3D Printing Wood–PLA Composites: The Impact of Wood Particle Size

Abstract

:1. Introduction

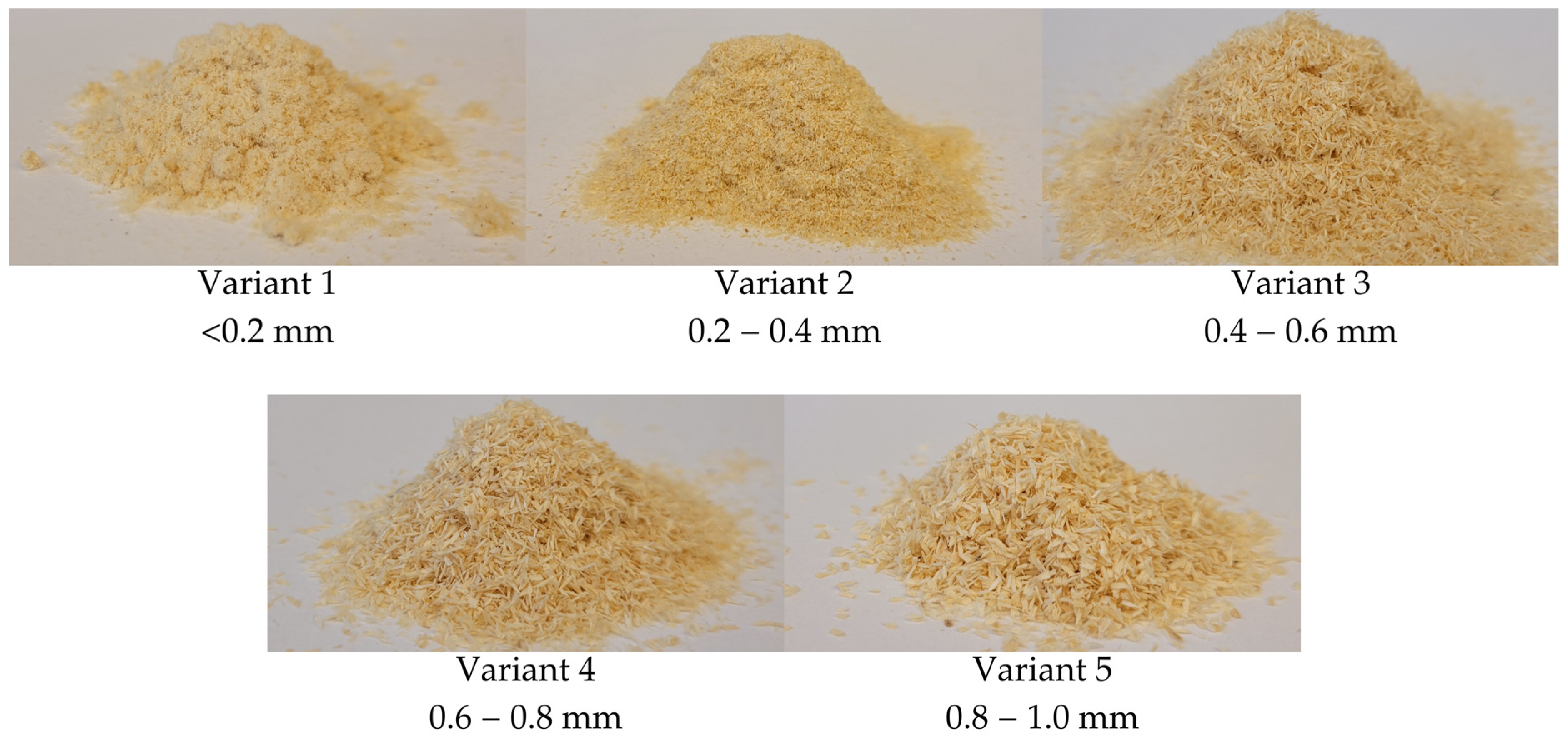

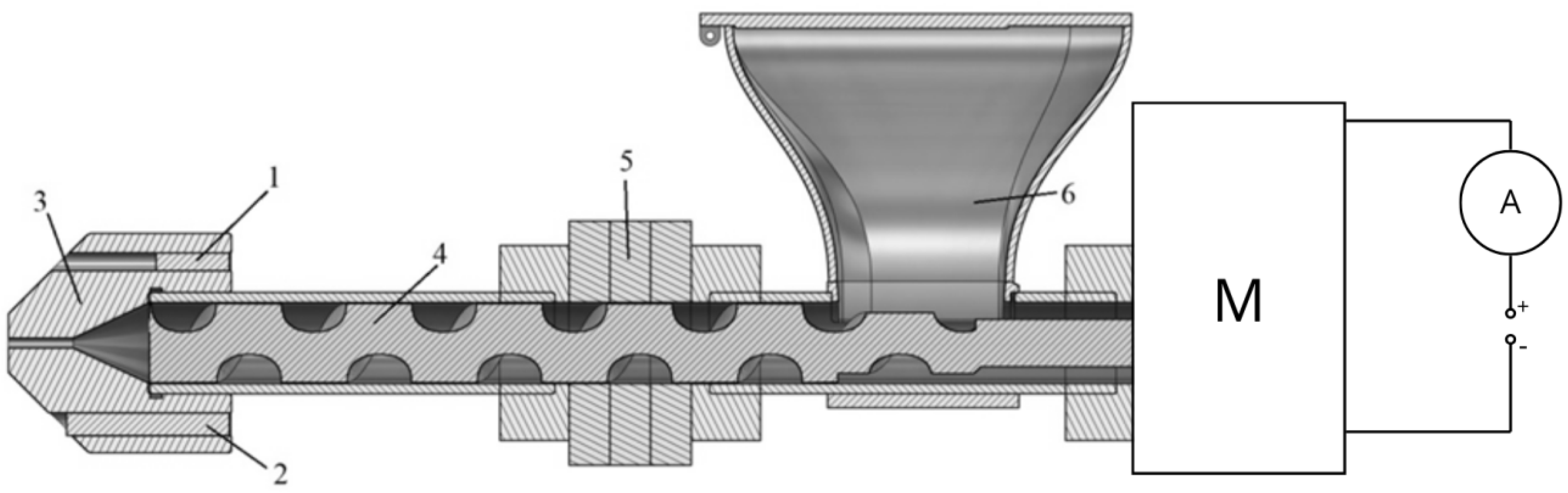

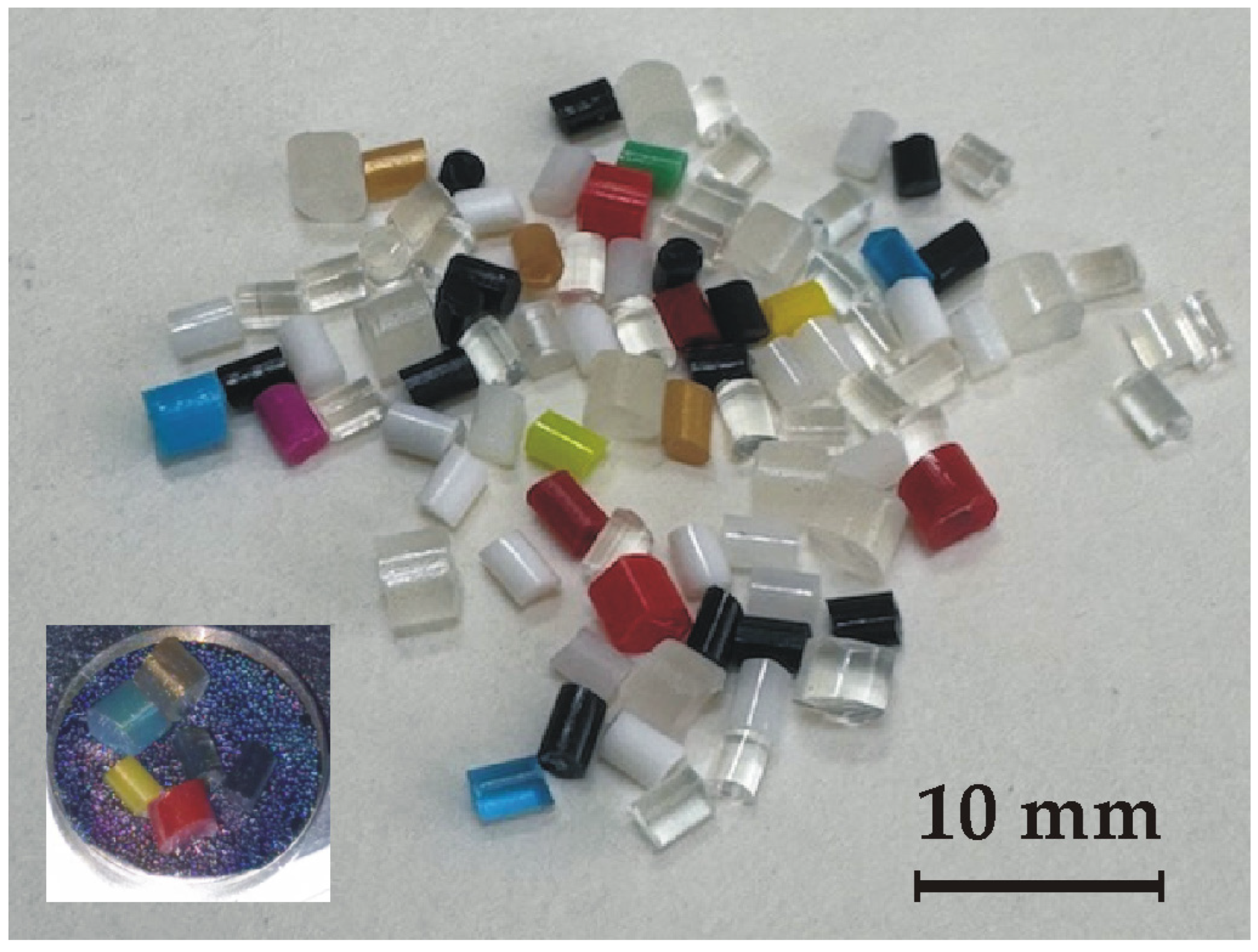

2. Materials and Methods

3. Results and Discussion

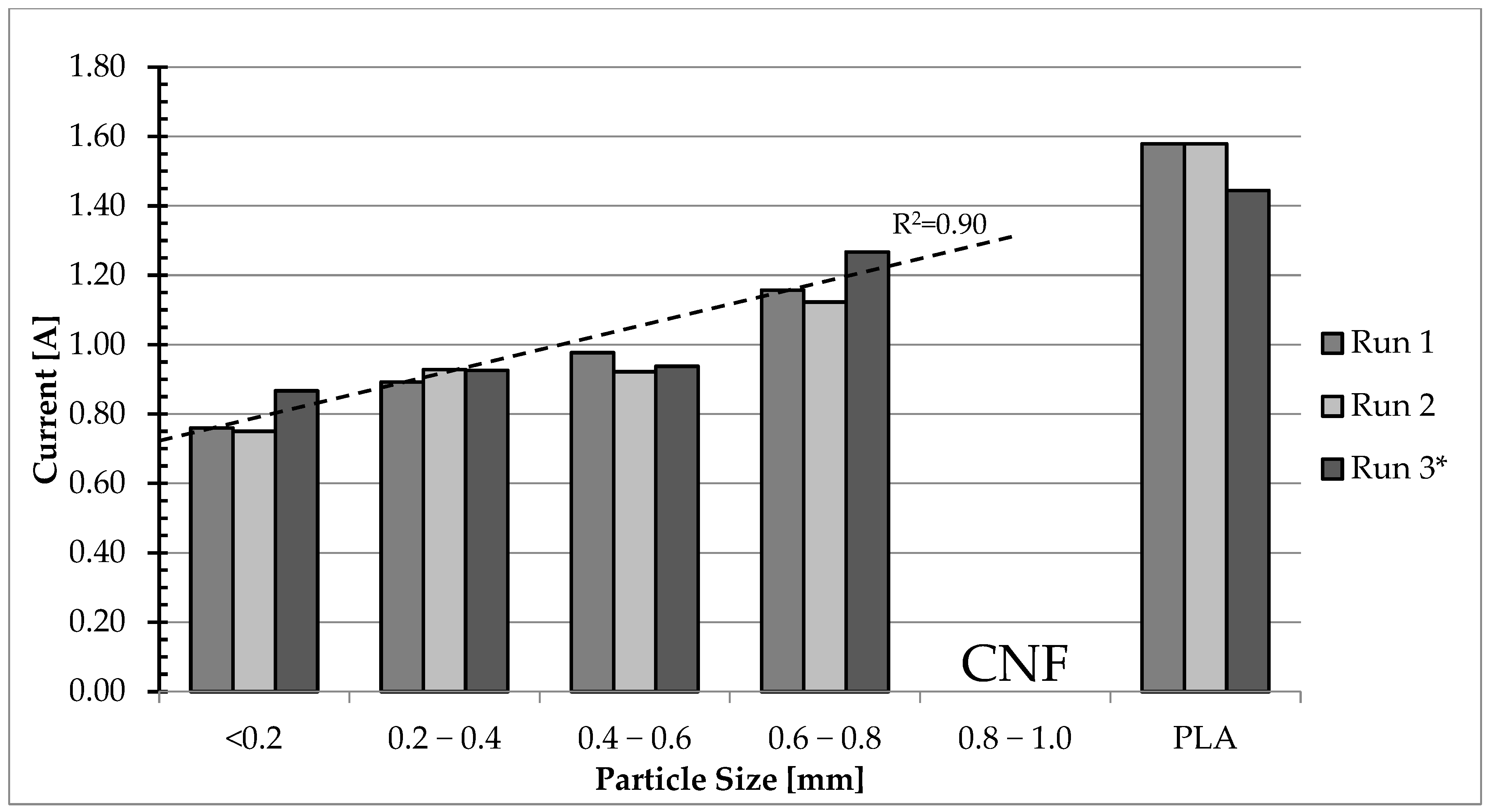

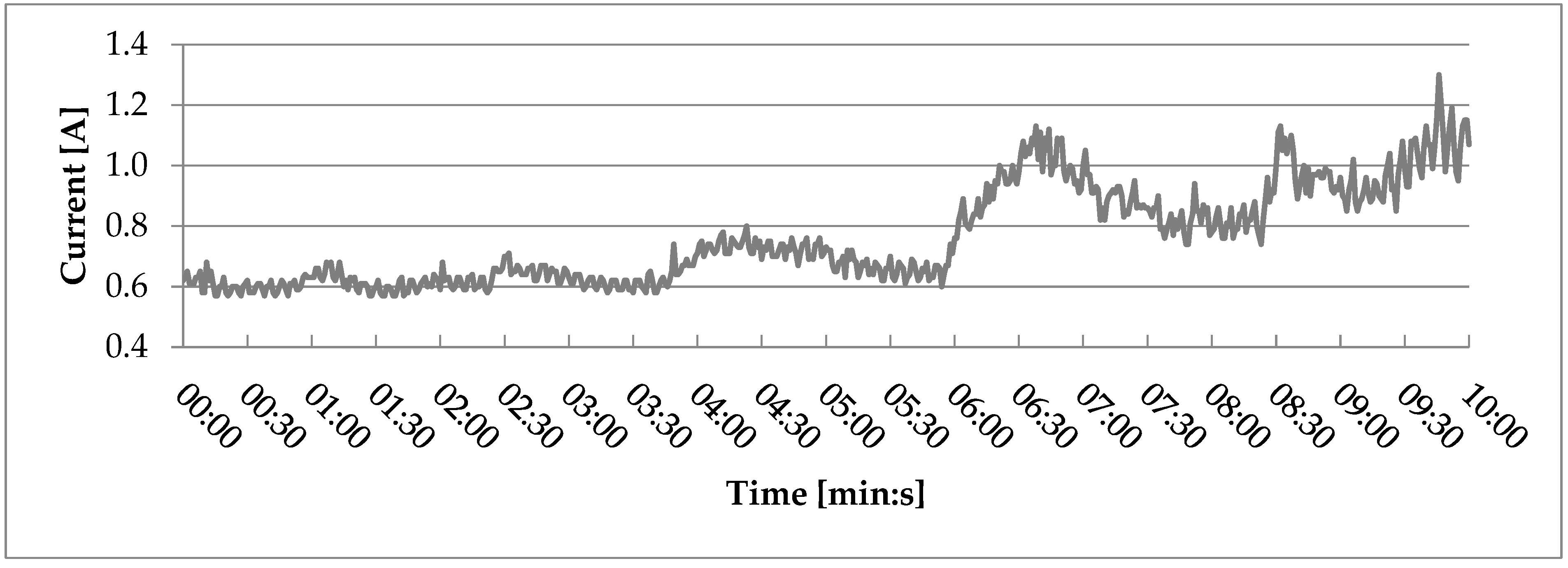

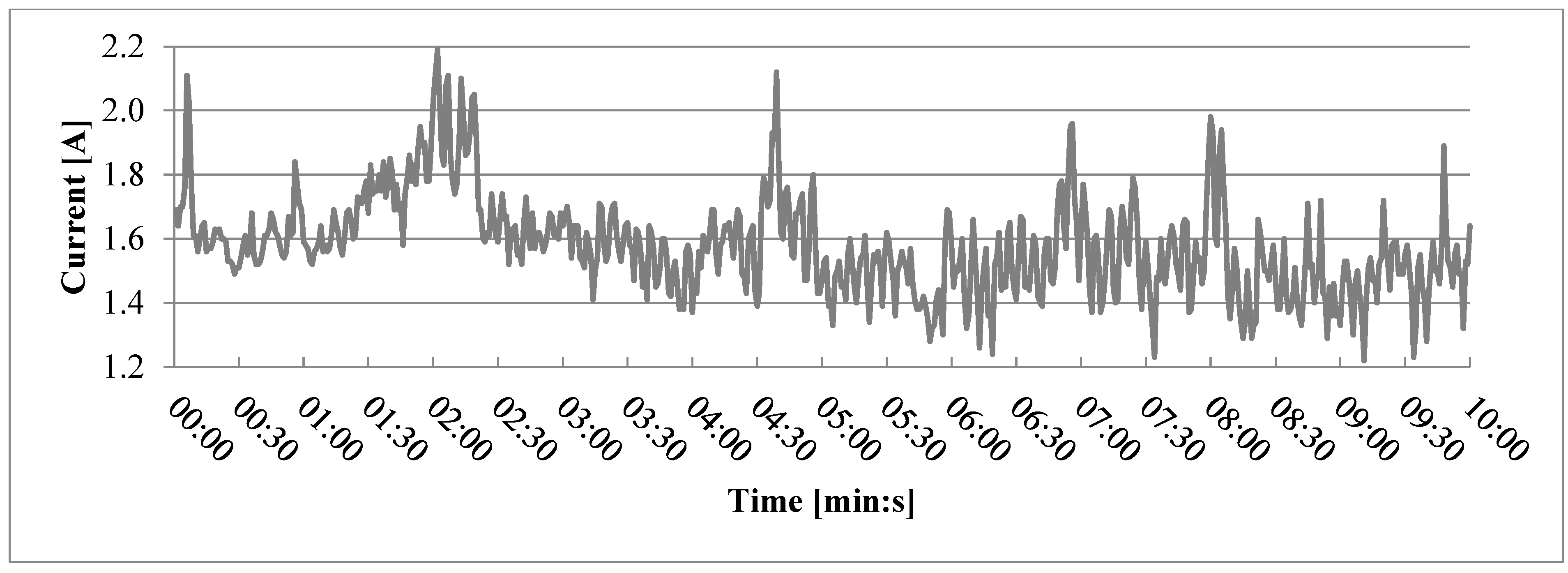

3.1. Printability

3.2. Tensile Properties

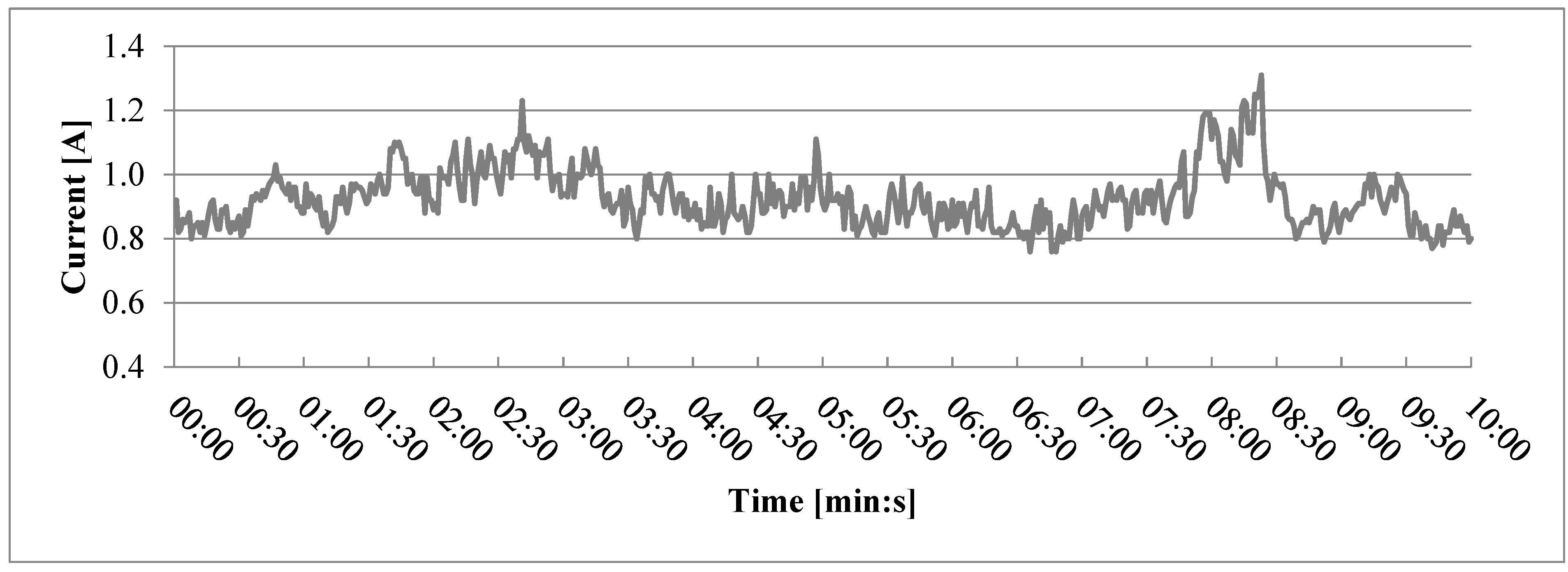

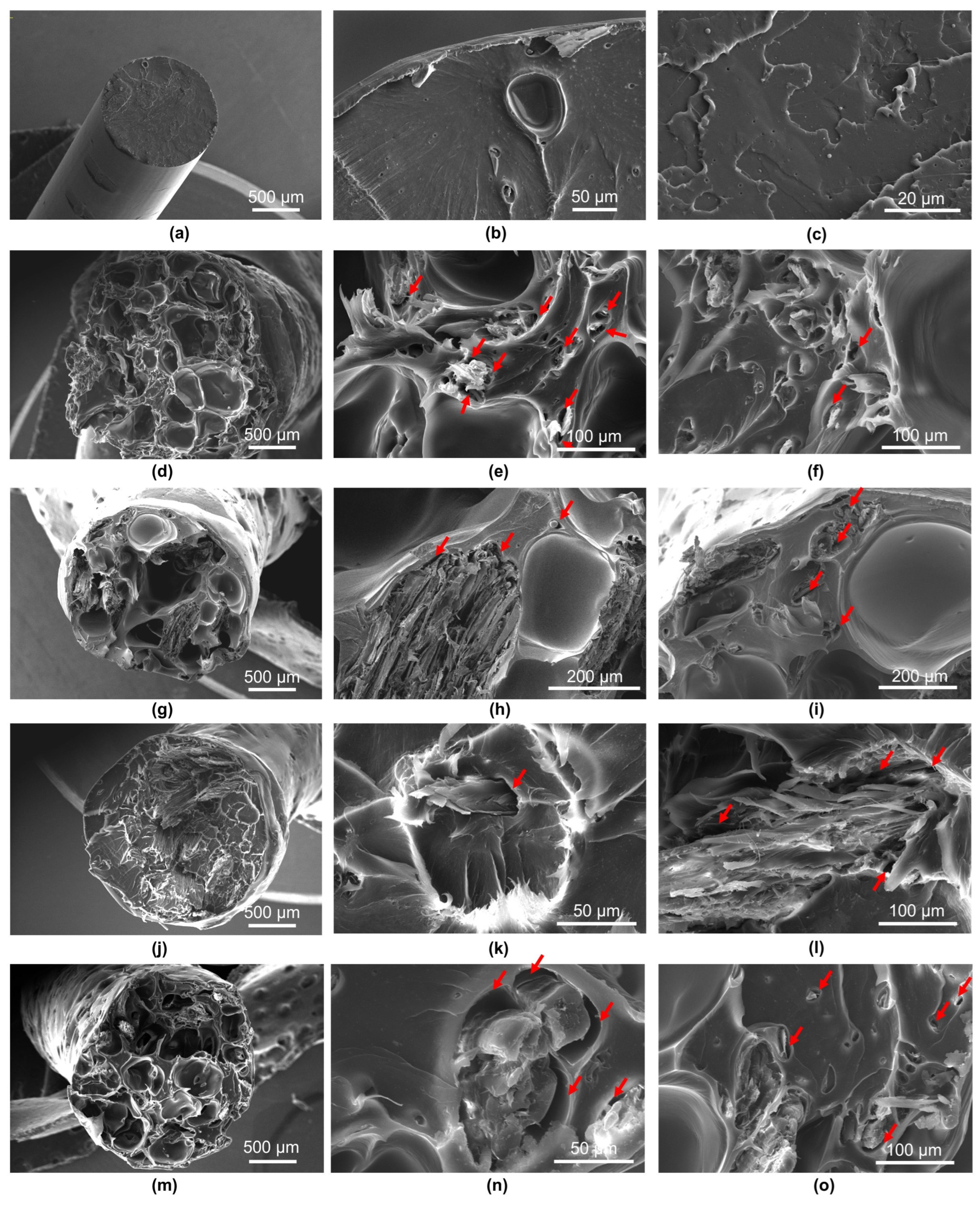

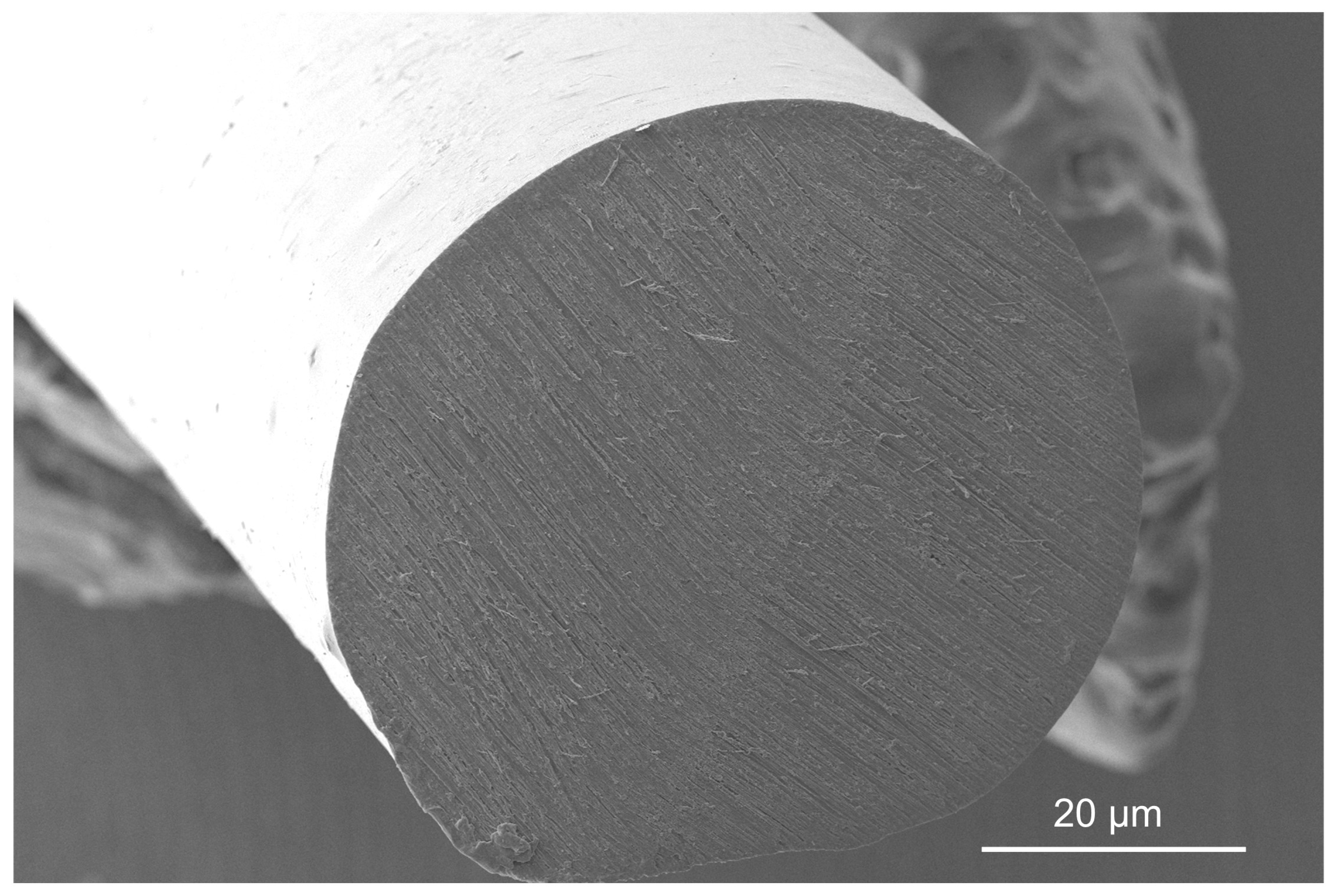

