Optimal Time for Haymaking and Potential Production of Grass Hay on Soybean Overseeding in Brazilian Savanna

Abstract

:1. Introduction

2. Materials and Methods

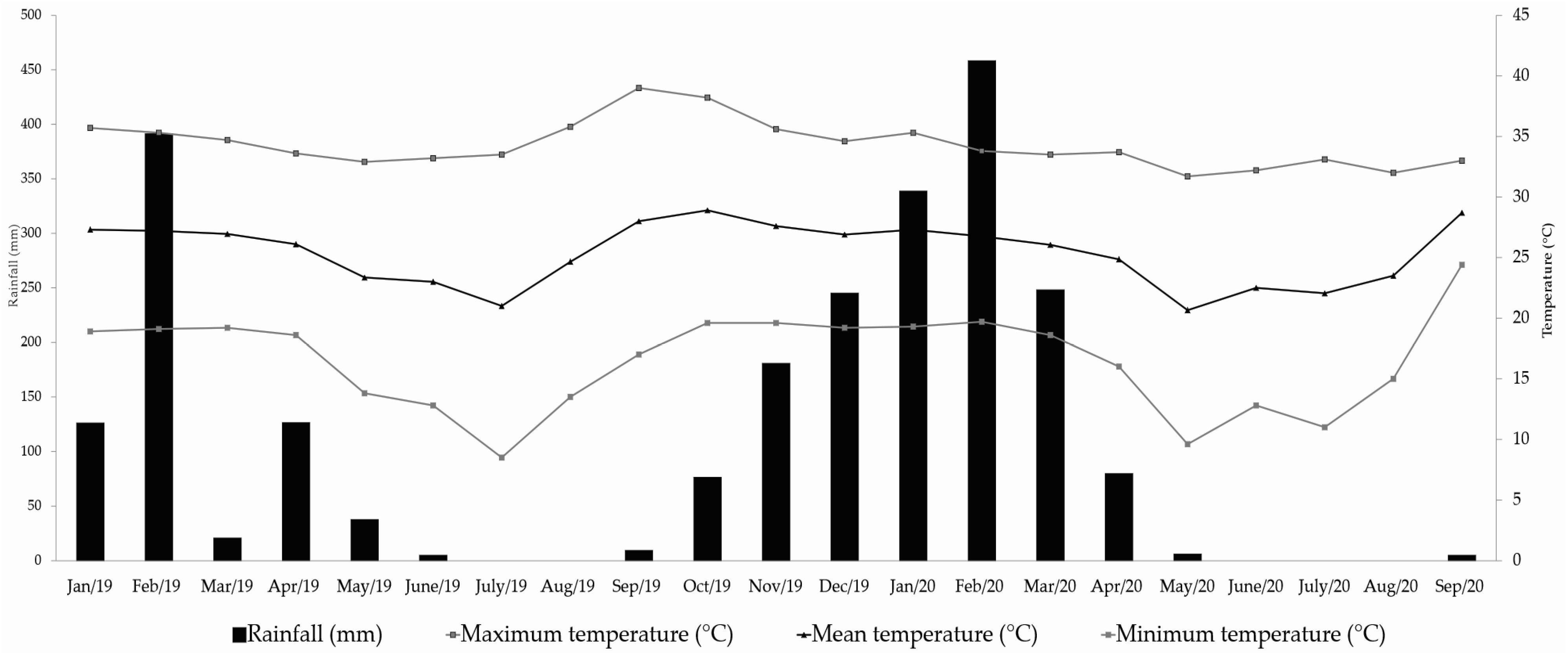

2.1. Experimental Field Characterization

2.2. Treatments in the Production System

2.3. Soil Characteristics

2.4. Forage Collection for Availability and Chemical Composition Analysis

2.5. Estimates of Milk and Carcass Production Potential

2.6. Statistical Analysis

3. Results

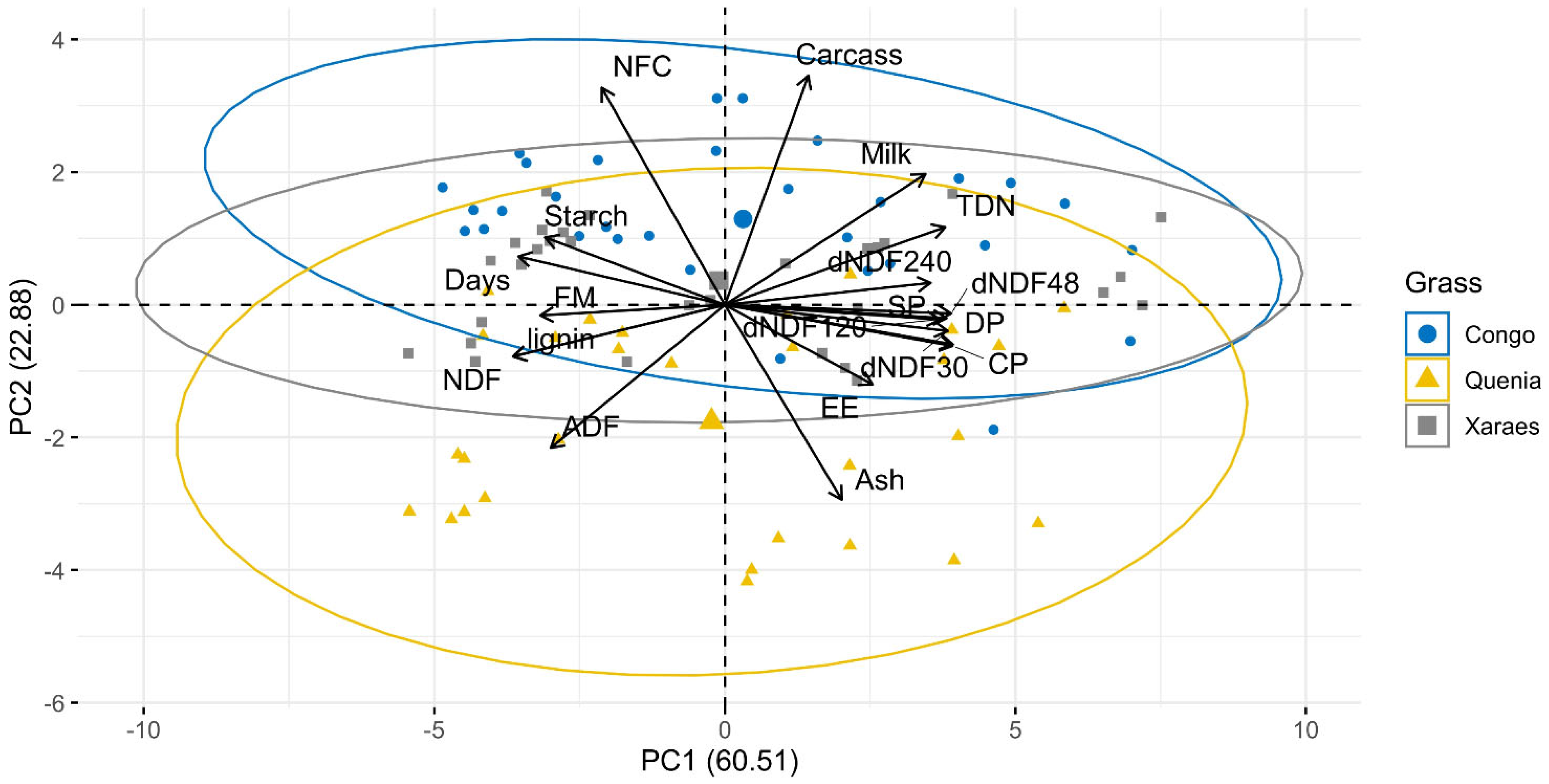

3.1. Association between Forage Mass, Chemical Composition, and Milk and Carcass Production Potential

3.2. Effect of Cutting Day on Forage Mass and Chemical Composition of Grasses Managed in Integrated Production Systems

3.3. Potential for Milk and Carcass Production in Integrated Production Systems

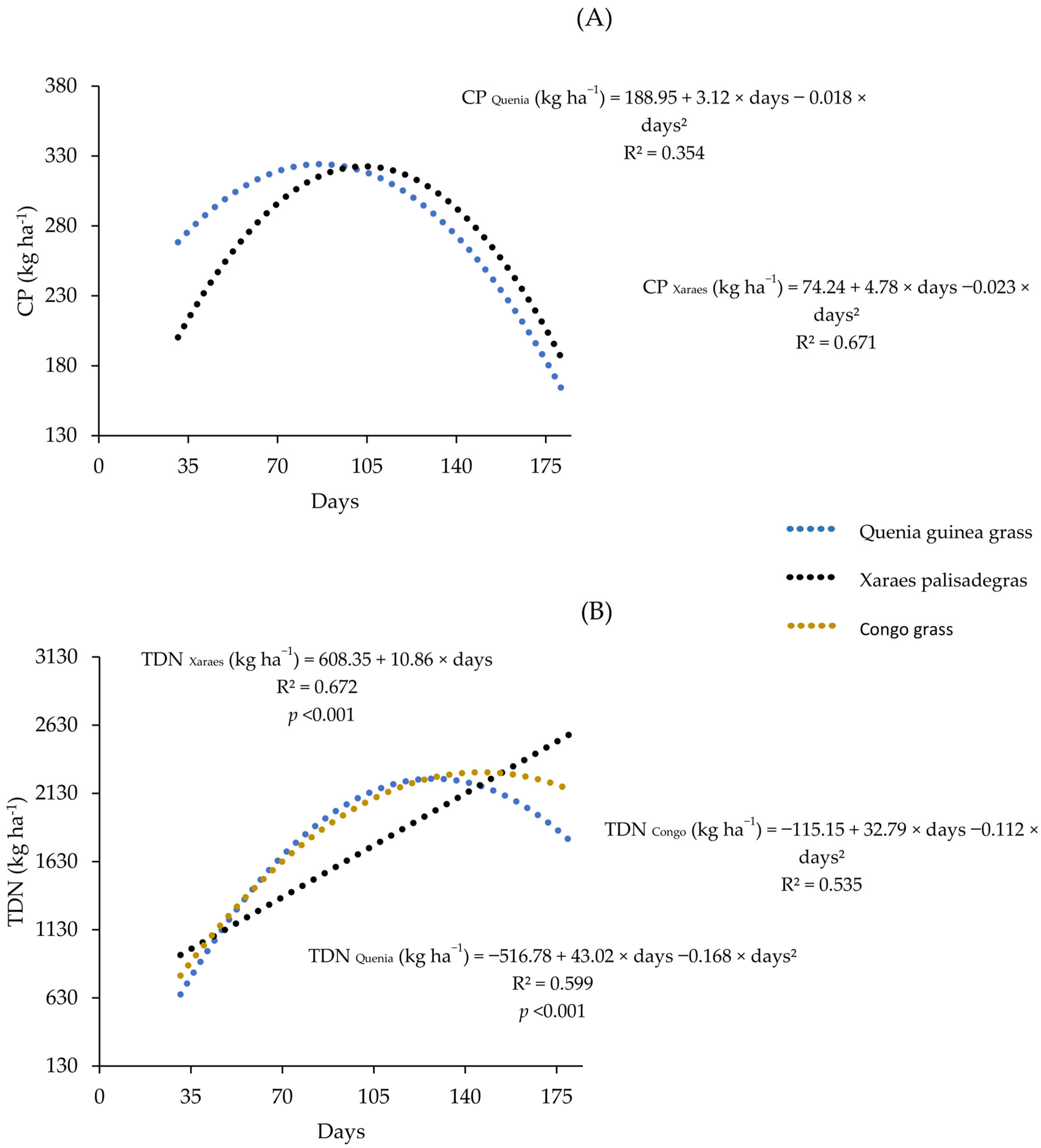

3.4. Production of Crude Protein, Total Digestible Nutrients, Milk, and Carcass Production Potential per Hectare

