A Simple, Semi-Automated, Gravimetric Method to Simulate Drought Stress on Plants

Abstract

:1. Introduction

2. Materials and Methods

2.1. Lysimeter System

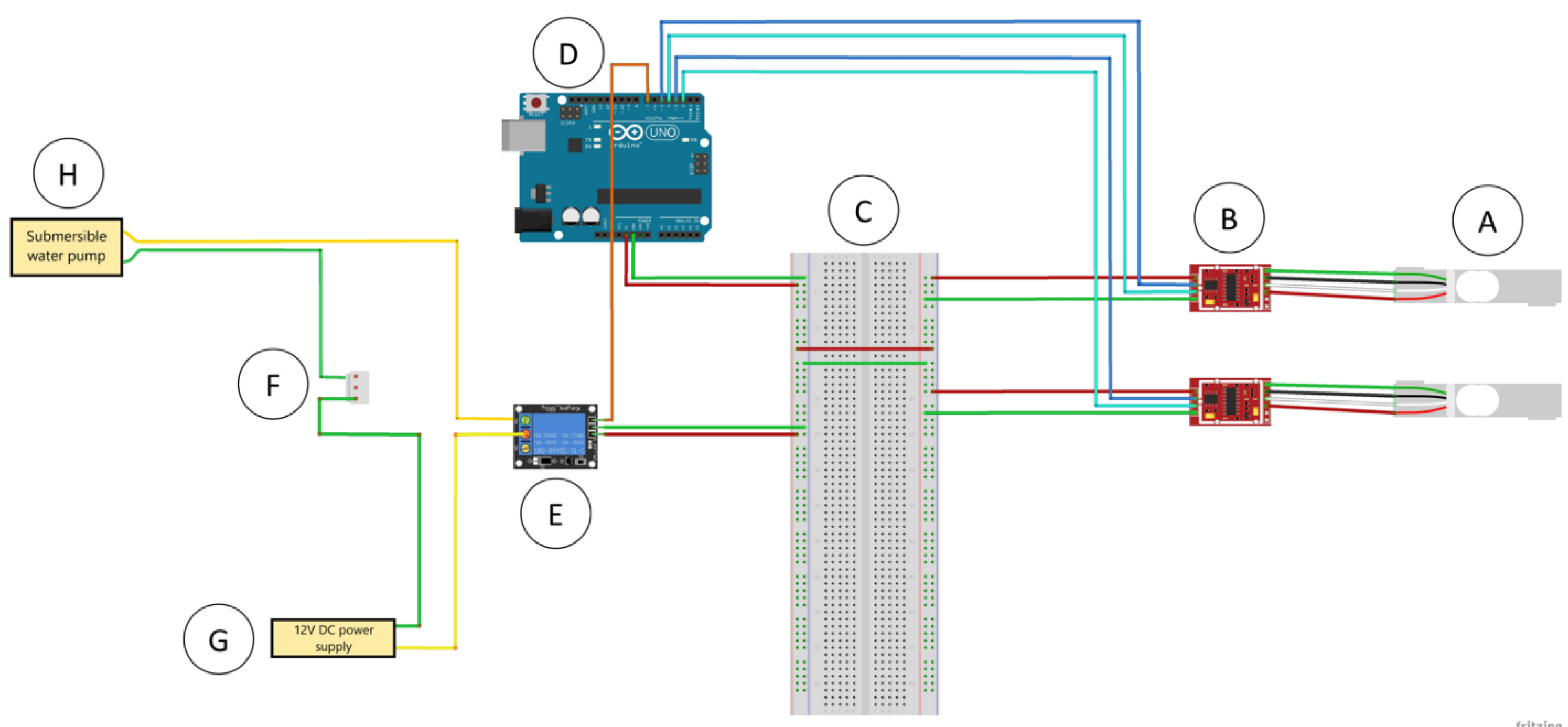

2.1.1. Design and Components