3.3. SEM/EDS Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ratanawilai, T.; Taneerat, K. Alternative polymeric matrices for wood-plastic composites: Effects on mechanical properties and resistance to natural weathering. Constr. Build. Mater. 2018, 172, 349–357. [Google Scholar] [CrossRef]

- Partanen, A.; Carus, M. Biocomposites, find the real alternative to plastic—An examination of biocomposites in the market. Reinf. Plast. 2019, 63, 317–321. [Google Scholar] [CrossRef]

- Quitadamo, A.; Massardier, V.; Valente, M. Eco-Friendly Approach and Potential Biodegradable Polymer Matrix for WPC Composite Materials in Outdoor Application. Int. J. Polym. Sci. 2019, 2019, 3894370. [Google Scholar] [CrossRef]

- Balart, J.F.; García-Sanoguera, D.; Balart, R.; Boronat, T.; Sánchez-Nacher, L. Manufacturing and properties of biobased thermoplastic composites from poly (lactid acid) and hazelnut shell wastes. Polym. Compos. 2018, 39, 848–857. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

- Auras, R.; Harte, B.; Selke, S. An Overview of Polylactides as Packaging Materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef]

- Das, P.P.; Chaudhary, V. Moving towards the era of bio fibre based polymer composites. Clean. Eng. Technol. 2021, 4, 100182. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Natural Fibers, Biopolymers, and Biocomposites, 1st ed.; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar] [CrossRef]

- Kim, J.-W.; Harper, D.P.; Taylor, A.M. Effect of wood species on the mechanical and thermal properties of wood-plastic composites. J. Appl. Polym. Sci. 2009, 112, 1378–1385. [Google Scholar] [CrossRef]

- Keresa, D.A.; Chang-Sik, H.; Abubeker, Y.A. Comprehensive overview of wood polymer composite: