Review of Two Mechanical Separation Technologies for the Sustainable Management of Agricultural Phosphorus in Nutrient-Vulnerable Zones

Abstract

1. Introduction

- Appropriate redistribution of slurries/derivatives between farms.

- Slurry could be separated by mechanical means to concentrate P into a separated solid fraction for export off farm.

- Research into whether lime treatment of dewatered slurry will allow safe and biosecure redistribution.

- Capital support to separate P from slurries on farms which cannot sustainably spread their nutrient to land.

- Increase the proportion of slurry which is applied on land by trailing-shoe, band spreader or shallow injector.

2. Solid–Liquid Separation

2.1. Length of Storage Time and Temperature Pre-Separation

2.2. Separation Efficiency

- Et = Simple separation efficiency,

- U = Quantity of solid fraction (kg),

- Mc = Concentration of component in solid fraction (g kg−1),

- Q = Quantity of slurry treated (kg), and

- Sc = Concentration of component in slurry (g kg−1).

- E’t = Reduced separation efficiency,

- Et = Simple separation efficiency, and

- Rf = U/Q (solid fraction to total digestate ratio).

2.3. Separation Throughput

3. Separation Methods

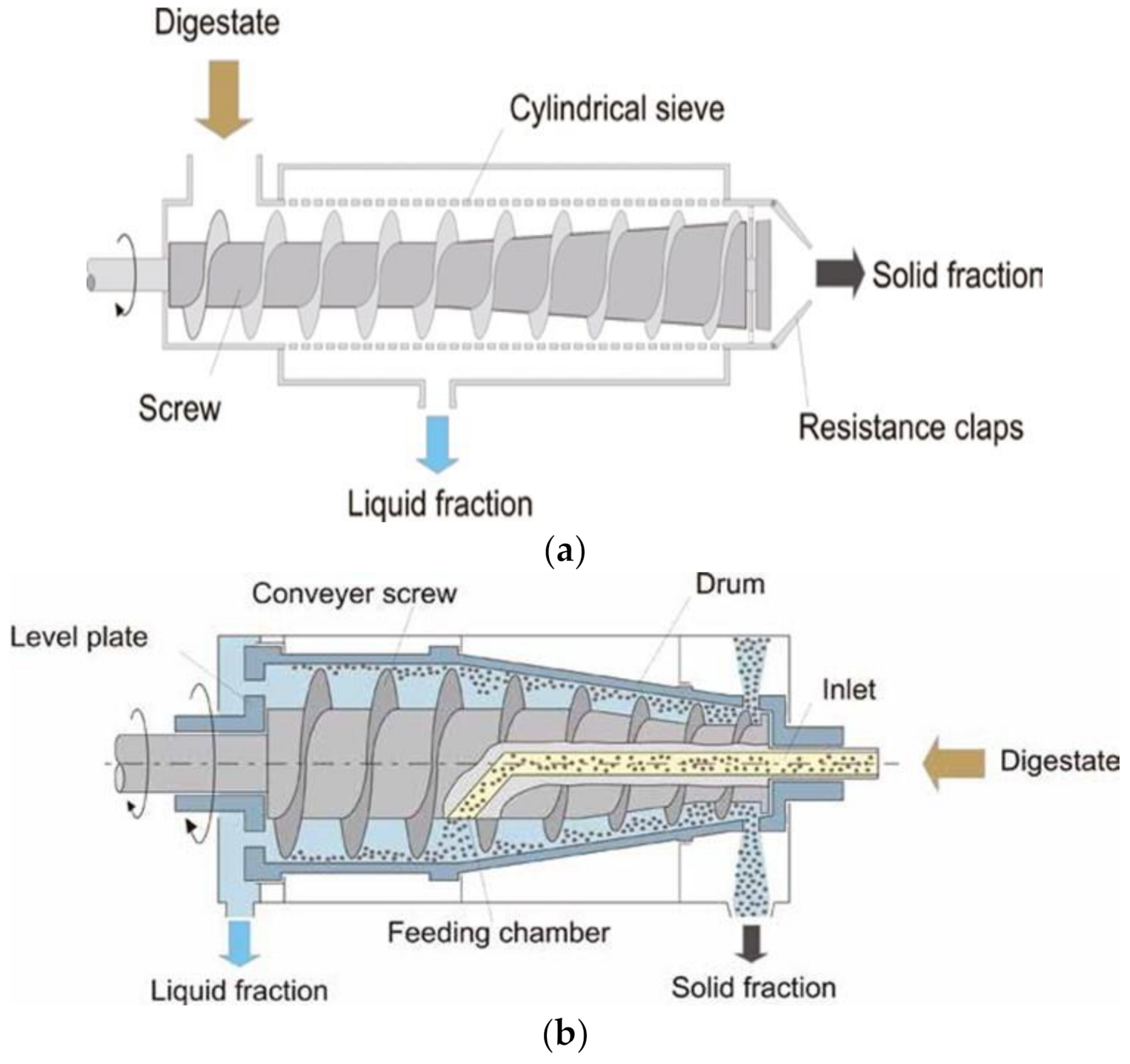

3.1. Screw Press Separator

3.2. Decanting Centrifuge Separator

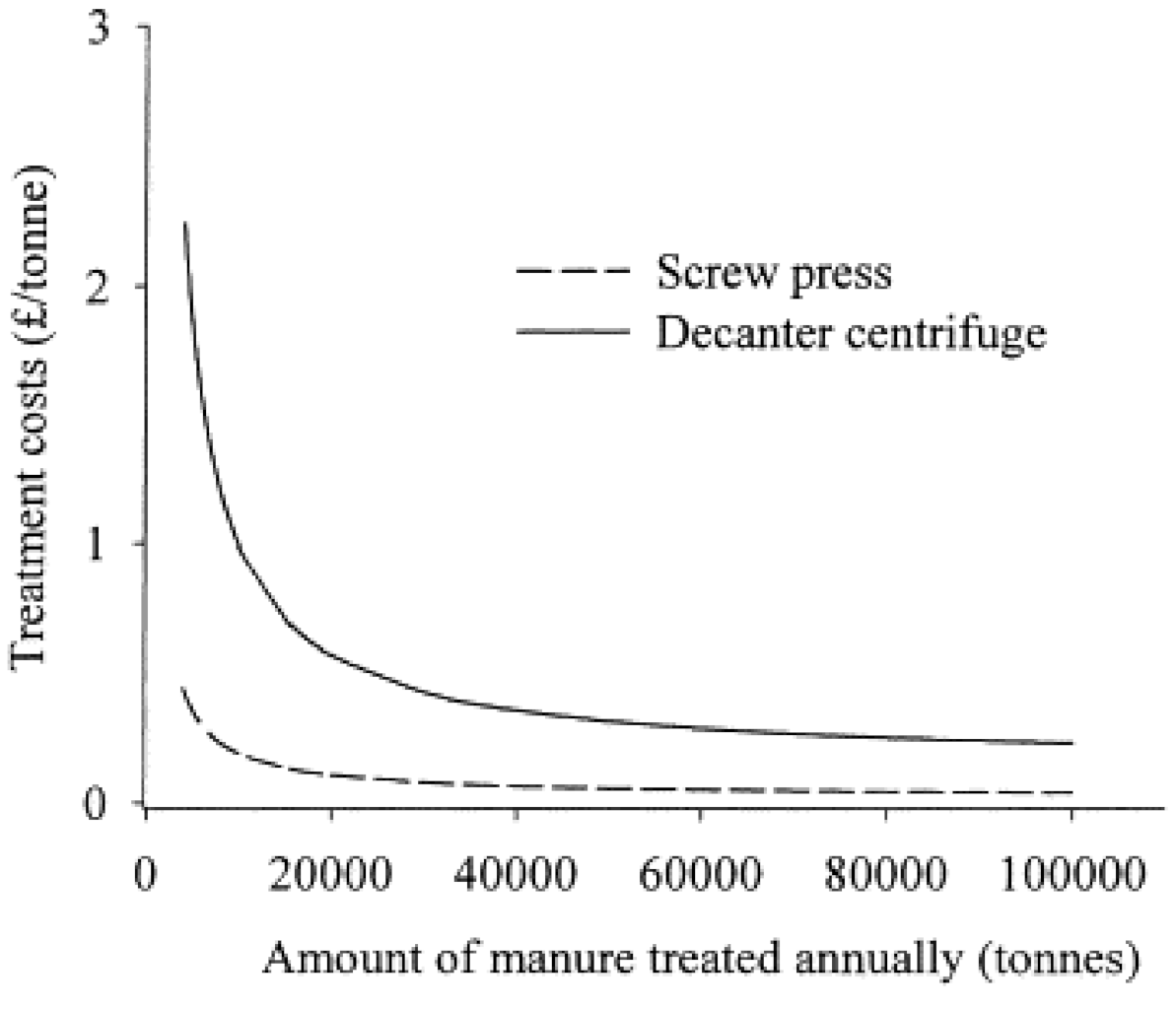

4. Economics/Costs of Separation

4.1. Capital Costs

4.2. Running Costs

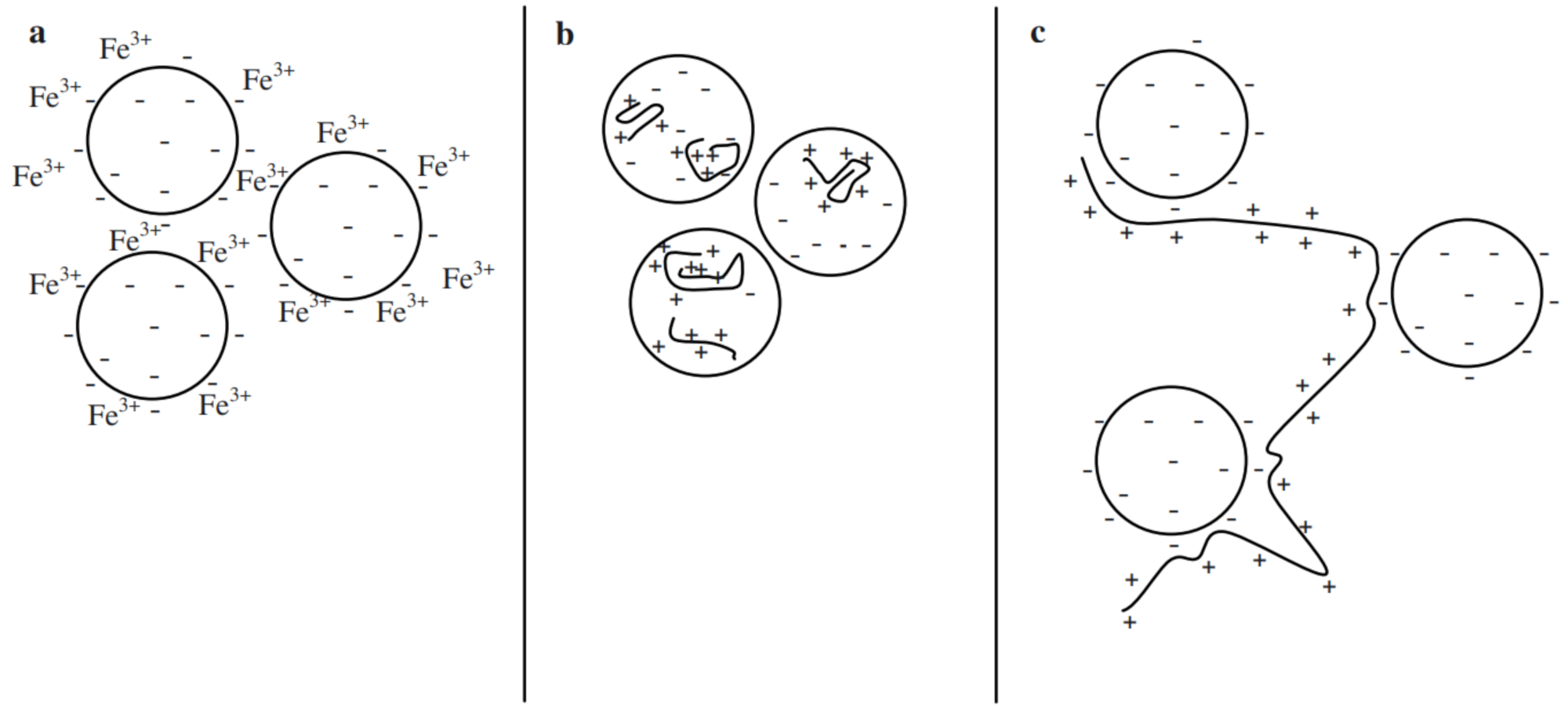

