Double-DQN-Based Path-Tracking Control Algorithm for Orchard Traction Spraying Robot

Abstract

:1. Introduction

2. Materials and Methods

2.1. Hardware and Software Setup

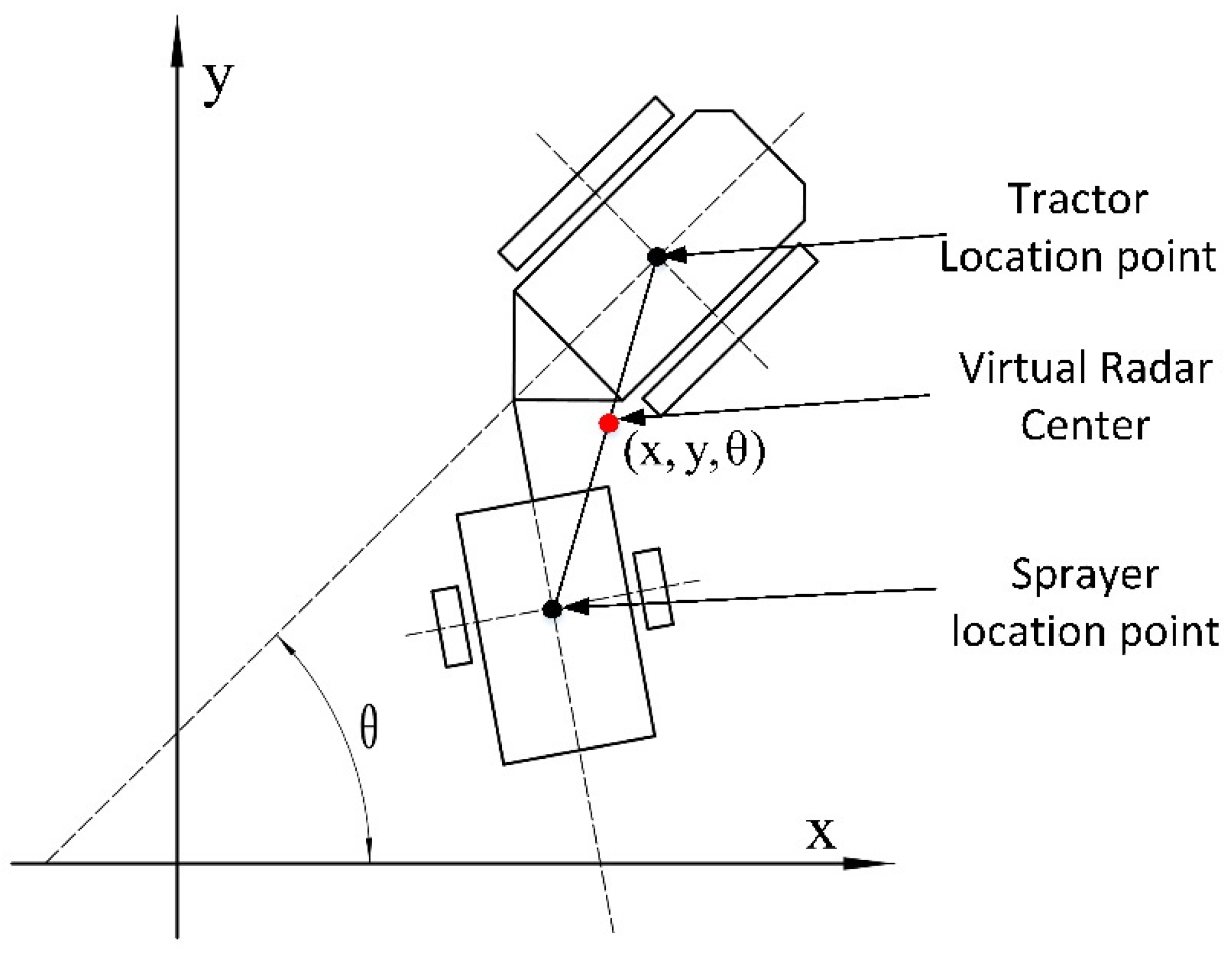

2.2. Kinematic Model of the Traction Spraying Robot

2.3. Double-DQN Model Development

2.3.1. Double-DQN Network Architecture

2.3.2. Double-DQN Training Algorithm

3. Simulation Test Results

3.1. Simulation Environment Creation

3.2. Simulation Test Results

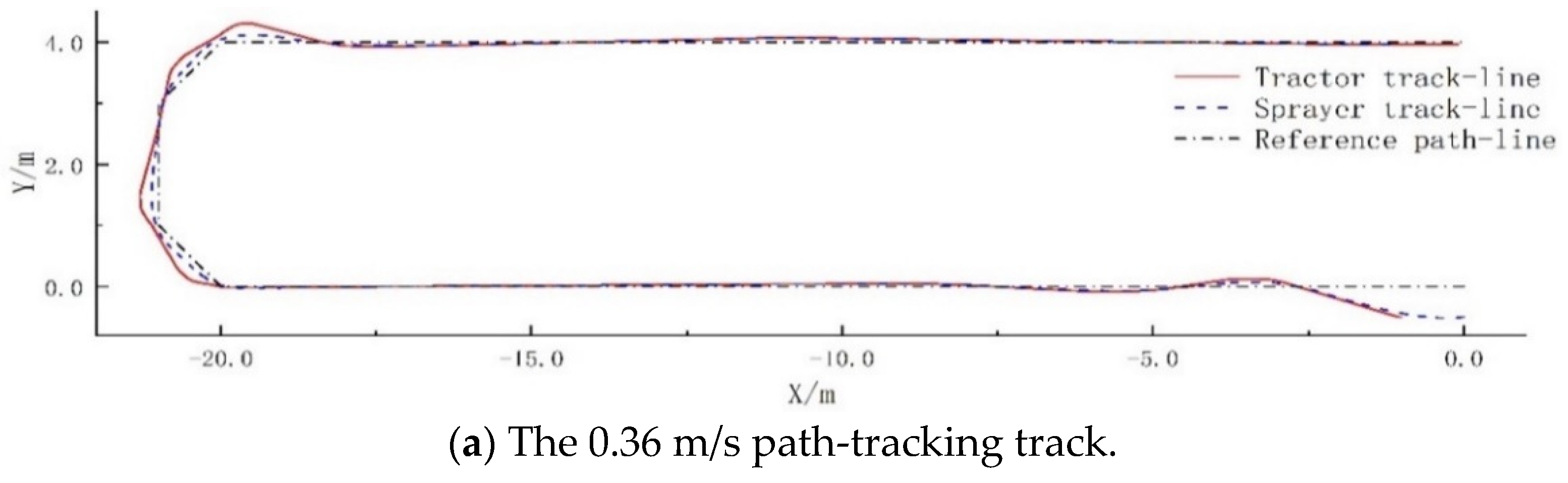

3.3. Validation of Simulation Results

4. Field Test Results

Experimental Results of Robot Path-Tracking Control Algorithm

5. Discussion

6. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, Y.; Xiao, H.; Mei, S.; Song, Z.; Ding, W.; Jin, Y.; Han, Y.; Xia, X.; Yang, G. Current status and development strategies of mechanized orchard production in China. J. China Agric. Univ. 2017, 22, 116–127. [Google Scholar]

- Zheng, Y.J.; Jiang, W.; Chen, B.T.; Lu, H.; Wan, C.; Kang, F. Advances in mechanization technology and equipment for orchards in hilly mountainous areas. J. Agric. Mach. 2020, 51, 1–20. [Google Scholar]

- He, X. Research status and development suggestions on precision application technology and equipment in China. Smart Agric. 2020, 2, 133–146. [Google Scholar]

