The Effect of Treating String Bean Pods with Modified Atmosphere Packaging and UV-C Irradiation on Their Storage Life

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plant Material

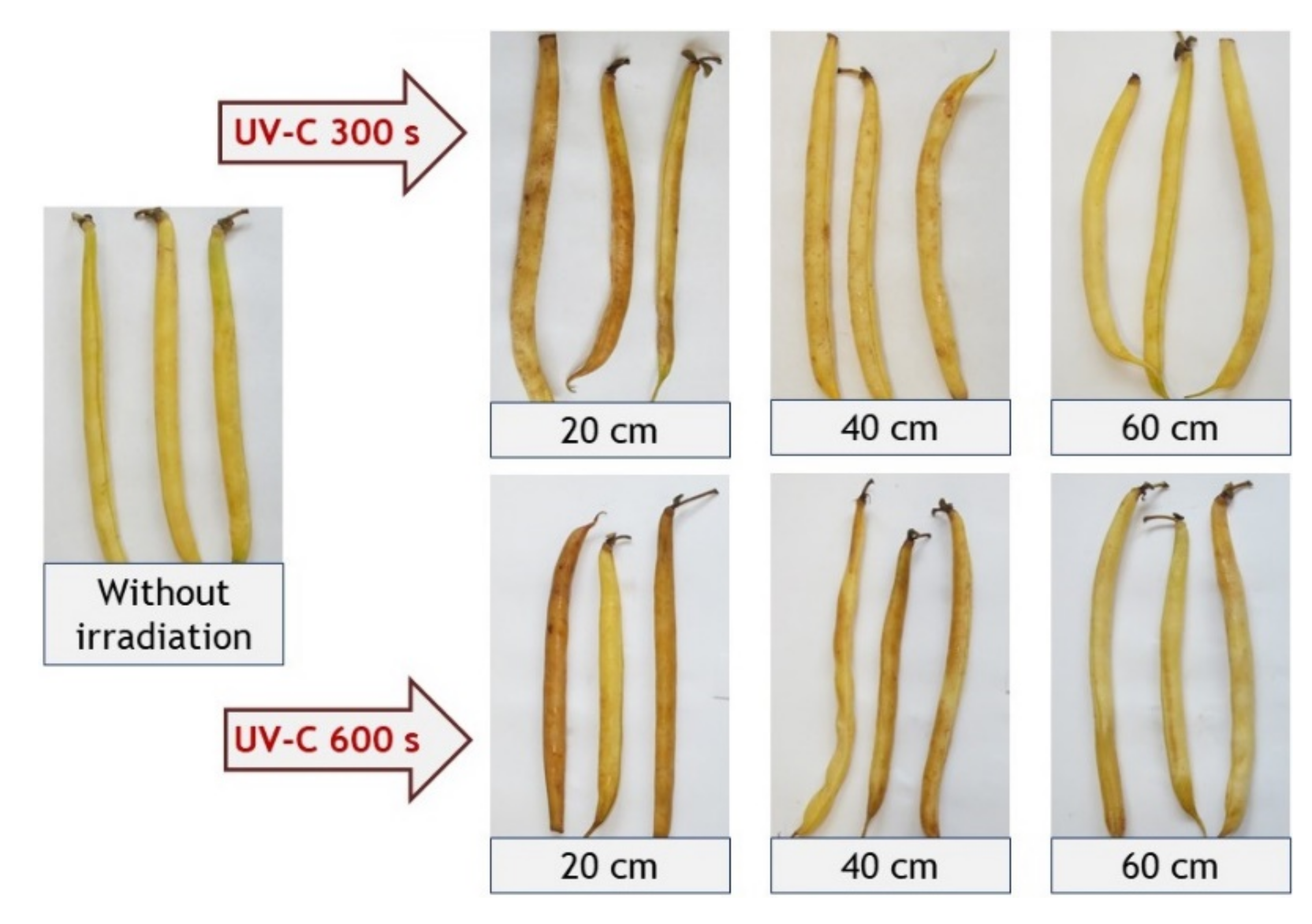

2.2. Experimental Factors, Sample Preparation

2.3. Xtend® Bags

2.4. UV-C Irradiation

2.5. Storage Conditions of Bean Pods

2.6. Chemical Observations, Measurements and Analyses

2.7. Statistical Analysis

- Yijl—the value of the characteristic, μ—population mean, Ai—the effect of the i-th level of factor A (pcking method), Bj—the effect of the j-th level of factor B (UV-C irradiation),

- ABij—the effect of the interaction of the i-th level of factor A with the j-th level of factor B,

- eijl—random error [32].

