Systematic Review of Technology in Aeroponics: Introducing the Technology Adoption and Integration in Sustainable Agriculture Model

Abstract

:1. Introduction

1.1. Aeroponics

1.2. Technology in Aeroponics

1.3. Related Work

1.4. Purpose of the Study

- What are the trends regarding the use of technology in aeroponic systems?

- What are the main advantages that technology integration can bring to aeroponic systems compared to conventional agriculture systems?

- What are the main challenges that technology integration can bring to aeroponic systems compared to conventional agriculture systems?

- What has been the purpose of technology integration in aeroponics?

2. The Model

2.1. Theoretical Foundation

2.2. The Proposed Model

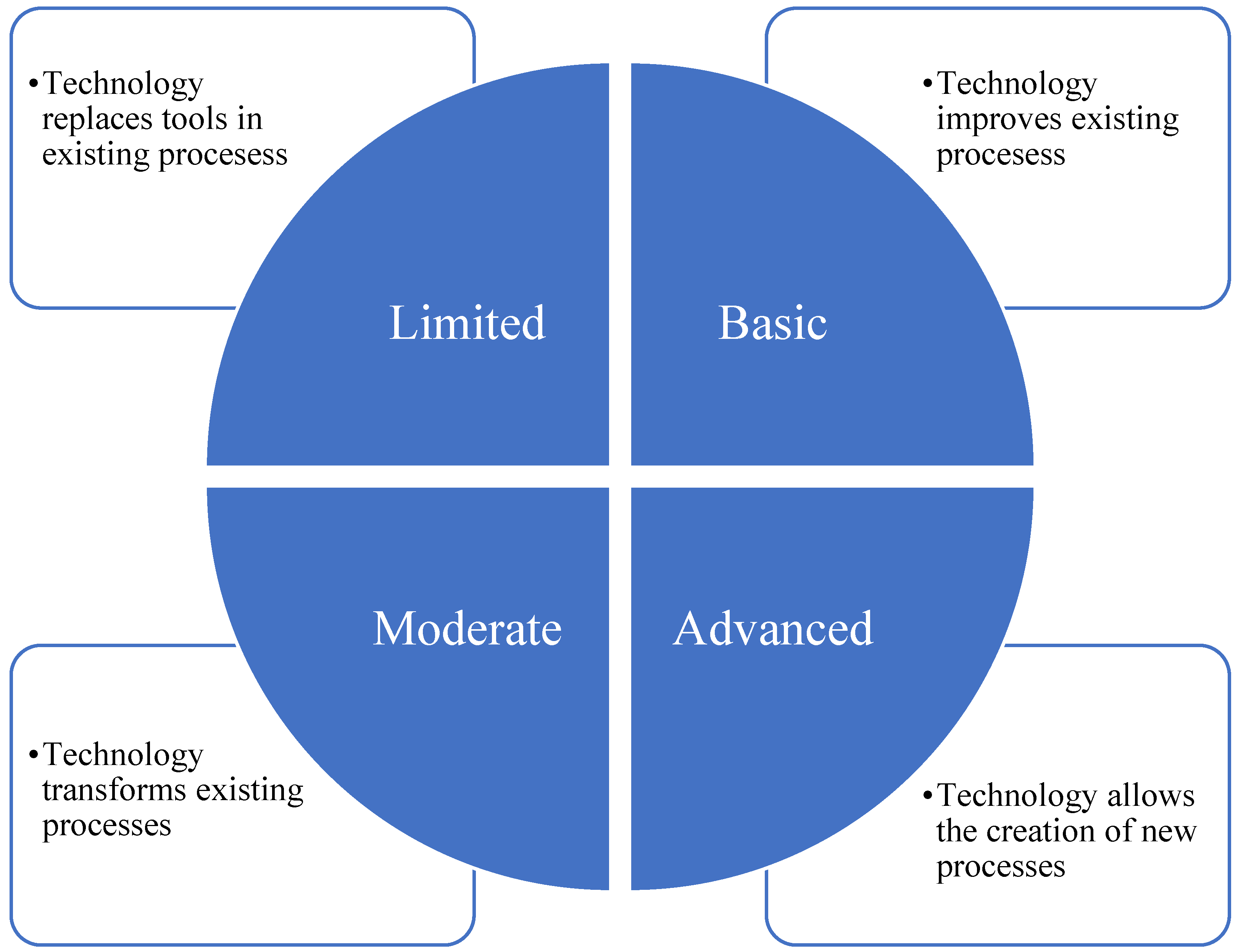

2.2.1. Definition of the Levels of Technology Integration

2.2.2. Significance of the Model

3. Methods

3.1. Planning the Review

Eligibility Criteria

3.2. Conducting the Review

3.3. Reporting the Review

4. Results and Discussion

4.1. Trends in the Use of Technology in Aeroponic Systems

4.1.1. Technology Type

4.1.2. Cultivated Products

4.1.3. Country of the Research

4.1.4. Publisher of the Study

4.1.5. Publication Date

4.2. Advantages of the Use of Technology in Aeroponic Systems

4.3. Disadvantages of the Use of Technology in Aeroponics

4.4. Level of Technology Integration in Aeroponics

4.4.1. Limited Integration of Technology in an Aeroponic System

4.4.2. Basic Integration of Technology in an Aeroponic System

4.4.3. Moderate Integration of Technology in an Aeroponic System

4.4.4. Advanced Integration of Technology in an Aeroponic System

4.5. Limitations of the Study and Future Research

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wimmerova, L.; Keken, Z.; Solcova, O.; Bartos, L.; Spacilova, M. A Comparative LCA of Aeroponic, Hydroponic, and Soil Cultivations of Bioactive Substance Producing Plants. Sustainability 2022, 14, 2421. [Google Scholar] [CrossRef]