- Lu, C.; Nie, P.; Wang, L.; Wang, J.; Tao, J. Overview of orchard mechanization development in China Deciduous Fruit Trees. J. Deciduous Fruits 2018, 50, 30–31. [Google Scholar]

- Jing, Y.; Liu, G.; Jin, Z. Navigation sideslip estimation and adaptive control method for farm grader. J. Agric. Mach. 2020, 51, 26–33. [Google Scholar]

- Liu, Z.J.; Wang, S.L.; Ren, Z.G.; Mao, W.J.; Yang, F.Z. A virtual radar model-based navigation path tracking control algorithm for crawler tractors. J. Agric. Mach. 2021, 52, 376–385. [Google Scholar]

- Wang, S.; Song, J.; Qi, P.; Yuan, C.; Wu, H.; Zhang, L.; Liu, W.; Liu, Y.; He, X. Design and development of orchard autonomous navigation spray system. Front. Plant Sci. 2022, 13, 960686. [Google Scholar] [CrossRef] [PubMed]

- Murillo, M.; Sánchez, G.; Deniz, N.; Genzelis, L.; Giovanini, L. Improving path-tracking performance of an articulated tractor-trailer system using a non-linear kinematic model. Comput. Electron. Agric. 2022, 196, 106826. [Google Scholar] [CrossRef]

- Backman, J.; Oksanen, T.; Visala, A. Navigation system for agricultural machines: Nonlinear Model Predictive path tracking. Comput. Electron. Agric. 2012, 82, 32–43. [Google Scholar] [CrossRef]

- Rawlings, J.B.; Risbeck, M.J. Model predictive control with discrete actuators: Theory and application. Automatica 2017, 78, 258–265. [Google Scholar] [CrossRef]

- Kayacan, E.; Kayacan, E.; Ramon, H.; Saeys, W. Distributed nonlinear model predictive control of an autonomous tractor–trailer system. Mechatronics 2014, 24, 926–933. [Google Scholar] [CrossRef]

- Yue, M.; Wu, X.; Guo, L.; Gao, J. Quintic Polynomial-based Obstacle Avoidance Trajectory Planning and Tracking Control Framework for Tractor-trailer System. Int. J. Control Autom. Syst. 2019, 17, 2634–2646. [Google Scholar] [CrossRef]

- Kayacan, E.; Ramon, H.; Saeys, W. Robust Trajectory Tracking Error Model-Based Predictive Control for Unmanned Ground Vehicles. IEEE/ASME Trans. Mechatron. 2015, 21, 806–814. [Google Scholar] [CrossRef]

- Tang, L.; Yan, F.; Zou, B.; Wang, K.; Lv, C. An Improved Kinematic Model Predictive Control for High-Speed Path Tracking of Autonomous Vehicles. IEEE Access 2020, 8, 51400–51413. [Google Scholar] [CrossRef]

- Mondal, K.; Rodriguez, A.A.; Manne, S.S.; Das, N.; Wallace, B. Comparison of Kinematic and Dynamic Model Based Linear Model Predictive Control of Non-Holonomic Robot for Trajectory Tracking: Critical Trade-offs Addressed. In Proceedings of the Control and Optimization of Renewable Energy Systems/860: Mechatronics and Control, Anaheim, CA, USA, 6–7 December 2019. [Google Scholar]

- Kong, J.; Pfeiffer, M.; Schildbach, G.; Borrelli, F. Kinematic and dynamic vehicle models for autonomous driving control design. In Proceedings of the 2015 IEEE Intelligent Vehicles Symposium (IV), Seoul, Korea, 28 June–1 July 2015; pp. 1094–1099. [Google Scholar]

- Werner, R.; Mueller, S.; Kormann, G. Path Tracking Control of Tractors and Steerable Towed Implements Based On Kinematic and Dynamic Modeling. In Proceedings of the 11th International Conference on Precision Agriculture, Indianapolis, IN, USA, 16 July 2012; pp. 15–18. [Google Scholar]

