Experimental Study of Quizalofop-p-Ethyl Herbicide Drift Damage to Corn and the Safety Amount of Drift Deposition

Abstract

1. Introduction

2. Materials and Methods

2.1. Potted Corn Test

2.1.1. Test Materials

2.1.2. Methods

2.2. Field Corn Test

2.2.1. Test Materials

2.2.2. Methods

2.3. Herbicide Damage Evaluation

- (1)

- Observation method

- (2)

- Growth inhibition method

3. Results

3.1. Potted Corn Test

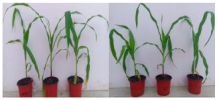

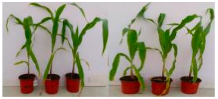

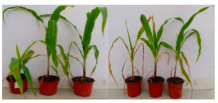

3.1.1. Observation of Herbicide Damage

3.1.2. Inhibition Rate of Plant Height

3.2. Field Corn Test

3.2.1. Observation of Herbicide Damage

3.2.2. Inhibition Rate of Plant Height

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qiu, L.J.; Chang, R.Z. The origin and history of soybean. In Botany, Production and Uses; CABI International: Wallingford, UK, 2010. [Google Scholar] [CrossRef]

- Li, J.S. Production, Breeding and Process of Corn in China. In Handbook of Corn: Its Biology; Bennetzen, J.L., Hake, S.C., Eds.; Springer: New York, NY, USA, 2009; pp. 563–576. [Google Scholar] [CrossRef]

- Du, J.B.; Han, T.F.; Gai, J.Y.; Yong, T.W.; Sun, X.; Wang, X.C.; Yang, F.; Liu, J.; Shu, K.; Liu, W.G.; et al. Soybean-corn strip intercropping: Achieved a balance between high productivity and sustainability. J. Integr. Agric. 2018, 17, 747–754. [Google Scholar] [CrossRef]

- Lesoing, G.W.; Francis, C.A. Strip intercropping effects on yield and yield components of corn, grain sorghum, and soybean. Agron. J. 1999, 91, 807–813. [Google Scholar] [CrossRef]

- Korav, S.; Dhaka, A.K.; Singh, R.; Premaradhya, N.; Reddy, G.C. A study on crop weed competition in field crops. J. Pharmacogn. Phytochem. 2018, 7, 3235–3240. [Google Scholar]

- Bourgeois, B.; Munoz, F.; Fried, G.; Mahaut, L.; Armengot, L.; Denelle, P.; Storkey, J.; Gaba, S.; Violle, C. What makes a weed a weed? A large-scale evaluation of arable weeds through a functional lens. Am. J. Bot. 2019, 106, 90–100. [Google Scholar] [CrossRef] [PubMed]

- Pandey, A.K.; Prakash, V. Weed management in corn and soybean intercropping system. Indian J. Weed Sci. 2002, 34, 58–62. [Google Scholar]

- Zhang, Z.P. Development of chemical weed control and integrated weed management in China. Weed Biol. Manag. 2003, 3, 197–203. [Google Scholar] [CrossRef]

- Marrs, R.H.; Williams, C.T.; Frost, A.J.; Plant, R.A. Assessment of the effects of herbicide spray drift on a range of plant species of conservation interest. Environ. Pollut. 1989, 59, 71–86. [Google Scholar] [CrossRef] [PubMed]

- Boerboom, C. Field case studies of dicamba movement to soybeans. In Proceedings of the Wisconsin Crop Management Conference, University of Wisconsin–Madison, Madison, WI, USA, 12 October 2004. [Google Scholar]

- Gunsolus, J.L.; Curran, W.S. Herbicide mode of action and damage symptoms. Order 1991, 612, 625–8173. [Google Scholar]

- Brown, L.R. Cumulative Herbicide Stress in Corn and Soybean. Ph.D. Thesis, University of Guelph, Guelph, SO, Canada, 2008. [Google Scholar]

- Meng, F.Z. Experiment of Quizalofop-p-ethyl Preventing Gramineous Weeds in Soybean Field. Heilongjiang Agric. Sci. 2003, 1, 38–39. (In Chinese) [Google Scholar]