Formulation and technology, properties, interphase modification, and characterization. SM&T 2024, 40, e00983. [Google Scholar] [CrossRef]

- Gozdecki, C.; Zajchowski, S.; Kociszewski, M.; Wilczyński, A.D.; Mirowski, J. Effect of wood particle size on mechanical properties of industrial wood particle-polyethylene composites. Polimery 2011, 56, 375–380. [Google Scholar] [CrossRef]

- Landon, G.; Lewis, G.; Boden, G.F. The influence of particle size on the tensile strength of particulate—Filled polymers. J. Mater. Sci. 1977, 12, 1605–1613. [Google Scholar] [CrossRef]

- Włodarczyk-Fligier, A.; Polok-Rubiniec, M.; Chmielnicki, B. Kompozyty polimerowe z napełniaczem naturalnym. Przetwórstwo Tworzyw 2018, 24, 50–57. [Google Scholar]

- Ratanawilai, T.; Nakawirot, K.; Deachsrijan, A.; Homkhiew, C. Influence of wood species and particle size on mechanical and thermal properties of wood polypropylene composites. Fibers Polym. 2014, 15, 2160–2168. [Google Scholar] [CrossRef]

- Bondtech 600-C-CHT-MOS-175 Technical Datasheet. Available online: https://www.bondtech.se/downloads/TDS/Bondtech_600-C-CHT-MOS-175-XX.pdf (accessed on 18 March 2025).

