Experimental and Numerical Research of 3D DLP-Printed Solid and Voronoi PLA Resin Specimens Under Tensile and Bending Loads

Abstract

:1. Introduction

2. Experimental Research

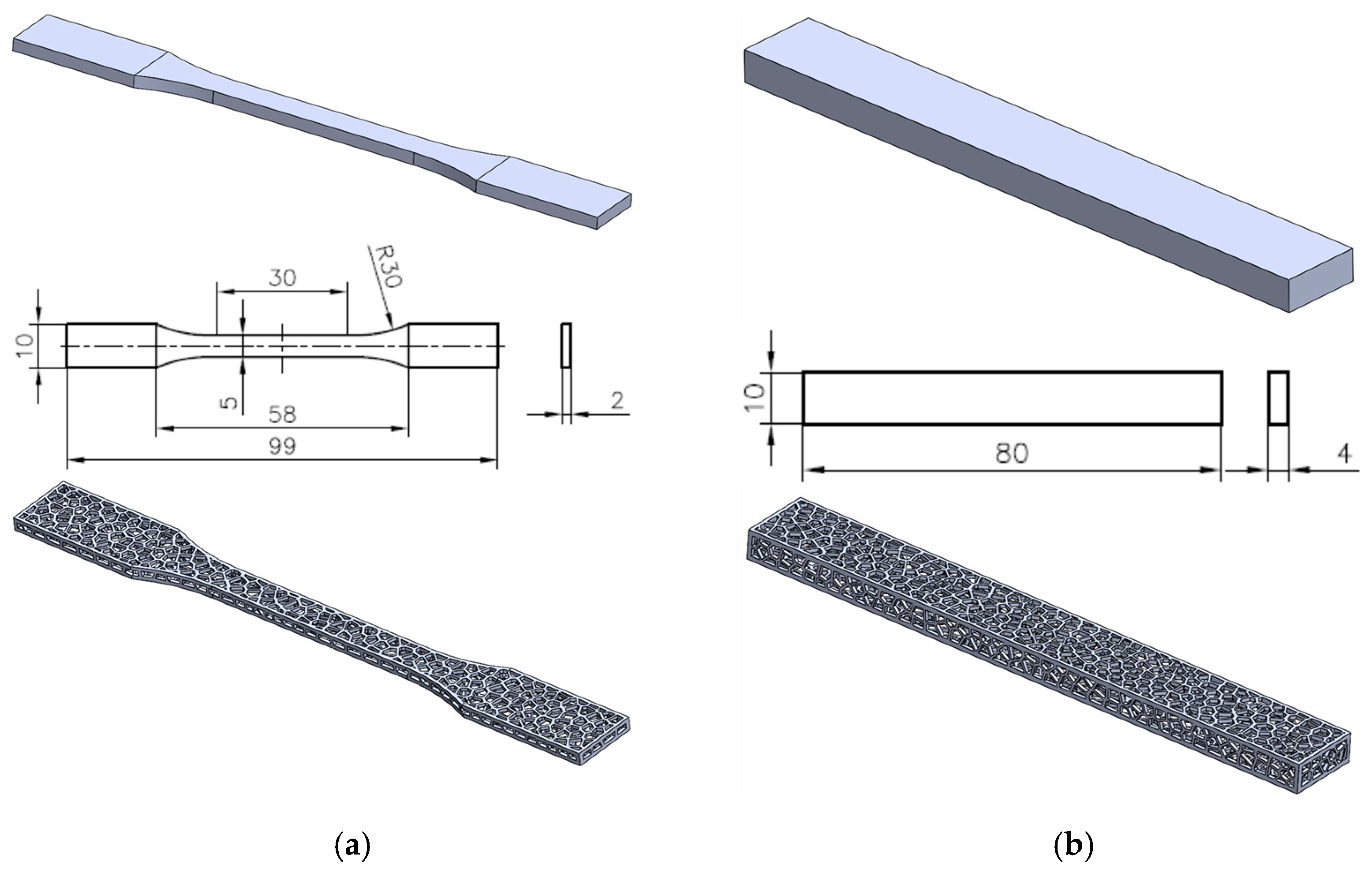

2.1. Specimen Preparation

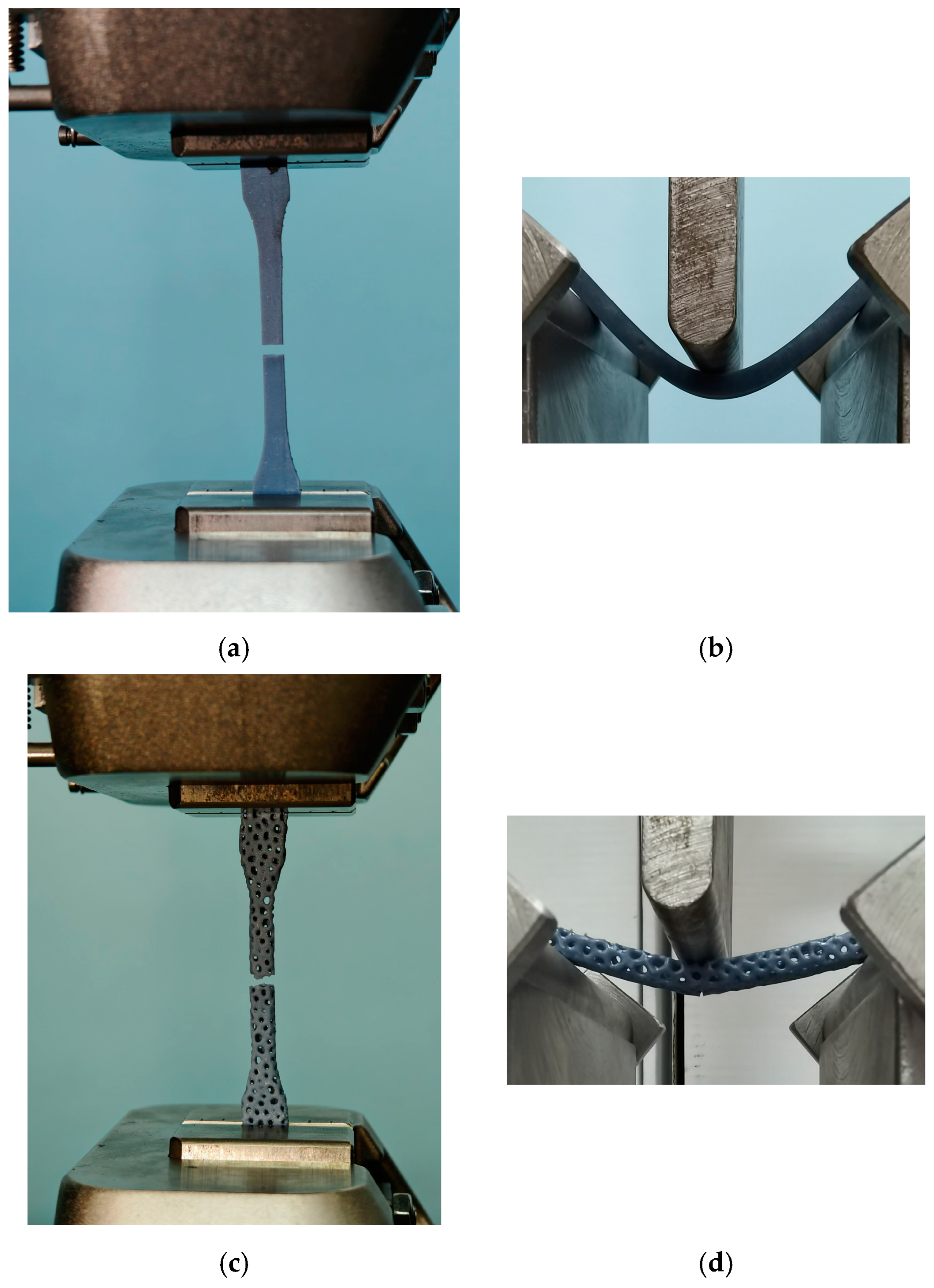

2.2. Mechanical Testing

2.3. Microscopy

3. Numerical Investigations

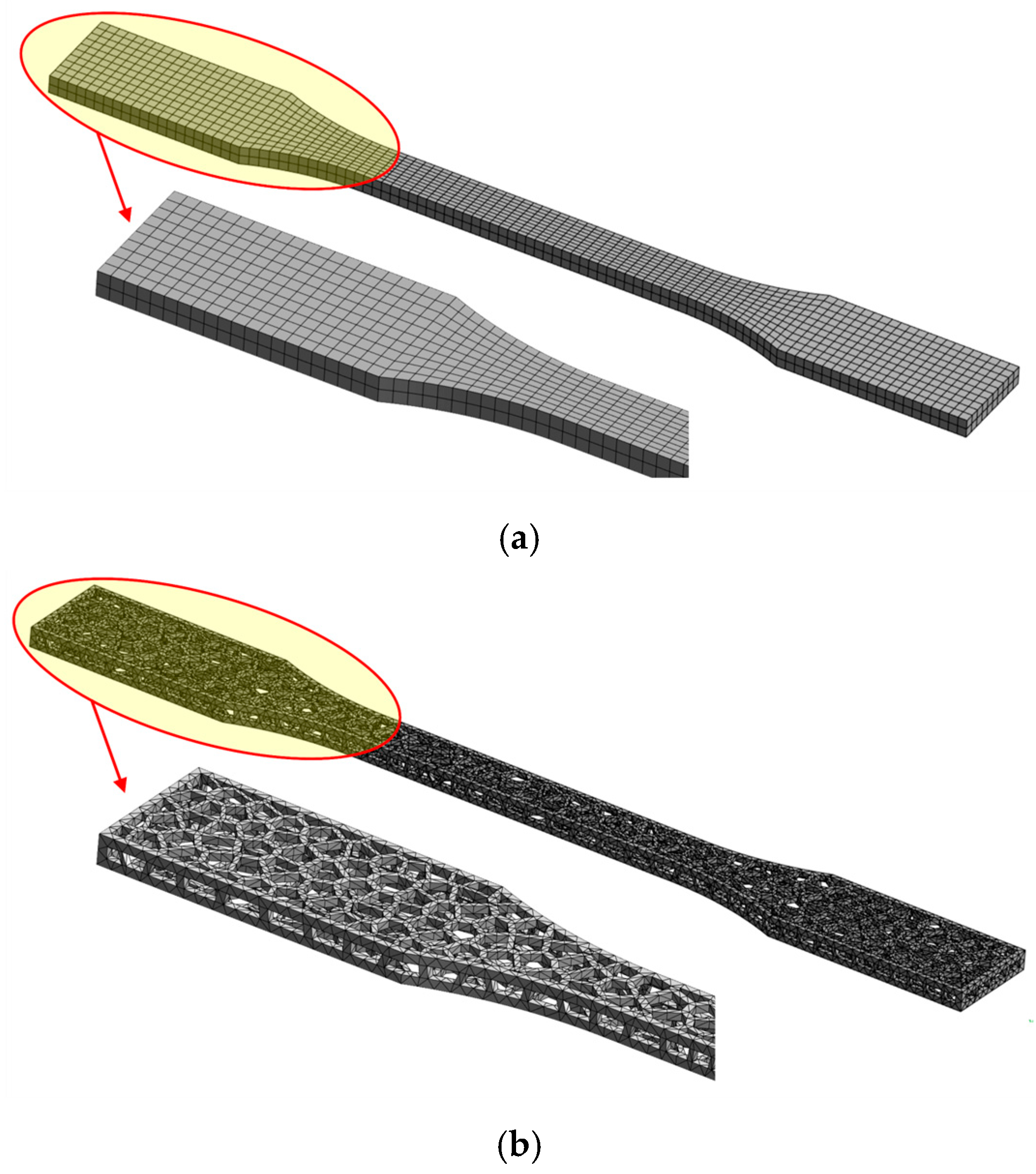

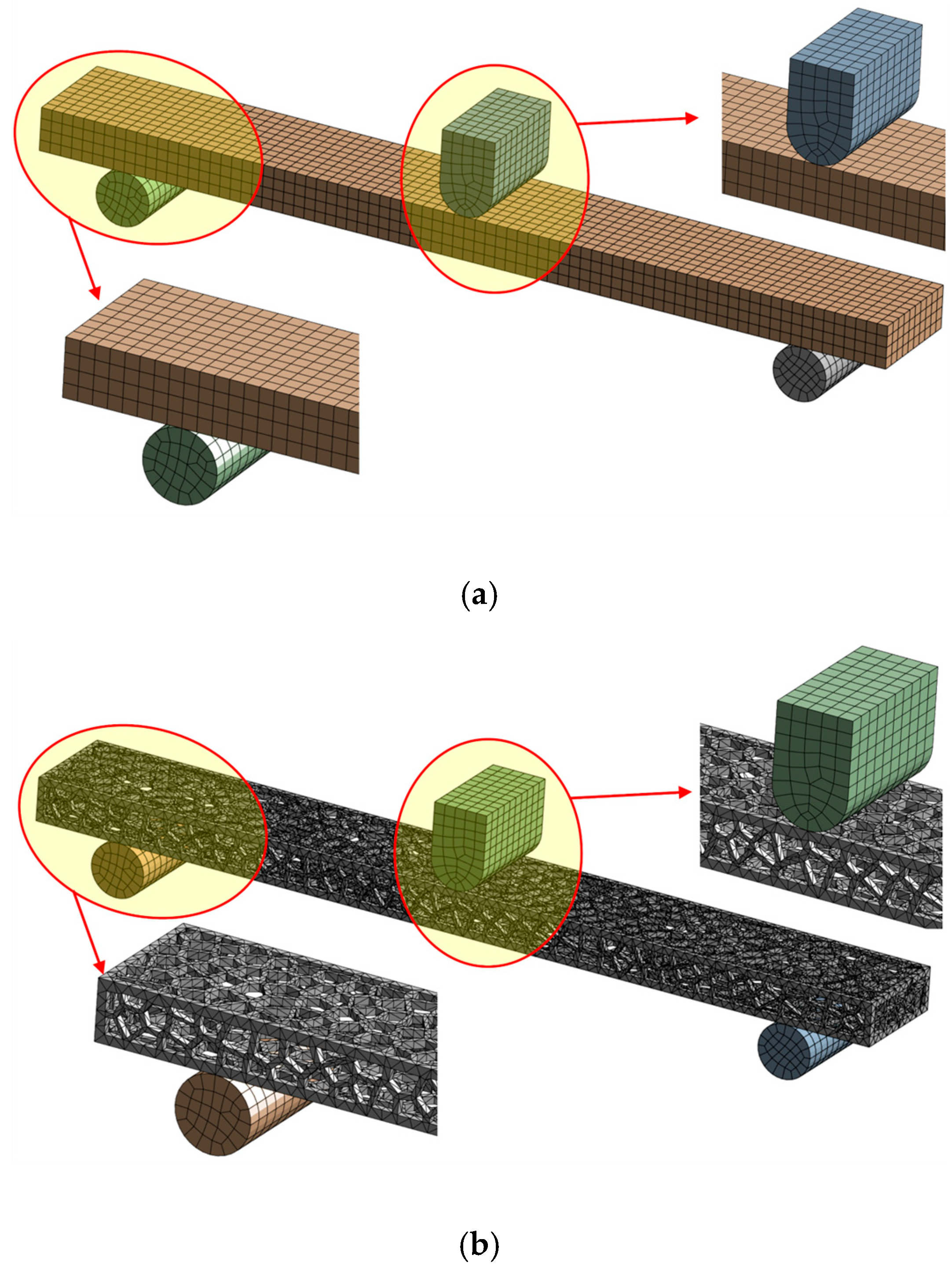

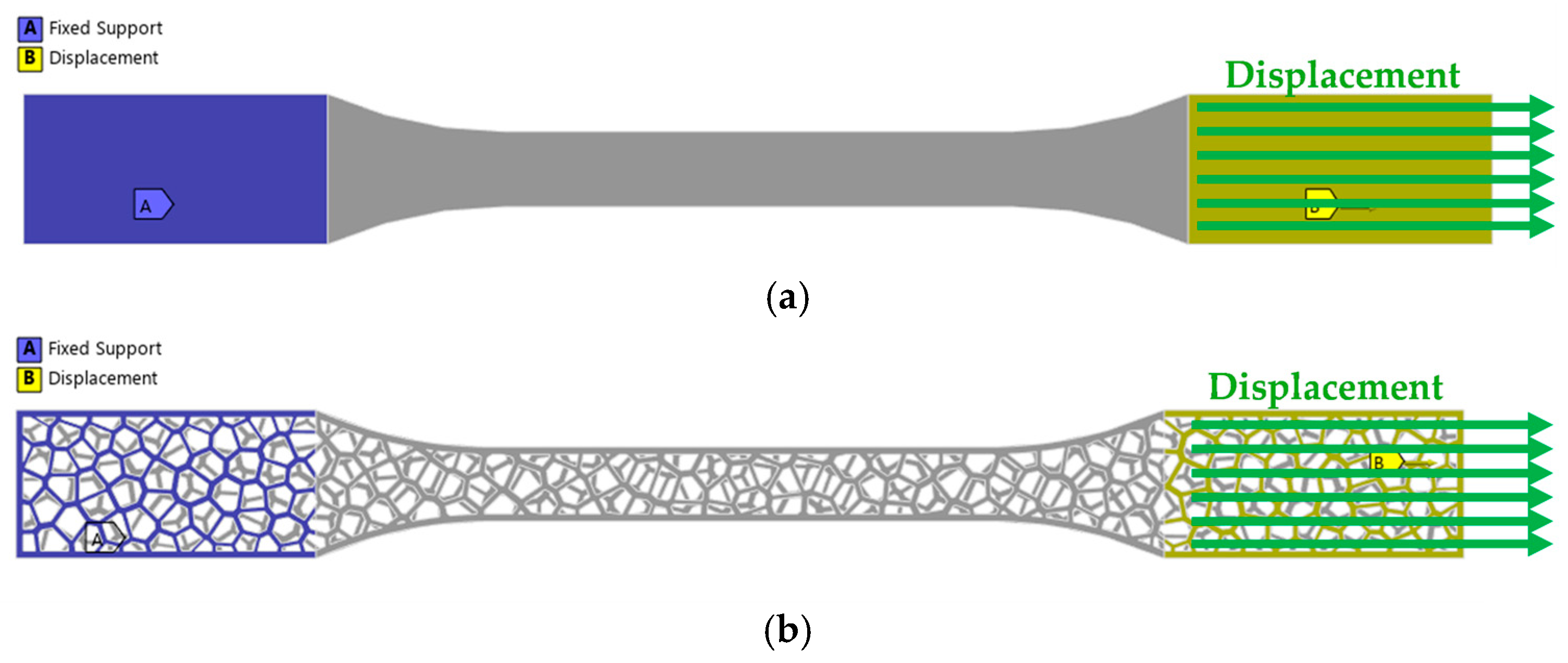

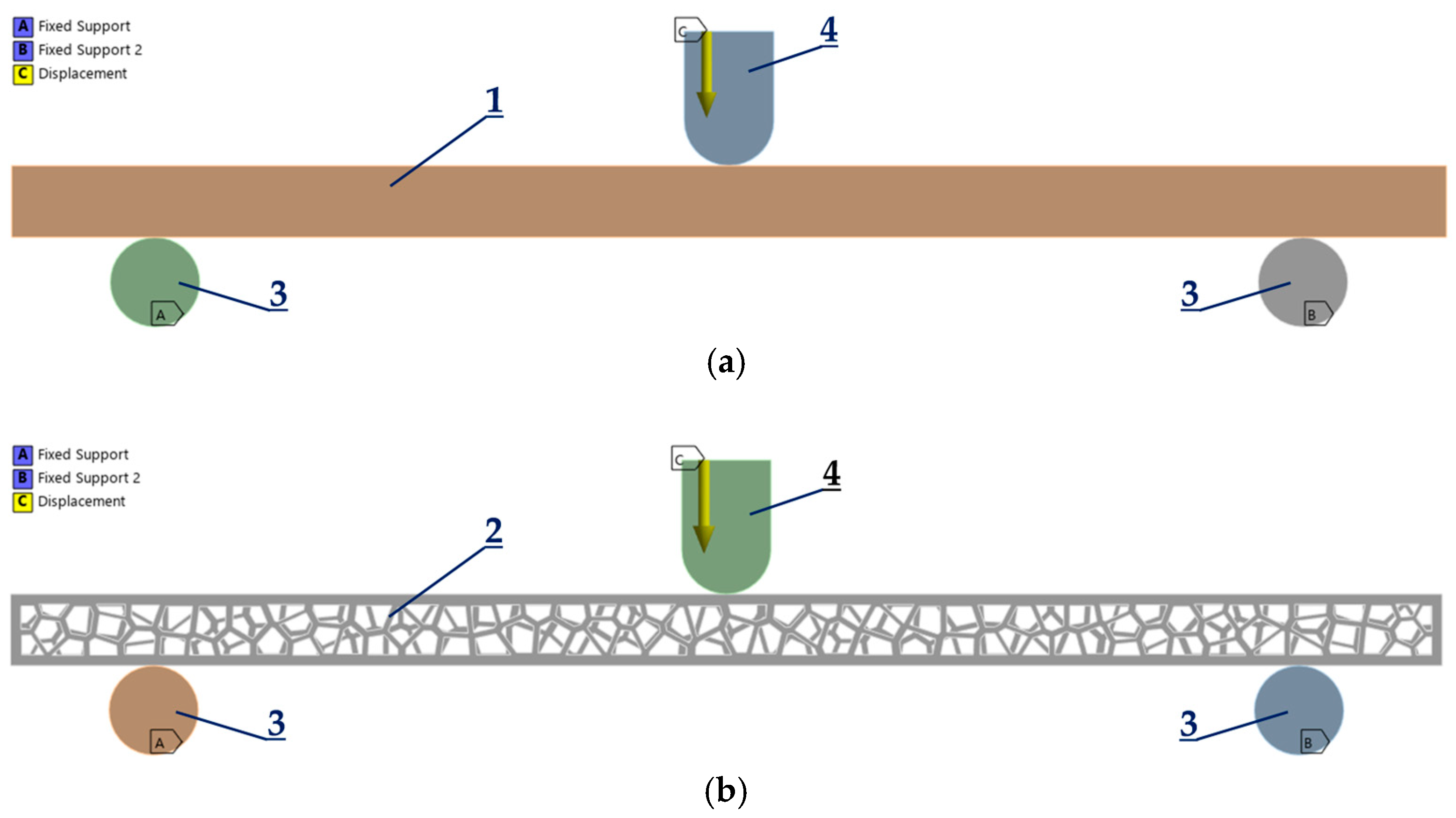

3.1. Finite Element Model (FEM)

3.2. Contact Algorithm and Boundary Conditions

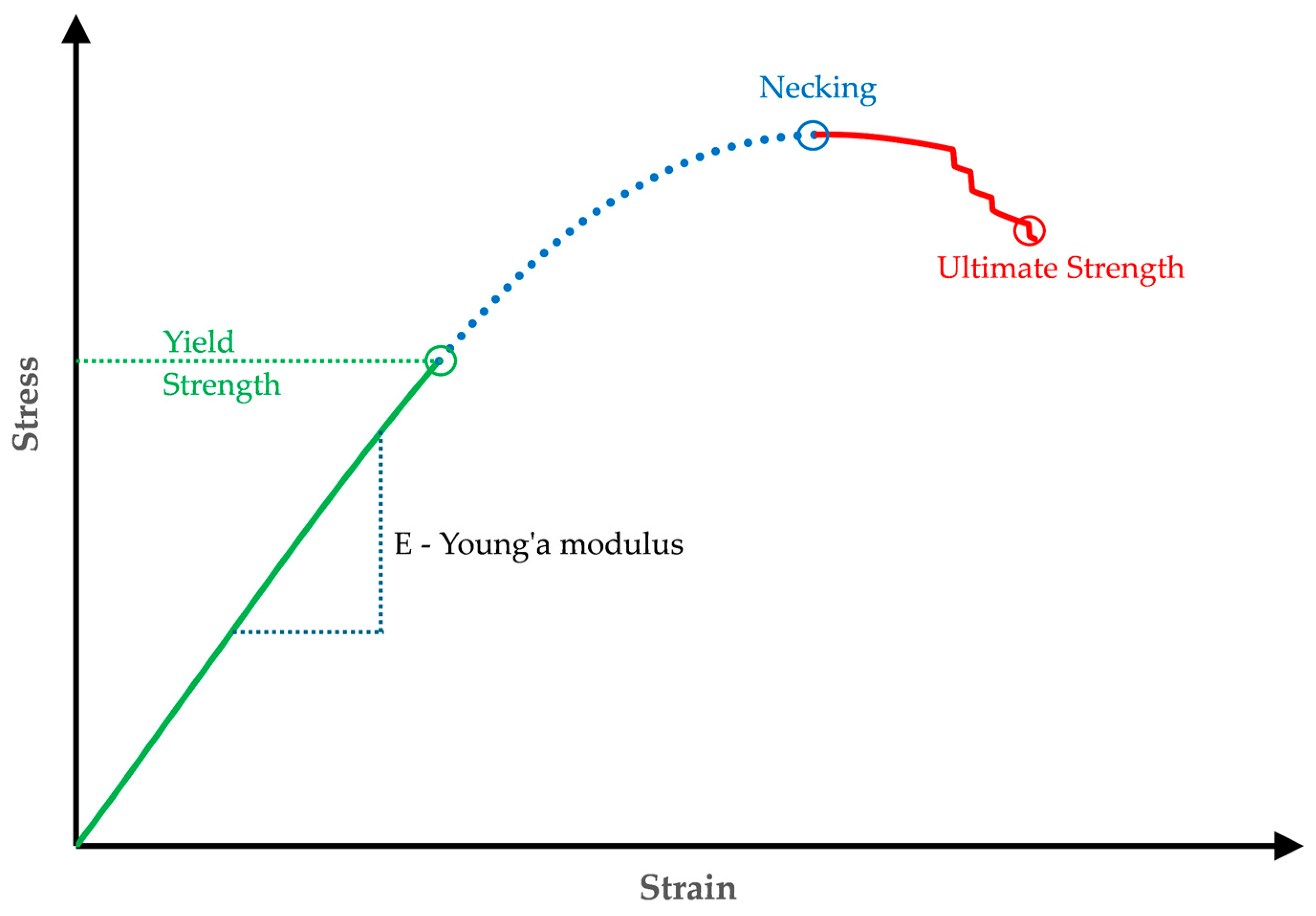

3.3. Material Model of PLA Specimens

4. Results and Discussions

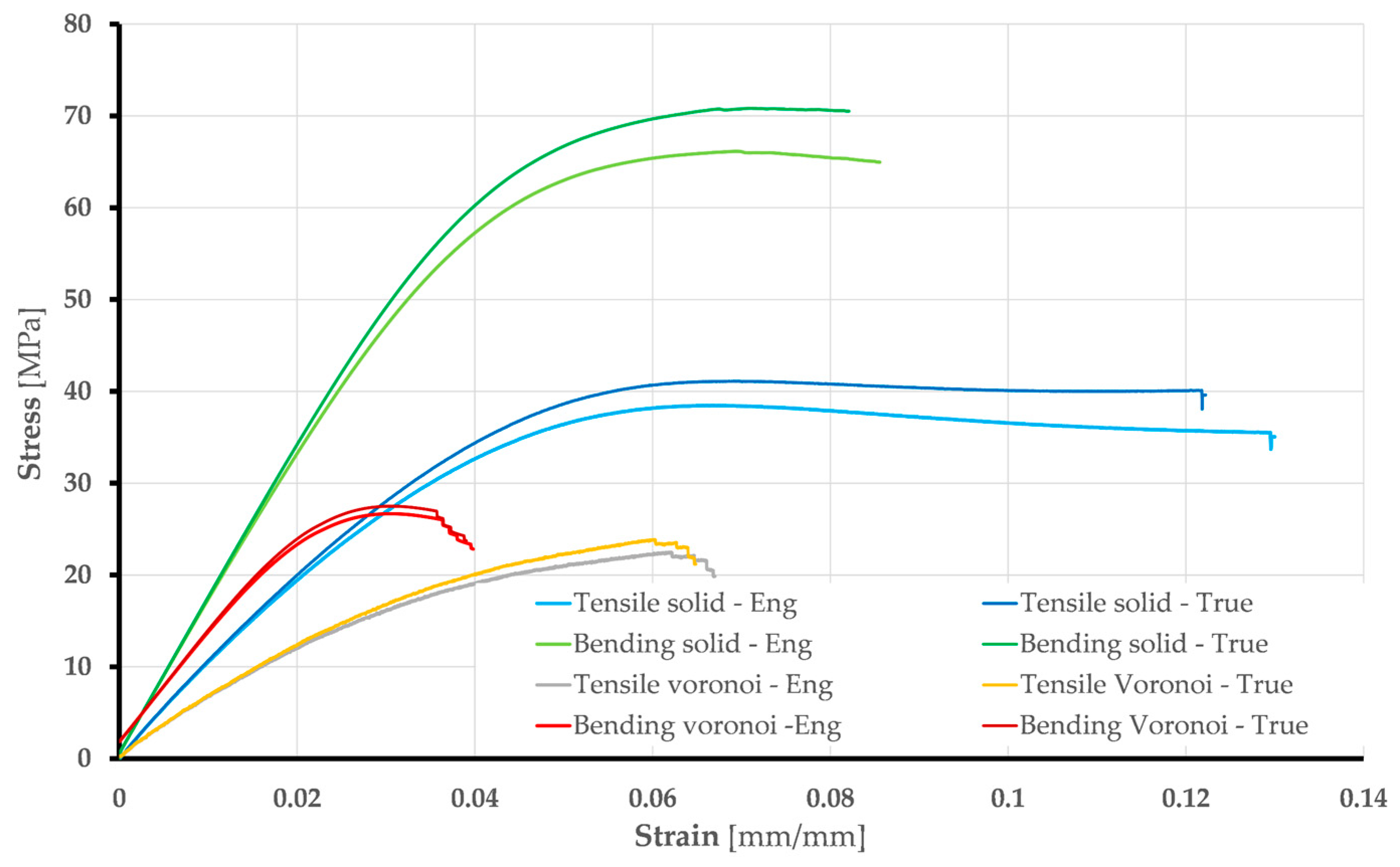

