Abstract

There is a growing trend toward the use of renewable sources to produce clean energy and mitigate the effects of climate change. Second-generation lignocellulose biomasses, such as agro-residues, comprise a potential energy source as a byproduct of agriculture. Ecuador has optimal climate conditions that allow for the cultivation of different types of crops. This makes agriculture a relevant economic activity in the country; however, the residues obtained from agriculture have not been investigated for the establishment of a bioenergy industry. This study evaluated the potential of three varieties of sugarcane bagasse, named PR 980, CC 85-92, and CB 40-59, for bioenergy production in the Ecuadorian Andes. The bagasse was quantified by means of weighing, and then evaluated via calorimetry and thermogravimetric analysis as well as proximal and elemental analysis. The results showed that these materials met the criteria for direct combustion, exhibiting both a low nitrogen content of 0.30 ± 0.12% and ash values of 6.20 ± 1.20%. Among the analyzed varieties, CB 40-69 stood out as the most suitable for power generation within the cogeneration system; this was attributed to its superior dry calorific value of 17.37 ± 1.45 MJ kg−1, greater presence of volatile materials, and negligible ash content. Variety CB 40-69 (157.91 t ha−1) reported the highest biomass and bagasse production (56.32 t ha−1). Analysis of the SCB structure concluded that the three varieties did not differ significantly in their contents of lignin, hemicellulose, and cellulose, which is essential to implementing an industrial process for bioethanol production.

1. Introduction

Competition between the energy and food industries for the utilization of first-generation biomass has raised significant concerns regarding food security [1]. To address this issue, various constraints have been introduced to discourage the use of first-generation feedstocks for energy production. Conversely, second-generation biomass feedstocks are characterized by their non-edible nature, encompassing waste biomass such as food leftovers, used vegetable oils, and lignocellulosic materials, which renders them suitable for energy generation. The research into the valorization of second-generation feedstocks to produce biodiesel, bioethanol, and biogas has gained substantial attention in recent years [2].

Ecuador boasts approximately 7.4 million hectares of cultivated land, and sugarcane (SC), corn (C), rice (R), and banana (B) are the most significant crops in the country in terms of area and production [3]. On the other hand, the use of agriculture residues as a bioenergy industry input is negligible. Currently, the only biomasses used as energy locally are firewood, stalks, and branches, primarily through direct combustion for heating and cooking. This practice is particularly prevalent in rural areas, constituting approximately 5.4% of the total primary energy supply (TPES) [4]. Among the crops cultivated in the Andean region, SC stands as one of the most productive. It is a plant that corresponds to the Saccharum genus belonging to the Poaceae family [5], and its bagasse residue can be used for bioenergy.

The production of SC has been frequently related to tropical zones; however, the crop is also grown in the Ecuadorian Andean zone up to 1000 m.a.s.l. Some of the most productive types of SC in this zone are named PR 980 (Puerto Rico), CC 85-92 (Cenicaña Colombia), and CB 40-69 (Campo Brazil) and have been cultivated in the northern part of the country by the Northern Sugar Mill (IANCEM). The area that these three varieties occupy fluctuates depending on the season. PR 980 has an area of 2373.6 ha, CC 85-92 an area of 304.6 ha, and CB 40-69 an area of 644.2 ha [6]. In this zone, these varieties display important traits in terms of morphology and sugar yields compared with the same varieties cultivated in other countries. They also show longer and thicker stems, which derive from obtaining greater quantities of sugarcane bagasse (SCB); this enhances the potential of biomass to produce renewable energy.

The morphological features of these varieties have attracted new interest in the characterization of SCB, as they could help explain the experimental profiles of biomass conversion to bioenergy, as well as the way in which the yield and quality of the products are related to the properties of the biomass [7]. To do this, thermogravimetry (TGA) can be performed; this method is designed to find the proximal composition of the biomass in global terms as moisture, volatile material, ash content, and fixed carbon [8]. TGA permits the estimation of the amounts of cellulose, hemicellulose, and lignin, which is necessary to carry out the thermochemical process [9]. Consequently, it is possible to assess whether the agro-residue is suitable for different types of energy transformation.

In addition, the implementation of elemental analysis on SCB allows the composition of a potential biomass fuel, such as carbon, hydrogen, sulfur, and nitrogen (C-H-S-N), to be known. SCB is a well-known source of bioenergy production in cogeneration systems; it is understood that it reduces pollution levels and contributes to energy savings. Conventional thermoelectric plants convert only 33% of energy contained in the fuel into electrical energy, while the remainder of it is wasted. Conversely, cogeneration systems convert an average of 84% of the energy contained in the fuel into electrical power and heat for other processes within the system (25–30% electrical and 59–54% thermal) [10]. The information obtained from this analysis will allow the selection of residues with the best carbon–nitrogen ratio (C/N) for the bio-digestion process to generate methane (CH4) that could be utilized for power generation or direct combustion.

Similarly, SCB can be suitable for transformation into bioethanol by means of enzymatic hydrolysis depending on structural analysis, as it is a method that allows lignocellulose to be broken down into fermentable sugars in a plant [11]. The main advantage of enzymatic processes lies in the lack of by-product formation and the reduction in energy demand in the process, as it does not require the use of high pressure or high temperatures [12].

This study aims to evaluate the characteristics of different types of SCB residues and determine whether there is potential for bioenergy in terms of optimal and suitable technology for its transformation. The results might bring about a better understanding of the value of agro-residues for farmers, investors, and decision makers, so that they can implement a bioenergy system and replicate it throughout the country depending on the availability of feedstock in each region.

