Impact of Cultivar, Harvest Date and Threshing Parameter Settings on Floret and Carthamidin Yield of Safflower

Abstract

:1. Introduction

2. Materials and Methods

2.1. Description of the Experimental Site and Design

2.2. Treatments

2.3. Data Collection

2.3.1. Harvesting and Post-Harvest Procedures

2.3.2. Laboratory Analyses for the Determination of Carthamidin Content

2.4. Statistical Analysis

3. Results and Discussion

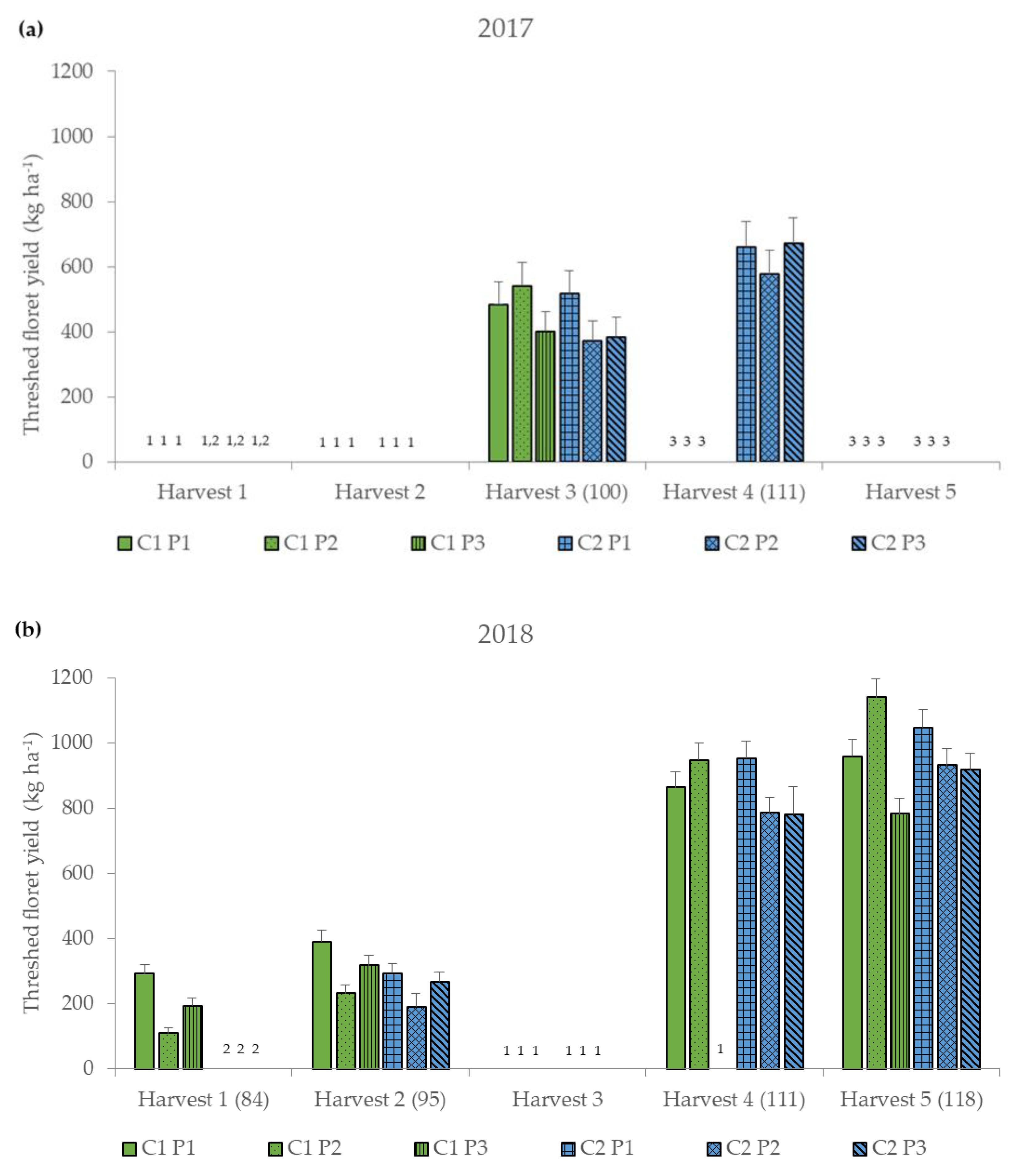

3.1. Threshed Floret Yield

3.2. Dry Matter Content

3.3. Carthamidin Content

3.4. Carthamidin Yield

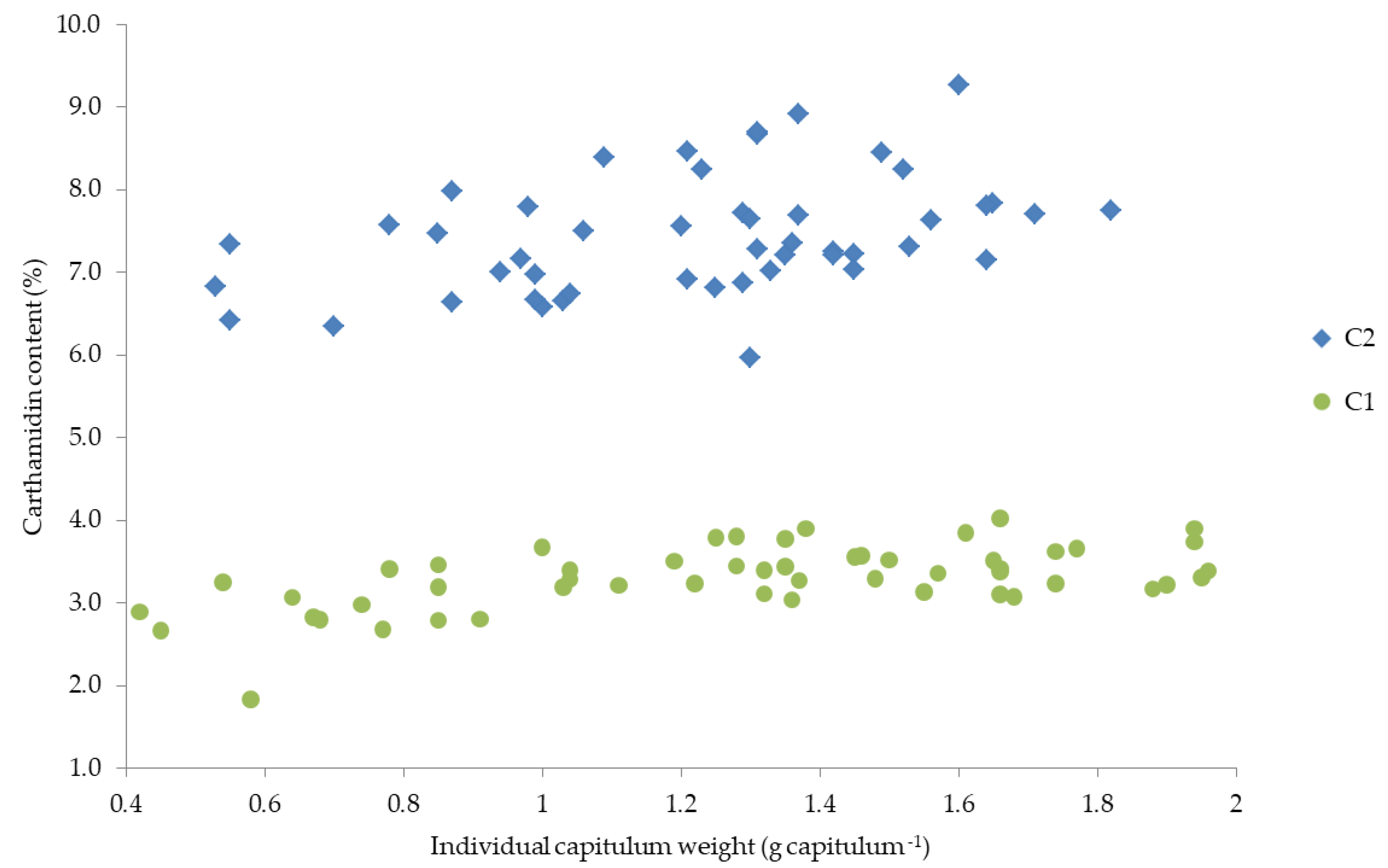

3.5. Relationship between Individual Head Weight and Carthamidin Content

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Parameter | Year | Harvest Date | Threshing Parameter Setting | Cultivar C1 | Cultivar C2 |

|---|---|---|---|---|---|

| Threshed floret yield(kg ha−1) | 2017 | 3 | 1 | 484.21 aAα ± 67.51 | 517.71 aAα ± 69.80 |