- FAO. The Future of Food and Agriculture—Trends and Challenges; FAO: Rome, Italy, 2017. [Google Scholar]

- Kumar, P.; Sampath, B.; Kumar, S.; Babu, B.; Ahalya, N. Hydroponics, Aeroponics, and Aquaponics Technologies in Modern Agricultural Cultivation. In Trends, Paradigms, and Advances in Mechatronics Engineering; IGI Global: Hershey, PA, USA, 2023; pp. 223–241. [Google Scholar]

- Balasundram, S.K.; Shamshiri, R.R.; Sridhara, S.; Rizan, N. The Role of Digital Agriculture in Mitigating Climate Change and Ensuring Food Security: An Overview. Sustainability 2023, 15, 5325. [Google Scholar] [CrossRef]

- Bhakta, I.; Phadikar, S.; Majumder, K. State-of-the-Art Technologies in Precision Agriculture: A Systematic Review. J. Sci. Food Agric. 2019, 99, 4878–4888. [Google Scholar] [CrossRef] [PubMed]

- Gurley, T.W. Aeroponics, 1st ed.; CRC Press: Boca Raton, FL, USA, 2020; ISBN 9780367810078. [Google Scholar]

- Chaudhry, A.R.; Mishra, V.P. A Comparative Analysis of Vertical Agriculture Systems in Residential Apartments. In Proceedings of the 2019 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 26 March–10 April 2019. [Google Scholar] [CrossRef]

- Lakhiar, I.A.; Gao, J.; Syed, T.N.; Chandio, F.A.; Buttar, N.A. Modern Plant Cultivation Technologies in Agriculture under Controlled Environment: A Review on Aeroponics. J. Plant Interact. 2018, 13, 338–352. [Google Scholar] [CrossRef]

- Yang, X.; Luo, Y.; Jiang, P. Sustainable Soilless Cultivation Mode: Cultivation Study on Droplet Settlement of Plant Roots under Ultrasonic Aeroponic Cultivation. Sustainability 2022, 14, 13705. [Google Scholar] [CrossRef]

- Niu, G.; Masabni, J. Hydroponics. In Plant Factory Basics, Applications and Advances; Elsevier: Amsterdam, The Netherlands, 2022; pp. 153–166. [Google Scholar]

- Abbasi, R.; Martinez, P.; Ahmad, R. The Digitization of Agricultural Industry—A Systematic Literature Review on Agriculture 4.0. Smart Agric. Technol. 2022, 2, 100042. [Google Scholar] [CrossRef]

- Sani, M.; Siregar, S.; Kumiawan, A.; Jauhari, R.; Mandalahi, C. Web-Based Monitoring and Control System for Aeroponics Growing Chamber. In Proceedings of the 2016 International Conference on Control, Electronics, Renewable Energy and Communications (ICCEREC), Bandung, Indonesia, 13–15 September 2016; pp. 162–168. [Google Scholar]

- Khan, M.; Akram, M.; Janke, R.; Khan, R.; Al-Sadi, A.; Farooque, A. Urban Horticulture for Food Secure Cities through and beyond COVID-19. Sustainability 2020, 12, 9592. [Google Scholar] [CrossRef]

- Lakhiar, I.A.; Gao, J.; Syed, T.N.; Ali Chandio, F.; Tunio, M.H.; Ahmad, F.; Ali Solangi, K. Overview of the Aeroponic Agriculture—An Emerging Technology for Global Food Security. Int. J. Agric. Biol. Eng. 2020, 13, 1–10. [Google Scholar] [CrossRef]

- Lakhiar, I.A.; Jianmin, G.; Syed, T.N.; Chandio, F.A.; Buttar, N.A.; Qureshi, W.A. Monitoring and Control Systems in Agriculture Using Intelligent Sensor Techniques: A Review of the Aeroponic System. J. Sens. 2018, 2018, 8672769. [Google Scholar] [CrossRef]

- Rahmad, I.; Tanti, L.; Puspasari, R.; Ekadiansyah, E.; Agung Fragastia, V. Automatic Monitoring and Control System in Aeroponic Plant Agriculture. In Proceedings of the 2020 8th International Conference on Cyber and IT Service Management (CITSM), Pangkal, Indonesia, 23–24 October 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Fasciolo, B.; Awouda, A.; Bruno, G.; Lombardi, F. A Smart Aeroponic System for Sustainable Indoor Farming. Procedia CIRP 2023, 116, 636–641. [Google Scholar] [CrossRef]