2. Materials and Methods

2.1. Study Area

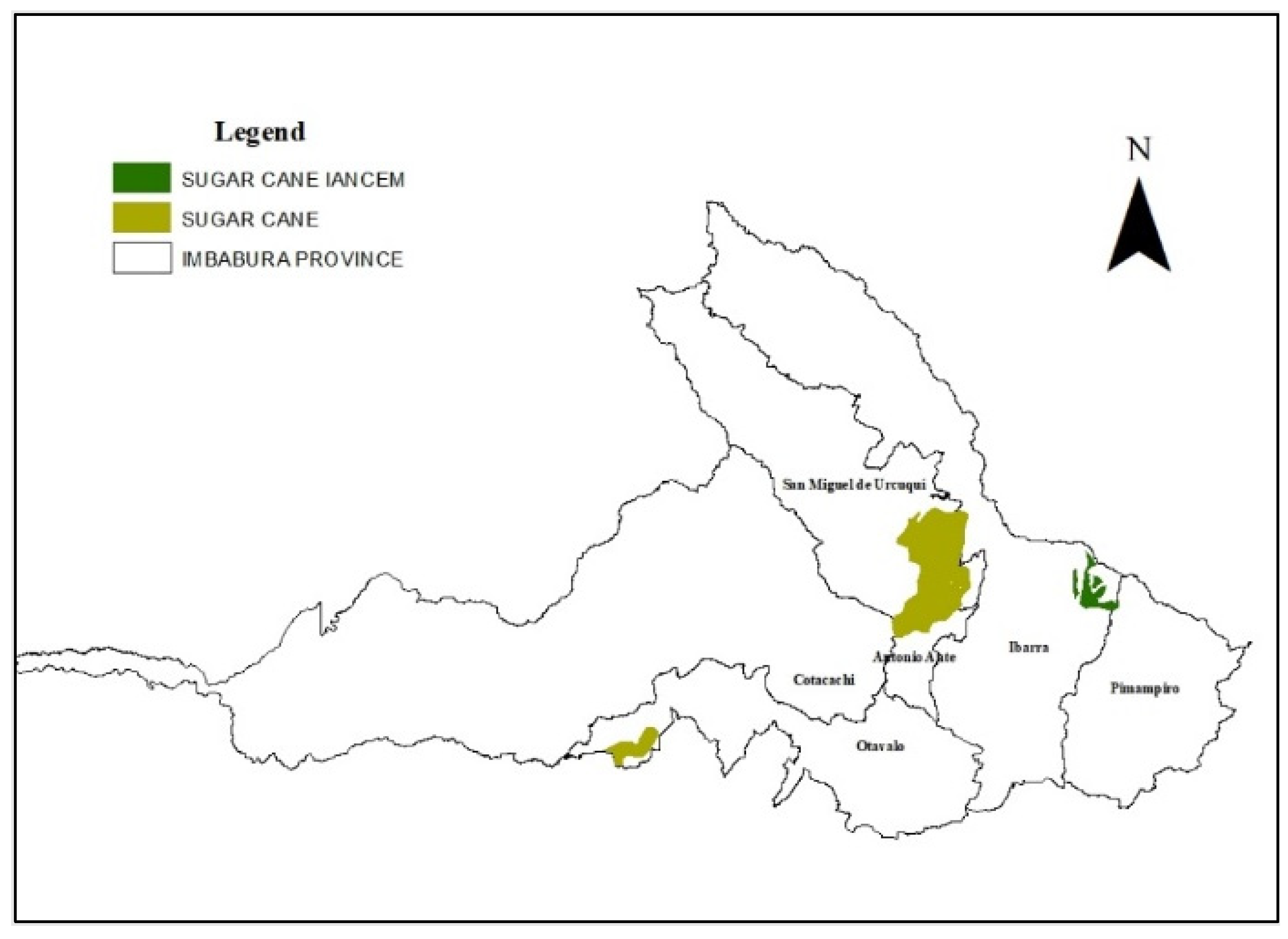

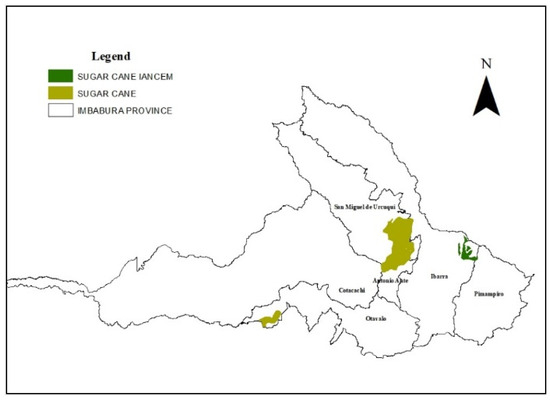

The study was conducted in the sugarcane (SC) growing areas situated at Ingenio Azucarero del Norte Compañía Mixta (IANCEM) in the Tababuela region of Imbabura Province. The experiment’s coordinates are 00°28′56″ N and 78°05′44″ W, with an elevation of 1520 m above sea level [6]. Figure 1 presents a geographical map illustrating the precise location of the study area. The cultivation field was divided into nine plots, each with an area of 25 m2. These plots were randomly delimited within the cultivation area for each SC variety, considering the crop’s inherent heterogeneity [13]. It is important to note that the samples were collected after a year and a half of growth, just before the plants were harvested, in accordance with the typical cultivation time for SC.

Figure 1.

Base map of the Northern Sugar Mill’s geopositioning.

2.2. Plant Morphology

The entire plant covering was removed from the plots, and the biomass obtained from it was measured and divided into two components: stems and leaves (without considering any below-ground biomass). Ten plants were randomly selected in each plot, and the average stem length and diameter were measured. For length, plants were measured from the base to the natural break point, while for diameter, measurements were taken at the closest internode to the root, at the intermediate internode, and at the last internode at the top of the stem. Stem production (t ha−1) was estimated via weighing the total stems in each plot. Leaf length and width (mm) were also quantified; length was measured from the base to the top of the leaf, and width was measured at the base, in the middle, and 20 cm from the tip of the leaf. Finally, the total number of leaves per sugar cane plant was counted.

2.3. Moisture Determination and Sample Preparation

The SCB was obtained through the extrusion of harvested SC biomass using a hydraulic press. Sampling followed the procedures described by Muñoz et al. (2016) [14]. Three 100 g samples were taken and analyzed for each type of SCB at the Environmental Research Laboratory (LABINAM) of Universidad Técnica del Norte (UTN). The samples were dried at 105 °C in a Memmert oven until the biomass content reached a constant weight. Subsequently, the dry material was ground to a particle size of at least 0.5 mm, using a grinder.

2.4. Higher Heating Value

The higher heating value (HHV) was estimated for the SCB samples using the procedure described in the ASTM D-5865 standard. In this method, 0.5 g of dry plant biomass was weighed using a digital balance (Sartorius). Each sample was then combusted with an excess of oxygen in a LECO AC 500 calorimetric pump for 8 min to determine the calorific value in MJ kg−1.

2.5. Thermogravimetric and Proximal Analysis

The characterization of sugarcane bagasse (SCB) was conducted using the TGA method. This methodology involved observing the loss of mass as the temperature increased over a certain duration [15]. Three samples, each weighing 0.15 g, of various SCB varieties were subjected to analysis using a TGA Analyzer (Mettler Toledo). During the analysis, SCB underwent combustion under various temperature ranges. Hemicellulose decomposition commenced between 200 and 400 °C, followed by cellulose decomposition within the range from 300 to 410 °C. Finally, lignin decomposition occurred between 400 and 800 °C [7,8,16,17]. Two hours later, the equipment provided the biomass composition, including humidity, volatile material, and fixed carbon. These data were recorded and analyzed using the Origin lab 2015 program, which displayed combustion curves.

2.6. Elemental Analysis

The contents of carbon (C), hydrogen (H), sulfur (S), and nitrogen (N) in the biomass of the three SCB varieties were analyzed according to the ASTM D8056-18 standard at the Chemistry Laboratory of the Universidad Central del Ecuador (UCE). The estimation of nitrogen was carried out through digestion using the Kjeldahl methodology, while sulfur estimation was accomplished through oxidation and the turbidimeter method. Carbon and hydrogen were determined through biomass combustion.

2.7. Statistical Analysis

The data were analyzed using an analysis of variance (ANOVA) adjusted for a completely randomized block design (CRBD) with the statistical software Infostat. Before the analysis, the variables were assessed for normality and homoscedasticity using the Shapiro–Wilk test and Levene’s test, respectively. Any data that did not meet these assumptions were transformed using natural logarithm (ln) transformation. Subsequently, Tukey’s test (α = 0.05) was conducted on variables that showed statistical significance in the ANOVA to group them into homogeneous categories. If the variables still did not meet the assumptions after transformation, we employed the Kruskal–Wallis test and conducted a Dunn’s test (α = 0.05).

