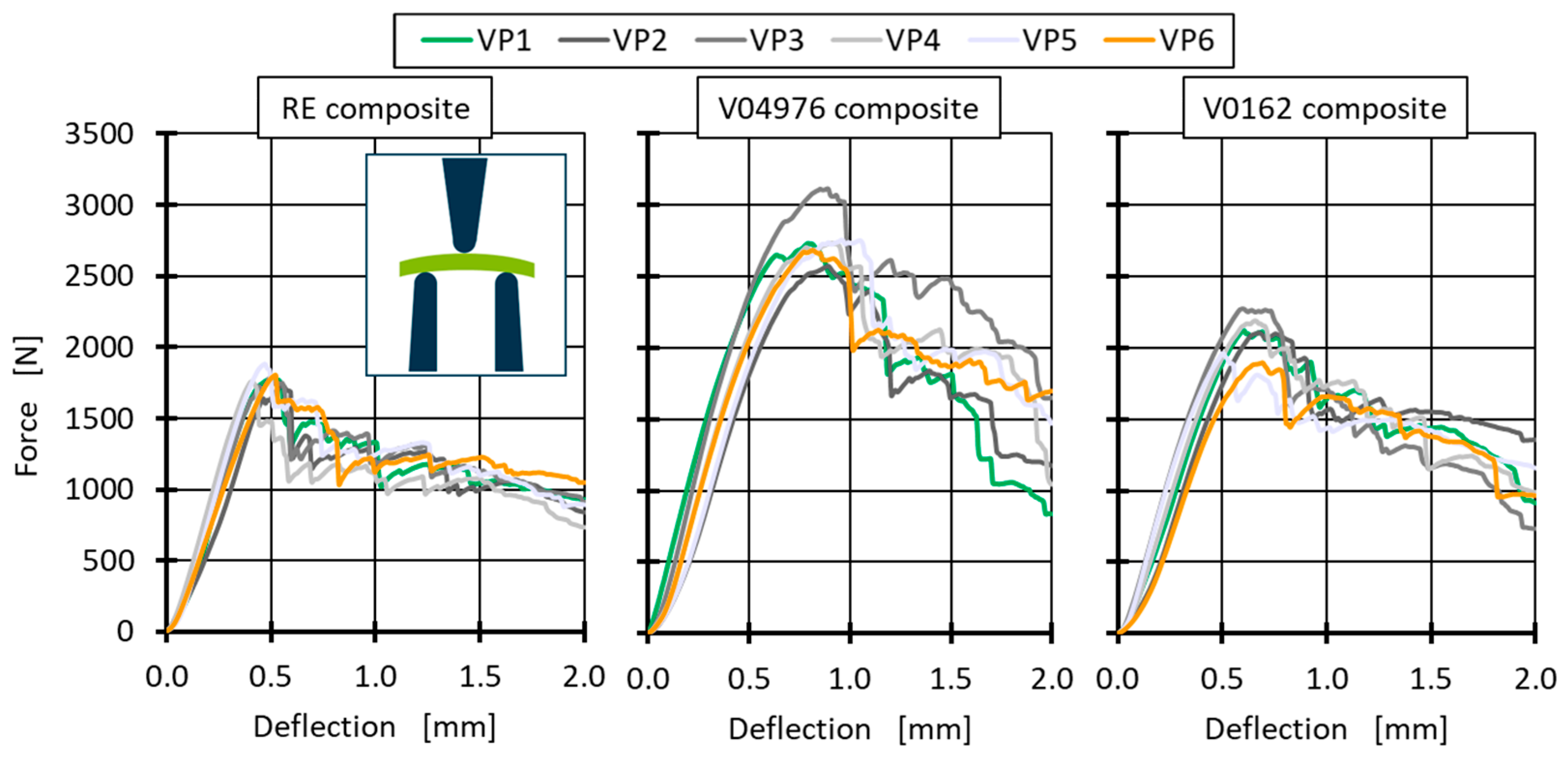

5.1. Analysis of Mechanical Strength of the CRFP Pipes

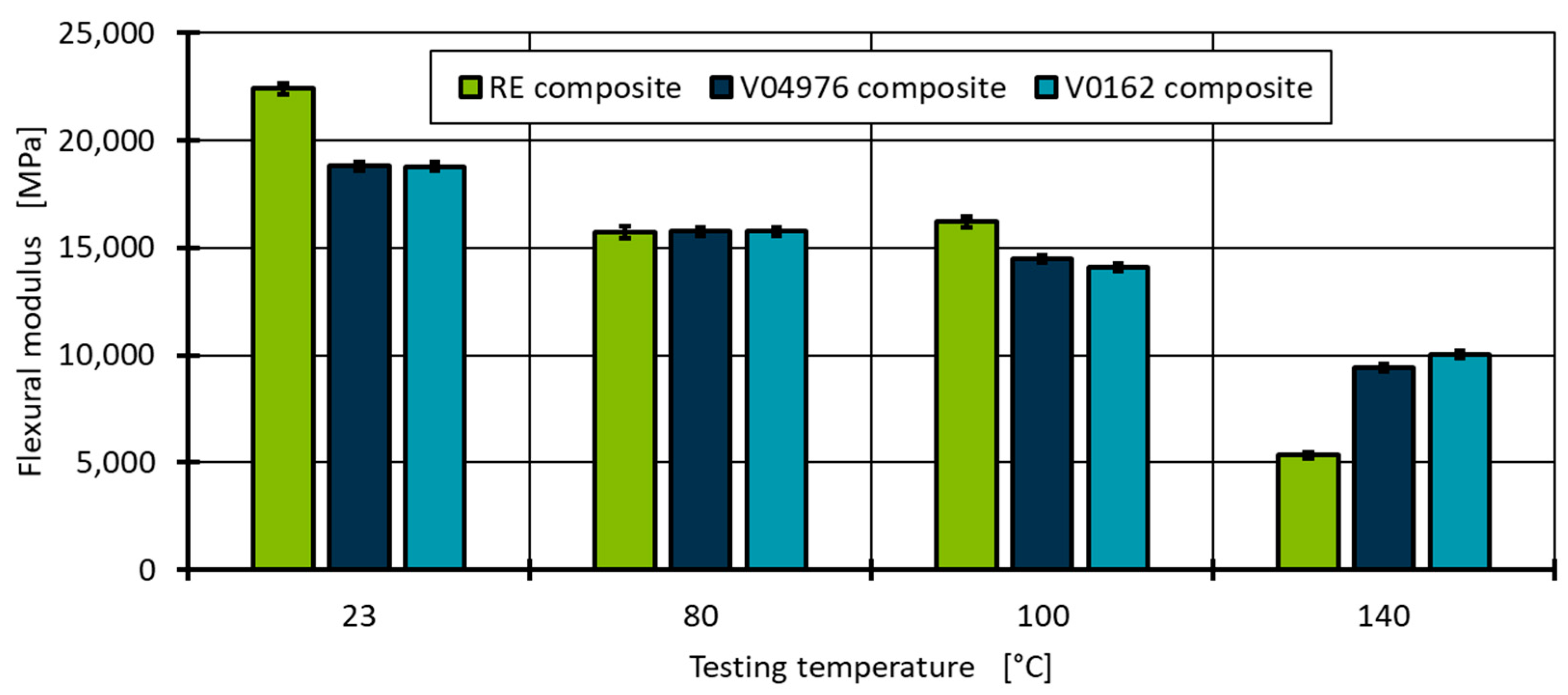

5.2. Interlaminar Shear Strength Comparison of Composites with Thermosetting and Vitrimeric Matrices

6. Discussion

7. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Klymyshyn, N.A.; Brooks, K.; Barrett, N. Methods for Estimating Hydrogen Fuel Tank Characteristics. J. Press. Vessel Technol. 2024, 146, 011501. [Google Scholar] [CrossRef]

- Gonzalez Henriquez, R.; Mertiny, P. 3.21 Filament Winding Applications. In Comprehensive Composite Materials II; Henriquez, R.G., Mertiny, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 556–577. ISBN 9780081005347. [Google Scholar]