- Lasi, H.; Fettke, P.; Kemper, H.-G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Roffi, T.M.; Jamhari, C.A. Internet of Things Based Automated Monitoring for Indoor Aeroponic System. Int. J. Electr. Comput. Eng. 2023, 13, 270. [Google Scholar] [CrossRef]

- Torres-Tello, J.; Ko, S.-B. Interpretability of Artificial Intelligence Models That Use Data Fusion to Predict Yield in Aeroponics. J. Ambient Intell. Humaniz. Comput. 2023, 14, 3331–3342. [Google Scholar] [CrossRef]

- Ragaveena, S.; Shirly Edward, A.; Surendran, U. Smart Controlled Environment Agriculture Methods: A Holistic Review. Rev. Environ. Sci. Bio/Technol. 2021, 20, 887–913. [Google Scholar] [CrossRef]

- Morgunov, A.P.; Kirgizova, I.V. Control Unit for the Dosed Feeding of the Nutrient Solution into the Industrial Aeroponic Installation System. J. Phys. Conf. Ser. 2019, 1210, 012099. [Google Scholar] [CrossRef]

- Eldridge, B.M.; Manzoni, L.R.; Graham, C.A.; Rodgers, B.; Farmer, J.R.; Dodd, A.N. Getting to the Roots of Aeroponic Indoor Farming. New Phytol. 2020, 228, 1183–1192. [Google Scholar] [CrossRef]

- Sumarni, E.; Hardanto, A.; Arsil, P. Effect of Root Zone Cooling and Evaporative Cooling in Greenhouse on the Growth and Yield of Potato Seed by Aeroponics in Tropical Lowlands. Agric. Eng. Int. CIGR J. 2021, 23, 28–35. [Google Scholar]

- Devederkin, I.V.; Antonov, S.N.; Permyakov, A.V. Aerosol Management of Nutrients in Aeroponic Potato Mini-Tubers Cultivation Technology. IOP Conf. Ser. Earth Environ. Sci. 2021, 852, 012021. [Google Scholar] [CrossRef]

- Ramalingannanavar, N.; Nemichandrappa, M.; Srinivasa Reddy, G.V.; Dandekar, A.T.; Kamble, J.B.; Dhanoji, M.M. Design, Development and Evaluation of Solar Powered Aeroponic System—A Case Study. Int. J. Curr. Microbiol. Appl. Sci. 2020, 9, 3102–3112. [Google Scholar] [CrossRef]

- Klarin, B.; Garafulić, E.; Vučetić, N.; Jakšić, T. New and Smart Approach to Aeroponic and Seafood Production. J. Clean. Prod. 2019, 239, 117665. [Google Scholar] [CrossRef]

- Fussy, A.; Papenbrock, J. An Overview of Soil and Soilless Cultivation Techniques—Chances, Challenges and the Neglected Question of Sustainability. Plants 2022, 11, 1153. [Google Scholar] [CrossRef] [PubMed]

- Basso, B.; Antle, J. Digital Agriculture to Design Sustainable Agricultural Systems. Nat. Sustain. 2020, 3, 254–256. [Google Scholar] [CrossRef]

- Ríos, J.; Candelo, J.; Hoyos, F. Growing Arugula Plants Using Aeroponic Culture with an Automated Irrigation System. Int. J. Agric. Biol. Eng. 2020, 13, 52–56. [Google Scholar] [CrossRef]

- Lucero, L.; Lucero, D.; Ormeno-Mejia, E.; Collaguazo, G. Automated Aeroponics Vegetable Growing System. Case Study Lettuce. In Proceedings of the 2020 IEEE ANDESCON, Quito, Ecuador, 13–16 October 2020. [Google Scholar] [CrossRef]

- Tunio, M.H.; Gao, J.; Shaikh, S.A.; Lakhiar, I.A.; Qureshi, W.A.; Solangi, K.A.; Chandio, F.A. Potato Production in Aeroponics: An Emerging Food Growing System in Sustainable Agriculture for Food Security. Chil. J. Agric. Res. 2020, 80, 118–132. [Google Scholar] [CrossRef]

- Jamshidi, A.; Moghaddam, A.; Ommani, A. Effect of Ultrasonic Atomizer on the Yield and Yield Components of Tomato Grown in a Vertical Aeroponic Planting System. Int. J. Hortic. Sci. Technol. 2019, 6, 237–246. [Google Scholar] [CrossRef]

- Puentedura, R. Transformation, Technology, and Education. Available online: http://www.hippasus.com/rrpweblog/archives/2013/05/29/SAMREnhancementToTransformation.pdf (accessed on 22 September 2023).

