Machine Learning in Polymeric Technical Textiles: A Review

Abstract

:1. Introduction

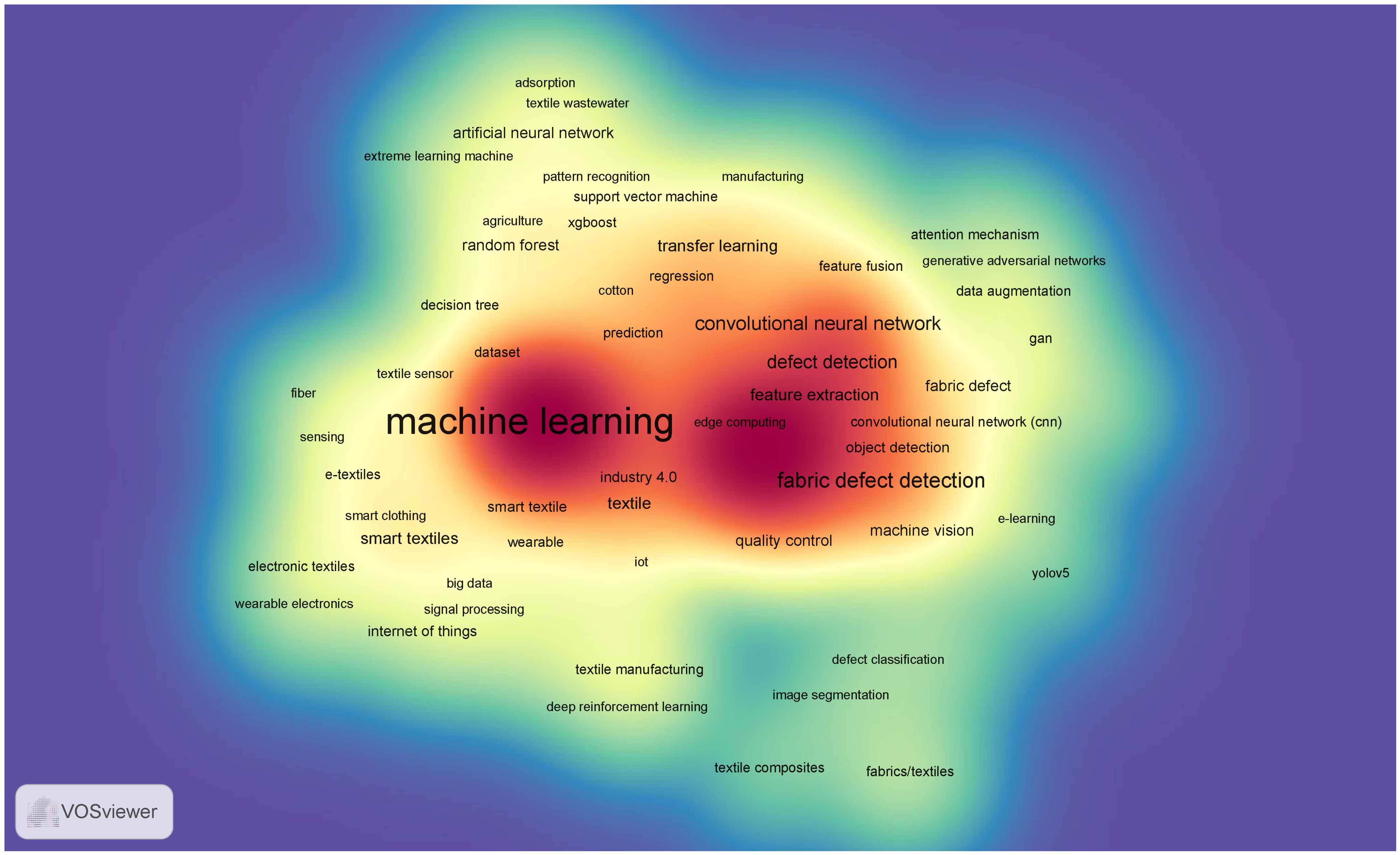

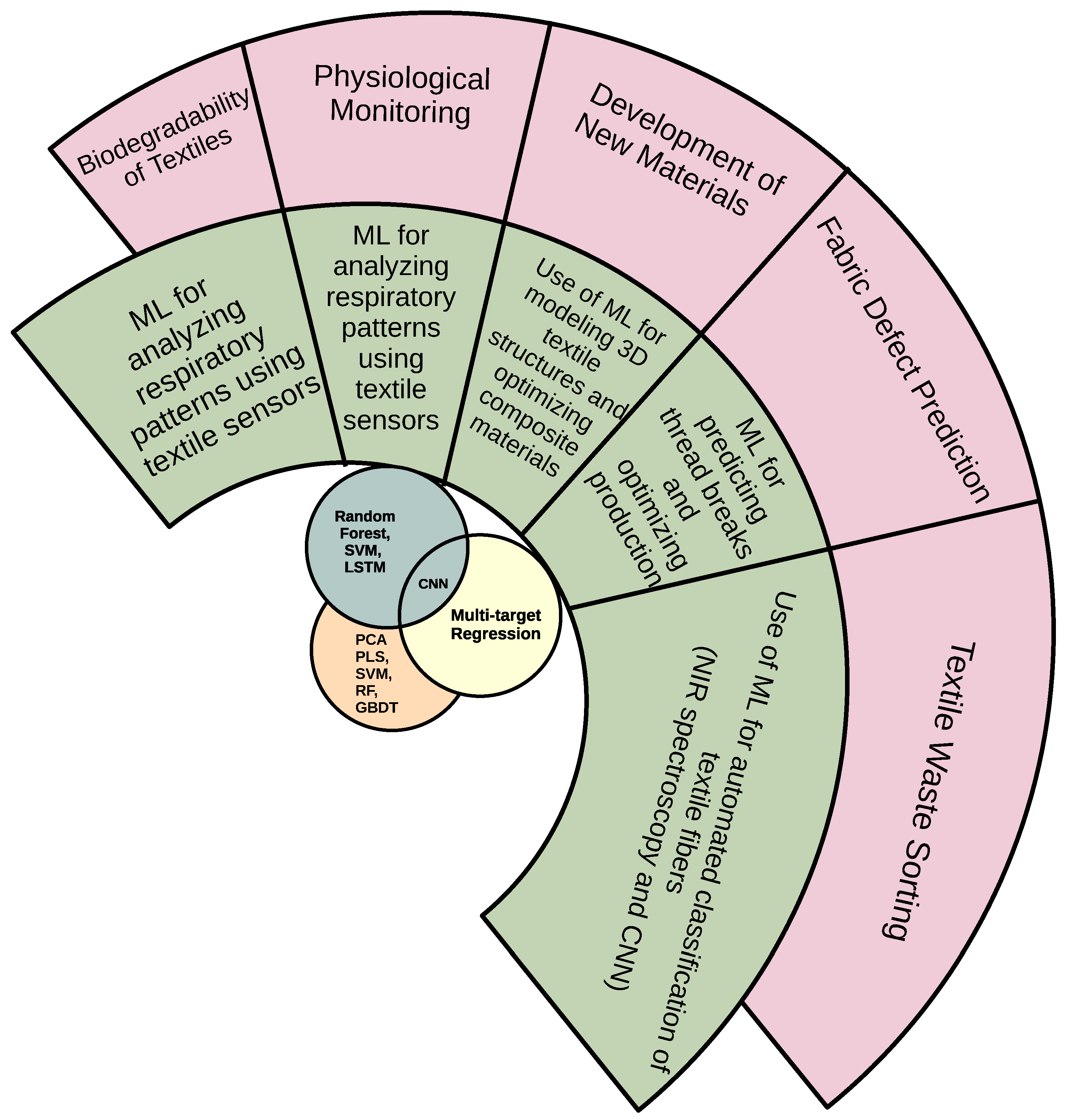

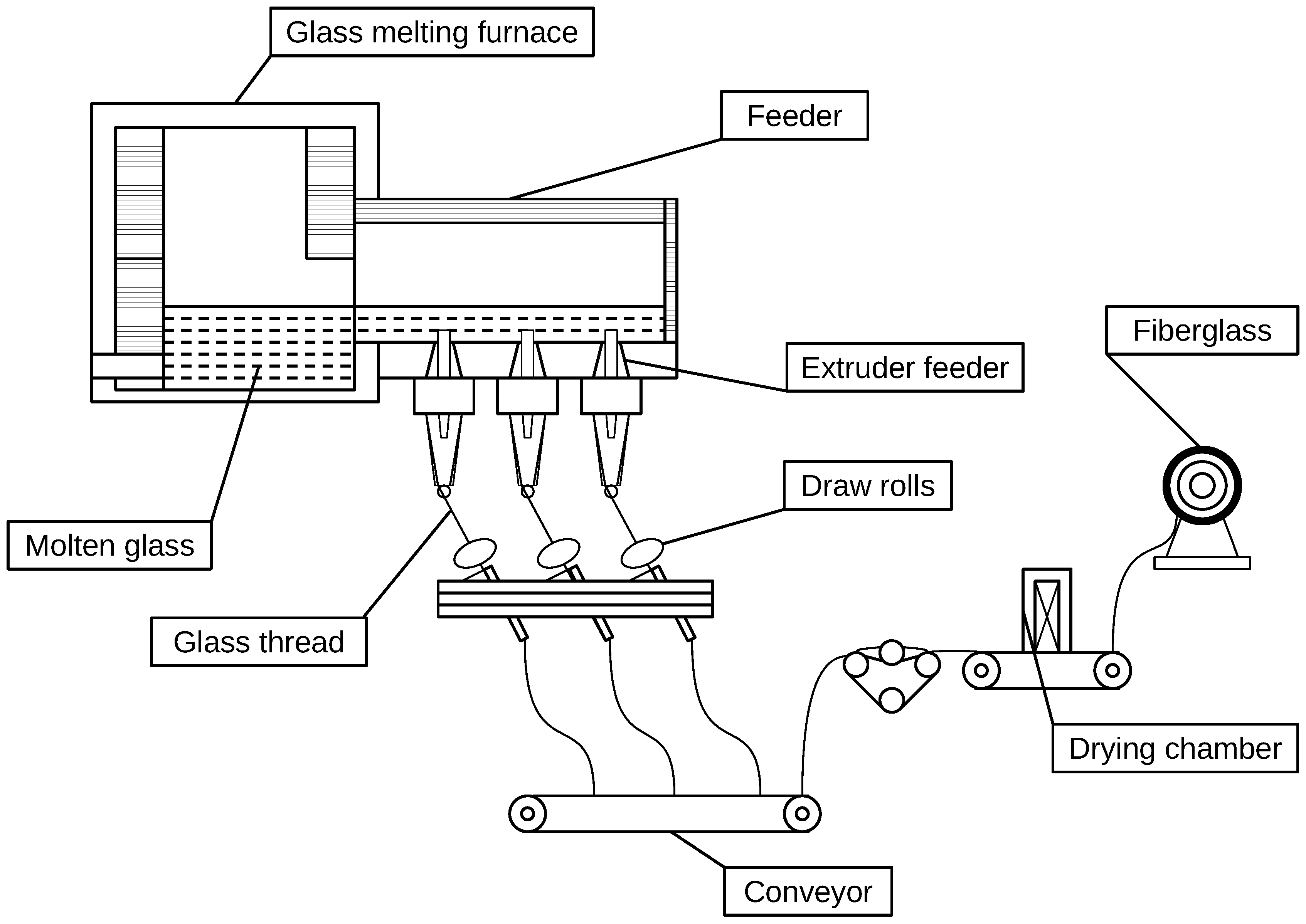

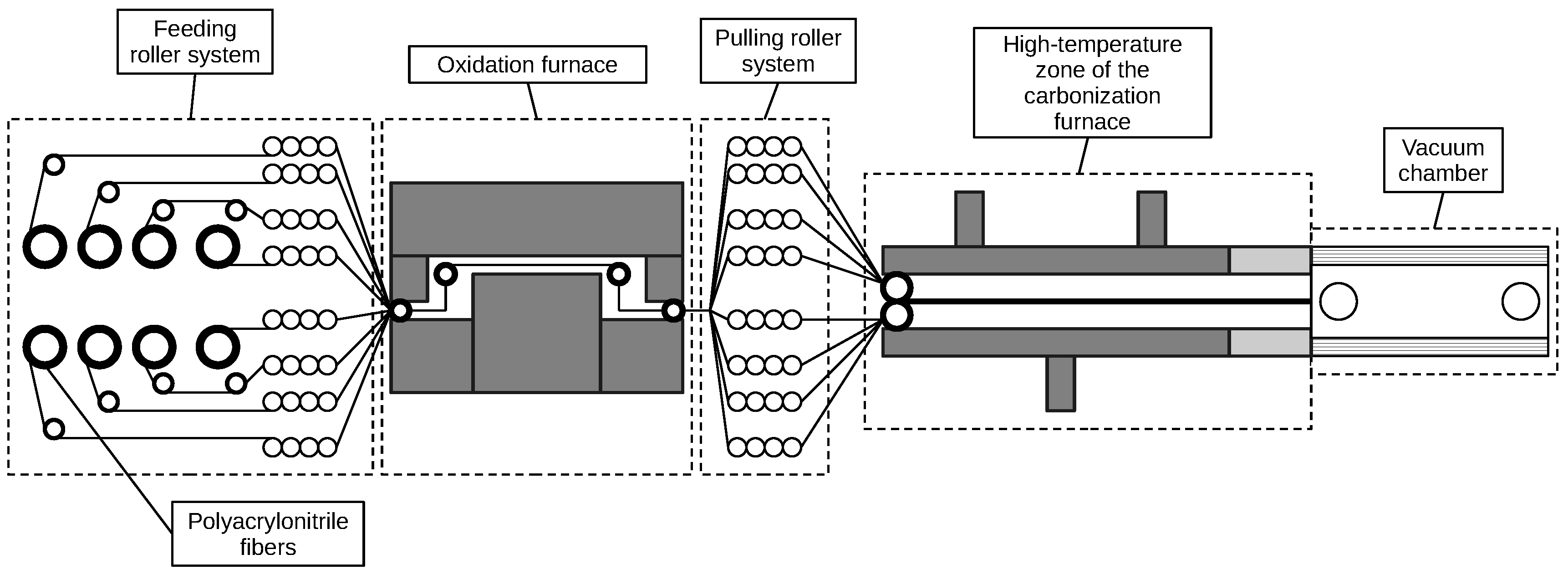

2. Production Methods in Technical Textiles

3. ML in Polymers-Based Textiles

4. Overview of Key Findings and Insights

4.1. Limitations

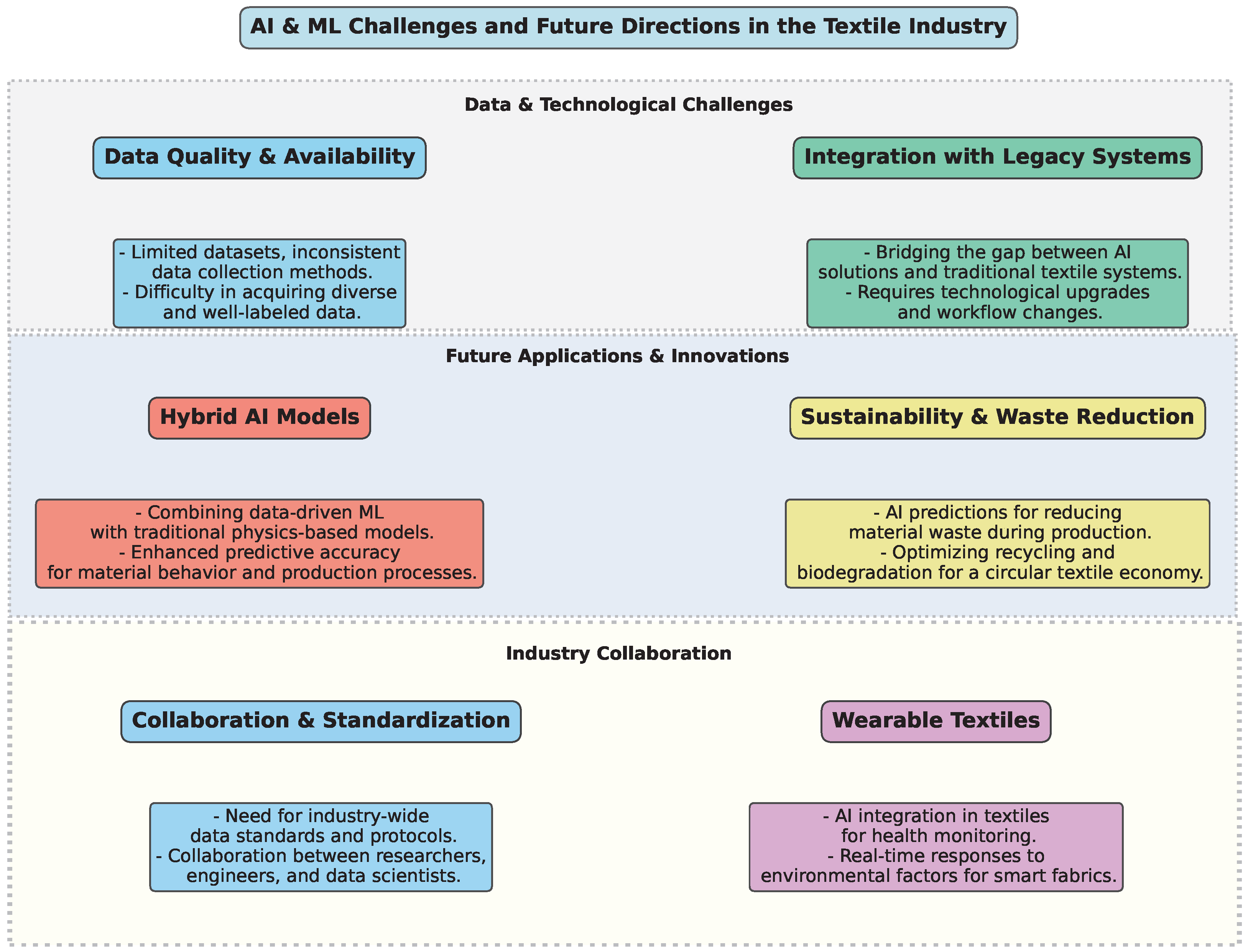

4.2. Challenges

4.3. Future Directions

5. Conclusions

Funding

Conflicts of Interest

References

- Zhao, Z.; Li, B.; Ma, P. Advances in mechanical properties of flexible textile composites. Compos. Struct. 2023, 303, 116350. [Google Scholar] [CrossRef]

- Dolez, P.I.; Marsha, S.; McQueen, R.H. Fibers and textiles for personal protective equipment: Review of recent progress and perspectives on future developments. Textiles 2022, 2, 349–381. [Google Scholar] [CrossRef]