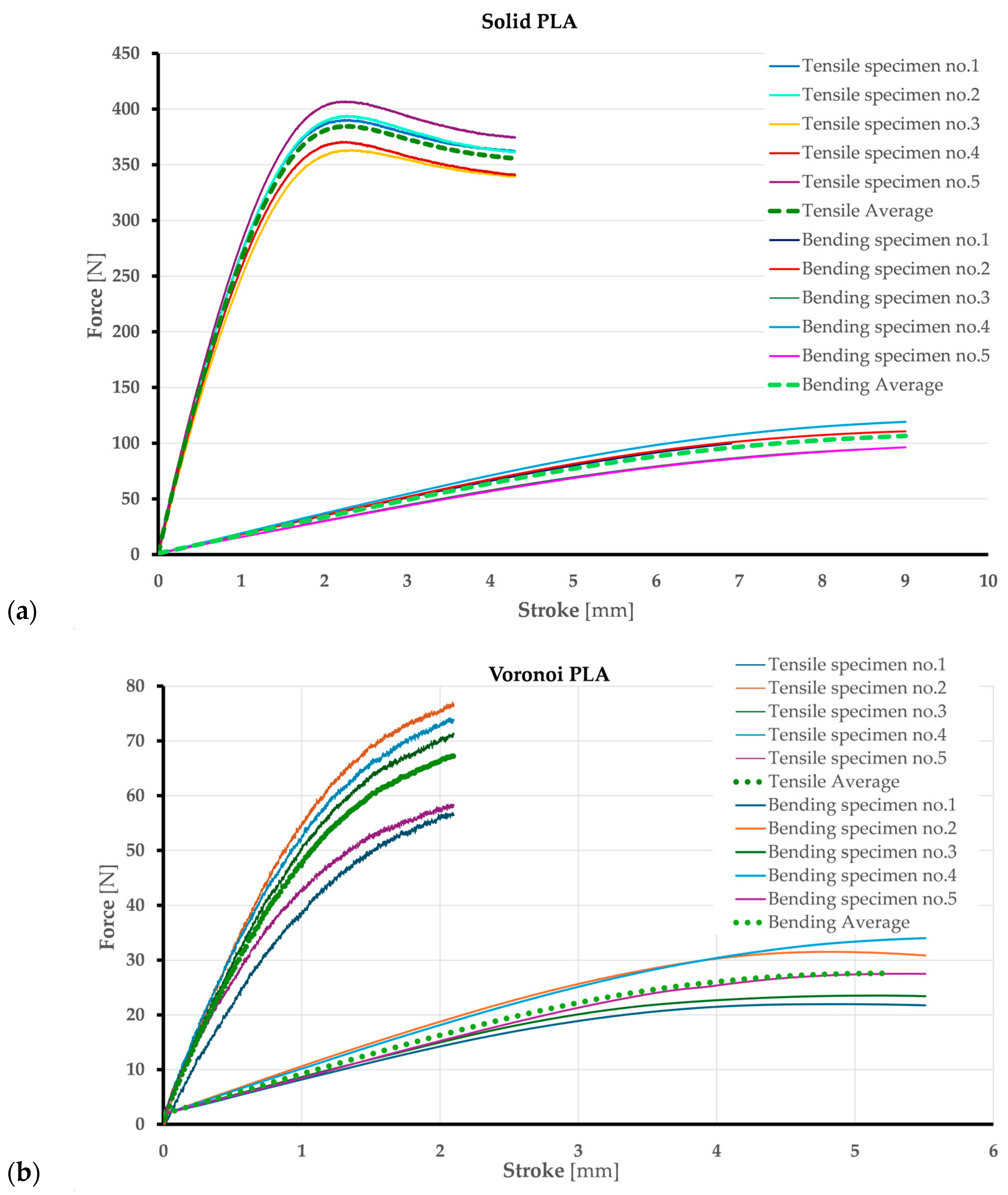

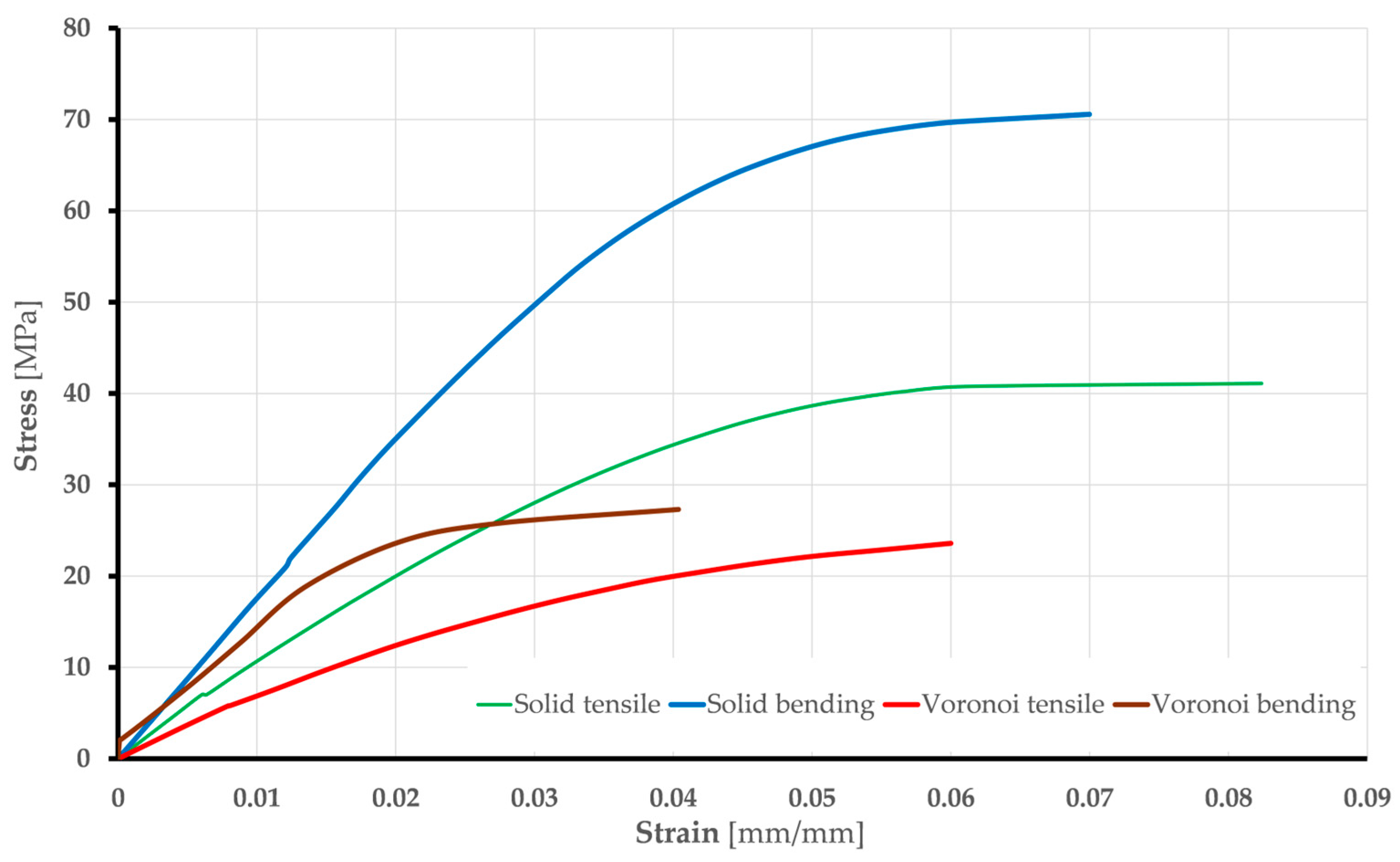

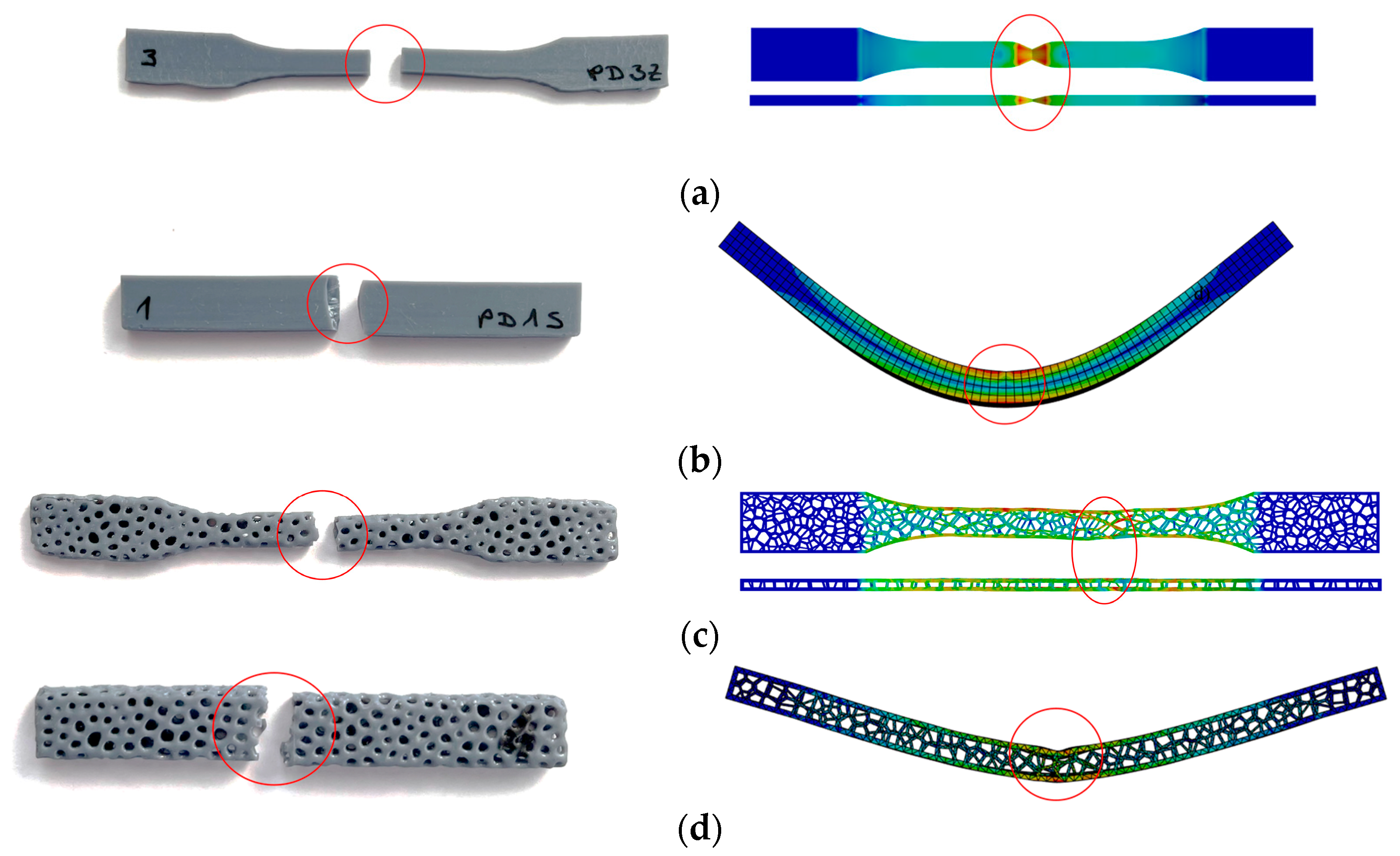

4.1. Experimental Results

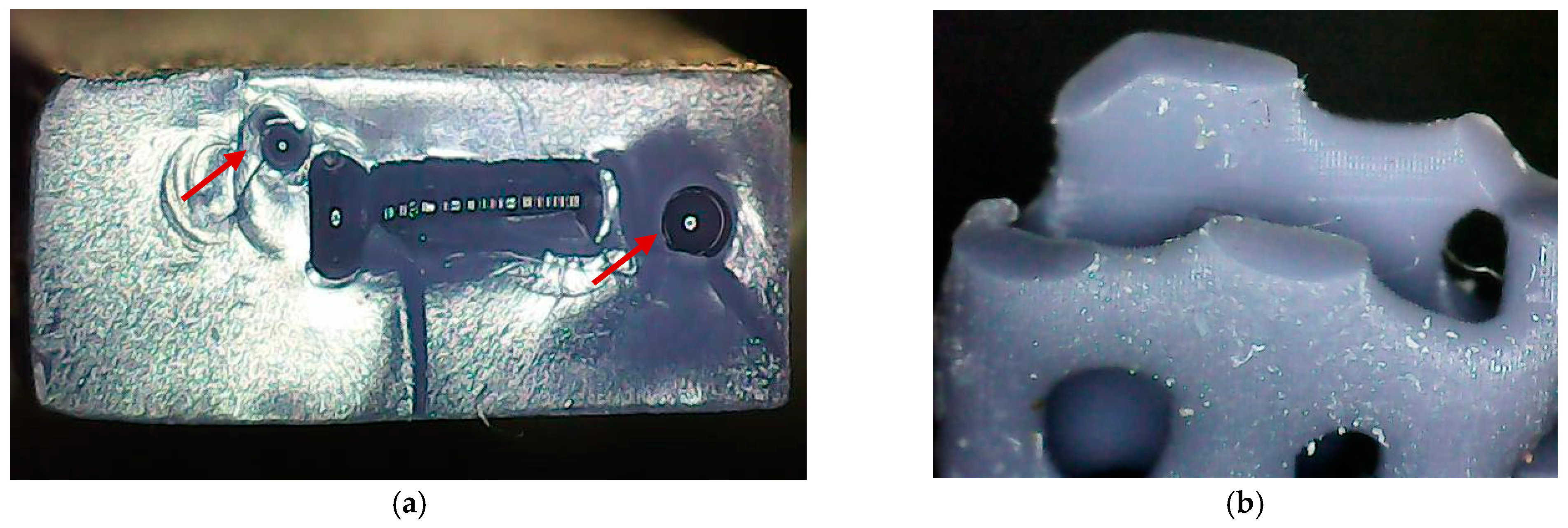

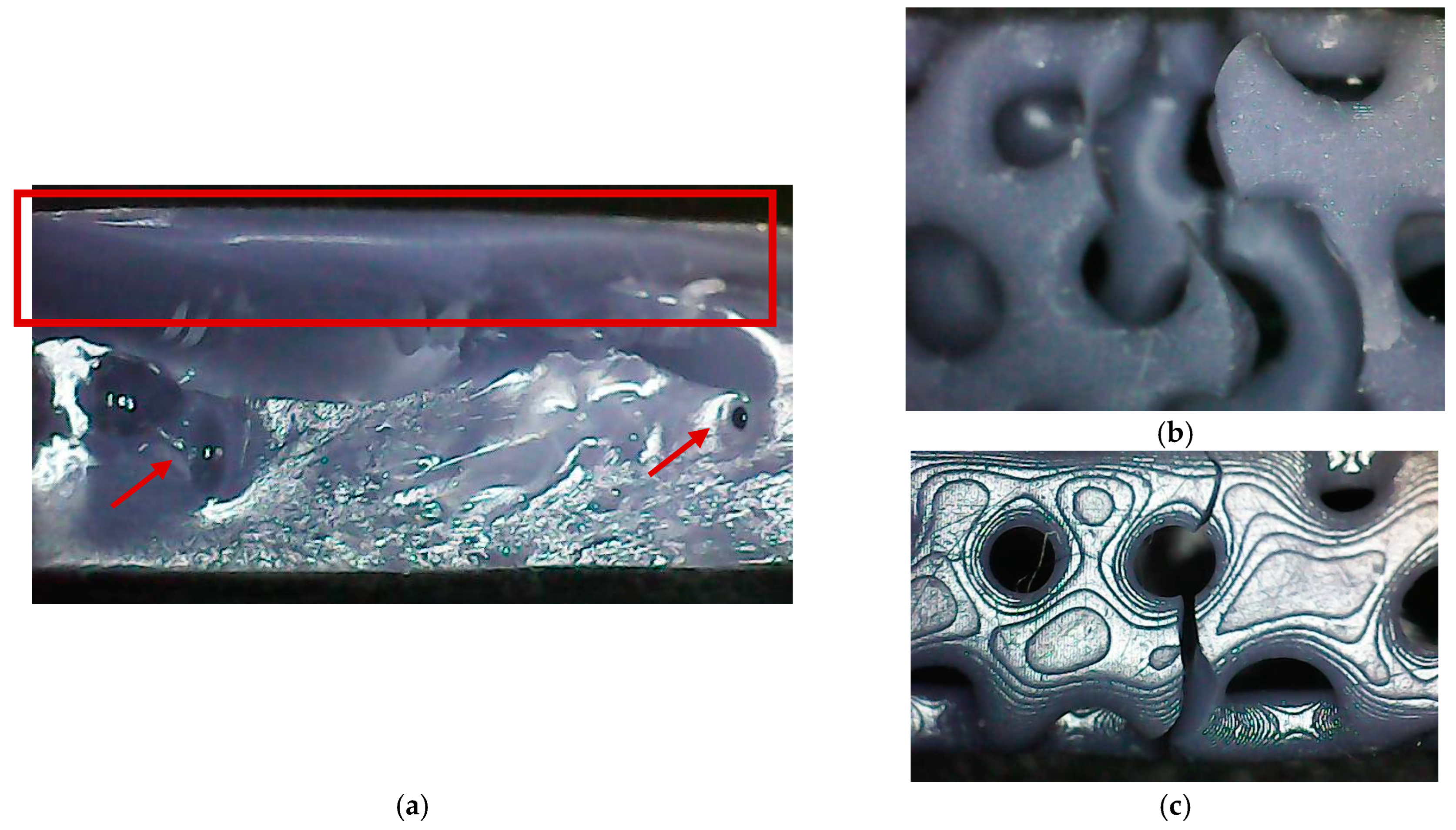

4.2. Micrographs

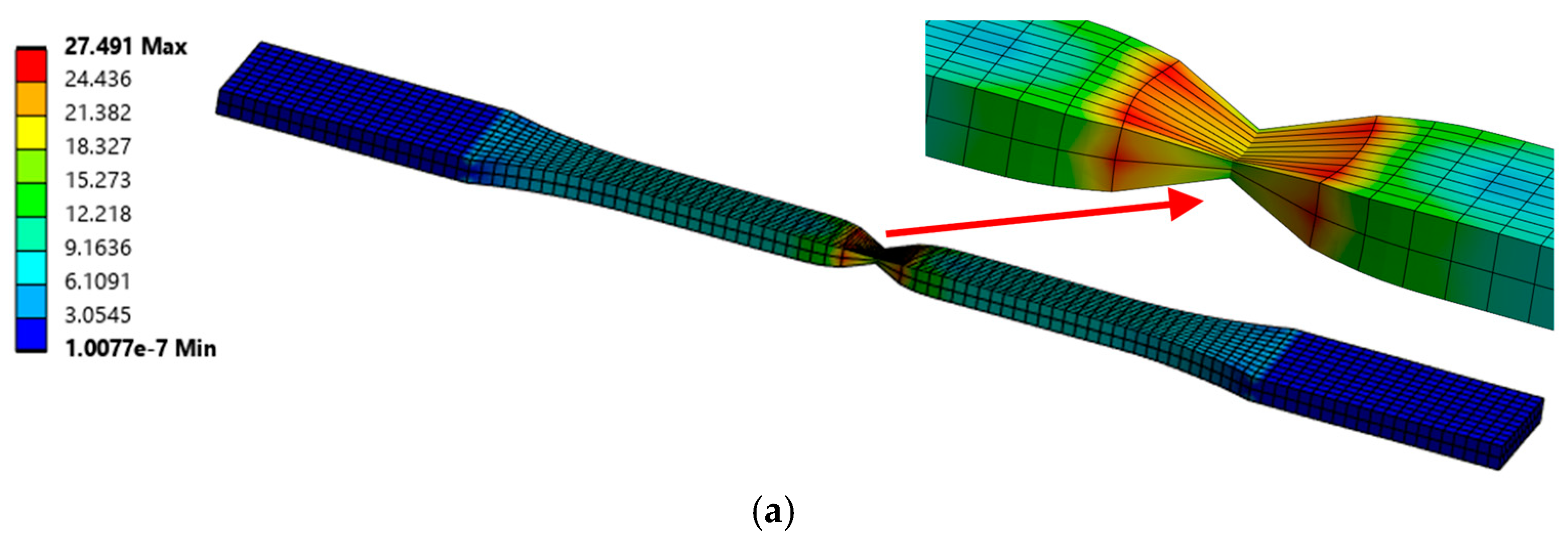

4.3. Numerical Results

Validation of Developed Numerical Models

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Dehghan, S.; Sattarpanah Karganroudi, S.; Echchakoui, S.; Barka, N. The Integration of Additive Manufacturing into Industry 4.0 and Industry 5.0: A Bibliometric Analysis (Trends, Opportunities, and Challenges). Machines 2025, 13, 62. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, R.A. Comprehensive Study on Additive Manufacturing Techniques, Machine Learning Integration, and Internet of Things-Driven Sustainability Opportunities. J. Mater. Eng. Perform. 2025, 34, 1234–1256. [Google Scholar] [CrossRef]

- Ponis, S.; Aretoulaki, E.; Maroutas, T.N.; Plakas, G.; Dimogiorgi, K. A Systematic Literature Review on Additive Manufacturing in the Context of Circular Economy. Sustainability 2021, 13, 6007. [Google Scholar] [CrossRef]

- Nath, S.D.; Nilufar, S. An Overview of Additive Manufacturing of Polymers and Associated Composites. Polymers 2020, 12, 2719. [Google Scholar] [CrossRef]

- Saleh Alghamdi, S.; John, S.; Roy Choudhury, N.; Dutta, N.K. Additive Manufacturing of Polymer Materials: Progress, Promise and Challenges. Polymers 2021, 13, 753. [Google Scholar] [CrossRef]

- Pagac, M.; Hajnys, J.; Ma, Q.P.; Jancar, L.; Jansa, J.; Stefek, P.; Mesicek, J. A Review of vat photopolymerization technology: Materials, applications, challenges, and future trends of 3D printing. Polymers 2021, 13, 598–618. [Google Scholar] [CrossRef]

- Lublin, D.; Hao, T.; Malyala, R.; Kisailus, D. Multiscale Mechanical Characterization of Biobased Photopolymers Towards Sustainable Vat Polymerization 3D Printing. RSC Adv. 2024, 14, 10422–10430. [Google Scholar] [CrossRef]

- Pan, Y.; Zhou, C.; Chen, Y. A Fast Mask Projection Stereolithography Process for Fabricating Digital Models in Minutes. ASME J. Manuf. Sci. Eng. 2012, 134, 051011. [Google Scholar] [CrossRef]