- Hamilton, E.R.; Rosenberg, J.M.; Akcaoglu, M. The Substitution Augmentation Modification Redefinition (SAMR) Model: A Critical Review and Suggestions for Its Use. TechTrends 2016, 60, 433–441. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. Syst. Rev. 2021, 10, 105906. [Google Scholar] [CrossRef]

- Kitchenham, B.; Charters, S. Guidelines for Performing Systematic Literature Reviews in Software Engineering Version 2.3; Keele University: Keele, UK; Durham University: Durham, UK, 2007. [Google Scholar]

- Krippendorff, K. Content Analysis: An Introduction to Its Methodology; Sage Publications: Thousand Oaks, CA, USA, 2018. [Google Scholar]

- Cohen, J. Weighted Kappa: Nominal Scale Agreement Provision for Scaled Disagreement or Partial Credit. Psychol. Bull. 1968, 70, 213. [Google Scholar] [CrossRef]

- Idris, I.; Sani, M.I. Monitoring and Control of Aeroponic Growing System for Potato Production. In Proceedings of the 2012 IEEE Conference on Control, Systems & Industrial Informatics, Bandung, Indonesia, 23–26 September 2012; pp. 120–125. [Google Scholar] [CrossRef]

- Reyes, J.L.; Montoya, R.; Ledesma, C.; Ramírez, R. Development of an Aeroponic System for Vegetable Production. Acta Hortic. 2012, 947, 153–156. [Google Scholar] [CrossRef]

- Pathania, N.; Trevorrow, P.; Hughes, M.; Marton, T.; Justo, V.; Salvani, J. Preliminary Research to Develop a Low_technology Aeroponic System for Producing Clean Seed Potato in the Philippines. In Proceedings of the ACIAR–PCAARRD Southern Philippines Fruits and Vegetables Program Meeting, Cebu, Philippines, 3 July 2012; pp. 138–147. [Google Scholar]

- Pathania, N.; Trevorrow, P.; Hughes, M.; Jovicich, E. Optimization of Aeroponic Technology for Future Integration in Quality Potato Seed Production Systems in Tropical Environments. Acta Hortic. 2016, 1118, 31–38. [Google Scholar] [CrossRef]

- He, J. Integrated Vertical Aeroponic Farming Systems for Vegetable Production in Space Limited Environments. Acta Hortic. 2017, 1176, 25–36. [Google Scholar] [CrossRef]

- Dannehl, D.; Taylor, Z.; Suhl, J.; Miranda, L.; Ulrichs, C.; Salazar, C.; Fitz-Rodriguez, E.; Lopez-Cruz, I.; Rojano-Aguliar, A.; Navas-Gomez, G.; et al. Sustainable Cities: Viability of a Hybrid Aeroponic/Nutrient Film Technique System for Cultivation of Tomatoes. Int. J. Agric. Biosyst. Eng. 2017, 11, 470–477. [Google Scholar]

- Montoya, A.P.; Obando, F.A.; Morales, J.G.; Vargas, G. Automatic Aeroponic Irrigation System Based on Arduino’s Platform. J. Phys. Conf. Ser. 2017, 850, 012003. [Google Scholar] [CrossRef]

- Belista, F.C.L.; Go, M.P.C.; Lucenara, L.L.; Policarpio, C.J.G.; Tan, X.J.M.; Baldovino, R.G. A Smart Aeroponic Tailored for IoT Vertical Agriculture Using Network Connected Modular Environmental Chambers. In Proceedings of the 2018 IEEE 10th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment and Management (HNICEM), Baguio City, Philippines, 29 November–2 December 2018; pp. 1–4. [Google Scholar]

- Rahman, F.; Ritun, I.J.; Ahmed Biplob, M.R.; Farhin, N.; Uddin, J. Automated Aeroponics System for Indoor Farming Using Arduino. In Proceedings of the 2018 Joint 7th International Conference on Informatics, Electronics & Vision (ICIEV) and 2018 2nd International Conference on Imaging, Vision & Pattern Recognition (icIVPR), Kitakyushu, Japan, 25–29 June 2018; pp. 137–141. [Google Scholar]

- Chang, H.-Y.; Wang, J.-J.; Lin, C.-Y.; Chen, C.-H. An Agricultural Data Gathering Platform Based on Internet of Things and Big Data. In Proceedings of the 2018 International Symposium on Computer, Consumer and Control (IS3C), Taichung, Taiwan, 6–8 December 2018; pp. 302–305. [Google Scholar]

- Hoyos, F.; Candelo, J.; Chavarria, H. Automation of Pesticide-Free Cilantro Aeroponic Crops. INGE CUC 2019, 15, 123–132. [Google Scholar] [CrossRef]

- Vera-Puerto, I.; Olave, J.; Tapia, S.; Chávez, W. Atacama Desert: Water Resources and Reuse of Municipal Wastewater in Irrigation of Cut Flower Aeroponic Cultivation System (First Laboratory Experiments). Desalination Water Treat. 2019, 150, 73–83. [Google Scholar] [CrossRef]

- Lakhiar, I.A.; Gao, J.; Xu, X.; Syed, T.N.; Chandio, F.A.; Jing, Z.; Buttar, N.A. Effects of Various Aeroponic Atomizers (Droplet Sizes) on Growth, Polyphenol Content, and Antioxidant Activity of Leaf Lettuce (Lactuca sativa L.). Trans. ASABE 2019, 62, 1475–1487. [Google Scholar] [CrossRef]