| 2 | 540.51 aAα ± 71.32 | 372.70 bAα ± 59.23 | |||

| 3 | 400.91 aAα ± 61.43 | 384.08 bAα ± 60.12 | |||

| 4 | 1 | n.d. | 660.91 aAα ± 78.87 | ||

| 2 | n.d. | 576.42 aAα ± 73.65 | |||

| 3 | n.d. | 671.82 aAα ± 79.51 | |||

| 2018 | 1 | 1 | 293.64 cAα ± 28.67 | n.d. | |

| 2 | 110.46 dCα ± 17.58 | n.d. | |||

| 3 | 194.61 cBα ± 23.34 | n.d. | |||

| 2 | 1 | 392.67 bAα ± 33.15 | 294.95 bAβ ± 28.73 | ||

| 2 | 233.66 cBα ± 25.57 | 192.05 cAα ± 40.89 | |||

| 3 | 319.66 bAα ± 29.91 | 269.67 bAα ± 27.47 | |||

| 4 | 1 | 864.74 aAα ± 49.20 | 954.45 aAα ± 51.69 | ||

| 2 | 949.77 bAα ± 51.56 | 788.98 bBβ ± 46.99 | |||

| 3 | n.d. | 783.15 aABα ± 82.58 | |||

| 5 | 1 | 961.24 aBα ± 51.87 | 1048.63 aAα ± 54.18 | ||

| 2 | 1141.76 aAα ± 56.53 | 933.83 aAβ ± 51.13 | |||

| 3 | 784.78 aCα ± 46.87 | 918.91 aAα ± 50.72 | |||

| Dry matter content (%) | 2017 | 3 | 1 | 28.47 aBα ± 0.70 | 28.47 bBα ± 0.70 |

| 2 | 31.23 aAα ± 0.70 | 31.20 bAα ± 0.70 | |||

| 3 | 32.50 aAα ± 0.70 | 30.73 bAα ± 0.70 | |||

| 4 | 1 | n.d. | 36.77 aBα ± 0.70 | ||

| 2 | n.d. | 40.13 aAα ± 0.70 | |||

| 3 | n.d. | 42.23 aAα ± 0.70 | |||

| 2018 | 1 | 1 | 34.22 cAα ± 0.90 | n.d. | |

| 2 | 33.39 cAα ± 0.90 | n.d. | |||

| 3 | 29.61 cBα ± 0.90 | n.d. | |||

| 2 | 1 | 33.12 cAα ± 0.89 | 27.82 cAβ ± 0.90 | ||

| 2 | 32.16 cAα ± 0.90 | 30.11 cAα ± 1.50 | |||

| 3 | 32.88 bAα ± 0.90 | 29.71 cAβ ± 0.91 | |||

| 4 | 1 | 51.84 bBα ± 0.90 | 52.09 bBα ± 0.91 | ||

| 2 | 58.48 bAα ± 0.89 | 55.42 bAβ ± 0.90 | |||

| 3 | 3 | 57.21 bAα ± 1.50 | |||

| 5 | 1 | 65.38 aCα ± 0.90 | 62.67 aCβ ± 0.91 | ||

| 2 | 70.86 aBα ± 0.90 | 68.31 aBα ± 0.91 | |||

| 3 | 77.77 aAα ± 0.91 | 72.53 aAβ ± 0.91 | |||

| Carthamidin content (%) | 2017 | 3 | 1 | 0.30 aBβ ± 0.03 | 0.48 aBα ± 0.04 |

| 2 | 0.23 aBβ ± 0.02 | 0.44 aBα ± 0.04 | |||

| 3 | 0.41 aAβ ± 0.04 | 0.96 aAα ± 0.09 | |||

| 4 | 1 | n.d. | 0.31 bAα ± 0.03 | ||

| 2 | n.d. | 0.27 bAα ± 0.02 | |||

| 3 | n.d. | 0.35 bAα ± 0.03 | |||

| 2018 | 1 | 1 | 0.87 aBα ± 0.05 | n.d. | |

| 2 | 0.80 aBα ± 0.05 | n.d. | |||

| 3 | 1.40 aAα ± 0.09 | n.d. | |||

| 2 | 1 | 0.53 bcBβ ± 0.03 | 2.42 aBα ± 0.15 | ||

| 2 | 0.54 bBβ ± 0.03 | 1.90 aCα ± 0.18 | |||

| 3 | 0.90 bAβ ± 0.05 | 3.14 aAα ± 0.19 | |||

| 4 | 1 | 0.59 bAβ ± 0.04 | 1.80 bBα ± 0.11 | ||

| 2 | 0.54 bAβ ± 0.03 | 1.74 abBα ± 0.11 | |||

| 3 | n.d. | 2.37 bAα ± 0.22 | |||

| 5 | 1 | 0.49 cBβ ± 0.03 | 1.33 cCα ± 0.08 | ||

| 2 | 0.43 cBβ ± 0.03 | 1.50 bBα ± 0.09 | |||

| 3 | 0.62 cAβ ± 0.04 | 2.05 bAα ± 0.13 | |||

| Carthamidin yield (kg ha−1) | 2017 | 3 | 1 | 1.45 aAβ ± 0.20 | 2.43 aABα ± 0.34 |

| 2 | 1.26 aAα ± 0.18 | 1.64 aBα ± 0.23 | |||

| 3 | 1.62 aAβ ± 0.23 | 3.68 aAα ± 0.52 | |||

