Investigating the Coupling Effect of High Pressure and Hot Air on External Friction Angle Based on Resistance Reduction Tests on Subsoiling Tillage Tools for Sandy Clay Loam

Abstract

:1. Introduction

2. Materials and Methods

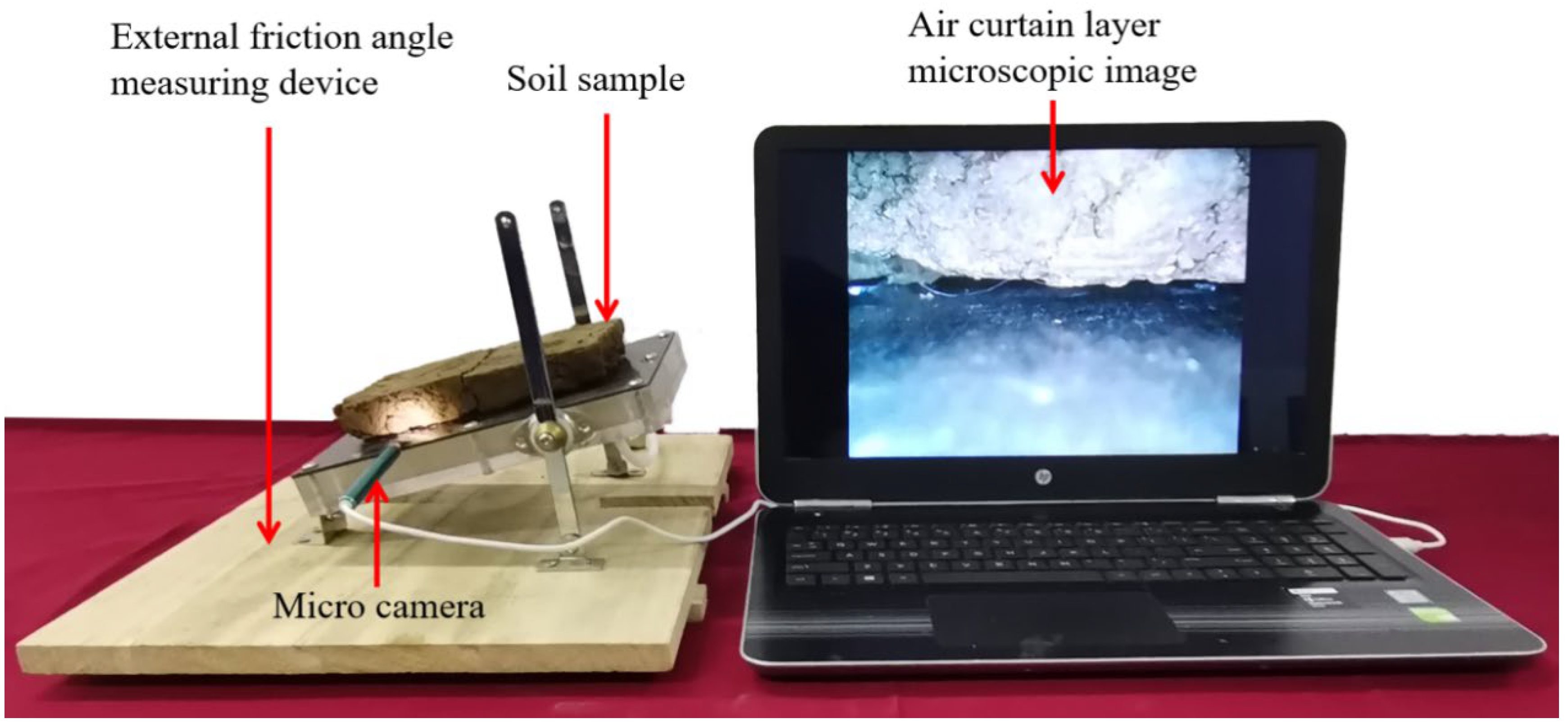

2.1. The Setup for the Measurement of the External Friction Angle

2.2. Soil Parameters and Sample Preparation

2.3. Methods

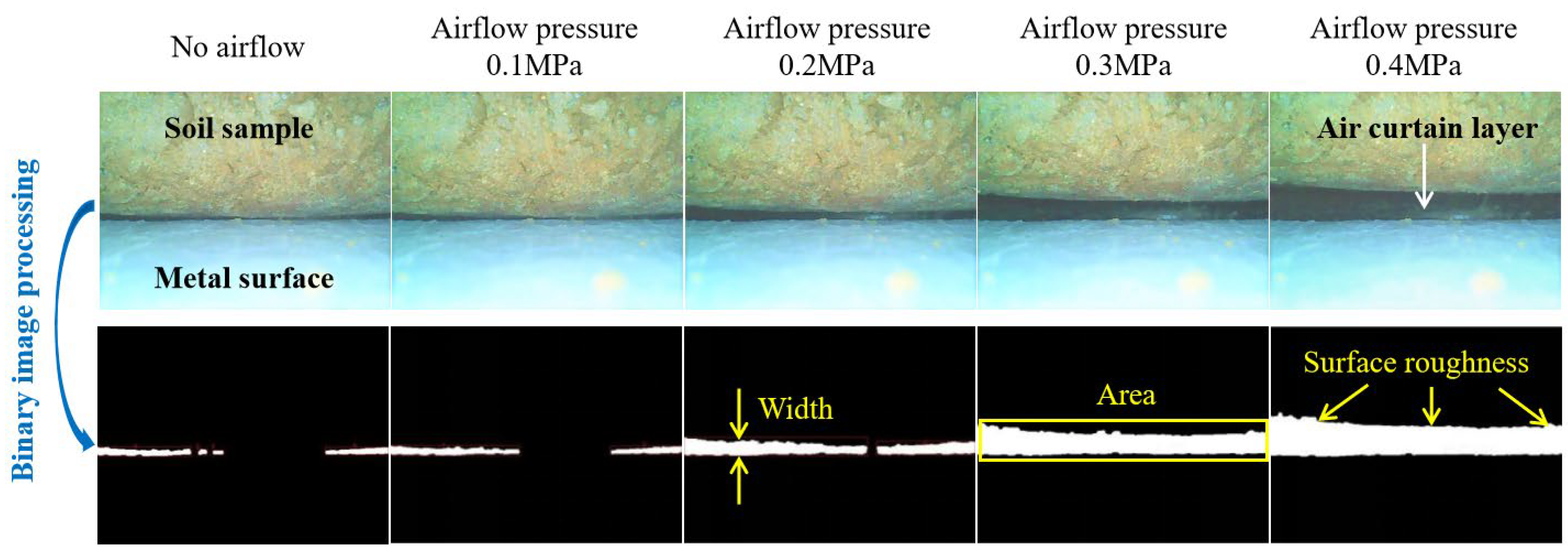

2.3.1. Tests for Air Pressure on the External Friction Angle

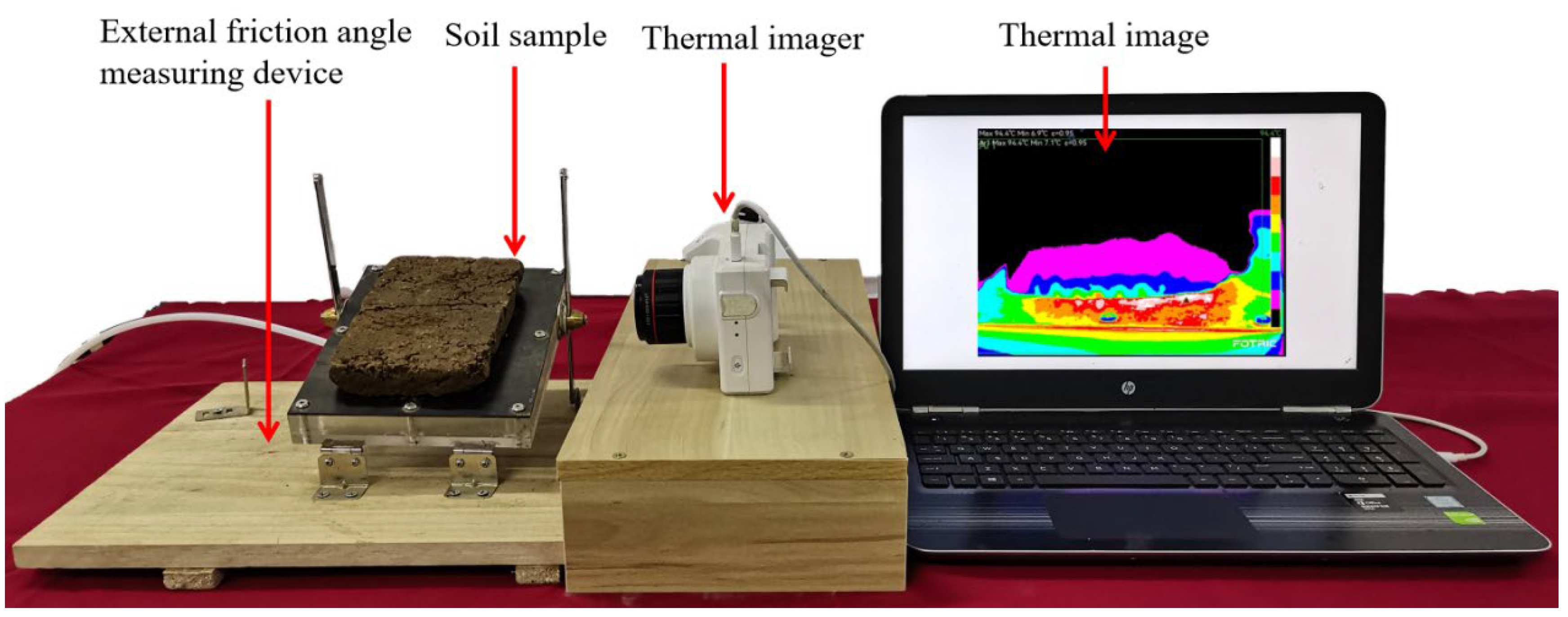

2.3.2. Testing the Coupling Effect of High Pressure and Hot Air on the External Friction Angle

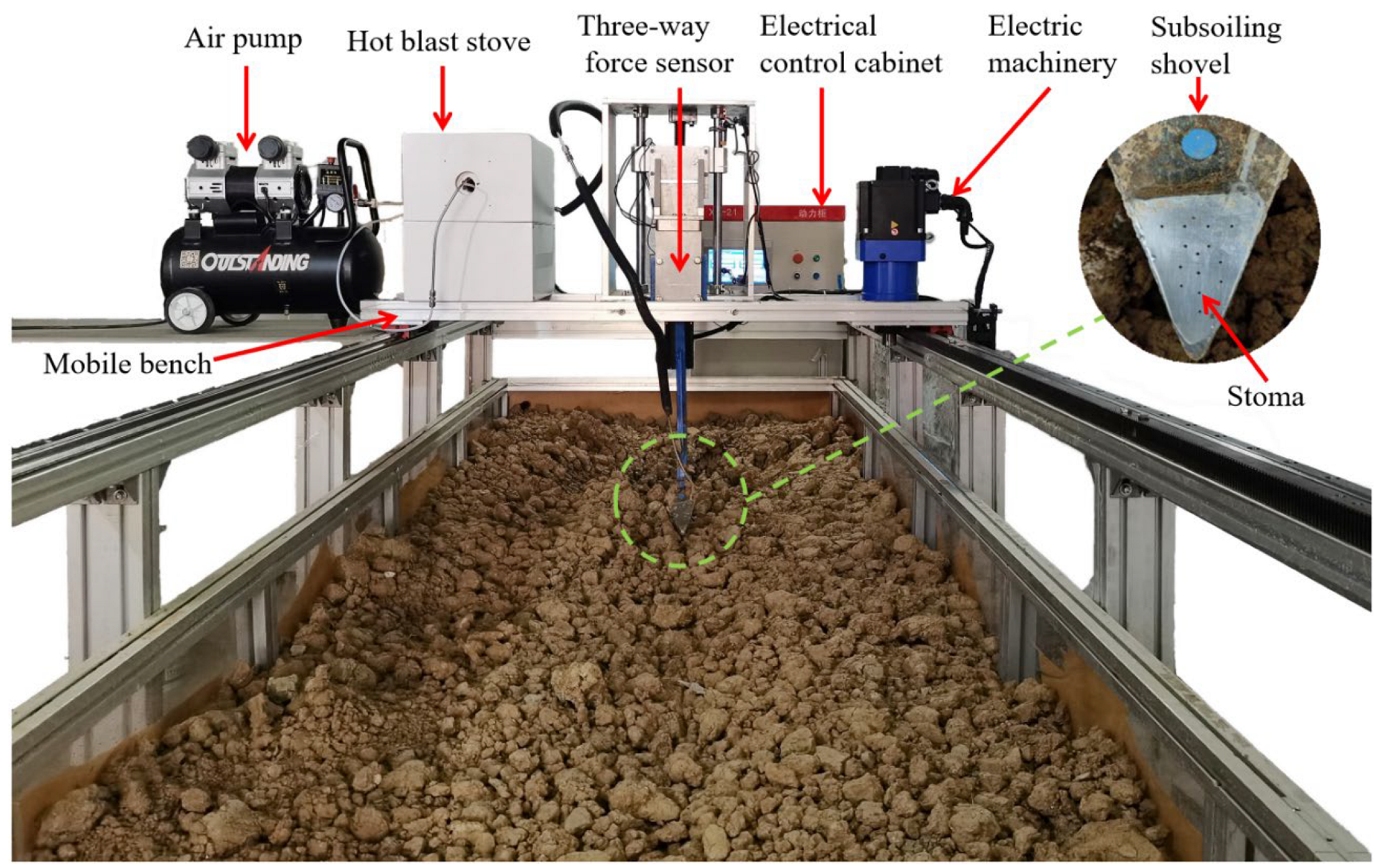

2.3.3. Subsoiling Test on the Coupling Effect of High Pressure and Hot Air

3. Results and Discussion

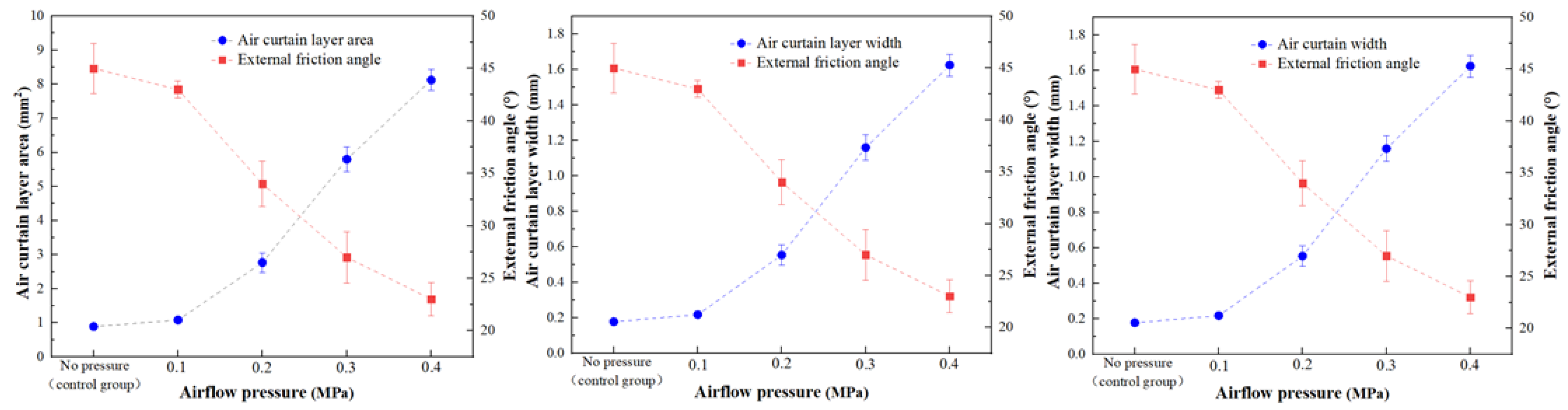

3.1. The Effect of Air Pressure on the External Friction Angle

