Design and Testing of a Wheeled Crop-Growth-Monitoring Robot Chassis

Abstract

:1. Introduction

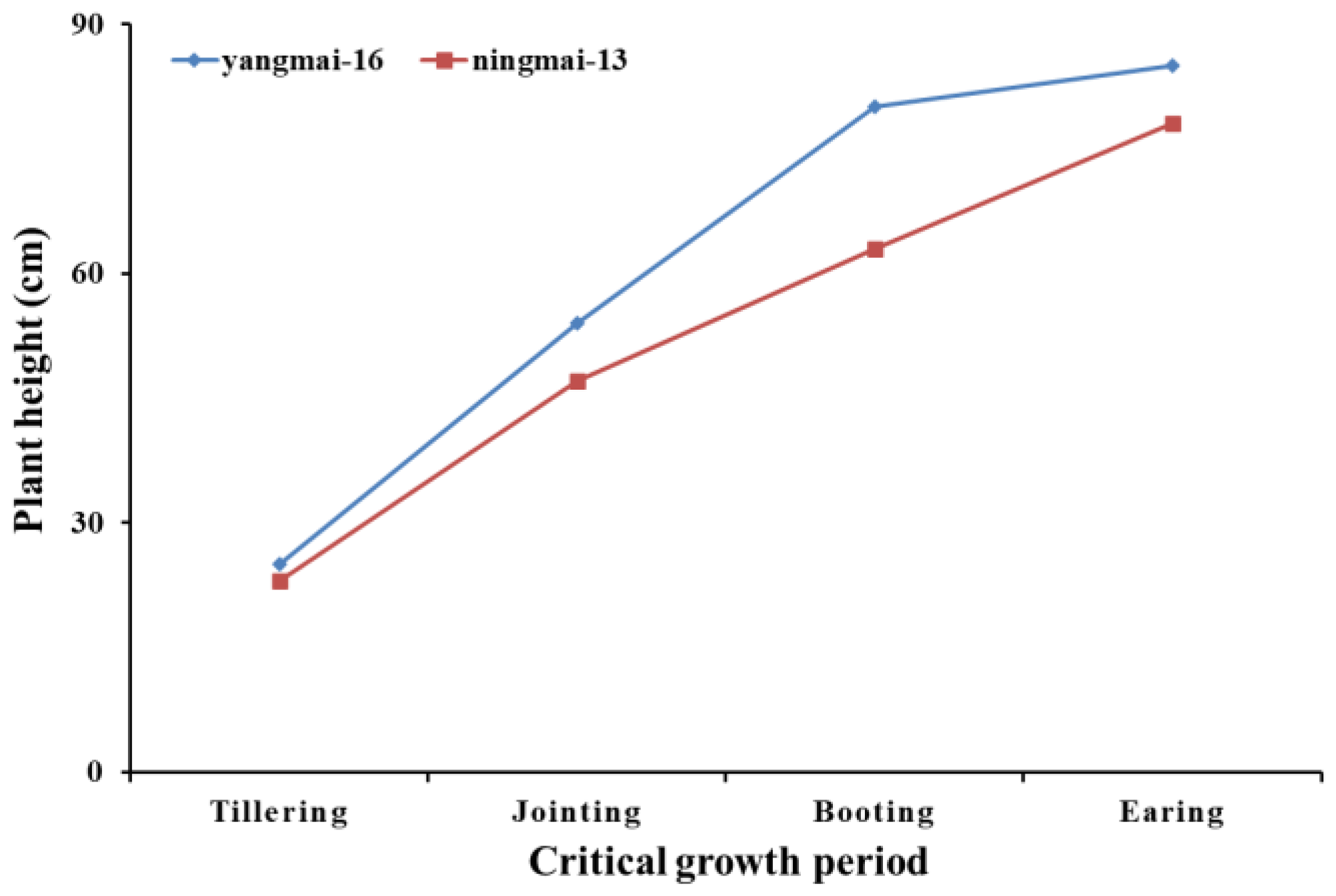

2. Materials and Methods

2.1. Overall Design of the Wheeled Robot

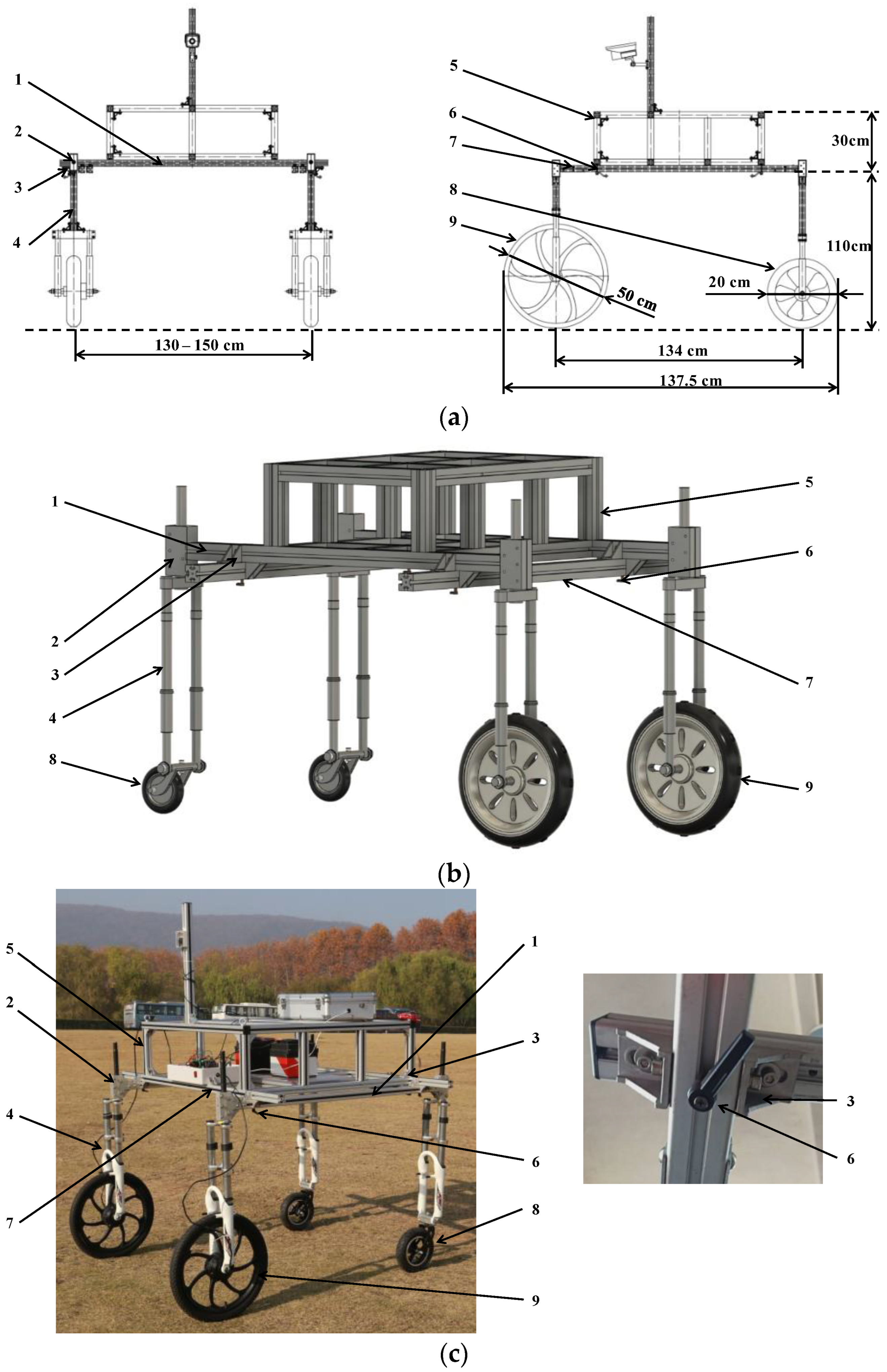

