Study on Effects of Different Concentration Adjuvants on the Properties of Prochloraz Emulsion in Water Solution Droplets and Deposition

Abstract

:1. Introduction

2. Materials and Methods

2.1. Pesticide and Spraying Adjuvant and Additive Concentrations

2.2. Determination of Surface Tension and Contact Angle

2.3. Field Crop Protection UAV Aerial Spraying Experiments

2.3.1. Experimental Site and Crop Protection UAV

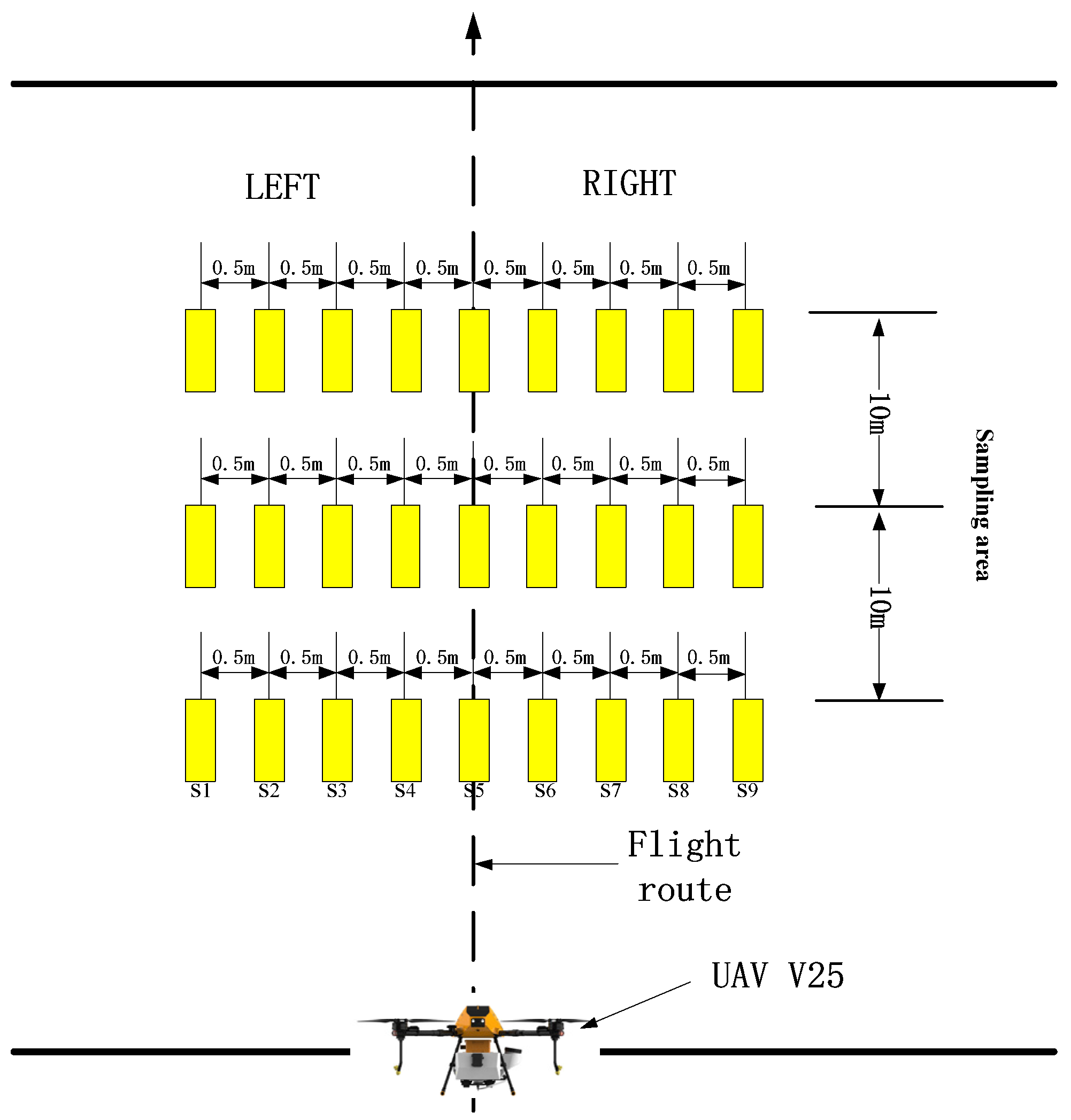

2.3.2. Experiment Design

2.3.3. Droplet Deposition Analysis

3. Results and Discussion

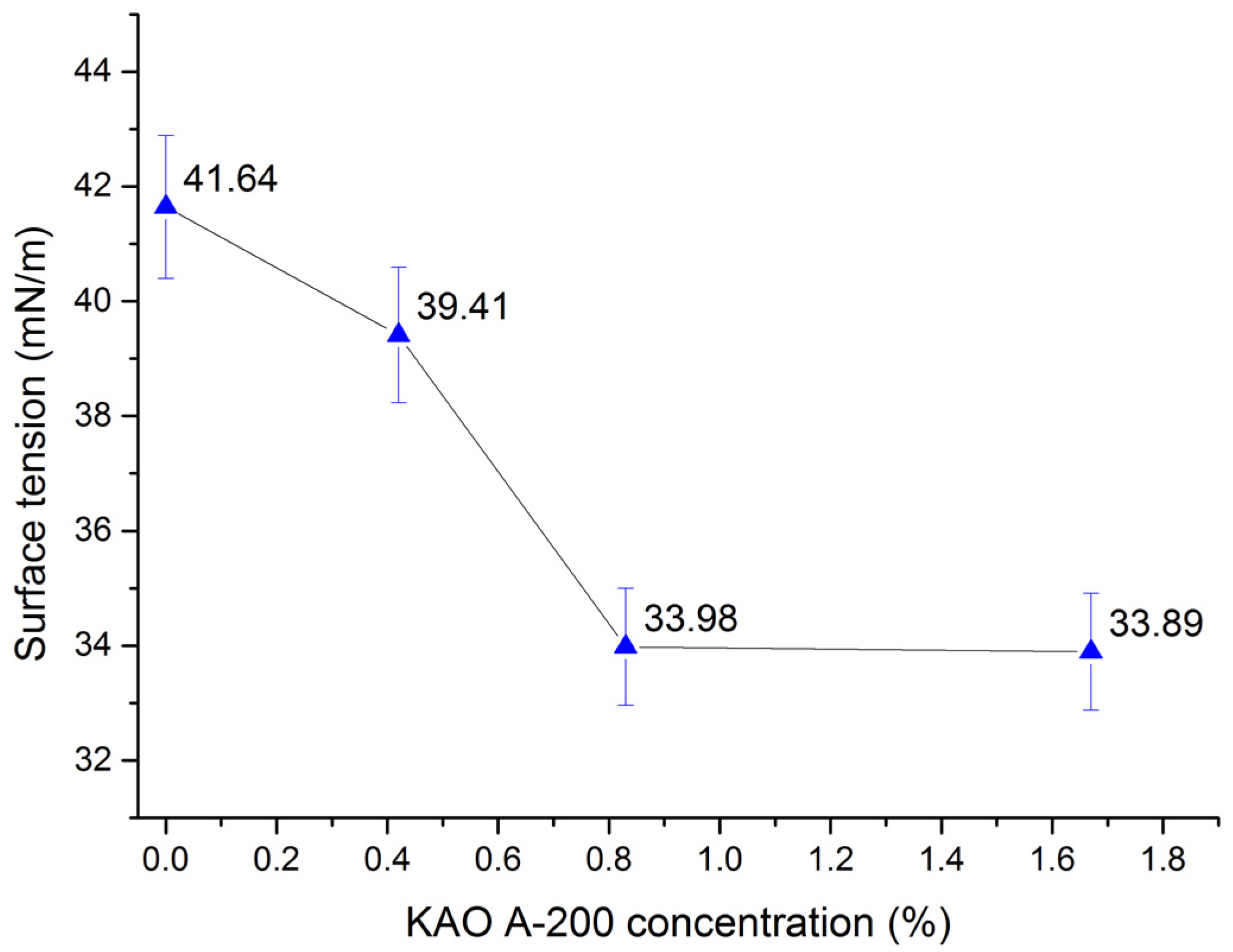

3.1. STs and CAs of PEW Solution Droplets with Different KAO A-200 Concentrations

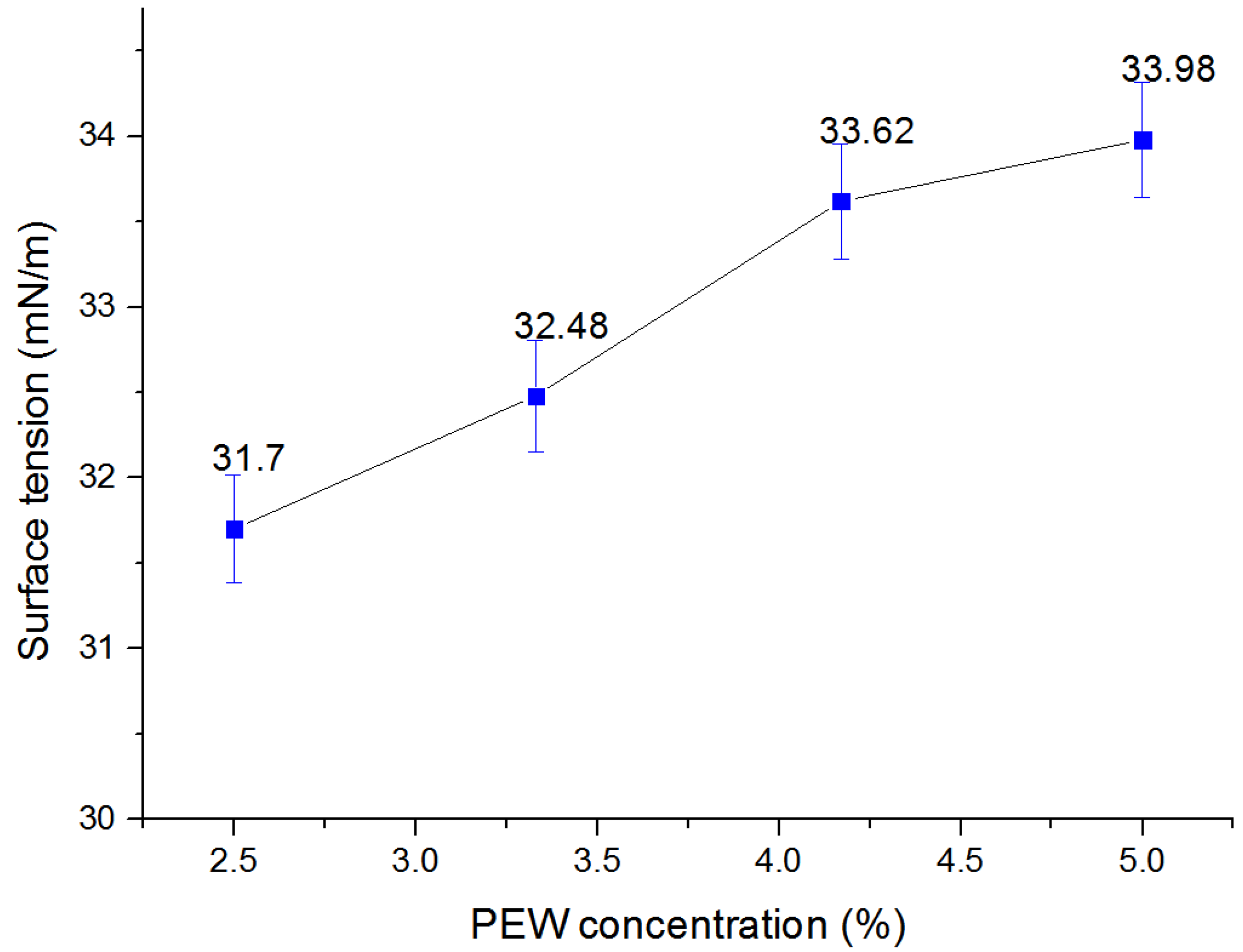

3.2. STs and CAs of PEW Solution Droplets with Different Concentrations of KAO A-200 OC