2.1.2. Software and Code

2.2. Operating the Lysimeter System

2.2.1. Determining Soil Water Holding Capacity

2.2.2. Applying Soil Water Treatments

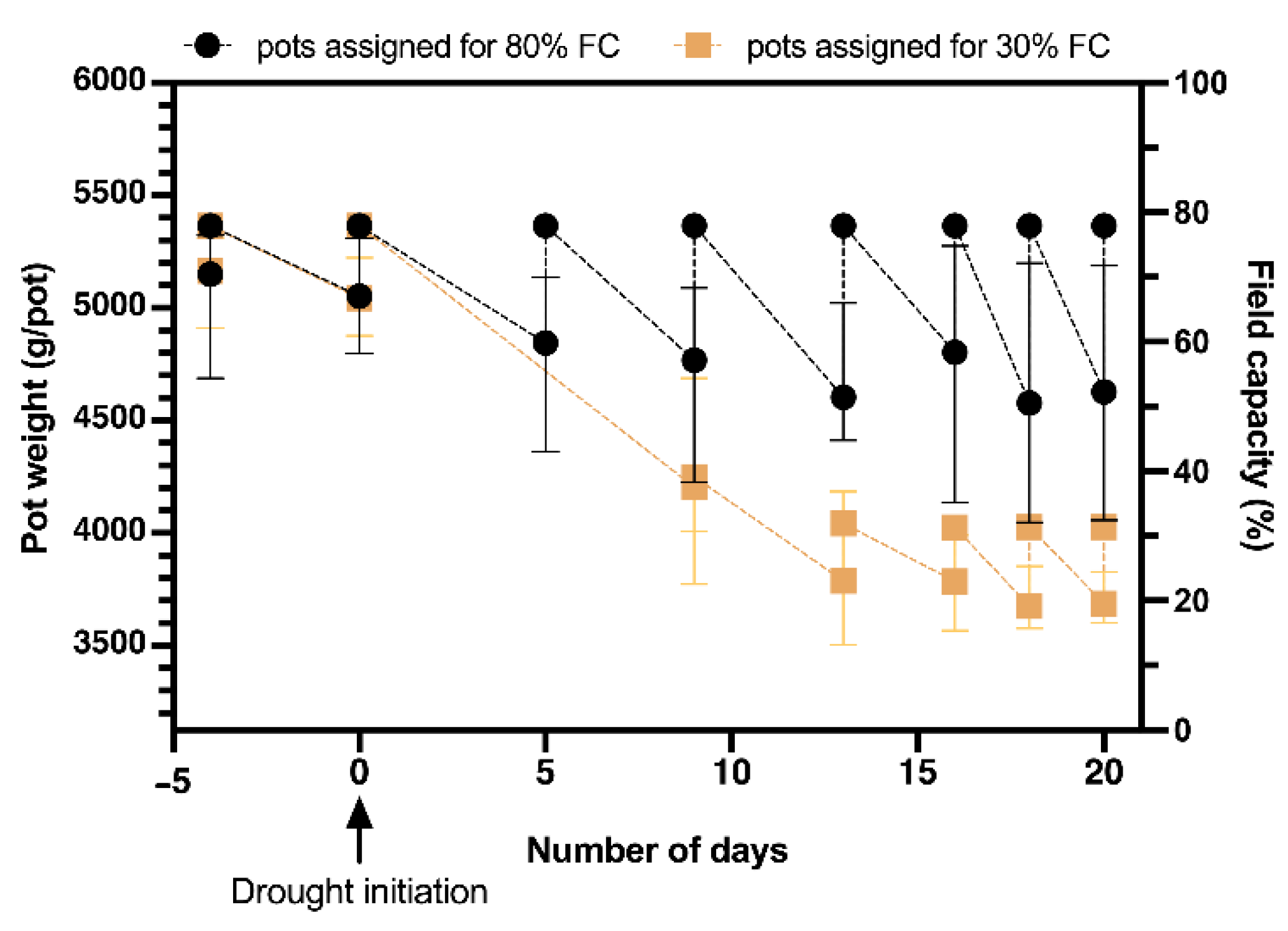

2.3. Validation of Arduino-Based Lysimeter