- Sun, Y.L.; Zhu, W.D.; Chen, W.Y.; Yuan, Y.M.; Wang, M.R. The weed control effects of quizalofop-p-ethyl and its influence on light and nutrition in summer soybean field. J. Huazhong Agric. Univ. 2009, 28, 161–163. (In Chinese) [Google Scholar]

- Yadav, R.; Bhullar, M.S.; Kaur, S.; Kaur, T.; Jhala, A.J. Weed control in conventional soybean with pendimethalin followed by imazethapyr+ imazamox/quizalofop-p-ethyl. Can. J. Plant Sci. 2017, 97, 654–664. [Google Scholar] [CrossRef][Green Version]

- National Agro-Tech Extension and Service Center. Guidance on herbicide use of soybean and corn strip compound planting. Agric. Mach. 2022, 4, 37–38. (In Chinese) [Google Scholar]

- Pacanoski, Z.; Svečnjak, Z.; Saliji, A. Herbicides impact on weed control and damage of corn and climbing bean grown in an intercropping system. Herbologia 2015, 15, 55. [Google Scholar] [CrossRef]

- Pacanoski, Z.; Saliji, A. Response of corn/bean intercrop on pre applied herbicides. Herbologia 2016, 16, 41–49. [Google Scholar] [CrossRef]

- Kim, D.W.; Song, Y.; Kim, J.; Fiaz, M.; Kwon, C.H. Effect of different herbicides on forage yield and nutritive value in soybean-corn mixture cropping. J. Korean Soc. Grassl. Forage Sci. 2017, 37, 108–115. [Google Scholar] [CrossRef]

- Dai, W.; Yang, J.Z.; Wang, X.C.; Yong, T.W.; Wang, Q.M.; Zhou, X.; Yang, W.Y. The Influence of Different Herbicides on Intercropping Soybean and Maize. Soybean Sci. 2017, 36, 287–294. (In Chinese) [Google Scholar]

- Wu, J.L.; Li, C.S. Evaluation on Herbicide damage to Rice in Various Cultivations. Mod. Agrochem. 2004, 3, 36–39. (In Chinese) [Google Scholar]

- NY/T 1155.8-2007; Guideline for Laboratory Bioassay of Pesticides—Part 8: Foliar Application Test for Herbicide Crop Safety Evaluation. Agricultural Industry Standard of the People’s Republic of China: Beijing, China, 2007. (In Chinese)

- Xu, D.J.; Xu, G.C.; Xu, X.L.; Gu, Z.Y. Spray parameter optimization based on the amount of pesticide deposition and its biological effect on cabbage diamondback moth. J. Plant Prot. 2015, 42, 755–762. (In Chinese) [Google Scholar]

- Xu, D.J.; Xu, G.C.; Xu, X.L.; Gu, Z.Y. Effect of application volume, droplet size, rice leaf incline angle and spray adjuvant on pesticide deposition. Southwest China J. Agric. Sci. 2015, 28, 2056–2062. (In Chinese) [Google Scholar]

- Dong, Y.X.; Gu, Z.Y.; Xu, D.J.; Xu, G.C.; Xu, X.L. Influence of droplet densities and spray methods on the efficiency of chlorpyrifos against brown planthopper. J. Plant Prot. 2012, 39, 75–80. [Google Scholar]

- Green, J.M. Differential tolerance of corn (Zea mays) inbreds to four sulfonylurea herbicides and bentazon. Weed Technol. 1998, 12, 474–477. [Google Scholar] [CrossRef]

- Richburg, J.T.; Norsworthy, J.K.; Barber, T.; Roberts, T.L.; Gbur, E.E. Tolerance of corn to PRE- and POST-applied photosystem II–inhibiting herbicides. Weed Technol. 2020, 34, 277–283. [Google Scholar] [CrossRef]

- Brown, L.R.; Robinson, D.E.; Young, B.G.; Loux, M.M.; Johnson, W.G.; Nurse, R.E.; Swanton, C.J.; Sikkema, P.H. Response of corn to simulated glyphosate drift followed by in-crop herbicides. Weed Technol. 2009, 23, 11–16. [Google Scholar] [CrossRef]