- Zhang, Y.; Xia, X.; Ma, K.; Xia, G.; Wu, M.; Cheung, Y.H.; Yu, H.; Zou, B.; Zhang, X.; Farha, O.K.; et al. Functional textiles with smart properties: Their fabrications and sustainable applications. Adv. Funct. Mater. 2023, 33, 2301607. [Google Scholar] [CrossRef]

- Aldalbahi, A.; El-Naggar, M.E.; El-Newehy, M.H.; Rahaman, M.; Hatshan, M.R.; Khattab, T.A. Effects of technical textiles and synthetic nanofibers on environmental pollution. Polymers 2021, 13, 155. [Google Scholar] [CrossRef]

- Maity, S.; Singha, K.; Pandit, P. Introduction to functional and technical textiles. In Functional and Technical Textiles; Elsevier: Amsterdam, The Netherlands, 2023; pp. 1–30. [Google Scholar]

- Thadepalli, S. Review of multifarious applications of polymers in medical and health care textiles. Mater. Today Proc. 2022, 55, 330–336. [Google Scholar] [CrossRef]

- Rashid, A.B.; Hoque, M.E. Polymer nanocomposites for defense applications. In Advanced Polymer Nanocomposites; Elsevier: Amsterdam, The Netherlands, 2022; pp. 373–414. [Google Scholar]