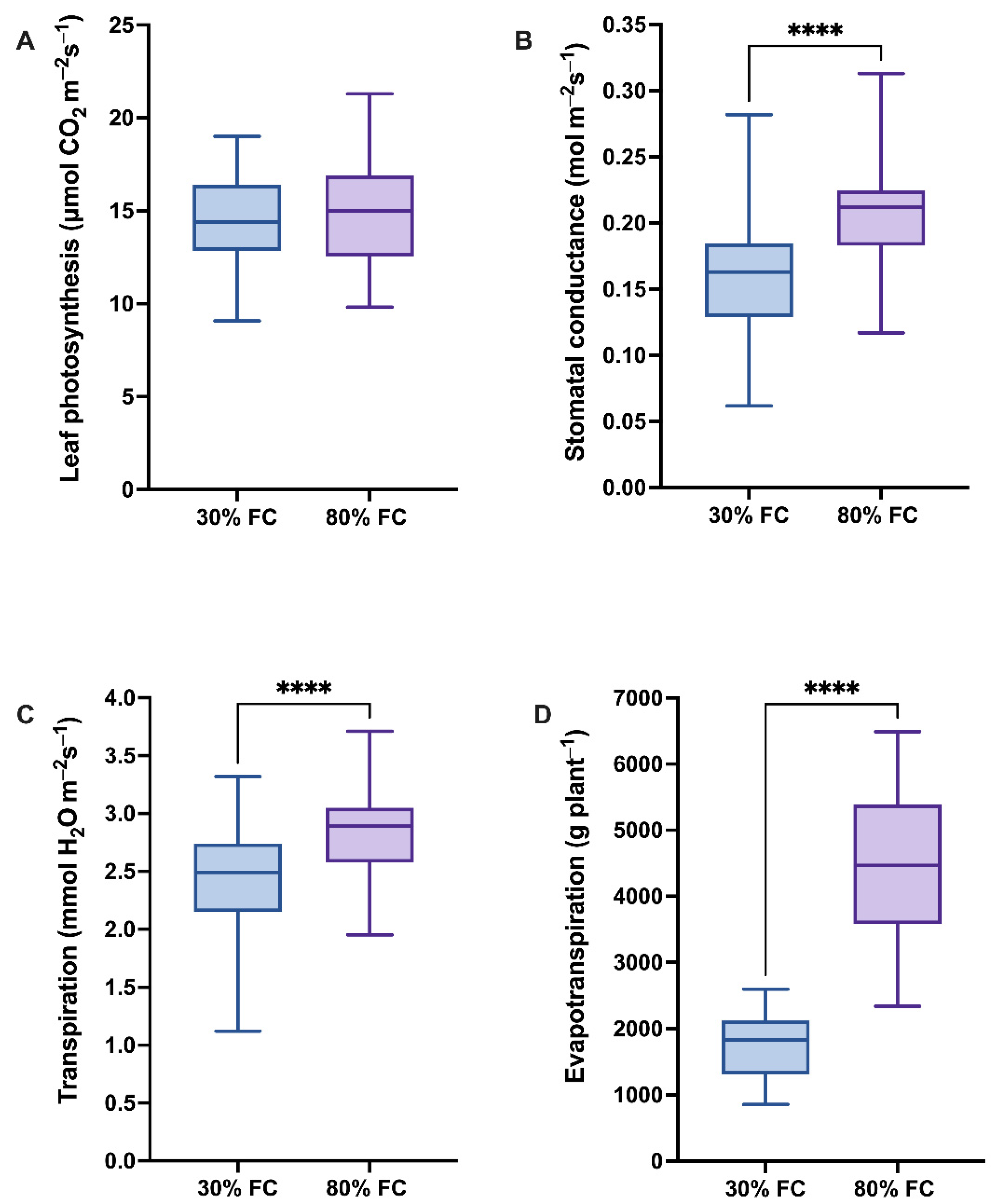

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Keyantash, J.; Dracup, J.A. The Quantification of Drought: An Evaluation of Drought Indices. Bull. Am. Meteorol. Soc. 2002, 83, 1167–1180. [Google Scholar] [CrossRef]

