Diaphragm-Type Pneumatic-Driven Soft Grippers for Precision Harvesting

Abstract

:1. Introduction

2. Design and Manufacturing Approach

2.1. Materials

2.2. Soft Design

2.3. Design of the Rigid Structure

2.4. Manufacturing and Assembly

3. Control System

Electronic and Pneumatic System

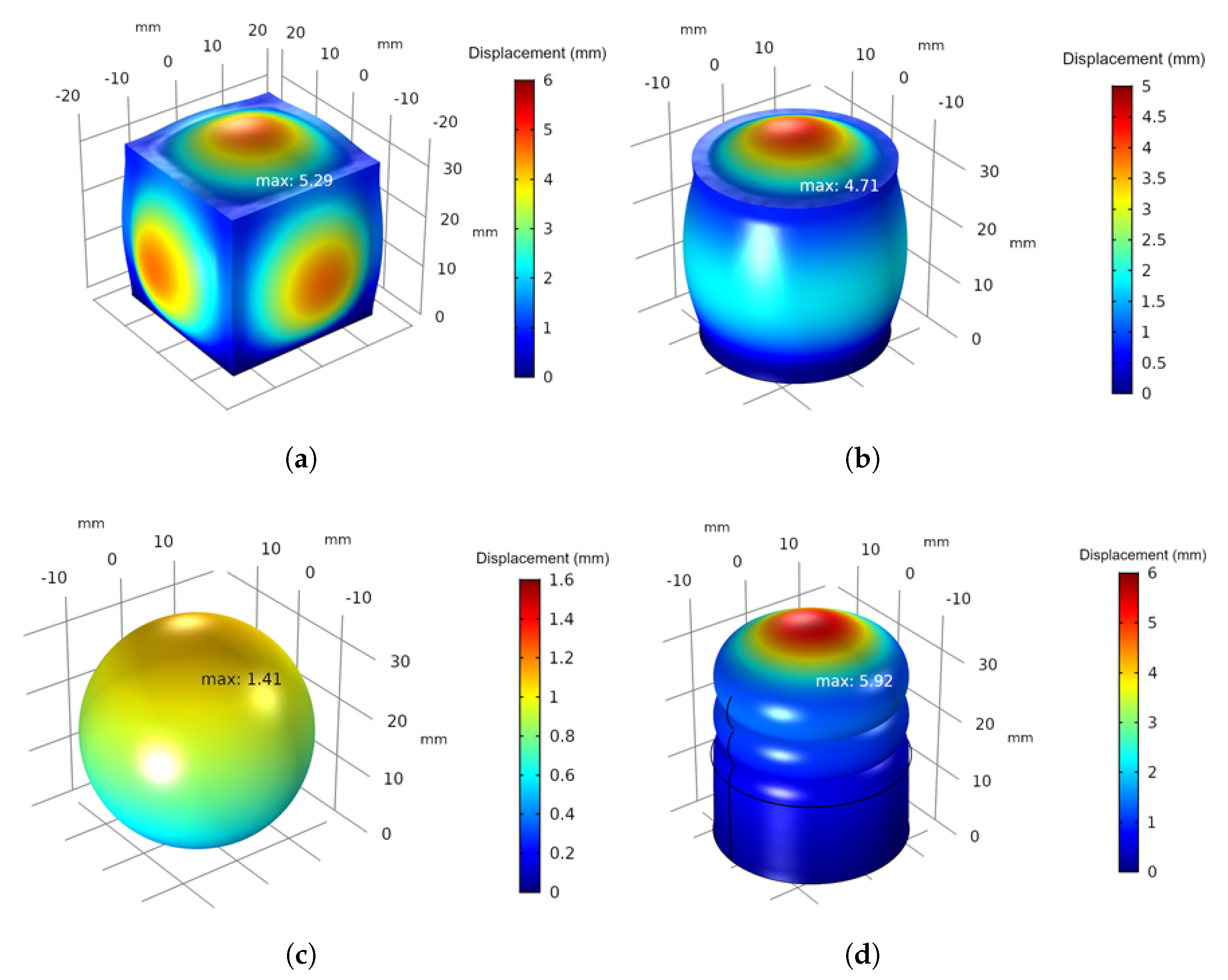

4. Determination of Soft Actuators Features

5. Evaluation

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Giannaccini, M.E.; Georgilas, I.; Horsfield, I.; Peiris, B.; Lenz, A.; Pipe, A.G.; Dogramadzi, S. A variable compliance, soft gripper. Auton. Robot. 2014, 36, 93–107. [Google Scholar] [CrossRef] [Green Version]