3. Results and Discussion

3.1. Morphology

The morphological characteristics showed statistically significant differences among the evaluated varieties. CB 40-69 emerged as the tallest variety, boasting an average height of 2.75 m and the broadest stem diameter in all sections (base, middle, and top) without exception (measuring 38.81 mm, 37.05 mm, and 35.04 mm, respectively). This variety also exhibited the longest leaves, irrespective of their location on the stem (1.32 m at the base and 1.30 m at the middle/top). Additionally, CB 40-69 displayed an average leaf count of 36.6 per plant, which was statistically higher than the leaf production of other varieties. However, it should be noted that CB 40-69 did not exhibit the widest leaves when the leaf width was analyzed. In this regard, PR 980 reported the broadest leaves in both the middle and top sections of the plant, with measurements of 7.04 mm and 3.45 mm at the lower part of the plant, 6.94 mm and 3.35 mm in the middle part, and 7.00 mm and 1.63 mm at the highest part (Table 1).

Table 1.

Morphological characteristics of the evaluated sugar cane varieties (means ± standard deviation).

Del Toro et al. (2011) [18] conducted a morphological study on the CB 40-69 variety cultivated in Argentina. Their research revealed that the plant had an average leaf length of 129 cm and a width of 5.5 cm, resulting in a total of nine green leaves per stem. Additionally, the stem’s length reached 2.25 m on average, with an average diameter of 34 mm. These values were found to be lower than those obtained in our study. This suggests that the conditions in the region and the management practices employed could influence the plant’s development. Considering that this variety has traditionally been cultivated in the region, it is possible to assume that it has adapted over time, potentially resulting in higher biomass production compared to other locations.

On the other hand, in their analysis of CC 85-92 in a study conducted in Colombia, Ramírez et al. (2014) [19] reported a stem length of 2.21 m and a diameter of 28.6 mm. These figures were also lower than those observed in our experiment. These results indicate that the variety is well-suited to the conditions in Ambuquí. In the case of both varieties, there is still room for improvement in crop management practices to bridge the gap between theoretical and actual yields. However, for the purposes of this study, the higher biomass production suggests that crop residue could have significant potential for energy production.

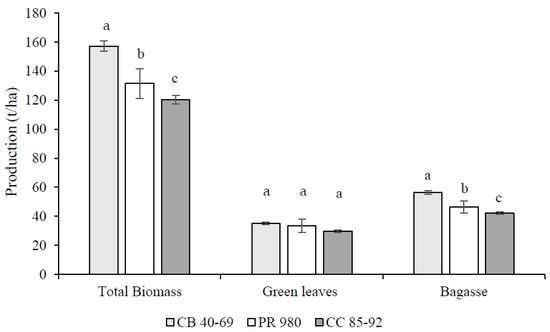

3.2. Residue Production Yields

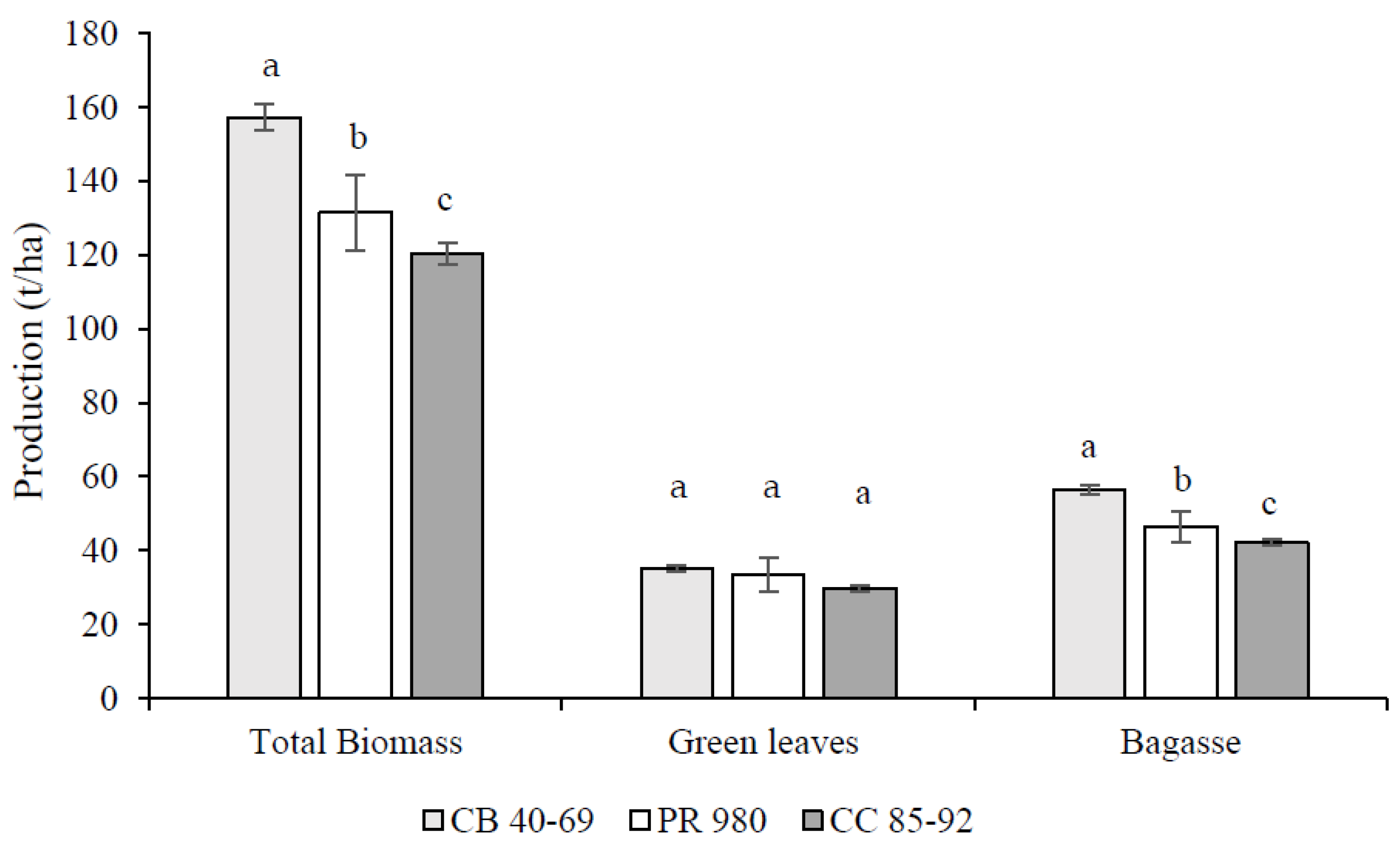

The CB 40-69 type yielded an average of 157.91 t ha−1, which was statistically higher than the yields for PR 980 (131.46 t ha−1) and CC 85-92 (120.36 t ha−1). Similarly, CB 40-69 had the highest bagasse production at 56.32 t ha−1, while PR 980 and CC 85-92 produced 46.47 t ha−1 and 42.16 t ha−1, respectively. All three varieties exhibited a similar leaf production with CB 40-69 at 35.24 t ha−1, PR 980 at 33.30 t ha−1, and CC 85-92 at 29.70 t ha−1 (Figure 2).

Figure 2.

The biomass, green leaf, and bagasse production of the CB 40-69, PR 980, and CC 85-92 varieties, presented as means with standard deviations. Significant differences between these varieties are indicated by letters (a, b, c), as determined by Tukey’s test at p < 0.05, with a sample size of n = 9.

In a study by Dariva et al. (1986) [20], CB 40-69 was reported to have an average yield of 108 t ha−1, while Pimentel et al. (1959) [21] obtained 109 t ha−1. Meanwhile, Secalla and Olivera (1967) [22] achieved a yield of 132 t ha−1. None of these studies were able to attain the yield values obtained in this research. Furthermore, their results solely focused on SC production and not on SCB as an agro-residue. This outcome contributes to a better understanding of crop management by highlighting the value of the byproducts. As indicated in the analysis of plant morphology, a higher biomass production suggests a greater potential for the bioenergy industry, thanks to the available residues.