- Pandita, S.D.; Irfan, M.S.; Machavaram, V.R.; Shotton-Gale, N.; Mahendran, R.S.; Wait, C.F.; Paget, M.A.; Harris, D.; Leek, C.; Fernando, G.F. Clean wet-filament winding—Part 1: Design concept and simulations. J. Compos. Mater. 2013, 47, 379–390. [Google Scholar] [CrossRef]

- Gebhart, T.M.; Seeberg, M.; Çelik, H.; Dahlmann, R.; Hopmann, C. Advanced methods for the detection of measurement outliers in fibre optic strain measurements for non-destructive monitoring of the structural health of composite over-wrapped pressure vessels of type-IV. Measurement 2024, 226, 114133. [Google Scholar] [CrossRef]

- Gebhart, T.M.; Spiller, M.; Çelik, H.; Dahlmann, R.; Hopmann, C. Experimental analyses of the spatial varying temperature development of type-IV hydrogen pressure vessels in cyclic tests considering different length to diameter ratios. Int. J. Hydrogen Energy 2023, 48, 27304–27318. [Google Scholar] [CrossRef]

- Roy, S.S.; Potluri, P. Braiding and filament winding. Design and Manufacture of Structural Composites; Elsevier: Amsterdam, The Netherlands, 2023; pp. 145–187. ISBN 9780128191606. [Google Scholar]

- Schäkel, M.; Janssen, H.; Brecher, C. Process analysis of manufacturing thermoplastic type-iv composite pressure vessels with helical winding pattern. Soc. Adv. Mater. Process Eng. 2021, 2021, 955–967. [Google Scholar]

- Utekar, S.; Suriya, V.K.; More, N.; Rao, A. Comprehensive study of recycling of thermosetting polymer composites—Driving force, challenges and methods. Compos. Part B Eng. 2021, 207, 108596. [Google Scholar] [CrossRef]

- Barnett, P.R.; Brackenridge, J.A.; Advincula, A.A.; Taussig, L.A.; Nepal, D. Reformable and sustainable thermosetting carbon fiber composites from epoxy vitrimer. Compos. Part B Eng. 2024, 274, 111270. [Google Scholar] [CrossRef]

- Mao, H.-I.; Hu, J.-Y.; Shiu, J.-W.; Rwei, S.-P.; Chen, C.-W. Sustainability and repeatedly recycled epoxy-based vitrimer electromagnetic shielding composite material. Polym. Test. 2023, 127, 108200. [Google Scholar] [CrossRef]

- Wan, B.; Xiao, M.; Dong, X.; Yang, X.; Zheng, M.-S.; Dang, Z.-M.; Chen, G.; Zha, J.-W. Dynamic Covalent Adaptable Polyimide Hybrid Dielectric Films with Superior Recyclability. Adv. Mater. 2023, 36, e2304175. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, A.; Zhang, L.; Chen, Z.; Qin, R.; Liu, Y.; Jiang, X.; Ye, D.; Liu, Z. Recyclable Carbon Fiber Reinforced Vanillin-Based Polyimine Vitrimers: Degradation and Mechanical Properties Study. Macromol. Mater. Eng. 2022, 307, 2100893. [Google Scholar] [CrossRef]

- Zhang, P.; Jia, S.; Xie, R.; Chen, L.; Xiong, Y. Furan-derived Schiff base covalent adaptable thermosets with recyclability and anti-flammability. Green Chem. Eng. 2024, 5, 364–373. [Google Scholar] [CrossRef]

- Kloxin, C.J.; Bowman, C.N. Covalent adaptable networks: Smart, reconfigurable and responsive network systems. Chem. Soc. Rev. 2013, 42, 7161–7173. [Google Scholar] [CrossRef]

- Kloxin, C.J.; Scott, T.F.; Adzima, B.J.; Bowman, C.N. Covalent Adaptable Networks (CANs): A Unique Paradigm in Crosslinked Polymers. Macromolecules 2010, 43, 2643–2653. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Cui, J.; Hu, G.; Zhang, B. Recycling strategies for vitrimers. Int. J. Smart Nano Mater. 2022, 13, 367–390. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, Y.; Ji, Y.; Wei, Y. Functional epoxy vitrimers and composites. Prog. Mater. Sci. 2021, 120, 100710. [Google Scholar] [CrossRef]