- Yap, H.K.; Lim, J.H.; Goh, J.C.H.; Yeow, C.H. Design of a Soft Robotic Glove for Hand Rehabilitation of Stroke Patients With Clenched Fist Deformity Using Inflatable Plastic Actuators. J. Med. Devices 2016, 10, 1932–6181. [Google Scholar] [CrossRef]

- Burgner-Kahrs, J.; Rucker, D.C.; Choset, H. Continuum Robots for Medical Applications: A Survey. IEEE Trans. Robot. 2015, 31, 1261–1280. [Google Scholar] [CrossRef]

- Polygerinos, P.; Wang, Z.; Galloway, K.C.; Wood, R.J.; Walsh, C.J. Soft robotic glove for combined assistance and at-home rehabilitation. Robot. Auton. Syst. 2015, 73, 135–143. [Google Scholar] [CrossRef] [Green Version]

- Ansari, Y.; Falotico, E.; Mollard, Y.; Busch, B.; Cianchetti, M.; Laschi, C. A Multiagent Reinforcement Learning approach for inverse kinematics of high dimensional manipulators with precision positioning. In Proceedings of the 2016 6th IEEE International Conference on Biomedical Robotics and Biomechatronics (BioRob), Singapore, 26–29 June 2016; pp. 457–463. [Google Scholar] [CrossRef] [Green Version]

- Goldfield, E.C.; Park, Y.L.; Chen, B.R.; Hsu, W.H.; Young, D.; Wehner, M.; Kelty-Stephen, D.G.; Stirling, L.; Weinberg, M.; Newman, D.; et al. Bio-Inspired Design of Soft Robotic Assistive Devices: The Interface of Physics, Biology, and Behavior. Ecol. Psychol. 2012, 24, 300–327. [Google Scholar] [CrossRef]

- Katzschmann, R.K.; DelPreto, J.; MacCurdy, R.; Rus, D. Exploration of underwater life with an acoustically controlled soft robotic fish. Sci. Robot. 2018, 3. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tolley, M.; Shepherd, R.; Mosadegh, B.; Galloway, K.; Wehner, M.; Karpelson, M.; Wood, R.; Whitesides, G. A Resilient, Untethered Soft Robot. Soft Robot. 2014, 1, 213–223. [Google Scholar] [CrossRef]

- Chowdhary, G.; Gazzola, M.; Krishnan, G.; Soman, C.; Lovell, S. Soft Robotics as an Enabling Technology for Agroforestry Practice and Research. Sustainability 2019, 11, 6751. [Google Scholar] [CrossRef] [Green Version]

- Anna, K. Shadow delivers first hand. Ind. Robot. Int. J. 2005, 32, 15–16. [Google Scholar] [CrossRef]

- Manti, M.; Hassan, T.; Passetti, G.; D’Elia, N.; Laschi, C.; Cianchetti, M. A bioinspired soft robotic gripper for adaptable and effective grasping. Soft Robot. 2015, 2, 107–116. [Google Scholar] [CrossRef]

- De Barrie, D.; Margetts, R.; Goher, K. Simpa: Soft-grasp infant myoelectric prosthetic arm. IEEE Robot. Autom. Lett. 2020, 5, 698–703. [Google Scholar] [CrossRef]

- Konishi, S.; Shimomura, S.; Tajima, S.; Tabata, Y. Implementation of soft microfingers for a hMSC aggregate manipulation system. Microsyst. Nanoeng. 2016, 2, 1–7. [Google Scholar] [CrossRef]

- Renda, F.; Cianchetti, M.; Giorelli, M.; Arienti, A.; Laschi, C. A 3D steady-state model of a tendon-driven continuum soft manipulator inspired by the octopus arm. Bioinspir. Biomim. 2012, 7, 025006. [Google Scholar] [CrossRef]