3.2. Influencing Mechanism of High-Pressure Airflow on the External Friction Angle

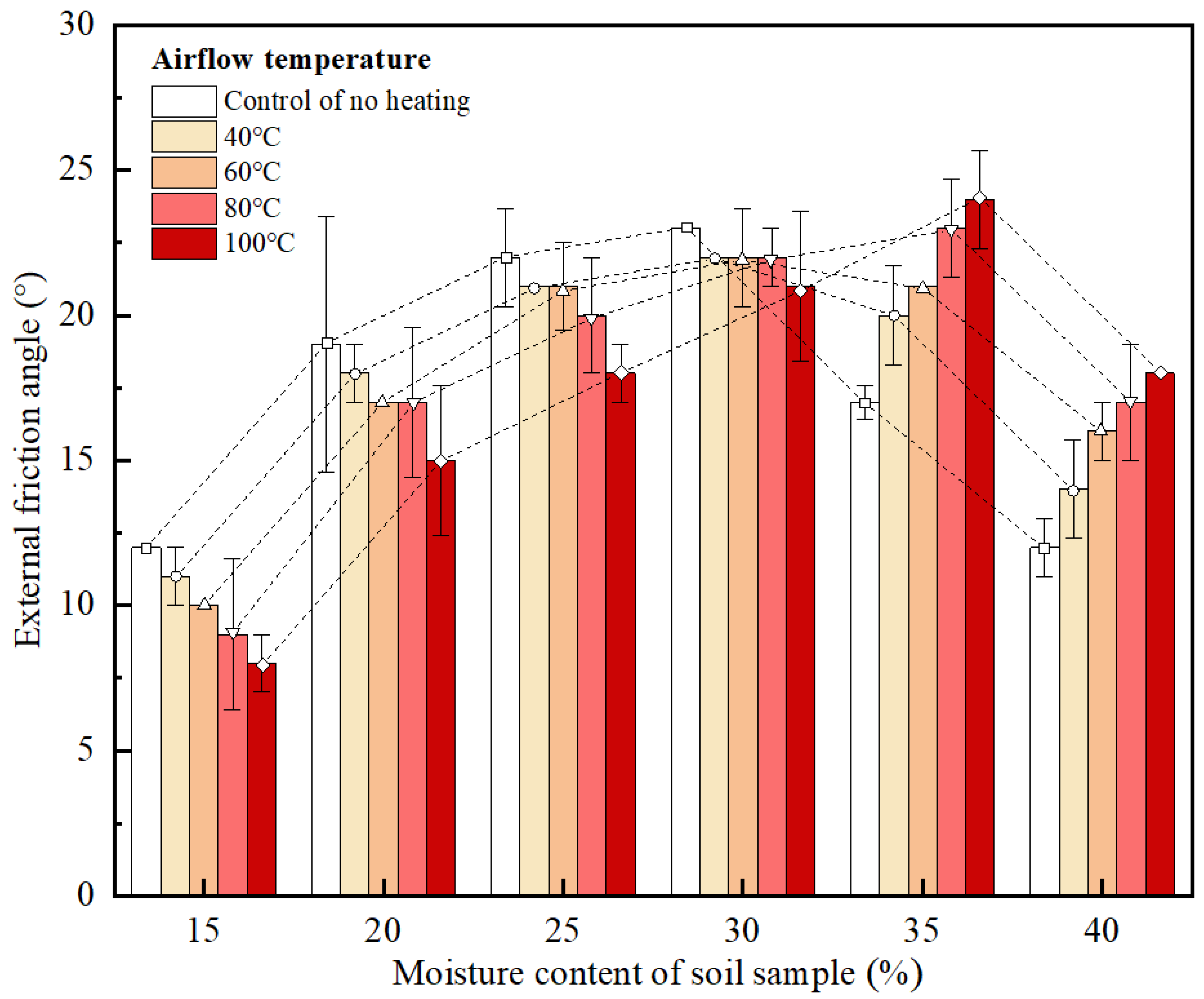

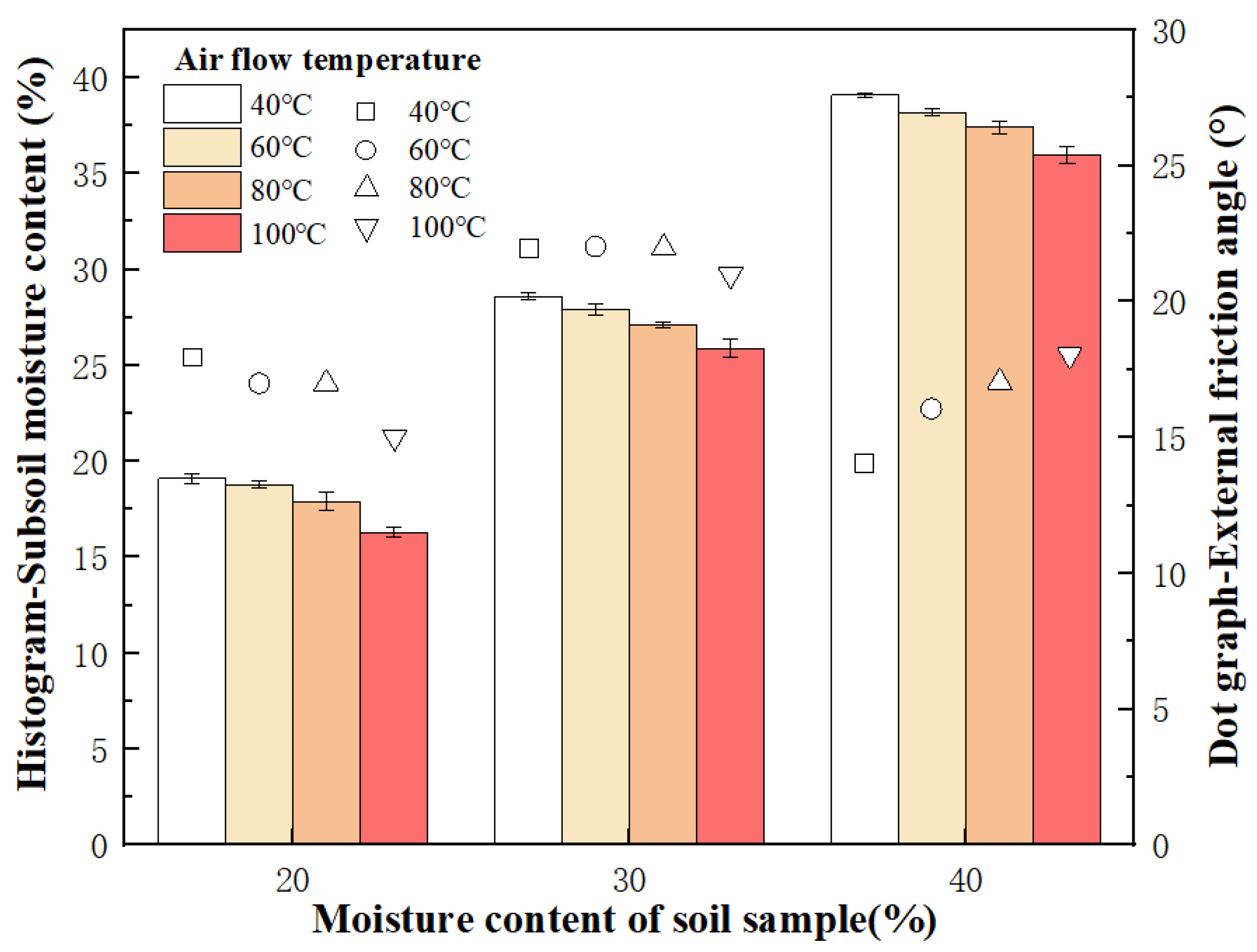

3.3. The Effect of High Pressure and Hot Air on the External Friction Angle

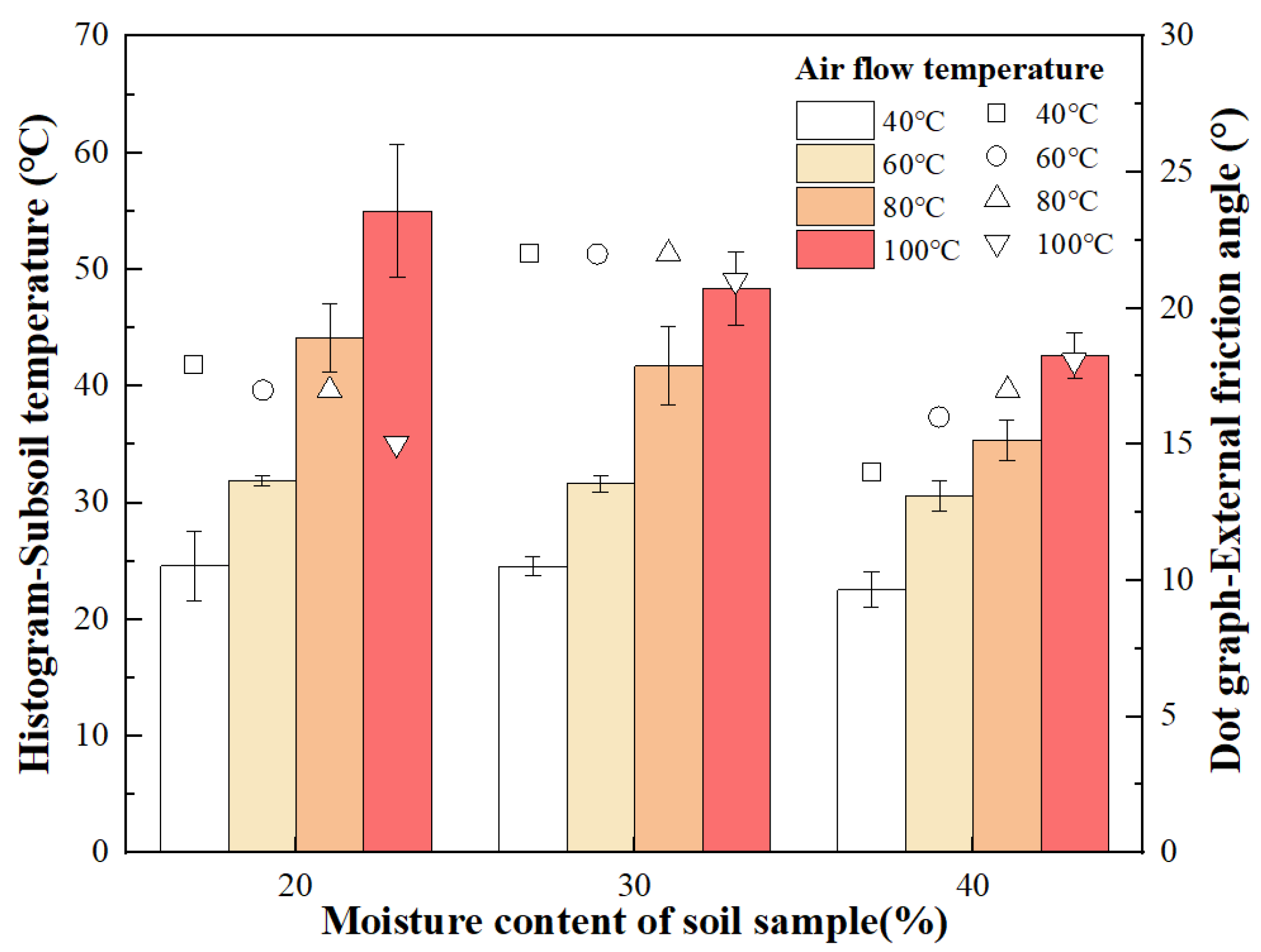

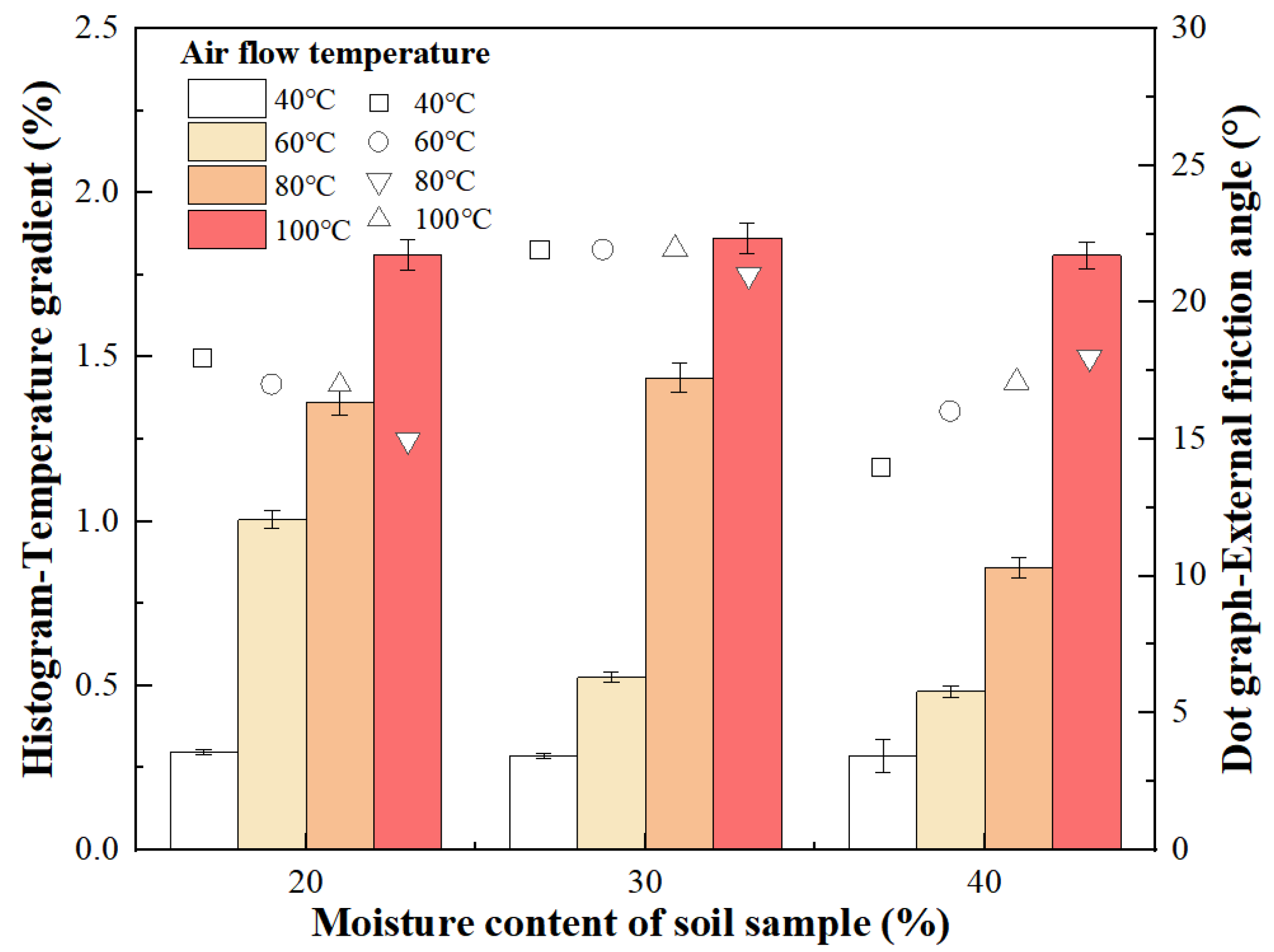

3.4. Influencing Mechanism of High-Pressure Hot Airflow on the External Friction Angle

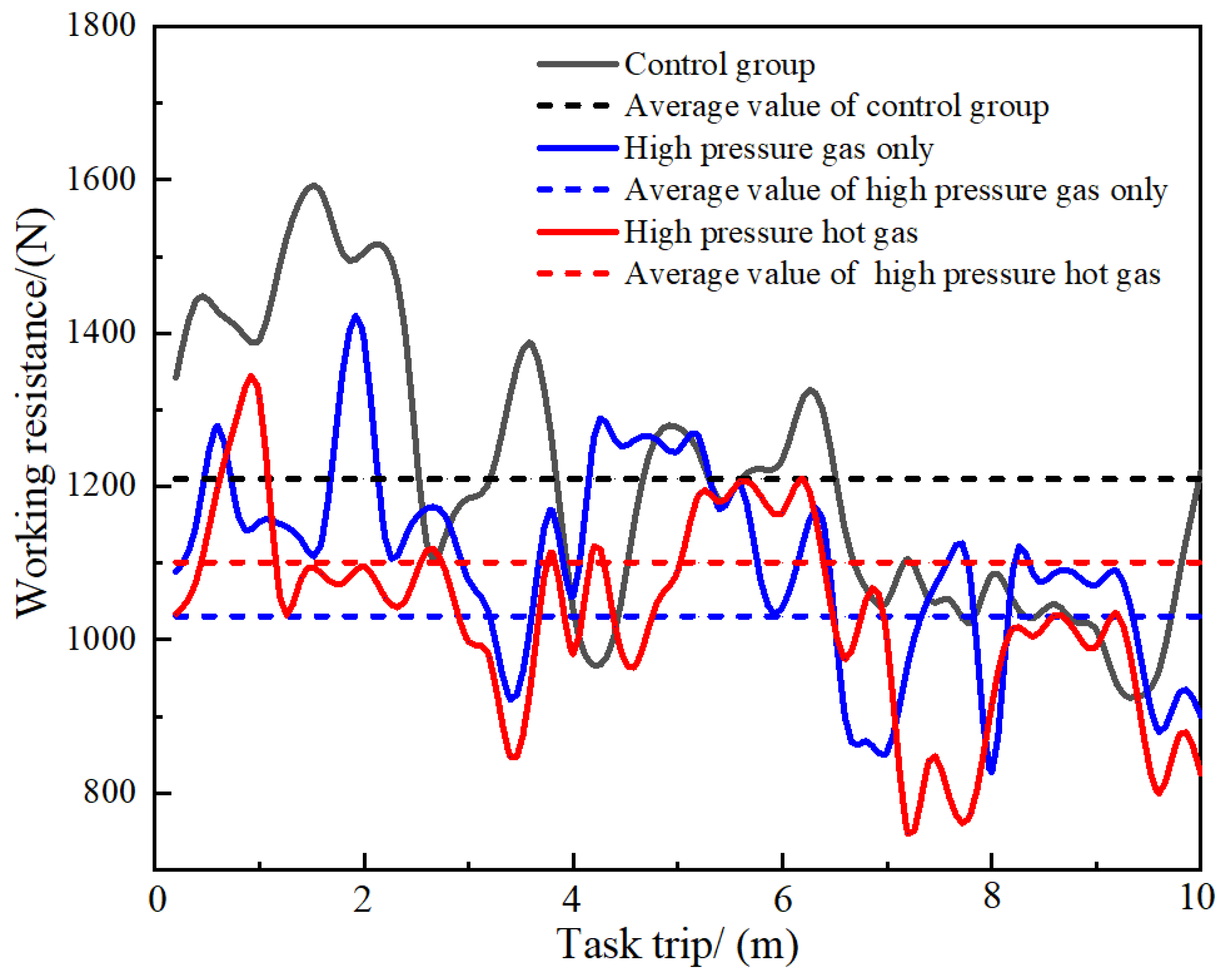

3.5. Results of the Soil-Bin Test on the Coupling Effect of High Pressure and Hot Air

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gill, J.S.; Sivasithamparam, K.; Smettem, K. Soil types with different texture affects development of Rhizoctonia root rot of wheat seedlings. Plant. Soil 2000, 221, 113–120. [Google Scholar] [CrossRef]