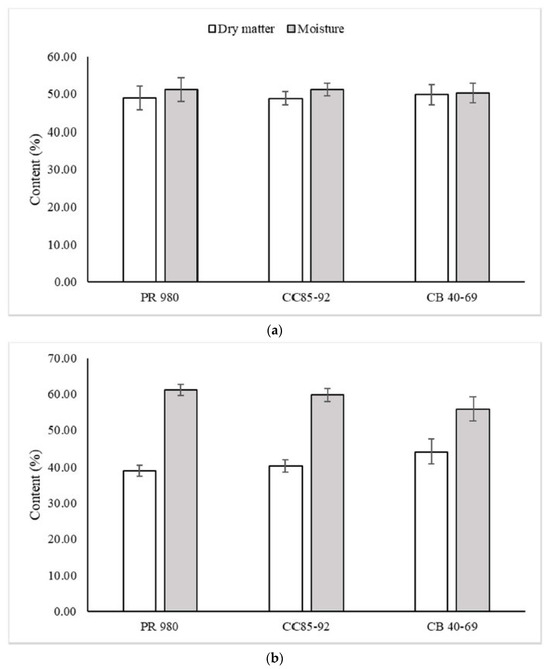

3.3. Moisture Content

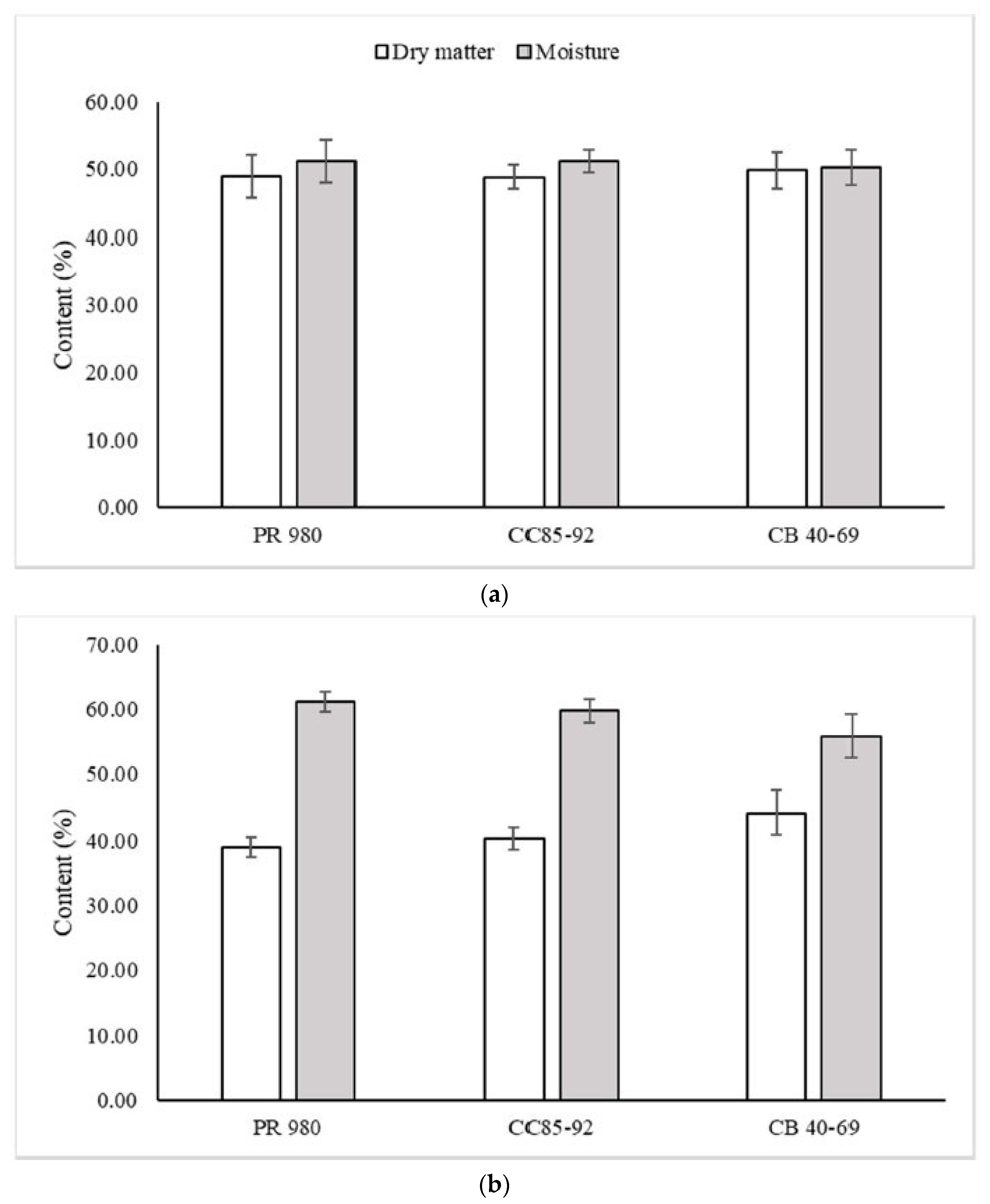

Among the varieties, PR 980 exhibited the highest moisture content in both the sugarcane bagasse (SCB) and leaves, with values of 51.37% and 61.07%, respectively. In contrast, the CB 40-69 variety had a lower moisture content in both the SCB and leaves, measuring 50.24% and 55.83%, respectively (see Figure 3). Nevertheless, no significant differences were observed between the varieties.

Figure 3.

(a) The dry matter and moisture content of bagasse. (b) The dry matter and moisture content of the leaves of the CB 40-69, PR 980, and CC 85-92 varieties (means ± standard deviation) (n = 9).

The moisture content in SCB across all three varieties was comparable to that in the findings reported by Kumar et al. (2019) [23], who stated that SCB leaving the final mill of the crushing plant typically contains around 50% moisture. Similarly, Onesippe et al. (2020) [24] mentioned that SCB had a relative humidity of 56%, which is higher than the results obtained in this study. Although this research did not reveal significant differences in moisture content, these results align with the yields produced by the three varieties. Therefore, agro-residues with lower humidity levels are more suitable for bioenergy production through direct combustion, as they yield more dry matter.