- Rajput, A.; Upma; Shukla, S.K.; Thakur, N.; Debnath, A.; Mangla, B. Advanced polymeric materials for aerospace applications. In Aerospace Polymeric Materials; Wiley Online Library: New York, NY, USA, 2022; pp. 117–136. [Google Scholar]

- Mavi, S.; Kadian, S.; Sarangi, P.K.; Sahoo, A.K.; Singh, S.; Yahya, M.; Abd Rahman, N.M.M. Advancements in Machine Learning and Artificial Intelligence in Polymer Science: A Comprehensive Review. In Proceedings of the Macromolecular Symposia; Wiley Online Library: New York, NY, USA, 2025; Volume 414, p. 2400185. [Google Scholar]

- Yuan, Q.; Yue, D.; Zhang, Z.; Feng, Y.; Chen, Q. Machine learning research advances in energy storage polymer-based dielectrics. Comput. Mater. Sci. 2025, 249, 113651. [Google Scholar] [CrossRef]

- Uddin, M.H.; Mulla, M.H.; Abedin, T.; Manap, A.; Yap, B.K.; Rajamony, R.K.; Shahapurkar, K.; Khan, T.Y.; Soudagar, M.E.M.; Nur-E-Alam, M. Advances in natural fiber polymer and PLA composites through artificial intelligence and machine learning integration. J. Polym. Res. 2025, 32, 76. [Google Scholar] [CrossRef]