2.2. Mechanical Mechanism Design and Dynamic Simulation of Wheeled Robot Chassis

2.2.1. Mechanical Mechanism Design of Wheeled Robot Chassis

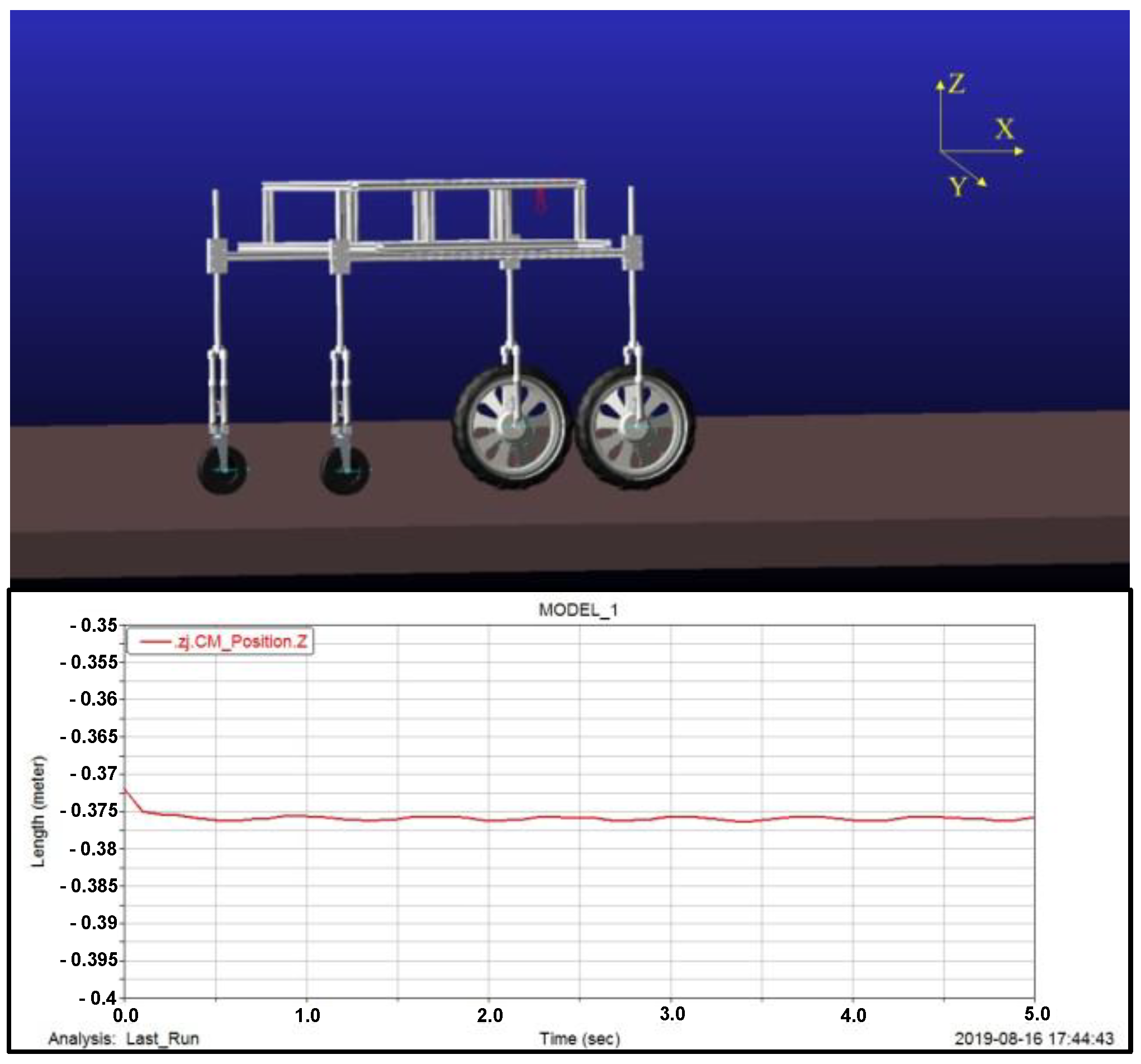

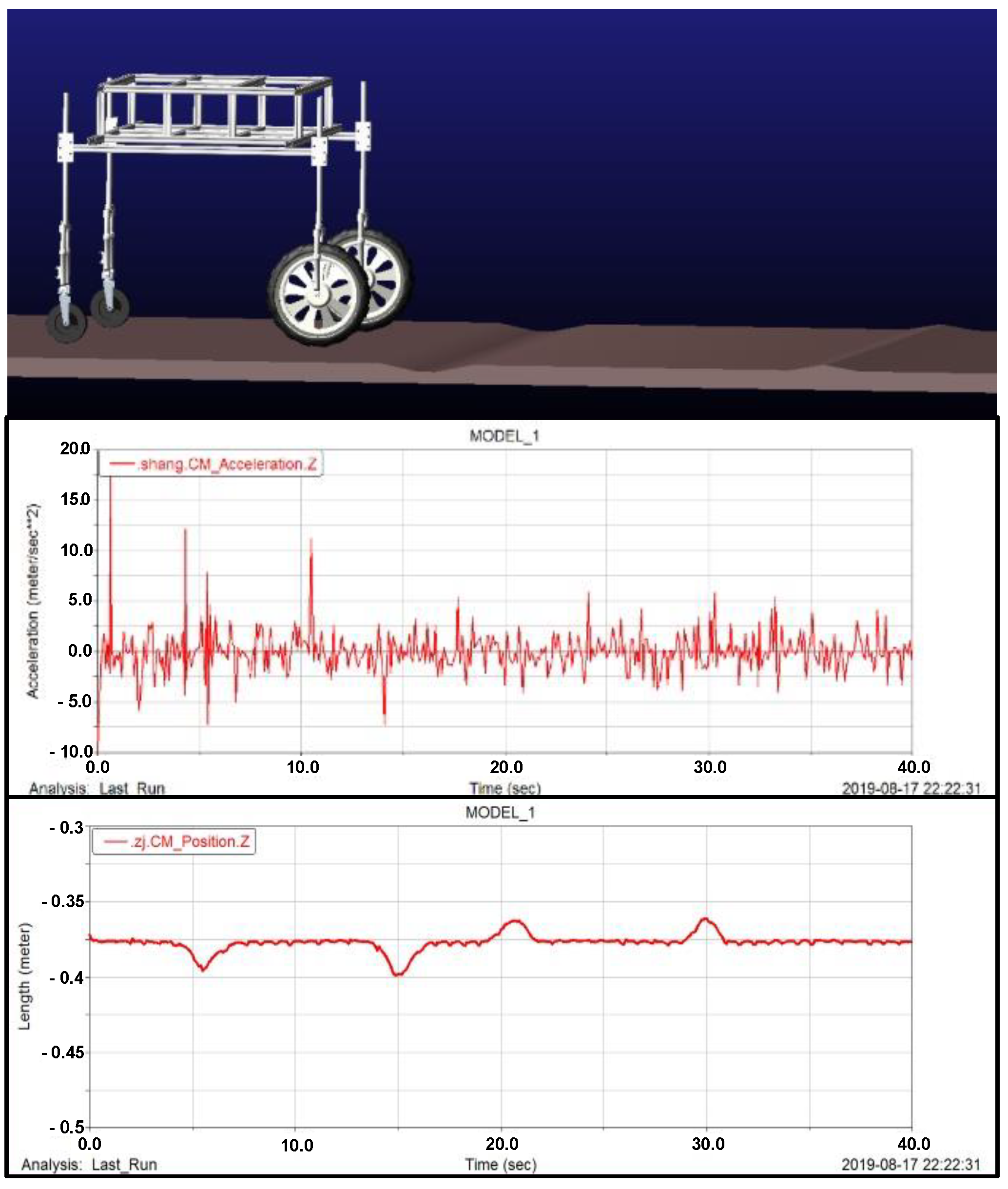

2.2.2. Dynamic Simulation in Adams