4. Discussion

4.1. Potential Dry Hay Mass Yield from Grasses in Integrated Production Systems

4.2. Perspectives for Milk and Carcass Production Using Hay from Grasses in Integrated Production Systems

4.3. General Considerations

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dominschek, R.; Barroso, A.A.M.; Lang, C.R.; de Moraes, A.; Sulc, R.M.; Schuster, M.Z. Crop rotations with temporary grassland shifts weed patterns and allows herbicide-free management without crop yield loss. J. Clean. Prod. 2021, 306, 127140. [Google Scholar] [CrossRef]

- Almeida, E.M.; de Araújo, A.R.; Difante, G.D.S.; Motta Macedo, M.C.; Montagner, D.B.; Gurgel, A.L.C.; Zimmer, A.H.; Ferreira, A.D. Do Different Soil Use and Management Systems Change Root Weight? N. Z. J. Agric. Res. 2023, 65, 1–19. [Google Scholar] [CrossRef]

- Dias, M.B.C.; Costa, K.A.P.; Severiano, E.C.; Bilego, U.O.; Furtine Neto, A.E.; Almeida, D.P.; Brand, S.C.; Vilela, L. Brachiaria and Panicum maximum in an integrated crop–livestock system and a second-crop maize system in succession with soybean. J. Agric. Sci. 2020, 158, 206–217. [Google Scholar] [CrossRef]

- Moraes, A.; de Faccio Carvalho, P.C.; Anghinoni, I.; Lustosa, S.B.C.; de Andrade, S.E.V.G.; Kunrath, T.R. Integrated Crop–Livestock Systems in the Brazilian Subtropics. Eur. J. Agron. 2014, 57, 4–9. [Google Scholar] [CrossRef]

- Oliveira, S.; Costa, K.A.; Severiano, E.; da Silva, A.; Dias, M.; Oliveira, G.; Costa, J.V. Performance of Grain Sorghum and Forage of the Genus Brachiaria in Integrated Agricultural Production Systems. Agronomy 2020, 10, 1714. [Google Scholar] [CrossRef]

- Muniz, M.P.; Costa, K.A.P.; Severiano, E.C.; Bilego, U.O.; Almeida, D.P.; Furtini Neto, A.E.; Vilela, L.; Lana, M.A.; Leandro, W.M.; Castro Dias, M.B. Soybean Yield in Integrated Crop–Livestock System in Comparison to Soybean–Maize Succession System. J. Agric. Sci. 2021, 159, 188–198. [Google Scholar] [CrossRef]