- Xie, C.; Qiu, H.; Liu, L.; You, Y.; Li, H.; Li, Y.; Sun, Z.; Lin, J.; An, L. Machine Learning Approaches in Polymer Science: Progress and Fundamental for a New Paradigm. SmartMat 2025, 6, e1320. [Google Scholar] [CrossRef]

- Niaki, M.H.; Ahangari, M.G.; Pashaian, M. A material-independent deep learning model to predict the tensile strength of polymer concrete. Compos. Commun. 2022, 36, 101400. [Google Scholar]

- Zhu, M.X.; Song, H.G.; Yu, Q.C.; Chen, J.M.; Zhang, H.Y. Machine-learning-driven discovery of polymers molecular structures with high thermal conductivity. Int. J. Heat Mass Transf. 2020, 162, 120381. [Google Scholar] [CrossRef]

- Casanola-Martin, G.M.; Karuth, A.; Pham-The, H.; González-Díaz, H.; Webster, D.C.; Rasulev, B. Machine learning analysis of a large set of homopolymers to predict glass transition temperatures. Commun. Chem. 2024, 7, 226. [Google Scholar] [CrossRef] [PubMed]

- Le, T.T. Prediction of tensile strength of polymer carbon nanotube composites using practical machine learning method. J. Compos. Mater. 2021, 55, 787–811. [Google Scholar] [CrossRef]

- Elkhaoudi, M.; El Bakkali, M.; Messnaoui, R.; Cherkaoui, O.; Soulhi, A. Literature review on artificial intelligence in dyeing and finishing processes. Data Metadata 2024, 3, 360. [Google Scholar] [CrossRef]

- Neo, P.K.; Leong, Y.W.; Soon, M.F.; Goh, Q.S.; Thumsorn, S.; Ito, H. Development of a Machine Learning Model to Predict the Color of Extruded Thermoplastic Resins. Polymers 2024, 16, 481. [Google Scholar] [CrossRef] [PubMed]

- Glass, S.; Schmidt, M.; Merten, P.; Abdul Latif, A.; Fischer, K.; Schulze, A.; Friederich, P.; Filiz, V. Design of Modified Polymer Membranes Using Machine Learning. ACS Appl. Mater. Interfaces 2024, 16, 20990–21000. [Google Scholar] [CrossRef]

- Souissi, M.; Chaouch, S.; Moussa, A.; Dhaouadi, H. Dyeing of advanced denim fabrics (blend of cotton/bicomponent polyester filaments) using different processes and artificial intelligence method. Sci. Rep. 2024, 14, 1952. [Google Scholar] [CrossRef]

- Xie, R.; He, X.; Liu, Y.; Zhang, Y.; Wang, X.; Xu, J.; Wang, H. Machine learning assisted mechanical properties prediction of fine denier polyester fiber. J. Text. Inst. 2024, 116, 1–9. [Google Scholar] [CrossRef]

- Wang, J.; Karimi, S.; Zeinalzad, P.; Zhang, J.; Gong, Z. Using machine learning and experimental study to correlate and predict accelerated aging with natural aging of GFRP composites in hygrothermal conditions. Constr. Build. Mater. 2024, 438, 137264. [Google Scholar] [CrossRef]

- Zhang, Q.; Cheng, H.; Zhang, S.; Li, Y.; Li, Z.; Ma, J.; Liu, X. Advancements and challenges in thermoregulating textiles: Smart clothing for enhanced personal thermal management. Chem. Eng. J. 2024, 488, 151040. [Google Scholar] [CrossRef]

- Behera, S.A.; Panda, S.; Hajra, S.; Kaja, K.R.; Pandey, A.K.; Barranco, A.; Jeong, S.M.; Vivekananthan, V.; Kim, H.J.; Achary, P.G.R. Current trends on advancement in smart textile device engineering. Adv. Sustain. Syst. 2024, 8, 2400344. [Google Scholar] [CrossRef]

- Iannacchero, M.; Löfgren, J.; Mohan, M.; Rinke, P.; Vapaavuori, J. Machine learning-assisted development of polypyrrole-grafted yarns for e-textiles. Mater. Des. 2025, 249, 113528. [Google Scholar] [CrossRef]

- Montazeri, M.; Mohammadi, M.; Zare, Y.; Rhee, K.Y. Predictive models for the tensile strength of polymer composites comprising spherical nano-starch using interphase properties. Ind. Crops Prod. 2025, 226, 120655. [Google Scholar] [CrossRef]

- Li, T.; He, T.; Wei, J.; Zhang, L.; Lu, X.; Qian, H. Study on the effect of degree of polymerization of cellulose on syngas composition based on established higher heating value prediction model. J. Anal. Appl. Pyrolysis 2025, 186, 106940. [Google Scholar] [CrossRef]

- Singh, I.; Arora, V.; Babu, P.; Mulaveesala, R. Advanced signal processing techniques for defect detection in Carbon Fibre Reinforced Polymers using Golay coded thermal wave imaging. Infrared Phys. Technol. 2025, 147, 105806. [Google Scholar] [CrossRef]

- Lim, W.H.; Sfarra, S.; Hsiao, T.Y.; Yao, Y. Physics-Informed Neural Networks for Defect Detection and Thermal Diffusivity Evaluation in Carbon Fiber Reinforced Polymer using Pulsed Thermography. IEEE Trans. Instrum. Meas. 2025, 74, 4500910. [Google Scholar]

- Alagulakshmi, R.; Ramalakshmi, R.; Veerasimman, A.; Palani, G.; Selvaraj, M.; Basumatary, S. Advancements of Machine Learning Techniques in Fiber-Filled Polymer Composites: A Review. Polym. Bull. 2025, 82, 2059–2089. [Google Scholar] [CrossRef]

- Liu, J.; Hu, L.; Lui, K.W.; Wong, S.W.f.; Jiang, S.x. Design and characterization of breathable 3D printed textiles with flexible lattice structures. J. Manuf. Processes 2025, 141, 48–58. [Google Scholar] [CrossRef]

- Cassola, S.; Duhovic, M.; Schmidt, T.; May, D. Machine learning for polymer composites process simulation—A review. Compos. Part B Eng. 2022, 246, 110208. [Google Scholar] [CrossRef]

- Karuppusamy, M.; Thirumalaisamy, R.; Palanisamy, S.; Nagamalai, S.; Massoud, E.E.S.; Ayrilmis, N. A review of machine learning applications in polymer composites: Advancements, challenges, and future prospects. J. Mater. Chem. A 2025. [Google Scholar] [CrossRef]

- Ge, W.; De Silva, R.; Fan, Y.; Sisson, S.A.; Stenzel, M.H. Machine Learning in Polymer Research. Adv. Mater. 2025, 37, 2413695. [Google Scholar] [CrossRef]

- Choi, J.; Jeon, C.; Lee, J.E.; Lee, G.H.; Hwang, S.; Han, M.; Lee, S.; Gwak, H.J.; Lee, E.; Won, J.S.; et al. Optimization of the carbonization process based on the evolution of microstructural components of polyacrylonitrile (PAN)-based fibers. Carbon 2025, 235, 120058. [Google Scholar] [CrossRef]

- Hufenus, R.; Yan, Y.; Dauner, M.; Kikutani, T. Melt-spun fibers for textile applications. Materials 2020, 13, 4298. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Hsiao, B.S. Electrospun nanofiber membranes. Curr. Opin. Chem. Eng. 2016, 12, 62–81. [Google Scholar] [CrossRef]