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sarron, E.; Gadonna-Widehem, P.; Aussenac, T. Ozone treatments for preserving fresh vegetables quality: A critical review. Foods 2021, 10, 605. [Google Scholar] [CrossRef] [PubMed]

- Miller, F.A.; Silva, C.L.M.; Brandão, T.R.S. A review on ozone-based treatments for fruit and vegetables preservation. Food Eng. Rev. 2013, 5, 77–106. [Google Scholar] [CrossRef]

- Horvitz, S.; Cantalejo, M.J. Application of ozone for the postharvest treatment of fruits and vegetables. Crit. Rev. Food Sci. Nutr. 2014, 54, 312–339. [Google Scholar] [CrossRef] [PubMed]

- Severino, R.; Vu, K.D.; Donsì, F.; Salmieri, S.; Ferrari, G.; Lacroix, M. Antibacterial and physical effects of modified chitosan based-coating containing nanoemulsion of mandaryn essential oil and three non-thermal treatments against Listeria innocua in green beans. Int. J. Food Microbiol. 2014, 191, 82–88. [Google Scholar] [CrossRef] [PubMed]

- El-Mogy, M.M.; Kitinoja, L. Review of Best Postharvest Practices for Fresh Market Green Beans; PEF White paper, No. 19-01; The Postharvest Education Foundation: La pine, OH, USA, 2019; p. 19. [Google Scholar]

- Turgis, M.; Han, J.; Caillet, S.; Lacroix, M. Antimicrobial activity of mustard essential oil against Escherichia coli O157:H7 and Salmonella typhi. Food Control 2009, 20, 1073–1079. [Google Scholar] [CrossRef]

- Severino, R.; Ferrari, G.; Vu, K.D.; Donsì, F.; Salmieri, S.; Lacroix, M. Antimicrobial effects of modified chitosan based coating containing nanoemulsion of essential oils, modified atmosphere packaging and gamma irradiation against Escherichia coli O157:H7 and Salmonella Typhimurium on green beans. Food Control 2015, 50, 215–222. [Google Scholar] [CrossRef]

- El-Mogy, M.M.; Alsanius, B.W. Cassia oil for controlling plant and human pathogens on fresh strawberries. Food Control 2012, 28, 157–162. [Google Scholar] [CrossRef]

- Donsì, F.; Marchese, E.; Maresca, P.; Pataro, G.; Vu, K.D.; Salmieri, S.; Lacroix, M.; Ferrari, G. Green beans preservation by combination of a modified chitosan based-coating containing nanoemulsion of mandarin essential oil with high pressure or pulsed light processing. Postharvest Biol. Technol. 2015, 106, 21–32. [Google Scholar] [CrossRef]

- Kashiwabuchi, R.T.; Khan, Y.; de Souza Carvalho, F.R.; Hirai, F.; Campos, M.S.; McDonnell, P.J. Antimicrobial susceptibility of photodynamic therapy (UVA/riboflavin) against Staphylococcus aureus. Arq. Bras. Oftalmol. 2012, 75, 423–426. [Google Scholar] [CrossRef]

- Tomaszewska-Sowa, M.; Figas, A.; Keutgen, N.; Keutgen, A.J. Establishing an efficient explant superficial sterilization protocol for in vitro micropropagation of bear’s garlic (Allium ursinum L.). Herba Polonica 2015, 61, 66–77. [Google Scholar] [CrossRef] [Green Version]

- Mercier, J.; Baka, M.; Reddy, B.; Corcuff, R.; Arul, J. Shortwave ultraviolet irradiation for control of decay caused by Botrytis cinereain bell pepper: Induced resistance and germicidal effects. J. Amer. Soc. Hort. Sci. 2001, 126, 128–133. [Google Scholar] [CrossRef] [Green Version]

- Escalona, V.H.; Aguayo, E.; Martinez-Hernandez, G.B.; Artes, F. UV-C doses to reduce pathogen and spoilage bacterial growth in vitro and in baby spinach. Postharvest Biol. Technol. 2010, 56, 223–231. [Google Scholar] [CrossRef]

- Lamikanra, O.; Kueneman, D.; Ukuku, D.; Bett-Garber, K.L. Effect of processing under ultraviolet light on the shelf life of fresh-cut cantaloupe melon. J. Food Sci. 2006, 70, 534–539. [Google Scholar] [CrossRef]

- Darvishi, S.; Fatemi, A.; Davari, K. Keeping quality of use of fresh ’Kurdistan’ strawberry by UV-C radiation. World Appl. Sci. J. 2012, 17, 826–831. [Google Scholar]