- Leal, V.N.; Santos, D.d.C.; Paim, T.d.P.; Santos, L.P.d.; Alves, E.M.; Claudio, F.L.; Calgaro, G., Jr.; Fernandes, P.B.; Salviano, P.A.P. Economic Results of Forage Species Choice in Crop–Livestock Integrated Systems. Agriculture 2023, 13, 637. [Google Scholar] [CrossRef]

- Domiciano, L.F.; Mombach, M.A.; Carvalho, P.; da Silva, N.M.F.; Pereira, D.H.; Cabral, L.S.; Lopes, L.B.; Pedreira, B.C. Performance and Behaviour of Nellore Steers on Integrated Systems. Anim. Prod. Sci. 2018, 58, 920–929. [Google Scholar] [CrossRef]

- Da Silva, F.S.; Domiciano, L.F.; Gomes, F.J.; Sollenberger, L.E.; Pedreira, C.G.; Pereira, D.H.; Pedreira, B.C. Herbage Accumulation, Nutritive Value and Beef Cattle Production on Marandu Palisadegrass Pastures in Integrated Systems. Agrofor. Syst. 2020, 94, 1891–1902. [Google Scholar] [CrossRef]

- Ferreira, G.A.; Oliveira, P.S.R.; Alves, S.J.; da Costa, A.C.T. Soybean Productivity under Different Grazing Heights of Brachiaria ruziziensis in an Integrated Crop-Livestock System. Rev. Ciênc. Agron. 2015, 46, 755–763. [Google Scholar] [CrossRef]

- Nascimento, K.S.; Edvan, R.L.; Santos, C.O.; Sousa, J.M.S.; Nascimento, R.R.; Miranda, R.S.; Bezerra, L.R.; Biagiotti, D.; Lima Neto, A.F.; Araujo, M.J. Production aspects of hay of pasture tropical of Urochloa brizantha, Megathyrsus maximus and Andropogon gayanus: Forage mass yield characteristics, evaluation of losses, dehydration and nutritional value of hays. Crop Pasture Sci. 2022, 74, 1425–1437. [Google Scholar] [CrossRef]

- Barrios, S.C.L.; Carromeu, C.; Silva, M.A.I.; Matsubara, E.T.; Valle, C.B.; Jank, L.; Santos, M.F.; Assis, G.M.L.; Crivellaro, L.L.; Gonçalves, T.D.T.; et al. Pasto Certo® Version 2.0—An Application about Brazilian Tropical Forage Cultivars for Mobile and Desktop Devices. Trop. Grassl. Forrajes Trop. 2020, 8, 162–166. [Google Scholar] [CrossRef]

- Gomes, E.N.O.; Dias, A.M.; Junges, L.; Ítavo, L.C.V.; Difante, G.S.; Batistoti, J.O. Influence of the cut intervals on hay quality of Panicum maximum cv. BRS Tamani. Rev. Mex. Cienc. Pecu. 2023, 14, 450–465. [Google Scholar] [CrossRef]

- Cardoso, M.R.D.; Marcuzzo, F.F.N.; Barros, J.R. Classificação Climática de Köppen-Geiger para o Estado de Goiás e o Distrito Federal. ACTA Geográfica 2014, 8, 40–55. [Google Scholar] [CrossRef]

- Santos, H.G.; Jacomine, P.K.T.; Anjos, L.H.C.; Oliveira, V.A.; Lumbreras, J.F.; Coelho, M.R.; Cunha, T. Sistema Brasileiro de Classificação de Solos; EMBRAPA: Brasília, Brazil, 2018; p. 356. [Google Scholar]

- Shaver, R. Corn Silage Evaluation: MILK 2000 Challenges and Opportunities with MILK 2006. Available online: https://www.foragelab.com/Media/milk2006weblinkslides.pdf (accessed on 1 March 2023).

- Dahlke, G.R. Corn Silage to Beef Calculator; Iowa State University Animal Industry Report; Iowa State University: Ames, IA, USA, 2017; Volume 14, pp. 1–2. [Google Scholar]

- National Research Council. Nutrient Requirements of Dairy Cattle, 7th ed.; National Academy Press: Washington, DC, USA, 2001. [Google Scholar]

- National Research Council. Nutrient Requirements of Beef Cattle, 8th ed.; National Academies Press: Washington, DC, USA, 2016. [Google Scholar]

- R Core Team 2022. R: A Language and Environment for Statistical Computing. 2022. Available online: https://www.R-project.org/ (accessed on 10 January 2022).