- Rodrigues, S.; Miri, S.; Cole, R.G.; Postigo, A.A.; Saleh, M.A.; Dondish, A.; Melenka, G.W.; Fayazbakhsh, K. Towards optimization of polymer filament tensile test for material extrusion additive manufacturing process. J. Mater. Res. Technol. 2023, 24, 8458–8472. [Google Scholar] [CrossRef]

- Sola, A.; Chong, W.J.; Simunec, D.P.; Li, Y.; Trinchi, A.; Kyratzis, I.L.; Wen, C. Open challenges in tensile testing of additively manufactured polymers: A literature survey and a case study in fused filament fabrication. Polym. Test. 2023, 117, 107859. [Google Scholar] [CrossRef]

- Kariz, M.; Sernek, M.; Obućina, M.; Kuzman, M.K. Effect of wood content in FDM filament on properties of 3D printed parts. Mater. Today Commun. 2018, 14, 135–140. [Google Scholar] [CrossRef]

- Yang, T.C.; Yeh, C.H. Morphology and Mechanical Properties of 3D Printed Wood Fiber/Polylactic Acid Composite Parts Using Fused Deposition Modeling (FDM): The Effects of Printing Speed. Polymers 2020, 12, 1334. [Google Scholar] [CrossRef]

- Mazur, K.E.; Borucka, A.; Kaczor, P.; Gądek, S.; Bogucki, R.; Mirzewiński, D.; Kuciel, S. Mechanical, Thermal and Microstructural Characteristic of 3D Printed Polylactide Composites with Natural Fibers: Wood, Bamboo and Cork. J. Polym. Environ. 2022, 30, 2341–2354. [Google Scholar] [CrossRef]

- Kim, C.H.; Kim, K.J.; Eom, T.J. Properties of WPC prepared with various size and amount of wood particle. J. Korea TAPPI 2008, 40, 59–64. [Google Scholar]

- Huang, Y.; Löschke, S.; Proust, G. In the mix: The effect of wood composition on the 3D printability and mechanical performance of wood-plastic composites. Compos. Part C Open Access 2021, 5, 100140. [Google Scholar] [CrossRef]

- Petchwattana, N.; Channuan, W.; Naknaen, P.; Narupai, B. 3D Printing filaments prepared from modified poly (lactic acid)/teak wood flour composites: An investigation on the particle size effects and silane coupling agent compatibilisation. J. Phys. Sci. 2019, 30, 169–188. [Google Scholar] [CrossRef]

- Hwang, S.; Fowler, G.; Han, Y.; Gardner, D.J. Material property characterization of 3D printed polypropylene wood plastic composites. Polym. Compos. 2024, 45, 16058–16074. [Google Scholar] [CrossRef]

- Syanatha, A.; Setiawan, R.; Steven, S.; Mardiyati, Y. Effect of manau rattan (Calamus manan miq.) particle size on processability and mechanical properties of 3D-printed PP/rattan WPC filaments. Prog. Addit. Manuf. 2025, 1–13. [Google Scholar] [CrossRef]

- Patti, A.; Acierno, S.; Cicala, G.; Acierno, D. Predicting the Printability of Poly (Lactide) Acid Filaments in Fused Deposition Modeling (FDM) Technology: Rheological Measurements and Experimental Evidence. ChemEngineering 2023, 7, 1. [Google Scholar] [CrossRef]

- Acierno, D.; Patti, A. Fused Deposition Modelling (FDM) of Thermoplastic-Based Filaments: Process and Rheological Properties—An Overview. Materials 2023, 16, 7664. [Google Scholar] [CrossRef]

- Zeng, Z.; Zhou, Y.; Wen, S.; Zhou, C. Predicting the tensile properties of wood plastic composites using material extrusion with meta-based Few-Shot learning. Compos.-A Appl. Sci. Manuf. 2025, 190, 108671. [Google Scholar] [CrossRef]

- ISO-527; Plastics—Determination of Tensile Properties. Part 1: General Principles. ISO: Geneva, Switzerland, 2019.

- Titone, V.; Correnti, A.; La Mantia, F.P. Effect of Moisture Content on the Processing and Mechanical Properties of a Biodegradable Polyester. Polymers 2021, 13, 1616. [Google Scholar] [CrossRef]

- Beran, T.; Mulholland, T.; Henning, F.; Rudolph, N.; Osswald, T.A. Nozzle clogging factors during fused filament fabrication of spherical particle filled polymers. Addit. Manuf. 2018, 23, 206–214. [Google Scholar] [CrossRef]

- Mazzanti, V.; Mollica, F. A Review of Wood Polymer Composites Rheology and Its Implications for Processing. Polymers 2020, 12, 2304. [Google Scholar] [CrossRef]

- Beke, B. Principles of Comminution; Akadémiai Kiadó: Budapest, Hungary, 1964. [Google Scholar]