- Wang, C.Y.; Chen, C.T.; Wang, S.Y. Changes of flavonoid content and antioxidant capacity in blueberries after illumination with UV-C. Food Chem. 2009, 117, 426–431. [Google Scholar] [CrossRef]

- Bintsis, T.; Litopoulou-Tzanetaki, E.; Robinson, R.K. Existing and potential application of ultraviolet light in the food industry—A critical review. J. Sci. Food Agric. 2000, 80, 637–645. [Google Scholar] [CrossRef]

- Krishnamurthy, K. Decontamination of Milk and Water by Pulsed UV-Light and Infrared Heating. Ph.D. Thesis, Pennsylvania State University, State College, PA, USA, 2006; p. 226. [Google Scholar]

- Pataro, G.; Donsìb, G.; Ferraria, G. Post-harvest UV-C and PL irradiation of fruits and vegetables. Chem. Eng. Trans. 2015, 44, 31–36. [Google Scholar]

- Ribeiro, C.; Canada, J.; Alvarenga, B. Prospects of UV radiation for application in post-harvest technology. Emir. J. Food Agric. 2012, 24, 586–597. [Google Scholar] [CrossRef]

- Saxena, A.; Bawa, A.S.; Srinivas Raju, P. Use of modified atmosphere packaging to extend shelf-life of minimally processed jackfruit (Artocarpus heterophyllus L.) bulbs. J. Food Eng. 2008, 87, 455–466. [Google Scholar] [CrossRef]

- Oliveira, M.; Usall, J.; Solsona, C.; Alegre, I.; Viñas, I.; Abadias, M. Effects of packaging type and storage temperature on the growth of foodborne pathogens on shredded ‘Romaine’ lettuce. Food Microbiol. 2010, 27, 375–380. [Google Scholar] [CrossRef]

- Esturk, O.; Ayhan, Z.; Ustunel, M.A. Modified atmosphere packaging of ‘Napoleon’ cherry: Effect of packaging material and storage time on physical, chemical, and sensory quality. Food Bioprocess Technol. 2012, 5, 1295–1304. [Google Scholar] [CrossRef]

- Sandhya. Modified atmosphere packaging of fresh produce: Current status and future needs. LWT—Food Sci. Technol. 2010, 43, 381–392. [Google Scholar] [CrossRef]

- Caleb, O.J.; Opara, U.L.; Witthuhn, C.R. Modified atmosphere packaging of pomegranate fruit and arils: A review. Food Bioprocess Technol. 2012, 5, 15–30. [Google Scholar] [CrossRef]

- Cantwell, M.; Suslow, T.V. Green Beans: Recommendations for Maintaining Postharvest Quality; Postharvest Technology Research Information Center, University of California: Davis, CA, USA, 2010. [Google Scholar]

- Sánchez-Mata, M.C.; Cámara, M.; Díez-Marqués, C. Extending shelf-life and nutritive value of green beans (Phaseolus vulgaris L.), by controlled atmosphere storage: Macronutrients. Food Chem. 2003, 80, 309–315. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis. Association of Official Analytical Chemists, 18th ed.; AOAC INTERNATIONAL: Gaithersburg, MA, USA, 2005. [Google Scholar]

- European Union. Commission Regulation NO 152/2009. Off. J. Eur. Union 2009, 54, 1–130. [Google Scholar]

- PN-A-04019. Food Products—Determination of Vitamin C Content—Produkty Spożywcze—Oznaczanie Zawartości Witaminy C; Polish Committee for Standardization: Warsaw, Poland, 1998. (In Polish) [Google Scholar]

- Stratil, P.; Klejdus, B.; Kubáň, V. Determination of total content of phenolic compounds and their antioxidant activity in vegetables evaluation of spectrophotometric methods. J. Agric. Food Chem. 2006, 54, 607–616. [Google Scholar] [CrossRef]

- Trętowski, J.; Wójcik, R. Methodology of Agricultural Experiments, (Metodologia Badań Rolniczych); University of Agriculture and Education: Siedlce, Poland, 1999; p. 500. (In Polish) [Google Scholar]

- Guler, S.K.; Karakaya, O.; Karakaya, M.; Ozturk, B.; Aglar, E.; Yarılgac, T.; Gün, S. Combined treatments of modified atmosphere packaging with aminoethoxyvinylglycine maintained fruit quality in sweet cherry throughout cold storage and shelf life. Acta Sci. Pol. Hortorum Cultus 2019, 18, 13–26. [Google Scholar] [CrossRef]