- Fanlo, P.; Ruiz de Luzuriaga, A.; Albizu, G.; Ximenis, M.; Rekondo, A.; Grande, H.J.; Sardon, H. Unraveling the thermal stability of aromatic disulfide epoxy vitrimers: A comprehensive study using principal component analysis (PCA). RSC Appl. Polym. 2024, 2, 826–837. [Google Scholar] [CrossRef]

- Schenk, V.; Labastie, K.; Destarac, M.; Olivier, P.; Guerre, M. Vitrimer composites: Current status and future challenges. Mater. Adv. 2022, 3, 8012–8029. [Google Scholar] [CrossRef]

- Perrin, H.; Vaudemont, R.; Del Frari, D.; Verge, P.; Puchot, L.; Bodaghi, M. On the cyclic delamination-healing capacity of vitrimer-based composite laminates. Compos. Part A Appl. Sci. Manuf. 2024, 177, 107899. [Google Scholar] [CrossRef]

- Rizzo, G.; Prasad, V.; Yasar, M.; Cicala, G.; Ivankovic, A.; Murphy, N.; Latteri, A. Investigation of mechanical properties and self-healing efficiency of carbon fibers composites infused with unsaturated polyester vitrimer. Polym. Compos. 2024, 45, 10404–10417. [Google Scholar] [CrossRef]

- Zhang, Z.; Biswal, A.K.; Nandi, A.; Frost, K.; Smith, J.A.; Nguyen, B.H.; Patel, S.; Vashisth, A.; Iyer, V. Recyclable vitrimer-based printed circuit boards for sustainable electronics. Nat. Sustain. 2024, 7, 616–627. [Google Scholar] [CrossRef]

- Lessard, J.J.; Scheutz, G.M.; Hughes, R.W.; Sumerlin, B.S. Polystyrene-Based Vitrimers: Inexpensive and Recyclable Thermosets. ACS Appl. Polym. Mater. 2020, 2, 3044–3048. [Google Scholar] [CrossRef]

- Kandemir, A.; Longana, M.L.; Hamerton, I.; Eichhorn, S.J. Developing aligned discontinuous flax fibre composites: Sustainable matrix selection and repair performance of vitrimers. Compos. Part B Eng. 2022, 243, 110139. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, E.; Liu, J.; Qin, J.; Wu, M.; Yang, C.; Liang, L. Self-healing, reprocessable, degradable, thermadapt shape memory multifunctional polymers based on dynamic imine bonds and their application in nondestructively recyclable carbon fiber composites. Chem. Eng. J. 2023, 454, 139992. [Google Scholar] [CrossRef]

- Chen, L.; Li, Z.; Ma, Y.; Shang, Q.; Hu, Y.; Huang, Q.; Zhang, M.; Jia, P.; Zhou, Y. Tung Oil-Based Degradable Vitrimer for Reprocessable and Recyclable Vitrimer–MWCNT Composites with Self-Healing Ability Triggered by Multiple Stimuli. ACS Appl. Polym. Mater. 2023, 5, 9203–9212. [Google Scholar] [CrossRef]

- Verdugo, P.; Santiago, D.; de La Flor, S.; Serra, À. A Biobased Epoxy Vitrimer with Dual Relaxation Mechanism: A Promising Material for Renewable, Reusable, and Recyclable Adhesives and Composites. ACS Sustain. Chem. Eng. 2024, 12, 5965–5978. [Google Scholar] [CrossRef]

- Xia, J.; Li, S.; Gao, R.; Zhang, Y.; Wang, L.; Ye, Y.; Cao, C.; Xue, H. Bio-Based Epoxy Vitrimers with Excellent Properties of Self-Healing, Recyclability, and Welding. Polymers 2024, 16, 2113. [Google Scholar] [CrossRef]

- Mariani, A.; Malucelli, G. Biobased vitrimers: Towards sustainability and circularity. Chem. Commun. 2025, 61, 2173–2189. [Google Scholar] [CrossRef]