3.3. Effect of KAO-A-200 on Aerial Spraying Droplet Deposition

3.3.1. Droplet Deposition Density

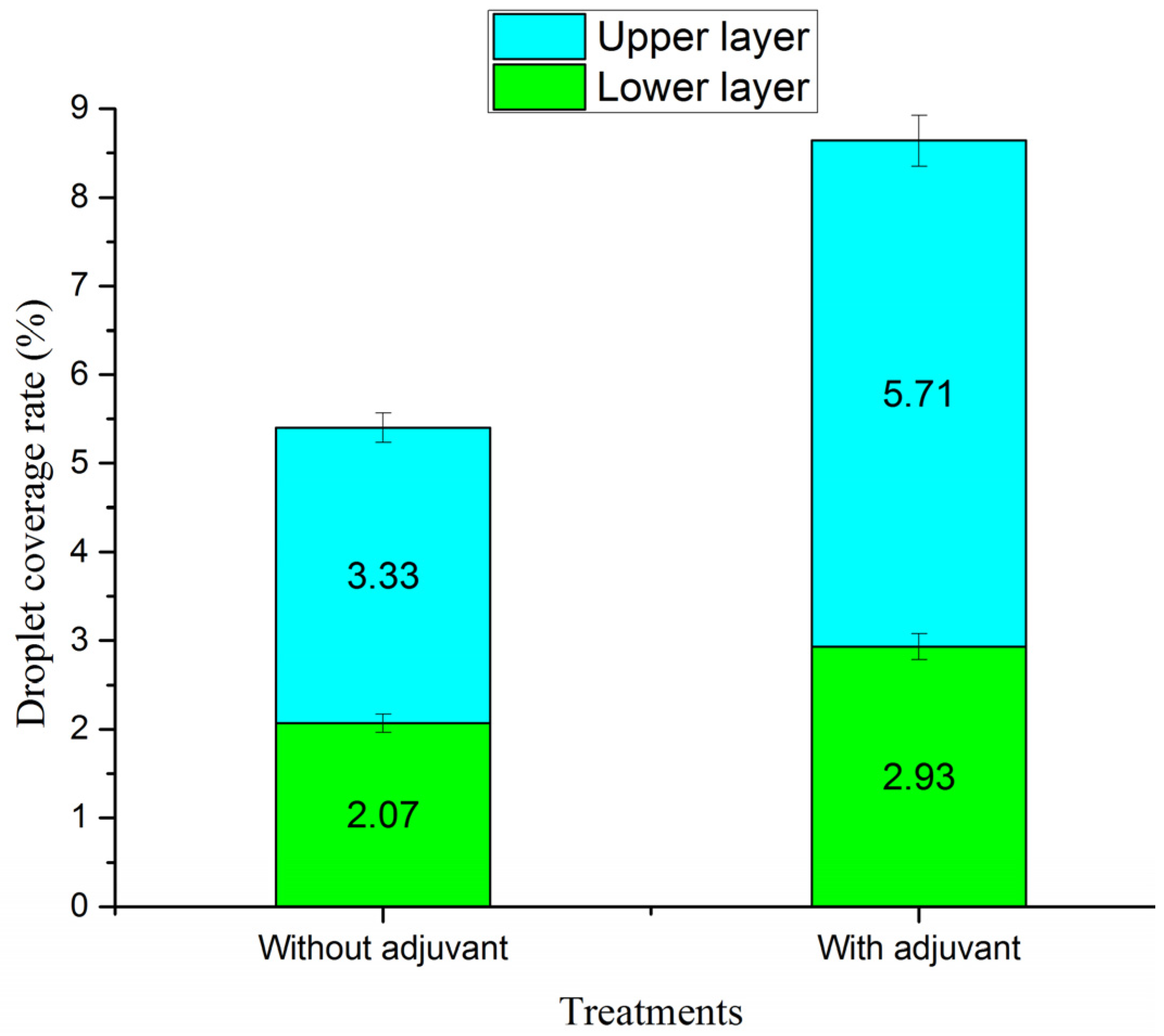

3.3.2. Droplet Coverage Rate

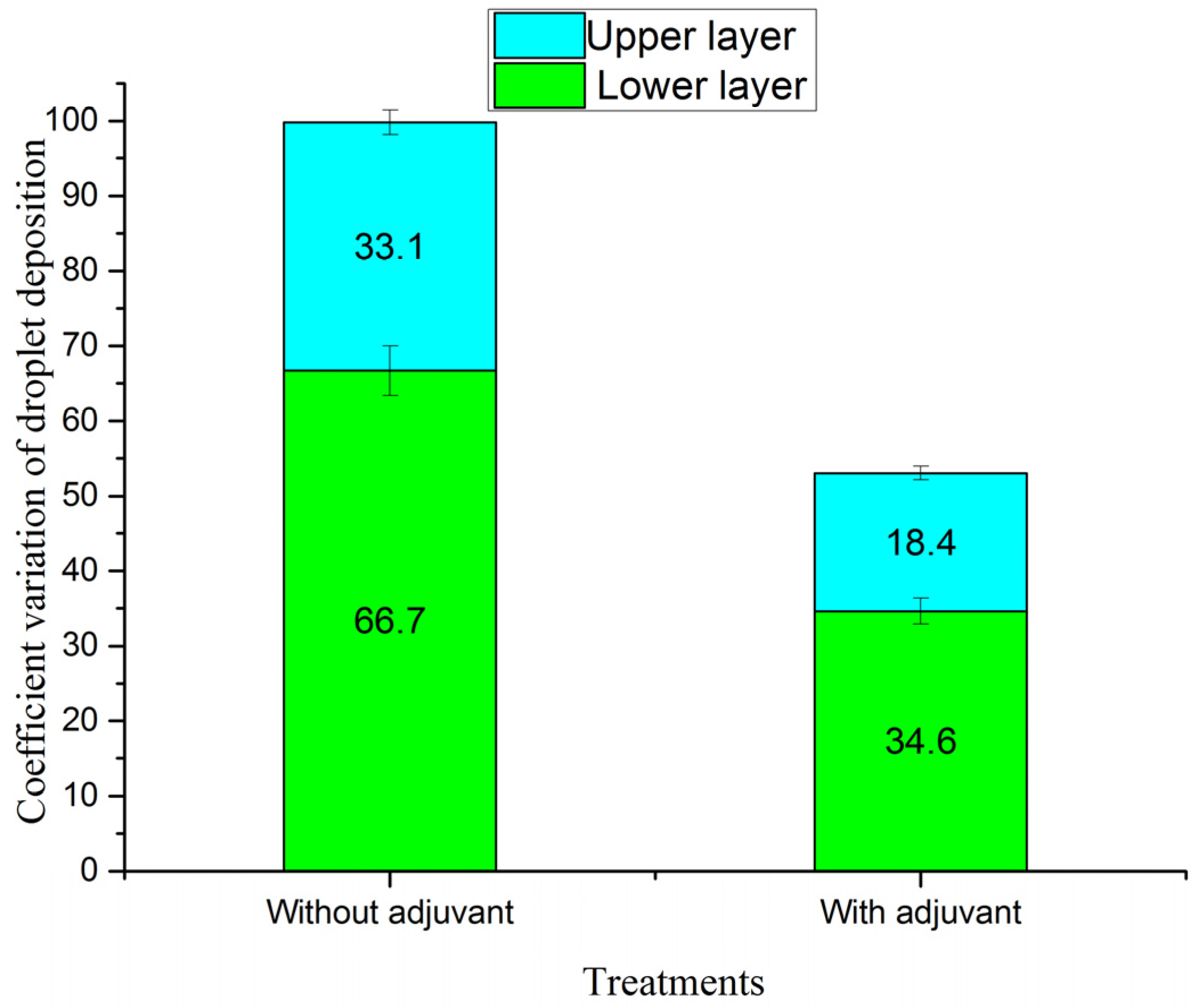

3.3.3. Droplet Deposition Uniformity

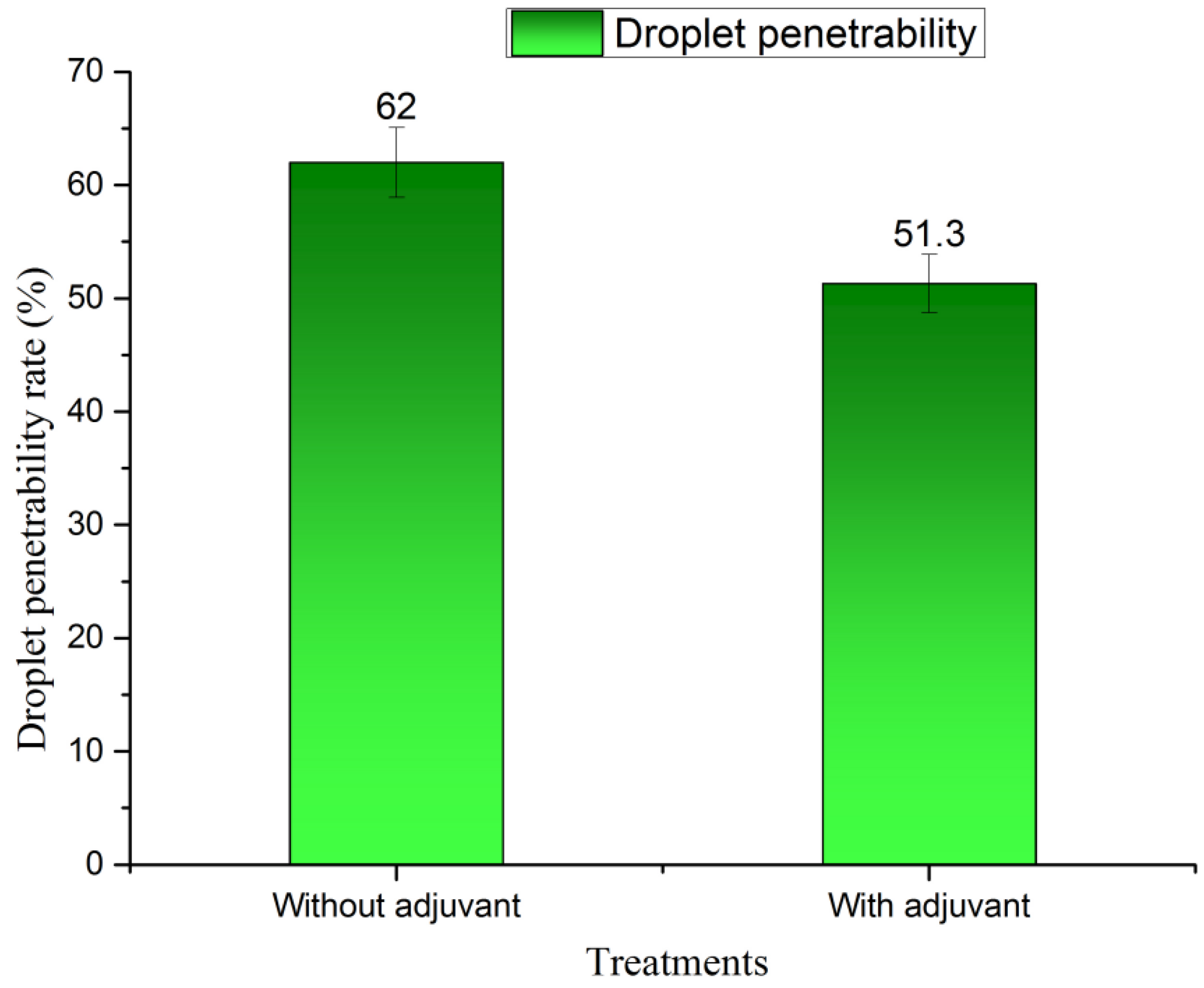

3.3.4. Droplet Penetrability

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, Q.; Ren, T.; Zhang, Y.; Li, X.; Gong, R.; Liu, S.; Fan, X.; Lu, J. Evaluating the application of controlled release urea for oilseed rape on Brassica napus in a regional scale: The optimal usage, yield and nitrogen use efficiency responses. Ind. Crops Prod. 2019, 140, 111560. [Google Scholar] [CrossRef]

- Ding, L.; Li, T.; Guo, X.; Liu, X.; Cao, J.; Tan, X. Sclerotinia Stem Rot Resistance in Rapeseed: Recent Progress and Future Prospects. J. Agric. Food Chem. 2021, 69, 2965–2978. [Google Scholar] [CrossRef] [PubMed]

- Song, M.; Ju, J.; Luo, S.; Han, Y.; Dong, Z.; Wang, Y.; Gu, Z.; Zhang, L.; Hao, R.; Jiang, L. Controlling liquid splash on superhydrophobic surfaces by a vesicle surfactant. Sci. Adv. 2017, 3, e1602188. [Google Scholar] [CrossRef] [PubMed]