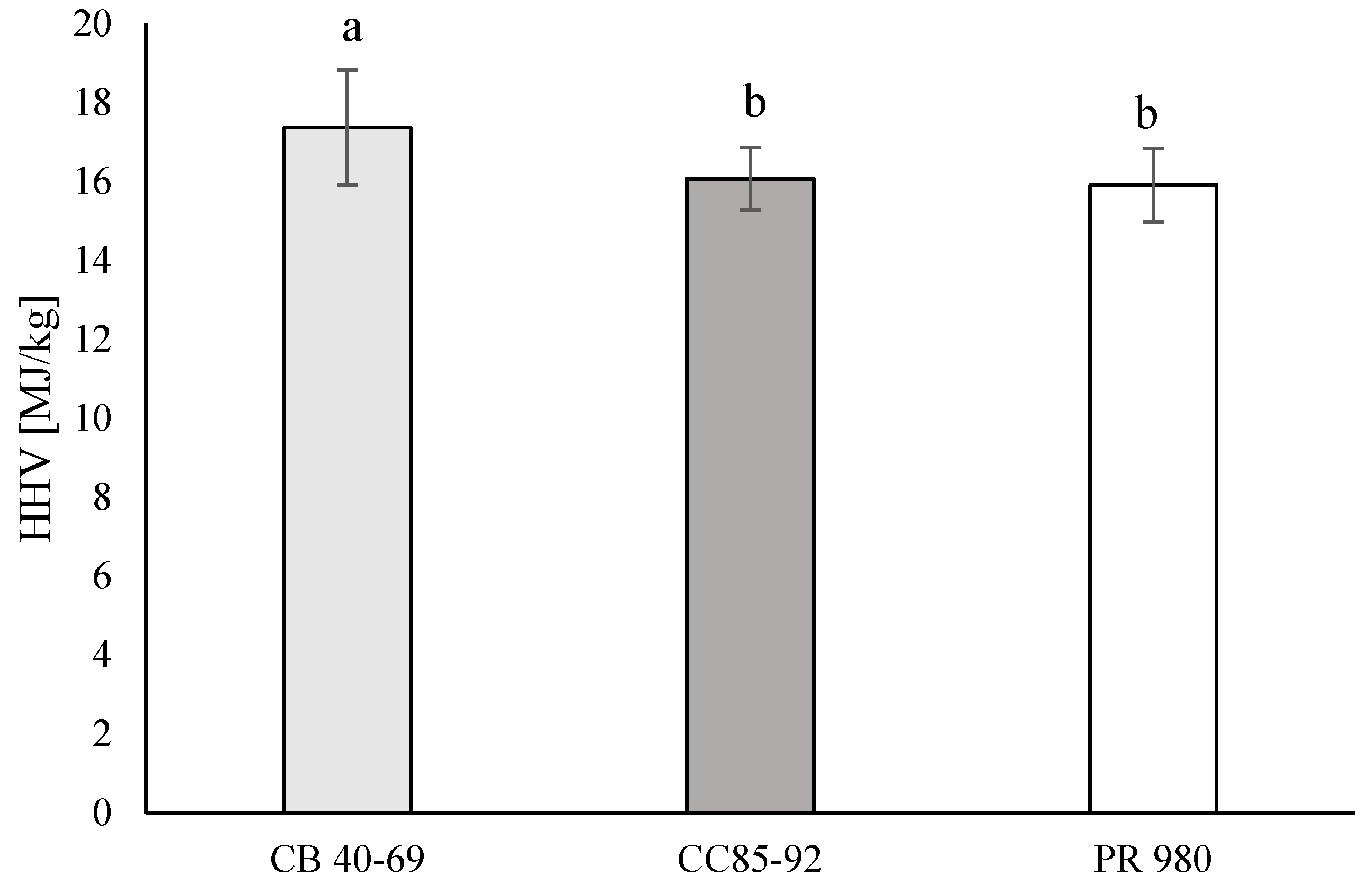

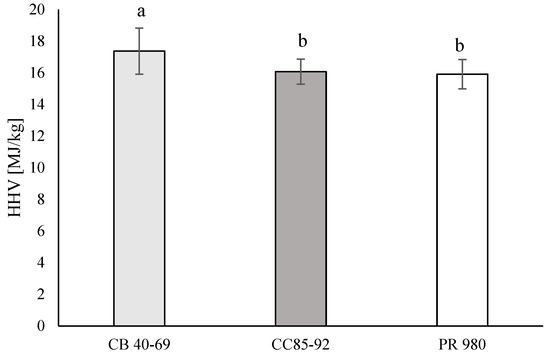

3.4. Higher Heat Value

The higher heat value (HHV) of CB 40-69 (17.37 MJ kg−1) was the highest compared to the other two varieties, making it more suitable for combustion. Meanwhile, CC 85-92 (16.07 MJ kg−1) and PR 980 (15.91 MJ kg−1) exhibited similar values (see Figure 4). The HHV of the CB 40-69 variety in this study closely matched the value reported by Chen et al. (2020) [25]; they calculated an HHV of 17.79 MJ kg−1. In contrast, Carriel et al. (2020) [26] obtained a higher HHV of 18.51 MJ kg−1, demonstrating that the two remaining varieties have values lower than those reported by other authors. However, Manyuchi et al. (2019) [27], using the ASTM D-2015-66 standard, determined an HHV of 14.8 ± 0.4 MJ kg−1, which is lower than the values observed for the PR 980 and CC 85-92 varieties. Unfortunately, the author did not specify which sugarcane variety was analyzed.

Figure 4.

The calorific value of the CB 40-69, PR 980, and CC 85-92 varieties (means ± standard deviation). Letters indicate significant differences using Tukey’s test at p < 0.05 (n = 9).

3.5. Elemental Composition of Sugarcane Bagasse

The results of the elemental analysis showed that the content of N and H and the C:N ratio were statistically similar for the three varieties. The C content was lower in CB 40-69 (42.17%) than in the other two varieties. Meanwhile, the S concentration was the highest in CB 40-69 (0.43%), as shown in Table 2. It is noteworthy that the content of N and S is less than 1%, which complies with the UNE EN ISO 17225-1 standard, allowing its use as a solid biofuel in Europe.

Table 2.

The elemental analysis of bagasse. Letters indicate significant differences using Tukey’s test at p < 0.05 for ANOVA.

It is important to emphasize that the CC 85-92 variety has a significant advantage in the burning of SCB, as it contains lower amounts of N and S, resulting in reduced emissions of NO and SO when carbon mixed with SCB is burned [16], in contrast to CB 40-69, which has higher concentrations of these elements. In the case of bio-digestion, the C:N ratio is critical for a more efficient process. However, these ratios are excessively high and are not suitable for the use of microbes as digesters.

3.6. Proximal Composition of Bagasse

The PR 980, CC 85-92, and CB 40-69 varieties exhibited identical levels of volatiles, registering at 78.62%, 80.35%, and 82.62%, respectively. Furthermore, all three varieties displayed similar fixed carbon percentages, with PR 980 at 14.57%, CC 85-92 at 14.82%, and CB 40-69 at 12.76%. Notably, PR 980 exhibited the significantly higher ash content of 7.74%, while CC 85-92 and CB 40-69 showed no significant difference, with ash contents of 5.44% and 5.43%, respectively (refer to Table 3).

Table 3.

The proximal composition of the SCB varieties evaluated (means ± standard deviation). Letters indicate significant differences using Tukey’s test at p < 0.05 for ANOVA.

The proximal composition of sugarcane bagasse (SCB) from each of the varieties is like that reported by López et al. (2013) [28]. Their findings indicated a moisture content of 3.01%, a volatile matter content of 72.66%, fixed carbon at 12.89%, and an ash content of 8.98%. Likewise, López et al. (2013) [28] determined a moisture content of 4.42%, a total volatile material content of 81.66%, fixed carbon at 8.82%, and an ash content of 5.10%. Furthermore, Moreira et al. (2020) [29] also conducted a similar analysis, finding a moisture content of 11.40%, volatile materials at 84.10% ± 1.20%, a fixed carbon content of 13.95%, and an ash content totaling 1.95%; these percentages align with the results observed in this study. However, none of the authors provided information regarding the specific variety of sugarcane used in their respective studies.