- Lucherelli, M.A.; Duval, A.; Avérous, L. Biobased vitrimers: Towards sustainable and adaptable performing polymer materials. Prog. Polym. Sci. 2022, 127, 101515. [Google Scholar] [CrossRef]

- Zhang, G.; Tian, C.; Chu, H.; Liu, J.; Guo, B.; Zhang, L. A facile strategy to achieve vitrimer-like elastomer composites with lignin as a renewable bio-filler toward excellent reinforcement and recyclability. J. Mater. Chem. A 2023, 11, 25356–25367. [Google Scholar] [CrossRef]

- Lorenz, N.; Zawadzki, T.; Keller, L.; Fuchs, J.; Fischer, K.; Hopmann, C. Characterization and modeling of an epoxy vitrimer based on disulfide exchange for wet filament winding applications. Polym. Eng. Sci. 2024, 64, 3682–3702. [Google Scholar] [CrossRef]

- Martinez-Diaz, D.; Cortés, A.; Jiménez-Suárez, A.; Prolongo, S.G. Hardener Isomerism and Content of Dynamic Disulfide Bond Effect on Chemical Recycling of Epoxy Networks. ACS Appl. Polym. Mater. 2022, 4, 5068–5076. [Google Scholar] [CrossRef]

- Guggari, S.; Magliozzi, F.; Malburet, S.; Graillot, A.; Destarac, M.; Guerre, M. Vanillin-Based Epoxy Vitrimers: Looking at the Cystamine Hardener from a Different Perspective. ACS Sustain. Chem. Eng. 2023, 11, 6021–6031. [Google Scholar] [CrossRef]

- Bianchi, I.; Greco, L.; Mignanelli, C.; Simoncini, M.; Vita, A. Environmental Sustainability of vitrimer-based composite materials. Procedia CIRP 2024, 122, 1059–1064. [Google Scholar] [CrossRef]

- Benazzo, F.; Sodano, H.A. Evaluation of Interfacial Shear Strength Healing Efficiency between Dynamic Covalent Bond-Based Epoxy and Functionalized Fiberglass. ACS Appl. Polym. Mater. 2022, 4, 2925–2934. [Google Scholar] [CrossRef]

- Schenk, V.; de Calbiac, J.; D’Elia, R.; Olivier, P.; Labastie, K.; Destarac, M.; Guerre, M. Epoxy Vitrimer Formulation for Resin Transfer Molding: Reactivity, Process, and Material Characterization. ACS Appl. Polym. Mater. 2024, 6, 6087–6095. [Google Scholar] [CrossRef]

- Aranberri, I.; Landa, M.; Elorza, E.; Salaberria, A.M.; Rekondo, A. Thermoformable and recyclable CFRP pultruded profile manufactured from an epoxy vitrimer. Polym. Test. 2021, 93, 106931. [Google Scholar] [CrossRef]

- Builes Cárdenas, C.; Gayraud, V.; Rodriguez, M.E.; Costa, J.; Salaberria, A.M.; Ruiz de Luzuriaga, A.; Markaide, N.; Dasan Keeryadath, P.; Calderón Zapatería, D. Study into the Mechanical Properties of a New Aeronautic-Grade Epoxy-Based Carbon-Fiber-Reinforced Vitrimer. Polymers 2022, 14, 1223. [Google Scholar] [CrossRef]

- Westlake Epoxy GmbH. Epoxy Epicote 04976 und 0162; oral meeting; Westlake Epoxy GmbH: Duisburg, Germany, 2024. [Google Scholar]

- Foley, M.E.; Gillespie, J.W. Modeling the Effect of Fiber Diameter and Fiber Bundle Count on Tow Impregnation during Liquid Molding Processes. J. Compos. Mater. 2005, 39, 1045–1065. [Google Scholar] [CrossRef]

- Michels, J.; Widmann, R.; Czaderski, C.; Allahvirdizadeh, R.; Motavalli, M. Glass transition evaluation of commercially available epoxy resins used for civil engineering applications. Compos. Part B Eng. 2015, 77, 484–493. [Google Scholar] [CrossRef]