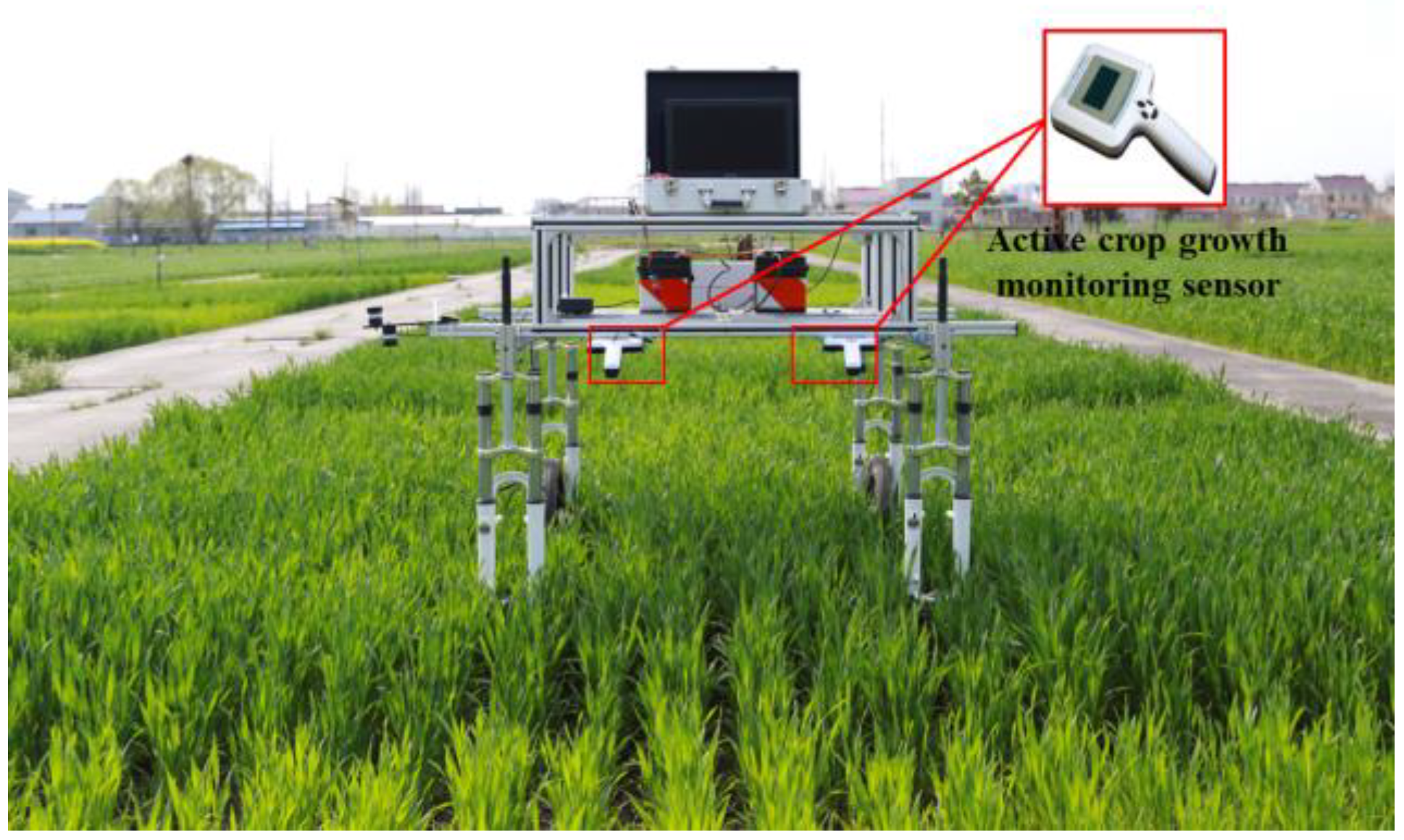

2.3. Sensing Unit

2.4. Control System

3. Test and Results

3.1. Test Design

3.2. Test Devices

3.2.1. Wheeled Crop-Growth-Monitoring Robot Chassis

3.2.2. ASD FieldSpec HandHeld 2 Handheld Field Spectrometer