| 4 | 1 | n.d. | 2.05 aAα ± 0.28 | ||

| 2 | n.d. | 1.55 aAα ± 0.22 | |||

| 3 | n.d. | 2.27 bAα ± 0.32 | |||

| 2018 | 1 | 1 | 2.65 bAα ± 0.28 | n.d. | |

| 2 | 0.91 cBα ± 0.10 | n.d. | |||

| 3 | 2.62 bAα ± 0.27 | n.d. | |||

| 2 | 1 | 2.16 bAβ ± 0.23 | 7.01 bAα ± 0.74 | ||

| 2 | 1.32 bBβ ± 0.14 | 3.49 bBα ± 0.65 | |||

| 3 | 2.75 bAβ ± 0.29 | 8.44 bAα ± 0.88 | |||

| 4 | 1 | 5.01 aAβ ± 0.53 | 17.55 aAα ± 1.84 | ||

| 2 | 4.80 aAβ ± 0.50 | 13.54 aAα ± 1.42 | |||

| 3 | n.d. | 19.05 aAα ± 3.53 | |||

| 5 | 1 | 4.65 aAβ ± 0.49 | 14.30 aBα ± 1.50 | ||

| 2 | 5.03 aAβ ± 0.53 | 13.83 aBα ± 1.45 | |||

| 3 | 4.74 aAβ ± 0.50 | 19.36 aAα ± 2.03 |

References

- Emongor, V. Safflower (Carthamus tinctorius L.) the underutilized and neglected crop: A review. Asian J. Plant Sci. 2010, 9, 299–306. [Google Scholar] [CrossRef] [Green Version]

- Dajue, L.; Mündel, H.H. Safflower Carthamus Tinctorius L.; IPGRI, IPK, Eds.; IPGRI: Rome, Italy, 1996; ISBN 9290432977. [Google Scholar]

- Weiss, E.A. Oilseed Crops, 2nd ed.; Blackwell Science: Oxford, UK, 2000; ISBN 0632052597. [Google Scholar]

- Mokhtassi-Bidgoli, A.; Akbari, G.A.; Mirhadi, M.J.; Pazoki, A.R.; Soufizadeh, S. Yield components, leaf pigment contents, patterns of seed filling, dry matter, LAI and LAID of some safflower (Carthamus tinctorius L.) genotypes in Iran. Pak. J. Biol. Sci. 2007, 10, 1406–1413. [Google Scholar] [CrossRef] [PubMed]

- Emongor, V.; Oagile, O. Safflower Production; Impression House Publication: Gaborone, Botswana, 2017; ISBN 978-99968-0-607-0. [Google Scholar]

- Corleto, A.; Alba, E.; Polignano, G.B.; Vonghio, G. Safflower: A multipurpose species with unexploited potential and world adaptability. The research in Italy. In Safflower: A Multipurpose Species with Unexploited Potential and World Adaptability, Proceedings of the Fourth International Safflower Conference, Bari, Italy, 2–7 June, 1997; Corleto, A., Mündel, H.-H., Eds.; Adruatica Editrice: Bari, Italy, 1997; pp. 23–31. [Google Scholar]

- Ekin, Z. Resurgence of safflower (Carthamus tinctorius L.) utilization: A global view. J. Agron. 2005, 4, 83–87. [Google Scholar]

- Velasco, L.; Fernández-Martínez, J.M. Progress in breeding for modified tocopherol content and composition in safflower. In Sesame and Safflower Newsletter; Institute of Sustainable Agriculture, Ed.; Institute of Sustainable Agriculture: Cordoba, Spain, 2002; pp. 98–102. [Google Scholar]

- Weiss, E.A. Castor, Sesame and Safflower; Hill: London, UK, 1971; ISBN 0249440210. [Google Scholar]

- Garfield, S. Mauve. How One Man Invented a Color that Changed the World; W.W. Norton & Company: New York, NY, USA, 2002; ISBN 9780393323139. [Google Scholar]