- Ding, Y.; He, Z.; Xia, Z.; Peng, J.; Wu, T. Design of a navigation-immune PID controller for a small tracked rape planter. J. Agric. Eng. 2019, 35, 12–20. [Google Scholar]

- Mnih, V.; Kavukcuoglu, K.; Silver, D.; Rusu, A.A.; Veness, J.; Bellemare, M.G.; Graves, A.; Riedmiller, M.; Fidjeland, A.K.; Ostrovski, G.; et al. Human-level control through deep reinforcement learning. Nature 2015, 518, 529–533. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Liu, J.R.; Luo, I. Parameter design of launch vehicle attitude controller based on DDQN Space Control. Aerosp. Control 2020, 38, 3–8. [Google Scholar] [CrossRef]

- Guo, S.; Zhang, X.; Du, Y.; Zheng, Y.; Cao, Z. Path Planning of Coastal Ships Based on Optimized DQN Reward Function. J. Mar. Sci. Eng. 2021, 9, 210. [Google Scholar] [CrossRef]

- Yang, Q.; Wang, S.; Sang, J.; Wang, C.; Huang, G.; Wu, C.; Song, S. Intelligent ship path planning and obstacle avoidance methods in complex open water. Comput. Integr. Manuf. Syst. 2022, 28, 2030–2040. [Google Scholar] [CrossRef]

- Shan, Y.; Zheng, B.; Chen, L.; Chen, L.; Chen, D. A Reinforcement Learning-Based Adaptive Path Tracking Approach for Autonomous Driving. IEEE Trans. Veh. Technol. 2020, 69, 10581–10595. [Google Scholar] [CrossRef]

| Project | The Parameter Value |

|---|---|

| Dimensions (length × width × height) (mm) | 3610 × 980 × 780 |

| Maximum operating speed (km·h−1) | 4.25 |

| Spraying height (m) | 2.6~3.2 |

| Spraying width (m) | 5~8 |

| Pesticide box volume (L) | 200 |

| Track ground length (mm) | 700 |

| Gauge (mm) | 700 |

| Tractor supporting power (kW) | 12 |

| Sprayer supporting power (kW) | 6.3 |

| Hyperparameter | Value |

|---|---|

| Minibatch size | 16 |

| Replay memory size | 20,000 |

| update frequency | 200 |

| Discount factor γ | 0.99 |

| Learning rate | 0.0001 |

| Initial exploration ε | 0.9 |

| (0, 70] | (−90, −10] | 1 (left turn) |

| −1 (other actions) | ||

| (−10, 0) | 1 (straight) | |

| −1 (other actions) | ||

| [0, 90) | 1 (right) | |

| −1 (other actions) | ||

| (70, 150] | (−90, −20] | 1 (left) |

| −1 (other actions) | ||

| (−20, −12) | 1 (straight) | |

| −1 (other actions) | ||

| [−12, 90) | 1 (right) | |

| −1 (other actions) | ||

| (150, 700] | (−90, −30] | 1 (left) |

| −1 (other actions) | ||

| (−30, −22) | 1 (straight) | |

| −1 (other actions) | ||

| [−22, 90) | 1 (right) | |

| −1 (other actions) |

| [−70, 0) | (−90, 0] | 1 (left) |

| −1 (other actions) | ||

| (0, 10) | 1 (straight) | |

| −1 (other actions) | ||

| [10, 90) | 1 (right) | |

| −1 (other actions) | ||

| [−150, −70) | (−90, 12] | 1 (left) |

| −1 (other actions) | ||

| (12, 20) | 1 (straight) | |

| −1 (other actions) | ||

| [20, 90) | 1 (right) | |

| −1 (other actions) | ||

| [−700, −150) | (−90, 22] | 1 (left) |

| −1 (other actions) | ||

| (22, 30) | 1 (straight) | |

| −1 (other actions) | ||

| [30, 90) | 1 (right) | |

| −1 (other actions) |

| v/(m/s) | Test No. | Sprayer Path-Tracking Deviation | |||||

|---|---|---|---|---|---|---|---|

| Maximum Lateral Deviation /(m) | Average Lateral Deviation /(m) | Standard Deviation/(m) | |||||