4.3. Chemical Addition

5. Dry Matter and Nutrient Partitioning

5.1. Screw Press vs. Decanting Centrifuge

5.2. Solid vs. Liquid Fractions and Their Fertilising Potential

6. Logistics of Handling and Transport Options

6.1. The Separated Liquid Fraction

6.2. The Separated Solid Fraction

6.2.1. Solid Fraction Transportability

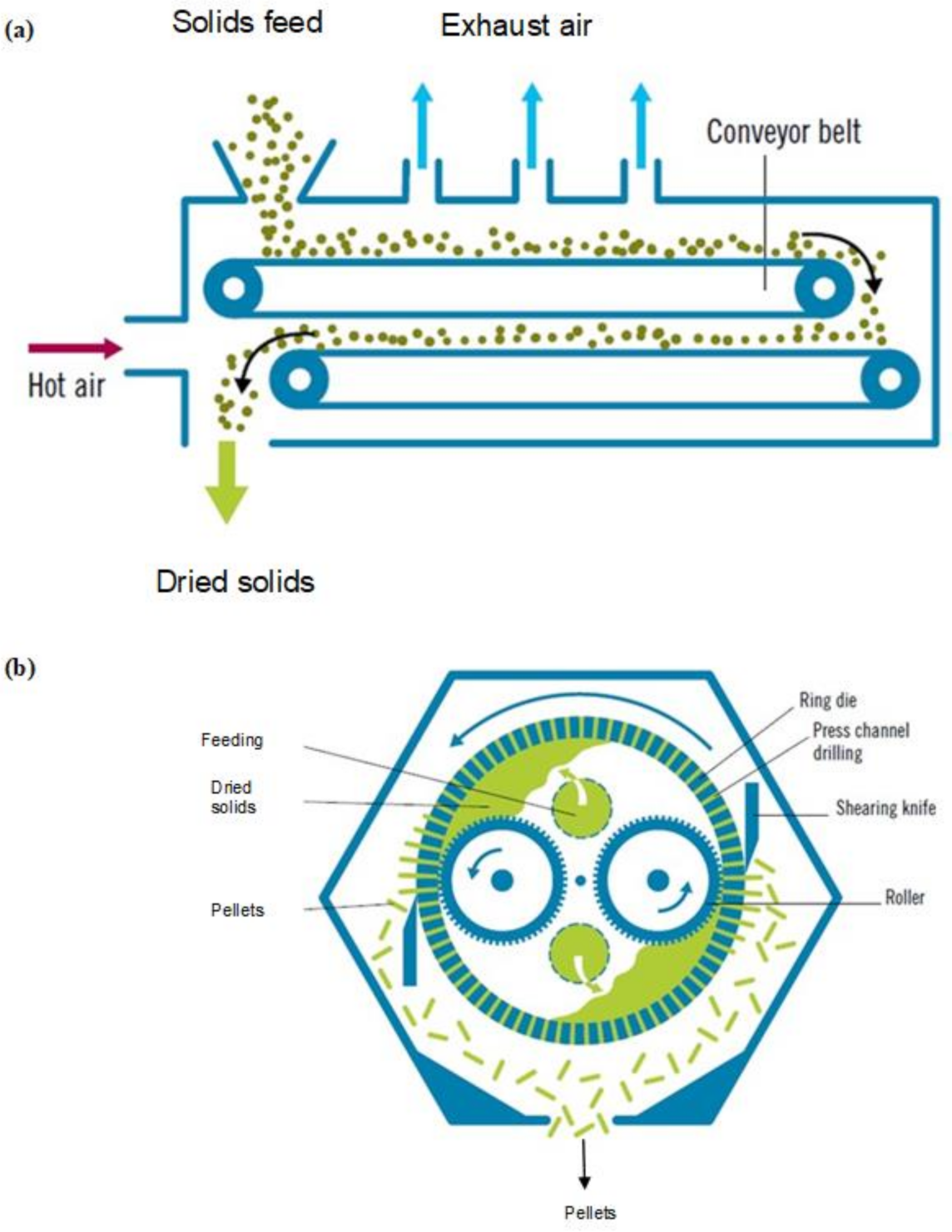

6.2.2. Further Processing of the Solid Fraction

6.3. Emissions from Separated Fractions

6.4. Biosecurity of Exported Separated Fractions

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Velthof, G.; Schoumans, O.; Zwart, K.; Oenema, O. Fertilisers from Processed Manure. In Proceedings of the BIOREFINE, UK Nutrient Platform Workshop, Leeds, UK, 12 November 2014. [Google Scholar]

- Smith, V.H.; Tilman, G.D.; Nekola, J.C. Eutrophication: Impacts of excess nutrient inputs on freshwater, marine and terrestrial ecosystems. Environ. Pollut. 1999, 100, 179–196. [Google Scholar] [CrossRef]

- Frost, J.P.; Bailey, J.S.; Stevens, R.J. Making best on-farm use of plant nutrients in livestock manures. In Proceedings of the 78th Annual Report of the Agricultural Research Institute of Northern Ireland, Hillsborough, UK, March 2006; pp. 54–68. [Google Scholar]

- Pedizzi, C.; Noya, I.; Sarli, J.; González-García, S.; Lema, J.M.; Moreira, M.T.; Carballa, M. Environmental assessment of alternative treatment schemes for energy and nutrient recovery from livestock manure. Waste Manag. 2018, 77, 276–286. [Google Scholar] [CrossRef]