- Lê, S.; Josse, J.; Husson, F. FactoMineR: An R package for multivariate analysis. J. Stat. Softw. 2008, 25, 1–18. [Google Scholar] [CrossRef]

- Kassambara, A.; Mundt, F. Factoextra: Extract and Visualize the Results of Multivariate Data Analyses. R Package Version 1.0.7. 2020. Available online: https://cran.r-project.org/package=factoextra (accessed on 15 March 2023).

- Bates, D.; Mächler, M.; Bolker, B.; Walker, S. Fitting Linear Mixed-Effects Models Using lme4. J. Stat. Softw. 2015, 67, 48. [Google Scholar] [CrossRef]

- Cacan, E.; Kokten, K.; Seydosoglu, S. Determining the performance of alfalfa population collected from a narrow agroeceological zone of Turkey. Ciênc. Rural 2020, 50, e20190721. [Google Scholar] [CrossRef]

- Corrêa, Y.; Santos, E.; Oliveira, J.; Carvalho, G.; Pinto, L.; Pereira, D.; Assis, D.; Cruz, G.; Panosso, N.; Perazzo, A.; et al. Diets Composed of Tifton 85 Grass Hay (Cynodon sp.) and Concentrate on the Quantitative and Qualitative Traits of Carcass and Meat from Lambs. Agriculture 2022, 12, 752. [Google Scholar] [CrossRef]

- Correia, J.R.; Reatto, A.; Spera, S.T. Solos e Suas Relações com o Uso e o Manejo. Capítulo 1. In Cerrado Correção do Solo e Adubação; EMBRAPA Cerrados: Brasília, Brazil, 2004; pp. 29–62, (In Portuguese). Available online: https://urlfr.ee/78vs9 (accessed on 2 February 2023).

- Jank, L.; Resende, R.M.S.; Valle, C.B.; Resende, M.D.V.; Chiari, L.; Cancado, L.J.; Simioni, C. Melhoramento Genético de Panicum maximum Jacq. In Melhoramento de Forrageiras Tropicais; Resende, R.M.S., Valle, C.B.d., Jank, L., Eds.; Embrapa Gado de Corte: Campo Grande, Brazil, 2008; pp. 55–87. [Google Scholar]

- Valle, C.B.; Jank, L.; Resende, R.M.S. O Melhoramento de Forrageiras Tropicais no Brasil. Rev. Ceres 2009, 56, 460–472. [Google Scholar]

- Euclides, V.P.B.; Montagner, D.B.; Difante, G.d.S.; Barbosa, R.A.; Fernandes, W.S. Sward Structure and Livestock Performance in Guinea Grass cv. Tanzania Pastures Managed by Rotational Stocking Strategies. Sci. Agric. 2014, 71, 451–457. [Google Scholar] [CrossRef]

- Pereira, M.; Morais, M.G.; Fernandes, P.B.; Santos, V.A.C.; Glatzle, S.; Almeida, R.G. Beef cattle production on Piatã grass pastures in silvopastoral systems. Trop. Grassl. Forrajes Trop. 2021, 9, 1–12. [Google Scholar] [CrossRef]

- Ferreira, E.A.; Abreu, J.G.; Martinez, J.C.; Braz, T.G.; Ferreira, D.P. Cutting ages of elephant grass for chopped hay production. Pesqui. Agropecu. Trop. 2018, 48, 245–253. [Google Scholar] [CrossRef]

- Detmann, E.; Valente, E.E.L.; Batista, E.D.; Huhtanen, P. An evaluation of the erformance and efficiency of nitrogen utilization in cattle fed tropical grass pastures with supplementation. Livest. Sci. 2014, 162, 141–153. [Google Scholar] [CrossRef]

- Silva, C.S.; Euclides, V.P.B.; Montagner, D.B.; Araújo, I.M.M.; Difante, G.S.; Orrico, M.A.P., Jr. Effects of different supplements on performance of steers grazing Mombaça guinea grass (Megathyrsus maximus) during the dry period. Trop. Grassl. Forrajes Trop. 2022, 10, 44–51. [Google Scholar] [CrossRef]

- Leite, R.G.; Cardoso, A.D.S.; Fonseca, N.V.B.; Silva, M.L.C.; Tedeschi, L.O.; Delevatti, L.M.; Ruggieri, A.C.; Reis, R.A. Effects of nitrogen fertilization on protein and carbohydrate fractions of Marandu palisadegrass. Sci. Rep. 2021, 11, 14786. [Google Scholar] [CrossRef] [PubMed]

- Euclides, V.P.B.; Macedo, M.C.M.; Valle, C.B.D.; Difante, G.D.S.; Barbosa, R.A.; Cacere, E.R. Valor nutritivo da forragem e produção animal em pastagens de Brachiaria brizantha. Pesqui. Agropecu. Bras. 2009, 44, 98–106. [Google Scholar] [CrossRef]