- Meng, T.; Chen, L.; Zhang, N.; Lin, R.; Hou, Y.; Qiu, L.; Jiang, H. Registration status of fungicides against sclerotinia disease on rape in China. Pestic. Sci. Adm. 2022, 43, 6–15. [Google Scholar]

- Lin, Q.; Huang, Y.; Li, G.; Luo, Z.; Wang, L.; Li, D.; Xiang, Y.; Liu, L.; Ban, Z.; Li, L. The journey of prochloraz pesticide in citrus sinensis: Residual distribution, impact on transcriptomic profiling and reduction by plasma-activated water. J. Hazard. Mater. 2023, 448, 130931. [Google Scholar] [CrossRef] [PubMed]

- Schulzt, R.; Bub, S.; Petschick, L.; Stehle, S.; Wolfram, J. Applied pesticide toxicity shifts toward plants and invertebrates, even in GM crops. Science 2021, 372, 81–84. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Yang, G.; Liu, Y.; Ye, H.; Qi, X.; Wang, Q. Residual behavior and risk assessment of prochloraz in bayberries and bayberry wine for the Chinese population. Environ. Monit. Assess. 2019, 191, 644. [Google Scholar] [CrossRef]

- Lundqvist, J.; Hellman, B.; Oskarsson, A. Fungicide prochloraz induces oxidative stress and DNA damage in vitro. Food Chem. Toxicol. 2016, 91, 36–41. [Google Scholar] [CrossRef]

- Marie, V.A.; Sofie, C.; Peter, L.; Erecius, P.M.; Vibeke, B.; Kirsten, J. Perinatal exposure to the fungicide prochloraz feminizes the male rat offspring. Toxicol. Sci. 2005, 85, 886–897. [Google Scholar]

- Baumann, L.; Knorr, S.; Keiter, S.; Nagel, T.; Segner, H.; Braunbeck, T. Prochloraz causes irreversible masculinization of zebrafish (Danio rerio). Environ. Sci. Pollut. Res. Int. 2015, 22, 16417–16422. [Google Scholar] [CrossRef]

- Hameed, B.H.; Tan, I.A.W.; Ahmad, A.L. Adsorption isotherm, kinetic modeling and mechanism of 2,4,6-trichlorophenol on coconut husk-based activated carbon. Chem. Eng. J. 2008, 144, 235–244. [Google Scholar] [CrossRef]

- Kang, F.; Wu, X.; Wang, Y.; Zheng, Y.; Li, S.; Chen, C. Research progress and prospect of pesticide droplet deposition characteristics. Trans. Chin. Soc. Agric. Eng. 2021, 37, 1–14. [Google Scholar]

- Oliveira, R.B.; Bonadio, P.L.M.; Gandolfo, M.A.; Oliveira, J.V.; Lucio, F.R. Effect of droplet size and leaf surface on retention of 2, 4-D formulations. Crop Prot. 2019, 119, 97–101. [Google Scholar] [CrossRef]

- Zhang, X.; Xiong, L. Effect of adjuvants on the spray droplet size of pesticide dilute emulsion. Colloids Surf. A-Physicochem. Eng. Asp. 2021, 619, 126557. [Google Scholar] [CrossRef]

- Appah, S.; Jia, W.; Ou, M.; Wang, P.; Asante, E.A. Analysis of potential impaction and phytotoxicity of surfactant-plant surface interaction in pesticide application. Crop Prot. 2020, 127, 104961. [Google Scholar] [CrossRef]

- He, L.; Ding, L.; Li, B.; Mu, W.; Li, P.; Liu, F. Regulating droplet wetting and pinning behaviors on pathogen-modified hydrophobic surfaces: Strategies and working mechanisms. J. Agric. Food Chem. 2021, 69, 11720–11732. [Google Scholar] [CrossRef]

- Stock, D.; Geoff, B. Physicochemical properties of adjuvants: Values and applications1. Weed Technol. 2000, 14, 798–806. [Google Scholar] [CrossRef]

- Song, Y.; Huang, Q.; Huang, G.; Liu, M.; Cao, L.; Li, F.; Zhao, P.; Cao, C. The Effects of adjuvants on the wetting and deposition of insecticide solutions on hydrophobic wheat leaves. Agronomy 2022, 12, 2148. [Google Scholar] [CrossRef]

- Knoche, M. Organosilicone surfactant performance in agricultural spray application: A review. Weed Res. 1994, 34, 221–239. [Google Scholar] [CrossRef]

- Stevens, P. Organosilicone surfactants as adjuvants for agrochemicals. Pestic. Sci. 1993, 38, 103–122. [Google Scholar] [CrossRef]

- He, L.; Ding, L.; Zhang, P.; Li, B.; Mu, W.; Liu, F. Impact of the equilibrium relationship between deposition and wettability behavior on the high-efficiency utilization of pesticides. Pest Manag. Sci. 2021, 77, 2485–2493. [Google Scholar] [CrossRef]