- Montarnal, D.; Capelot, M.; Tournilhac, F.; Leibler, L. Silica-like malleable materials from permanent organic networks. Science 2011, 334, 965–968. [Google Scholar] [CrossRef]

- Capelot, M.; Montarnal, D.; Tournilhac, F.; Leibler, L. Metal-catalyzed transesterification for healing and assembling of thermosets. J. Am. Chem. Soc. 2012, 134, 7664–7667. [Google Scholar] [CrossRef] [PubMed]

- Capelot, M.; Unterlass, M.M.; Tournilhac, F.; Leibler, L. Catalytic Control of the Vitrimer Glass Transition. ACS Macro Lett. 2012, 1, 789–792. [Google Scholar] [CrossRef]

- Zheng, J.; Png, Z.M.; Ng, S.H.; Tham, G.X.; Ye, E.; Goh, S.S.; Loh, X.J.; Li, Z. Vitrimers: Current research trends and their emerging applications. Mater. Today 2021, 51, 586–625. [Google Scholar] [CrossRef]

- Ruiz de Luzuriaga, A.; Solera, G.; Azcarate-Ascasua, I.; Boucher, V.; Grande, H.-J.; Rekondo, A. Chemical control of the aromatic disulfide exchange kinetics for tailor-made epoxy vitrimers. Polymer 2022, 239, 124457. [Google Scholar] [CrossRef]

- Azcune, I.; Huegun, A.; Ruiz de Luzuriaga, A.; Saiz, E.; Rekondo, A. The effect of matrix on shape properties of aromatic disulfide based epoxy vitrimers. Eur. Polym. J. 2021, 148, 110362. [Google Scholar] [CrossRef]

- Martins, M.L.; Zhao, X.; Demchuk, Z.; Luo, J.; Carden, G.P.; Toleutay, G.; Sokolov, A.P. Viscoelasticity of Polymers with Dynamic Covalent Bonds: Concepts and Misconceptions. Macromolecules 2023, 56, 8688–8696. [Google Scholar] [CrossRef]

- Klingler, A.; Reisinger, D.; Schlögl, S.; Wetzel, B.; Breuer, U.; Krüger, J.-K. Vitrimer Transition Phenomena from the Perspective of Thermal Volume Expansion and Shape (In)stability. Macromolecules 2024, 57, 4246–4253. [Google Scholar] [CrossRef]

- DIN EN ISO 11357-1:2023-06; Kunststoffe_-Dynamische Differenzkalorimetrie_(DSC)_-Teil_1: Allgemeine Grundlagen (ISO_11357-1:2023), Deutsche Fassung EN_ISO_11357-1:2023. DIN Media GmbH: Berlin, Germany, 2023.

- Si, H.; Zhou, L.; Wu, Y.; Song, L.; Kang, M.; Zhao, X.; Chen, M. Rapidly reprocessable, degradable epoxy vitrimer and recyclable carbon fiber reinforced thermoset composites relied on high contents of exchangeable aromatic disulfide crosslinks. Compos. Part B Eng. 2020, 199, 108278. [Google Scholar] [CrossRef]

- DIN EN ISO 527-2:2012-06; Kunststoffe_-Bestimmung der Zugeigenschaften_-Teil_2: Prüfbedingungen für Form- und Extrusionsmassen (ISO_527-2:2012), Deutsche Fassung EN_ISO_527-2:2012. DIN Media GmbH: Berlin, Germany, 2012.

- Hopmann, C.; Magura, N.; Müller, R.; Schneider, D.; Fischer, K. Impact of winding parameters on the fiber bandwidth in the cylindrical area of a hydrogen pressure vessel for generating a digital twin. Polym. Compos. 2022, 43, 1577–1589. [Google Scholar] [CrossRef]

- Hopmann, C.; Magura, N.; Rozo Lopez, N.; Schneider, D.; Fischer, K. Detection and evaluation of the fibers’ deposition parameters during wet filament winding. Polym. Eng. Sci. 2021, 61, 1353–1367. [Google Scholar] [CrossRef]

- Arganda-Carreras, I.; Kaynig, V.; Rueden, C.; Schindelin, J.; Cardona, A.; Seung, H.S. Trainable_Segmentation: Release v3.1.2; Zenodo: Geneva, Switzerland, 2016. [Google Scholar]

- ASTM D2290a; Test Method for Apparent Hoop Tensile Strength of Plastic or Reinforced Plastic Pipe. ASTM International: West Conshohocken, PA, USA, 2019.