- Schoumans, O.F.; Bouraoui, F.; Kabbe, C.; Oenema, O.; van Dijk, K.C. Phosphorus management in Europe in a changing world. Ambio 2015, 44, 180–192. [Google Scholar] [CrossRef]

- European Nitrates Directive. Council Directive of 12 December 1991 Concerning the Protection of Waters against Pollution Caused by Nitrates from Agricultural Sources (91/676/EEC). 1991. Available online: http://eurlex.europa.eu/LexUriServ/LexUriServ.do?uri=CELEX:31991L0676:EN:HTL (accessed on 2 December 2020).

- EU Water Framework Directive. Directive 2000/60/EC of the European Parliament and of the Council Establishing a Framework for the Community Action in the Field of Water Policy. 2000. Available online: https://ec.europa.eu/environment/water/water-framework/index_en.html (accessed on 2 December 2020).

- Schoumans, O.F.; Chardon, W.J.; Bechmann, M.E.; Gascuel-Odoux, C.; Hofman, G.; Kronvang, B.; Litaor, M.I.; Lo Porto, A.; Newell-Price, P.; Rubæk, G. Mitigation options to reduce phosphorus losses from the agricultural sector and improve surface water quality: A review. Sci. Total Environ. 2014, 468–469, 1255–1266. [Google Scholar] [CrossRef]

- Sustainable Agricultural Land Management Strategy (SALMS). Delivering Our Future, Valuing Our Soils. A Sustainable Agricultural Land Management Strategy for Northern Ireland. Available online: https://www.daerani.gov.uk/sites/default/files/publications/daera/JohnGillilandPresentation.pdf (accessed on 3 December 2020).