- Straw, E.A.; Brown, M.J.F. Co-formulant in a commercial fungicide product causes lethal and sub-lethal effects in bumble bees. Sci. Reports. 2021, 11, 21653. [Google Scholar] [CrossRef]

- Brandon, S.; Emily, W.; Reed, M. Toxicity of spray adjuvants and tank mix combinations used in almond orchards to adult honey bees (Apis mellifera). J. Econ. Entomol. 2023, 116, 1467–1480. [Google Scholar]

- Gao, R.; Huang, L.; Wen, S.; Yin, X.; Zhang, J. Factors influencing the spreading areas of pesticide droplets on the surface of maize leaves. Trans. Chin. Soc. Agric. Eng. 2022, 38, 41–48. [Google Scholar]

- Xu, L.; Zhu, H.; Ozkan, H.E.; Bagley, W.E.; Krause, C.R. Droplet evaporation and spread on waxy and hairy leaves associated with type and concentration of adjuvants. Pest Manag. Sci. 2011, 67, 842–851. [Google Scholar] [CrossRef]

- He, L.; Xi, S.; Ding, L.; Li, B.; Mu, W.; Li, P.; Liu, F. Regulating the entire journey of pesticide application on surfaces of hydrophobic leaves modified by pathogens at different growth stages. ACS Nano 2021, 16, 1318–1331. [Google Scholar] [CrossRef]

- Zhou, Z.; Cao, C.; Cao, L.; Zheng, L.; Xu, J.; Li, F.; Huang, Q. Effect of surfactant concentration on the evaporation of droplets on cotton (Gossypium hirsutum L.) leaves. Colloids Surf. B-Biointerfaces 2018, 167, 206–212. [Google Scholar] [CrossRef] [PubMed]

- Yuan, H.; Qi, S.; Yang, D. Study on the point of run-off and the maximum retention of spray liquid on crop leaves. Chin. J. Pestic. Sci. 2000, 2, 66–71. [Google Scholar]

- Wirth, W.; Storp, S.; Jacobsen, W. Mechanisms controlling leaf retention of agricultural spray solutions. Pestic. Sci. 1991, 33, 411420. [Google Scholar] [CrossRef]

- Zhang, S.; Qiu, B.; Xue, X.; Sun, T.; Peng, B. Parameters optimization of crop protection UAS based on the first industry standard of China. Int. J. Agric. Biol. Eng. 2020, 13, 29–35. [Google Scholar] [CrossRef]

- Wang, G.B.; Han, Y.X.; Li, X.; Andaloro, J.; Chen, P.C.; Hoffmann, W.C.; Han, X.Q.; Chen, S.D.; Lan, Y.B. Field evaluation of spray drift and environmental impact using an agricultural unmanned aerial vehicle (UAV) sprayer. Sci. Total Environ. 2020, 737, 139793. [Google Scholar] [CrossRef]

- Sun, T.; Zhang, S.; Xue, X.; Jiao, Y. Comparison of droplet distribution and control effect of wheat aphids under different operation parameters of the crop protection UAV in the wheat flowering stage. Agronomy 2022, 12, 3175. [Google Scholar] [CrossRef]

- Zhou, Q.; Zhang, S.; Xue, X.; Cai, C.; Wang, B. Performance evaluation of UAVs in wheat disease control. Agronomy 2023, 13, 2131. [Google Scholar] [CrossRef]

- Chen, S.; Lan, Y.; Li, J.; Xu, X.; Wang, Z.; Peng, B. Evaluation and test of effective spraying width of aerial spraying on plant protection UAV. Trans. Chin. Soc. Agric. Eng. 2017, 33, 82–90. [Google Scholar]

- Yang, S.; Yang, X.; Mo, J. The application of unmanned aircraft systems to plant protection in China. Precis. Agric. 2018, 19, 278–292. [Google Scholar] [CrossRef]

- Tang, Q.; Zhang, R.; Chen, L.; Xu, M.; Yi, T.; Zhang, B. Droplets movement and deposition of an eight-rotor agricultural UAV in downwash flow field. Int. J. Agric. Biol. Eng. 2017, 10, 47–56. [Google Scholar]

- Arand, K.; Asmus, E.; Popp, C.; Schneider, D.; Riederer, M. The mode of action of adjuvants-relevance of physicochemical properties for effects on the foliar application, cuticular permeability, and greenhouse performance of pinoxaden. J. Agric. Food Chem. 2018, 66, 5770–5777. [Google Scholar] [CrossRef]

- Liu, S.; Dutcher, C. Measurements of static and dynamic bubble surface tension using a deformation-based microfluidic tensiometer. J. Phys. Chem. B 2021, 125, 13916–13927. [Google Scholar] [CrossRef]

- Rosalind, D.; Buchan, G.; Field, R. The role of surface tension of spreading droplets in absorption of a herbicide. Pestic. Sci. 1993, 38, 227–235. [Google Scholar]