3.2.3. LAI-2200C Vegetation Canopy Analyzer

3.3. Test Method

3.4. Data Analysis

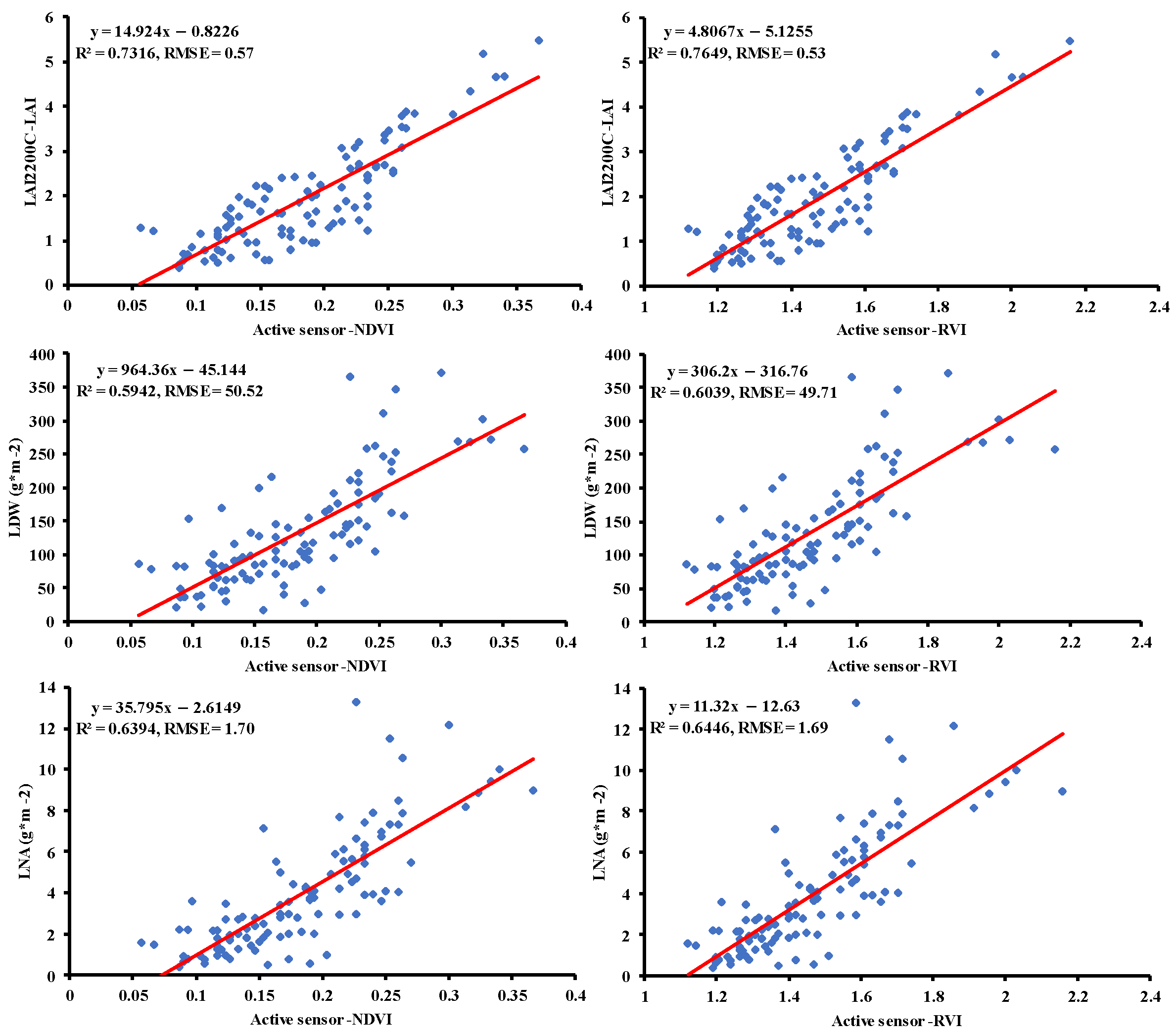

3.5. Test Results

3.6. Discussion

4. Conclusions

- (1)

- This article focused on disclosing the mechanical structure of a high-clearance robot chassis and demonstrated its application in wheat growth monitoring. Subsequent research will further consider using this chassis combined with AI technology to better realize smart functions such as automatic navigation and intelligent obstacle avoidance;

- (2)