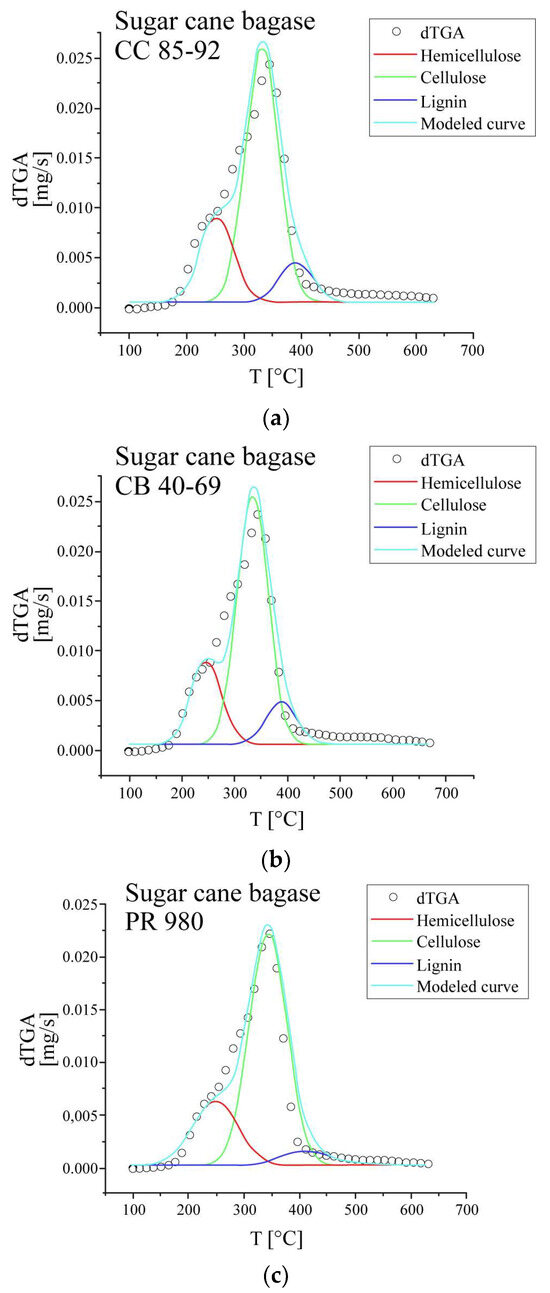

3.7. Structural Composition of Sugarcane Bagasse

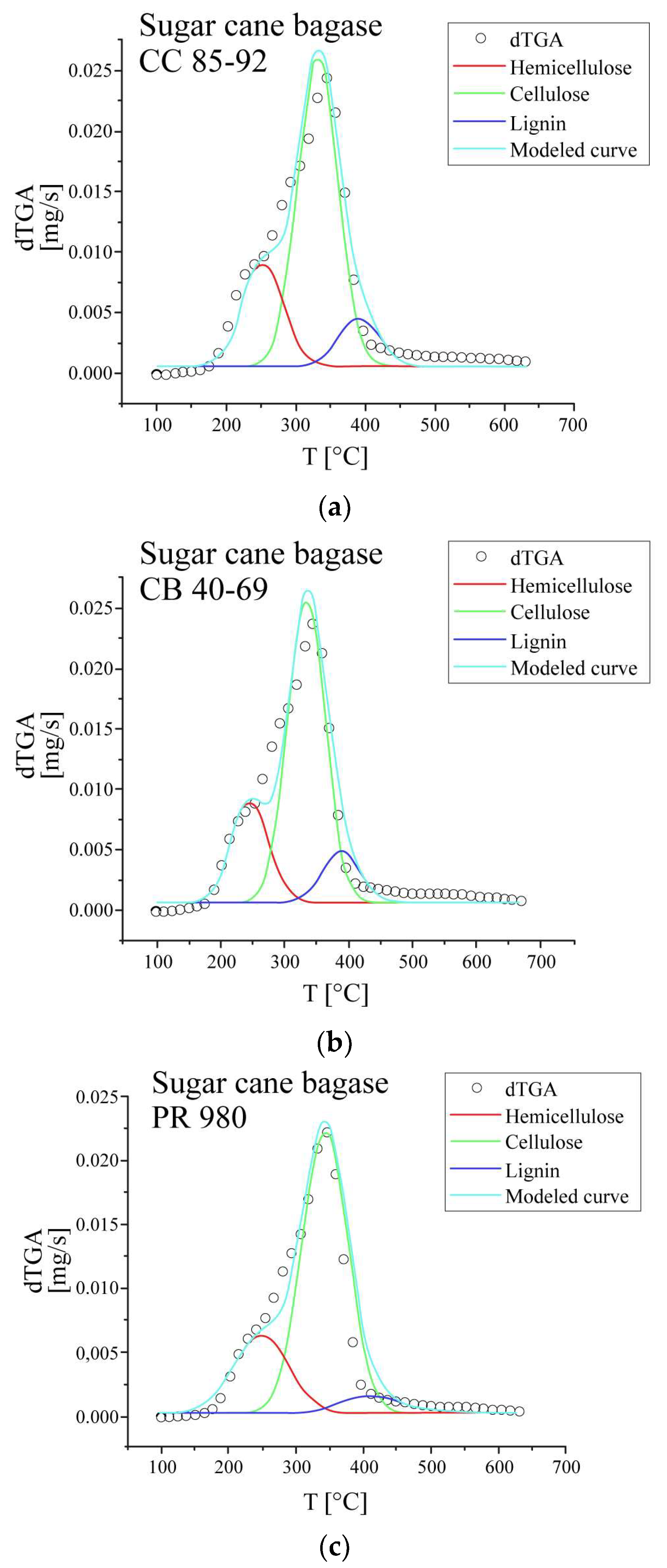

The conversion rate curves as a function of the temperature (in °C) and TGA derivative (in mg s−1) for the different sugarcane varieties are displayed in Figure 5. The curve resulting from the fixed kinetic parameters using the autonomous parallel reaction scheme is illustrated as a continuous line, while the experimental data points are represented by symbols (o) (Figure 5).

Figure 5.

The conversion rate curve as a function of the variety vs. the temperature: the SCB in (a) CC 85-92, (b) CB 40-69, (c) PR 980.

Within the TGA derivative curve, certain peaks or deformities indicate the points at which the lignocellulose components undergo combustion. Through the employment of the Originlab 2015 program for deconvolution, colored curves are generated. In this context, the red line represents hemicellulose, the green line represents cellulose, and the blue line represents lignin.