- McMahan, W.; Chitrakaran, V.; Csencsits, M.; Dawson, D.; Walker, I.D.; Jones, B.A.; Pritts, M.; Dienno, D.; Grissom, M.; Rahn, C.D. Field trials and testing of the OctArm continuum manipulator. In Proceedings of the 2006 IEEE International Conference on Robotics and Automation, ICRA 2006, Orlando, FL, USA, 15–19 May 2006; pp. 2336–2341. [Google Scholar]

- Marchese, A.D.; Onal, C.D.; Rus, D. Autonomous soft robotic fish capable of escape maneuvers using fluidic elastomer actuators. Soft Robot. 2014, 1, 75–87. [Google Scholar] [CrossRef] [Green Version]

- Calisti, M.; Arienti, A.; Giannaccini, M.E.; Follador, M.; Giorelli, M.; Cianchetti, M.; Mazzolai, B.; Laschi, C.; Dario, P. Study and fabrication of bioinspired octopus arm mockups tested on a multipurpose platform. In Proceedings of the 2010 3rd IEEE RAS & EMBS International Conference on Biomedical Robotics and Biomechatronics, Tokyo, Japan, 26–29 September 2010; pp. 461–466. [Google Scholar]

- Manti, M.; Cacucciolo, V.; Cianchetti, M. Stiffening in soft robotics: A review of the state of the art. IEEE Robot. Autom. Mag. 2016, 23, 93–106. [Google Scholar] [CrossRef]

- Duckett, T.; Pearson, S.; Blackmore, S.; Grieve, B.; Chen, W.H.; Cielniak, G.; Cleaversmith, J.; Dai, J.; Davis, S.; Fox, C.; et al. Agricultural robotics: The future of robotic agriculture. arXiv 2018, arXiv:1806.06762. [Google Scholar]

- Li, Z.; Miao, F.; Yang, Z.; Wang, H. An anthropometric study for the anthropomorphic design of tomato-harvesting robots. Comput. Electron. Agric. 2019, 163, 104881. [Google Scholar] [CrossRef]

- Yaguchi, H.; Nagahama, K.; Hasegawa, T.; Inaba, M. Development of an autonomous tomato harvesting robot with rotational plucking gripper. In Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Korea, 9–14 October 2016; pp. 652–657. [Google Scholar]

- Mu, L.; Cui, G.; Liu, Y.; Cui, Y.; Fu, L.; Gejima, Y. Design and simulation of an integrated end-effector for picking kiwifruit by robot. Inf. Process. Agric. 2020, 7, 58–71. [Google Scholar] [CrossRef]

- Huang, Z.; Sklar, E.; Parsons, S. Design of automatic strawberry harvest robot suitable in complex environments. In Proceedings of the Companion of the 2020 ACM/IEEE International Conference on Human-Robot Interaction, Cambridge, UK, 23–26 March 2020; pp. 567–569. [Google Scholar]

- United Nations Department of Economic and Social Affairs. United Nations Department of Economic and Social Affairs, Population Division. World Population Prospects: The 2015 Revision, Key Findings and Advance Tables; Technical Report; Working Paper No. ESA/P/WP. 241; United Nations Department of Economic and Social Affairs: New York, NY, USA, 2015. [Google Scholar]

- Vu, Q.; Kuzov, M.; Ronzhin, A. Hierarchical classification of robotic grippers applied for agricultural object manipulations. In Proceedings of the MATEC Web of Conferences, St. Petersburg, Russia, 18–29 April 2018; Volume 161, p. 03015. [Google Scholar]

- Gonzalez-de-Santos, P.; Fernández, R.; Sepúlveda, D.; Navas, E.; Emmi, L.; Armada, M. Field Robots for Intelligent Farms—Inhering Features from Industry. Agronomy 2020, 10, 1638. [Google Scholar] [CrossRef]

- Font, D.; Pallejà, T.; Tresanchez, M.; Runcan, D.; Moreno, J.; Martínez, D.; Teixidó, M.; Palacín, J. A proposal for automatic fruit harvesting by combining a low cost stereovision camera and a robotic arm. Sensors 2014, 14, 11557–11579. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Salinas, C.; Fernández, R.; Montes, H.; Armada, M. A New Approach for Combining Time-of-Flight and RGB Cameras Based on Depth-Dependent Planar Projective Transformations. Sensors 2015, 15, 24615–24643. [Google Scholar] [CrossRef] [Green Version]