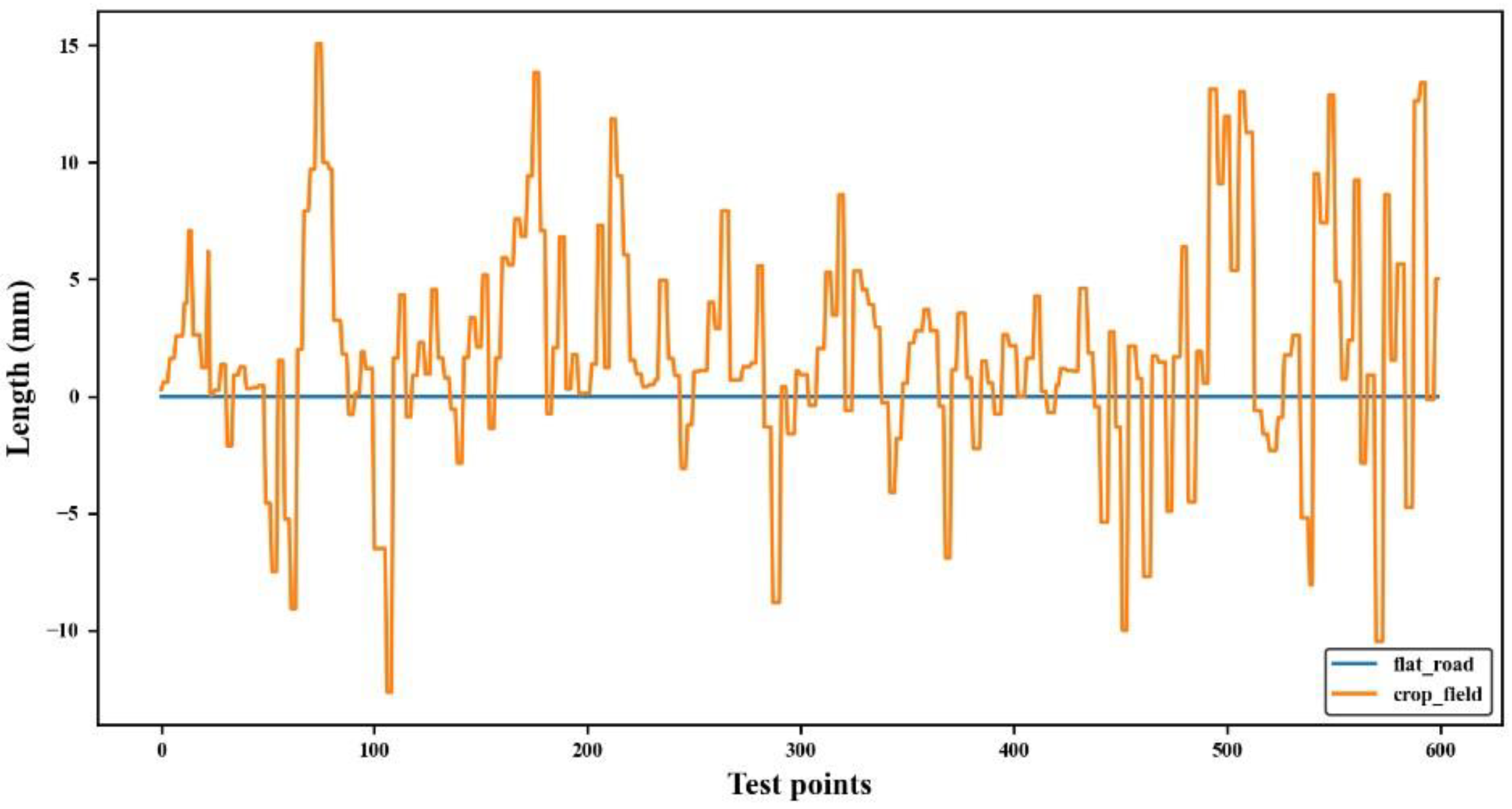

- A model of the wheeled crop-growth-monitoring robot chassis was built in Pro/E based on the mechanical structural design. The kinematic stability was analyzed in Adams. According to the simulation results, the displacement of its mass center was smaller than 2 mm and the pitching angle stayed at 0° when the robot chassis was on flat pavement. When crossing obstacles (10 cm deep pits and 10 cm high bumps), the displacements along the body height direction were 1.78 cm and 1.46 cm, which were only 1.6% and 1.3% of the body height, respectively. The test results showed that the mass center remained unchanged when the wheeled robot chassis was running on flat pavement; during field operation, the maximum mass center displacement was 1.51 cm, which was only 1.3% of the body height. Thus, the wheeled robot chassis shows high operational stability;

- (3)

- The motions of the wheeled crop-growth-monitoring robot chassis in the field were controlled by the self-developed LabVIEW upper-computer software platform. Functions such as the acquisition, analysis, display, and management of data collected from the environment information sensors and crop growth sensors are integrated into this software platform, which helped to overcome the shortcomings of separate operations between the robot chassis control system and the sensor test software and simplified the test flow;

- (4)

- According to the tests, the NDVI and RVI obtained by the wheeled robot chassis were highly consistent with those obtained with the ASD FieldSpec HandHeld 2 spectrometer. The agronomic parameters suggest that the spectral vegetation indexes acquired by the wheeled robot chassis can favorably predict the LAI, LDW, and LNA of wheat. In conclusion, the proposed wheeled crop-growth-monitoring robot chassis can achieve stable, real-time, and accurate monitoring of wheat growth.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rogovska, N.; Laird, D.A.; Chiou, C.-P.; Bond, L.J. Development of field mobile soil nitrate sensor technology to facilitate precision fertilizer management. Precis. Agric. 2019, 20, 40–55. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, M.; Wang, N. Precision agriculture—A worldwide overview. Comput. Electron. Agric. 2002, 36, 113–132. [Google Scholar] [CrossRef]

- Das, J.; Cross, G.; Qu, C.; Makineni, A.; Tokekar, P.; Mulgaonkar, Y.; Kumar, V. Devices, systems, and methods for automated monitoring enabling precision agriculture. In Proceedings of the 2015 IEEE International Conference on Automation Science and Engineering (CASE), Gothenburg, Sweden, 24–28 August 2015; pp. 462–469. [Google Scholar]

- Seelan, S.K.; Laguette, S.; Casady, G.M.; Seielstad, G.A. Remote sensing applications for precision agriculture: A learning community approach. Remote Sens. Environ. 2003, 88, 157–169. [Google Scholar] [CrossRef]

- Tang, Y.; Wang, R.; Huang, J. Relations between red edge characteristics and agronomic parameters of crops. Pedosphere 2004, 14, 467–474. [Google Scholar]

- Zhang, X.; Li, M.; Cui, D.; Zhao, P.; Sun, J.; Tang, N. New method and instrument to diagnose crop growth status in greenhouse based on spectroscopy. Eur. PubMed Cent. 2006, 26, 887–890. [Google Scholar]