- Euclides, V.P.B.; Montagner, D.B.; Barbosa, R.A.; Valle, C.B.D.; Nantes, N.N. Animal performance and sward characteristics of two cultivars of Brachiaria brizantha (BRS Paiaguás and BRS Piatã). Rev. Bras. Zootec. 2016, 45, 85–92. [Google Scholar] [CrossRef]

- Euclides, V.B.P.; Carpejani, G.C.; Montagner, D.B.; Nascimento, D., Jr.; Barbosa, R.A.; Difante, G.S. Maintaining post-grazing sward height of Panicum maximum (cv. Mombaça) at 50 cm led to higher animal performance compared with post-grazing height of 30 cm. Grass Forage Sci. 2017, 73, 174–182. [Google Scholar] [CrossRef]

- Costa, R.R.G.F.; Costa, K.A.P.; Souza, W.F.; Epifanio, P.S.; Santos, C.B.; Silva, J.T.; Oliveira, S.S. Production and Quality of Silages Pearl Millet and Paiaguas Palisadegrass in Monocropping and Intercropping in Different Forage Systems. Biosci. J. 2018, 34, 957–967. [Google Scholar] [CrossRef]

- Euclides, V.P.B.; Flores, R.S.; Medeiros, R.N.; Oliveira, M.P. Diferimento de Pastos de Braquiária Cultivares Basilisk e Marandu, na Região do Cerrado. Pesq. Agropec. Bras. 2007, 42, 273–280. [Google Scholar] [CrossRef]

- Rodrigues, C.S.; Nascimento, D., Jr.; Detmann, E.; Silva, S.C.; Sousa, B.M.D.L.; Silveira, M.C.T.D. Functional Clusters of Tropical Forage Grasses. Rev. Bras. Zootec. 2012, 41, 1385–1393. [Google Scholar] [CrossRef]

- Silva, J.A.G.; Habermann, E.; Costa, K.A.P.; Costa, K.A.P.; Silva, L.M.; Severiano, E.C.; Costa, A.C.; Silva, F.G.; Oliveira, T.C.; Dario, B.M.M.; et al. Integration crop-livestock system increases the sustainability of soybean cultivation through improved soil health and plant physiology. Agric. Ecosyst. Environ. 2024, 359, 108770. [Google Scholar] [CrossRef]

- Vilela, D.; Andrade, R.G.; Leite, J.L.B.; Hott, M.C.; Magalhães, W.C.P., Jr. Produção de leite no Cerrado: Conjuntura e análises. In Geotecnologias: Aplicações na Cadeia Produtiva do Leite, 1st ed.; Hott, M.C., Andrade, R.G., Magalhães, W.C.P., Jr., Eds.; Atena Editora: Ponta Grossa, Brazil, 2022; Volume 1, pp. 77–81. [Google Scholar]

- Barbero, R.P.; Ribeiro, A.C.C.; Moura, A.M.; Longhini, V.Z.; Mattos, T.F.A.; Barbero, M.M.D. Production potential of beef cattle in tropical pastures: A review. Ciênc. Anim. Bras. 2021, 22, e69609. [Google Scholar] [CrossRef]

| Soil Layers (cm) | |||

|---|---|---|---|

| Item | 0–10 | 10–20 | 20–40 |

| Potential acidity (pH in CaCl2) | 5.07 | 4.54 | 5.57 |

| Potential acidity (cmolc dm−1) | 2.77 | 3.17 | 2.63 |

| Aluminum (cmolc dm−3) | 0.00 | 0.06 | 0.03 |

| Cation Exchange Capacity (cmolc dm−1) | 5.51 | 4.49 | 3.59 |

| Calcium (cmolc dm−1) | 1.97 | 0.87 | 0.63 |

| Magnesium (cmolc dm−3) | 0.59 | 0.33 | 0.26 |

| * Phosphorus (mg dm−3) | 3.67 | 1.67 | 2.22 |

| Potassium (mg dm−3) | 75.5 | 46.9 | 28.4 |

| Base Saturation (%) | 49.8 | 29.3 | 26.8 |

| Item | Abbreviation |

|---|---|

| Dry matter (% NM) | DM |

| Crude protein (% DM) | CP |

| Soluble protein (% CP) | SP |

| Digestible protein (% DM) | DP |

| Ash (% DM) | MM |

| Neutral detergent fiber (% DM) | NDF |

| Neutral detergent fiber digestibility after 48 h (% DM) | dNDF30 |

| Neutral detergent fiber digestibility after 30 h (% DM) | dNDF48 |

| Neutral detergent fiber digestibility after 120 h (% DM) | dNDF120 |

| Neutral detergent fiber digestibility after 240 h (% DM) | NDF24 |

| Acid detergent fiber (% DM) | ADF |

| Non-fiber carbohydrates (% DM) | NFC |

| Starch (% DM) | NA |

| Lignin (% DM) | NA |

| Ether extract (% DM) | EE |

| Total digestible nutrients | TDN |

| p-Value | |||||

|---|---|---|---|---|---|

| Item | Grass | Equation | R2 | L | Q |

| FM (kg ha−1) | Quenia guinea grass | FM = −1761.87 + 89.05 × days − 0.333 × days2 | 0.791 | <0.001 | <0.001 |

