Development of Superabsorbent Polymer (SAP) Seed Coating Technology to Enhance Germination and Stand Establishment in Red Clover Cover Crop

Abstract

:1. Introduction

2. Materials and Methods

2.1. SAP Materials and Determination of Water Absorbency of SAP Materials

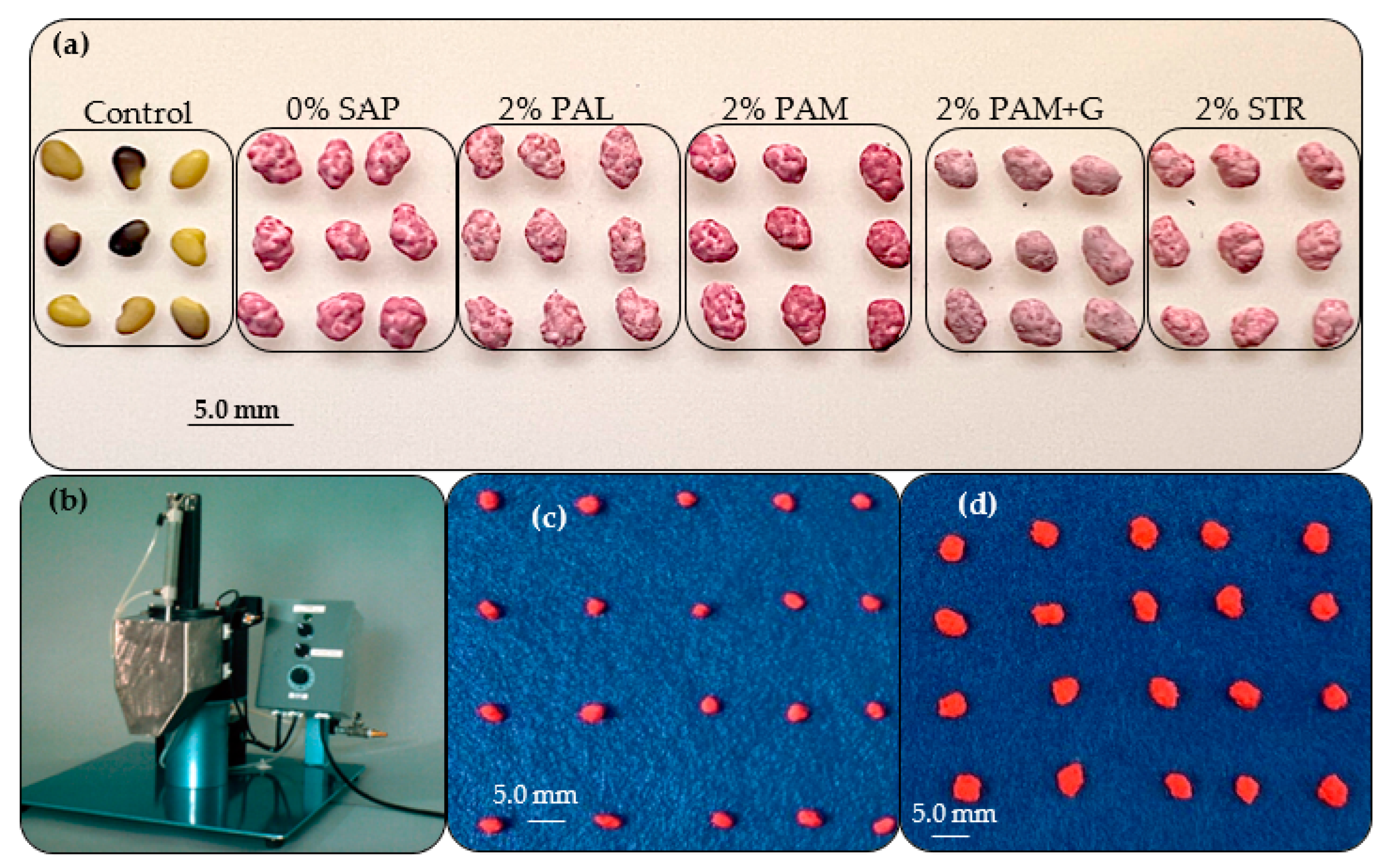

2.2. Seed Coating Method

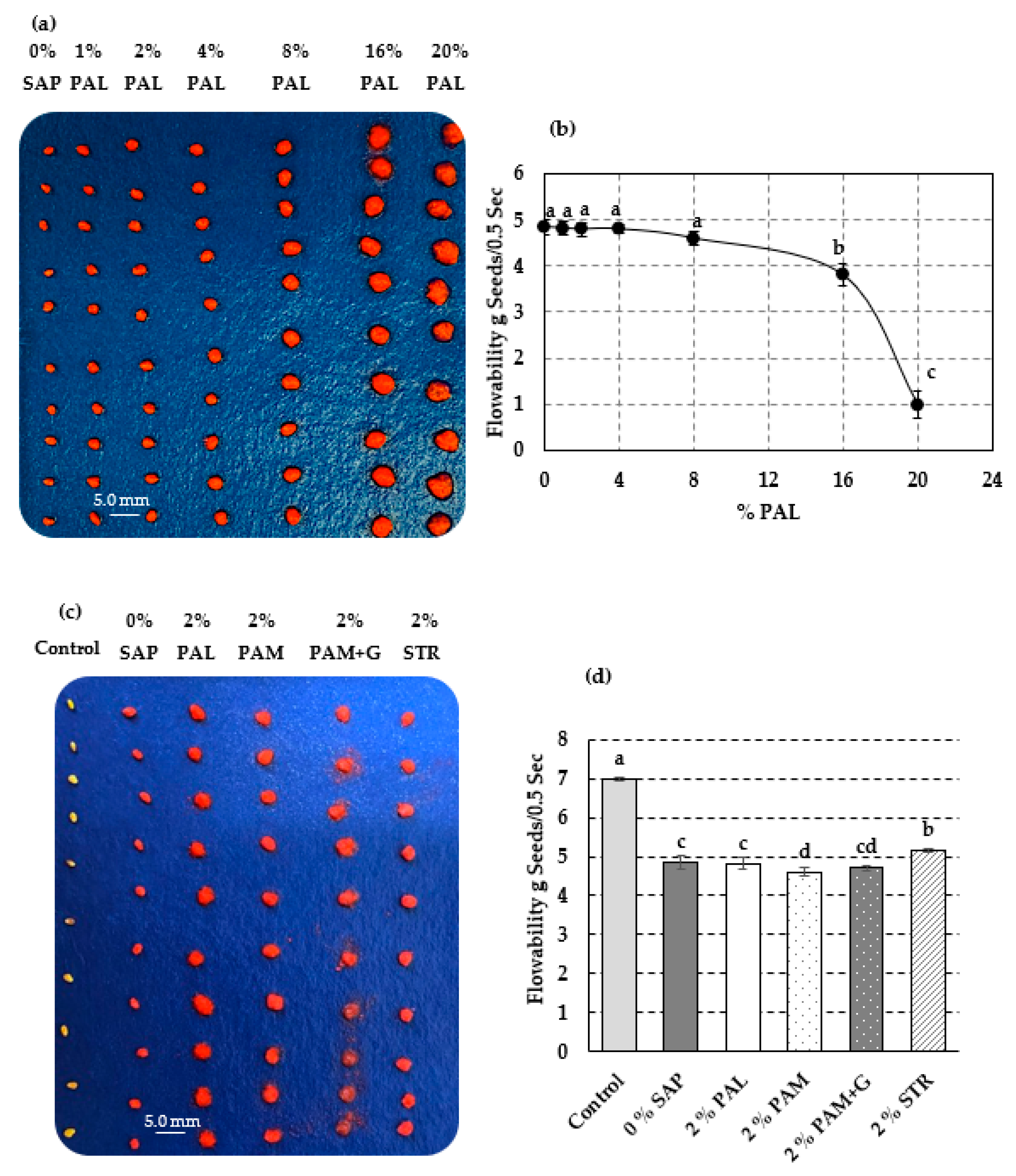

2.3. Determination of Flowability of SAP Coated Seeds

2.4. Laboratory Investigations of Coated Seeds

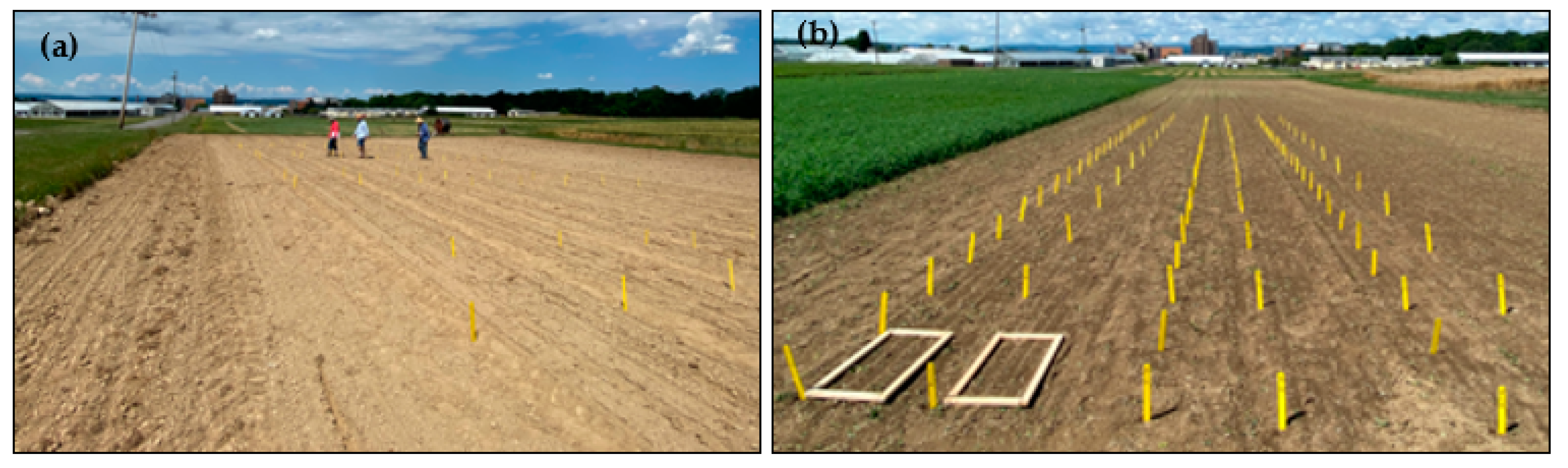

2.5. Field Studies of Coated Seeds

2.6. Statistical Analysis

3. Results and Discussion

3.1. Determination of Water Absorbency of SAP Materials

3.2. Seed Coating Method

3.3. Seed Flowability of the SAP-Coated Seeds

3.4. Laboratory Investigations of Coated Seeds

3.5. Field Studies of Coated Seeds

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Quastel, J.H. ‘Krilium’ and Synthetic Soil Conditioners. Nature 1953, 171, 7–10. [Google Scholar] [CrossRef]

- Mikkelsen, R.L. Using hydrophilic polymers to control nutrient release. Fertil. Res. 1994, 38, 53–59. [Google Scholar] [CrossRef]

- Vundavalli, R.; Vundavalli, S.; Nakka, M.; Rao, D.S. Biodegradable nano-hydrogels in agricultural farming-alternative source for water resources. Proc. Mater. Sci. 2015, 10, 548–554. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, H.; Huang, L.; Zhang, S.; He, Y.; Gao, Q.; Ye, Q. Effects of Superabsorbent Polymers on the Fate of Fungicidal Carbendazim in Soils. J. Hazard. Mater. 2017, 328, 70–79. [Google Scholar] [CrossRef]