- Bacelar, E.L.V.A.; Moutinho-Pereira, J.M.; Gonçalves, B.M.C.; Brito, C.V.Q.; Gomes-Laranjo, J.; Ferreira, H.M.F.; Correia, C.M. Water Use Strategies of Plants under Drought Conditions. In Plant Responses to Drought Stress; Aroca, R., Ed.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 145–170. ISBN 9783642326530. [Google Scholar]

- United Nations. Department of Economics and Social Affairs. 2019. Available online: https://www.un.org/development/desa/en/news/population/world-population-prospects-2019.html.Html (accessed on 21 November 2021).

- Sheffield, J.; Wood, E.F.; Roderick, M.L. Little Change in Global Drought over the Past 60 Years. Nature 2012, 491, 435–438. [Google Scholar] [CrossRef] [PubMed]

- Basu, S.; Ramegowda, V.; Kumar, A.; Pereira, A. Plant Adaptation to Drought Stress. F1000Research 2016, 5, 1554. [Google Scholar] [CrossRef] [PubMed]

- Wasaya, A.; Zhang, X.; Fang, Q.; Yan, Z. Root Phenotyping for Drought Tolerance: A Review. Agronomy 2018, 8, 241. [Google Scholar] [CrossRef] [Green Version]

- Earl, H.J.; Davis, R.F. Effect of Drought Stress on Leaf and Whole Canopy Radiation Use Efficiency and Yield of Maize. Agron. J. 2003, 95, 688–696. [Google Scholar] [CrossRef]

- Ganjeali, A.; Porsa, H.; Bagheri, A. Assessment of Iranian Chickpea (Cicer Arietinum L.) Germplasms for Drought Tolerance. Agric. Water Manag. 2011, 98, 1477–1484. [Google Scholar] [CrossRef]

- Janiak, A.; Kwaśniewski, M.; Szarejko, I. Gene Expression Regulation in Roots under Drought. J. Exp. Bot. 2016, 67, 1003–1014. [Google Scholar] [CrossRef] [Green Version]

- Jabbari, M.; Fakheri, B.A.; Aghnoum, R.; Nezhad, N.M.; Ataei, R. GWAS Analysis in Spring Barley (Hordeum Vulgare L.) for Morphological Traits Exposed to Drought. PLoS ONE 2018, 13, e0204952. [Google Scholar] [CrossRef] [Green Version]

- Tarawneh, R.A.; Alqudah, A.M.; Nagel, M.; Börner, A. Genome-Wide Association Mapping Reveals Putative Candidate Genes for Drought Tolerance in Barley. Environ. Exp. Bot. 2020, 180, 104237. [Google Scholar] [CrossRef]

- Marchin, R.M.; Ossola, A.; Leishman, M.R.; Ellsworth, D.S. A Simple Method for Simulating Drought Effects on Plants. Front. Plant Sci. 2020, 10, 1715. [Google Scholar] [CrossRef] [Green Version]

- Gorim, L.Y.; Vandenberg, A. Evaluation of Wild Lentil Species as Genetic Resources to Improve Drought Tolerance in Cultivated Lentil. Front. Plant Sci. 2017, 8, 1129. [Google Scholar] [CrossRef] [PubMed]

- Gorim, L.Y.; Vandenberg, A. Root Traits, Nodulation and Root Distribution in Soil for Five Wild Lentil Species and Lens Culinaris (Medik.) Grown under Well-Watered Conditions. Front. Plant Sci. 2017, 8, 1632. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lehnert, H.; Serfling, A.; Friedt, W.; Ordon, F. Genome-Wide Association Studies Reveal Genomic Regions Associated with the Response of Wheat (Triticum Aestivum L.) to Mycorrhizae under Drought Stress Conditions. Front. Plant Sci. 2018, 9, 1728. [Google Scholar] [CrossRef] [PubMed]