- Fernández, R.; Montes, H.; Salinas, C. VIS-NIR, SWIR and LWIR Imagery for Estimation of Ground Bearing Capacity. Sensors 2015, 15, 13994–14015. [Google Scholar] [CrossRef] [Green Version]

- Fernandez, R.; Montes, H.; Surdilovic, J.; Surdilovic, D.; Gonzalez-De-Santos, P.; Armada, M. Automatic detection of field-grown cucumbers for robotic harvesting. IEEE Access 2018, 6, 35512–35527. [Google Scholar] [CrossRef]

- Agostini, A.; Alenya, G.; Fischbach, A.; Scharr, H.; Woergoetter, F.; Torras, C. A cognitive architecture for automatic gardening. Comput. Electron. Agric. 2017, 138, 69–79. [Google Scholar] [CrossRef] [Green Version]

- Zion, B.; Mann, M.; Levin, D.; Shilo, A.; Rubinstein, D.; Shmulevich, I. Harvest-order planning for a multiarm robotic harvester. Comput. Electron. Agric. 2014, 103, 75–81. [Google Scholar] [CrossRef]

- Masuzawa, H.; Miura, J.; Oishi, S. Development of a mobile robot for harvest support in greenhouse horticulture—Person following and mapping. In Proceedings of the 2017 IEEE/SICE International Symposium on System Integration (SII), Taipei, Taiwan, 11–14 December 2017; pp. 541–546. [Google Scholar] [CrossRef]

- Boyraz, P.; Runge, G.; Raatz, A. An overview of novel actuators for soft robotics. Actuators 2018, 7, 48. [Google Scholar] [CrossRef] [Green Version]

- Shintake, J.; Cacucciolo, V.; Floreano, D.; Shea, H. Soft robotic grippers. Adv. Mater. 2018, 30, 1707035. [Google Scholar] [CrossRef] [Green Version]

- Navas, E.; Fernández, R.; Sepúlveda, D.; Armada, M.; Gonzalez-de Santos, P. Soft Grippers for Automatic Crop Harvesting: A Review. Sensors 2021, 21, 2689. [Google Scholar] [CrossRef] [PubMed]

- Falco, J.; Van Wyk, K.; Liu, S.; Carpin, S. Grasping the performance: Facilitating replicable performance measures via benchmarking and standardized methodologies. IEEE Robot. Autom. Mag. 2015, 22, 125–136. [Google Scholar] [CrossRef]

- Navas, E.; Fernandez, R.; Sepúlveda, D.; Armada, M.; Gonzalez-de Santos, P. A Design Criterion Based on Shear Energy Consumption for Robotic Harvesting Tools. Agronomy 2020, 10, 734. [Google Scholar] [CrossRef]

- Sepúlveda, D.; Fernández, R.; Navas, E.; González-de Santos, P.; Armada, M. ROS framework for perception and dual-arm manipulation in unstructured environments. In Iberian Robotics Conference; Springer: Cham, Switzerland, 2019; pp. 137–147. [Google Scholar]

- Navas, E.; Fernández, R.; Sepúlveda, D.; Armada, M.; Gonzalez-de Santos, P. Soft Gripper for Robotic Harvesting in Precision Agriculture Applications. In Proceedings of the 2021 IEEE International Conference on Autonomous Robot Systems and Competitions (ICARSC), Santa Maria da Feira, Portugal, 28–29 April 2021; pp. 167–172. [Google Scholar]

- Hsiao, L.Y.; Jing, L.; Li, K.; Yang, H.; Li, Y.; Chen, P.Y. Carbon nanotube-integrated conductive hydrogels as multifunctional robotic skin. Carbon 2020, 161, 784–793. [Google Scholar] [CrossRef]

- Mosadegh, B.; Polygerinos, P.; Keplinger, C.; Wennstedt, S.; Shepherd, R.F.; Gupta, U.; Shim, J.; Bertoldi, K.; Walsh, C.J.; Whitesides, G.M. Pneumatic networks for soft robotics that actuate rapidly. Adv. Funct. Mater. 2014, 24, 2163–2170. [Google Scholar] [CrossRef]

- Wang, Z.; Or, K.; Hirai, S. A dual-mode soft gripper for food packaging. Robot. Auton. Syst. 2020, 125, 103427. [Google Scholar] [CrossRef]