- Soukup, J.; Jursík, M.; Hamouz, P.; Holec, J.; Krupka, J. Influence of soil pH, rainfall, dosage, and application timing of herbicide Merlin 750 WG (isoxaflutole) on phytotoxicity level in corn (Zea mays L.). Plant Soil Environ. 2004, 50, 88–94. [Google Scholar] [CrossRef]

- Singh, R.; Pramanick, B.; Singh, A.P.; Kumar, S.; Kumar, A.; Singh, G. Bio-efficacy of Fenoxaprop-P-Ethyl for grassy weed control in onion and its residual effect on succeeding maize crop. Indian J. Weed Sci. 2017, 49, 63–66. [Google Scholar]

- Janak, T.W.; Grichar, W.J. Weed control in corn (Zea mays L.) as influenced by preemergence herbicides. Int. J. Agron. 2016, 2016, 2607671. [Google Scholar] [CrossRef]

- Al-Sadoon, S.N. Effect of herbicides and frequence of irrigation on yield of corn (Zea mays L.) and accompanied weeds. J. Tikrit Univ. Agric. Sci. 2012, 12, 93–102. [Google Scholar]

- Hons, F.M.; Saladino, V.A. Yield contribution of nitrogen fertilizer, herbicide, and insecticide in a corn-soybean rotation. Commun. Soil Sci. Plant Anal. 1995, 26, 3083–3097. [Google Scholar] [CrossRef]

- Hunter, J.E.; Gannon, T.W.; Richardson, R.J.; Yelverton, F.H.; Leon, R.G. Coverage and drift potential associated with nozzle and speed selection for herbicide applications using an unmanned aerial sprayer. Weed Technol. 2020, 34, 235–240. [Google Scholar] [CrossRef]

- Balsari, P.; Bozzer, C.; Manzone, M.; Tamagnone, M. Drift assessment during chemical weed control. Acta Hortic. 2012, 978, 205–209. [Google Scholar] [CrossRef]

- Havens, P.L.; Hillger, D.E.; Hewitt, A.J.; Kruger, G.R.; Marchi-Werle, L.; Czaczyk, Z. Field measurements of drift of conventional and drift control formulations of 2, 4-D plus glyphosate. Weed Technol. 2018, 32, 550–556. [Google Scholar] [CrossRef]

- Creech, C.F.; Henry, R.S.; Hewitt, A.J.; Kruger, G.R. Herbicide spray penetration into corn and soybean canopies using air-induction nozzles and a drift control adjuvant. Weed Technol. 2018, 32, 72–79. [Google Scholar] [CrossRef]

- Johnson, A.K.; Roeth, F.W.; Martin, A.R.; Klein, R.N. Glyphosate spray drift management with drift-reducing nozzles and adjuvants. Weed Technol. 2006, 20, 893–897. [Google Scholar] [CrossRef]

- Nuyttens, D.; Dekeyser, D.; De Schampheleire, M.; Baetens, K. The effect of air support on droplet characteristics and spray drift. Commun. Agric. Appl. Biol. Sci. 2007, 72, 71–79. [Google Scholar] [PubMed]

- Grella, M.; Marucco, P.; Balafoutis, A.T.; Balsari, P. Spray drift generated in vineyard during under-row weed control and suckering: Evaluation of direct and indirect drift-reducing techniques. Sustainability 2020, 12, 5068. [Google Scholar] [CrossRef]

- Sidahmed, M.M.; Awadalla, H.H.; Haidar, M.A. Symmetrical multi-foil shields for reducing spray drift. Biosyst. Eng. 2004, 88, 305–312. [Google Scholar] [CrossRef]

- Deng, X.L.; Zheng, W.N.; Zhou, X.M.; Bai, L.Y. The effect of salicylic acid and 20 substituted molecules on alleviating metolachlor herbicide damage in rice (Oryza sativa). Agronomy 2020, 10, 317. [Google Scholar] [CrossRef]