- Pan, J.; Vicente, A.R.; Martinez, G.A.; Chaves, A.R.; Civello, P.M. Combined use of UV-C irradiation and heat treatment to improve postharvest life of strawberry fruit. J. Sci. Food Agric. 2004, 84, 1831–1838. [Google Scholar] [CrossRef]

- Manzocco, L.; Plazzotta, S.; Maifreni, M.; Calligaris, S.; Anese, M.; Nicoli, M.C. Impact of UV-C light on storage quality of fresh-cut pineapple in two different packages. LWT—Food Sci. Technol. 2016, 65, 1138–1143. [Google Scholar] [CrossRef]

- Proulx, E.; Yagiz, Y.; Nunes, M.C.N.; Emond, J. Quality attributes limiting green bean (Phaseolus vulgaris L.) postharvest life at chilling and non-chilling temperatures. HortScience 2010, 45, 1238–1249. [Google Scholar] [CrossRef] [Green Version]

- Ben-Yehoshua, S.; Rodov, V.; Kim, J.J.; Carmeli, S. Preformed and induced antifungal materials of citrus fruits in relation to the enhancement of decay resistance by heat and ultraviolet treatments. J. Agric. Food Chem. 1992, 40, 1217–1221. [Google Scholar] [CrossRef]

- Chaudhary, P.R.; Jayaprakasha, G.K.; Porat, R.; Patil, B.S. Influence of modified atmosphere packaging on ‘Star Ruby’ grapefruit phytochemicals. J. Agric. Food Chem. 2015, 63, 1020–1028. [Google Scholar] [CrossRef]

- Erkan, M.; Wang, C.Y.; Krizek, D.T. UV-C irradiation reduces microbial populations and deterioration in Cucurbita pepo fruit tissue. Environ. Exp. Bot. 2001, 45, 1–9. [Google Scholar] [CrossRef]

- Artés-Hernández, F.; Robles, P.A.; Gómez, P.A.; Tomás-Callejas, A.; Artés, F. Low UV-C illumination for keeping overall quality of fresh-cut watermelon. Postharvest Biol. Technol. 2010, 55, 114–120. [Google Scholar] [CrossRef]

- Costa, L.; Vicente, A.R.; Civello, P.M.; Chaves, A.R.; Martínez, G.A. UV-C treatment delays postharvest senescence in broccoli florets. Postharvest Biol. Technol. 2006, 39, 204–210. [Google Scholar] [CrossRef]

- Artés-Hernández, F.; Escalona, V.H.; Robles, P.A.; Martínez-Hernández, G.B.; Artés, F. Effect of UV-C radiation on quality of minimally processed spinach leaves. J. Sci. Food Agric. 2009, 89, 414–421. [Google Scholar] [CrossRef]

- Perkins-Veazie, P.; Collins, J.K.; Howard, L. Blueberry fruit response to postharvest application of ultraviolet radiation. Postharvest Biol. Technol. 2008, 47, 280–285. [Google Scholar] [CrossRef]

- Cisneros-Zevallos, L. The use of controlled postharvest abiotic stresses as a tool for enhancing the nutraceutical content and adding-value of fresh fruits and vegetables. J. Food Sci. 2003, 68, 1560–1565. [Google Scholar] [CrossRef]

- Martínez-Hernández, G.B.; Gómez, P.A.; Pradas, I.; Artés, F.; Artés-Hernández, F. Moderate UV-C pretreatment as a quality enhancement tool in fresh-cut Bimi® broccoli. Postharvest Biol. Technol. 2011, 62, 327–337. [Google Scholar] [CrossRef]

| UV-C Irradiation | Packing | |

|---|---|---|

| Exposure Time (s)/Distance of Lamps from the Surface (cm) | Xtend® Bags | No Bags |

| UV-C 300/20 | 4.36 | 5.12 |

| UV-C 300/40 | 2.12 | 2.69 |

| UV-C 300/60 | 1.25 | 1.55 |

| UV-C 600/20 | 8.72 | 10.24 |

| UV-C 600/40 | 4.24 | 5.38 |

| UV-C 600/60 | 2.51 | 3.11 |

| UV-C irradiation Exposure Time (s)/Distance of Lamps from the Surface (cm) | Mass of Good-Quality Pods (g) | Number of Good-Quality Pods | Mass Loss of Pods (g) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Xtend® Bags | No Bags | Means | Xtend® Bags | No Bags | Means | Xtend® Bags | No Bags | Means | ||