- Arnold, L.E.; Lofthouse, N.; Hurt, E. Artificial food colors and attention-deficit/hyperactivity symptoms: Conclusions to dye for. Neurotherapeutics 2012, 9, 599–609. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bateman, B.; Warner, J.O.; Hutchinson, E.; Dean, T.; Rowlandson, P.; Gant, C.; Grundy, J.; Fitzgerald, C.; Stevenson, J. The effects of a double blind, placebo controlled, artificial food colourings and benzoate preservative challenge on hyperactivity in a general population sample of preschool children. Arch. Dis. Child. 2004, 89, 506–511. [Google Scholar] [CrossRef] [Green Version]

- Křížová, H. Natural dyes: Their past, present, future and sustainability. Recent Dev. Fibrous Mater. Sci. 2015, 12, 59–71. [Google Scholar]

- Kumar, J.K.; Sinha, A.K. Resurgence of natural colourants: A holistic view. Nat. Prod. Res. 2004, 18, 59–84. [Google Scholar] [CrossRef]

- Yusuf, M.; Shabbir, M.; Mohammad, F. Natural colorants: Historical, processing and sustainable prospects. Nat. Prod. Bioprospect. 2017, 7, 123–145. [Google Scholar] [CrossRef] [Green Version]

- Grand View Research, Inc. Natural Food Colors Market Estimates & Trend Analysis by Product (Curcumin, Carotenoids, Anthocyanin, Carmine, Chlorophyllin), by Application (Bakery & Confectionery, Beverages, Dairy & Frozen Products, Meat Products), and Segment Forecasts, 2018–2025. Available online: https://www.grandviewresearch.com/industry-analysis/natural-food-colors-market (accessed on 6 May 2020).

- Future Market Insights. Natural Food Colours Market: Significant Demand for Clean Label and Naturally Sourced Ingredients in Food Products Spurring Revenue Growth: Global Industry Analysis (2013–2017) & Opportunity Assessment (2018–2028). Available online: https://www.futuremarketinsights.com/reports/global-natural-food-colours-market (accessed on 6 May 2020).

- European Comission. Guidance Notes on the Classification if Food Extracts with Colouring Properties. Available online: https://ec.europa.eu/food/safety/food_improvement_agents/additives/eu_rules_en (accessed on 6 May 2020).

- Bratinova, S. Provision of Scientific and Technical Support with Respect to the Classification of Extracts/Concentrates with Colouring Properties either as Food Colours (Food Additives Falling under Regulation (EC) No 1333/2008) or Colouring Foods; Publications Office of the European Union: Luxembourg, 2015; ISBN 978-92-79-50607-9. [Google Scholar]

- GNT International B.V. Europäische Union Verabschiedet Guidance Notes zur Klassifizierung Färbender Lebensmittel, 2013. Available online: https://www.food-monitor.de/2013/12/europaeische-union-verabschiedet-giudance-notes-zur-klassifizierung-faerbender-lebensmittel/ (accessed on 8 May 2020).

- Rudolf Wild GmbH & Co. KG. EU-Leitlinien: Die Übergangsfrist für färbende Lebensmittel Endet, 2015. Available online: https://www.lvt-web.de/topstories/fooddesign-hygiene-und-ueberwachung/eu-leitlinien-die-uebergangsfrist-fuer-faerbende-lebe (accessed on 8 May 2020).

- Dajue, L. Progress research and production in China. In Proceedings of the Third International Safflower Conference, Beijing, China, 14–18 June 1993; Dajue, L., Yuanzhou, H., Eds.; Beijing Botanical Garden, Institute of Botany, Chinese Academy of Sciences: Beijing, China, 1993; pp. 35–46. [Google Scholar]

- Shin, Y.-S.; Yoo, D.-I. Storage stability and color reproducibility of yellow and red dyes extracted from Carthamus tinctorius L. Text. Coloration Finish. 2012, 24, 165–172. [Google Scholar] [CrossRef]

- Yoon, J.-M.; Cho, M.-H.; Park, J.-E.; Kim, Y.-H.; Hahn, T.-R.; Paik, Y.-S. Thermal stability of the pigments hydroxysafflor yellow A, safflor yellow B, and precarthamin from safflower (Carthamus tinctorius). J. Food Sci. 2003, 68, 839–843. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. FAOSTAT-Crop statistics: Safflower. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 7 May 2020).

- Gao, W.Y.; Fan, L.; Paek, K.Y. Yellow and red pigment production by cell cultures of Carthamus tinctorius in a bioreactor. Plant Cell Tissue Organ Cult. 2000, 60, 95–100. [Google Scholar] [CrossRef]

- Singh, V.; Nimbkar, N. Safflower (Carthamus tinctorius L.), Chapter 6. In Genetic Resources, Chromosome Engineering, and Crop Improvement; Singh, R.J., Ed.; CRC Press: Boca Raton, FL, USA, 2007; pp. 167–194. ISBN 9780849336393. [Google Scholar]

- Nagaraj, G. Oilseeds. Properties, Processing, Products and Procedures; New India Public Agency: Pitam Pura, New Delhi, India, 2009; ISBN 9788190723756. [Google Scholar]

- Fatahi, N.; Carapetian, J.; Heidari, R. Spectrophotometric measurement of valuable pigments from petals of safflower (Carthamus tinctorius L.) and their identification by TLC method. Res. J. Biol. Sci. 2008, 3, 761–763. [Google Scholar]

- Srinivas, C.V.S.; Praveena, B.; Nagaraj, G. Safflower petals: A source of gamma linolenic acid. Plant Foods Hum. Nutr. 1999, 54, 89–92. [Google Scholar] [CrossRef] [PubMed]

- Singh, V.; Kolekar, N.M.; Nimbkar, N. Breeding strategy for improvement of flowers and seed yields in safflower. In Safflower: Unexploited Potential and World Adaptability, Proceedings of the Seventh International Safflower Conference, Wagga Wagga, New South Wales, Australia, 3–6 November 2008; Knights, S.E., Potter, T.D., Eds.; Agri-MC Marketing and Communication: Bendigo, Australia, 2008; ISBN 978-0-646-50329-5. [Google Scholar]