- Shih, B.; Drotman, D.; Christianson, C.; Huo, Z.; White, R.; Christensen, H.I.; Tolley, M.T. Custom soft robotic gripper sensor skins for haptic object visualization. In Proceedings of the 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; pp. 494–501. [Google Scholar]

- Connolly, F.; Walsh, C.J.; Bertoldi, K. Automatic design of fiber-reinforced soft actuators for trajectory matching. Proc. Natl. Acad. Sci. USA 2017, 114, 51–56. [Google Scholar] [CrossRef] [Green Version]

- Seibel, A.; Yıldız, M.; Zorlubaş, B. A Gecko-Inspired Soft Passive Gripper. Biomimetics 2020, 5, 12. [Google Scholar] [CrossRef] [Green Version]

- Teeple, C.B.; Koutros, T.N.; Graule, M.A.; Wood, R.J. Multi-segment soft robotic fingers enable robust precision grasping. Int. J. Robot. Res. 2020, 39, 1647–1667. [Google Scholar] [CrossRef]

- Galloway, K.C.; Becker, K.P.; Phillips, B.; Kirby, J.; Licht, S.; Tchernov, D.; Wood, R.J.; Gruber, D.F. Soft robotic grippers for biological sampling on deep reefs. Soft Robot. 2016, 3, 23–33. [Google Scholar] [CrossRef]

- Galley, A.; Knopf, G.K.; Kashkoush, M. Pneumatic Hyperelastic Actuators for Grasping Curved Organic Objects. Actuators 2019, 8, 76. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Rodrigue, H.; Kim, H.I.; Han, M.W.; Ahn, S.H. Soft composite hinge actuator and application to compliant robotic gripper. Compos. Part B Eng. 2016, 98, 397–405. [Google Scholar] [CrossRef]

- Rodrigue, H.; Wang, W.; Kim, D.R.; Ahn, S.H. Curved shape memory alloy-based soft actuators and application to soft gripper. Compos. Struct. 2017, 176, 398–406. [Google Scholar] [CrossRef]

- Modabberifar, M.; Spenko, M. A shape memory alloy-actuated gecko-inspired robotic gripper. Sens. Actuators A Phys. 2018, 276, 76–82. [Google Scholar] [CrossRef]

- Johnston, I.; McCluskey, D.; Tan, C.; Tracey, M. Mechanical characterization of bulk Sylgard 184 for microfluidics and microengineering. J. Micromech. Microeng. 2014, 24, 035017. [Google Scholar] [CrossRef]

- Wang, Z.; Xiang, C.; Yao, X.; Le Floch, P.; Mendez, J.; Suo, Z. Stretchable materials of high toughness and low hysteresis. Proc. Natl. Acad. Sci. USA 2019, 116, 5967–5972. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, T.K.; Kim, J.K.; Jeong, O.C. Measurement of nonlinear mechanical properties of PDMS elastomer. Microelectron. Eng. 2011, 88, 1982–1985. [Google Scholar] [CrossRef]

- Ogden, R.W. Large deformation isotropic elasticity–on the correlation of theory and experiment for incompressible rubberlike solids. Proc. R. Soc. Lond. A Math. Phys. Sci. 1972, 326, 565–584. [Google Scholar] [CrossRef]

- The future of plastic. Nat. Commun. 2018, 9, 1723–2041.

- Krishnan, S.; Pandey, P.; Mohanty, S.; Nayak, S.K. Toughening of polylactic acid: An overview of research progress. Polymer-Plast. Technol. Eng. 2016, 55, 1623–1652. [Google Scholar] [CrossRef]

- Odent, J.; Raquez, J.M.; Dubois, P. Highly toughened polylactide-based materials through melt-blending techniques. Biodegrad. Polyest. 2015, 235–274. [Google Scholar] [CrossRef]

- Zeng, J.B.; Li, K.A.; Du, A.K. Compatibilization strategies in poly (lactic acid)-based blends. RSC Adv. 2015, 5, 32546–32565. [Google Scholar] [CrossRef]

- Kfoury, G.; Raquez, J.M.; Hassouna, F.; Odent, J.; Toniazzo, V.; Ruch, D.; Dubois, P. Recent advances in high performance poly (lactide): From “green” plasticization to super-tough materials via (reactive) compounding. Front. Chem. 2013, 1, 32. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, H.; Zhang, J. Research progress in toughening modification of poly (lactic acid). J. Polym. Sci. Part B Polym. Phys. 2011, 49, 1051–1083. [Google Scholar] [CrossRef]