- Rothwell, S.A.; Doody, D.G.; Johnston, C.; Forber, K.J.; Cencic, O.; Rechberger, H.; Withers, P.J.A. Phosphorus stocks and flows in an intensive livestock dominated food system. Resour. Conserv. Recycl. 2020, 55, 1146–1153. [Google Scholar]

- Steinfeld, H.; Gerber, P.; Wassenaar, T.; Castel, V.; Rosales, M.; de Haan, C. Livestock’s Long Shadow—Environmental Issues and Options; FAO: Rome, Italy, 2006; pp. 125–176. [Google Scholar]

- Balsari, P.; Santoro, E.; Dinuccio, E.; Gioelli, F. Assessment of the performances of different mechanical slid-liquid separators for pig and cattle slurries. In DIAS Deport Plant Production; Danish Institute of Agricultural Sciences: Tjele, Denmark, 2006; pp. 157–159. [Google Scholar]

- Guilayn, F.; Jimenez, J.; Rouez, M.; Crest, M.; Patureau, D. Digestate mechanical separation: Efficiency profiles based on anaerobic digestion feedstock and equipment choice. Bioresour. Technol. 2019, 274, 180–189. [Google Scholar] [CrossRef]

- Møller, K.; Müller, T. Effects of anaerobic digestion on digestate nutrient availability and crop growth: A review. Eng. Life Sci. 2012, 12, 242–257. [Google Scholar] [CrossRef]

- Hjorth, M.; Christensen, K.V.; Christensen, M.L. Solid–liquid separation of animal slurry in theory and practice: A Review. Agron. Sustain. Dev. 2010, 30, 153–180. [Google Scholar] [CrossRef]

- Petersen, J.; Sørensen, P. Loss of nitrogen and carbon during storage of the fibrous fraction of separated pig slurry and influence on nitrogen availability. J. Agric. Sci. Camb. 2008, 146, 403–413. [Google Scholar] [CrossRef]

- Hansen, M.N.; Henriksen, K.; Sommer, S.G. Observations of production and emission of greenhouse gases and ammonia during storage of solids separated from pig slurry: Effects of covering. Atmos. Environ. 2006, 40, 4172–4181. [Google Scholar] [CrossRef]

- Møller, K.; Schulz, R.; Muller, T. Substrate inputs, nutrient flows and nitrogen loss of two centralized biogas plants in southern Germany. Nutr. Cycl. Agroecosys. 2010, 87, 307–325. [Google Scholar] [CrossRef]

- Pedrazzi, S.; Allesina, G.; Belló, T.; Rinaldini, C.A.; Tartarini, P. Digestate as bio-fuel in domestic furnaces. Fuel Process. Technol. 2015, 130, 172–178. [Google Scholar] [CrossRef]

- Garcia, M.C.; Szogi, A.A.; Vanotti, M.B.; Chastain, J.P.; Millner, P.D. Enhanced solid—Liquid separation of dairy manure with natural flocculants. Bioresour. Technol. 2009, 100, 5417–5423. [Google Scholar] [CrossRef] [PubMed]

- Møller, H.B.; Lund, I.; Sommer, S.B. Solid-liquid separation of livestock slurry: Efficiency and cost. Bioresour. Technol. 2000, 74, 223–229. [Google Scholar] [CrossRef]

- Gilkinson, S.J.; Frost, J.P. Evaluation of Mechanical Separation of Pig and Cattle Slurries by a Decanting Centrifuge and a Brushed Screen Separator. AFBI-Northern Ireland. 2007. Available online: https://www.afbini.gov.uk/articles/evaluation-mechanical-separation-pig-and-cattle-slurries (accessed on 24 November 2020).

- Frost, J.P.; Stevens, R.J.; Laughlin, R.J. Effect of separation and acidification of cattle slurry on ammonia volatilization and on the efficiency of slurry nitrogen for herbage production. J. Agric. Sci. 1990, 115, 49–56. [Google Scholar] [CrossRef]

- Zhu, J.; Ndegwa, P.M.; Luo, A. Effect of solid-liquid separation on BOD and VFA in swine manure. Environ. Technol. 2001, 22, 1237–1243. [Google Scholar] [CrossRef] [PubMed]

- Pos, J.; Trapp, R.; Harvey, M. Performance of a brushed screen/roller press manure separator. Trans. ASAE 1984, 27, 1112–1118. [Google Scholar] [CrossRef]

- Møller, H.B.; Sommer, S.G.; Ahring, B.K. Separation efficiency and particle size distribution in relation to manure type and storage conditions. Bioresour. Technol. 2002, 85, 189–196. [Google Scholar] [CrossRef]

- Browne, J.; Gilkinson, S.R.; Frost, J.P. The effects of storage time and temperature on biogas production from dairy cow slurry. Biosys. Eng. 2014, 129, 48–56. [Google Scholar] [CrossRef]

- Popovic, O.; Gioelli, F.; Dinuccio, E.; Balsari, P. Improved pig slurry mechanical separation using chitosan and biochar. Biosys. Eng. 2014, 127, 115–124. [Google Scholar] [CrossRef]

- Balticdeal. 2013. Available online: www.balticdeal.eu/measure/slurry-separation (accessed on 25 November 2020).

- Verification of Environmental Technologies for Agricultural Production Test Protocol for Slurry Separation Technologies.VERA. Version 3:2018-07. 2018. Available online: www.vera-verification.eu (accessed on 12 March 2021).

- Bauer, A.; Mayr, H.; Hopfner-Sixt, K.; Amon, T. Detailed monitoring of two biogas plants and mechanical solid—Liquid separation of fermentation residues. J. Biotech. 2009, 142, 56–63. [Google Scholar] [CrossRef]

- Christensen, G.L.; Dick, R.I. Specific resistance measurements: Nonparabolic data. J. Environ. Eng. ASCE 1985, 111, 243–257. [Google Scholar] [CrossRef]

- Sørensen, P.B.; Christensen, J.R.; Bruus, J.H. Effect of small scale solids migration in filter cakes during filtration of wastewater solids suspensions. Water Environ. Res. 1995, 67, 25–32. [Google Scholar] [CrossRef]

- Christensen, M.L.; Keiding, K. Filtration model for suspensions that form filter cakes with creep behaviour. AIChE J. 2007, 53, 598–609. [Google Scholar] [CrossRef]

- Hjorth, M.; Christensen, M.L.; Christensen, K.V. Flocculation, coagulation and precipitation of manure affecting three separation techniques. Bioresour. Technol. 2008, 99, 8598–8604. [Google Scholar] [CrossRef] [PubMed]

- Weiland, P. Gärrestaufbereitung. In 17. Symposium Bioenergie, OTTI 20-21.11.2008; Kloster Banz: Bad Staffelstein, Germany, 2008. [Google Scholar]

- Fuchs, W.; Drosg, B. Technologiebewertung von Gärrestbehandlungs-und Verwertungskonzepten; Eigenverlag der Universität für Bodenkultur Wien: Tulln, Austria, 2010; ISBN 978-3-900962-86-9. [Google Scholar]