- Yu, H.; Xu, L.X. Separation and determination of flavonols in the flowers of Carthamus tinctorius by RP-HPLC. Acta Pharm. Sin. 1997, 32, 120–122. [Google Scholar]

- Elfadl, E.; Reinbrecht, C.; Claupein, W. Evaluation of phenotypic variation in a worldwide germplasm collection of safflower (Carthamus tinctorius L.) grown under organic farming conditions in Germany. Genet. Resour. Crop. Evol. 2010, 57, 155–170. [Google Scholar] [CrossRef]

- Elfadl, E.; Reinbrecht, C.; Claupein, W. Safflower (Carthamus tinctorius L.) as a new oil crop in organic farming system: Potential and stability in central Europe. Int. J. AgriScience 2012, 2, 477–495. [Google Scholar]

- Elfadl, E.Y.; Reinbrecht, C.; Frick, C.; von Witzke, S.; Rudolphi, S.; Claupein, W.; Esendal, E.; Bergman, J.W.; Kandemir, N.; Johnson, R.C.; et al. Genotype by environment interaction in safflower (Carthamus tinctorius L.) grown under organic farming system in Central Europe. In Safflower: A Unique Crop for Oil Spices and Health Consequently, a Better Life for You, Proceedings of the Sixth International Safflower Conference, Istanbul, Turkey, 6–10 June 2005; Esendal, E., Bergman, J.W., Eds.; Engin Maatbacılık Ltd. Şti: Istanbul, Turkey, 2005; pp. 39–43. [Google Scholar]

- Frick, C.; Hebeisen, T.; Reinbrecht, C. Safflower Oil Production in Switzerland, 2005. Available online: https://www.agrarforschungschweiz.ch/en/2005/04/safflower-oil-production-in-switzerland/ (accessed on 8 May 2020).

- Reinbrecht, C.; Barth, S.; von Witzke-Ehbrecht, S.; Frick, C.; Elfadl, E.; Kahnt, G.; Becker, H.C.; Claupein, W.; Esendal, E.; Bergman, J.W.; et al. Screening of a worldwide safflower collection for adaptation to humid temperate climates and cultivation in organic farming. In Safflower: A Unique Crop for Oil Spices and Health Consequently, a Better Life for You, Proceedings of the Sixth International Safflower Conference, Istanbul, Turkey, 6–10 June 2005; Esendal, E., Bergman, J.W., Eds.; Engin Maatbacılık Ltd. Şti: Istanbul, Turkey, 2005; pp. 236–242. [Google Scholar]

- Steberl, K.; Hartung, J.; Munz, S.; Graeff-Hönninger, S. Effect of Row Spacing, Sowing Density, and Harvest Time on Floret Yield and Yield Components of Two Safflower Cultivars Grown in Southwestern Germany. Agronomy 2020, 10, 664. [Google Scholar] [CrossRef]

- Mohammadi, M.; Tavakoli, A. Effect of harvest time of spring safflower (Carthamus tinctorius L.) florets on the production of red and yellow pigments. Qual. Assur. Saf. Crop. Foods 2015, 7, 581–588. [Google Scholar] [CrossRef]

- Kizil, S.; Çakmak, Ö.; Kirici, S.; İnan, M. A Comprehensive Study on Safflower (Carthamus tinctorius L.) in Semi-Arid Conditions. Biotechnol. Biotechnol. Equip. 2008, 22, 947–953. [Google Scholar] [CrossRef]

- Azari, A.; Khajehpour, M.R. Effect of planting pattern on development, growth, yield components and seed and petal yields of safflower in summer planting, local variety of Isfahan, Koseh. Person. J. Sci. Technol. Agric. Nat. Resour. 2005, 9, 131–142. [Google Scholar]

- Hamza, M. Influence of different plant densities on crop yield of six safflower genotypes under Egyptian newly reclaimed soils conditions. Int. J. Agric. Crop. Sci. 2015, 8, 168–173. [Google Scholar]

- Jianguo, Y. Carthamin Yellow, As, Pb and Hg contents in different safflower cultivars. In Proceedings of the Second International Safflower Conference, Hyderabad, India, 9–13 January 1989; Ranga Rao, V., Ramachandram, M., Eds.; Indian Society of Oilseeds Research: Hyderabad, India, 1989; pp. 367–371. [Google Scholar]

- Azimi, S.; Chegini, G.; Kianmehr, M.H. Design and manufacture of safflower petal harvester machine. Mech. Ind. 2012, 13, 301–305. [Google Scholar] [CrossRef]

- Yun, G.; Lixin, Z.; Ying, Q.; Xiaopan, J.; Yuanbo, C. Dynamic model for sucking process of pneumatic cutting-type safflower harvest device. Int. J. Agric. Biol. Eng. 2016, 9, 43–50. [Google Scholar] [CrossRef]

- McGuire, P.E.; Damania, A.B.; Qualset, C.O. Safflower in California. The Paulden F. Knowles personal history of plant exploration and research on evolution, genetics, and breeding. In Agronomy Progress Report No. 313; University of California: Davis, CA, USA; pp. 1–44.

- Kailashkumar, E.B. Study of Different Kinds of Threshers & Factors Influencing threshing of Crops: A Revies. Int. J. Sci. Res. Dev. 2019, 6, 65–73. [Google Scholar]

- Naveen Kumar, D.B.; Kumar, P.; Arun Kumar, H.S.; Sandeep, T.N.; Sudjadevi, G. Efficiency of mechanical thresher over traditional method of threshing finger millet. Int. J. Agric. Eng. 2013, 6, 184–188. [Google Scholar]

- Zimmer, S.; Müller, J. Literatursammlung und -auswertung zur Erntetechnologie von Arznei- und Gewürzpflanzen: Schlussbericht zum Vorhaben. Laufzeit, 1 December 2002. [Google Scholar] [CrossRef]

- Flemmer, A.C.; Franchini, M.C.; Lindström, L.I. Description of safflower (Carthamus tinctorius) phenological growth stages according to the extended BBCH scale. Ann. Appl. Biol. 2015, 166, 331–339. [Google Scholar] [CrossRef]