- Shirinbayan, S.; Khosravi, H.; Malakouti, M.J. Alleviation of Drought Stress in Maize (Zea mays) by Inoculation with Azotobacter Strains Isolated from Semi-Arid Regions. Appl. Soil Ecol. 2019, 133, 138–145. [Google Scholar] [CrossRef]

- Turner, N.C. Imposing and Maintaining Soil Water Deficits in Drought Studies in Pots. Plant Soil 2019, 439, 45–55. [Google Scholar] [CrossRef]

- Blonquist, J.M.; Jones, S.B.; Robinson, D.A. Standardizing Characterization of Electromagnetic Water Content Sensors: Part 2. Evaluation of Seven Sensing Systems. Vadose Zone J. 2005, 4, 1059–1069. [Google Scholar] [CrossRef]

- Bogena, H.R.; Huisman, J.A.; Schilling, B.; Weuthen, A.; Vereecken, H. Effective Calibration of Low-Cost Soil Water Content Sensors. Sensors 2017, 17, 208. [Google Scholar] [CrossRef] [Green Version]

- Campbell, D.I.; Laybourne, C.E.; Ian, J. Blair Measuring Peat Moisture Content Using the Dual-Probe Heat Pulse Technique. Aust. J. Soil Sci. 2002, 40, 177–190. [Google Scholar]

- Earl, H.J. A Precise Gravimetric Method for Simulating Drought Stress in Pot Experiments. Crop Sci. 2003, 43, 1868–1873. [Google Scholar] [CrossRef]

- Kojima, Y.; Shigeta, R.; Miyamoto, N.; Shirahama, Y.; Nishioka, K.; Mizoguchi, M.; Kawahara, Y. Low-Cost Soil Moisture Profile Probe Using Thin-Film Capacitors and a Capacitive Touch Sensor. Sensors 2016, 16, 1292. [Google Scholar] [CrossRef]

- Ortiz, D.; Litvin, A.G.; Salas Fernandez, M.G. A Cost-Effective and Customizable Automated Irrigation System for Precise High-Throughput Phenotyping in Drought Stress Studies. PLoS ONE 2018, 13, e0198546. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Susha Lekshmi, S.U.; Singh, D.N.; Shojaei Baghini, M. A Critical Review of Soil Moisture Measurement. J. Int. Meas. Confed. 2014, 54, 92–105. [Google Scholar] [CrossRef]

- Robinson, D.A.; Jones, S.B.; Wraith, J.M.; Or, D.; Friedman, S.P. A Review of Advances in Dielectric and Electrical Conductivity Measurement in Soils Using Time Domain Reflectometry. Vadose Zo. J. 2003, 2, 444–475. [Google Scholar] [CrossRef]

- Dobriyal, P.; Qureshi, A.; Badola, R.; Hussain, S.A. A Review of the Methods Available for Estimating Soil Moisture and Its Implications for Water Resource Management. J. Hydrol. 2012, 458, 110–117. [Google Scholar] [CrossRef]

- Chard, J.; van Iersel, M.W.; Bugbee, B. Mini-Lysimeters to Monitor Transpiration and Control Drought Stress: System Design and Unique Applications; Utah State University: Logan, UT, USA, 2010. [Google Scholar]

- Gebre, M.G.; Earl, H.J. Effects of Growth Medium and Water Stress on Soybean [Glycine Max (L.) Merr.] Growth, Soil Water Extraction and Rooting Profiles by Depth in 1-m Rooting Columns. Front. Plant Sci. 2020, 11, 487. [Google Scholar] [CrossRef]

- McCauley, D.; Levin, A.; Nackley, L. Reviewing Mini-Lysimeter Controlled Irrigation in Container Crop Systems. Hort Technol. 2021, 31, 634–641. [Google Scholar] [CrossRef]