| Straight Line (0~20 m) | Full Range | Straight Line (0~20 m) | Full Range | Straight Line (0~20 m) | Full Range | ||

| 0.36 | r361 | 0.128 | 0.233 | 0.043 | 0.070 | 0.026 | 0.051 |

| r362 | 0.120 | 0.225 | 0.041 | 0.069 | 0.025 | 0.049 | |

| r363 | 0.134 | 0.240 | 0.045 | 0.073 | 0.028 | 0.054 | |

| 0.127 | 0.233 | 0.043 | 0.071 | 0.026 | 0.051 | ||

| l361 | 0.126 | 0.536 | 0.051 | 0.084 | 0.021 | 0.059 | |

| l362 | 0.146 | 0.558 | 0.061 | 0.080 | 0.023 | 0.069 | |

| l363 | 0.113 | 0.509 | 0.056 | 0.066 | 0.026 | 0.063 | |

| 0.128 | 0.534 | 0.056 | 0.077 | 0.023 | 0.064 | ||

| 0.75 | r751 | 0.145 | 0.263 | 0.055 | 0.076 | 0.033 | 0.056 |

| r752 | 0.155 | 0.275 | 0.057 | 0.079 | 0.034 | 0.058 | |

| r753 | 0.140 | 0.259 | 0.054 | 0.074 | 0.032 | 0.056 | |

| 0.147 | 0.266 | 0.055 | 0.076 | 0.033 | 0.057 | ||

| l751 | 0.149 | 0.536 | 0.057 | 0.081 | 0.030 | 0.062 | |

| l752 | 0.178 | 0.554 | 0.054 | 0.081 | 0.034 | 0.066 | |

| l753 | 0.207 | 0.558 | 0.061 | 0.078 | 0.034 | 0.059 | |

| 0.178 | 0.549 | 0.057 | 0.080 | 0.033 | 0.062 | ||

| v/(m/s) | Test No. | Maximum Lateral Deviation /(m) | Average Lateral Deviation /(m) | Standard Deviation /(m) |

|---|---|---|---|---|

| 0.36 | 0.127 | 0.043 | 0.026 | |

| 0.128 | 0.056 | 0.023 | ||

| −0.001 (0.78%) | −0.013 (23.21%) | 0.003 (13.04%) | ||

| 0.75 | 0.147 | 0.055 | 0.033 | |

| 0.178 | 0.057 | 0.033 | ||

| −0.031 (17.41%) | −0.002 (3.51%) | 0 (0%) |

| v/(m/s) | Test No. | Maximum Lateral Deviation /(m) | Average Lateral Deviation /(m) | Standard Deviation /(m) |

|---|---|---|---|---|

| 0.36 | 0.233 | 0.071 | 0.051 | |

| 0.534 | 0.077 | 0.064 | ||

| −0.301 (56.37%) | −0.006 (7.8%) | 0.013 (20.31%) | ||

| 0.75 | 0.266 | 0.076 | 0.057 | |

| 0.549 | 0.080 | 0.062 | ||

| −0.283 (51.54%) | −0.004 (5.0%) | −0.005 (8.1%) |

| v/(m/s) | Path Shape | Test No. | Maximum Lateral Deviation /(m) | Average Lateral Deviation /(m) | Standard Deviation /(m) |