- Bonfil, D.J. Wheat phenomics in the field by RapidScan: NDVI vs. NDRE. Isr. J. Plant Sci. 2017, 64, 41–54. [Google Scholar] [CrossRef]

- Lu, J.; Miao, Y.; Shi, W.; Li, J.; Wan, J.; Gao, X.; Zhang, J.; Zha, H. Using portable RapidSCAN active canopy sensor for rice nitrogen status diagnosis. Adv. Anim. Biosci. 2017, 8, 349–352. [Google Scholar] [CrossRef]

- Scharf, P.; Oliveira, L.; Vories, E.; Dunn, D.; Stevens, G. Crop sensors for variable-rate nitrogen application to cotton. In Proceedings of the ASA-CSSA-SSSA Annual Meeting, Columbia, CA, USA, 5–9 October 2008. [Google Scholar]

- Berni, J.A.; Zarco-Tejada, P.J.; Suárez, L.; Fereres, E. Thermal and narrowband multispectral remote sensing for vegetation monitoring from an unmanned aerial vehicle. IEEE Trans. Geosci. Remote Sens. 2009, 47, 722–738. [Google Scholar] [CrossRef]

- Jin, X.; Liu, S.; Baret, F.; Hemerlé, M.; Comar, A. Estimates of plant density of wheat crops at emergence from very low altitude UAV imagery. Remote Sens. Environ. 2017, 198, 105–114. [Google Scholar] [CrossRef]

- Schirrmann, M.; Giebel, A.; Gleiniger, F.; Pflanz, M.; Lentschke, J.; Dammer, K.-H. Monitoring agronomic parameters of winter wheat crops with low-cost UAV imagery. Remote Sens. 2016, 8, 706. [Google Scholar] [CrossRef]

- Sankey, T.; Donager, J.; McVay, J.; Sankey, J.B. UAV lidar and hyperspectral fusion for forest monitoring in the southwestern USA. Remote Sens. Environ. 2017, 195, 30–43. [Google Scholar] [CrossRef]

- Varco, J.; Fox, A.; Raper, T.; Hubbard, K. Development of sensor based detection of crop nitrogen status for utilization in variable rate nitrogen fertilization. In Precision Agriculture; Springer: Berlin/Heidelberg, Germany, 2013; pp. 145–150. [Google Scholar]

- Rosell Polo, J.R.; Sanz Cortiella, R.; Llorens Calveras, J.; Arnó Satorra, J.; Ribes Dasi, M.; Masip Vilalta, J.; Camp, F.; Gràcia, F.; Solanelles Batlle, F.; Pallejà Cabrè, T. A tractor-mounted scanning LIDAR for the non-destructive measurement of vegetative volume and surface area of tree-row plantations: A comparison with conventional destructive measurements. Biosyst. Eng. 2009, 102, 128–134. [Google Scholar] [CrossRef]

- Sudduth, K.; Kitchen, N.; Drummond, S. Comparison of three canopy reflectance sensors for variable-rate nitrogen application in corn. In Proceedings of the 10th International Conference on Precision Agriculture, Denver, CO, USA, 18–21 July 2010; pp. 18–21. [Google Scholar]

- Fernandez, M.G.S.; Bao, Y.; Tang, L.; Schnable, P.S. A high-throughput, field-based phenotyping technology for tall biomass crops. Plant Physiol. 2017, 174, 2008–2022. [Google Scholar] [CrossRef] [PubMed]

- Deery, D.; Jimenez-Berni, J.; Jones, H.; Sirault, X.; Furbank, R. Proximal remote sensing buggies and potential applications for field-based phenotyping. Agronomy 2014, 4, 349–379. [Google Scholar] [CrossRef]

- Lan, Y.; Zhang, H.; Lacey, R.; Hoffmann, W.; Wu, W. Development of an integrated sensor and instrumentation system for measuring crop conditions. Agric. Eng. Int. CIGR Ejournal 2009, 11, 1–16. [Google Scholar]

- Erdle, K.; Mistele, B.; Schmidhalter, U. Comparison of active and passive spectral sensors in discriminating biomass parameters and nitrogen status in wheat cultivars. Field Crops Res. 2011, 124, 74–84. [Google Scholar] [CrossRef]

- Beauchêne, K.; Leroy, F.; Fournier, A.; Huet, C.; Bonnefoy, M.; Lorgeou, J.; De Solan, B.; Piquemal, B.; Thomas, S.; Cohan, J.-P. Management and characterization of abiotic stress via PhénoField®, a high-throughput field phenotyping platform. Front. Plant Sci. 2019, 10, 904. [Google Scholar] [CrossRef]

- Virlet, N.; Sabermanesh, K.; Sadeghi-Tehran, P.; Hawkesford, M.J. Field Scanalyzer: An automated robotic field phenotyping platform for detailed crop monitoring. Funct. Plant Biol. 2017, 44, 143–153. [Google Scholar] [CrossRef]

- Susko, A.Q.; Gilbertson, F.; Heuschele, D.J.; Smith, K.; Marchetto, P. An automatable, field camera track system for phenotyping crop lodging and crop movement. HardwareX 2018, 4, e00029. [Google Scholar] [CrossRef]