- Bernards, M.L.; Simmons, J.T.; Guza, C.J.; Schulz, C.R.; Penner, D.; Kells, J.J. Inbred corn response to acetamide herbicides as affected by safeners and microencapsulation. Weed Technol. 2006, 20, 458–465. [Google Scholar] [CrossRef]

| Drift Deposition Rate (%) | 1 | 5 | 10 | 30 | |

|---|---|---|---|---|---|

| Spray Volume (L/ha) | |||||

| 150 | 0.954 | 4.772 | 9.543 | 28.629 | |

| 300 | 1.909 | 9.543 | 19.086 | 57.258 | |

| 450 | 2.863 | 14.315 | 28.629 | 85.887 | |

| Damage Grade | Description of Herbicide Damage Symptoms |

|---|---|

| 0 | The growth is consistent with CK. |

| 1 | The plant height and leaf color are slightly different from CK. |

| 2 | The plant is slightly deformed and its height is lower than CK. |

| 3 | The plant is obviously dwarfed, the stem is thickened, the leaves are slightly thickened and the color is deepened, or the leaves turn yellow. |

| 4 | The plant stops growing, has severe deformity and stiff seedlings, or the whole leaf withers and dies. |

| 5 | The plant dies. |

| Inhibition Rate | Inhibition Degree |

|---|---|

| ≤0 | Normal growth |

| 0.1~20% | Mild inhibition |

| 20.1~40% | Moderate inhibition |

| 40.1~60% | Significant inhibition |

| 60.1~80% | Severe inhibition |

| ≥80% | Complete inhibition |

| Symptoms | Dwarfization | Deformity | Yellow Spot | Yellowing | Leaf Rolling | Wither |

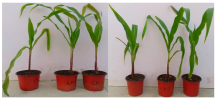

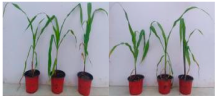

| Treatment | 7 days after Spray | 14 days after Spray | Herbicide Damage Symptoms | Damage Grade |

|---|---|---|---|---|

| CK |  |  | / | / |

| 10-1 |  |  | No Symptoms | 7 d: Grade 0 14 d: Grade 0 |

| 10-5 |  |  | 14 d: Corn No. 5 appeared yellow spot and corn No. 6 yellowed | 7 d: Grade 0 14 d: 2 corn plants Grade 1 |

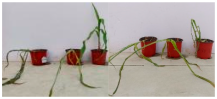

| 10-10 |  |  | 7 d: Corn No. 1, 3, and 6 yellowed, and corn No. 5 withered 14 d: Corn No. 1, 2, and 4 yellowed and rolled leaves, and corn No. 3 and 6 withered | 7 d: 3 corn plants Grade 1 and 1 corn plant Grade 5 14 d: 3 corn plants Grade 3 and 3 corn plants Grade 5 |

| 10-30 |  |  | 7 d: Corn No. 1, 2, 4, 5, and 6 withered; 14 d: Corn No. 3 withered | 7 d: 5 corn plants Grade 5 14 d: 6 corn plants Grade 5 |

| 20-1 |  |  | No Symptoms | 7 d: Grade 0 14 d: Grade 0 |

| 20-5 |  |  | 7 d: Corn No. 1 dwarfed 14 d: Corn No. 1 yellowed and deformed, corn No. 4 yellowed and rolled leaves, corn No. 5 yellowed, and corn No. 6 appeared yellow spot | 7 d: 1 corn plant Grade 1 14 d: 2 corn plants Grade 1 and 2 corn plants Grade 3 |

| 20-10 |  |  | 7 d: Corn No. 1, 2, and 5 withered, and corn No. 4 yellowed and deformed 14 d: Corn No. 3 and 4 withered, and corn No. 6 yellowed | 7 d: 1 corn plant Grade 3 and 3 corn plants Grade 5 14 d: 1 corn plant Grade 1 and 5 corn plants Grade 5 |

| 20-30 |  |  | 7 d: Corn No. 2 and 3 yellowed and rolled leaves, corn No. 4 deformed and rolled leaves, and corn No. 1, 5, and 6 withered 14 d: Corn No. 2, 3, and 4 withered | 7 d: 3 corn plants Grade 3 and 3 corn plants Grade 5 14 d: 6 corn plants Grade 5 |