- Chinnappan, B.A.; Krishnaswamy, M.; Xu, H.; Hoque, M.E. Electrospinning of biomedical nanofibers/nanomembranes: Effects of process parameters. Polymers 2022, 14, 3719. [Google Scholar] [CrossRef]

- Heinz, M.; Stephan, P.; Gambaryan-Roisman, T. Influence of nanofiber coating thickness and drop volume on spreading, imbibition, and evaporation. Colloids Surfaces A Physicochem. Eng. Asp. 2021, 631, 127450. [Google Scholar] [CrossRef]

- Li, M.; Chen, K.; Zhang, D.; Ye, Z.; Yang, Z.; Wang, Q.; Jiang, Z.; Zhang, Y.; Shang, Y.; Cao, A. Wet-Spinning Carbon Nanotube/Shape Memory Polymer Composite Fibers with High Actuation Stress and Predesigned Shape Change. Adv. Sci. 2024, 11, 2404913. [Google Scholar] [CrossRef]

- Liu, L.; Chang, D.; Gao, C. A review of multifunctional nanocomposite fibers: Design, preparation and applications. Adv. Fiber Mater. 2024, 6, 68–105. [Google Scholar] [CrossRef]

- Biyada, S.; Urbonavičius, J. Circularity in textile waste: Challenges and pathways to sustainability. Clean. Eng. Technol. 2025, 24, 100905. [Google Scholar] [CrossRef]

- Sharma, S.; Jahanzaib, M.; Lee, J.; Park, D. Global Legislation, Schemes and Standards to Control Environmental Concern for Textile-Generated Waste. In Nanotechnology-Assisted Recycling of Textile Waste; Wiley: New York, NY, USA, 2025; pp. 435–459. [Google Scholar] [CrossRef]

- Carvalho, C.; Silva, C.J.; Abreu, M.J. Circular Economy: Literature Review on the Implementation of the Digital Product Passport (DPP) in the Textile Industry. Sustainability 2025, 17, 1802. [Google Scholar] [CrossRef]

- Abdelmonem, A.; Elsabbagh, A.; Attia, T. Carpet textile waste in thermoplastic polymer composites: A systematic review. J. Thermoplast. Compos. Mater. 2025, 08927057251316238. [Google Scholar] [CrossRef]

- Riba, J.R.; Cantero, R.; Riba-Mosoll, P.; Puig, R. Post-consumer textile waste classification through near-infrared spectroscopy, using an advanced deep learning approach. Polymers 2022, 14, 2475. [Google Scholar] [CrossRef] [PubMed]

- Ingle, N.; Jasper, W.J. A review of the evolution and concepts of deep learning and AI in the textile industry. Text. Res. J. 2025, 00405175241310632. [Google Scholar] [CrossRef]

- Koptelov, A.; Thompson, A.; Hallett, S.R.; El Said, B. A deep learning approach for predicting the architecture of 3D textile fabrics. Mater. Des. 2024, 239, 112803. [Google Scholar] [CrossRef]

- Huang, J.; Cai, Y.; Xie, G.; Xu, X.; Geng, Z.; Jiang, Y.; Su, Y. Hierarchical carbon nanotube-decorated polyacrylonitrile smart textiles for wearable biomonitoring. Wearable Electron. 2024, 1, 180–188. [Google Scholar] [CrossRef]

- Azevedo, J.; Ribeiro, R.; Matos, L.M.; Sousa, R.; Silva, J.P.; Pilastri, A.; Cortez, P. Predicting yarn breaks in textile fabrics: A machine learning approach. Procedia Comput. Sci. 2022, 207, 2301–2310. [Google Scholar] [CrossRef]

- Daniel, C. AutoGluon-enabled machine learning models for predicting recycled aggregate concrete’s compressive strength. Aust. J. Struct. Eng. 2025, 1–15. [Google Scholar] [CrossRef]

- Jin, H.; Chollet, F.; Song, Q.; Hu, X. Autokeras: An automl library for deep learning. J. Mach. Learn. Res. 2023, 24, 1–6. [Google Scholar]

- Bao, Q.; Zhang, Z.; Luo, H.; Tao, X. Evaluating and modeling the degradation of PLA/PHB fabrics in marine water. Polymers 2022, 15, 82. [Google Scholar] [CrossRef]

- Murariu, M.; Paint, Y.; Murariu, O.; Laoutid, F.; Dubois, P. Recent advances in production of ecofriendly polylactide (PLA)–calcium sulfate (anhydrite II) composites: From the evidence of filler stability to the effects of PLA matrix and filling on key properties. Polymers 2022, 14, 2360. [Google Scholar] [CrossRef]

- Boey, J.; Kong, U.; Lee, C.; Lim, G.; Oo, C.; Tan, C.; Ng, C.; Azniwati, A.; Tay, G. The effect of spent coffee ground (SCG) loading, matrix ratio and biological treatment of SCG on poly (hydroxybutyrate)(PHB)/poly (lactic acid)(PLA) polymer blend. Int. J. Biol. Macromol. 2024, 266, 131079. [Google Scholar] [CrossRef]

- Boey, J.Y.; Mohamad, L.; Khok, Y.S.; Tay, G.S.; Baidurah, S. A review of the applications and biodegradation of polyhydroxyalkanoates and poly (lactic acid) and its composites. Polymers 2021, 13, 1544. [Google Scholar] [CrossRef] [PubMed]

- Fogašová, M.; Figalla, S.; Danišová, L.; Medlenová, E.; Hlaváčiková, S.; Vanovčanová, Z.; Omaníková, L.; Baco, A.; Horváth, V.; Mikolajová, M.; et al. PLA/PHB-based materials fully biodegradable under both industrial and home-composting conditions. Polymers 2022, 14, 4113. [Google Scholar] [CrossRef] [PubMed]

- Mallegni, N.; Cicogna, F.; Passaglia, E.; Gigante, V.; Coltelli, M.B.; Coiai, S. Natural Antioxidants: Advancing Stability and Performance in Sustainable Biobased and Biodegradable Plastics. Compounds 2025, 5, 4. [Google Scholar] [CrossRef]

- Kervran, M.; Vagner, C.; Cochez, M.; Ponçot, M.; Saeb, M.R.; Vahabi, H. Thermal degradation of polylactic acid (PLA)/polyhydroxybutyrate (PHB) blends: A systematic review. Polym. Degrad. Stab. 2022, 201, 109995. [Google Scholar] [CrossRef]

- Gorrasi, G.; Pantani, R. Effect of PLA grades and morphologies on hydrolytic degradation at composting temperature: Assessment of structural modification and kinetic parameters. Polym. Degrad. Stab. 2013, 98, 1006–1014. [Google Scholar] [CrossRef]

- Pickett, J.E.; Coyle, D.J. Hydrolysis kinetics of condensation polymers under humidity aging conditions. Polym. Degrad. Stab. 2013, 98, 1311–1320. [Google Scholar] [CrossRef]

- Aslanzadeh, S.; Haghighat Kish, M. Photo-oxidation of polypropylene fibers exposed to short wavelength UV radiations. Fibers Polym. 2010, 11, 710–718. [Google Scholar] [CrossRef]

- Chanprateep, S. Current trends in biodegradable polyhydroxyalkanoates. J. Biosci. Bioeng. 2010, 110, 621–632. [Google Scholar] [CrossRef]