- Argo, B.D.; Hendrawan, Y.; Ubaidillah, U. A Fuzzy Micro-Climate Controller for Small Indoor Aeroponics Systems. Telkomnika Telecommun. Comput. Electron. Control 2019, 17, 3019–3026. [Google Scholar] [CrossRef]

- Jamhari, C.A.; Wibowo, W.K.; Annisa, A.R.; Roffi, T.M. Design and Implementation of IoT System for Aeroponic Chamber Temperature Monitoring. In Proceedings of the 2020 Third International Conference on Vocational Education and Electrical Engineering (ICVEE), Surabaya, Indonesia, 3–4 October 2020; pp. 1–4. [Google Scholar] [CrossRef]

- Torres-Tello, J.; Venkatachalam, S.; Moreno, L.; Ko, S.B. Ensemble Learning for Improving Generalization in Aeroponics Yield Prediction. In Proceedings of the 2020 IEEE International Symposium on Circuits and Systems (ISCAS), Seville, Spain, 12–14 October 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Cabascango, M.; Mejia-Echeverria, C.; Morales, D.O.; Ojeda Pena, D. Modeling of Forced Airflow in a Greenhouse. In Proceedings of the 2020 IEEE ANDESCON, Quito, Ecuador, 13–16 October 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Caya, M.V.C.; Dela Cruz, J.C.; Estrella, A.M.C.; Mendoza, J.C.A. Fuzzy Controlled LED Lighting Compensation for Aeroponics System. In Proceedings of the 2021 IEEE 13th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), Manila, Philippines, 28–30 November 2021; pp. 1–6. [Google Scholar]

- Karuniawati, S.; Gautama Putrada, A.; Rakhmatsyah, A. Optimization of Grow Lights Control in IoT-Based Aeroponic Systems with Sensor Fusion and Random Forest Classification. In Proceedings of the 2021 International Symposium on Electronics and Smart Devices (ISESD), Bandung, Indonesia, 29–30 June 2021; pp. 1–6. [Google Scholar]

- Kuncoro, B.; Sutandi, T.; Adristi, C.; Kuan, Y. Aeroponics Root Chamber Temperature Conditioning Design for Smart Mini-Tuber Potato Seed Cultivation. Sustainability 2021, 13, 5140. [Google Scholar] [CrossRef]

- Chowdhury, M.; Islam, M.N.; Reza, M.N.; Ali, M.; Rasool, K.; Kiraga, S.; Lee, D.H.; Chung, S.O. Sensor-Based Nutrient Recirculation for Aeroponic Lettuce Cultivation. J. Biosyst. Eng. 2021, 46, 81–92. [Google Scholar] [CrossRef]

- Narimani, M.; Hajiahmad, A.; Moghimi, A.; Alimardani, R.; Rafiee, S.; Mirzabe, A.H. Developing an Aeroponic Smart Experimental Greenhouse for Controlling Irrigation and Plant Disease Detection Using Deep Learning and IoT. In Proceedings of the 2021 ASABE Annual International Virtual Meeting, Online, 12–16 July 2021; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2021. [Google Scholar]

- Tang, H.C.K.; Cheng, T.Y.S.; Wong, J.C.Y.; Cheung, R.C.C.; Lam, A.H.F. Aero-Hydroponic Agriculture IoT System. In Proceedings of the 2021 IEEE 7th World Forum on Internet of Things (WF-IoT), New Orleans, LA, USA, 14 June–31 July 2021; pp. 741–746. [Google Scholar]

- Tunio, M.H.; Gao, J.; Lakhiar, I.A.; Solangi, K.A.; Qureshi, W.A.; Shaikh, S.A.; Chen, J. Influence of Atomization Nozzles and Spraying Intervals on Growth, Biomass Yield, and Nutrient Uptake of Butter-Head Lettuce under Aeroponics System. Agronomy 2021, 11, 97. [Google Scholar] [CrossRef]

- Rahman, M.H.; Islam, M.J.; Azad, M.O.K.; Rana, M.S.; Ryu, B.R.; Lim, Y.S. Led Light Pre-Treatment Improves Pre-Basic Seed Potato (Solanum Tuberosum l. Cv. Golden King) Production in the Aeroponic System. Agronomy 2021, 11, 1627. [Google Scholar] [CrossRef]

- Riswandi; Niswar, M.; Tahir, Z.; Zainal; Wey, C.Y. Design and Implementation of IoT-Based Aeroponic Farming System. In Proceedings of the 2022 IEEE International Conference on Cybernetics and Computational Intelligence (CyberneticsCom), Malang, Indonesia, 16–18 June 2022; pp. 308–311. [Google Scholar]

- Martinez-Nolasco, C.; Padilla-Medina, J.A.; Nolasco, J.J.M.; Guevara-Gonzalez, R.G.; Barranco-Gutiérrez, A.I.; Diaz-Carmona, J.J. Non-Invasive Monitoring of the Thermal and Morphometric Characteristics of Lettuce Grown in an Aeroponic System through Multispectral Image System. Appl. Sci. 2022, 12, 6540. [Google Scholar] [CrossRef]