- Paral, S.K.; Jeng, J.Y.; Cheng, Y.L.; Lin, D.Z. Novel vat design for liquid crystal display vat photopolymerization: Reduction of separation force and pixelated effect. Virtual Phys. Prototyp. 2025, 20, e2470920. [Google Scholar] [CrossRef]

- Tumbleston, J.R.; Shirvanyants, D.; Ermoshkin, N.; Janusziewicz, R.; Johnson, A.R.; Kelly, D.; Chen, K.; Pinschmidt, R.; Rolland, J.P.; Ermoshkin, A.; et al. Continuous liquid interface production of 3D objects. Science 2015, 347, 1349–1352. [Google Scholar] [CrossRef]

- Wada, J.; Wada, K.; Gibreel, M.; Wakabayashi, N.; Iwamoto, T.; Vallittu, P.K.; Lassila, L. Effect of 3D Printer Type and Use of Protection Gas During Post-Curing on Some Physical Properties of Soft Occlusal Splint Material. Polymers 2022, 14, 4618. [Google Scholar] [CrossRef] [PubMed]

- Chaudhary, R.; Fabbri, P.; Leoni, E.; Mazzanti, F.; Akbari, R.; Antonini, C. Additive manufacturing by digital light processing: A review. Prog. Addit. Manuf. 2023, 8, 331–351. [Google Scholar] [CrossRef]

- Shao, S.; Zhou, Z. Design and Fabrication of lightweight structures using topology optimization techniques. Int. J. Mach. Tools Maint. Eng. 2024, 5, 28–31. [Google Scholar]

- Efstathiadis, A.; Symeonidou, I.; Tsongas, K.; Tzimtzimis, E.K.; Tzetzis, D. Parametric Design and Mechanical Characterization of 3D-Printed PLA Composite Biomimetic Voronoi Lattices Inspired by the Stereom of Sea Urchins. J. Compos. Sci. 2023, 7, 3. [Google Scholar] [CrossRef]

- Wang, X.; Xu, X.; Gu, Y. Dynamic response of Voronoi structures with gradient perpendicular to the impact direction. Rev. Adv. Mater. Sci. 2022, 61, 513–525. [Google Scholar] [CrossRef]

- Chen, L.; Pan, Y.; Chu, X.; Hui, H.; Wang, X. Multiscale design and experimental verification of Voronoi graded stochastic lattice structures for the natural frequency maximization problem. Acta Mech. Sin. 2023, 39, 422445. [Google Scholar] [CrossRef]

- Liu, R.; Chen, W.; Zhao, J. A Review on Factors Affecting the Mechanical Properties of Additively-Manufactured Lattice Structures. J. Mater. Eng. Perform. 2024, 33, 4685–4711. [Google Scholar] [CrossRef]

- Taib, N.-A.A.B.; Rahman, R.; Huda, D.; Kuok, K.K.; Hamdan, S.; Bin Bakri, M.K.; Bin Julaihi, M.R.M.; Khan, A. A review on poly lactic acid (PLA) as a biodegradable polymer. Polym. Bull. 2023, 80, 1179–1213. [Google Scholar] [CrossRef]