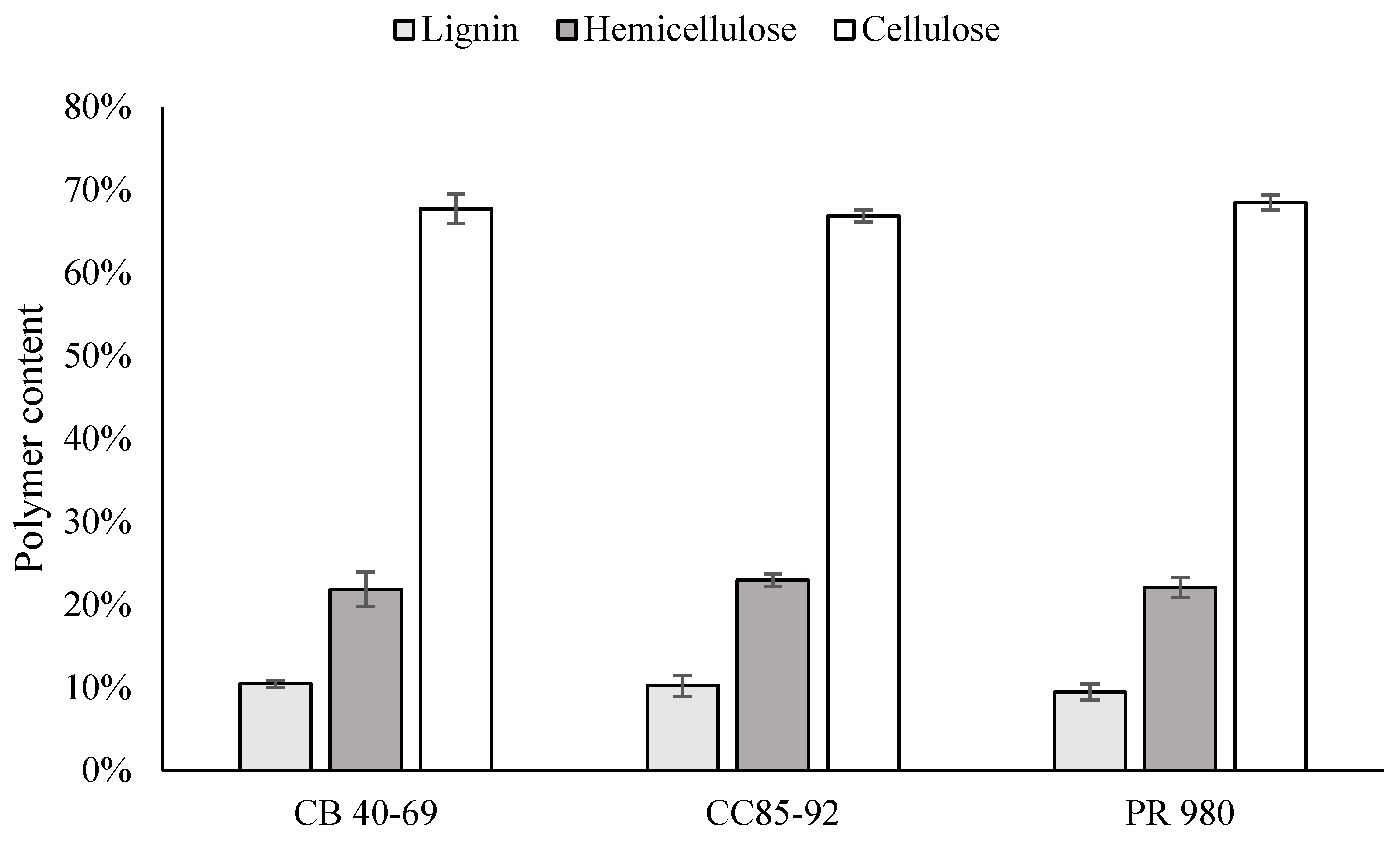

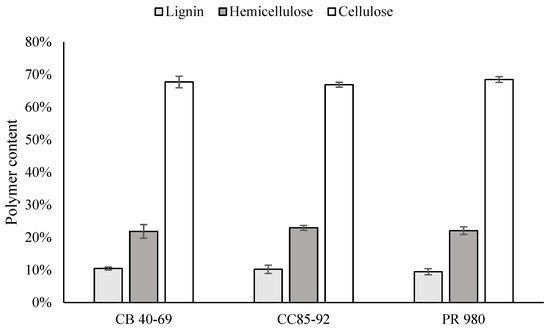

The analysis of the SCB structure revealed that three varieties did not exhibit significant differences in lignin, hemicellulose, or cellulose content. CB 40-69 displayed a hemicellulose content of 21.91%, which was lower than the 22.08% observed in CC 85-92. PR 980 had the highest cellulose content, at 68.04%, among all the varieties studied. Meanwhile, CB 40-69 exhibited the highest lignin content, at 10.67% (see Figure 6).

Figure 6.

The structural parameters of bagasse from the CB 40-69, PR 980, and CC 85-92 varieties, presented as means with standard deviations (n = 9).

The results concerning hemicellulose fall within the range observed by other authors. However, there are notable discrepancies in the cases of cellulose and lignin compared to the findings of Espírito Santo (2019) [30], who determined cellulose to be at 40.1% and lignin at 23.6% using this technique. Similarly, Liu et al. (2014) [31] reported hemicellulose at 29.47%, cellulose at 43.76%, and lignin at 18.22%. Among these results, the CC 40-69 variety comes closest, with lignin at 10.67% and cellulose at 67.42%. These differences could potentially be attributed to variations in cultivation methods, soil types, and meteorological factors, as previously mentioned.

Lastly, it is worth noting that a higher quantity of cellulose and hemicellulose is advantageous to producing bioethanol through enzymatic hydrolysis, while a lower lignin content enhances production yields.

4. Conclusions

CB 40-69 is the variety with the highest cane production, averaging 157.91 t ha−1. Consequently, it also yields a higher quantity of wet bagasse, totaling 55.27 t ha−1. This variety is considered to offer the best crop yield.

The chemical composition analysis of SCB reveals that CC 85-92 has lower quantities of nitrogen (0.21%) and sulfur (0.17%) compared to other varieties. This indicates that when bagasse is burned through direct combustion, it produces fewer emissions of NOx and SOx. These values fall below the maximum limits allowed by UNE EN ISO 17225-1, which outlines the specifications and classes of solid biofuels.

Analyzing the chemical composition of the CB 40-69 variety, we can see that it shows the lowest ash content at 5.43% and the highest volatile material content at 82.68%. Consequently, it boasts a higher PCSS of 17.37 MJ kg−1. This demonstrates its efficiency in producing thermal energy when SCB is subjected to direct combustion processes, resulting in a total of 6.50 MJ kg−1 wet bagasse in a cogeneration system.

The analysis of lignocellulose components reveals that PR 980 stands out among the three varieties, with a significant cellulose content of 68.04%, hemicellulose at 21.96%, and lignin at 9.99%. This positions PR 980 as the variety with the highest bioethanol production, yielding a total of 335.74 L t−1 SCB-wet through enzymatic hydrolysis.

Author Contributions

Project administration, supervision, methodology validation, analysis, and writing: J.G.-M.; fieldwork, methodology, and formal analysis: O.Q.; statistical analysis, manuscript writing, and editing: G.C.-Y.; scientific review and revision: L.Á. and B.V.-M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data can be made available upon request.

Acknowledgments

The authors would like to express their sincere gratitude to the Universidad Técnica del Norte for the funding and its facilities. We would also like to thank the Laboratory of Chemical Analysis at the Central University of Ecuador and its technical team for their contributions to the TGA and elemental analysis. Their expertise and insights were invaluable in shaping our research and helping us overcome challenges.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Muscat, A.; De Olde, E.M.; De Boer, I.J.M.; Ripoll-Bosch, R. The battle for biomass: A systematic review of food-feed-fuel competition. Glob. Food Secur. 2020, 25, 100330. [Google Scholar] [CrossRef]

- Zadeh, Z.; Abdulkhani, A.; Aboelazayem, O.; Saha, B. Recent Insights into Lignocellulosic Biomass Pyrolysis: A Critical Review on Pretreatment, Characterization, and Products Upgrading. Processes 2020, 8, 799. [Google Scholar] [CrossRef]

- García, J.; Machimura, T.; Matsui, T. Optimizing Plant Allocation for Bioethanol Production from Agro-residues Considering CO2 Emission and Energy Demand–Supply Balance: A Case Study in Ecuador. Waste Biomass Valorization 2012, 3, 435–442. [Google Scholar] [CrossRef]

- Combustible Renewables and Waste (% of Total Energy). Available online: https://data.worldbank.org/indicator/EG.USE.CRNW.ZS (accessed on 4 July 2023).