- Gebre, M.G.; Earl, H.J. Soil Water Deficit and Fertilizer Placement Effects on Root Biomass Distribution, Soil Water Extraction, Water Use, Yield, and Yield Components of Soybean [Glycine Max (L.) Merr.] Grown in 1-m Rooting Columns. Front. Plant Sci. 2021, 12, 581127. [Google Scholar] [CrossRef]

- Wright, D.E.J.; Cline, J.A.; Earl, H.J. Physiological Responses of Four Apple (Malus × Domestica Borkh.) Rootstock Genotypes to Soil Water Deficits. Can. J. Plant Sci. 2019, 99, 510–524. [Google Scholar] [CrossRef]

- Ahuja, L.R.; Nachabe, M.H.; Rockiki, R. Soils: Field Capacity. Encycl. Water Sci. Second Ed. 2008, 2, 1128–1131. [Google Scholar]

- Thilakarathna, M.S.; Moroz, N.; Raizada, M.N. A Biosensor-Based Leaf Punch Assay for Glutamine Correlates to Symbiotic Nitrogen Fixation Measurements in Legumes to Permit Rapid Screening of Rhizobia Inoculants under Controlled Conditions. Front. Plant Sci. 2017, 8, 1714. [Google Scholar] [CrossRef] [Green Version]

- Liu, F.; Jensen, C.R.; Andersen, M.N. Hydraulic and Chemical Signals in the Control of Leaf Expansion and Stomatal Conductance in Soybean Exposed to Drought Stress. Funct. Plant Biol. 2003, 30, 65–73. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Andersen, M.N.; Jacobsen, S.E.; Jensen, C.R. Stomatal Control and Water Use Efficiency of Soybean (Glycine Max L. Merr.) during Progressive Soil Drying. Environ. Exp. Bot. 2005, 54, 33–40. [Google Scholar] [CrossRef]

- Ohashi, Y.; Nakayama, N.; Saneoka, H.; Fujita, K. Effects of Drought Stress on Photosynthetic Gas Exchange, Chlorophyll Fluorescence and Stem Diameter of Soybean Plants. Biol. Plant. 2006, 50, 138–141. [Google Scholar] [CrossRef]

- He, J.; Du, Y.L.; Wang, T.; Turner, N.C.; Yang, R.P.; Jin, Y.; Xi, Y.; Zhang, C.; Cui, T.; Fang, X.W.; et al. Conserved Water Use Improves the Yield Performance of Soybean (Glycine Max (L.) Merr.) under Drought. Agric. Water Manag. 2017, 179, 236–245. [Google Scholar] [CrossRef]

- Medina, V.; Gilbert, M.E. Physiological Trade-Offs of Stomatal Closure under High Evaporative Gradients in Field Grown Soybean. Funct. Plant Biol. 2016, 43, 40–51. [Google Scholar] [CrossRef] [PubMed]

- Misra, R.K.; Padhi, J.; Payero, J.O. A Calibration Procedure for Load Cells to Improve Accuracy of Mini-Lysimeters in Monitoring Evapotranspiration. J. Hydrol. 2011, 406, 113–118. [Google Scholar] [CrossRef] [Green Version]

- Meena, H.M.; Singh, R.K.; Santra, P. Design and Development of a Load-Cell Based Cost Effective Mini-Lysimeter. J. Agric. Phys. 2015, 15, 1–6. [Google Scholar]

- Walden-Coleman, A.E.; Rajcan, I.; Earl, H.J. Dark-Adapted Leaf Conductance, but Not Minimum Leaf Conductance, Predicts Water Use Efficiency of Soybean (Glycine max L. Merr.). Can. J. Plant Sci. 2013, 93, 13–22. [Google Scholar] [CrossRef]