- Anderson, K.S.; Schreck, K.M.; Hillmyer, M.A. Toughening polylactide. Polym. Rev. 2008, 48, 85–108. [Google Scholar] [CrossRef]

- Rasal, R.M.; Janorkar, A.V.; Hirt, D.E. Poly (lactic acid) modifications. Prog. Polym. Sci. 2010, 35, 338–356. [Google Scholar] [CrossRef]

- Nagarajan, V.; Mohanty, A.K.; Misra, M. Perspective on polylactic acid (PLA) based sustainable materials for durable applications: Focus on toughness and heat resistance. ACS Sustain. Chem. Eng. 2016, 4, 2899–2916. [Google Scholar] [CrossRef]

- Martinez, R.V.; Branch, J.L.; Fish, C.R.; Jin, L.; Shepherd, R.F.; Nunes, R.M.; Suo, Z.; Whitesides, G.M. Robotic tentacles with three-dimensional mobility based on flexible elastomers. Adv. Mater. 2013, 25, 205–212. [Google Scholar] [CrossRef] [PubMed]

- Hao, Y.; Gong, Z.; Xie, Z.; Guan, S.; Yang, X.; Ren, Z.; Wang, T.; Wen, L. Universal soft pneumatic robotic gripper with variable effective length. In Proceedings of the 2016 35th Chinese Control Conference (CCC), Chengdu, China, 27–29 July 2016; pp. 6109–6114. [Google Scholar]

- Zhou, J.; Chen, S.; Wang, Z. A soft-robotic gripper with enhanced object adaptation and grasping reliability. IEEE Robot. Autom. Lett. 2017, 2, 2287–2293. [Google Scholar] [CrossRef]

- Friend, J.; Yeo, L. Fabrication of microfluidic devices using polydimethylsiloxane. Biomicrofluidics 2010, 4, 026502. [Google Scholar] [CrossRef] [Green Version]

- Rateni, G.; Cianchetti, M.; Ciuti, G.; Menciassi, A.; Laschi, C. Design and development of a soft robotic gripper for manipulation in minimally invasive surgery: A proof of concept. Meccanica 2015, 50, 2855–2863. [Google Scholar] [CrossRef] [Green Version]

- Linghu, C.; Zhang, S.; Wang, C.; Yu, K.; Li, C.; Zeng, Y.; Zhu, H.; Jin, X.; You, Z.; Song, J. Universal SMP gripper with massive and selective capabilities for multiscaled, arbitrarily shaped objects. Sci. Adv. 2020, 6, eaay5120. [Google Scholar] [CrossRef] [Green Version]

- Rus, D.; Tolley, M.T. Design, fabrication and control of soft robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef] [Green Version]

- Duriez, C. Control of elastic soft robots based on real-time finite element method. In Proceedings of the 2013 IEEE International Conference on Robotics and Automation, Karlsruhe, Germany, 6–10 May 2013; pp. 3982–3987. [Google Scholar]

- Park, W.; Seo, S.; Oh, J.; Bae, J. A Sensorized Hybrid Gripper to Evaluate a Grasping Quality Based on a Largest Minimum Wrench. IEEE Robot. Autom. Lett. 2020, 5, 3243–3250. [Google Scholar] [CrossRef]

- McKenzie, R.M.; Barraclough, T.W.; Stokes, A.A. Integrating soft robotics with the robot operating system: A hybrid pick and place arm. Front. Robot. AI 2017, 4, 39. [Google Scholar] [CrossRef] [Green Version]

- Xydas, N.; Kao, I. Modeling of contact mechanics and friction limit surfaces for soft fingers in robotics, with experimental results. Int. J. Robot. Res. 1999, 18, 941–950. [Google Scholar] [CrossRef]

- Li, Y.; Kao, I. A review of modeling of soft-contact fingers and stiffness control for dextrous manipulation in robotics. In Proceedings of the Proceedings 2001 ICRA. IEEE International Conference on Robotics and Automation (Cat. No. 01CH37164), Seoul, Korea, 21–26 May 2001; Volume 3, pp. 3055–3060. [Google Scholar]

- Robotics Company | Robotic Assistive Technology | Kinova. 2019. Available online: https://www.kinovarobotics.com (accessed on 29 August 2021).