- Drosg, B.; Fuchs, W.; Al Seadi, T.; Madsen, M.; Linke, B. Nutrient Recovery by Biogas Digestate Processing; IEA Bioenergy: Paris, France, 2015; ISBN 978-1-910154-16-8. [Google Scholar]

- Records, A.; Sutherland, K. Decanter Centrifuge Handbook, 1st ed.; Elsevier Advanced Technology: Oxford, UK, 2001. [Google Scholar]

- Provolo, G. Trattamenti per la separazione dei solidi dall’ effluente. In Effluenti Zootecnici; Impiantistica e Soluzioni Tecnologiche per la Gestione Sostenibile; Impresa Agricola: Bastia Umbra, Italy, 2012; pp. 105–137. [Google Scholar]

- Tambone, F.; Orzi, V.; D’Imporzano, G.; Adani, F. Solid and liquid fractionation of digestate: Mass balance, chemical characterization, and agronomic and environmental value. Bioresour. Technol. 2017, 243, 1251–1256. [Google Scholar] [CrossRef] [PubMed]

- Burton, C.H.; Turner, C. Manure Treatment Strategies for Sustainable Agriculture, 2nd ed.; Silsoe Research Institute: Bedford, UK, 2003. [Google Scholar]

- DANETV. Verification Statement for GEA Westfalia Decanter Centrifuge for Post-Treatment of Digested Biomass. The Danish Centre for Verification of Climate and Environmental Technologies (DANETV). AgroTech Verification Centre. 2010. DANETV—The Danish Centre for Verification of Climate and Environmental Technologies. Available online: etv-denmark.com (accessed on 22 December 2020).

- Perazzolo, F.; Mattachini, G.; Tambone, F.; Misselbrook, T. Effect of mechanical separation on emissions during storage of two anaerobically codigested animal slurries. Agric. Ecosys. Environ. 2015, 207, 1–9. [Google Scholar] [CrossRef]

- Bolzonella, D.; Fatone, F.; Gottardo, M.; Frison, N. Nutrients recovery from anaerobic digestate of agro-waste: Techno-economic assessment of full scale applications. J. Environ. Manag. 2018, 216, 111–119. [Google Scholar] [CrossRef] [PubMed]

- Fournel, S.; Godbout, S.; Ruel, P.; Fortin, A.; Généreux, M.; Coté, C.; Landry, C.; Pellerin, D. Production of recycled manure solids for bedding in Canadian dairy farms: I. Solid–liquid separation. J. Dairy Sci. 2019, 102, 832–1846. [Google Scholar] [CrossRef]

- Finzi, A.; Mattachini, G.; Lovarelli, D.; Riva, E.; Provolo, G. Technical, Economic, and Environmental Assessment of a Collective Integrated Treatment System for Energy Recovery and Nutrient Removal from Livestock Manure. Sustainability 2020, 12, 2756. [Google Scholar] [CrossRef]

- Pantelopoulos, A.; Aronsson, H. Two-stage separation and acidification of pig slurry—Nutrient separation efficiency and agronomical implications. J. Environ. Manag. 2021, 280, 111653. [Google Scholar] [CrossRef] [PubMed]

- Playfair, D. Northern Ireland Agri-Food Sector Key Statistics July 2020. Department of Agriculture, Environment and Rural Affairs (DAERA). Available online: https://www.daerani.gov.uk/sites/default/files/publications/daera/Key%20Statistics%202020.pdf (accessed on 21 January 2021).

- Nolan, T.; Troy, S.; Healy, M.; Kwapinski, W.; Leahy, J.; Lawlor, P. Characterization of compost produced from separated pig manure and a variety of bulking agents at low initial C/N ratios. Bioresour. Technol. 2011, 102, 7131–7138. [Google Scholar] [CrossRef] [PubMed]

- Gregory, J. Rates of flocculation of latex particles by cationic polymers. J. Colloid Interf. Sci. 1973, 42, 448–456. [Google Scholar] [CrossRef]

- Smith-Palmer, T.; Campbell, N.; Bowman, J.L.; Dewar, P. Flocculation behaviour of some cationic polyelectrolytes. J. Appl. Polym. Sci. 1994, 52, 1317–1325. [Google Scholar] [CrossRef]

- Nowostawska, U.; Sander, S.G.; McGrath, K.M.; Hunter, K.A. Effect of trivalent metal sulfates on the coagulation and particle interactions of alumina colloids. Colloids Surface A 2005, 266, 200–206. [Google Scholar] [CrossRef]

- Gregory, J. Fundamentals of flocculation. Crit. Rev. Environ. Cont. 1989, 19, 185–229. [Google Scholar] [CrossRef]

- Fangueiro, D.; Hjorth, M.; Gioelli, F. Acidification of animal slurry—A review. J. Environ. Manag. 2015, 149, 46–56. [Google Scholar] [CrossRef]

- Hjorth, M.; Cocolo, G.; Jonassen, K.; Sommer, S.G. Acidifications effect on transformations in and composition of animal slurry. In Proceedings of the 15th RAMIRAN Conference, Versailles, France, 3–5 June 2013. [Google Scholar]

- Sneath, R.W.; Shaw, M.; Williams, A.G. Centrifugation for separating piggery slurry. 1. The performance of a decanting centrifuge. J. Agric. Eng. Res. 1988, 39, 181–190. [Google Scholar] [CrossRef]

- Sommer, S.G.; Husted, S. The chemical buffer system in raw and digested animal slurry. J. Agric. Sci. Camb. 1995, 124, 45–53. [Google Scholar] [CrossRef]

- Riva, C.; Orzi, V.; Carozzi, M.; Acutis, M.; Boccasile, G.; Lonati, S.; Tambone, F. Short-term experiments in using digestate products as substitutes for mineral (N) fertilizer: Agronomic performance, odours, and ammonia emission impacts. Sci. Total Environ. 2016, 547, 206–214. [Google Scholar] [CrossRef] [PubMed]

- Dahlin, S.; Kirchmann, H.; Katterer, T.; Gunnarsson, S.; Bergstrom, L. Possibilities for improving nitrogen use from organic materials in agricultural cropping systems. Ambio 2005, 34, 288–295. [Google Scholar] [CrossRef]

- Chantigny, M.H.; Angers, D.A.; Belanger, G.; Rochette, P.; Eriksen-Hamel, N.; Bittman, S.; Buckley, K.; Masse, D.; Gasser, M.-O. Yield and nutrient export of grain corn fertilized with raw and treated liquid swine manure. Agron. J. 2008, 100, 1303–1309. [Google Scholar] [CrossRef]