- Mündel, H.H.; Blackshaw, R.E.; Byers, J.R.; Huang, H.C.; Johnson, D.L.; Keon, R.; Kubik, J.; McKenzie, R.; Otto, B.; Roth, B.; et al. Safflower Production on the Canadian Prairies: Revisited in 2004; Graphcom Printers Ltd.: Lethbridge, AB, Canada, 2004; ISBN 0662382099. [Google Scholar]

- Anderson, R.L. Broadleaf weed control in safflower (Carthamus tinctorius) with sulfonylurea herbicides. Weed Technol. 1987, 1, 242–246. [Google Scholar] [CrossRef]

- Blackshaw, R.E.; Mündel, H.-H.; Derksen, D.A. Herbicides for weed control in safflower (Carthamus tinctorius). Can. J. Plant Sci. 1990, 70, 237–245. [Google Scholar] [CrossRef]

- Gbabo, A.; Gana, I.M.; Amoto, M.S. Design, fabrication and testing of a millet thresher. Net J. Agric. Sci. 2013, 1, 100–106. [Google Scholar]

- Goel, A.K.; Behera, D.; Swain, S.; Behera, B.K. Performance of a low-cost manual sunflower thresher. Indian J. Agric. Res. 2009, 43, 37–41. [Google Scholar]

- Adekanye, T.A.; Osakpamwan, A.B.; Osaivbie, I.E. Evaluation of a soybean threshing machine for small scale farmers. Agric. Eng. Int. CIGR e-J. 2016, 18, 426–434. [Google Scholar]

- Röhricht, C.; Karte, T.; Schubert, M. Blütendrogen. In Analyse der ökologischen Produktionsverfahren von Heil- und Gewürzpflanzen in Deutschland; Geschäftsstelle Bundesprogramm Ökologischer Landbau in der Bundesanstalt für Landwirtschaft und Ernährung, Ed.; Sächsische Landesanstalt für Landwirtschaft: Leipzig, Germany, 2003; pp. 126–130. [Google Scholar]

- Food and Agriculture Organization of the United Nations. Carthamus yellow. In Compendium of Food Additive Specifications, Addendum 6, 52, Add. 6; Food and Nutrition Paper; FAO: Rome, Italy, 1998. [Google Scholar]

- Piepho, H.P.; Buchse, A.; Emrich, K. A Hitchhiker’s Guide to Mixed Models for Randomized Experiments. J. Agron. Crop. Sci. 2003, 189, 310–322. [Google Scholar] [CrossRef]

- Piepho, H.-P. A SAS macro for generating letter displays of pairwise mean comparisons. Commun. Biometry Crop Sci. 2012, 7, 4–13. [Google Scholar]

- Knowles, P.F. Safflower—Production, processing and utilization. Econ. Bot. 1955, 9, 273–299. [Google Scholar] [CrossRef]

- Omidi, A.H.; Sharifmogadas, M.R. Evaluation of Iranian safflower cultivars reaction to different sowing dates and plant densities. World Appl. Sci. J. 2010, 8, 953–958. [Google Scholar]

- Knowles, P.F. The plant geneticist’ contribution toward changing lipid and amino acid composition of safflower. J. Am. Oil Chem. Soc. 1972, 49, 27–29. [Google Scholar] [CrossRef]

- Armah-Agyeman, G.; Loiland, J.; Karow, R.; Hang, A.N. Safflower. In Dryland Cropping Systems, EM 8792; Oregon State University, Extension Service: Corvallis, OR, USA, 2002; pp. 1–7. [Google Scholar]

- Koutroubas, S.D.; Papakosta, D.K.; Doitsinis, A. Phenotypic variation in physiological determinants of yield in spring sown safflower under Mediterranean conditions. Field Crop. Res. 2009, 112, 199–204. [Google Scholar] [CrossRef]

- Veselinov, B.; Adamovic, D.; Martinov, M.; Viskovic, M.; Golub, M.; Bojic, S. Mechanized harvesting and primary processing of Calendula officinalis L. inflorescences. Span. J. Agric. Res. 2014, 12, 329. [Google Scholar] [CrossRef] [Green Version]

- Munusamy, P.; Ravi, P.; Ramasamy, K.; Kennedy, J. Effect of feed rate, concave clearance and peripheral speed on the performance evaluation of pre thresher for onion umbels (Allium cepa var Aggregatum L.). Agric. Eng. 2015, 3, 13–22. [Google Scholar]

- Hecht, H.; Mohr, T.; Lembrecht, S. Mechanizing the harvest of flower medicinal plants. Landtechnik 1992, 47, 276–280. [Google Scholar]

- Corleto, A.; Cazzato, E.; Laudadio, V.; Petrera, F. Evolution of Biomass and Quality of Safflower During the Reproductive Stage for Hay and Ensiling Purposes. In Safflower: A Unique Crop for Oil Spices and Health Consequently, a Better Life for You, Proceedings of the Sixth International Safflower Conference, Istanbul, Turkey, 6–10 June 2005; Esendal, E., Bergman, J.W., Eds.; Engin Maatbacılık Ltd. Şti: Istanbul, Turkey, 2005; pp. 69–73. [Google Scholar]

- Peiretti, P.G. Nutritional aspects and potential uses of safflower (Carthamus tinctorius L.) in livestock. In Agricultural Research Updates. Volume 19; Gorawala, P., Mandhatri, S., Eds.; Nova Science Publishers, Inc.: Hauuppauge, NY, USA, 2017; pp. 3–22. ISBN 9781536110128. [Google Scholar]

- Peiretti, P.G. Effects of growth stage on chemical composition, organic matter digestibility, gross energy and fatty acid content of safflower (Carthamus tinctorius L.). Livest. Res. Rural Dev. 2009, 21, 206. [Google Scholar]

- Cazzato, E.; Laudadio, V.; Corleto, A.; Tufarelli, V. Effects of harvest date, wilting and inoculation on yield and forage quality of ensiling safflower (Carthamus tinctorius L.) biomass. J. Sci. Food Agric. 2011, 91, 2298–2302. [Google Scholar] [CrossRef] [PubMed]