| Congo grass | FM = −593.30 + 59.92 × days − 0.194 × days2 | 0.696 | <0.001 | 0.007 | |

| Xaraes palisade grass | FM = −1042.00 + 59.77 × days − 0.163 × days2 | 0.759 | <0.001 | 0.023 | |

| MM (% DM) | Quenia guinea grass | MM = 9.95 − 0.045 × days + 0.0002 × days2 | 0.969 | <0.001 | <0.001 |

| Congo grass | MM = 10.30 − 0.107 × days + 0.0004 × days2 | 0.813 | <0.001 | <0.001 | |

| Xaraes palisade grass | MM = 9.97 − 0.092 × days + 0.0003 × days2 | 0.916 | <0.001 | <0.001 | |

| CP (% DM) | Quenia guinea grass | CP = 29.37 − 0.280 × days + 0.0008 × days2 | 0.936 | <0.001 | <0.001 |

| Congo grass | CP = 29.50 − 0.319 × days + 0.0010 × days2 | 0.948 | <0.001 | <0.001 | |

| Xaraes palisade grass | CP = 29.49 − 0.290 × days + 0.0008 × days2 | 0.977 | <0.001 | <0.001 | |

| SP (% CP) | Quenia guinea grass | SP = 47.28 − 0.461 × days + 0.002 × days2 | 0.831 | <0.001 | <0.001 |

| Congo grass | SP = 59.64 − 0.618 × days + 0.002 × days2 | 0.853 | <0.001 | 0.009 | |

| Xaraes palisade grass | SP = 60.89 − 0.678 × days + 0.002 × days2 | 0.917 | <0.001 | <0.001 | |

| DP (% DM) | Quenia guinea grass | DP = 28.91 − 0.278 × days + 0.0008 × days2 | 0.932 | <0.001 | <0.001 |

| Congo grass | DP = 29.07 − 0.314 × days + 0.0010 × days2 | 0.945 | <0.001 | <0.001 | |

| Xaraes palisade grass | DP = 29.20 − 0.288 × days + 0.0008 × days2 | 0.917 | <0.001 | <0.001 | |

| p-Value | |||||

|---|---|---|---|---|---|

| Item | Grass | Equation | R2 | L | Q |

| TDN (% DM) | Quenia guinea grass | TDN = 69.18 − 0.140 × days + 0.0004 × days2 | 0.947 | <0.001 | 0.001 |

| Congo grass | TDN = 71.21 − 0.139 × days + 0.0004 × days2 | 0.871 | <0.001 | 0.001 | |

| Xaraes palisade grass | TDN = 72.30 − 0.180 × days + 0.0005 × days2 | 0.916 | <0.001 | <0.001 | |

| Starch (% DM) | Quenia guinea grass | Starch = 1.94 | - | 0.352 | 0.901 |

| Congo grass | Starch = −0.035 + 0.049 × days − 0.0002 × days2 | 0.798 | <0.001 | 0.001 | |

| Xaraes palisade grass | Starch = −0.202 + 0.042 × days − 0.0002 × days2 | 0.882 | <0.001 | <0.001 | |

| NFC (% DM) | Quenia guinea grass | NFC = 1.50 | - | 0.205 | 0.877 |

| Congo grass | NFC = 14.23 + 0.183 × days − 0.0006 × days2 | 0.725 | <0.001 | 0.001 | |

| Xaraes palisade grass | NFC = 18.87 + 0.044 × days | 0.636 | 0.005 | 0.154 | |

| NDF (% DM) | Quenia guinea grass | NDF = 45.12 + 0.256 × days − 0.0008 × days2 | 0.832 | <0.001 | <0.001 |

| Congo grass | NDF = 43.80 + 0.253 × days − 0.0009 × days2 | 0.733 | <0.001 | <0.001 | |

| Xaraes palisade grass | NDF = 41.83 + 0.296 × days − 0.0010 × days2 | 0.798 | <0.001 | <0.001 | |

| ADF (% DM) | Quenia guinea grass | ADF = 29.53 + 0.106 × days − 0.0004 × days2 | 0.746 | 0.002 | 0.034 |

| Congo grass | ADF = 26.25 + 0.119 × days − 0.0004 × days2 | 0.657 | 0.004 | 0.039 | |

| Xaraes palisade grass | ADF = 26.89 + 0.116 × days − 0.0004 × days2 | 0.591 | <0.001 | 0.006 | |