| After 14 days | ||||||||||

| Without irradiation | 90.7 ± 14.0a | 61.0 ± 11.0a | 75.8 ± 19.8a | 14.0 ± 2.0 | 10.0 ± 2.0 | 12.0 ± 2.8a | 5.0 ± 3.0 | 12.3 ± 6.1 | 8.7 ± 5.9 | |

| UV-C 300/20 | 118.7 ± 7.6b | 92.0 ± 3.6b | 105.3 ± 15.5b | 18.3 ± 1.2 | 14.7 ± 0.6 | 16.5 ± 2.2b | 4.8 ± 2.6 | 13.3 ± 4.2 | 9.1 ± 5.6 | |

| UV-C 300/40 | 109.7 ± 10.7ab | 86.3 ± 12.5b | 98.0 ± 16.5b | 17.0 ± 1.7 | 14.0 ± 2.0 | 15.5 ± 2.3b | 4.7 ± 0.6 | 16.7 ± 2.3 | 10.7 ± 6.7 | |

| UV-C 300/60 | 112.3 ± 7.2ab | 70.7 ± 2.1ab | 91.5 ± 23.3ab | 17.3 ± 1.2 | 11.3 ± 0.6 | 14.3 ± 3.4b | 5.7 ± 0.6 | 13.3 ± 5.3 | 9.3 ± 5.2 | |

| UV-C 600/20 | 122.3 ± 6.5b | 69.7 ± 8.4ab | 96.0 ± 29.6b | 19.0 ± 1.0 | 11.3 ± 1.2 | 15.2 ± 4.3b | 5.8 ± 2.6 | 11.3 ± 2.9 | 8.6 ± 3.9 | |

| UV-C 600/40 | 122.7 ± 6.8b | 83.3 ± 11.2ab | 103.0 ± 23.1b | 19.0 ± 1.0 | 13.3 ± 2.1 | 16.2 ± 3.4b | 3.7 ± 0.6 | 12.3 ± 3.8 | 8.0 ± 5.2 | |

| UV-C 600/60 | 125.0 ± 6.2b | 90.3 ± 10.6b | 107.7 ± 20.5b | 19.3 ± 1.2 | 14.7 ± 1.5 | 17.0 ± 2.8b | 3.3 ± 1.5 | 17.7 ± 10.3 | 10.5 ± 10.2 | |

| Means | 114.5 ± 13.5B | 79.1 ± 13.7A | 96.8 ± 22.4 | 17.7 ± 2.1B | 12.8 ± 2.2A | 15.2 ± 3.3 | 4.7 ± 1.8A | 13.8 ± 5.2B | 9.3 ± 6.0 | |

| Source of variation | df | F | P | LSD0.05 | F | P | LSD0.05 | F | P | LSD0.05 |

| Packaging method | 1 | 47.67 | 0.020 | 23.83 | 37.04 | 0.026 | 3.78 | 172.90 | 0.006 | 3.21 |

| UV-C irradiation | 6 | 10.48 | <0.001 | 16.20 | 11.06 | <0.001 | 2.30 | 0.29 | >0.05 | NS |

| Interaction | 6 | 3.17 | 0.042 | 23.80 | 1.98 | >0.05 | NS | 0.78 | >0.05 | NS |

| After 28 days | ||||||||||

| Without irradiation | 50.7 ± 6.7a | 0.0 | 25.3 ± 28.1a | 8.3 ± 1.2a | 0.0 | 4.2 ± 4.6a | 10.3 ± 2.3 | 17.3 ± 5.0 | 13.8 ± 5.0 | |

| UV-C 300/20 | 72.3 ± 6.5bc | 3.3 ± 2.9 | 37.8 ± 38.1abc | 12.0 ± 1.0bc | 0.7 ± 0.6 | 6.3 ± 6.3abc | 14.7 ± 10.8 | 21.0 ± 11.3 | 17.8 ± 11.3 | |

| UV-C 300/40 | 85.7 ± 6.1c | 7.7 ± 2.9 | 46.7 ± 42.9c | 14.0 ± 1.0c | 1.3 ± 0.6 | 7.7 ± 7.0c | 10.7 ± 1.2 | 22.3 ± 6.7 | 16.5 ± 6.7 | |

| UV-C 300/60 | 57.7 ± 7.2ab | 0.0 | 28.8 ± 31.9ab | 9.7 ± 1.2ab | 0.0 | 4.8 ± 5.3ab | 12.8 ± 13.1 | 20.7 ± 9.1 | 16.8 ± 9.1 | |