- Hatfield, J.L.; Prueger, J.H. Temperature extremes: Effect on plant growth and development. Weather Clim. Extrem. 2015, 10, 4–10. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Wang, E.; Luo, Q.; Kirby, M. Modelling the sensitivity of wheat growth and water balance to climate change in Southeast Australia. Clim. Chang. 2009, 96, 79–96. [Google Scholar] [CrossRef]

- Tabrizi, A.H.O. Floret removal effects on grain and oil yield and their components in spring safflower. In Sesame and Safflower Newsletter; Instituto de Agricultura Sostenible: Cordoba, Spain, 2002; pp. 71–75. [Google Scholar]

- Omidi, A.H.; Sharifmoghaddasi, M. Study of safflower varieties for flower and grain yields and fatty acids composition. Adv. Environ. Biol. 2010, 4, 524–527. [Google Scholar]

- Ghorbani, E.; Keleshteri, R.H.; Shahbazi, M.; Moradi, F.; Sadri, M. Optimization of extraction yield of carthamine and safflower yellow pigments from safflower (Carthamus tinctorious L.) under different treatments and solvent systems. Res. J. Pharmacogn. 2015, 2, 17–23. [Google Scholar]

- Cho, M.H.; Paik, Y.S.; Hahn, T.R. Enzymatic conversion of precarthamin to carthamin by a purified enzyme from the yellow petals of safflower. J. Agric. Food Chem. 2000, 48, 3917–3921. [Google Scholar] [CrossRef]

- Saito, K. A new enzymatic method for the extraction of preearthamine from dyer’s saffron florets. Z. Lebensmitel Unters. Forsch. 1993, 197, 34–36. [Google Scholar] [CrossRef]

- Ehlert, D.; Beier, K. Development of picking devices for chamomile harvesters. J. Appl. Res. Med. Aromat. Plants 2014, 1, 73–80. [Google Scholar] [CrossRef]

- Oni, K.C.; Ali, M.A. Factors influencing threshability of maize in Nigeria. Agric. Mech. Asia Afr. Lat. Am. 1986, 17, 39–44. [Google Scholar]

- Lupton, F.G.H. Wheat Breeding; Springer: Dordrecht, The Netherlands, 1987; ISBN 9789400931312. [Google Scholar]

- Sharma, J.S.; Running, K.L.D.; Xu, S.S.; Zhang, Q.; Peters Haugrud, A.R.; Sharma, S.; McClean, P.E.; Faris, J.D. Genetic analysis of threshability and other spike traits in the evolution of cultivated emmer to fully domesticated durum wheat. Mol. Genet. Genom. 2019, 294, 757–771. [Google Scholar] [CrossRef] [PubMed]

- Mozaffari, K.; Asadi, A.A. Relationships Among Traits Using Correlation, Principal Components and Path Analysis in Safflower Mutants Sown in Irrigated and Drought Stress Condition. Asian J. Plant Sci. 2006, 5, 977–983. [Google Scholar]

- Ramachandram, M.; Ranga Rao, V. Some Considerations For Restructing Traditional Plant Type In Safflower. In Proceedings of the Second International Safflower Conference, Hyderabad, India, 9–13 January 1989; Ranga Rao, V., Ramachandram, M., Eds.; Indian Society of Oilseeds Research: Hyderabad, India, 1989; pp. 133–144. [Google Scholar]

- Beier, K.; Ehlert, D. Methods for evaluation of picking performance of chamomile (Matricaria recutita L.) harvesters. Part II: Development of new methods. J. Appl. Res. Med. Aromat. Plants 2014, 1, 35–42. [Google Scholar] [CrossRef]

- Arslan, B. Assessing of heritability and variance components of yield and some agronomic traits in different safflower (Carthamus tinctorius L.) cultivars. Asian J. Plant Sci. 2007, 6, 554–557. [Google Scholar]

- Camaş, N.; Esendal, E. Estimates of broad-sense heritability for seed yield and yield components of safflower (Carthamus tinctorius L.). Hereditas 2006, 143, 55–57. [Google Scholar] [CrossRef]

- Knowles, P.F. Centers of plant diversity and conservation of crop germ plasm: Safflower. Econ. Bot. 1969, 23, 324–329. [Google Scholar] [CrossRef]

- Salem, N.; Msaada, K.; Hamdaoui, G.; Limam, F.; Marzouk, B. Variation in phenolic composition and antioxidant activity during flower development of safflower (Carthamus tinctorius L.). J. Agric. Food Chem. 2011, 59, 4455–4463. [Google Scholar] [CrossRef]

- Vvedenskaya, I.O.; Vorsa, N. Flavonoid composition over fruit development and maturation in American cranberry, Vaccinium macrocarpon Ait. Plant Sci. 2004, 167, 1043–1054. [Google Scholar] [CrossRef]

- Vandercook, C.E.; Tisserat, B. Flavonoid changes in developing lemons grown in vivo and in vitro. Phytochemistry 1989, 28, 799–803. [Google Scholar] [CrossRef]

- Worland, A.J.; Gale, M.D.; Law, C.N. Wheat genetics. In Wheat Breeding: Its Scientific Basis; Lupton, F., Ed.; Springer: Dordrecht, The Netherlands, 2014; ISBN 9789400931312. [Google Scholar]

| Characteristics | P1 | P2 | P3 |

|---|---|---|---|

| Top sieve (lamella sieve) | 15 mm opened | 9 mm opened | 15 mm opened |

| Bottom sieve (round hole sieve) | 16 mm | 10 mm | 16 mm |

| Wind | 400 min−1 | 400 min−1 | 500 min−1 |

| Threshing drum | 1200 min−1 | 1200 min−1 | 700 min−1 |

| Concave setting | Step 1 | Step 1 | Step 3 |

| Rub bars | - | - | 3 |

| Year | Sowing Date | Harvest Time | Date of Harvest (DAS) |

|---|---|---|---|

| 2017 | 25 April 2017 | 3 (69/67) | 03.08 (100) |

| 4 (71/69) | 14.08 (111) | ||

| 2018 | 20 April 2018 | 1 (61/59) | 13.07 (84) |

| 2 (67/65) | 24.07 (95) | ||

| 4 (71/69) | 09.08 (111) | ||

| 5 (75/71) | 16.08 (118) |

| ANOVA Table of the Highest Significant Terms and Interactions | ||

|---|---|---|

| Model Term | Degrees of Freedom | p-Value 1 |

| Year | 1 | 0.0015 |

| Cultivar * Threshing parameter setting | 2 | 0.0284 |

| Harvest date * Threshing parameter setting | 8 | <0.0001 |

| Year | Treatment | Harvest Date | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| 100 DAS | 111 DAS | |||||