- Ravichandran, B.; Balasubramanian, M. Joining methods for Fiber Reinforced Polymer (FRP) composites—A critical review. Compos. Part A Appl. Sci. Manuf. 2024, 186, 108394. [Google Scholar] [CrossRef]

- Salameh, A.; Hawileh, R.; Safieh, H.; Assad, M.; Abdalla, J. Elevated Temperature Effects on FRP–Concrete Bond Behavior: A Comprehensive Review and Machine Learning-Based Bond Strength Prediction. Infrastructures 2024, 9, 183. [Google Scholar] [CrossRef]

- Lee, H.; Kim, K.W.; Choi, M.K.; Kim, B.J.; Choi, Y.C.; Terrones, M. Enhancing bond performance of carbon fiber reinforced plastic bars in concrete structures: Insights and guidelines. Carbon 2024, 230, 119685. [Google Scholar] [CrossRef]

- Sinchuk, Y.; Kibleur, P.; Aelterman, J.; Boone, M.N.; Van Paepegem, W. Variational and deep learning segmentation of very-low-contrast X-ray computed tomography images of carbon/epoxy woven composites. Materials 2020, 13, 936. [Google Scholar] [CrossRef]

- Zhou, Y.; Mao, Z.; Xu, J.J. Recent advances in near infrared (NIR) electrochemiluminescence luminophores. Chin. Chem. Lett. 2024, 35, 109622. [Google Scholar] [CrossRef]

- Yang, M.; Chen, S.; Xu, D.; Zhao, X.; Shi, Z.; Qian, H.; Zhang, Z. Removing the moisture effect on predicting soil organic matter using vis-NIR spectroscopy with external parameter orthogonalization. Geoderma Reg. 2024, 37, e00797. [Google Scholar] [CrossRef]

- Qiu, X.; Liu, Y.; Zhang, X.; Liu, D.; Wang, R.; Wang, C.; Liu, J.; Liu, W.; Gong, Y. Moisture insensitive analysis of polyester/viscose waste textiles using Near-Infrared spectroscopy and Orthogonalization of external parameters algorithm. J. Ind. Text. 2023, 53, 15280837231187671. [Google Scholar] [CrossRef]

- Gope, A.K.; Liao, Y.S.; Kuo, C.F.J. Quality prediction and abnormal processing parameter identification in polypropylene fiber melt spinning using artificial intelligence machine learning and deep learning algorithms. Polymers 2022, 14, 2739. [Google Scholar] [CrossRef]

- Bashirgonbadi, A.; Ureel, Y.; Delva, L.; Fiorio, R.; Van Geem, K.M.; Ragaert, K. Accurate determination of polyethylene (PE) and polypropylene (PP) content in polyolefin blends using machine learning-assisted differential scanning calorimetry (DSC) analysis. Polym. Test. 2024, 131, 108353. [Google Scholar] [CrossRef]

- Kateb, P.; Fornaciari, A.; Ahmadizadeh, C.; Shokurov, A.; Cicoira, F.; Menon, C. High-Performance Textile-Based Capacitive Strain Sensors via Enhanced Vapor Phase Polymerization of Pyrrole and Their Application to Machine Learning-Assisted Hand Gesture Recognition. Adv. Intell. Syst. 2024, 6, 2400292. [Google Scholar] [CrossRef]

- Jin, X.; Li, D.; Fu, H.; Sun, B.; Yang, Y.; Guo, N.; Zhang, J. Research on fatigue self-healing of asphalts modified by thermoplastic polyurethane (TPU) with different soft segments. Constr. Build. Mater. 2024, 420, 135574. [Google Scholar] [CrossRef]

- Provencher, B.; Badran, A.; Kroll, J.; Marsh, M. Hyperparameter tuning for deep learning semantic image segmentation of micro computed tomography scanned fiber-reinforced composites. Tomogr. Mater. Struct. 2024, 5, 100032. [Google Scholar] [CrossRef]

- Sinchuk, Y.; Kibleur, P.; Aelterman, J.; Boone, M.N.; Van Paepegem, W. Geometrical and deep learning approaches for instance segmentation of CFRP fiber bundles in textile composites. Compos. Struct. 2021, 277, 114626. [Google Scholar] [CrossRef]

- Tang, C.; Zou, J.; Xiong, Y.; Liang, B.; Zhang, W. Automatic reconstruction of closely packed fabric composite RVEs using yarn-level micro-CT images processed by convolutional neural networks (CNNs) and based on physical characteristics. Compos. Sci. Technol. 2024, 252, 110616. [Google Scholar] [CrossRef]

- Song, Y.; Qu, Z.; Liao, H.; Ai, S. Material twins generation of woven polymer composites based on ResL-U-Net convolutional neural networks. Compos. Struct. 2023, 307, 116672. [Google Scholar] [CrossRef]

- Sarkar, J.; Prottoy, Z.H.; Bari, M.T.; Al Faruque, M.A. Comparison of ANFIS and ANN modeling for predicting the water absorption behavior of polyurethane treated polyester fabric. Heliyon 2021, 7, e08000. [Google Scholar] [CrossRef]

- Gulihonenahali Rajkumar, A.; Hemath, M.; Kurki Nagaraja, B.; Neerakallu, S.; Thiagamani, S.M.K.; Asrofi, M. An artificial neural network prediction on physical, mechanical, and thermal characteristics of giant reed fiber reinforced polyethylene terephthalate composite. J. Ind. Text. 2022, 51, 769S–803S. [Google Scholar] [CrossRef]

- Madhavi, T.C. A study on mechanical properties of inorganic binders used in textile reinforced concrete using artificial neural network. Asian J. Civ. Eng. 2024, 25, 4513–4527. [Google Scholar]

- Jang, J.; Kim, J. Prediction of electrical resistance with conductive Sewing patterns by combining artificial neural networks and multiple linear regressions. Polymers 2023, 15, 4138. [Google Scholar] [CrossRef]

- Amor, N.; Noman, M.T.; Ismail, A.; Petru, M.; Sebastian, N. Use of an artificial neural network for tensile strength prediction of nano titanium dioxide coated cotton. Polymers 2022, 14, 937. [Google Scholar] [CrossRef]

- Kim, E.; Kim, S.; Chun, S.; Kim, J. Measurement of conductive fabrics electrical resistance by combining of image processing and convolutional neural network methods. J. Ind. Text. 2024, 54, 15280837241252182. [Google Scholar] [CrossRef]

- Razbin, M.; Gharehaghaji, A.A.; Salehian, M.; Zhu, Y.; Kish, M.H.; Kouchehbaghi, N.H. Artificial neural network-assisted theoretical model to predict the viscoelastic–plastic tensile behavior of polyamide-6 multi-ply yarns. Neural Comput. Appl. 2024, 36, 18107–18123. [Google Scholar] [CrossRef]

- Cleary, F.; Srisa-An, W.; Henshall, D.C.; Balasubramaniam, S. Emerging AI technologies inspiring the next generation of E-textiles. IEEE Access 2023, 11, 56494–56508. [Google Scholar] [CrossRef]

- Azeem, M.; Shahid, M.; Masin, I.; Petru, M. Design and development of textile-based wearable sensors for real-time biomedical monitoring; a review. J. Text. Inst. 2025, 116, 80–95. [Google Scholar] [CrossRef]