- Nimah, M.; Ryan, J.; Chaudhry, M. Effect of Synthetic Conditioners on soil water retention, hydraulic conductivity, porosity, and aggregation. Soil Sci. Soc. Am. J. 1983, 47, 742–745. [Google Scholar] [CrossRef]

- El-Rehim, H.A.; Hegazy, E.-S.A.; El-Mohdy, H.L. Radiation synthesis of hydrogels to enhance sandy soils water retention and increase plant performance. J. Appl. Polym. Sci. 2004, 93, 1360–1371. [Google Scholar] [CrossRef]

- Agaba, H.; Orikiriza, L.J.B.; Esegu, J.F.O.; Obua, J.; Kabasa, J.D.; Hüttermann, A. Effects of hydrogel amendment to different soils on plant available water and survival of trees under drought conditions. Clean Soil Air Water 2010, 38, 328–335. [Google Scholar] [CrossRef]

- Tsujimoto, T.; Sato, H.; Matsushita, S. Hydration of Seeds with Partially Hydrated Superabsorbent Polymer Particles. U.S. Patent 5,930,949, 3 August 1999. [Google Scholar]

- Leinauer, B.; Serena, M.; Singh, D. Seed coating and seeding rate effects on turfgrass germination and establishment. HortTech 2010, 20, 179–185. [Google Scholar] [CrossRef]

- Berdahl, J.D.; Barker, R.E. Germination and emergence of Russian wildrye seeds coated with hydrophilic materials. Agron. J. 1980, 72, 1006–1008. [Google Scholar] [CrossRef]

- Baxter, L.; Waters, L.J.R. Effect of a hydrophilic polymer seed coating on the imbibition respiration and germination of sweet corn at four matric potentials. J. Am. Soc. Hortic. Sci. 1986, 111, 517–520. [Google Scholar] [CrossRef]

- Chen, H.W.; Jiang, S.T.; Zhou, J.Q.; Zhao, Y.Y.; Wang, J.H. Superabsorbent polymer seed coating and its effect on physiological features of corn seed. J. Hefei Univ. Technol. Nat. Sci. 2004, 27, 242–246. [Google Scholar]

- Su, L.Q.; Li, J.G.; Xue, H.; Wang, X.F. Superabsorbent polymer seed coatings promote seed germination and seedling growth of Caragana korshinskii in drought. J. Zhejiang Univ. Sci. B 2017, 18, 696–706. [Google Scholar] [CrossRef]

- Gorim, L.; Asch, F. Seed Coating with Hydro-Absorbers as Potential Mitigation of Early Season Drought in Sorghum (Sorghum bicolor L. Moench). Biology 2017, 6, 33. [Google Scholar] [CrossRef]

- Amirkhani, M.; Salon, P.; Barrow, M.; Taylor, A.G. Hydrophilic seed coating to enhance stand establishment under drought stress. In Proceedings of the 12th Triennial Conference of International Society for Seed Science, Monterey, CA, USA, 10–14 September 2017. [Google Scholar]

- Amirkhani, M.; Mayton, H.; Taylor, A.G. Seed Coating with Superabsorbent Polymers as an Alternative to Mitigate Transient Drought Stress on Cover Crop during Seedling Establishment; ASHS: Denver, CO, USA, 2021; Available online: https://ashs.confex.com/ashs/2021/meetingapp.cgi/Paper/34964 (accessed on 20 October 2021).

- Afzal, I.; Javed, T.; Amirkhani, M.; Taylor, A.G. Modern seed technology: Seed coating delivery systems for enhancing seed and crop performance. Agriculture 2020, 10, 526. [Google Scholar] [CrossRef]

- Curran, W.S.; Hoover, R.J.; Mirsky, S.B.; Roth, G.W.; Ryan, M.R.; Ackroyd, V.J.; Wallace, J.M.; Dempsey, M.A.; Pelzer, C.J. Evaluation of cover crops drill interseeded into corn across the Mid-Atlantic region. Agron. J. 2018, 110, 435–443. [Google Scholar] [CrossRef]