| 2017 | C1 P1 | 1 | 1 | 28.47 ± 0.70 | 3 | 3 |

| C1 P2 | 1 | 1 | 31.23 ± 0.70 | 3 | 3 | |

| C1 P3 | 1 | 1 | 32.50 ± 0.70 | 3 | 3 | |

| C2 P1 | 1,2 | 1 | 28.47 ± 0.70 | 36.77 ± 0.70 | 3 | |

| C2 P2 | 1,2 | 1 | 31.20 ± 0.70 | 40.13 ± 0.70 | 3 | |

| C2 P3 | 1,2 | 1 | 30.73 ± 0.70 | 42.23 ± 0.70 | 3 | |

| 84 DAS | 95 DAS | 111 DAS | 118 DAS | |||

| 2018 | C1 P1 | 34.22 ± 0.90 | 33.12 ± 0.89 | 1 | 51.84 ± 0.90 | 65.38 ± 0.90 |

| C1 P2 | 33.39 ± 0.90 | 32.16 ± 0.90 | 1 | 58.48 ± 0.89 | 70.86 ± 0.90 | |

| C1 P3 | 29.61 ± 0.90 | 32.88 ± 0.90 | 1 | 1 | 77.77 ± 0.91 | |

| C2 P1 | 2 | 27.82 ± 0.90 | 1 | 52.09 ± 0.91 | 62.67 ± 0.91 | |

| C2 P2 | 2 | 30.11 ± 1.50 | 1 | 55.42 ± 0.90 | 68.31 ± 0.91 | |

| C2 P3 | 2 | 29.71 ± 0.91 | 1 | 57.21 ± 1.50 | 72.53 ± 0.91 | |

| ANOVA table of the significant terms and interactions. | ||||||

| Model term | Degrees of freedom | p-value4 | ||||

| Year | 1 | <0.0001 | ||||

| Harvest date * Cultivar * Threshing parameter setting | 3 | 0.0188 | ||||

| Year | Treatment | Harvest Date | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| 100 DAS | 111 DAS | |||||

| 2017 | C1 P1 | 1 | 1 | 0.30 ± 0.03 | 3 | 3 |

| C1 P2 | 1 | 1 | 0.23 ± 0.02 | 3 | 3 | |

| C1 P3 | 1 | 1 | 0.41 ± 0.04 | 3 | 3 | |

| C2 P1 | 1,2 | 1 | 0.48 ± 0.04 | 0.31 ± 0.03 | 3 | |

| C2 P2 | 1,2 | 1 | 0.44 ± 0.04 | 0.27 ± 0.02 | 3 | |

| C2 P3 | 1,2 | 1 | 0.96 ± 0.09 | 0.35 ± 0.03 | 3 | |

| 84 DAS | 95 DAS | 111 DAS | 118 DAS | |||

| 2018 | C1 P1 | 0.87 ± 0.05 | 0.53 ± 0.03 | 1 | 0.59 ± 0.04 | 0.49 ± 0.03 |

| C1 P2 | 0.80 ± 0.05 | 0.54 ± 0.03 | 1 | 0.54 ± 0.03 | 0.43 ± 0.03 | |

| C1 P3 | 1.40 ± 0.09 | 0.90 ± 0.05 | 1 | 1 | 0.62 ± 0.04 | |

| C2 P1 | 2 | 2.42 ± 0.15 | 1 | 1.80 ± 0.11 | 1.33 ± 0.08 | |

| C2 P2 | 2 | 1.90 ± 0.18 | 1 | 1.74 ± 0.11 | 1.50 ± 0.09 | |

| C2 P3 | 2 | 3.14 ± 0.19 | 1 | 2.37 ± 0.22 | 2.05 ± 0.13 | |

| ANOVA table of the significant terms and interactions. | ||||||

| Model term | Degrees of freedom | p-value4 | ||||

| Year | 1 | <0.0001 | ||||

| Harvest date * Cultivar * Threshing parameter setting | 3 | 0.0016 | ||||

| ANOVA Table of the Highest Significant Terms and Interactions | ||

|---|---|---|

| Model Term | Degrees of Freedom | p-Value 1 |

| Year | 1 | <0.0001 |

| Cultivar * Threshing parameter setting | 2 | 0.0350 |

| Harvest date * Threshing parameter setting | 8 | <0.0001 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Steberl, K.; Hartung, J.; Graeff-Hönninger, S. Impact of Cultivar, Harvest Date and Threshing Parameter Settings on Floret and Carthamidin Yield of Safflower. Agronomy 2020, 10, 1272. https://doi.org/10.3390/agronomy10091272

Steberl K, Hartung J, Graeff-Hönninger S. Impact of Cultivar, Harvest Date and Threshing Parameter Settings on Floret and Carthamidin Yield of Safflower. Agronomy. 2020; 10(9):1272. https://doi.org/10.3390/agronomy10091272

Chicago/Turabian StyleSteberl, Kathrin, Jens Hartung, and Simone Graeff-Hönninger. 2020. "Impact of Cultivar, Harvest Date and Threshing Parameter Settings on Floret and Carthamidin Yield of Safflower" Agronomy 10, no. 9: 1272. https://doi.org/10.3390/agronomy10091272

APA StyleSteberl, K., Hartung, J., & Graeff-Hönninger, S. (2020). Impact of Cultivar, Harvest Date and Threshing Parameter Settings on Floret and Carthamidin Yield of Safflower. Agronomy, 10(9), 1272. https://doi.org/10.3390/agronomy10091272