|---|---|---|---|---|---|

| 0.36 | Straight | 0.127 | 0.043 | 0.026 | |

| ‘U’-shaped | 0.233 | 0.071 | 0.051 | ||

| 0.106 (83.46%) | 0.028 (65.12%) | 0.025 (96.15%) | |||

| Straight | 0.128 | 0.056 | 0.023 | ||

| ‘U’-shaped | 0.534 | 0.077 | 0.064 | ||

| 0.406 (317.19%) | 0.021 (37.5%) | 0.041 (178.26%) | |||

| 0.75 | Straight | 0.147 | 0.055 | 0.033 | |

| ‘U’-shaped | 0.266 | 0.076 | 0.057 | ||

| 0.119 (80.95%) | 0.021 (38.18%) | 0.024 (72.72%) | |||

| Straight | 0.178 | 0.057 | 0.033 | ||

| ‘U’-shaped | 0.549 | 0.080 | 0.062 | ||

| 0.371 (208.43%) | 0.023 (40.35%) | 0.029 (87.88%) |

| v/(m/s) | Model | Test No. | Maximum Lateral Deviation /(m) | Average Lateral Deviation /(m) | Standard Deviation /(m) |

|---|---|---|---|---|---|

| 0.36 | Tractor | 0.382 | 0.087 | 0.075 | |

| Trailer | 0.233 | 0.071 | 0.051 | ||

| −0.149 (39.0%) | −0.016 (18.39%) | −0.024 (32%) | |||

| Tractor | 0.150 | 0.031 | 0.025 | ||

| Trailer | 0.534 | 0.077 | 0.064 | ||

| 0.384 (256.0%) | 0.046 (148.39%) | 0.039 (156.0%) | |||

| 0.75 | Tractor | 0.448 | 0.110 | 0.095 | |

| Trailer | 0.266 | 0.076 | 0.057 | ||

| −0.222 (45.5%) | −0.034 (30.9%) | −0.038 (40%) | |||

| Tractor | 0.191 | 0.051 | 0.036 | ||

| Trailer | 0.549 | 0.080 | 0.062 | ||

| 0.358 (187.43%) | 0.029 (56.86%) | 0.026 (72.22%) |

| v/(m/s) | Test Type | Maximum Lateral Deviation /(m) | Average Lateral Deviation /(m) | Standard Deviation /(m) |

|---|---|---|---|---|

| 0.36 | Simulation | 0.117 | 0.038 | 0.028 |

| Field | 0.233 | 0.071 | 0.051 | |

| 0.116 (99.14%) | 0.033 (86.84%) | 0.023 (82.14%) | ||

| 0.75 | Simulation | 0.119 | 0.040 | 0.029 |

| Field | 0.266 | 0.076 | 0.057 | |

| 0.147 (123.53%) | 0.036 (90%) | 0.028 (96.55%) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, Z.; Liu, Z.; Yuan, M.; Liu, H.; Wang, W.; Qin, J.; Yang, F. Double-DQN-Based Path-Tracking Control Algorithm for Orchard Traction Spraying Robot. Agronomy 2022, 12, 2803. https://doi.org/10.3390/agronomy12112803

Ren Z, Liu Z, Yuan M, Liu H, Wang W, Qin J, Yang F. Double-DQN-Based Path-Tracking Control Algorithm for Orchard Traction Spraying Robot. Agronomy. 2022; 12(11):2803. https://doi.org/10.3390/agronomy12112803

Chicago/Turabian StyleRen, Zhigang, Zhijie Liu, Minxin Yuan, Heng Liu, Wang Wang, Jifeng Qin, and Fuzeng Yang. 2022. "Double-DQN-Based Path-Tracking Control Algorithm for Orchard Traction Spraying Robot" Agronomy 12, no. 11: 2803. https://doi.org/10.3390/agronomy12112803

APA StyleRen, Z., Liu, Z., Yuan, M., Liu, H., Wang, W., Qin, J., & Yang, F. (2022). Double-DQN-Based Path-Tracking Control Algorithm for Orchard Traction Spraying Robot. Agronomy, 12(11), 2803. https://doi.org/10.3390/agronomy12112803