- Marta, W.; Anna, S.; Aneta, L.; Agnieszka, M.; Katarzyna, S.; Michalina, W.; Maciej, K.; Katarzyna, M. Synthesis and surface properties of piperidinium-based herbicidal ionic liquids as a potential tool for weed control. J. Agric. Food Chem. 2023, 71, 4550–4560. [Google Scholar]

- Gu, Z. Analysis of relationship between hydrophilic or hydrophobic property of plant and action of pesticides solution on plants leaves. Jiangsu J. Agr. Sci. 2009, 25, 276–281. [Google Scholar]

- Qin, W.; Xue, X.; Zhang, S.; Gu, W.; Wang, B. Droplet deposition and efficiency of fungicides sprayed with small UAV against wheat powdery mildew. Int. J. Agric. Biol. Eng. 2018, 11, 27–32. [Google Scholar] [CrossRef]

- Meng, Y.; Lan, Y.; Mei, G.; Guo, Y.; Song, J.; Wang, Z. Effect of aerial spray adjuvant applying on the efficiency of small unmanned aerial vehicle for wheat aphids control. Int. J. Agric. Biol. Eng. 2018, 11, 46–53. [Google Scholar] [CrossRef]

- Zhao, R.; Yu, M.; Sun, Z.; Li, L.; Shang, H.; Xi, W.; Li, B.; Li, Y.; Cu, Y.; Wu, X. Using tank-mix adjuvant improves the physicochemical properties and dosage delivery to reduce the use of pesticides in unmanned aerial vehicles for plant protection in wheat. Pest. Manag. Sci. 2022, 78, 2512–2522. [Google Scholar] [CrossRef] [PubMed]

- Xiao, J.; Chen, L.; Pan, F.; Deng, Y.; Ding, C.; Liao, M.; Su, X.; Cao, H. Application method affects pesticide efficiency and effectiveness in wheat fields. Pest. Manag. Sci. 2020, 76, 1256–1264. [Google Scholar] [CrossRef] [PubMed]

| Items | Dosage (mL/1.2 L) | v/v Concentration (%) |

|---|---|---|

| PEW | 30 (13.5 g a.i.) | 2.5 |

| 40 (18 g a.i.) | 3.33 | |

| 50 (22.5 g a.i.) | 4.17 | |

| 60 (27 g a.i.) | 5 | |

| KAO A-200 | 5 | 0.42 |

| 10 | 0.83 | |

| 20 | 1.67 |

| Items | Parameters |

|---|---|

| CA measurement range | 0–180° |

| CA resolution | 0.1° |

| ST measurement range | 0.01–100 mN/m |

| ST resolution | 0.01 mN/m |

| Optical system magnification | 7 times |

| Sample observation field of view | 3.2–22.5 mm (diagonal size) |

| Video system frame rate | 1000 fp/s |

| Items | Parameters |

|---|---|

| UAAS size | 1235 mm × 1235 mm × 647 mm |

| Rotor diameter | 838 mm |

| Battery capacity | 20,000 mAh–51.8 V |

| Flight speed | 1.0–7.0 m/s |

| Flight height | 0.5–5.0 m |

| Tank volume | 22 L |

| Aerial spraying rate | 2.3–7.4 L/min |

| Crops | Critical Surface Tension (mN/m) |

|---|---|

| Cabbage-type rape | 36.40 * |

| Rice | 36.70 * |

| Wheat | 36.90 * |

| Corn | 47.40–58.00 |

| Cotton | 63.30–71.81 |

| Pepper | 43.38–45.27 |

| Cowpea | 39.00–43.38 |

| Eggplant | 43.38–45.27 |

| Concentration (%) | ST (mN/m) | CA (°) | Dosage (mL/1.2 L) |

|---|---|---|---|

| 2.5 | 31.7 | 27.79 | 30 (13.5 g a.i.) |

| 3.33 | 32.48 | 15.13 | 40 (18 g a.i.) |

| 4.17 | 33.62 | 16.48 | 50 (22.5 g a.i.) |

| 5 | 33.98 | 26.24 | 60 * (27 g a.i.) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Huang, M.; Zhou, Q.; Jiao, Y.; Sun, H.; Cheng, X.; Xue, X. Study on Effects of Different Concentration Adjuvants on the Properties of Prochloraz Emulsion in Water Solution Droplets and Deposition. Agronomy 2023, 13, 2635. https://doi.org/10.3390/agronomy13102635

Zhang S, Huang M, Zhou Q, Jiao Y, Sun H, Cheng X, Xue X. Study on Effects of Different Concentration Adjuvants on the Properties of Prochloraz Emulsion in Water Solution Droplets and Deposition. Agronomy. 2023; 13(10):2635. https://doi.org/10.3390/agronomy13102635

Chicago/Turabian StyleZhang, Songchao, Meng Huang, Qingqing Zhou, Yuxuan Jiao, Hua Sun, Xiaohui Cheng, and Xinyu Xue. 2023. "Study on Effects of Different Concentration Adjuvants on the Properties of Prochloraz Emulsion in Water Solution Droplets and Deposition" Agronomy 13, no. 10: 2635. https://doi.org/10.3390/agronomy13102635