| 30-1 |  |  | No symptoms | 7 d: Grade 0 14 d: Grade 0 |

| 30-5 |  |  | 7 d: Corn No. 2 and 4 dwarfed and rolled leaves 14 d: Corn No. 1 dwarfed, corn No. 2 deformed, corn No. 5 and 6 yellowed, and corn No. 4 withered | 7 d: 3 corn plants Grade 3 and 1 corn plant Grade 5 14 d: 3 corn plants Grade 1 and 1 corn plant Grade 5 |

| 30-10 |  |  | 7 d: Corn No. 3 dwarfed, corn No. 5 rolled leaves, and corn No. 1 and 4 dwarfed and yellowed 14 d: Corn No. 5 yellowed and rolled leaves, and corn No. 1, 3, 4 and 6 withered | 7 d: 2 corn plants Grade 1 and 2 corn plants Grade 3 14 d: 1 corn plant Grade 3 and 4 corn plants Grade 5 |

| 30-30 |  |  | 7 d: Corn No. 1, 3, 4, 5, and 6 dwarfed and yellowed; 14 d: Corn No. 2 yellowed and corn No. 1, 3, 4, 5, and 6 withered | 7 d: 5 corn plants Grade 3 14 d: 1 corn plant Grade 1 and 5 corn plants Grade 5 |

| Plant Height/cm | Inhibition Rate/% | Inhibition Degree | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Plant No. | 1 | 2 | 3 | 4 | 5 | 6 | Average | |||

| Treatment | ||||||||||

| CK | 70.9 | 74 | 71.1 | 68.7 | 68.2 | 73.7 | 71.10 ± 2.42 a | / | / | |

| 10-1 | 73.1 | 75.3 | 77.2 | 74.8 | 81.3 | 63.7 | 74.23 ± 5.87 a | −4.41 | Normal growth | |

| 10-5 | 78 | 73.9 | 72.1 | 67.9 | 68.2 | 69.8 | 71.65 ± 3.87 a | −0.77 | Normal growth | |

| 10-10 | 0 | 47.5 | 0 | 54.9 | 0 | 0 | 17.07 ± 26.54 | 76.00 | Severe inhibition | |

| 10-30 | 0 | 0 | 0 | 0 | 0 | 0 | 0.00 ± 0.00 | 100.00 | Complete inhibition | |

| 20-1 | 73.1 | 74.6 | 73.3 | 63.3 | 74.2 | 71.1 | 71.60 ± 4.24 a | −0.70 | Normal growth | |

| 20-5 | 35.3 | 72 | 70.5 | 56.2 | 68.8 | 75.5 | 63.05 ± 14.74 | 11.32 | Mild inhibition | |

| 20-10 | 0 | 0 | 0 | 0 | 0 | 72.1 | 12.02 ± 29.43 | 83.10 | Complete inhibition | |

| 20-30 | 0 | 0 | 0 | 0 | 0 | 0 | 0.00 ± 0.00 b | 100.00 | Complete inhibition | |

| 30-1 | 70 | 82.9 | 71.3 | 78.5 | 72.5 | 77 | 75.37 ± 4.96 a | −6.00 | Normal growth | |

| 30-5 | 66.3 | 49.6 | 77.3 | 0 | 66.6 | 64 | 53.97 ± 27.87 | 24.10 | Moderate inhibition | |

| 30-10 | 0 | 77.5 | 0 | 0 | 56.7 | 0 | 22.37 ± 35.26 | 68.54 | Severe inhibition | |

| 30-30 | 0 | 61.1 | 0 | 0 | 0 | 0 | 10.18 ± 24.94 | 85.68 | Complete inhibition | |

| Source | df | F | Sig. |

|---|---|---|---|

| Spray Volume | 2 | 0.296 | 0.745 |

| Drift Deposition Rate | 3 | 56.909 | 1.53 × 10−7 |

| Spray Volume × Drift Deposition Rate | 6 | 0.589 | 0.738 |

| Sampling Point | Drift Deposition Rate/% | Coefficient of Variation/% | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Position | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | ||