- Cardona, C.; Danches, O.; Montoya, I.; Quintero, J. Producción de etanol carburante. Materias primas convencionales Ingeniería de Recursos Naturales y del Ambiente 2005, 2, 47–55. [Google Scholar]

- Auditoría Ambiental Inicial (Estudio de Impacto Ambiental Expost) y Plan de Manejo Ambiental Del “Ingenio Azucarero Del Norte Compañía de Economía Mixta (IANCEM)”. Available online: https://vdocuments.net/auditora-ambiental-inicial-ingenio-de-la-importancia-de-impactos-ambientales.html (accessed on 6 May 2016).

- Charis, G.; Danha, G.; Muzenda, E. Characterizations of Biomasses for Subsequent Thermochemical Conversion: A Comparative Study of Pine Sawdust and Acacia Tortilis. Processes 2020, 8, 546. [Google Scholar] [CrossRef]

- Montoya, J.; Chejne, F.; Castillo, E.; Acero, J.; Gómez, C.; Sarmiento, J.; Valdés, C.; Garzón, L.; Osorio, J.; Tirado, D.; et al. Pirólisis Rápido de Biomasa, 1st ed.; ECOPETROL: Medellín, Colombia, 2014; pp. 45–78. [Google Scholar]

- Saldarriaga, J.; Aguado, R.; Pablos, A.; Amutio, M.; Olazar, M.; Bilbao, J. Fast characterization of biomass fuels by thermogravimetric analysis (TGA). Fuel 2015, 140, 744–751. [Google Scholar] [CrossRef]

- Becerra, A.; Buitrago, A.; Pinto, P. Sostenibilidad del aprovechamiento del bagazo de caña de azúcar en el Valle del Cauca. Ing. Solidar. 2016, 12, 133–149. [Google Scholar] [CrossRef]

- Yang, B.; Dai, Z.; Ding, S.; Wyman, C. Enzymatic hydrolysis of cellulosic biomass. Biofuels 2014, 2, 421–449. [Google Scholar] [CrossRef]

- Castaño, P.; Mejía, C. Producción de etanol a partir de almidón de yuca utilizando la estrategia de proceso sacarificación-fermentación simultáneas (ssf). VITAE 2008, 15, 251–258. [Google Scholar]

- Urgiles, N.; Cofre, D.; Loján, P.; Maita, J.; Alvarez, P.; Báez, S.; Tamargo, E.; Eguiguren, P.; Ojeda, L.; Aguirre, N. Composición florística, estructura y estimación de la biomasa vegetal de los páramos de Cajanuma, parque Nacional Podocarpus. Bosques Latid. Cero 2018, 8, 44–53. [Google Scholar]

- Muñoz, F.; Cancino, J.; Rodríguez, R.; Olave, R. Evaluación de crecimiento, rendimiento y calorimetría de la biomasa de Miscanthus x giganteus (Poaceae) establecimiento en el centro-sur de Chile. FCA UNCUYO 2016, 50, 47–60. [Google Scholar]

- Fonseca, S.; Rodríguez, H.; Camargo, G. Caracterización de residuos de maíz del municipio de Ventaquemada. Av. Cienc. Ing. 2017, 8, 29–36. [Google Scholar]

- Rueda, Y.; Tannous, K. Análisis cinético de la descomposición térmica de biomasas aplicando un esquema de reacciones paralelas independientes. UIS Ing. 2017, 16, 119–128. [Google Scholar] [CrossRef]

- Manals, E.; Penedo, M.; Salas, D. Caracterización del bagazo de caña como biomasa vegetal. RTQ 2015, 35, 244–255. [Google Scholar]

- Del Toro, F. Characterization of sugarcane varieties in the province of Misiones. Argent. Feijóo 2011, 57–60. [Google Scholar]

- Ramírez, J.; Insuasty, O.; Murcia, M. Varieties of sugarcane used in the sugarcane agroindustry in Colombia 2014. Corpoica 2014, 59–61. [Google Scholar]

- Dariva, T.; Da Silva, M.; Marchezan, E. Competição de cultivares de cana-de-açücar em Santa Maria, RS. Pesq. Agropec. Bras. 1986, 21, 515–522. [Google Scholar]

- Pimentel, F.; Pompilio, C. Novas Variedades de Cana-de-Açúcar. An. Esc. Super. Agric. Luiz Queiroz 1959, 16, 200–210. [Google Scholar]

- Secalla, A.; Olivera, H. Variedades de cana-de-açúcar VII—Série de ensaios realizado no período de 1959 a 1962. Bragantia 1967, 26, 198–212. [Google Scholar] [CrossRef]

- Kumar, O. Exergy analysis of a grid-connected bagasse-based cogeneration plant of sugar factory and exhaust heat utilization for running a cold storage. Renew. Energy 2019, 143, 149–163. [Google Scholar]

- Onésippe, C.; Bilba, K.; Zaknoune, A.; Arsène, M. Auto-coherent homogenization applied to the assessment of thermal conductivity: Case of SCB bagasse fibers and moisture content effect. Build. Eng. 2020, 33, 101537. [Google Scholar] [CrossRef]

- Chen, C.; Huang, Y.; Yang, S.; Qin, S.; Chen, F. Effect of oxygen enriched atmospheres on combustion of bagasse, coal and theirs blends by thermogravimetric análisis. Environ. Chem. Eng. 2020, 8, 104398. [Google Scholar] [CrossRef]

- Carriel, C.; Moreirab, R.; Cruz, R.; Richtera, D.; Funkea, A.; Raffelta, K.; Grunwaldta, J.; Dahmen, N. From agriculture residue to upgraded product: The thermochemical conversion of sugarcane bagasse for fuel and chemical products. Fuel Process. Technol. 2020, 197, 106199. [Google Scholar]

- Manyuchi, M.; Mbohwa, C.; Muzenda, E. Evaluating the Usability of Bio Coal from SCB Bagasse as a Solid Fuel. Procedia Manuf. 2019, 33, 516–521. [Google Scholar] [CrossRef]

- López, A.; Neri, F.; Sandoval, R.; Marques da Silva, M.; Arias del Campo, E.; Salinas, J.; Escobedo, M.; Collins-Martínez, V. Low temperature SCB bagasse pyrolysis for the production of high purity hydrogen through steam reforming and CO2 capture. Hydrog. Energy 2013, 28, 12580–12588. [Google Scholar] [CrossRef]

- Moreira, B.; Viana, R.; Magalhães, A.; Caraschi, J.; Zied, D.; Dias, E.; Rinker, D. Production of Pleurotus ostreatus var. florida on briquettes and recycling its spent substrate as briquettes for fuel grade biosolids. Clean. Prod. 2020, 274, 123919. [Google Scholar] [CrossRef]

- Espírito Santo, M.; Brito, E.; Gontijo, F.; de Azevedo, E.; Cunha, G.P.; Novotny, E.; Oliveira, V.; Kumar, A.; Silveira, M.; Polikarpov, I. Multifaceted characterization of sugarcane bagasse under different steam explosion severity conditions leading to distinct enzymatic hydrolysis yields. Ind. Crops Prod. 2019, 139, 111542. [Google Scholar]

- Liu, Z.; Quek, A.; Balasubramanian, R. Preparation and characterization of fuel pellets from woody biomass, agro-residues and their corresponding hydrochars. Appl. Energy 2014, 113, 1315–1322. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).