- Baharav, T.; Bariya, M.; Zakhor, A. Computing height and width of in situ sorghum plants using 2.5 d infrared images. In Proceedings of the IS&T International Symposium on Electronic Imaging, Burlingame, CA, USA, 29 January–2 February 2017. [Google Scholar]

- Young, S.N.; Kayacan, E.; Peschel, J.M. Design and field evaluation of a ground robot for high-throughput phenotyping of energy sorghum. Precis. Agric. 2019, 20, 697–722. [Google Scholar] [CrossRef]

- Basu, S.; Omotubora, A.; Beeson, M.; Fox, C. Legal framework for small autonomous agricultural robots. AI Soc. 2020, 35, 113–134. [Google Scholar] [CrossRef]

- Dorhout, D. Ripe for Robots. Available online: https://www.cropscience.bayer.com/innovations/data-science/a/ripe-robots (accessed on 25 January 2023).

- Bai, G.; Ge, Y.; Hussain, W.; Baenziger, P.S.; Graef, G. A multi-sensor system for high throughput field phenotyping in soybean and wheat breeding. Comput. Electron. Agric. 2016, 128, 181–192. [Google Scholar] [CrossRef]

- Yuan, W.; Li, J.; Bhatta, M.; Shi, Y.; Baenziger, P.S.; Ge, Y. Wheat height estimation using LiDAR in comparison to ultrasonic sensor and UAS. Sensors 2018, 18, 3731. [Google Scholar] [CrossRef] [PubMed]

- White, J.W.; Conley, M.M. A flexible, low-cost cart for proximal sensing. Crop Sci. 2013, 53, 1646–1649. [Google Scholar] [CrossRef]

- Qiu, Q.; Sun, N.; Wang, Y.; Fan, Z.; Meng, Z.; Li, B.; Cong, Y. Field-based high-throughput phenotyping for Maize plant using 3D LiDAR point cloud generated with a “Phenomobile”. Front. Plant Sci. 2019, 10, 554. [Google Scholar] [CrossRef] [PubMed]

- Qiu, Q.; Fan, Z.; Meng, Z.; Zhang, Q.; Cong, Y.; Li, B.; Wang, N.; Zhao, C. Extended ackerman steering principle for the coordinated movement control of a four wheel drive agricultural mobile robot. Comput. Electron. Agric. 2018, 152, 40–50. [Google Scholar] [CrossRef]

- Shafiekhani, A.; Kadam, S.; Fritschi, F.B.; DeSouza, G.N. Vinobot and vinoculer: Two robotic platforms for high-throughput field phenotyping. Sensors 2017, 17, 214. [Google Scholar] [CrossRef] [PubMed]

- Weiss, U.; Biber, P. Plant detection and mapping for agricultural robots using a 3D LIDAR sensor. Robot. Auton. Syst. 2011, 59, 265–273. [Google Scholar] [CrossRef]

- Reina, G.; Vargas, A.; Nagatani, K.; Yoshida, K. Adaptive kalman filtering for gps-based mobile robot localization. In Proceedings of the 2007 IEEE International Workshop on Safety, Security and Rescue Robotics, Rome, Italy, 27–29 September 2007; pp. 1–6. [Google Scholar]

- Carpio, R.F.; Potena, C.; Maiolini, J.; Ulivi, G.; Rosselló, N.B.; Garone, E.; Gasparri, A. A navigation architecture for ackermann vehicles in precision farming. IEEE Robot. Autom. Lett. 2020, 5, 1103–1110. [Google Scholar] [CrossRef]

- Bangert, W.; Kielhorn, A.; Rahe, F.; Albert, A.; Biber, P.; Grzonka, S.; Haug, S.; Michaels, A.; Mentrup, D.; Hänsel, M. Field-robot-based agriculture: “RemoteFarming. 1” and “BoniRob-Apps”. VDI-Berichte 2013, 2193, 2. [Google Scholar]

- Yao, L.; Wu, R.; Wu, S.; Jiang, X.; Zhu, Y.; Cao, W.; Ni, J. Design and Testing of an Active Light Source Apparatus for Crop Growth Monitoring and Diagnosis. IEEE Access 2020, 8, 206474–206490. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, L.; Yuan, H.; Zhu, Y.; Jiang, X.; Cao, W.; Ni, J. Design and Testing of a Wheeled Crop-Growth-Monitoring Robot Chassis. Agronomy 2023, 13, 3043. https://doi.org/10.3390/agronomy13123043

Yao L, Yuan H, Zhu Y, Jiang X, Cao W, Ni J. Design and Testing of a Wheeled Crop-Growth-Monitoring Robot Chassis. Agronomy. 2023; 13(12):3043. https://doi.org/10.3390/agronomy13123043

Chicago/Turabian StyleYao, Lili, Huali Yuan, Yan Zhu, Xiaoping Jiang, Weixing Cao, and Jun Ni. 2023. "Design and Testing of a Wheeled Crop-Growth-Monitoring Robot Chassis" Agronomy 13, no. 12: 3043. https://doi.org/10.3390/agronomy13123043

APA StyleYao, L., Yuan, H., Zhu, Y., Jiang, X., Cao, W., & Ni, J. (2023). Design and Testing of a Wheeled Crop-Growth-Monitoring Robot Chassis. Agronomy, 13(12), 3043. https://doi.org/10.3390/agronomy13123043