The Development of an Electric-Driven Control System for a High-Speed Precision Planter Based on the Double Closed-Loop Fuzzy PID Algorithm

Abstract

1. Introduction

- Directly analyze the longitude and latitude signal sent by BDS as the system signal input source to drive the motor to complete the sowing operation without installing additional sensors, which saves the production cost to a certain extent.

- The double closed-loop fuzzy PID control algorithm is used to accurately control the motor and shorten the response time of the motor.

- CAN bus (Controller Area Network) is used as the communication medium of the system to improve the fault tolerance and scalability of the system.

2. Materials and Methods

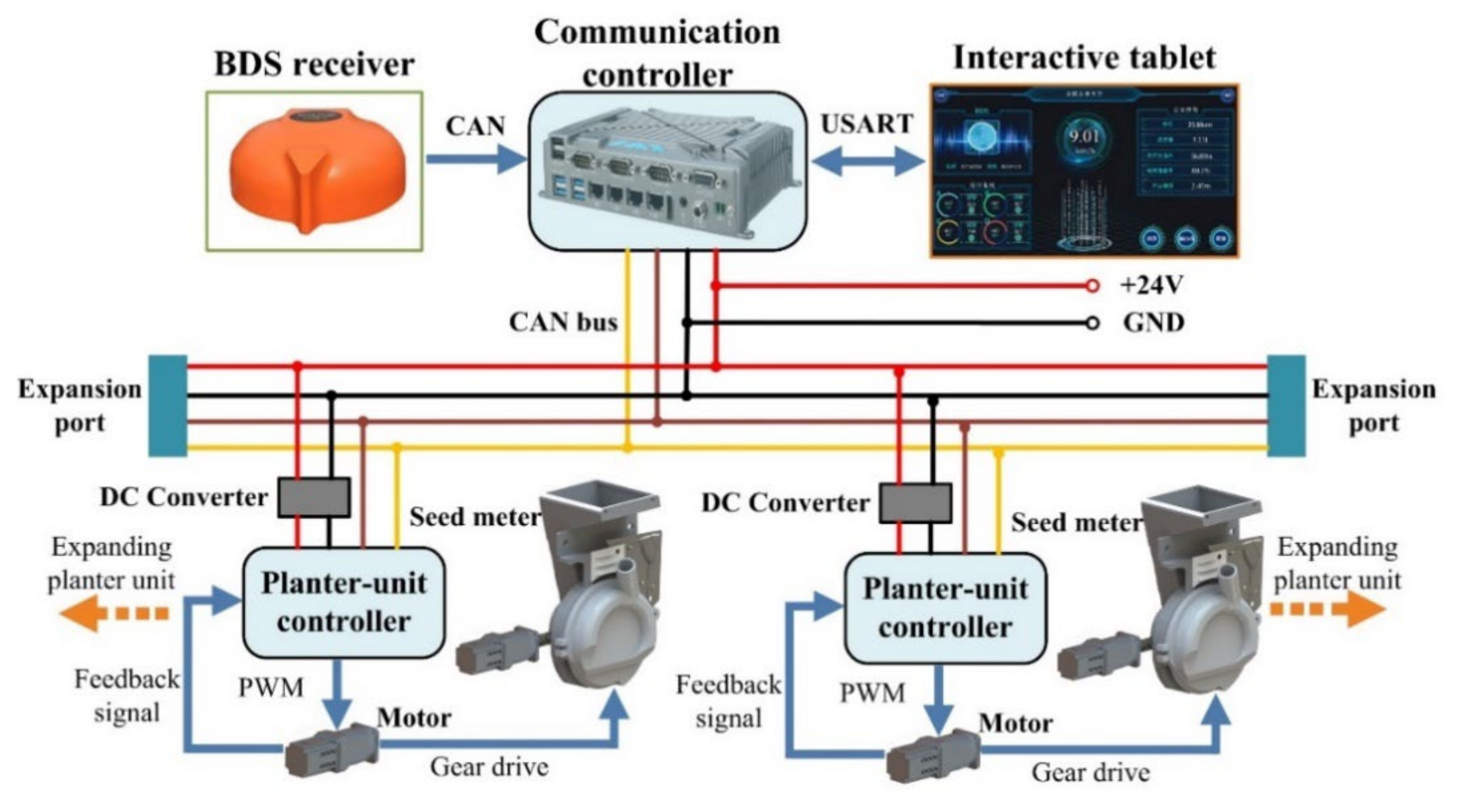

2.1. High-Speed Precision Seeding Control System

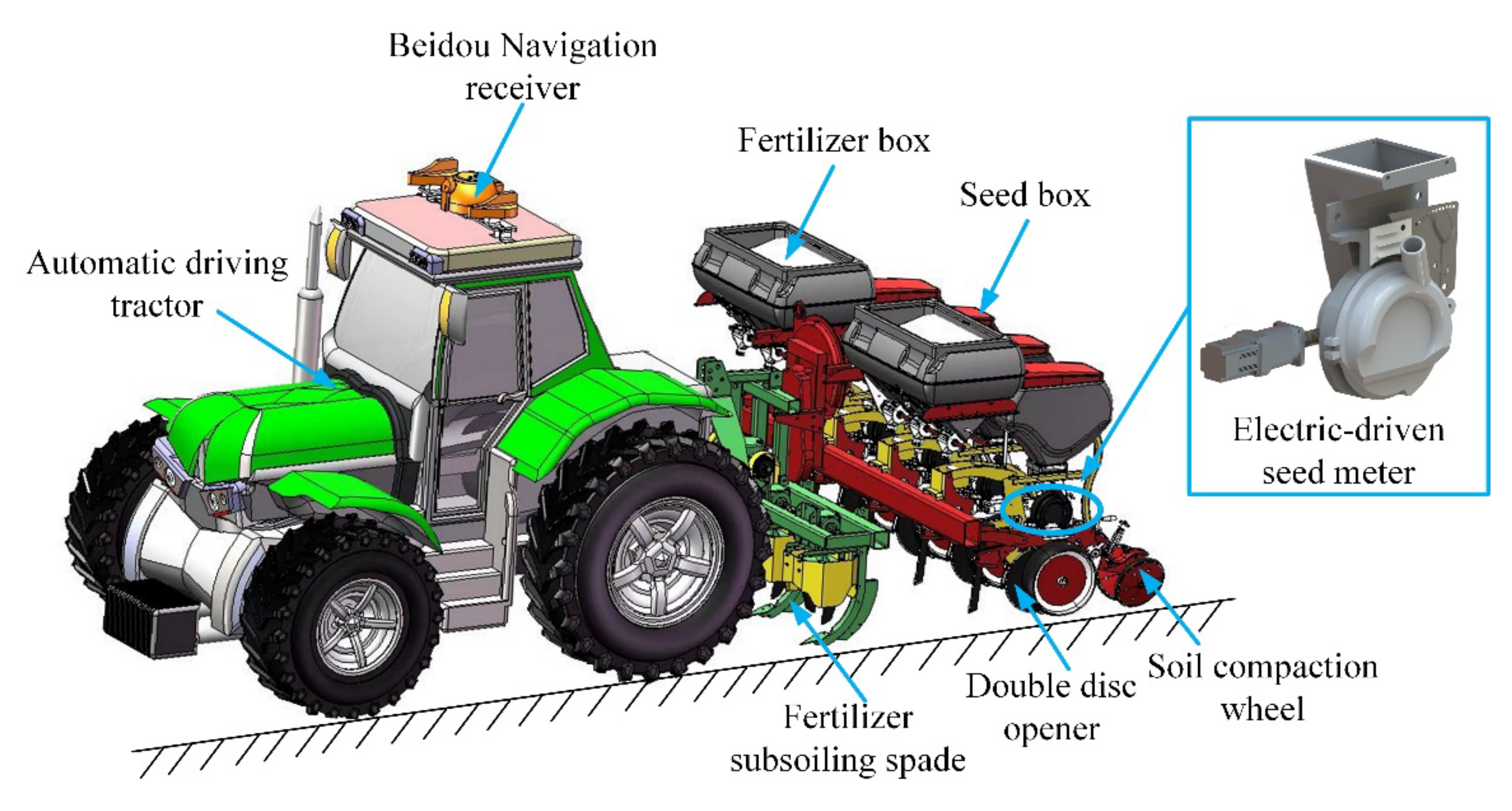

2.1.1. Overall Structure of Seeding Unit

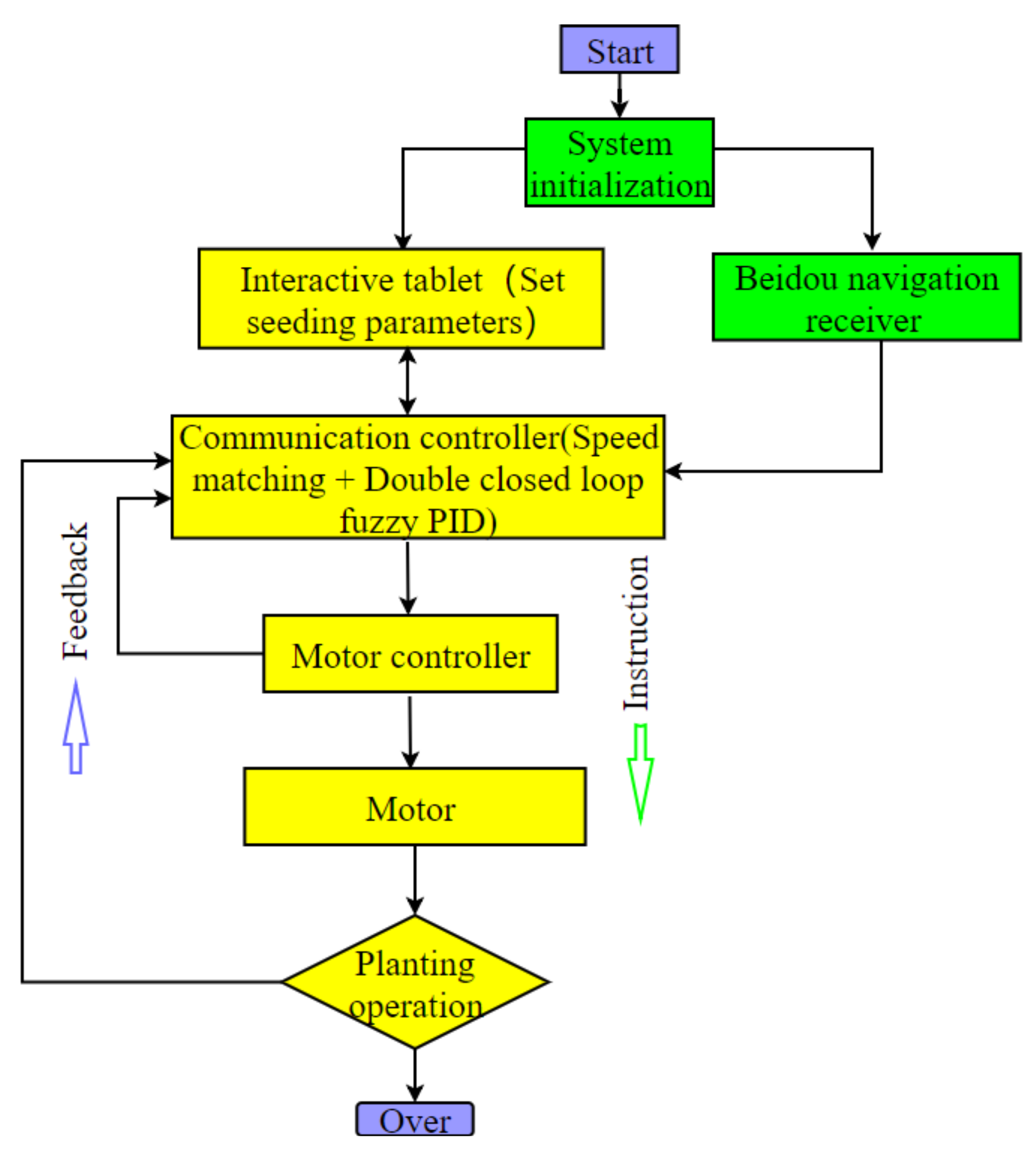

2.1.2. System Working Overview

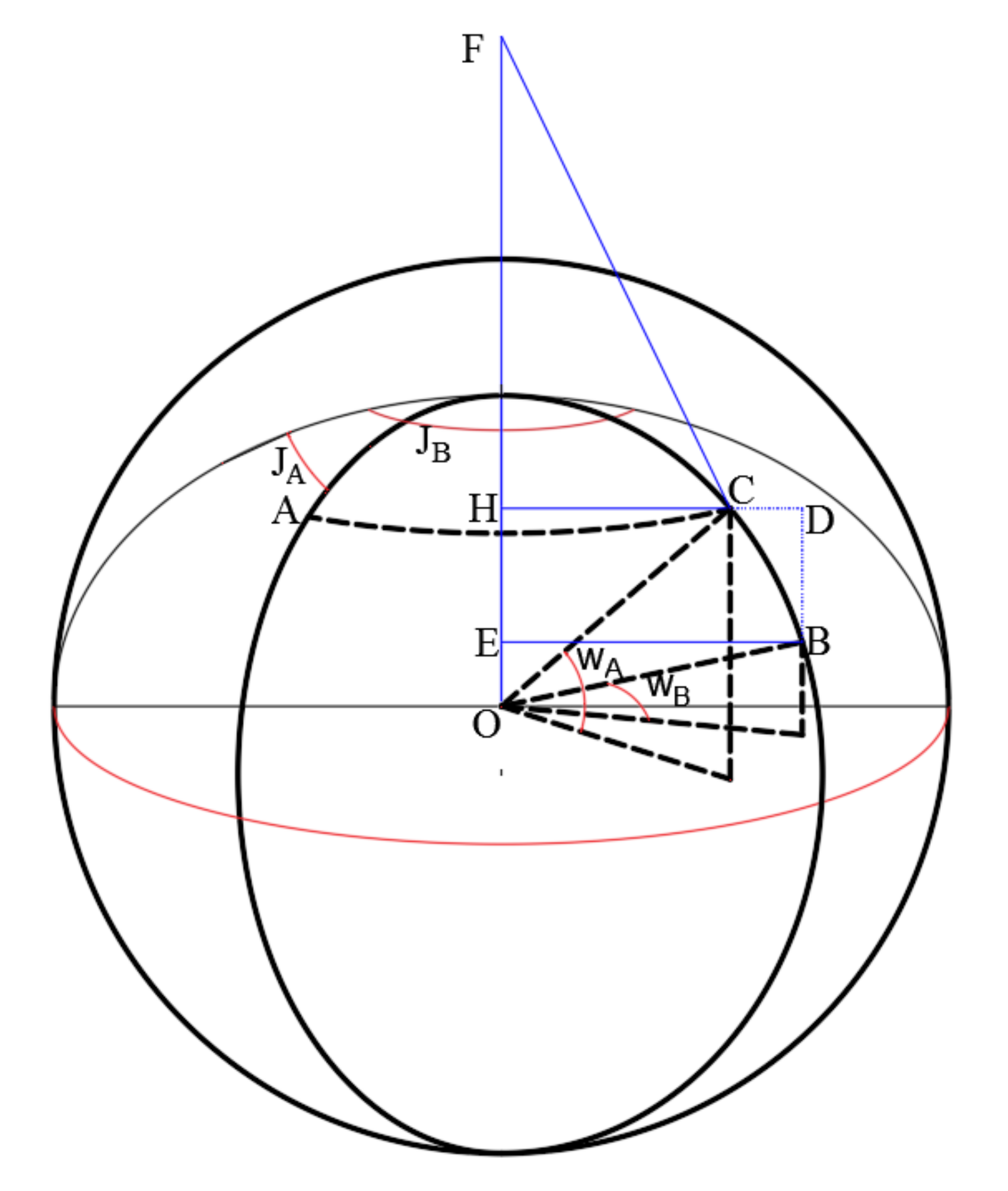

2.1.3. Relationship between Forward Speed and Dosing Motor Rotary Speed

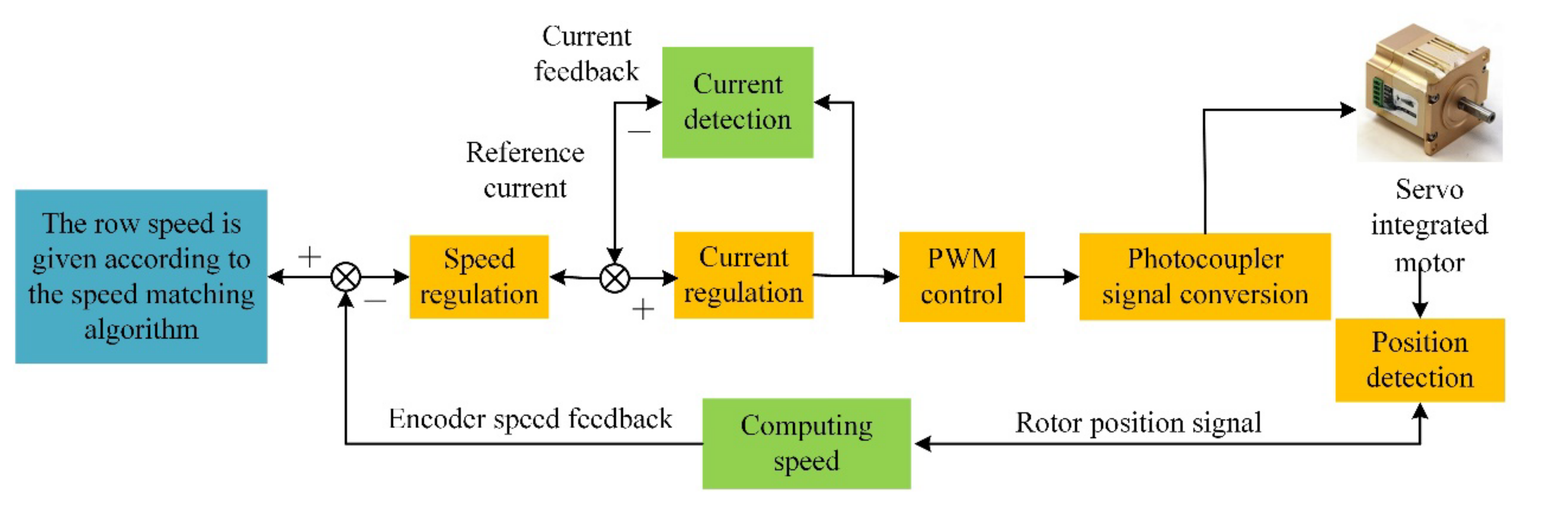

2.2. Motor Control Algorithm Design

2.2.1. Model Establishment of Double Closed-Loop Fuzzy PID