- DIN EN ISO 14130:1998-02; Faserverstärkte Kunststoffe_-Bestimmung der scheinbaren interlaminaren Scherfestigkeit nach dem Dreipunktverfahren mit kurzem Balken (ISO_14130:1997), Deutsche Fassung EN_ISO_14130:1997. DIN Media GmbH: Berlin, Germany, 1997.

| Resin | Curing Agent | Catalyst | Abbreviation |

|---|---|---|---|

| 55.3 wt % EPIKOTE 04976 | 44.2 wt % EPIKURE 04976 | 0.55 wt % EPIKURE Catalyst 04976 | RE |

| 69.9 wt % EPIKOTE 04976 | 30.1 wt % 4-AFD | - | V04976 |

| 69.9 wt % EPIKOTE 0162 | 30.1 wt % 4-AFD | - | V0162 |

| Material | RE | V04976 | V0162 |

|---|---|---|---|

| Tg | 144 °C | 138 °C | 158 °C |

| Material | Temperature [°C] | Test Duration | Test Weight |

|---|---|---|---|

| V04976 | 220 °C | 1.5 h | Mould not weighted down |

| 1 h | 185 g | ||

| 1 h | 317 g | ||

| V0162 | 240 °C | 2 h | Mould not weighted down |

| 1 h | 185 g | ||

| 0.5 h | 317 g | ||

| 0.5 h | 609.5 g | ||

| 0.5 h | 800 g | ||

| 1 h | 1577 g |

| Matrix Material | Specimen Strength | Share of Fibre Strength |

|---|---|---|

| RE | 4.46 ± 0.11 GPa | 87.4% |

| V04976 | 4.49 ± 0.39 GPa | 88.0% |

| V0162 | 4.58 ± 0.17 GPa | 89.8% |

| Matrix Material | Average Thickness | Average Width |

|---|---|---|

| RE | 2.45 ± 0.06 mm | 10.08 ± 0.02 mm |

| V04976 | 3.20 ± 0.14 mm | 10.11 ± 0.02 mm |

| V0162 | 2.81 ± 0.06 mm | 10.12 ± 0.01 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alms, J.; Sambale, A.K.; Fuchs, J.; Lorenz, N.; von den Berg, N.; Conen, T.; Çelik, H.; Dahlmann, R.; Hopmann, C.; Stommel, M. Qualification of the Vitrimeric Matrices in Industrial-Scale Wet Filament Winding Processes for Type-4 Pressure Vessels. Polymers 2025, 17, 1146. https://doi.org/10.3390/polym17091146

Alms J, Sambale AK, Fuchs J, Lorenz N, von den Berg N, Conen T, Çelik H, Dahlmann R, Hopmann C, Stommel M. Qualification of the Vitrimeric Matrices in Industrial-Scale Wet Filament Winding Processes for Type-4 Pressure Vessels. Polymers. 2025; 17(9):1146. https://doi.org/10.3390/polym17091146

Chicago/Turabian StyleAlms, Jonathan, Anna Katharina Sambale, Jannick Fuchs, Niklas Lorenz, Nina von den Berg, Tobias Conen, Hakan Çelik, Rainer Dahlmann, Christian Hopmann, and Markus Stommel. 2025. "Qualification of the Vitrimeric Matrices in Industrial-Scale Wet Filament Winding Processes for Type-4 Pressure Vessels" Polymers 17, no. 9: 1146. https://doi.org/10.3390/polym17091146

APA StyleAlms, J., Sambale, A. K., Fuchs, J., Lorenz, N., von den Berg, N., Conen, T., Çelik, H., Dahlmann, R., Hopmann, C., & Stommel, M. (2025). Qualification of the Vitrimeric Matrices in Industrial-Scale Wet Filament Winding Processes for Type-4 Pressure Vessels. Polymers, 17(9), 1146. https://doi.org/10.3390/polym17091146