- Navas, E.; Fernández, R.; Sepúlveda, D.; Armada, M.; Gonzalez-de Santos, P. Modular dual-arm robot for precision harvesting. In Iberian Robotics Conference; Springer: Cham, Switzerland, 2019; pp. 148–158. [Google Scholar]

- Sepúlveda, D.; Fernández, R.; Navas, E.; Armada, M.; González-De-Santos, P. Robotic aubergine harvesting using dual-arm manipulation. IEEE Access 2020, 8, 121889–121904. [Google Scholar] [CrossRef]

- Krahn, J.M.; Fabbro, F.; Menon, C. A soft-touch gripper for grasping delicate objects. IEEE/ASME Trans. Mechatronics 2017, 22, 1276–1286. [Google Scholar] [CrossRef]

- Wang, Y.; Gupta, U.; Parulekar, N.; Zhu, J. A soft gripper of fast speed and low energy consumption. Sci. China Technol. Sci. 2019, 62, 31–38. [Google Scholar] [CrossRef]

- Igathinathane, C.; Pordesimo, L.; Schilling, M.; Columbus, E. Fast and simple measurement of cutting energy requirement of plant stalk and prediction model development. Ind. Crop. Prod. 2011, 33, 518–523. [Google Scholar] [CrossRef]

- Visvanathan, R.; Sreenarayanan, V.; Swaminathan, K. Effect of knife angle and velocity on the energy required to cut cassava tubers. J. Agric. Eng. Res. 1996, 64, 99–102. [Google Scholar] [CrossRef]

- Azadbakht, M.; Asl, A.R.; Zahedi, K.T. Energy requirement for cutting corn stalks (Single Cross 704 Var.). Int. J. Biol. Food Vet. Agric. Eng 2014, 8, 471–474. [Google Scholar]

| Characteristic | Value |

|---|---|

| Pressure range | 0.005–0.9 Mpa |

| Max. supply pressure | 1.0 MPa |

| Power consumption | 4 W |

| Max. flow rate | 1500 L/min |

| Input signal | 0–10 Vdc |

| Mass | 0.350 kg |

| Linearity | ±1% |

| Hysteresis | 0.5% |

| Repeatability | ±0.5% |

| Response time | 0.1 s |

| Characteristic | Value |

|---|---|

| Nonlinearity | ±1% |

| Hysteresis | ±1% |

| Thermal Zero Shift | ±2.5 mV/50 °C |

| Thermal Sensitivity | ±2.5%/50 °C |

| Deflection at “FS” | <0.013 mm nom. |

| Operating Temperature | (−40 to 120) °C |

| Thickness | 3.81 mm |

| Diameter | 25.4 mm |

| Characteristic | Value |

|---|---|

| Mass of a single module fully mounted | kg |

| Max. displacement of the soft actuator (75 kPa) | 0.017 m |

| Max. contact force (75 kPa) | 54 N |

| Operating pressure range | 0–75 kPa |

| Mass of a fully assembled single floor hexagon configuration | 0.3 kg |

| Slip payload test (50 kPa) | 10 kg |

| Mean response time | ≈1 s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Navas, E.; Fernández, R.; Armada, M.; Gonzalez-de-Santos, P. Diaphragm-Type Pneumatic-Driven Soft Grippers for Precision Harvesting. Agronomy 2021, 11, 1727. https://doi.org/10.3390/agronomy11091727

Navas E, Fernández R, Armada M, Gonzalez-de-Santos P. Diaphragm-Type Pneumatic-Driven Soft Grippers for Precision Harvesting. Agronomy. 2021; 11(9):1727. https://doi.org/10.3390/agronomy11091727

Chicago/Turabian StyleNavas, Eduardo, Roemi Fernández, Manuel Armada, and Pablo Gonzalez-de-Santos. 2021. "Diaphragm-Type Pneumatic-Driven Soft Grippers for Precision Harvesting" Agronomy 11, no. 9: 1727. https://doi.org/10.3390/agronomy11091727

APA StyleNavas, E., Fernández, R., Armada, M., & Gonzalez-de-Santos, P. (2021). Diaphragm-Type Pneumatic-Driven Soft Grippers for Precision Harvesting. Agronomy, 11(9), 1727. https://doi.org/10.3390/agronomy11091727