- Bolivar, P.B.N.; Clar, J.L.G.; Constantino, M.J.L.; Roguin, E.A.; Beano, M.G.P.; Capuno, M.E.A.D.; Agustin, E.V.; Soriano, A.J.; Sigue, A.F. IoT-Based Aeroponic System for Seasonal Plants Using Fuzzy Logic. In Proceedings of the TENCON 2022–2022 IEEE Region 10 Conference (TENCON), Hong Kong, China, 1–4 November 2022; pp. 1–6. [Google Scholar]

- Estuita, J.A.; Arthur Monillas, J.; Ramos, J.; Reas, R.; Bandala, A.; Concepcion, R.; Francisco, K.; Vicerra, R.R.; Dadios, E.P. Structure and Misting Subsystem Design of Automated Aeroponic System for Lactuca Sativa Production. In Proceedings of the 2022 IEEE 14th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), Boracay Island, Philippines, 1–4 December 2022; pp. 1–7. [Google Scholar]

- Qi, S.; Ma, Y.; Zhang, M.; Yin, B.; Xu, Z.; Liu, S. Design and Experiment of a Barrel-Shaped Aeroponic Cultivation System. Int. J. Agric. Biol. Eng. 2022, 15, 90–94. [Google Scholar] [CrossRef]

- Méndez-Guzmán, H.A.; Padilla-Medina, J.A.; Martínez-Nolasco, C.; Martinez-Nolasco, J.J.; Barranco-Gutiérrez, A.I.; Contreras-Medina, L.M.; Leon-Rodriguez, M. IoT-Based Monitoring System Applied to Aeroponics Greenhouse. Sensors 2022, 22, 5646. [Google Scholar] [CrossRef] [PubMed]

- Mehmood, U.; Khaliq, A.; Ahmad, F.; Awais, M. Test and Evaluation of Prototype Aeroponic System for Indoor Vegetable Plant Growth. In Proceedings of the 1st International Conference on Innovative Academic Studies, Konya, Turkey, 10–13 September 2022; pp. 1–6. [Google Scholar]

- Mohamed, T.; Gao, J.; Tunio, M. Development and Experiment of the Intelligent Control System for Rhizosphere Temperature of Aeroponic Lettuce via the Internet of Things. Int. J. Agric. Biol. Eng. 2022, 15, 225–233. [Google Scholar] [CrossRef]

- Setiowati, S.; Wardhani, R.N.; Riandini; Agustina Siregar, E.B.; Saputra, R.; Sabrina, R.A. Fertigation Control System on Smart Aeroponics Using Sugeno’s Fuzzy Logic Method. In Proceedings of the 2022 8th International Conference on Science and Technology (ICST), Yogyakarta, Indonesia, 7–8 September 2022; pp. 1–6. [Google Scholar]

- Dhanasekar, S.; Abarna, V.K.; Gayathri, V.; Valarmathi, G.; Madhumita, D.; Jeevitha, R. An Efficient Smart Agriculture System Based on The Internet of Things Using Aeroponics Method. In Proceedings of the 2023 9th International Conference on Advanced Computing and Communication Systems (ICACCS), Coimbatore, India, 17–18 March 2023; pp. 1386–1391. [Google Scholar]

- Sadek, N.; Kamal, N.; Shehata, D. Internet of Things Based Smart Automated Indoor Hydroponics and Aeroponics Greenhouse in Egypt. Ain Shams Eng. J. 2023, in press. [CrossRef]

- Calzita, C.R.; Jubilo, K.A.; Permejo, G.; Reas, R.; Baun, J.J.; Concepcion, R.; De Leon, J.A.; Bandala, A.; Mayol, A.P.; Vicerra, R.R.; et al. Intelligent Aeroponic System for Real-Time Control and Monitoring of Lactuca Sativa Production. In Proceedings of the 2023 17th International Conference on Ubiquitous Information Management and Communication (IMCOM), Seoul, Republic of Korea, 3–5 January 2023; pp. 1–7. [Google Scholar]

- Paponov, M.; Ziegler, J.; Paponov, I.A. Light Exposure of Roots in Aeroponics Enhances the Accumulation of Phytochemicals in Aboveground Parts of the Medicinal Plants Artemisia Annua and Hypericum Perforatum. Front. Plant Sci. 2023, 14, 1079656. [Google Scholar] [CrossRef]

- Guo, Y.; Gao, J.; Tunio, M.H.; Wang, L. Study on the Identification of Mildew Disease of Cuttings at the Base of Mulberry Cuttings by Aeroponics Rapid Propagation Based on a BP Neural Network. Agronomy 2022, 13, 106. [Google Scholar] [CrossRef]

- Totin, E.; Segnon, A.C.; Schut, M.; Affognon, H.; Zougmoré, R.B.; Rosenstock, T.; Thornton, P.K. Institutional Perspectives of Climate-Smart Agriculture: A Systematic Literature Review. Sustainability 2018, 10, 1990. [Google Scholar] [CrossRef]