- Lithourgidis, A.S.; Damalas, C.A.; Gagianas, A.A. Long-term yield patterns for continuous winter wheat cropping in northern Greece. Eur. J. Agron. 2006, 25, 208–214. [Google Scholar] [CrossRef]

- Razzaghi, F.; Plauborg, F.; Jacobsen, S.E.; Jensen, C.R.; Andersen, M.N. Effect of nitrogen and water availability of three soil types on yield, radiation use efficiency and evapotranspiration in field-grown quinoa. Agr. Water. Manag. 2012, 109, 20–29. [Google Scholar] [CrossRef]

- Kumar, A.A.; Tewari, V.K. Analysis of suitable of traction model for sandy clay loam soils on farm use of tractor. J. Agr. Food. Res. 2021, 5, 100180. [Google Scholar] [CrossRef]

- Zhang, L.; Zhai, Y.B.; Chen, J.N.; Zhang, Z.E.; Huang, S.Z. Optimization design and performance study of a subsoiler underlying the tea garden subsoiling mechanism based on bionics and EDEM. Soil Till. Res. 2022, 220, 105375. [Google Scholar] [CrossRef]

- Massah, J.; Fard, M.R.; Aghel, H. An optimized bionic electro-osmotic soilengaging implement for soil adhesion reduction. J. Terramechanics. 2021, 95, 1–6. [Google Scholar] [CrossRef]

- Guan, C.S.; Fu, J.J.; Xu, L.; Jiang, X.Z.; Wang, S.L.; Cui, Z.C. Study on the reduction of soil adhesion and tillage force of bionic cutter teeth in secondary soil crushing. Soil Till. Res. 2022, 213, 133–147. [Google Scholar] [CrossRef]

- Hoseinian, S.H.; Hemmat, A.; Esehaghbeygi, A.; Shahgoli, G.; Baghbanan, A. Development of a dual sideway-share subsurface tillage implement: Part 2. Effect of tool geometry on tillage forces and soil disturbance characteristics. Soil Till. Res. 2022, 215, 105200. [Google Scholar] [CrossRef]

- El Salem, A.; Zhang, G.Z.; Abdeen, M.A.M.; Wang, H.C.; Gao, Y. Optimizing the adhesion of soil-touching parts based on biomimetic concepts using the Taguchi method. Int. J. Agr. Biol. Eng. 2022, 15, 147–154. [Google Scholar] [CrossRef]