- Bhagia, S.; Lowden, R.R.; Erdman, D.; Rodriguez, M.; Haga, B.A.; Solano, I.R.M.; Gallego, N.C.; Pu, Y.; Muchero, W.; Kunc, V.; et al. Tensile properties of 3D-printed wood-filled PLA materials using poplar trees. Appl. Mater. Today 2020, 21, 100832. [Google Scholar] [CrossRef]

- Velghe, I.; Buffel, B.; Vandeginste, V.; Thielemans, W.; Desplentere, F. Review on the Degradation of Poly (lactic acid) during Melt Processing. Polymers 2023, 15, 2047. [Google Scholar] [CrossRef] [PubMed]

- Le Marec, P.E.; Ferry, L.; Quantin, J.C.; Bénézet, J.C.; Bonfils, F.; Guilbert, S.; Bergeret, A. Influence of melt processing conditions on poly(lactic acid) degradation: Molar mass distribution and crystallization. Polym. Degrad. Stab. 2014, 110, 353–363. [Google Scholar] [CrossRef]

- Mysiukiewicz, O.; Barczewski, M.; Skórczewska, K.; Matykiewicz, D. Correlation between processing parameters and degradation of different polylactide grades during twin-screw extrusion. Polymers 2020, 12, 1333. [Google Scholar] [CrossRef] [PubMed]

| Material | Particle Size [mm] | Moisture Content |

|---|---|---|

| PLA | - | 0.54% |

| WP | <0.2 | 4.45% |

| WP | 0.2–0.4 | 4.78% |

| WP | 0.4–0.6 | 5.58% |

| WP | 0.6–0.8 | 5.43% |

| WP | 0.8–1.0 | 5.82% |

| Variant | Particle Size [mm] | Tensile Strength [MPa] | Tensile Modulus [MPa] |

|---|---|---|---|

| 0 | - | 33.43 A | 1580 a |

| 1 | <0.2 | 12.53 BC | 926 bc |

| 2 | 0.2–0.4 | 11.32 BC | 802 bc |

| 3 | 0.4–0.6 | 9.21 B | 1014 b |

| 4 | 0.6–0.8 | 14.28 C | 960 c |

| 5 | 0.8–1.0 | - | - |

| Variant | Particle Size [mm] | Tensile Strength [MPa] | |

|---|---|---|---|

| Highest | Lowest | ||

| 0 | - | 37.92 A | 27.72 a |

| 1 | <0.2 | 16.51 B | 6.78 b |

| 2 | 0.2–0.4 | 15.36 B | 6.05 b |

| 3 | 0.4–0.6 | 15.08 B | 5.75 b |

| 4 | 0.6–0.8 | 19.61 C | 6.73 b |

| 5 | 0.8–1.0 | - | - |

| N Total | Mean [µm] | Standard Deviation | Sum | Minimum | Median | Maximum | ||

|---|---|---|---|---|---|---|---|---|

| Variant 1 <0.2 mm | Length | 12 | 20.60714 | 8.13771 | 288.5 | 9.4 | 20.95 | 37.3 |

| Width | 12 | 9.41429 | 3.27317 | 131.8 | 4.1 | 9.15 | 16.2 | |

| Variant 2 0.2–0.4 mm | Length | 7 | 40.05714 | 18.09741 | 280.4 | 15.7 | 37.2 | 58.5 |

| Width | 7 | 14.47143 | 5.07599 | 101.3 | 8.4 | 14.5 | 23.7 | |

| Variant 3 0.24–0.6 mm | Length | 4 | 28.45 | 17.44754 | 113.8 | 14.9 | 22.55 | 53.8 |

| Width | 5 | 15.68 | 8.68976 | 78.4 | 8.7 | 13.7 | 30.7 | |

| Variant 4 0.6–0.8 mm | Length | 3 | 21.66667 | 17.26306 | 65 | 11.6 | 11.8 | 41.6 |

| Width | 10 | 10.14 | 4.88676 | 101.4 | 3.5 | 10.95 | 16.4 | |

| Material | Element | Average [wt.%] | Std. Deviation [wt.%] |

|---|---|---|---|

| PLA before extrusion | C | 39.56 A | 1.576 |

| O | 60.44 a | ||

| PLA after extrusion | C | 39.11 A | 3.021 |

| O | 60.89 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jasiński, W.; Szymanowski, K.; Nasiłowska, B.; Barlak, M.; Betlej, I.; Prokopiuk, A.; Borysiuk, P. 3D Printing Wood–PLA Composites: The Impact of Wood Particle Size. Polymers 2025, 17, 1165. https://doi.org/10.3390/polym17091165

Jasiński W, Szymanowski K, Nasiłowska B, Barlak M, Betlej I, Prokopiuk A, Borysiuk P. 3D Printing Wood–PLA Composites: The Impact of Wood Particle Size. Polymers. 2025; 17(9):1165. https://doi.org/10.3390/polym17091165

Chicago/Turabian StyleJasiński, Wojciech, Karol Szymanowski, Barbara Nasiłowska, Marek Barlak, Izabela Betlej, Artur Prokopiuk, and Piotr Borysiuk. 2025. "3D Printing Wood–PLA Composites: The Impact of Wood Particle Size" Polymers 17, no. 9: 1165. https://doi.org/10.3390/polym17091165

APA StyleJasiński, W., Szymanowski, K., Nasiłowska, B., Barlak, M., Betlej, I., Prokopiuk, A., & Borysiuk, P. (2025). 3D Printing Wood–PLA Composites: The Impact of Wood Particle Size. Polymers, 17(9), 1165. https://doi.org/10.3390/polym17091165