| UV-C 600/20 | 73.0 ± 20.8bc | 7.7 ± 2.9 | 40.3 ± 38.2bc | 12.0 ± 3.5bc | 1.3 ± 0.6 | 6.7 ± 6.3abc | 13.5 ± 2.2 | 17.0 ± 2.7 | 15.3 ± 2.7 | |

| UV-C 600/40 | 84.3 ± 13.1c | 13.3 ± 2.9 | 48.8 ± 39.8c | 13.7 ± 2.1c | 2.7 ± 0.6 | 8.2 ± 6.2c | 9.3 ± 1.5 | 23.0 ± 8.5 | 16.2 ± 8.5 | |

| UV-C 600/60 | 78.7 ± 15.5c | 6.7 ± 5.8 | 42.7 ± 40.8c | 13.0 ± 2.6c | 1.3 ± 1.2 | 7.2 ± 6.6bc | 10.7 ± 0.6 | 24.3 ± 9.0 | 17.5 ± 9.0 | |

| Means | 71.8 ± 16.1B | 5.5 ± 5.2A | 38.6 ± 35.5 | 11.8 ± 2.6B | 1.1 ± 1.0 A | 6.4 ± 5.8 | 11.7 ± 7.6A | 20.8 ± 4.9B | 16.3 ± 7.8 | |

| Source of variation | df | F | P | LSD0.05 | F | P | LSD0.05 | F | P | LSD0.05 |

| Packaging method | 1 | 205.12 | 0.005 | 21.48 | 209.33 | 0.005 | 3.45 | 189.02 | 0.005 | 3.07 |

| UV-C irradiation | 6 | 8.38 | 0.001 | 14.89 | 7.84 | 0.001 | 2.56 | 1.16 | >0.05 | NS |

| Interaction | 6 | 3.61 | 0.028 | 17.29 | 3.15 | 0.043 | 2.94 | 1.82 | >0.05 | NS |

| UV-C Irradiation | Packing Method | Means | ||

|---|---|---|---|---|

| Exposure Time (s)/Distance of Lamps from the Surface (cm) | Xtend® Bags | No Bags | ||

| Without irradiation | 0.0a | 0.0a | 0.0 a | |

| UV-C 300/20 | 4.0 ± 2.6ab | 8.7 ± 1.2bc | 6.3 ± 3.1b | |

| UV-C 300/40 | 1.7 ± 1.5ab | 2.7 ± 1.2ab | 2.2 ± 1.3a | |

| UV-C 300/60 | 0.0a | 0.7 ± 0.6a | 0.3 ± 0.5a | |

| UV-C 600/20 | 6.7 ± 5.1ab | 17.3 ± 2.9d | 12.0 ± 6.9c | |

| UV-C 600/40 | 8.7 ± 2.5b | 14.7 ± 3.1cd | 11.7 ± 4.1c | |

| UV-C 600/60 | 6.7 ± 3.2ab | 15.3 ± 0.6cd | 11.0 ± 5.2c | |

| Means | 4.0 ± 4.0 | 8.5 ± 7.2 | 6.2 ± 6.2 | |

| Source of variation | df | F | P | LSD0.05 |

| Packaging method | 1 | 14.94 | >0.05 | NS |

| UV-C irradiation | 6 | 64.64 | <0.001 | 3.33 |

| Interaction | 6 | 3.74 | 0.024 | 7.54 |

| Unit | Quantity | |

|---|---|---|

| Dry matter | % | 8.15 ± 0.32 |

| Total sugars | g·100 g−1 | 2.61 ± 0.10 |

| Protein | g·100 g−1 | 2.62 ± 0.13 |

| Ascorbic acid | mg·100 g−1 | 18.29 ± 0.22 |

| Phenolics | mg·100 g−1 | 20.93 ± 1.21 |

| Flavonoids | mg·100 g−1 | 6.63 ± 0.09 |

| UV-C Irradiation | Packing Method | Means | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Exposure Time (s)/Distance of Lamps from the Surface (cm) | Xtend® Bags | No Bags | ||||||||

