Integrated Horticultural Practices for Improving Apple Supply Chain Sustainability: A Case Study in the North China Plain

Abstract

:1. Introduction

2. Materials and Methods

2.1. Overview of the Research Area

2.2. Farmer Survey

2.3. Composition of the Apple Supply Chain in Quzhou County

2.4. Data Calculation

2.4.1. N Flow, N Loss, and N-Use Efficiency

2.4.2. Partial Productivity of Fertilizer

2.4.3. Data Processing and Statistical Analysis

3. Results

3.1. Classification and Screening of Smallholders

3.2. Differences in Horticultural Management

3.3. N Input and Flow in the Apple Supply Chain

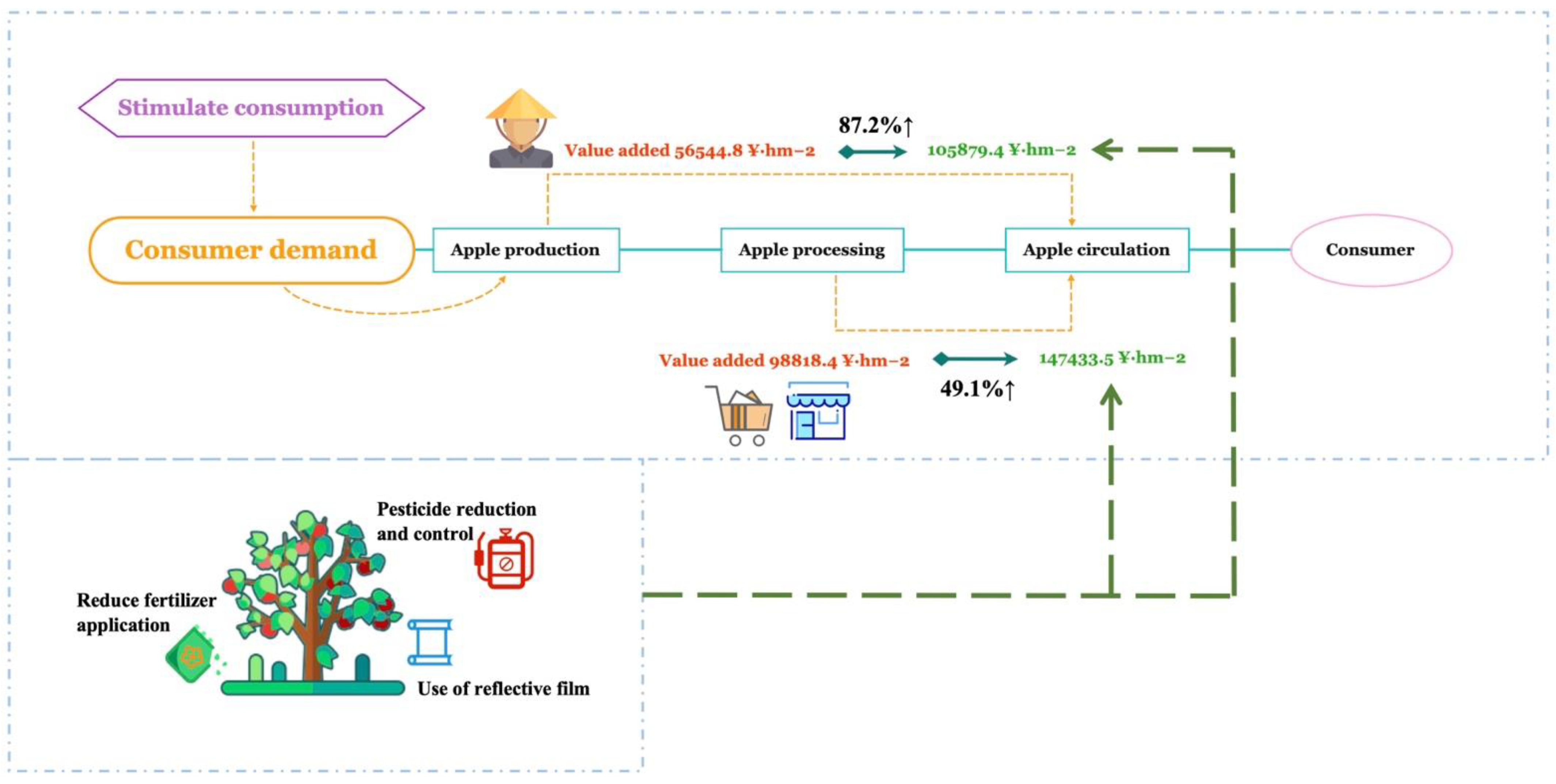

3.4. Promoting Effect of Horticultural Practices on Economic Benefits from the Apple Supply Chain

4. Discussion

4.1. Smallholders with High Yield and High-Efficiency Apple Production Potential and Localization Technology

4.2. Effect of Localization Technology on High-Yield and Efficient Apple Production through the Supply Chain

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- The Food and Agriculture Organization (FAO). Available online: http://www.fao.org/faostat/en/#data/QC4 (accessed on 19 January 2018).