- Manfredini, A.; Nergri, M.; Cavalli, D.; Bechini, L.; Marino, P. Carbon and nitrogen mineralization of raw and separated, digested animal manures. In Proceedings of the 14th RAMIRAN International Conference: Treatment and Use of organic residues in agriculture: Challenges and opportunities towards sustainable management, Lisbon, Portugal, 13–15 September 2010. [Google Scholar]

- Fangueiro, D.; Coutinho, J.; Chadwick, D.; Moreira, N.; Trindade, H. Effect of cattle slurry separation on greenhouse gas and ammonia emissions during storage. J. Environ. Qual. 2008, 37, 2322–2331. [Google Scholar] [CrossRef] [PubMed]

- Owusu-Twum, M.Y.; Polastre, A.; Subedi, R.; Santos, A.S.; Ferreira, L.M.M.; Coutinho, J.; Trindade, H. Gaseous emissions and modification of slurry composition during storage and after field application: Effect of slurry additives and mechanical separation. J. Environ. Manag. 2017, 200, 416–422. [Google Scholar] [CrossRef] [PubMed]

- Liedl, B.E.; Bombardiere, J.; Chatfield, J.M. Fertilizer potential of liquid and solid effluent from thermophilic anaerobic digestion of poultry waste. Water Sci. Technol. 2006, 53, 69–79. [Google Scholar] [CrossRef] [PubMed]

- Laboski, C.A.M.; Earhart, S.M.; Baxter, C.A. Evaluation of nitrogen availability from raw and treated dairy manures. In Proceedings of the 19th World Congress of Soil Science, Soil Solutions for a Changing World, Brisbane, Australia, 1–6 August 2010; pp. 115–118. [Google Scholar]

- Dinuccio, E.; Berg, W.; Balsari, P. Gaseous emissions from the storage of untreated slurries and the fractions obtained after mechanical separation. Atmos. Environ. 2008, 42, 2448–2459. [Google Scholar] [CrossRef]

- Chadwick, D.R. Emissions of ammonia, nitrous oxide and methane from cattle manure heaps: Effect of compaction and covering. Atmos. Environ. 2005, 39, 787–799. [Google Scholar] [CrossRef]

- Digestate and Compost Use in Agriculture—Good Practice Guidance. WRAP. 2016. Available online: http://www.wrap.org.uk/sites/files/wrap/Digestate_compost_good_practice_guide_reference_version.pdf (accessed on 14 January 2021).

- Nolan, T.; Troy, S.M.; Gilkinson, S.; Frost, P.; Xie, S.; Zhan, X.; Harrington, C.; Healy, M.G.; Lawlor, P.G. Economic analyses of pig manure treatment options in Ireland. Bioresour. Technol. 2012, 105, 15–23. [Google Scholar] [CrossRef]

- Huijsmans, J.F.M.; Verwijs, B.; Rodhe, L.K.K.; Smith, K.A. Costs of emission reducing manure application. Bioresour. Technol. 2004, 93, 11–19. [Google Scholar] [CrossRef]

- Kroger, R.; Theuvsen, L. Separation of Cattle Slurry: Technical Solutions and Economic Aspects, Proceedings of the First International Conference on Resource Efficiency in Interorganizational Networks, Gottingen, Germany, 13–14 November 2013; Geldermann, J., Schumann, M., Eds.; Universitatsdrucke: Gottingen, Germany, 2013. [Google Scholar]

- Keatley, P. Farm Business Data. Department of Agriculture, Environment and Rural Affairs for Northern Ireland. 2018. Available online: https://www.daerani.gov.uk/sites/default/files/publications/daera/Farm%20Business%20Data%202018.pdf (accessed on 15 December 2020).

- Wilken, D.; Rauh, S.; Fruhner-Weiss, R.; Strippel, F.; Bontempo, G.; Kramer, A.; Fürst, M.; Wiesheu, M.; Kedia, G.; Hernández Chanto, C.; et al. Digestate as Fertilizer; Fachverband Biogas e.V: Fresing, Germany. 2018. Available online: www.digestate-as-fertilizer.com (accessed on 4 February 2021).

- Nagy, D.; Balogh, P.; Gabnai, Z.; Popp, J.; Oláh, J.; Bai, A. Economic analysis of pellet production in co-digestion biogas plants. Energies 2018, 11, 1135. [Google Scholar] [CrossRef]

- Kratzeisen, M.; Starcevic, N.; Martinov, M.; Maurer, C.; Müller, J. Applicability of biogas digestate as solid fuel. Fuel 2010, 89, 2544–2548. [Google Scholar] [CrossRef]

- Sues, A.; Juraščík, M.; Ptasinski, K. Exergetic evaluation of 5 biowastes-to-biofuels routes via gasification. Energy 2010, 35, 996–1007. [Google Scholar] [CrossRef]

- Priyadarsan, S.; Annamalai, K.; Sweeten, J.M.; Mukhtar, S.T.; Holtzapple, M. Fixed-bed gasification of feedlot manure and poultry litter biomass. Trans. ASAE 2004, 47, 1689–1696. [Google Scholar] [CrossRef]

- Schouten, S.; van Groenigen, J.W.; Oenema, O.; Cayuela, M.L. Bioenergy from cattle manure? Implications of anaerobic digestion and subsequent pyrolysis for carbon and nitrogen dynamics in soil. GCB Bioenergy 2012, 4, 751–760. [Google Scholar] [CrossRef]

- Gaunt, J.L.; Lehmann, J. Energy balance and emissions associated with biochar sequestration and pyrolysis bioenergy production. Environ. Sci. Technol. 2008, 42, 4152–4158. [Google Scholar] [CrossRef] [PubMed]

- Lehmann, J.; Gaunt, J.; Rondon, M. Bio-char sequestration in terrestrial ecosystems—A review. Mitig. Adapt. Strateg. Glob. Chang. 2006, 11, 395–419. [Google Scholar] [CrossRef]

- Maurer, C.; Muller, J. Drying characteristics and nitrogen loss of biogas digestate during the drying process. In Proceedings of the 27th World Congress of the International Commission of Agricultural and Biosystems Engineering, Québec City, QC, Canada, 13–17 June 2010; pp. 1–8. [Google Scholar]

- Aguirre-Villegas, H.A.; Larson, R.A.; Sharara, M.A. Anaerobic digestion, solid-liquid separation, and drying of dairy manure: Measuring constituents and modelling emissions. Sci. Total Environ. 2019, 696, 134059. [Google Scholar] [CrossRef]

- Meissl, K.; Smidt, E. High quality composts by means of co-composting of residues from anaerobic digestion. Compost Sci. Util. 2007, 15, 78–83. [Google Scholar] [CrossRef]

- Teglia, C.; Tremier, A.; Martel, J.-L. Characterization of solid digestates: Part 2, assessment of the quality and suitability for composting of six digested products. Waste Biomass Valor. 2011, 2, 113–126. [Google Scholar] [CrossRef]