2.2.2. Control Strategy Design

2.3. Bench Test and Field Experiment

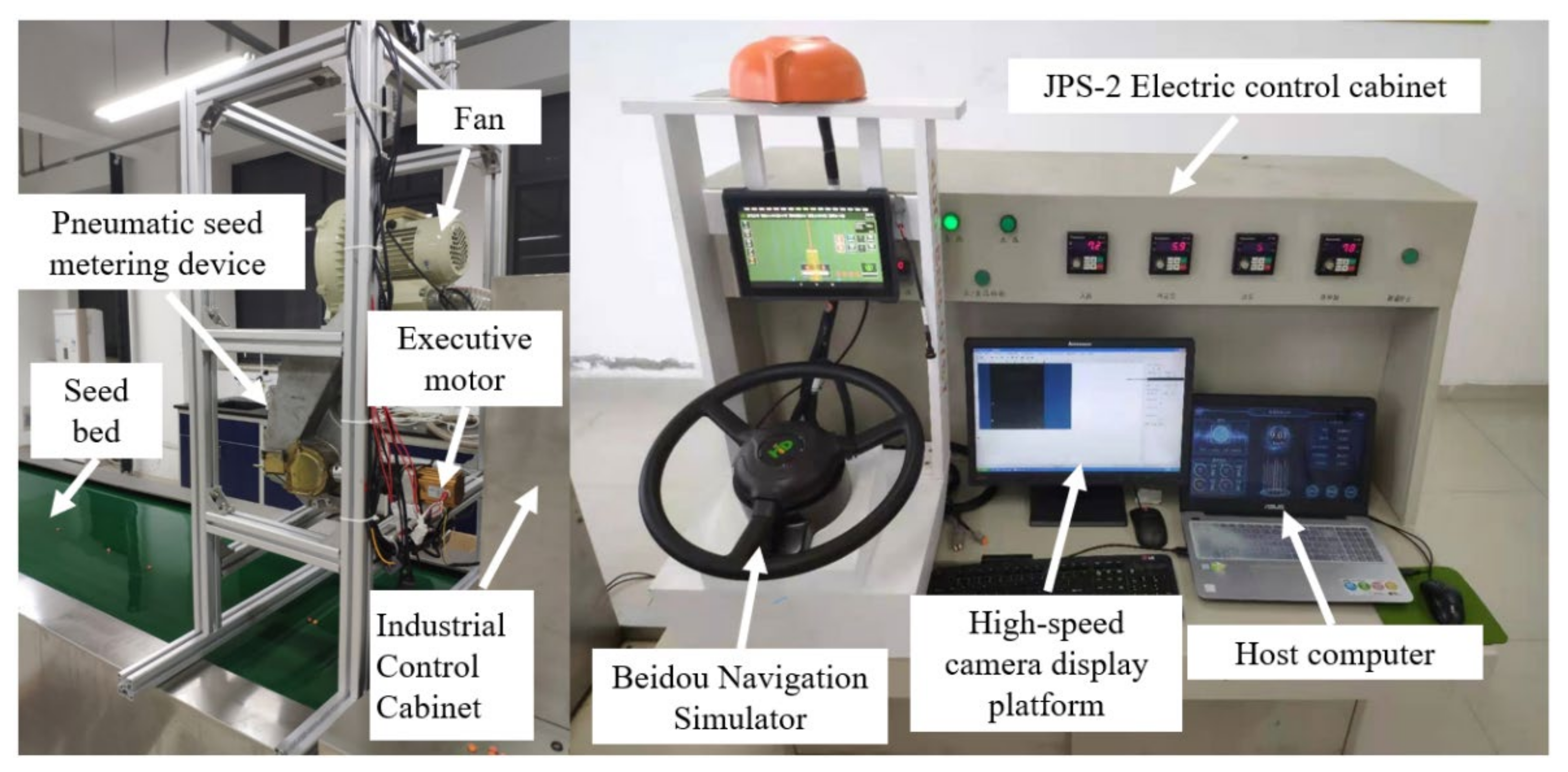

2.3.1. Bench Test Method

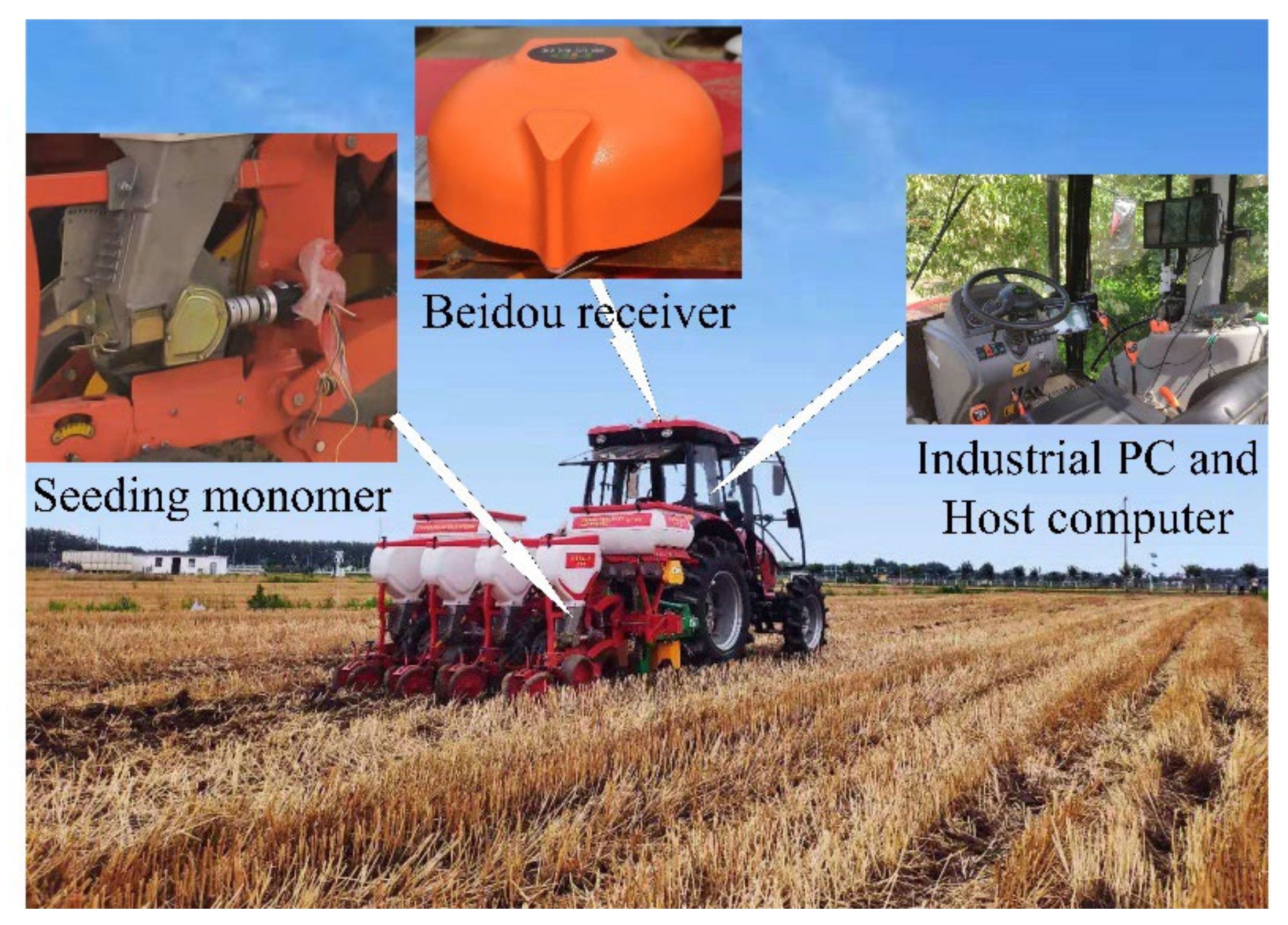

2.3.2. Field Experiments

3. Results and Discussion

3.1. Bench Test Results and Analysis

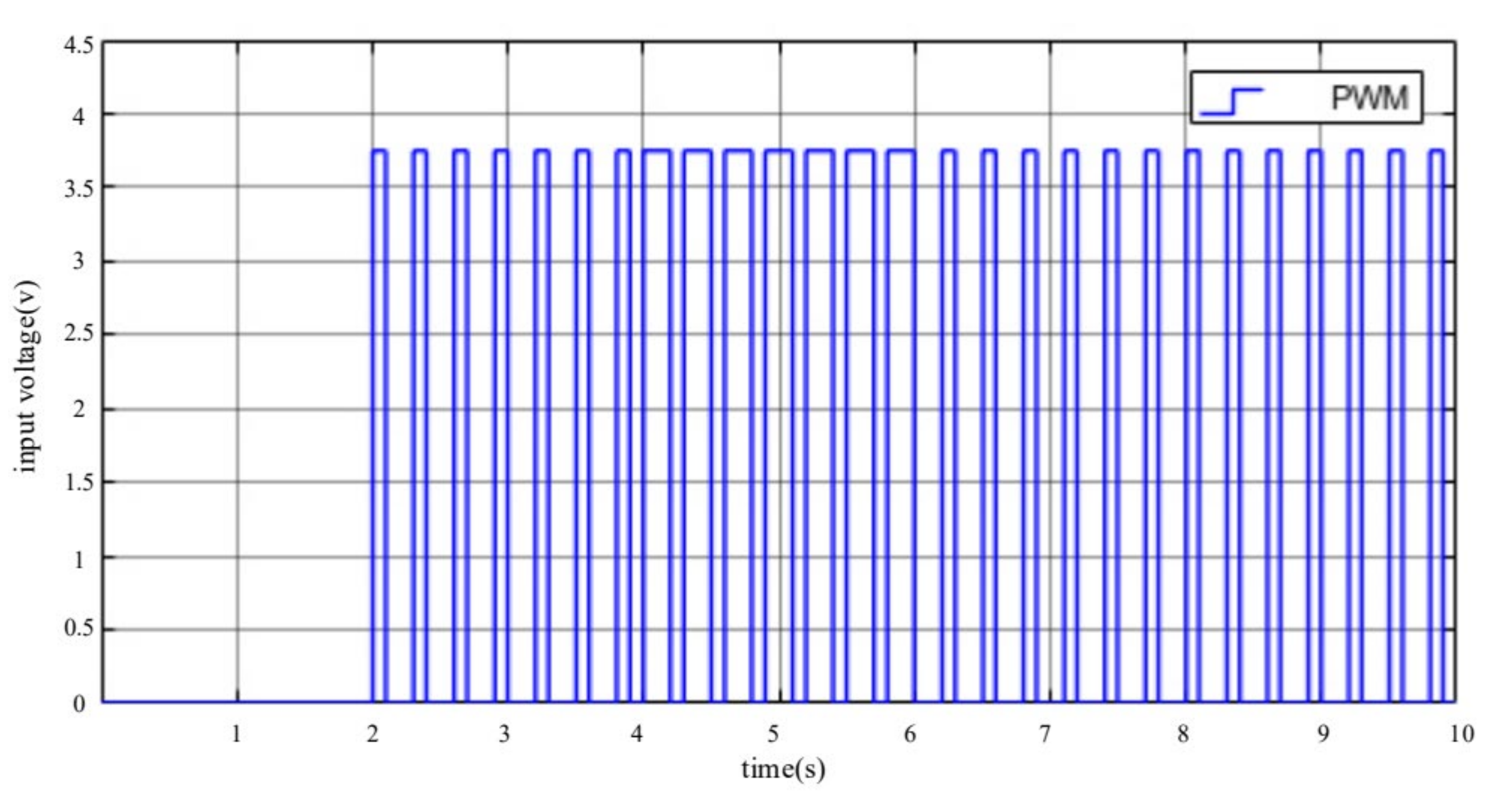

3.1.1. Motor Control Algorithm Verification Test

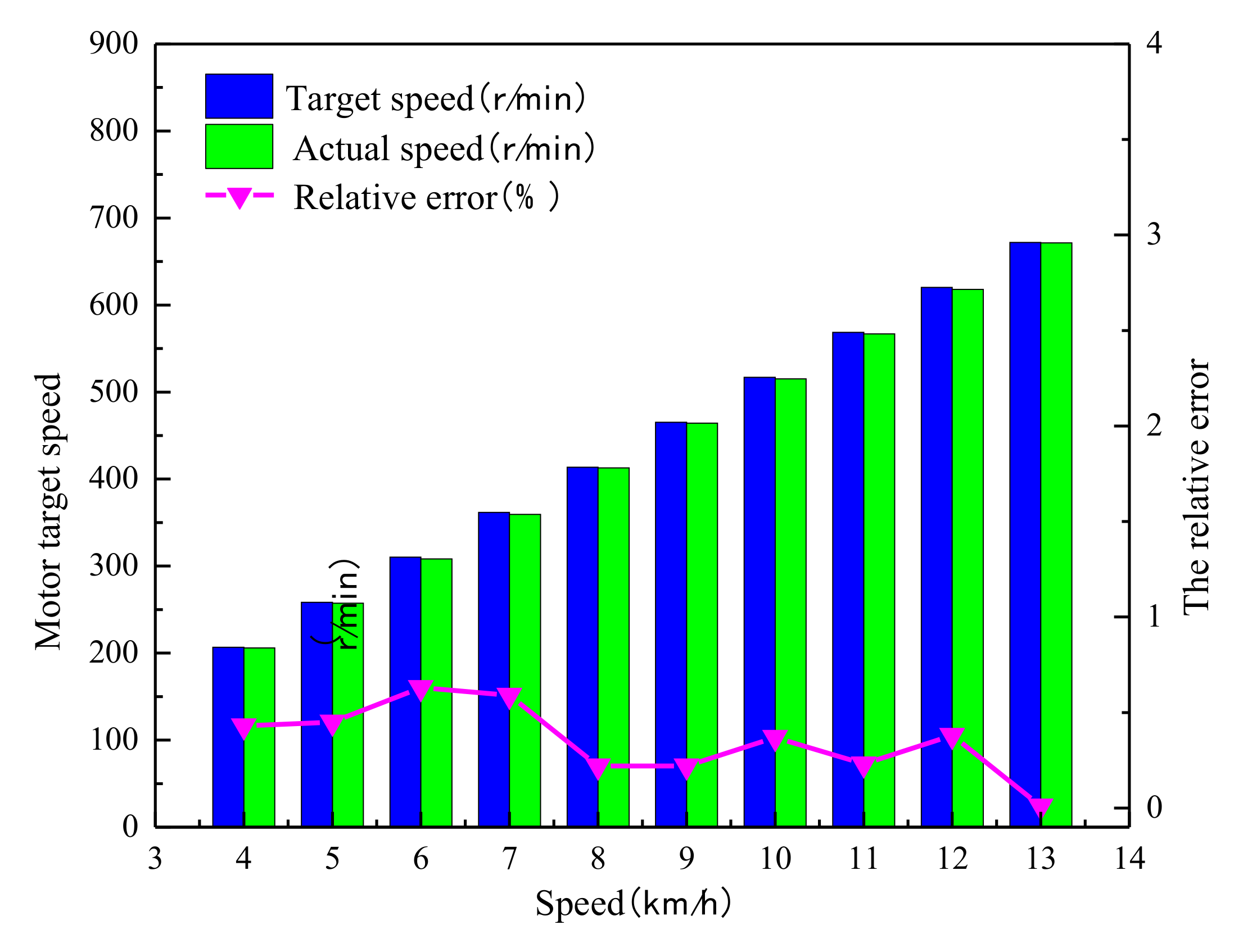

3.1.2. Tests on the Speed Regulation Accuracy of the Dosing Motor of the Seed Metering Device

3.2. Field Experiment Results and Discussion

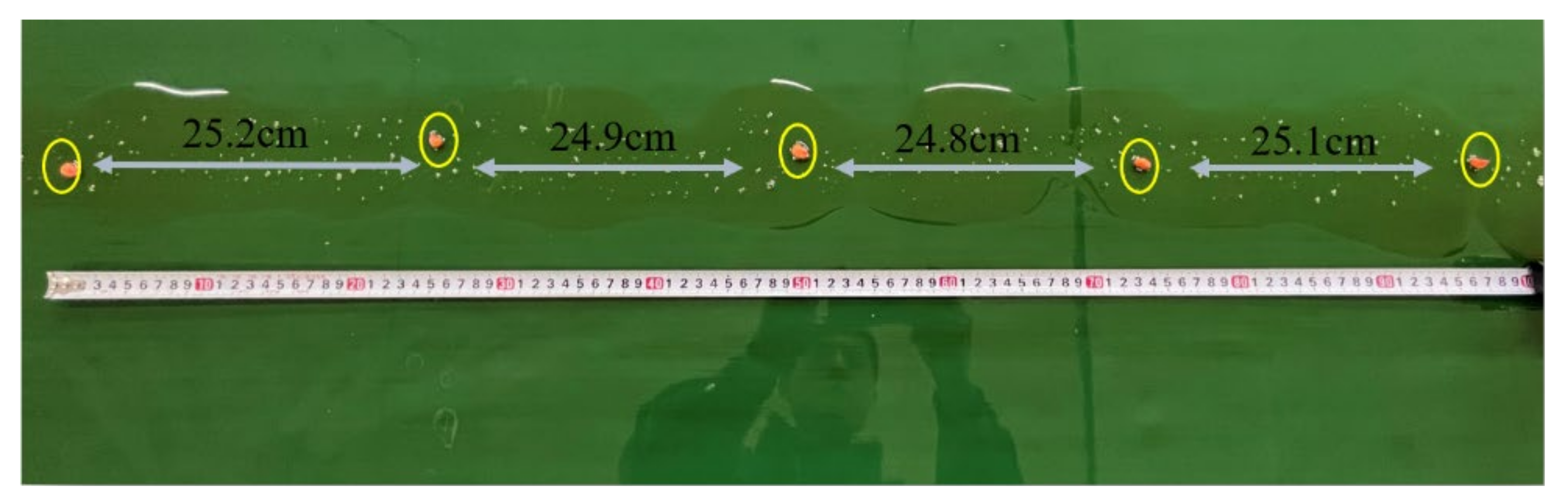