- Yin, L.; Sun, X. Textile-based sensors for human motion sensing: Recent developments and future perspectives. Nanocomposites 2025, 11, 79–98. [Google Scholar] [CrossRef]

- Zhu, J.; Cho, M.; Li, Y.; He, T.; Ahn, J.; Park, J.; Ren, T.L.; Lee, C.; Park, I. Machine learning-enabled textile-based graphene gas sensing with energy harvesting-assisted IoT application. Nano Energy 2021, 86, 106035. [Google Scholar] [CrossRef]

- Keswani, B.; Mohapatra, A.G.; Keswani, P.; Khanna, A.; Gupta, D.; Rodrigues, J. Improving weather dependent zone specific irrigation control scheme in IoT and big data enabled self driven precision agriculture mechanism. Enterp. Inf. Syst. 2020, 14, 1494–1515. [Google Scholar] [CrossRef]

- Adams, B.; Dils, C.; Kühne, T.; Kretzler, L. AI-Enhanced Smart Textile System for the Monitoring of Cardiovascular Insufficiency. In Proceedings of the 2024 International Conference on the Challenges, Opportunities, Innovations and Applications in Electronic Textiles (E-Textiles), Berlin, Germany, 19–21 November 2024; pp. 46–57. [Google Scholar]

- Sharma, A.; Badea, M.; Tiwari, S.; Marty, J.L. Wearable biosensors: An alternative and practical approach in healthcare and disease monitoring. Molecules 2021, 26, 748. [Google Scholar] [CrossRef]

- Karmali, I.M.; Valilai, O.F. Exploring the Role of Artificial Intelligence for Pattern Recognition of Textile Sorting and Recycling for Circular Economy. Procedia Comput. Sci. 2025, 253, 346–356. [Google Scholar] [CrossRef]

- Chu, W.L.; Chang, Q.W.; Jian, B.L. Unsupervised anomaly detection in the textile texture database. Microsyst. Technol. 2024, 30, 1609–1621. [Google Scholar] [CrossRef]

- Ahamed, Z.; Asanka, D.; Rajapakse, C. Optimizing Production Efficiency in the Garment Industry: The Role of Predictive Analytics Techniques in Sri Lanka’s Textile Sector. In Proceedings of the 2024 8th SLAAI International Conference on Artificial Intelligence (SLAAI-ICAI), Ratmalana, Sri Lanka, 18–19 December 2024; pp. 1–6. [Google Scholar]

- Wang, C.; Fu, L.; Ametefe, D.S.; Wang, S.; John, D. E-textiles in healthcare: A systematic literature review of wearable technologies for monitoring and enhancing human health. Neural Comput. Appl. 2024, 37, 2089–2111. [Google Scholar] [CrossRef]

- Gorka, R.; Subramaniyan, A.K.; Velu, R. Integrating Advanced Technologies in Post-operative Rehabilitation: 3D-Knitting, 3D-Printed Electronics, and Sensor-Embedded Textiles. In Digital Design and Manufacturing of Medical Devices and Systems; Springer: New Nork, NY, USA, 2024; pp. 93–110. [Google Scholar]

- Kruse, K.; Sauerwein, W.; Lübben, J.; Dodel, R. Smart technologies and textiles and their potential use and application in the care and support of elderly individuals: A systematic review. Rev. Adv. Mater. Sci. 2024, 63, 20230174. [Google Scholar] [CrossRef]

- Orjuela-Garzón, I.C.; Rodríguez, C.F.; Cruz, J.C.; Briceño, J.C. Design, Characterization, and Evaluation of Textile Systems and Coatings for Sports Use: Applications in the Design of High-Thermal Comfort Wearables. ACS Omega 2024, 9, 49143–49162. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Zhao, X.; Yan, K.; Zhang, P.; Zhang, S.; Fan, H. Smart textiles for chronic disease management: Advancements, applications, and future prospects. Mater. Sci. Eng. R Rep. 2025, 164, 100987. [Google Scholar] [CrossRef]

- Zhao, B.; Richardson, R.E.; You, F. Advancing microplastic analysis in the era of artificial intelligence: From current applications to the promise of generative AI. Nexus 2024, 1, 100043. [Google Scholar] [CrossRef]

- Korodi, A.; Nițulescu, I.V.; Fülöp, A.A.; Vesa, V.C.; Demian, P.; Braneci, R.A.; Popescu, D. Integration of Legacy Industrial Equipment in a Building-Management System Industry 5.0 Scenario. Electronics 2024, 13, 3229. [Google Scholar] [CrossRef]

- Patel, D.K.; Sharma, V.K.; Sharma, H.O.; Kumar, P. Application of AI in Material Science to Accelerate Material Innovation. In Artificial Intelligence in Material Science; CRC Press: Boca Raton, FL, USA, 2024; pp. 198–207. [Google Scholar]

- Kush, J.C. Integrating Sensor Technologies with Conversational AI: Enhancing Context-Sensitive Interaction Through Real-Time Data Fusion. Sensors 2025, 25, 249. [Google Scholar] [CrossRef]

- Nayak, R.; Quang, H.T.; Pal, R. Recent Trends in the Role of Digital Technologies in Fashion and Textile Manufacturing. In Use of Digital and Advanced Technologies in the Fashion Supply Chain; Springer Nature: Singapore, 2025; pp. 1–23. [Google Scholar]

| Factor | Influence on Degradation | Quantitative Data |

|---|---|---|

| Temperature | Accelerates hydrolysis and biodegradation | At 58 °C, the hydrolysis rate of PLA increases 6–8 times compared to 25 °C |

| Humidity | Activates hydrolysis | At 80% relative humidity, degradation proceeds 2–3 times faster |

| UV Radiation | Initiates photo-oxidation | After 300 h of UV exposure—tensile strength decreases by 40% |

| Medium type (compost, soil, aquatic environment) | Determines microbial activity | In compost, PLA/PHB degrades by 90% within 60 days; in soil—less than 30% over the same period |

| PLA/PHB ratio | Affects strength and degradation rate | Increasing PHB content by 20% accelerates biodegradation by 15–25% |

| Study | Topic | Key Approach | Key Findings | Challenges | Potential Directions and Applications |

|---|---|---|---|---|---|

| Riba et al. (2022) [46] | Automated classification of textile waste | Near-infrared (NIR) spectroscopy & convolutional neural networks (CNNs) | 100% accuracy for pure fibers, 90-100% for binary blends, supports recycling | Variability in textile blends and moisture content | Improve model robustness to diverse fabrics and industry adoption for waste sorting. |

| Koptelov et al. (2024) [48] | DL for simulating 3D textile geometry | Convolutional and recurrent neural networks | Efficient simulation of textile structures with 10% error in stiffness prediction | High computational cost for 3D simulations | Integration with real-world production environments for real-time simulations. |

| Huang et al. (2024) [49] | Breath monitoring using composite membrane | Composite membrane with polyacrylonitrile, carbon nanotubes, latex, and ML | Real-time respiratory monitoring with fast response and high sensitivity | Challenges in ensuring long-term stability and robustness of sensors | Expand sensor integration into wearables for health monitoring. |

| Azevedo et al. (2022) [50] | Predicting faults in fabric production | ML for predicting faults such as weft breaks, warp breaks, and yarn bursts | High predictive performance for faults, = 0.73 for weft breaks | Limited training data and variance in fault types | Explore advanced models for dynamic and real-time fault prediction. |