- National Bureau of Statistics. China Statistical Yearbook; China Statistics Press: Beijing, China, 2020; pp. 387–389. [Google Scholar]

- Wang, N.; Joost, W.; Zhang, F. Towards sustainable intensification of apple production in China-Yield gaps and nutrient use efficiency in apple farming systems. J. Integr. Agric. 2016, 15, 716–725. [Google Scholar] [CrossRef] [Green Version]

- Zhai, H.; Shi, D.; Shu, H. Current status and developing trend of apple industry in China. J. Fruit Sci. 2007, 24, 355–360, (In Chinese with English Abstract). [Google Scholar]

- Wang, F.; Tian, G.; Liu, J.; Ge, S.; Jiang, Y. Fate of fertilizer nitrogen and soil nitrogen pool budget of fuji apple from germination stage to new shoot growing stage. Chin. J. Appl. Ecol. 2019, 29, 931–937, (In Chinese with English Abstract). [Google Scholar]

- Manish, S.; Sanjay, J. Agri-fresh produce supply chain management: A state-of-theart literature review. Int. J. Oper. Prod. Manag. 2013, 33, 114–158. [Google Scholar]

- Paam, P.; Berretta, R.; Heydar, M.; García-Flores, R. The impact of inventory management on economic and environmental sustainability in the apple industry. Comput. Electron. Agr. 2019, 163, 104848. [Google Scholar] [CrossRef]

- Soto-Silva, W.; González-Araya, M.; Oliva-Fernández, M.; Plà-Aragonés, L. Optimizing fresh food logistics for processing: Application for a large Chilean apple supply chain. Comput. Electron. Agr. 2017, 136, 42–57. [Google Scholar] [CrossRef]

- Khan, M.; Han, B.J. The Environmental Perspectives of Apple Fruit Supply Chain Management in Chitral, Northern Pakistan. Int. J. Supply Chain Manag. 2016, 6, 1–16. [Google Scholar]

- Wang, J.; Li, Z.; Li, M.; Zhao, D.; Li, E.; Chen, C.; Li, Y. Based on Chinese situation, built a powerful country with Chinese characteristics in apple production. China Fruits 2019, 5, 1–6, (In Chinese with English Abstract). [Google Scholar]

- Huang, C. Economy and Development on Shaanxi Apple Industry. Master’s Thesis, Northwest A&F University, Yangling, China, 2005. [Google Scholar]

- Sun, Y.; Hu, R.; Zhang, C. Does the adoption of complex fertilizers contribute to fertilizer overuse? Evidence from rice production in China. J. Clean Prod. 2019, 219, 677–685, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Ge, S.; Zhu, Z.; Wei, S.; Jiang, Y. Technical approach and research prospect of saving and improving efficiency of chemical fertilizers for apple in China. Acta Hortic. Sin. 2017, 44, 1681–1692, (In Chinese with English Abstract). [Google Scholar]

- Sun, Y.; Ren, B.; Wang, H.; Wang, D. Effect of organic fertilizer application on apple yield and fruit quality in North Hebei Mountainous area. China Fruits 2018, 5, 19–22, (In Chinese with English Abstract). [Google Scholar]

- Zhang, F.; Chen, X.; Chen, Q. The Guide to Fertilization of Major Crops in China; China Agricultural University Press: Beijing, China, 2009; pp. 161–164. [Google Scholar]

- Jiang, S.; Zhang, H.; Cong, W.; Liang, Z.; Ren, Q.; Wang, C.; Zhang, F.; Jiao, X. Multi-Objective Optimization of Smallholder Apple Production: Lessons from the Bohai Bay Region. Sustainability 2020, 12, 6496. [Google Scholar] [CrossRef]

- Bai, X.; Wang, Y.; Huo, X.; Salim, R.; Bloch, H.; Zhang, H. Assessing fertilizer use efficiency and its determinants for apple production in China. Ecol. Indic. 2019, 104, 268–278. [Google Scholar] [CrossRef]

- Ju, X.; Xing, G.; Chen, X.; Zhang, S.; Zhang, L.; Liu, X.; Cui, Z.; Yin, B.; Christie, P.; Zhu, Z.; et al. Reducing environmental risk by improving N management in intensive Chinese agricultural systems. Proc. Natl. Acad. Sci. USA 2009, 106, 3041–3046. [Google Scholar] [CrossRef] [Green Version]