- Mateus-Rodriguez, J.R.; de Haan, S.; Andrade-Piedra, J.L.; Maldonado, L.; Hareau, G.; Barker, I.; Chuquillanqui, C.; Otazú, V.; Frisancho, R.; Bastos, C.; et al. Technical and Economic Analysis of Aeroponics and Other Systems for Potato Mini-Tuber Production in Latin America. Am. J. Potato Res. 2013, 90, 357–368. [Google Scholar] [CrossRef]

- Fleming, L.; Sorenson, O. Technology as a Complex Adaptive System: Evidence from Patent Data. Res. Policy 2001, 30, 1019–1039. [Google Scholar] [CrossRef]

| Study | Authors (Year) [Cite] | Cultivated Product | Technology Level |

|---|---|---|---|

| 1 | Idris and Sani (2012) [40] | Tuber | Advanced |

| 2 | Reyes et al. (2012) [41] | Vegetable | Moderate |

| 3 | Pathania et al. (2012) [42] | Tuber | Moderate |

| 4 | Sani et al. (2016) [12] | Fruit | Advanced |

| 5 | Pathania et al. (2016) [43] | Tuber | Advanced |

| 6 | He (2017) [44] | Vegetable | Advanced |

| 7 | Dannehl et al. (2017) [45] | Fruit | Limited |

| 8 | Montoya et al. (2017) [46] | Vegetable | Moderate |

| 9 | Belista et al. (2018) [47] | Vegetable | Advanced |

| 10 | Rahman et al. (2018) [48] | Vegetable | Moderate |

| 11 | Chang et al. (2018) [49] | Vegetable | Moderate |

| 12 | Jamshidi et al. (2019) [33] | Fruit | Basic |

| 13 | Klarin et al. (2019) [27] | Fruit; vegetable | Advanced |

| 14 | Hoyos et al. (2019) [50] | Aromatic plant | Advanced |

| 15 | Vera et al. (2019) [51] | Flower | Advanced |

| 16 | Lakhiar et al. (2019) [52] | Vegetable | Basic |

| 17 | Argo et al. (2019) [53] | Vegetable | Advanced |

| 18 | Lucero et al. (2020) [31] | Vegetable | Advanced |

| 19 | Rahmad et al. (2020) [16] | Vegetable | Advanced |

| 20 | Jamhari et al. (2020) [54] | Vegetable | Advanced |

| 21 | Torres et al. (2020) [55] | Vegetable | Advanced |

| 22 | Ríos et al. (2020) [30] | Vegetable | Advanced |

| 23 | Cabascango et al. (2020) [56] | Tuber | Basic |

| 24 | Caya et al. (2021) [57] | Vegetable | Advanced |

| 25 | Karuniawati et al. (2021) [58] | Vegetable | Moderate |

| 26 | Kuncoro et al. (2021) [59] | Tuber | Moderate |

| 27 | Devederkin et al. (2021) [25] | Tuber | Basic |

| 28 | Chowdhury et al. (2021) [60] | Vegetable | Moderate |

| 29 | Narimani et al. (2021) [61] | Flower | Advanced |

| 30 | Tang et al. (2021) [62] | Vegetable | Advanced |

| 31 | Tunio et al. (2021) [63] | Vegetable | Basic |

| 32 | Rahman et al. (2021) [64] | Tuber | Advanced |

| 33 | Riswandi et al. (2022) [65] | Vegetable | Advanced |

| 34 | Martinea et al. (2022) [66] | Vegetable | Moderate |

| 35 | Bolivar et al. (2022) [67] | Fruit; vegetable | Moderate |

| 36 | Estuita et al. (2022) [68] | Vegetable | Advanced |

| 37 | Qi et al. (2022) [69] | Vegetable | Moderate |

| 38 | Méndez et al. (2022) [70] | Vegetable | Advanced |

| 39 | Yang et al. (2022) [9] | Vegetable | Moderate |

| 40 | Mehmood et al. (2022) [71] | Fruit | Moderate |

| 41 | Mohamed et al. (2022) [72] | Vegetable | Advanced |

| 42 | Setiowati et al. (2022) [73] | Vegetable | Advanced |

| 43 | Dhanasekar et al. (2023) [74] | Vegetable; tuber; fruit | Advanced |

| 44 | Sadek et al. (2023) [75] | Vegetable | Advanced |

| 45 | Calzita et al. (2023) [76] | Vegetable | Advanced |

| 46 | Paponov et al. (2023) [77] | Aromatic plant | Moderate |

| 47 | Guo et al. (2023) [78] | Fruit | Moderate |

| Category | Description | Examples | Number of Studies |

|---|---|---|---|

| Sensing technology | Devices that detect and measure physical or environmental conditions, converting them into electrical signals for analysis. | Temperature sensors, flow sensors, cameras, and microphones | 32 |