- Fillingham, M.A.; VanderZaag, A.C.; Burtt, S.; Baldé, H.; Ngwabie, N.M.; Smith, W.; Hakami, A.; Wagner-Riddle, C.; Bittman, S.; MacDonald, D. Greenhouse gas and ammonia emissions from production of compost bedding on a dairy farm. Waste Manag. 2017, 70, 45–52. [Google Scholar] [CrossRef]

- Rauhe, K. Effects of organic manuring and cropping on soil humus and fertility. In Proceedings of the 4th International CIEC Symposium Agricultural Waste Management and Environmental Protection, Braunschweig, Germany, 11–14 May 1987; pp. 55–76. [Google Scholar]

- Amon, B.; Kryvoruchko, V.; Amon, T.; Zechmeister-Boltenstern, S. Methane, nitrous oxide and ammonia emissions during storage and after application of dairy cattle slurry and influence of slurry treatment. Agric. Ecosys. Environ. 2006, 112, 153–162. [Google Scholar] [CrossRef]

- UNECE. Guidance Document on Preventing and Abating Ammonia Emissions from Agricultural Sources; ECE/EB. AIR/120. & February 2014; UNECE: Geneva, Switzerland; 100p.

- Hou, Y.; Velthof, G.L.; Oenema, O. Mitigation of ammonia, nitrous oxide and methane emissions from manure management chains: A meta-analysis and integrated assessment. Glob. Chang. Biol. 2015, 21, 1293–1312. [Google Scholar] [CrossRef] [PubMed]

- Neerackal, G.M.; Ndegwa, P.M.; Joo, H.S.; Wang, X.; Harrison, J.H.; Heber, A.J.; Ni, J.Q.; Frear, C. Effects of anaerobic digestion and solids separation on ammonia emissions from stored and land applied dairy manure. Water Air Soil Pollut. 2015, 226, 301. [Google Scholar] [CrossRef]

- Holly, M.A.; Larson, R.A.; Powell, J.M.; Ruark, M.D.; Aguirre-Villegas, H. Greenhouse gas and ammonia emissions from digested and separated dairy manure during storage and after land application. Agric. Ecosys. Environ. 2017, 239, 410–419. [Google Scholar] [CrossRef]

- Rotz, A.; Montes, F.; Hafner, S.D.; Heber, A.J.; Grant, R.H. Ammonia emission model for whole farm evaluation of dairy production systems. J. Environ. Qual. 2014, 43, 1143–1158. [Google Scholar] [CrossRef] [PubMed]

- Webb, J.; Chadwick, D.; Ellis, S. Emissions of ammonia and nitrous oxide following incorporation into the soil of farmyard manures stored at different densities. Nutr. Cycl. Agroecosys. 2004, 70, 67–76. [Google Scholar] [CrossRef]

- Fangueiro, D.; Pereira, J.L.S.; Macedo, S.; Trindade, H.; Vasconcelos, E.; Coutinho, J. Surface application of acidified cattle slurry compared to slurry injection: Impact on NH3, N2O, CO2 and CH4 emissions and crop uptake. Geoderma 2017, 306, 160–166. [Google Scholar] [CrossRef]

- Hutchison, M.L.; Walters, L.D.; Avery, S.M.; Munro, F.; Moore, A. Analyses of livestock production, waste storage and pathogen levels and prevalences in farm manures. App. Environ. Microbio. 2005, 71, 1231–1236. [Google Scholar] [CrossRef] [PubMed]

- Heinonen-Tanski, H.; Mohaibes, M.; Karinen, P.; Koivunen, J. Methods to reduce pathogen microorganisms in manure. Livestock Sci. 2006, 102, 248–255. [Google Scholar] [CrossRef]

- Ottoson, J.; Nordin, A.; von Rosen, D.; Vinneras, B. Salmonella reduction in manure by the addition of urea and ammonia. Bioresour. Technol. 2008, 99, 1610–1615. [Google Scholar] [CrossRef]

- Turner, C. The thermal inactivation of E. coli in straw and pig manure. Bioresour. Technol. 2002, 84, 57–61. [Google Scholar] [CrossRef]

- Turner, C.; Burton, C. The inactivation of viruses in pig slurries: A review. Bioresour Technol. 1997, 61, 9–20. [Google Scholar] [CrossRef]

- Pulvirenti, A.; Ronga, D.; Zaghi, M.; Tomasselli, A.R.; Mannella, L.; Pecchioni, N. Pelleting is a successful method to eliminate the presence of Clostridium spp. from the digestate of biogas plants. Biomass Bioenergy 2015, 81, 479–482. [Google Scholar] [CrossRef]

- Kearney, T.E.; Larkin, M.J.; Frost, J.P.; Levett, P.N. Survival of pathogenic bacteria during mesophilic anaerobic digestion of animal waste. J. Appl. Bacteriol. 1993, 75, 215–219. [Google Scholar] [CrossRef]

- Wagner, A.O.; Gstraunthaler, G.; Illmer, P. Survival of bacterial pathogens during the thermophilic anaerobic digestion of biowaste: Laboratory experiments and in situ validation. Anaerobe 2008, 14, 181–183. [Google Scholar] [CrossRef]

- Pornsukarom, S.; Thakur, S. Assessing the Impact of Manure Application in Commercial Swine Farms on the Transmission of Antimicrobial Resistant Salmonella in the Environment. PLoS ONE 2016, 11, e0164621. [Google Scholar] [CrossRef] [PubMed]

- Vilar, M.J.; García Peña, F.J.; Pérez, I.; Diéguez, F.J.; Sanjuán, M.L.; Rodríguez-Otero, J.L.; Yus, E. Presence of Listeria, Arcobacter, and Campylobacter spp. in dairy farms in Spain. Berl. Munch. Tierarztl. Wochenschr. 2010, 123, 58–62. [Google Scholar]

- Guan, T.Y.; Holley, R.A. Pathogen Survival in Swine Manure Environments and Transmission of Human Enteric Illness—A Review. J. Environ. Qual. 2003, 32, 383–392. [Google Scholar] [CrossRef] [PubMed]