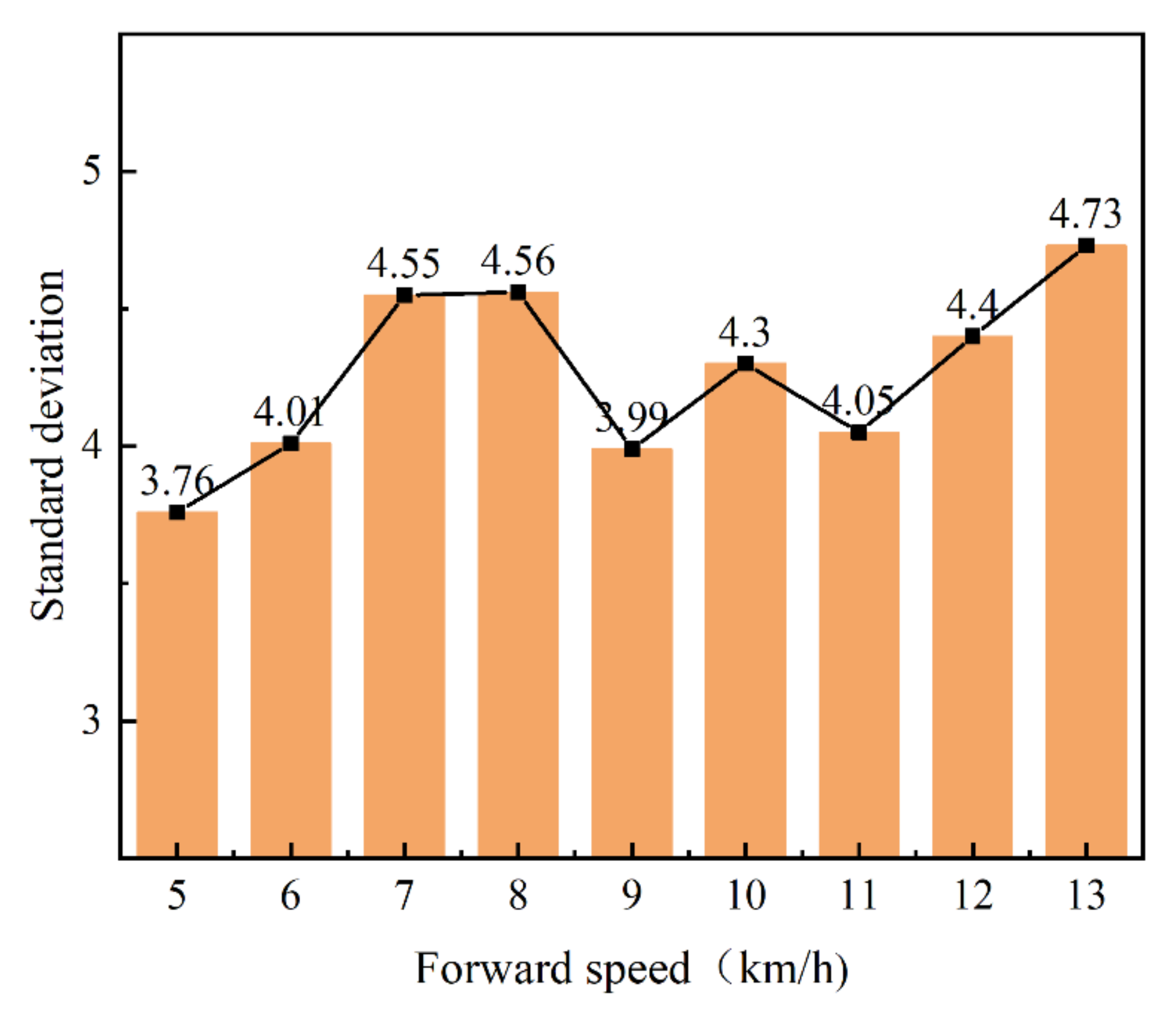

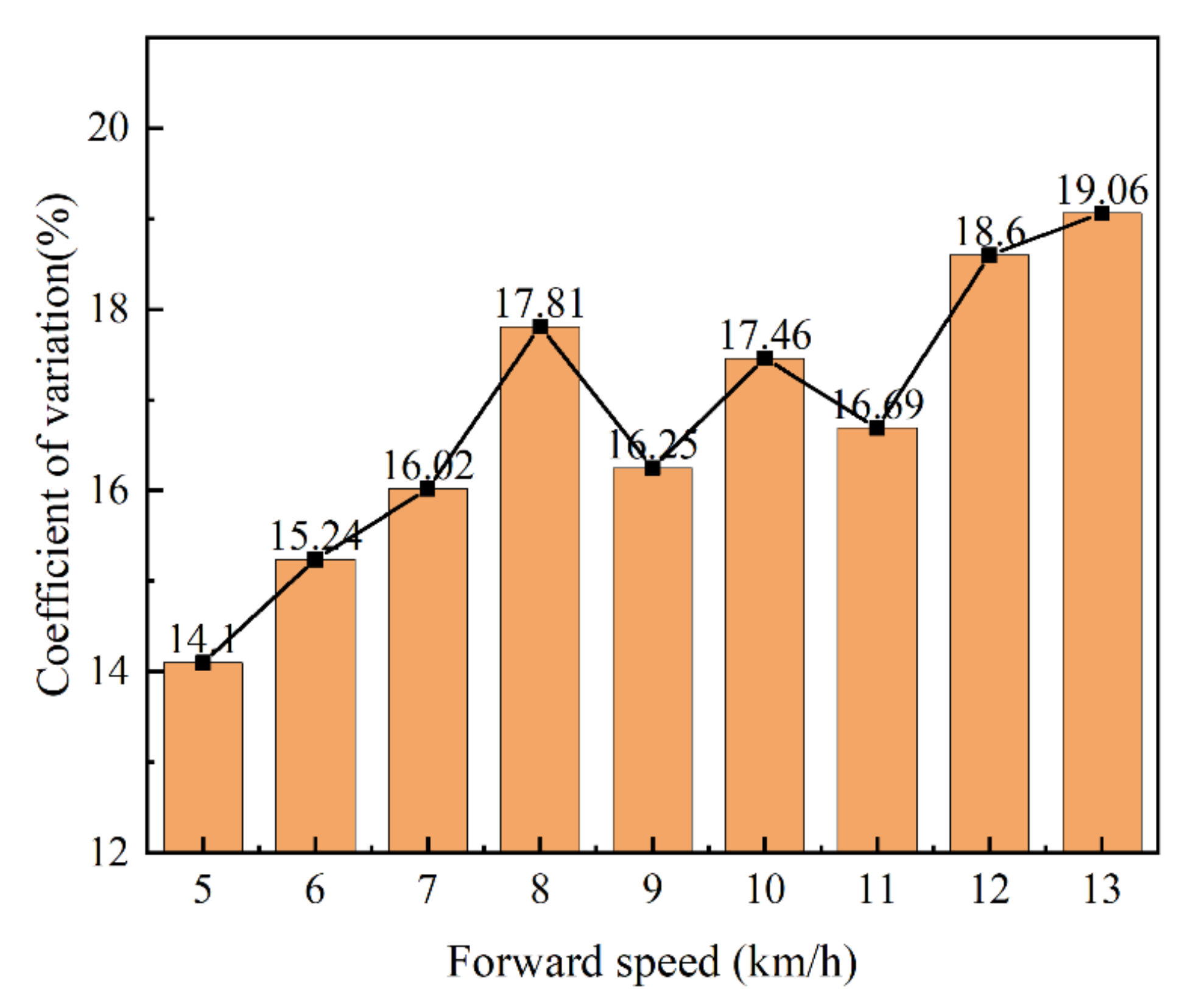

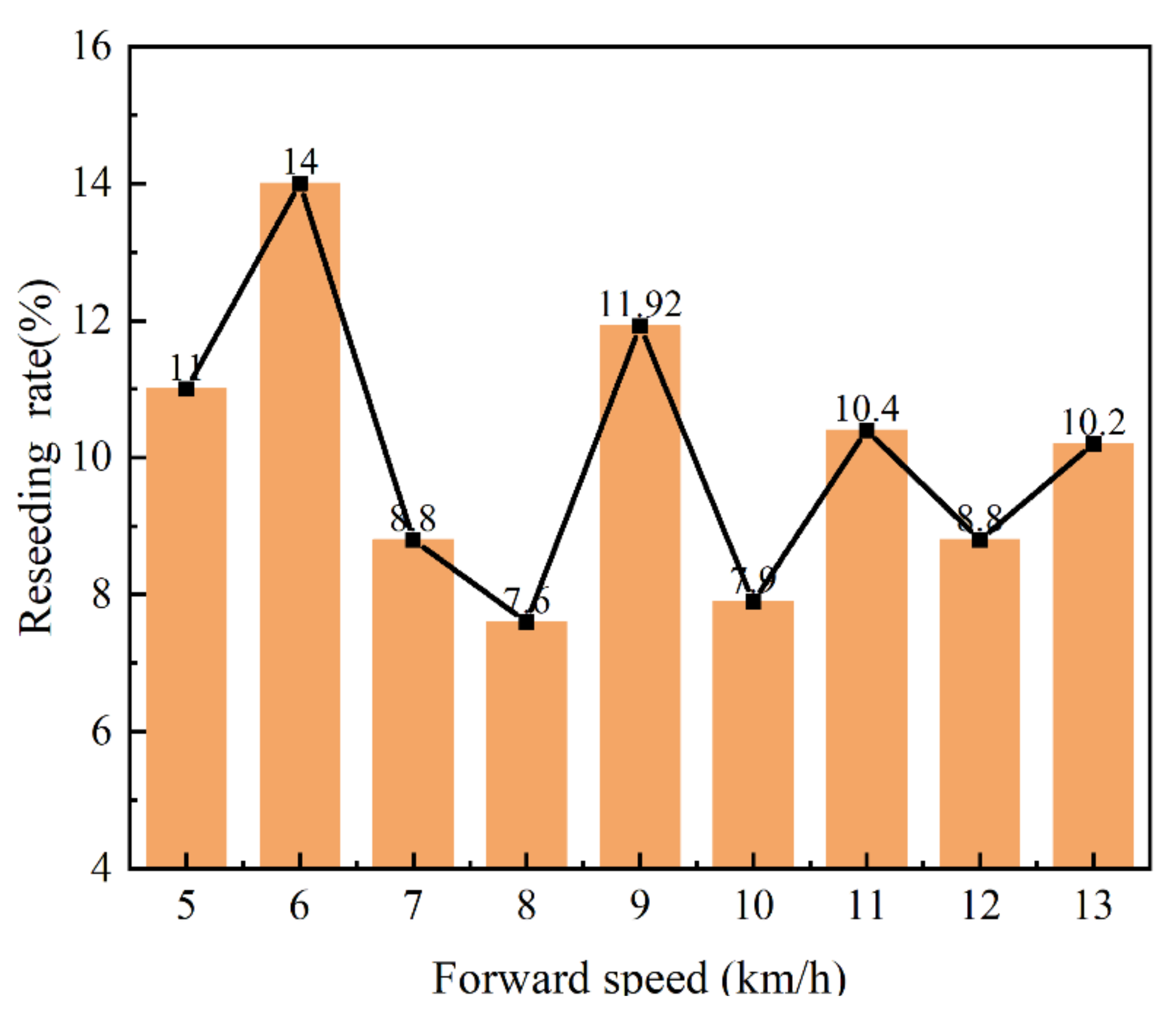

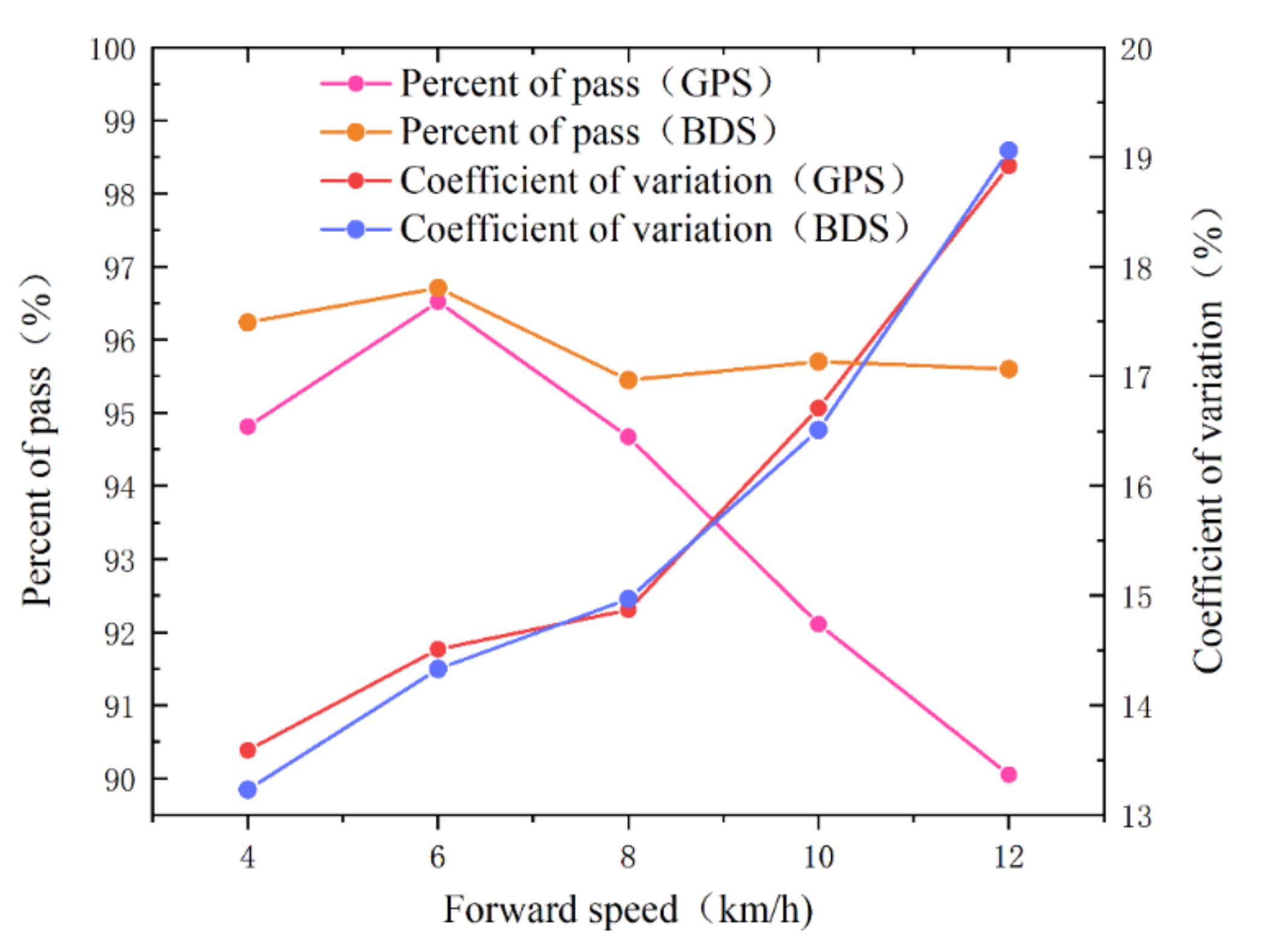

3.2.1. Field Experiment Results

3.2.2. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, C.C.; Fang, X.M. Development of precision service system for intelligent agriculture field crop production based on BeiDou system. Smart Agric. 2019, 1, 83–90. [Google Scholar]

- Li, C.L.; Jiang, Z.Y. Design of Urban vehicle dynamic and real-Time navigation system based on WSNs, GPS, and GPRS techniques. Adv. Mater. Res. 2013, 2584, 765–767. [Google Scholar] [CrossRef]