| Industry 4.0 | Digital transformation of processes through advanced technologies based on smart automation. | AI, IoT, machine learning, microcontrollers, robotics, artificial lighting. | 32 |

| Dispenser technology | Systems that automatically dispense liquids, solids, or gases in controlled quantities and precise locations. | Sprayers, nebulizers, ultrasonic dispersion, and pumps. | 27 |

| Renewable energy | Energy derived from naturally replenishing sources such as sunlight, wind, water, and geothermal heat, with minimal ecological impact. | Biomass, fuel cells, solar panel, wind turbines, and hydropower. | 5 |

| Category | Product Examples | Number of Studies |

|---|---|---|

| Vegetable Tuber Fruit Flowers | Lettuce, spinach, and arugula Potato, yucca, and yam Tomato, mulberry, and strawberry Lily, sunflower, and anthurium | 32 8 7 2 |

| Aromatic plant | Coriander, artemisia, and mint | 2 |

| Advantage | Description | Number of Studies |

|---|---|---|

| Sustainability | Aeroponics is considered a sustainable farming method due to its efficient use of resources. Technology can further enhance sustainability by optimizing resource consumption, such as water and nutrients. Advanced monitoring systems can detect and address any inefficiencies, minimizing waste and maximizing resource utilization. | 25 |

| Time efficiency | Technology in aeroponics allows for precise control over various environmental factors, which helps plants grow faster, leading to shorter crop cycles and increased productivity compared to traditional farming methods. | 21 |

| Increased Production | Technology has a substantial impact on increasing production in aeroponics by optimizing various aspects of plant growth and resource management. For example, collecting and analyzing data on plant growth, nutrient levels, and environmental conditions can yield insights that facilitate the development of effective and sustainable growth strategies. | 15 |

| Clean production | The controlled environment of aeroponic systems can lead to fewer pest and disease problems. This can reduce the need for chemical pesticides and herbicides, leading to cleaner and healthier products. | 14 |

| Cost-effective | Investment in technology for aeroponics results in long-term cost savings. By eliminating the need for soil and reducing water usage, aeroponics lower production costs over time. Additionally, the high yield potential and faster crop cycles lead to increased profitability. | 11 |

| Space Efficiency | Technology allows for the designing and constructing of modular growing structures tailored to the available space. These structures can be optimized for efficient space utilization while accommodating the specific needs of plants. | 9 |

| Product size | Technology allows real-time monitoring of environmental factors such as temperature, humidity, CO2 levels, and light intensity. Automated control systems can adjust these parameters to create the ideal growing conditions, maximizing plant growth and yield. | 8 |

| Continuous production | Technology helps aeroponic systems operate continuously, allowing for year-round production. By providing a controlled environment, plants can be grown regardless of external seasonal variations, ensuring a steady and reliable supply of produce. | 6 |

| Disadvantage | Description | Number of Studies |

|---|---|---|

| Technical Complexity | High-tech systems require a certain level of technical expertise to set up, operate, and troubleshoot. Growers must understand the technology involved to ensure proper functioning and prevent potential issues. | 6 |

| Power Dependency | Advanced technology relies heavily on a stable and reliable power supply. If there are power outages or disruptions, it could impact the functioning of automated systems and disrupt plant growth. | 3 |

| Setup Cost | Implementing and maintaining advanced technology in aeroponic systems can be expensive. The initial investment for high-tech equipment, sensors, automation systems, and energy sources can be a significant barrier, especially for small-scale growers. | 1 |

| Maintenance and Monitoring | High-tech systems require regular maintenance to ensure they function optimally. Downtime for maintenance and repairs could interrupt production schedules and lead to decreased yields. | 1 |

| Learning Curve | Introducing technology into an aeroponic setup requires a learning curve. Transitioning to technology-driven systems involves a learning curve for growers. Adapting to new methods, understanding software interfaces, and troubleshooting technical issues can take time and effort. | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garzón, J.; Montes, L.; Garzón, J.; Lampropoulos, G. Systematic Review of Technology in Aeroponics: Introducing the Technology Adoption and Integration in Sustainable Agriculture Model. Agronomy 2023, 13, 2517. https://doi.org/10.3390/agronomy13102517

Garzón J, Montes L, Garzón J, Lampropoulos G. Systematic Review of Technology in Aeroponics: Introducing the Technology Adoption and Integration in Sustainable Agriculture Model. Agronomy. 2023; 13(10):2517. https://doi.org/10.3390/agronomy13102517

Chicago/Turabian StyleGarzón, Juan, Luis Montes, Jorge Garzón, and Georgios Lampropoulos. 2023. "Systematic Review of Technology in Aeroponics: Introducing the Technology Adoption and Integration in Sustainable Agriculture Model" Agronomy 13, no. 10: 2517. https://doi.org/10.3390/agronomy13102517

APA StyleGarzón, J., Montes, L., Garzón, J., & Lampropoulos, G. (2023). Systematic Review of Technology in Aeroponics: Introducing the Technology Adoption and Integration in Sustainable Agriculture Model. Agronomy, 13(10), 2517. https://doi.org/10.3390/agronomy13102517