| Left | 1.63 ± 0.07 | 1.43 ± 0.05 | 1.57 ± 0.09 | 1.61 ± 0.02 | 1.48 ± 0.02 | 1.56 ± 0.07 | 1.26 ± 0.05 | 1.42 ± 0.08 | 1.37 ± 0.06 | 1.22 ± 0.03 | 11.5 | |

| Right | 1.41 ± 0.04 | 1.24 ± 0.06 | 1.3 ± 0.04 | 1.69 ± 0.07 | 1.35 ± 0.04 | 1.24 ± 0.04 | 1.39 ± 0.09 | 1.27 ± 0.07 | 1.39 ± 0.06 | 1.37 ± 0.04 | 9.7 | |

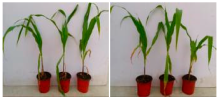

| Sampling Point | Plant Height/cm | Inhibition Rate/% | Inhibition Degree | ||

|---|---|---|---|---|---|

| CK | 81.7 | / | / | ||

| Left | Right | Left | Right | ||

| 1 | 83.0 ± 2.5 | 84.3 ± 2.1 | −1.59 | −3.14 | Normal growth |

| 2 | 85.6 ± 2.0 | 85.8 ± 1.5 | −4.77 | −5.05 | Normal growth |

| 3 | 82.1 ± 1.4 | 83.4 ± 1.8 | −0.49 | −2.07 | Normal growth |

| 4 | 84.2 ± 2.7 | 87.6 ± 2.9 | −3.06 | −7.19 | Normal growth |

| 5 | 83.2 ± 1. 7 | 84.6 ± 1.3 | −1.84 | −3.54 | Normal growth |

| 6 | 88.1 ± 2.0 | 86.9 ± 3.2 | −7.83 | −6.33 | Normal growth |

| 7 | 82.4 ± 1.1 | 83.6 ± 1.3 | −0.86 | −2.37 | Normal growth |

| 8 | 88.7 ± 3.2 | 87.2 ± 3.8 | −8.57 | −6.79 | Normal growth |

| 9 | 86.9 ± 1.5 | 81.9 ± 1.5 | −6.36 | −0.22 | Normal growth |

| 10 | 85.2 ± 1.3 | 84.8 ± 1.6 | −4.28 | −3.74 | Normal growth |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiao, Y.; Zhang, S.; Zhou, Q.; Xue, C.; Ye, J.; Ye, S.; Wu, C.; Han, H.; Mao, Z.; Ding, S.; et al. Experimental Study of Quizalofop-p-Ethyl Herbicide Drift Damage to Corn and the Safety Amount of Drift Deposition. Agronomy 2023, 13, 2890. https://doi.org/10.3390/agronomy13122890

Jiao Y, Zhang S, Zhou Q, Xue C, Ye J, Ye S, Wu C, Han H, Mao Z, Ding S, et al. Experimental Study of Quizalofop-p-Ethyl Herbicide Drift Damage to Corn and the Safety Amount of Drift Deposition. Agronomy. 2023; 13(12):2890. https://doi.org/10.3390/agronomy13122890

Chicago/Turabian StyleJiao, Yuxuan, Songchao Zhang, Qingqing Zhou, Chenchen Xue, Jinwen Ye, Shenghao Ye, Chundu Wu, Huanchao Han, Zhanxing Mao, Suming Ding, and et al. 2023. "Experimental Study of Quizalofop-p-Ethyl Herbicide Drift Damage to Corn and the Safety Amount of Drift Deposition" Agronomy 13, no. 12: 2890. https://doi.org/10.3390/agronomy13122890

APA StyleJiao, Y., Zhang, S., Zhou, Q., Xue, C., Ye, J., Ye, S., Wu, C., Han, H., Mao, Z., Ding, S., & Xue, X. (2023). Experimental Study of Quizalofop-p-Ethyl Herbicide Drift Damage to Corn and the Safety Amount of Drift Deposition. Agronomy, 13(12), 2890. https://doi.org/10.3390/agronomy13122890