| Lignin (% DM) | Quenia guinea grass | Lignin = 3.02 + 0.071 × days − 0.0009 × days2 | 0.846 | <0.001 | 0.008 |

| Congo grass | Lignin = 2.12 + 0.045 × days − 0.0003 × days2 | 0.847 | <0.001 | <0.001 | |

| Xaraes palisade grass | Lignin = 2.91 + 0.030 × days − 0.0002 × days2 | 0.853 | <0.001 | <0.001 | |

| p-Value | |||||

|---|---|---|---|---|---|

| Item | Grass | Equation | R2 | L | Q |

| dNDF30 (% DM) | Quenia guinea grass | dNDF30 = 62.78 − 0.122 × days | 0.967 | <0.001 | 0.551 |

| Congo grass | dNDF30 = 69.58 − 0.273 × days + 0.0008 × days2 | 0.953 | <0.001 | <0.001 | |

| Xaraes palisade grass | dNDF30 = 70.86 − 0.313 × days + 0.0009 × days2 | 0.973 | <0.001 | <0.001 | |

| dNDF48 (% DM) | Quenia guinea grass | dNDF48 = 83.00 − 0.155 × days | 0.884 | <0.001 | 0.448 |

| Congo grass | dNDF48 = 95.66 − 0.429 × days + 0.0013 × days2 | 0.912 | <0.001 | <0.001 | |

| Xaraes palisade grass | dNDF48 = 92.06 − 0.382 × days + 0.0011 × days2 | 0.937 | <0.001 | <0.001 | |

| dNDF120 (% DM) | Quenia guinea grass | dNDF120 = 95.65 − 0.363 × days + 0.0011 × days2 | 0.840 | <0.001 | <0.001 |

| Congo grass | dNDF120 = 88.84 − 0.149 × days | 0.701 | <0.001 | 0.075 | |

| Xaraes palisade grass | dNDF120 = 97.05 − 0.396 × days + 0.0011 × days2 | 0.864 | <0.001 | <0.001 | |

| dNDF240 (% DM) | Quenia guinea grass | dNDF240 = 96.21 − 0.244 × days + 0.0007 × days2 | 0.945 | <0.001 | <0.001 |

| Congo grass | dNDF240 = 102.90 − 0.395 × days + 0.0013 × days2 | 0.925 | <0.001 | <0.001 | |

| Xaraes palisade grass | dNDF240 = 96.93 − 0.289 × days + 0.0008 × days2 | 0.972 | <0.001 | <0.001 | |

| p-Value | |||||

|---|---|---|---|---|---|

| Item | Grass | Equation | R2 | L | Q |

| Milk (kg t FM−1) | Quenia guinea grass | Milk = 1646.00 − 5.31 × days + 0.015 × days2 | 0.931 | <0.001 | <0.001 |

| Congo grass | Milk = 1593.73 − 1.63 × days | 0.741 | <0.001 | 0.092 | |

| Xaraes palisade grass | Milk = 1727.11 − 5.25 × days + 0.015 × days2 | 0.838 | <0.001 | 0.001 | |

| Carcass (kg t FM−1) | Quenia guinea grass | Carcass = 61.29 | - | 0.640 | 0.256 |

| Congo grass | Carcass = 76.09 + 0.644 × days − 0.003 × days2 | 0.373 | <0.001 | <0.001 | |

| Xaraes palisade grass | Carcass = 101.10 | - | 0.724 | 0.496 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernandes, P.B.; Paim, T.d.P.; Santos, L.P.d.; Souza, B.R.; Leal, V.N.; Gonçalves, L.F.; Claudio, F.L.; Santos, D.d.C.; Guimarães, K.C.; Alves, E.M. Optimal Time for Haymaking and Potential Production of Grass Hay on Soybean Overseeding in Brazilian Savanna. Agronomy 2023, 13, 3046. https://doi.org/10.3390/agronomy13123046

Fernandes PB, Paim TdP, Santos LPd, Souza BR, Leal VN, Gonçalves LF, Claudio FL, Santos DdC, Guimarães KC, Alves EM. Optimal Time for Haymaking and Potential Production of Grass Hay on Soybean Overseeding in Brazilian Savanna. Agronomy. 2023; 13(12):3046. https://doi.org/10.3390/agronomy13123046

Chicago/Turabian StyleFernandes, Patrick Bezerra, Tiago do Prado Paim, Luizmar Peixoto dos Santos, Brunna Rafaela Souza, Vanessa Nunes Leal, Lucas Ferreira Gonçalves, Flávio Lopes Claudio, Darliane de Castro Santos, Katia Cylene Guimarães, and Estenio Moreira Alves. 2023. "Optimal Time for Haymaking and Potential Production of Grass Hay on Soybean Overseeding in Brazilian Savanna" Agronomy 13, no. 12: 3046. https://doi.org/10.3390/agronomy13123046