| Dry matter (%) | ||||||||||

| Without irradiation | 8.34 ± 0.17 | 9.97 ± 0.58 | 9.16 ± 0.97a | |||||||

| UV-C 300/20 | 8.44 ± 0.93 | 10.92 ± 2.06 | 9.68 ± 1.97abc | |||||||

| UV-C 300/40 | 10.30 ± 1.90 | 13.00 ± 0.66 | 11.65 ± 1.95d | |||||||

| UV-C 300/60 | 9.47 ± 0.43 | 10.61 ± 0.81 | 10.04 ± 0.85bc | |||||||

| UV-C 600/20 | 8.86 ± 0.80 | 9.97 ± 1.15 | 9.42 ± 1.07ab | |||||||

| UV-C 600/40 | 8.85 ± 1.06 | 10.10 ± 0.31 | 9.47 ± 0.98abc | |||||||

| UV-C 600/60 | 9.05 ± 1.78 | 11.37 ± 1.28 | 10.21 ± 1.88c | |||||||

| Means | 9.05 ± 1.17A | 10.85 ± 1.39B | 9.95 ± 1.56 | |||||||

| Total sugars (g·100 g−1 f.m.) | ||||||||||

| Without irradiation | 2.93 ± 0.10 | 3.25 ± 0.08 | 3.09 ± 0.20 | |||||||

| UV-C 300/20 | 3.19 ± 0.41 | 3.47 ± 0.22 | 3.33 ± 0.33 | |||||||

| UV-C 300/40 | 3.11 ± 0.31 | 3.54 ± 0.26 | 3.33 ± 0.35 | |||||||

| UV-C 300/60 | 3.40 ± 0.26 | 3.31 ± 0.01 | 3.36 ± 0.17 | |||||||

| UV-C 600/20 | 3.17 ± 0.13 | 3.38 ± 0.46 | 3.27 ± 0.32 | |||||||

| UV-C 600/40 | 2.89 ± 0.32 | 3.33 ± 0.16 | 3.11 ± 0.33 | |||||||

| UV-C 600/60 | 3.35 ± 0.47 | 3.47 ± 0.22 | 3.41 ± 0.34 | |||||||

| Means | 3.15 ± 0.32A | 3.39 ± 0.23B | 3.27 ± 0.30 | |||||||

| Protein (g·100 g−1 f.m.) | ||||||||||

| Without irradiation | 2.92 ± 0.12ab | 3.36 ± 0.05 | 3.14 ± 0.25 | |||||||

| UV-C 300/20 | 3.10 ± 0.12abc | 3.15 ± 0.09 | 3.13 ± 0.10 | |||||||

| UV-C 300/40 | 2.87 ± 0.30a | 3.28 ± 0.09 | 3.08 ± 0.30 | |||||||

| UV-C 300/60 | 3.25 ± 0.32abc | 3.16 ± 0.09 | 3.21 ± 0.21 | |||||||

| UV-C 600/20 | 3.01 ± 0.06abc | 3.14 ± 0.16 | 3.08 ± 0.13 | |||||||

| UV-C 600/40 | 3.47 ± 0.19c | 3.26 ± 0.49 | 3.37 ± 0.35 | |||||||

| UV-C 600/60 | 3.36 ± 0.04bc | 3.48 ± 0.08 | 3.42 ± 0.08 | |||||||

| Means | 3.14 ± 0.27A | 3.26 ± 0.21B | 3.20 ± 0.24 | |||||||

| Source of variation | df | Dry matter | Total sugars | Protein | ||||||

| F | P | LSD0.05 | F | P | LSD0.05 | F | P | LSD0.05 | ||

| Packaging method | 1 | 123.17 | 0.008 | 0.754 | 40.56 | 0.024 | 0.179 | 23.32 | 0.040 | 0.116 |

| UV-C irradiation | 6 | 12.66 | <0.001 | 1.162 | 0.82 | >0.05 | NS | 2.21 | >0.05 | NS |

| Interaction | 6 | 0.38 | >0.05 | NS | 0.86 | >0.05 | NS | 3.13 | 0.044 | 0.470 |

| UV-C Irradiation | Packing Method | Means | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Exposure Time (s)/Distance of Lamps from the Surface (cm) | Xtend® Bags | No Bags | ||||||||