- Skonieczny, K. Modeling the effects of surcharge accumulation on terrestrial and planetary wide-blade soil–tillage tool interactions. Soil Till. Res. 2018, 176, 104–111. [Google Scholar] [CrossRef]

- Harrison, H.P. Soil profile meter for simple tillage tools. Transact. ASAE 1990, 33, 0021–0024. [Google Scholar] [CrossRef]

- Kheiralla, A.F.; Yahya, A.; Zohadie, M.; Ishak, W. Modelling of power and energy requirements for tillage implements operating in Serdang sandy clay loam, Malaysia. Soil Till. Res. 2004, 78, 21–34. [Google Scholar] [CrossRef]

- Wang, Y.M.; Li, N.; Ma, Y.H.; Tong, J.; Pfleging, W.; Sun, J.Y. Field experiments evaluating a biomimetic shark-inspired (BioS) subsoiler for tillage resistance reduction. Soil Till. Res. 2020, 196, 104432. [Google Scholar] [CrossRef]

- Zhao, J.; Lu, Y.; Guo, M.; Fu, J.; Wang, Y.J. Design and experiment of bionic stubble breaking-deep loosening combined tillage machine. Int. J. Agr. Biol. Eng. 2021, 14, 123–134. [Google Scholar] [CrossRef]

- Zhang, X.R.; Wang, C.; Chen, Z.S.; Zeng, Z.W. Design and experiment of a bionic vibratory subsoiler for banana fields in southern China. Int. J. Agr. Biol. Eng. 2016, 9, 75–83. [Google Scholar] [CrossRef]

- Zhang, D.G.; Chen, Y.X.; Ma, Y.H.; Guo, L.; Sun, J.Y.; Tong, J. Earthworm epidermal mucus: Rheological behavior reveals drag-reducing characteristics in soil. Soil Till. Res. 2016, 158, 57–66. [Google Scholar] [CrossRef]

- Guan, C.S.; Fu, J.J.; Cui, Z.C.; Wang, S.L.; Gao, Q.S.; Yang, Y.T. Evaluation of the tribological and anti-adhesive properties of different materials coated rotary tillage blades. Soil Till Res. 2021, 209, 104933. [Google Scholar] [CrossRef]