- Lee, D.-H.; Kim, H.-J.; Park, J.-H. UAV, a farm map, and machine learning technology convergence classification method of a corn cultivation area. Agronomy 2021, 11, 1554. [Google Scholar] [CrossRef]

- May, S.; Kocabiyik, H. Design and development of an electronic drive and control system for micro-granular fertilizer metering unit. Comput. Electr. Agric. 2019, 162, 921–930. [Google Scholar] [CrossRef]

- He, X.; Ding, Y.; Zhang, D. Development of a variable-rate seeding control system for corn planters Part II: Field performance. Comput. Electr. Agric. 2019, 162, 309–317. [Google Scholar] [CrossRef]

- Devin, L.; Mangus; Ajay, S.; Daniel, F.; Ryan, S.; Terry, G. Research on the planting drive system based on a tractor front-wheel speed. Comput. Electr. Agric. 2017, 142, 314–325. [Google Scholar]

- Quan, L.Z.; Jiang, W.; Li, H.L.; Li, H.D.; Wang, Q.; Chen, L.Q. Intelligent intra-row robotic weeding system combining deep learning technology with a targeted weeding mode. Biosyst. Eng. 2022, 48, 51–59. [Google Scholar] [CrossRef]

- Zhang, C.L.; Wu, R.; Chen, L.Q. Design and test of electronic control seeding system for maize. Trans. Chin. Soc. Agric. Mach. 2017, 48, 51–59. [Google Scholar]

- Iacomi, C.; Popescu, O. A new concept for seed precision planting. Agric. Agric. Sci. Proc. 2015, 6, 38–43. [Google Scholar] [CrossRef][Green Version]

- Ding, Y.Q.; Yang, L.; Zhang, D.X.; Cui, T. Novel low-cost control system for large high-speed corn precision planters. Int. J. Agric. Biol. Eng. 2021, 14, 151–158. [Google Scholar] [CrossRef]

- Yang, S.; Wang, X.; Gao, Y.Y.; Zhai, C.Y.; Zhang, X.G.; Zhao, C.J. Investigation on motor-driving maize precision seed meter system supporting on-site calibration of rotate speed of seed plate. Trans. Chin. Soc. Agric. Mach. 2020, 51, 47–55. [Google Scholar]