| Bao et al. (2022) [53] | Degradability of PLA/PHB blend fabrics in marine environments | Degradability testing and artificial neural network (ANN) modeling | ANN effectively predicts biodegradation behavior, material structure impacts degradation | Variability in degradation due to environmental factors | Extend research to other environmental conditions and enhance material designs. |

| Salameh et al. (2024) [65] | Bond performance of FRP composites in high temperatures | ML using random forest regression for bond strength prediction under thermal conditions | High predictive accuracy ( = 0.86) for bond strength degradation in fire | Limited data on high-temperature behavior of materials | Apply findings to improve fire-resistant materials in construction. |

| Sinchuk et al. (2020) [67] | Image segmentation for CFRP composites | Variational and DL-based segmentation for low contrast data | DL achieved the highest segmentation accuracy for CFRP composites | Difficulty in segmenting low-contrast images due to noise | Enhance segmentation algorithms for use in automated manufacturing. |

| Qiu et al. (2023) [70] | NIR-based textile waste sorting with moisture interference | Orthogonalization of External Parameters (EPO) algorithm and various ML models | EPO improves accuracy of NIR sorting in moist textiles, score increase of 0.83 | Moisture variation in textiles complicates sorting accuracy | Expand the method to broader types of textile waste sorting. |

| Gope et al. (2022) [71] | Optimizing melt spinning parameters for PP | DL and random forest models for identifying abnormal processing parameters | 100% classification accuracy for abnormal settings, improved quality control | Challenge of integrating these models into real-time production systems | Future work could involve real-time processing monitoring in textile factories. |

| Kateb et al. (2024) [73] | Textile-based capacitive strain sensors | Capacitive sensors embedded in textiles using conductive textiles and ML for gesture recognition | 100% accuracy in gesture classification, high sensitivity compared to resistive sensors | Integration of sensors with other wearable devices | Applications in healthcare and sports for real-time monitoring. |

| Sinchuk et al. (2021) [76] | Segmentation of textile composites in CT images | Geometrical analysis and Deep Learning (DL) for tow-splitting in carbon fiber reinforced composites | Both methods reduce segmentation error to less than 0.3%, effectively splitting compacted tows despite challenges like low contrast and noise. | Noise and artifact removal from CT images can still be challenging | Enhance the methods for wider industrial applications in composite materials. |

| Song et al. (2023) [78] | Digital material twins for woven composite fabric architectures | ResL-U-Net CNN with leaky-ReLU and residual structure to improve segmentation of low-contrast images | Digital twins accurately simulate mechanical performance, predicting damage locations and failure patterns with improved segmentation robustness. | High computational complexity in real-time simulations | Broader applications in composite material lifecycle monitoring and maintenance. |

| Iannacchero et al. (2025) [25] | ML for conductive textile prototypes | ML-assisted design with Bayesian optimization and Pareto front analysis for optimizing conductivity and cost | Optimal processing conditions were found for creating conductive fabrics; p-toluenesulfonic acid had minimal impact on conductivity. | Need for better materials to enhance conductivity and reduce costs | Applications in smart textile industries for sensors and energy harvesting. |

| Sarkar et al. (2021) [79] | Predictive modeling of textile absorption | Used ANFIS and ANN to predict water absorption in PU-treated polyester fabrics | ANFIS model had higher accuracy ( = 0.98) compared to ANN ( = 0.93), both effective in predicting water absorption. | Variability in textile treatments and fabric types | Expand modeling for other textile treatments and develop real-time monitoring systems for water absorption in textiles. |

| Gulihonenahali et al. (2022) [80] | PET composites with giant reed fiber | Used compression molding and ANN to optimize fiber loading (5%, 10%, 20%) | 10% fiber content yielded optimal mechanical properties. ANN model accurately predicted fiber loading, reducing experimental trials. | Variability in fiber properties and molding conditions | Future work could focus on integrating fiber optimization into mass production and scaling the application of natural fibers in composites. |

| Madhavi et al. (2024) [81] | Mechanical behavior of Textile-Reinforced Concrete (TRC) | Compared cementitious, geopolymer, and epoxy binders with different textile reinforcements. ANN model used for property prediction. | Cementitious binder with hybrid textiles showed superior strength. ANN accurately predicted TRC properties with > 0.99. | Limited data on long-term behavior of TRC under different conditions | Extend research to include durability and environmental factors for optimized construction materials. |

| Jang et al. (2023) [82] | Resistance behavior of conductive yarns | Studied the impact of sewing thread patterns (stitch length, angle) on resistance using MLR and ANN. | Shorter stitch lengths reduced resistance. ANN provided better accuracy for predicting resistance. | Stitching complexity and variability in fabric constructions | Apply the findings to improve the performance of wearable electronics and smart textiles in real-world applications. |

| Amor et al. (2022) [83] | Prediction of tensile strength of -coated cotton | Used ANN to predict tensile strength of cotton coated with under varying UV conditions. | ANN outperformed MLR and PRA with an of 0.993 and low error (MAPE = 1.82%) in predicting tensile strength. | Impact of UV degradation and surface coating uniformity | Explore extending this model to predict the performance of other coated textiles and in various environmental conditions. |

| Kim et al. (2024) [84] | Sheet resistance prediction in conductive fabrics | Developed a CNN model using brightness from scanned images to predict sheet resistance. | CNN model showed excellent performance with RMSE of 0.0558 and = 0.9557, accurately predicting resistance. | Variability in fabric characteristics and scanner resolution | Implement the model in real-time quality control systems in smart textile manufacturing. |

| Razbin et al. (2024) [85] | Tensile behavior of polyamide-6 yarns | Combined geometrical analysis and ANN to model tensile behavior of multi-ply yarns. | The ANN model achieved high accuracy ( = 0.97, MAPE = 4.65%), providing an effective method for predicting tensile behavior. | Complexity of multi-ply yarn geometry and data acquisition | Develop advanced models to predict the behavior of different yarn constructions in various textile applications. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malashin, I.; Martysyuk, D.; Tynchenko, V.; Gantimurov, A.; Nelyub, V.; Borodulin, A.; Galinovsky, A. Machine Learning in Polymeric Technical Textiles: A Review. Polymers 2025, 17, 1172. https://doi.org/10.3390/polym17091172

Malashin I, Martysyuk D, Tynchenko V, Gantimurov A, Nelyub V, Borodulin A, Galinovsky A. Machine Learning in Polymeric Technical Textiles: A Review. Polymers. 2025; 17(9):1172. https://doi.org/10.3390/polym17091172

Chicago/Turabian StyleMalashin, Ivan, Dmitry Martysyuk, Vadim Tynchenko, Andrei Gantimurov, Vladimir Nelyub, Aleksei Borodulin, and Andrey Galinovsky. 2025. "Machine Learning in Polymeric Technical Textiles: A Review" Polymers 17, no. 9: 1172. https://doi.org/10.3390/polym17091172

APA StyleMalashin, I., Martysyuk, D., Tynchenko, V., Gantimurov, A., Nelyub, V., Borodulin, A., & Galinovsky, A. (2025). Machine Learning in Polymeric Technical Textiles: A Review. Polymers, 17(9), 1172. https://doi.org/10.3390/polym17091172