- Galloway, J.N.; Townsend, A.; Erisman, J.; Bekunda, M.; Cai, Z.; Freney, J.; Martinelli, L.; Seitzinger, S.; Sutton, M. Transformation of the Nitrogen Cycle: Recent Trends, Questions, and Potential Solutions. Science 2008, 320, 889–892. [Google Scholar] [CrossRef] [Green Version]

- Miloevi, T.; Miloevi, N. Apple fruit quality, yield and leaf macronutrients content as affected by fertilizer treatment. J. Soil Sci. Plant Nut 2015, 151, 76–83. [Google Scholar]

- Wang, H.; Wang, L.; Wang, J.; Jiang, F.; Liu, H.; Ye, J.; Deng, N.; Xu, W.; Zhang, C.; Wang, S. Effects of vapor-permeable reflective film mulching on citrus tree micro-environment, shoot growth and fruit development. J. Friut Sci. 2017, 34, 996–1006, (In Chinese with English Abstract). [Google Scholar]

- Zhang, J.; Wang, C.; He, J.; Zhang, D. Effects of reflective film mulching time on apple fruit quality. Deciduous Fruits 2020, 52, 22–24, (In Chinese with English Abstract). [Google Scholar]

- Zhou, T.; Fan, Q. Effects of organic fertilizer on growth and qulity of red fuji apple. China Soils Fert. 2008, 2, 56–59, (In Chinese with English Abstract). [Google Scholar]

- Wang, S.; Zhang, Z.; Shi, S.; Yang, S. Effect of biogas residue fertilizer on the yield and fruit quality of apple trees. China Biogas 2018, 36, 74–79, (In Chinese with English Abstract). [Google Scholar]

- Gong, M.; Wang, H.; Zhang, X.; Liu, Y.; Li, H.; Guo, S. Effects of different organic fertilizer amounts on soil nutrient and enzyme activity of apple orchard. J. Northwest For. Univ. 2019, 34, 74–78, (In Chinese with English Abstract). [Google Scholar]

- Chen, Q.; Ding, N.; Peng, L.; Zhu, Z.; Ge, S. Nitrogen application technology in dwarfed apple trees. J. Appl. Ecol. 2018, 29, 1429–1436, (In Chinese with English Abstract). [Google Scholar]

- Kumar, P.; Suman, S.; Spehia, R.; Kumar, V.; Kaith, N. Studies on method and rate of fertilizer application in apple under mulch in north-western Himalayas. J. Plant Nutr. 2016, 39, 219–226. [Google Scholar] [CrossRef]

- Alkaabneh, F.; Lee, J.; MI, G.; Gao, H. A systems approach to carbon policy for fruit supply chains: Carbon tax, technology innovation, or land sparing? Sci. Total Environ. 2020, 767, 144211. [Google Scholar] [CrossRef]

- Cai, Y.; Qiao, Y.; Xu, J.; Meng, F.; Wu, W. Environmental impact assessment via life cycle analysis for organic and conventional apple productions. Chin. J. Eco-Agric. 2017, 25, 1527–1534, (In Chinese with English Abstract). [Google Scholar]

- Longo, S.; Mistretta, M.; Guarino, F.; Cellura, M. Life Cycle Assessment of organic and conventional apple supply chains in the north of Italy. J. Clean Prod. 2017, 140, 654–663. [Google Scholar] [CrossRef]

- Parajuli, R.; Thoma, G.; Matlock, M. Environmental sustainability of fruit and vegetable production supply chains in the face of climate change: A review. Sci. Total Environ. 2019, 650, 2863–2879. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, S.; Yang, C.; Guo, Y.; Jiao, X. Integrated Horticultural Practices for Improving Apple Supply Chain Sustainability: A Case Study in the North China Plain. Agronomy 2021, 11, 1975. https://doi.org/10.3390/agronomy11101975

Jiang S, Yang C, Guo Y, Jiao X. Integrated Horticultural Practices for Improving Apple Supply Chain Sustainability: A Case Study in the North China Plain. Agronomy. 2021; 11(10):1975. https://doi.org/10.3390/agronomy11101975

Chicago/Turabian StyleJiang, Shan, Chen Yang, Yu Guo, and Xiaoqiang Jiao. 2021. "Integrated Horticultural Practices for Improving Apple Supply Chain Sustainability: A Case Study in the North China Plain" Agronomy 11, no. 10: 1975. https://doi.org/10.3390/agronomy11101975