- Yan, Y.Y.; Hull, J.B. The Concept of Electroosmotically Driven Flow and Its Application to Biomimetics. J. Bionic. Eng. 2004, 1, 46–52. [Google Scholar] [CrossRef]

- Liu, G.M.; Wu, X.Q.; Zou, M.; Yan, Y.Y.; Li, J.Q. Experimental Study on Drag Reduction Characteristics of Bionic Earthworm Self-Lubrication Surface. Appl. Bionics. Biomech. 2019, 2019, 4984756. [Google Scholar] [CrossRef]

- Ahmadi, I. Effect of soil, machine, and working state parameters on the required draft force of a subsoiler using a theoretical draft-calculating model. Soil Res. 2017, 55, 389–400. [Google Scholar] [CrossRef]

- Ren, L.Q.; Han, Z.W.; Li, J.Q.; Tong, J. Experimental investigation of bionic rough curved soil cutting blade surface to reduce soil adhesion and friction. Soil Till. Res. 2006, 85, 1–12. [Google Scholar] [CrossRef]

- Yang, H.; Guo, Z.; Li, Y.J.; Wang, H.Y.; Dou, Y.Z. Experimental study on microbubble drag reduction on soil-steel interface. Appl. Ocean. Res. 2021, 116, 102891. [Google Scholar] [CrossRef]

- Ayers, P.D. Moisture and bulk density effects on soil shear strength parameters for coarse grained soils. Transact. ASABE 1987, 30, 1282–1287. [Google Scholar] [CrossRef]

- Lopes, P.C.; Lopes, M.L.; Lopes, M.P. Shear Behaviour of Geosynthetics in the Inclined Plane Test—Influence of Soil Particle Size and Geosynthetic Structure. Geosyn. Int. 2001, 8, 327–342. [Google Scholar] [CrossRef]

- Briancon, L.; Girard, H.; Gourc, J.P. A new procedure for measuring geosynthetic friction with an inclined plane. Geotext. Geomembranes. 2011, 29, 472–482. [Google Scholar] [CrossRef]

- Aldeeky, H.; Al Hattamleh, O.; Abu Alfoul, B. Effect of Sand Placement Method on the Interface Friction of Sand and Geotextile. Int. J. Civ. Eng. 2016, 14, 133–138. [Google Scholar] [CrossRef]

- Tan, Z.X.; Ai, P.; Wang, Q.M. Recent developments in organic contaminated soil remediation with the use of thermal desorption technology. Environ. Eng. Manag. J. 2017, 16, 1145–1154. [Google Scholar] [CrossRef]

- Robbins, D.H.; Johnson, C.E.; Schafer, R.L.; Way, T.R. Modeling Soil-Metal Sliding Resistance. Transact. ASABE 2021, 64, 435–446. [Google Scholar] [CrossRef]

- Zhao, Y.Y.; Duan, X.; Han, J.J.; Yang, K.; Xue, Y. The main influencing factors of soil mechanical characteristics of the gravity erosion environment in the dry-hot valley of Jinsha river. Open. Chem. 2018, 16, 796–809. [Google Scholar] [CrossRef]

- Malvajerdi, S.S.; Malvajerdi, A.S.; Ghanaatshoar, M.; Habibi, M. TiCrN-TiAlN-TiAlSiN-TiAlSiCN multi-layers utilized to increase tillage tools useful lifetime. Sci. Rep.-UK 2019, 9, 19101. [Google Scholar] [CrossRef]

- Ani, O.A.; Uzoejinwa, B.B.; Ezeama, A.O.; Onwualu, A.P.; Ugwu, S.N.; Ohagwu, C.J. Overview of soil-machine interaction studies in soil bins. Soil Till. Res. 2018, 175, 13–27. [Google Scholar] [CrossRef]

- Qin, K.; Zhao, Y.; Zhang, Y.; Cao, C.; Shen, Z. Lateral stress and its transmission law caused by operation of a double-wing subsoiler in sandy loam soil. Front. Environ. Sci. 2022, 10, 986361. [Google Scholar] [CrossRef]

- Tang, H.; Xu, C.; Wang, Z.; Wang, Q.; Wang, J. Optimized Design, Monitoring System Development and Experiment for a Long-Belt Finger-Clip Precision Corn Seed Metering Device. Front. Plant Sci. 2022, 13, 814747. [Google Scholar] [CrossRef]

- Tang, H.; Xu, C.; Xu, W.; Xu, Y.; Xiang, Y.; Wang, J. Method of straw ditchburied returning, development of supporting machine and analysis of influencing factors. Front. Plant Sci. 2022, 13, 967838. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.Z.; Tian, L.; Cao, C.M.; Zhu, C.L.; Qin, K.; Ge, J. Optimization and validation of blade parameters for inter-row weeding wheel in paddy fields. Front. Plant Sci. 2022, 13, 1003471. [Google Scholar] [CrossRef]

- Tang, H.; Xu, C.; Qi, X.; Wang, Z.; Wang, J.; Zhou, W.; Wang, Q.; Wang, J. Study on Periodic Pulsation Characteristics of Corn Grain in a Grain Cylinder during the Unloading Stage. Foods 2021, 10, 2314. [Google Scholar] [CrossRef] [PubMed]

- Sindagi, S.; Vijayakumar, R. Succinct review of MBDR/BDR technique in reducing ship’s drag. Ships. Offshore Struc. 2020, 3, 1–12. [Google Scholar] [CrossRef]

- Yu, X.; Wang, Y.; Huang, C.; Wei, Y.; Fang, X.; Du, T.; Wu, X. Experiment and simulation on air layer drag reduction of high-speed underwater axisymmetric projectile. Eur. J. Mech. B-Fluids. 2015, 52, 45–54. [Google Scholar] [CrossRef] [Green Version]

- Marani, S.M.; Shahgholi, G.; Moinfar, A. Effect of nano coating materials on reduction of soil adhesion and external friction. Soil Till. Res. 2019, 193, 42–49. [Google Scholar] [CrossRef]

- Wang, X.Q.; Zhang, Q.K.; Huang, Y.X.; Ji, J.T. An efficient method for determining DEM parameters of a loose cohesive soil modelled using hysteretic spring and linear cohesion contact models. Biosyst. Eng. 2021, 215, 283–294. [Google Scholar] [CrossRef]

- Wu, S.J.; Ouyang, K.; Shiah, S.W. Robust design and numerical simulation on drag reduction by a mixture film for liquid turbulence in a channel. Int. J. Numer. Meth. Fl. 2009, 60, 1079–1102. [Google Scholar] [CrossRef]