| Component | Component Image | Specifications | Number of Units Required |

|---|---|---|---|

| Arduino Uno R3 USB Microcontroller |  | Microcontroller: ATmega328 Operating Voltage: 5 V Input Voltage (recommended): 7–12 V Input Voltage (limits): 6–20 V Digital I/O Pins: 14 (of which 6 provide PWM output) Analog Input Pins: 6 DC Current per I/O Pin: 40 mA DC Current for 3.3 V Pin: 50 mA Flash Memory: 32 KB (ATmega328) of which 0.5 KB used by the bootloader SRAM: 2 KB (ATmega328) EEPROM: 1 KB (ATmega328) Clock Speed: 16 MHz | 1 |

| Submersible water pump |  | Ultra-quiet DC12 V 4.2 W Power: Electric Pressure: Low Pressure Structure: Submersible Pump Theory: Brushless Submersible pump | 1 |

| Power Adaptor |  | 1 A Output Voltage: 12 V Plug Type: US Plug | 1 |

| Relay Module for Arduino |  | 1 Channel 5 V | 1 |

| Flexible Hose |  | Material: Silicon Main Color: Clear Inner Dia (ID): 8 mm Outer Dia (OD): 10 mm; Wall Thickness: 1.2 mm Length: 1 m | 1 |

| Compact Wire Wiring Connector with lever |  | Model Number: 222–412 413 415 Material of Insulation: modified nylon (PA66) Contact material: phosphor copper Wire Cross section: 0.08~2.5 mm2 (single hardwire), 0.08~4 mm2 (multi soft wire) Rated Current: 32 A Rated power: 7 KW Gauge: 28~12 AWG Strip length: 9–10 mm | 1 |

| Transparent Box Case Shell for Arduino UNO R3 |  | Material: Acrylic Locking mechanism: Screwless locking Color: Transparent | 1 |

| USB cable |  | Material: Metal and environmental PVC Connectors: 4-pin USB type A (male) to 4-pin USB type B (male) Shield: Metal woven mesh + aluminum foil Transmission Rate: Up to 480 Mbps Approval: RoHS Color: Black, light blue Length: 1 m/3.28 ft | 1 |

| 20 kg pressure sensor + HX711AD module weighing scale |  | 20 kg Tray diameter 10 cm Operating voltage DC 5 V HX711AD (24-bit conversion) | 2 |

| Solderless Breadboard |  | 400 tie points in total, 100 in 2 power rails, 300 in a 30 × 10 matrix Transparent plastic, with black legend. Colored power rails For wires 21 to 26 AWG 2-sided peelable adhesive tape | 1 |

| Dupont Jumper Wire |  | Length: 30 cm Package: 20 wires per each category | 1 |

| Lab Trolly |  | Material: Hard Plastic Functions: portable Weight: Lightweight | 1 |

| Burette holder/clamp |  | Material: Metal Functions: Fully adjustable | 1 |

| Laptop |  | Operating system: Windows/Apple operating systems | 1 |

| Power extension code |  | Length: As per your requirement | 1 |

| Water reservoir |  | Any plastic container to hold sufficient amount of water | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liyanage, D.K.; Chathuranga, I.; Mori, B.A.; Thilakarathna, M.S. A Simple, Semi-Automated, Gravimetric Method to Simulate Drought Stress on Plants. Agronomy 2022, 12, 349. https://doi.org/10.3390/agronomy12020349

Liyanage DK, Chathuranga I, Mori BA, Thilakarathna MS. A Simple, Semi-Automated, Gravimetric Method to Simulate Drought Stress on Plants. Agronomy. 2022; 12(2):349. https://doi.org/10.3390/agronomy12020349

Chicago/Turabian StyleLiyanage, Dilrukshi Kombala, Ishan Chathuranga, Boyd A. Mori, and Malinda S. Thilakarathna. 2022. "A Simple, Semi-Automated, Gravimetric Method to Simulate Drought Stress on Plants" Agronomy 12, no. 2: 349. https://doi.org/10.3390/agronomy12020349

APA StyleLiyanage, D. K., Chathuranga, I., Mori, B. A., & Thilakarathna, M. S. (2022). A Simple, Semi-Automated, Gravimetric Method to Simulate Drought Stress on Plants. Agronomy, 12(2), 349. https://doi.org/10.3390/agronomy12020349