- Xie, C.J.; Zhang, D.X.; Yang, L. Remote monitoring system for maize seeding parameters based on android and wireless communication. Int. J. Agric. Biol. Eng. 2020, 13, 159–165. [Google Scholar] [CrossRef]

- Chen, L.Q.; Xu, Z.Z.; Xie, B.B.; Liu, L.; Xu, M.; Zheng, Q. Design and test of electronic control system for unmanned drive sprayer. Trans. Chin. Soc. Agric. Mach. 2019, 50, 122–128. [Google Scholar]

- Ding, Y.C.; Liu, W.P.; Dong, W.J.; Chen, L.Y.; Liu, X.D.; Jin, W. Design and experiment of seed metering device for rapeseed based on seeding frequency feedback. Trans. Chin. Soc. Agric. Mach. 2021, 52, 73–82. [Google Scholar]

- Zhao, X.; Chen, L.; Gao, Y. Optimization method for accurate positioning seeding based on sowing decision. Int. J. Agric. Biol. Eng. 2021, 14, 151–158. [Google Scholar] [CrossRef]

- Chen, L.Q.; Xie, B.B.; Li, Z.D.; Yang, L.; Chen, Y.X. Design of control system of maize precision seeding based on double closed loop PID fuzzy algorithm. Trans. Chin. Soc. Agric. Eng. 2018, 34, 33–41. [Google Scholar]

- Li, J.L.; Wang, B.; Wang, A.B.; Zhu, E.H.; Yuan, H.Y. BDS/GPS dual-frequency carrier-phase single point positioning model and accuracy analysis. Navig. Position. Timing 2021, 8, 120–128. [Google Scholar]

- Liu, Y.C. High-precision positioning analysis of BDS observation data. Share Geospat. Inf. 2021, 19, 46–48. [Google Scholar]

- Singh, T.P.; Mane, D.M. Development and laboratory performance of an electronically controlled metering mechanism for okra seed. Agric. Mech. Asia Afr. Lat. Am. 2011, 42, 63–69. [Google Scholar]

- Wang, G.; Sun, W.; Zhang, H.; Liu, X.; Zhu, L. Research on a kind of seeding-monitoring and compensating control system for potato planter without additional seed-metering channel. Comput. Electr. Agric. 2020, 177, 105681. [Google Scholar] [CrossRef]

- Zhao, L.; Han, Z.; Yang, J.; Hua, Q. Single seed precise sowing of maize using computer simulation. PLoS ONE 2018, 13, e0193750. [Google Scholar] [CrossRef] [PubMed]

- He, X.; Cui, T.; Zhang, D. Development of an electric-driven control system for a precision planter based on a closed-loop PID algorithm. Comput. Electr. Agric. 2017, 136, 184–192. [Google Scholar] [CrossRef]

- Ding, Y.Q.; Liu, Y.W.; Yang, L.; Zhang, D.X.; Cui, T.; Zhong, X.J. Monitoring system of maize precision planter based on android and CAN Bus. Trans. Chin. Soc. Agric. Mach. 2019, 50, 33–41. [Google Scholar]

- Chen, C.; Lv, J.; Song, G.; Liu, H. Adaptive fuzzy sliding mode control algorithm based on input-output linearization for vehicle’s lateral control. In Proceedings of the 2016 IEEE Chinese Guidance, Navigation and Control Conference (CGNCC), Nanjing, China, 12–14 August 2016; IEEE: Piscataway Township, NJ, USA, 2016. [Google Scholar]

- Stoll, J.T.; Schanz, K.; Pott, A. Mechatronic Control System for a Compliant and Precise Pneumatic Rotary Drive Unit. Actuators 2020, 9, 1. [Google Scholar] [CrossRef]

- Nguyen, H.P.; Nguyen, X.B.; Bui, T.T.; Ueno, S.; Nguyen, Q.D. Analysis and Control of Slotless Self-Bearing Motor. Actuators 2019, 8, 57. [Google Scholar] [CrossRef]

- Vinosh, M.; Kumar, S.S.; Nithish, D.; Naveen, G. Development of tray type nursery seeding equipment. Mater. Today Proc. 2021, 37, 3209–3212. [Google Scholar] [CrossRef]

- Lou, S.; He, J.; Lu, C.; Liu, P.; Li, H.; Zhang, Z. A Tillage Depth Monitoring and Control System for the Independent Adjustment of Each Subsoiling Shovel. Actuators 2021, 10, 250. [Google Scholar] [CrossRef]

- Yang, Y.; Li, Y.K.; Wen, X.; Zhang, G.; Ma, Q.L.; Cheng, S.K.; Qi, J.; Xu, L.Y.; Chen, L.Q.; Popescu, O. An optimal goal point determination algorithm for automatic navigation of agricultural machinery: Improving the tracking accuracy of the Pure Pursuit algorithm. Comput. Electr. Agric. 2022, 194, 106760. [Google Scholar] [CrossRef]

- Darwin, B.; Dharmaraj, P.; Prince, S.; Popescu, D.E.; Hemanth, D.J. Recognition of Bloom/Yield in Crop Images Using Deep Learning Models for Smart Agriculture: A Review. Agronomy 2021, 11, 646. [Google Scholar] [CrossRef]

- Folprecht, M.; Cervinka, D.; Prochazka, P. Compact High-Voltage AC Generator with Pulse Transformer for High-Frequency Irreversible Electroporation (H-FIRE). Electronics 2021, 10, 2898. [Google Scholar] [CrossRef]

- Cay, A.; Kocabiyik, H.; May, S. Development of an electro-mechanic control system for seed-metering unit of single seed corn planters Part I: Design and laboratory simulation. Comput. Electr. Agric. 2018, 144, 71–79. [Google Scholar] [CrossRef]

- Cay, A.; Kocabiyik, H.; May, S. Development of an electro-mechanic control system for seed-metering unit of single seed corn planters Part II: Field performance. Comput. Electr. Agric. 2018, 145, 11–17. [Google Scholar] [CrossRef]

| Ec | |||||

|---|---|---|---|---|---|

| E | NB | NS | ZO | PS | PB |

| NB | PB PB NB | PB PS NB | PB PS NS | ZO NB NS | ZO NS NB |

| NS | PB PS NB | PB PS NS | PS ZO ZO | ZO NS NS | NS NS NB |

| ZO | PS ZO NS | PS ZO ZO | ZO ZO PS | NS ZO ZO | NS ZO ZO |

| PS | PS ZO ZO | ZO NS PS | NS ZO PS | NB PS PS | NB PS ZO |

| PB | ZO NS ZO | ZO NB PS | NB NS PB | NB PS PS | NB PB ZO |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Wu, K.; Zhang, Y.; Wang, M.; Zhang, C.; Chen, L. The Development of an Electric-Driven Control System for a High-Speed Precision Planter Based on the Double Closed-Loop Fuzzy PID Algorithm. Agronomy 2022, 12, 945. https://doi.org/10.3390/agronomy12040945

Wang W, Wu K, Zhang Y, Wang M, Zhang C, Chen L. The Development of an Electric-Driven Control System for a High-Speed Precision Planter Based on the Double Closed-Loop Fuzzy PID Algorithm. Agronomy. 2022; 12(4):945. https://doi.org/10.3390/agronomy12040945

Chicago/Turabian StyleWang, Weiwei, Kunpeng Wu, Yin Zhang, Minxue Wang, Chunling Zhang, and Liqing Chen. 2022. "The Development of an Electric-Driven Control System for a High-Speed Precision Planter Based on the Double Closed-Loop Fuzzy PID Algorithm" Agronomy 12, no. 4: 945. https://doi.org/10.3390/agronomy12040945

APA StyleWang, W., Wu, K., Zhang, Y., Wang, M., Zhang, C., & Chen, L. (2022). The Development of an Electric-Driven Control System for a High-Speed Precision Planter Based on the Double Closed-Loop Fuzzy PID Algorithm. Agronomy, 12(4), 945. https://doi.org/10.3390/agronomy12040945