- Martens, W.; Böhm, R. Overview of the ability of different treatment methods for liquid and solid manure to inactivate pathogens. Bioresour. Technol. 2009, 100, 5374–5378. [Google Scholar] [CrossRef] [PubMed]

| Variable | Screw Press | Decanting Centrifuge |

|---|---|---|

| Maintenance and repair | 250 | 1250 |

| Electricity (0.04 £/kWh) | 80 | 480 |

| Capital costs | 1424 | 7119 |

| Total yearly costs | 1754 | 8849 |

| Total costs £/tonne | 0.44 | 2.21 |

| Total costs £/kg of TP in solid fraction b | 1.6 | 2.0 |

| Source | Feedstock/Separator Type | Separation Efficiencies | ||

|---|---|---|---|---|

| DM (%) | TN (%) | TP (%) | ||

| Hjorth et al. 2010 [15] (mean values from 16 studies) | Pig + cattle slurries SP | 37 | 15 | 17 |

| Pig + cattle slurries DC | 61 | 28 | 71 | |

| Gilkinson and Frost, 2007 [22] | Cattle slurry DC no polymer | 51 | 25 | 64 |

| Cattle slurry DC with polymer | 65 | 41 | 82 | |

| Pig slurry DC no polymer | 53 | 21 | 79 | |

| Pig slurry DC with polymer | 71 | 34 | 93 | |

| Møller et al. 2002 [26] | Pig digestate SP | 18 | 7 | 10 |

| Cattle digestate SP | 23 | 6 | 9 | |

| Pig digestate DC | 69 | 24 | 91 | |

| Cattle digestate DC | 54 | 24 | 54 | |

| Tambone et al. 2017 [41] (11 different AD plants studied) | Pig + energy crops digestate SP | 17–36 | 6–10 | 8–14 |

| Cattle + energy crops digestate SP | 21–49 | 8–24 | 4–17 | |

| Burton and Turner, 2003 [42] | Pig + cattle slurry SP | 20–65 | 5–28 | 7–33 |

| Pig + cattle slurry DC | 54–68 | 20–40 | 52–78 | |

| Danetv 2010 [43] | Digestate DC | 63 | 25 | 72 |

| Cattle slurry DC | 36–49 | 13–18 | 40–55 | |

| Perazzolo et al. 2015 [44] | Pig + cattle digestate SP | 23 | 6 | ND |

| Cattle digestate SP | 15 | 5 | ND | |

| Bolzonella et al. 2018 [45] | Cattle digestate SP | 30 | 9 | 23 |

| Pig digestate SP Cattle digestate SP + DC Pig digestate SP + DC | 488496 | 135029 | 348475 | |

| Fournel et al. 2018 [46] | Cattle slurry SP | 28–43 | 9–17 | 14–24 |

| Cattle slurry DC | 36–49 | 13–18 | 40–55 | |

| Finzi et al. 2020 [47] | Pig, cattle and poultry manures SP | 13 | 3 | 6 |

| Pig, cattle and poultry manures DC | 35 | 13 | 30 | |

| Pantelopoulos et al. 2021 [48] | Pig slurry SP + DC | 56 | 18 | 73 |

| Distance Travelled (km) | Tractor Outward Speed (km h−1) | Tractor Annual Costs (€) | Tractor (€ m−3) | Truck Outward Speed (km h−1) | Truck Annual Costs (€) | Truck (€ m−3) |

|---|---|---|---|---|---|---|

| 1 | 20.00 | 13,877 | 1.3 | 45.0 | 36,048 | 3.4 |

| 2 | 20.50 | 16,936 | 1.6 | 45.0 | 37,220 | 3.5 |

| 5 | 21.25 | 25,824 | 2.5 | 45.0 | 40,736 | 3.9 |

| 10 | 22.50 | 39,427 | 3.8 | 47.5 | 46,006 | 4.4 |

| 14 | 23.50 | 49,350 | 4.7 | 48.5 | 50,151 | 4.8 |

| 15 | 23.75 | 51,711 | 4.9 | 48.8 | 51,161 | 4.9 |

| 20 | 25.00 | 62,860 | 6.0 | 50.0 | 56,070 | 5.3 |

| 30 | 27.50 | 82,334 | 7.8 | 52.5 | 65,216 | 6.2 |

| 50 | 60.0 | 81,213 | 7.7 | |||

| 75 | 60.0 | 101,591 | 9.7 | |||

| 100 | 60.0 | 123,830 | 11.8 | |||

| 125 | 60.0 | 146,068 | 13.9 | |||

| 150 | 60.0 | 168,306 | 16.0 | |||

| 200 | 60.0 | 212,782 | 20.3 | |||

| 250 | 60.0 | 479,641 | 45.7 |

| Transport Distance | Raw Slurry | Separated Solids | ||||

|---|---|---|---|---|---|---|

| 50 km | 100 km | 150 km | 50 km | 100 km | 150 km | |

| Nutrient value €/t Energy Value €/t | 7.2 4.0 | 7.2 4.0 | 7.2 4.0 | 8.5 8.7 | 8.5 8.7 | 8.5 8.7 |

| Total Value €/t | 11.2 | 11.2 | 11.2 | 17.2 | 17.2 | 17.2 |

| Separation Costs €/t Transportation Costs €/t | 0 10.0 | 0 16.0 | 0 21.0 | 3.9 10.0 | 3.9 16.0 | 3.9 21.0 |

| Total Costs €/t | 10.0 | 16.0 | 21.0 | 13.9 | 19.9 | 24.9 |

| Total €/t | 1.2 | −4.8 | −9.8 | 3.3 | −2.7 | −7.7 |

| Total per kg N €/t | 0.3 | −1.2 | −2.4 | 0.6 | −0.5 | −1.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lyons, G.A.; Cathcart, A.; Frost, J.P.; Wills, M.; Johnston, C.; Ramsey, R.; Smyth, B. Review of Two Mechanical Separation Technologies for the Sustainable Management of Agricultural Phosphorus in Nutrient-Vulnerable Zones. Agronomy 2021, 11, 836. https://doi.org/10.3390/agronomy11050836

Lyons GA, Cathcart A, Frost JP, Wills M, Johnston C, Ramsey R, Smyth B. Review of Two Mechanical Separation Technologies for the Sustainable Management of Agricultural Phosphorus in Nutrient-Vulnerable Zones. Agronomy. 2021; 11(5):836. https://doi.org/10.3390/agronomy11050836

Chicago/Turabian StyleLyons, Gary A., Ashley Cathcart, J. Peter Frost, Michael Wills, Christopher Johnston, Rachael Ramsey, and Beatrice Smyth. 2021. "Review of Two Mechanical Separation Technologies for the Sustainable Management of Agricultural Phosphorus in Nutrient-Vulnerable Zones" Agronomy 11, no. 5: 836. https://doi.org/10.3390/agronomy11050836

APA StyleLyons, G. A., Cathcart, A., Frost, J. P., Wills, M., Johnston, C., Ramsey, R., & Smyth, B. (2021). Review of Two Mechanical Separation Technologies for the Sustainable Management of Agricultural Phosphorus in Nutrient-Vulnerable Zones. Agronomy, 11(5), 836. https://doi.org/10.3390/agronomy11050836