| Ascorbic acid (mg·100 g−1 f.m.) | ||||||||||

| Without irradiation | 18.73 ± 0.09 | 18.81 ± 0.44 | 18.77 ± 0.29a | |||||||

| UV-C 300/20 | 19.80 ± 0.69 | 19.76 ± 0.51 | 19.78 ± 0.54ab | |||||||

| UV-C 300/40 | 20.67 ± 1.09 | 20.08 ± 0.43 | 20.37 ± 0.81b | |||||||

| UV-C 300/60 | 19.80 ± 0.23 | 19.80 ± 0.80 | 19.80 ± 0.53ab | |||||||

| UV-C 600/20 | 19.85 ± 0.25 | 19.45 ± 0.34 | 19.65 ± 0.35ab | |||||||

| UV-C 600/40 | 19.27 ± 0.64 | 19.80 ± 0.77 | 19.53 ± 0.70ab | |||||||

| UV-C 600/60 | 19.01 ± 0.63 | 19.37 ± 0.15 | 19.19 ± 0.45a | |||||||

| Means | 19.59 ± 0.80 | 19.58 ± 0.60 | 19.59 ± 0.69 | |||||||

| Phenolics (mg·100 g−1 f.m.) | ||||||||||

| Without irradiation | 29.6 ± 3.2a | 21.1 ± 1.5a | 25.3 ± 5.2a | |||||||

| UV-C 300/20 | 43.6 ± 2.5c | 37.4 ± 3.8bc | 40.5 ± 4.5b | |||||||

| UV-C 300/40 | 41.0 ± 2.2bc | 28.5 ± 0.7ab | 34.8 ± 7.0ab | |||||||

| UV-C 300/60 | 33.0 ± 8.5ab | 38.2 ± 10.7bc | 35.6 ± 9.1ab | |||||||

| UV-C 600/20 | 54.7 ± 2.6d | 28.4 ± 0.8ab | 41.6 ± 14.5b | |||||||

| UV-C 600/40 | 32.1 ± 2.9ab | 38.8 ± 1.7c | 35.4 ± 4.2ab | |||||||

| UV-C 600/60 | 30.1 ± 6.2a | 35.0 ± 6.1bc | 32.5 ± 6.2ab | |||||||

| Means | 37.7 ± 9.6 | 32.5 ± 7.6 | 35.1 ± 8.9 | |||||||

| Flavonoids (mg·100 g−1 f.m.) | ||||||||||

| Without irradiation | 6.58 ± 0.04a | 6.62 ± 0.10a | 6.60 ± 0.07a | |||||||

| UV-C 300/20 | 8.66 ± 0.72c | 8.30 ± 0.75c | 8.48 ± 0.68b | |||||||

| UV-C 300/40 | 8.63 ± 0.94c | 7.78 ± 0.43bc | 8.20 ± 0.80b | |||||||

| UV-C 300/60 | 8.16 ± 0.70bc | 6.96 ± 0.51ab | 7.56 ± 0.85ab | |||||||

| UV-C 600/20 | 7.54 ± 0.1b | 7.64 ± 0.08bc | 7.59 ± 0.13ab | |||||||

| UV-C 600/40 | 8.25 ± 0.13bc | 7.67 ± 0.19bc | 7.96 ± 0.35b | |||||||

| UV-C 600/60 | 7.75 ± 0.42bc | 7.91 ± 0.05c | 7.83 ± 0.28b | |||||||

| Means | 7.94 ± 0.83 | 7.55 ± 0.63 | 7.75 ± 0.76 | |||||||

| Source of variation | df | Ascorbic acid | Phenolics | Flavonoids | ||||||

| F | P | LSD0.05 | F | P | LSD0.05 | F | P | LSD0.05 | ||

| Packaging method | 1 | 0.02 | >0.05 | NS | 7.48 | >0.05 | NS | 16.57 | >0.05 | NS |

| UV-C irradiation | 6 | 4.72 | 0.011 | 1.149 | 5.51 | 0.006 | 11.33 | 7.06 | 0.002 | 1.120 |

| Interaction | 6 | 0.61 | >0.05 | NS | 17.59 | <0.001 | 10.03 | 3.84 | 0.023 | 0.930 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Franczuk, J.; Rosa, R.; Zaniewicz-Bajkowska, A.; Ginter, A. The Effect of Treating String Bean Pods with Modified Atmosphere Packaging and UV-C Irradiation on Their Storage Life. Agronomy 2021, 11, 1747. https://doi.org/10.3390/agronomy11091747

Franczuk J, Rosa R, Zaniewicz-Bajkowska A, Ginter A. The Effect of Treating String Bean Pods with Modified Atmosphere Packaging and UV-C Irradiation on Their Storage Life. Agronomy. 2021; 11(9):1747. https://doi.org/10.3390/agronomy11091747

Chicago/Turabian StyleFranczuk, Jolanta, Robert Rosa, Anna Zaniewicz-Bajkowska, and Agnieszka Ginter. 2021. "The Effect of Treating String Bean Pods with Modified Atmosphere Packaging and UV-C Irradiation on Their Storage Life" Agronomy 11, no. 9: 1747. https://doi.org/10.3390/agronomy11091747

APA StyleFranczuk, J., Rosa, R., Zaniewicz-Bajkowska, A., & Ginter, A. (2021). The Effect of Treating String Bean Pods with Modified Atmosphere Packaging and UV-C Irradiation on Their Storage Life. Agronomy, 11(9), 1747. https://doi.org/10.3390/agronomy11091747