- Wu, H.; Ou, Y.P. Analysis of air layer shape formed by air injection at the bottom of flat plate. Ocean. Eng. 2020, 216, 108091. [Google Scholar] [CrossRef]

- Zhang, G.Q.; Schlüter, J.; Hu, X. Parametric investigation of drag reduction for marine vessels using air-filled dimpled surfaces. Ships. Offshore. Struc. 2018, 13, 244–255. [Google Scholar] [CrossRef]

- Shaikh, S.A.; Li, Y.M.; Ma, Z.; Chandio, F.A.; Tunio, M.H.; Liang, Z.W.; Solangi, K.A. Discrete element method (DEM) simulation of single grouser shoe-soil interaction at varied moisture contents. Comput. Electron. Agr. 2021, 191, 106538. [Google Scholar] [CrossRef]

- Ohayon, Y.H.; Pinkert, S. Experimental Evaluation of the Reference, Shear-Rate Independent, Undrained Shear Strength of Soft Clays. Int. J. Geomech. 2021, 21, 06021031. [Google Scholar] [CrossRef]

- Mouazen, A.M.; Ramon, H.; de Baerdemaeker, J. Effects of bulk density and moisture content on selected mechanical properties of sandy loam soil. Biosys. Eng. 2002, 83, 217–224. [Google Scholar] [CrossRef]

- Li, J.; Kou, B.; Liu, G.; Fan, W.; Liu, L. Resistance reduction by bionic coupling of the earthworm lubrication function. Sci. China. Technol. Sc. 2010, 53, 2989–2995. [Google Scholar] [CrossRef]

- Ren, L.Q.; Tong, J.; Li, J.Q.; Chen, B.C. Soil adhesion and biomimetics of soil-engaging components: A review. J. Agr. Eng. Res. 2001, 79, 239–263. [Google Scholar] [CrossRef] [Green Version]

- Ji, W.F.; Wu, Q.M.; Jia, H.L.; Liu, T. Design of Bionic Subsoiling Shovel and its Finite Element Analysis. Adv. Mater. Res. 2013, 694–697, 3053–3057. [Google Scholar] [CrossRef]

- Wang, X.; Ito, N.; Kito, K.; Garcia, P. Study on use of vibration to reduce soil adhesion. J. Terramechanics. 1998, 35, 87–101. [Google Scholar] [CrossRef]

- Li, J.W.; Tong, J.; Hu, B.; Ma, Y.H. Biomimetic functional surface of reducing soil adhesion on 65 Mn steel. Adv. Mech. Eng. 2019, 11, 168781401988980. [Google Scholar] [CrossRef]

- Sun, J.Y.; Wang, Y.M.; Zhang, S.J.; Ma, Y.J.; Tong, J.; Zhang, Z.J. The mechanism of resistance-reducing/anti-adhesion and its application on biomimetic disc furrow opener. Math. Biosci. Eng. 2020, 17, 4657–4677. [Google Scholar] [CrossRef]

- Liu, Y.; Qian, Z. Test study on the stcucture parameters of resistance reduced device with hole-pattern air curtain. T. CSAM 1993, 1, 1–5. [Google Scholar]

- Qian, Z. Calculation of Resistance-Reduction Efficiency in an Air Curtain Between a Slide and Soil and Its Experimental Verification. T. CSAE 1994, 1, 29–35. [Google Scholar]

| Air Pump | Hot Blast Stove | ||

|---|---|---|---|

| Parameters | Values | Parameter | Value |

| Rated power (W) | 1600 | Heating power (W) | 6000 |

| Exhaust pressure (MPa) | 0.05–0.85 | Temperature (°C) | 0–620 |

| Storage capacity (L) | 30 | Temperature control accuracy (°C) | 1 |

| Soil Parameters | Values |

|---|---|

| Moisture content | 25.0% |

| Soil compaction | 1516 kPa |

| Soil bulk density | 1920 kg/m3 |

| Soil content (Clay, silt, and sand contents) | 38.1%, 25.7%, 36.2% |

| Cohesion | 15.67 kPa |

| Parameters | Values |

|---|---|

| Size of the unit (L × W × H; m) | 10 × 1.2 × 1.6 |

| Operating speed (m/s) | 0–1.5 |

| Subsoiling depth (mm) | 0–300 |

| Highest air temperature at shovel surface (°C) | 100 |

| Air pressure at shovel surface (MPa) | 0–0.4 |

| Measuring range of the three-way force (kN) | FX = FY = FZ = 5 |

| Data Group | Air Curtain Layer Area and External Friction Angle | Air Curtain Layer Width and External Friction Angle | Soil Surface Roughness and External Friction Angle |

|---|---|---|---|

| Correlation coefficient (r1) | −0.9726 | −0.9721 | −0.9407 |

| Soil Moisture Content | 20% | 30% | 40% | Numerical Average | |

|---|---|---|---|---|---|

| Correlation coefficient (r2) | Subsoil temperature and external friction angle | −0.918 | −0.745 | 0.990 | 0.884 |

| Temperature gradient and external friction angle | −0.915 | −0.746 | 0.879 | 0.847 | |

| Subsoil moisture content and external friction angle | 0.953 | 0.849 | −0.760 | 0.854 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, K.; Zhang, Y.; Shen, Z.; Cao, C.; Wu, Z.; Ge, J.; Fang, L.; Bi, H. Investigating the Coupling Effect of High Pressure and Hot Air on External Friction Angle Based on Resistance Reduction Tests on Subsoiling Tillage Tools for Sandy Clay Loam. Agronomy 2022, 12, 2663. https://doi.org/10.3390/agronomy12112663

Qin K, Zhang Y, Shen Z, Cao C, Wu Z, Ge J, Fang L, Bi H. Investigating the Coupling Effect of High Pressure and Hot Air on External Friction Angle Based on Resistance Reduction Tests on Subsoiling Tillage Tools for Sandy Clay Loam. Agronomy. 2022; 12(11):2663. https://doi.org/10.3390/agronomy12112663

Chicago/Turabian StyleQin, Kuan, Yongzheng Zhang, Zhougao Shen, Chengmao Cao, Zhengmin Wu, Jun Ge, Liangfei Fang, and Haijun Bi. 2022. "Investigating the Coupling Effect of High Pressure and Hot Air on External Friction Angle Based on Resistance Reduction Tests on Subsoiling Tillage Tools for Sandy Clay Loam" Agronomy 12, no. 11: 2663. https://doi.org/10.3390/agronomy12112663

APA StyleQin, K., Zhang, Y., Shen, Z., Cao, C., Wu, Z., Ge, J., Fang, L., & Bi, H. (2022). Investigating the Coupling Effect of High Pressure and Hot Air on External Friction Angle Based on Resistance Reduction Tests on Subsoiling Tillage Tools for Sandy Clay Loam. Agronomy, 12(11), 2663. https://doi.org/10.3390/agronomy12112663