- Wu, Y.; Gao, X.; Wu, J.; Zhou, T.; Nguyen, T.T.; Wang, Y. Biodegradable Polylactic Acid and Its Composites: Characteristics, Processing, and Sustainable Applications in Sports. Polymers 2023, 15, 3096. [Google Scholar] [CrossRef]

- Guessasma, S.; Stephant, N.; Durand, S.; Belhabib, S. Digital Light Processing Route for 3D Printing of Acrylate-Modified PLA/Lignin Blends: Microstructure and Mechanical Performance. Polymers 2024, 16, 1342. [Google Scholar] [CrossRef]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [PubMed]

- Cahyono, S.I.; Sandi, A.; Salim, U.A.; Suyitno, S.; Arifvianto, B.; Saptoadi, H.; Mahardika, M. Flame Retardant Additives in Polylactic Acid (PLA) Photopolymer Resin for 3D Printing Digital Light Processing (DLP). Appl. Mech. Mater. 2024, 920, 49–59. [Google Scholar] [CrossRef]

- Golubović, Z.; Bojović, B.; Kirin, S.; Milovanović, A.; Petrov, L.; Anđelković, B.; Sofrenić, I. Effect of Aging on Tensile and Chemical Properties of Polylactic Acid and Polylactic Acid-Like Polymer Materials for Additive Manufacturing. Polymers 2024, 16, 1035. [Google Scholar] [CrossRef]

- Efstathiadis, A.; Symeonidou, I.; Tsongas, K.; Tzimtzimis, E.K.; Tzetzis, D. 3D Printed Voronoi Structures Inspired by Paracentrotus lividus Shells. Designs 2023, 7, 113. [Google Scholar] [CrossRef]

- Hanon, M.M.; Dobos, J.; Zsidai, L. The influence of 3D printing process parameters on the mechanical performance of PLA polymer and its correlation with hardness. Procedia Manuf. 2021, 54, 244–249. [Google Scholar] [CrossRef]

- Hsueh, M.-H.; Lai, C.-J.; Chung, C.-F.; Wang, S.-H.; Huang, W.-C.; Pan, C.-Y.; Zeng, Y.-S.; Hsieh, C.-H. Effect of Printing Parameters on the Tensile Properties of 3D-Printed Polylactic Acid (PLA) Based on Fused Deposition Modeling. Polymers 2021, 13, 2387. [Google Scholar] [CrossRef]

- Ali Khan, W.; Hassan, M.; Ahmed, I.; Xiao, M.; Faraz, M.I.; Li, K.; Khan, I.; Muhammad, R.; Wu, H.; Hussain, G. Insights into flexural and impact properties of polymer based materials printed through fused filament fabrication: Progress in the last decade. Int. J. Lightweight Mater. Manuf. 2024, 7, 925–957. [Google Scholar] [CrossRef]

- Yalçın, M.M. Flexural Behavior of 3D-Printed Carbon Fiber-Reinforced Nylon Lattice Beams. Polymers 2024, 16, 2991. [Google Scholar] [CrossRef]

- Anand Kumar, S.; Shivraj Narayan, Y. Tensile Testing and Evaluation of 3D-Printed PLA Specimens as per ASTM D638 Type IV Standard. In Innovative Design, Analysis and Development Practices in Aerospace and Automotive Engineering (I-DAD 2018). Lecture Notes in Mechanical Engineering; Chandrasekhar, U., Yang, L.J., Gowthaman, S., Eds.; Springer: Singapore, 2019; pp. 79–95. [Google Scholar] [CrossRef]

- Tavuz, K.A.; Al-Haj Husain, N.; Mätzener, K.J.; Ateş, M.M.; Eyüboğlu, T.F.; Özcan, M. Evaluation of flexural strength of additively manufactured resin materials compared to auto-polymerized provisional resin with and without hydrothermal aging. J. Mech. Behav. Biomed. Mater. 2025, 161, 106817. [Google Scholar] [CrossRef]

- Li, X.; McMains, S. A Voronoi diagram approach for detecting defects in 3D printed fiber-reinforced polymers from microscope images. Comp. Vis. Media 2023, 9, 41–56. [Google Scholar] [CrossRef]

- SolidWorks Premium 2024 SP05, University of Belgrade Faculty of Mechanical Engineering: Belgrade, Serbia, 2024.

- ISO 527-2; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. ISO: Geneva, Switzerland, 2012.

- ISO 178:2019; Plastics—Determination of Flexural Properties. ISO: Geneva, Switzerland, 2019.

- Hayes, B.S.; Gammon, L.M. Optical Microscopy of Fiber-Reinforced Composites 2010; ASM International: Almere, The Netherlands, 2010; ISBN 978-1-61503-044-6. [Google Scholar]

- Ansys® Academic Research Mechanical, Release 2025R01, License No. 670265.

- Bassani, R.; Levita, G.; Meozzi, M.; Palla, G. Friction and wear of epoxy resin on inox steel: Remarks on the influence of velocity, load and induced thermal state. Wear 2001, 247, 125–132. [Google Scholar] [CrossRef]

- Palaniandy, L.; Ismail, K.I.; Yap, T.C. Trbological Behaviour of 3D printed Polylactic Acid (PLA) Sliding Against Steel at Different Sliding Speed. J. Phys. Conf. Ser. 2023, 2542, 012003. [Google Scholar] [CrossRef]

- Fouly, A.; Assaifan, A.K.; Alnaser, I.A.; Hussein, O.A.; Abdo, H.S. Evaluating the Mechanical and Tribological Properties of 3D Printed Polylactic-Acid (PLA) Green-Composite for Artificial Implant: Hip Joint Case Study. Polymers 2022, 14, 5299. [Google Scholar] [CrossRef] [PubMed]

- Golubović, Z.; Danilov, I.; Bojović, B.; Petrov, L.; Sedmak, A.; Mišković, Ž.; Mitrović, N. A Comprehensive Mechanical Examination of ABS and ABS-like Polymers Additively Manufactured by Material Extrusion and Vat Photopolymerization Processes. Polymers 2023, 15, 4197. [Google Scholar] [CrossRef]

| Parameter | Value/Units |

|---|---|

| Layer height | 0.05 mm |

| Bottom layer count | 10 |

| Exposure time | 8 s |

| Bottom exposure time | 50 s |

| Bottom lift distance | 5 mm |

| Bottom lift speed | 65 s |

| Testing | mvoro (g) | msolid (g) | mratio (%) | Fmaxvoro (N) | Fmaxsolid (N) | Fratio (%) | strokemaxvoro (mm) | strokemaxsolid (mm) | strokeratio (%) |

|---|---|---|---|---|---|---|---|---|---|

| Tensile | 1.1 | 1.6 | 68.75 | 67.43 | 384.7 | 0.17 | 2.28 | 4.4 | 0.52 |

| Bending | 1.5 | 3.5 | 42.85 | 27.59 | 110.24 | 0.25 | 5.49 | 9.06 | 0.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Golubović, Z.; Tanasković, J.; Milovanović, A.; Bojović, B. Experimental and Numerical Research of 3D DLP-Printed Solid and Voronoi PLA Resin Specimens Under Tensile and Bending Loads. Polymers 2025, 17, 1180. https://doi.org/10.3390/polym17091180

Golubović Z, Tanasković J, Milovanović A, Bojović B. Experimental and Numerical Research of 3D DLP-Printed Solid and Voronoi PLA Resin Specimens Under Tensile and Bending Loads. Polymers. 2025; 17(9):1180. https://doi.org/10.3390/polym17091180

Chicago/Turabian StyleGolubović, Zorana, Jovan Tanasković, Aleksa Milovanović, and Božica Bojović. 2025. "Experimental and Numerical Research of 3D DLP-Printed Solid and Voronoi PLA Resin Specimens Under Tensile and Bending Loads" Polymers 17, no. 9: 1180. https://doi.org/10.3390/polym17091180

APA StyleGolubović, Z., Tanasković, J., Milovanović, A., & Bojović, B. (2025). Experimental and Numerical Research of 3D DLP-Printed Solid and Voronoi PLA Resin Specimens Under Tensile and Bending Loads. Polymers, 17(9), 1180. https://doi.org/10.3390/polym17091180