- Long, E.; Ketterings, Q.; Czymmek, K. Survey of cover crop use on New York dairy farms. Crop Manag. 2013, 12, 1–5. [Google Scholar] [CrossRef]

- Wilson, M.L.; Allan, D.L.; Baker, J.M. Aerially seeding cover crops in the northern US Corn Belt: Limitations, future research needs, and alternative practices. J. Soil Water Conserv. 2014, 69, 67A–72A. [Google Scholar] [CrossRef]

- Qiu, Y.; Amirkhani, M.; Mayton, H.; Chen, Z.; Taylor, A.G. Biostimulant seed coating treatments to improve cover crop germination and seedling growth. Agronomy 2020, 10, 154. [Google Scholar] [CrossRef]

- Centor Oceania Seed Improvement Technologies. Measure Seed Flow. Seed Analytical Equipment. Lab FlowTek. Available online: https://www.centoroceania.com/_files/ugd/99a2ca_78bd07f2f6324d13aa1ae1b53bb8c609.pdf (accessed on 4 October 2022).

- Halecky, A.; Ren, N.; Lu, J.; Wang, J.Q.; Lockwood, F.E. Correlation of the Mechanical Properties of Seed Coating Films and Dust-Off, Flowability, and Plantability Tests. In Pesticide Formulation and Delivery Systems: 36th Volume, Emerging Trends Building on a Solid Foundation; ASTM Special Technical Publication STP 1595; ASTM International: West Conshohocken, PA, USA, 2016; pp. 183–201. [Google Scholar] [CrossRef]

- Summary of Polymer Seed Coating and Soil Amendment Evaluation Studies. Available online: https://www.nrcs.usda.gov/Internet/FSE_PLANTMATERIALS/publications/idpmcar9313.pdf (accessed on 7 April 2022).

- Taylor, A.G.; (Cornell University, Geneva, NY, USA); Mitra, B.; (Evonik Corporation, 2401 Doyle Street, Greensboro, NC, USA). Personal communication, 2021.

- Timson, J. New method of recording germination data. Nature 1965, 207, 216–217. [Google Scholar] [CrossRef]

- JMP®, Version 14. SAS Institute Inc.: Cary, NC, USA, 1989–2021. Available online: https://www.jmp.com/en_us/home.html (accessed on 1 November 2020).

- Reena, B.; Kumar, M.U. Studies on water absorbency of polyacrylamide hydrogels. J. Mater. Sci. Eng. B 2015, 5, 399–405. [Google Scholar] [CrossRef] [Green Version]

- United Phosphorus, Ltd. (UPL). A Comparison of Superabsorbent Polymers. Available online: https://www.upl-ltd.com/solutions/soil-and-water-technologies (accessed on 15 April 2022).

- United Phosphorus, Ltd. (UPL). About Water Conservation. Available online: https://www.upl-ltd.com/in/crop-protection/water-conservation/zeba (accessed on 10 October 2022).

- Taylor, A.G.; (Cornell University, Geneva, NY, USA); McPherson, M.; (Evonik Corporation, 2401 Doyle Street, Greensboro, NC, USA). Personal communication, 2022.

- Pawlicki, A.A.; Borodinov, N.; Giri, N.; Moore, S.; Brown, C.; Belianinov, A.; Ievlev, A.V.; Olga, S.; Ovchinnikova, O.S. Multimodal chemical imaging for linking adhesion with local chemistry in agrochemical multicomponent polymeric coatings. Anal. Chem. 2019, 91, 2791–2796. [Google Scholar] [CrossRef] [PubMed]

- Tao, J.; Zhang, W.; Liang, L.; Lei, Z. Effects of eco-friendly carbohydrate-based superabsorbent polymers on seed germination and seedling growth of maize. R. Soc. Open Sci. 2018, 5, 171184. [Google Scholar] [CrossRef] [PubMed]

- Baxter, L.; Waters, L.J.R. Effect of a hydrophilic polymer seed coating on the field performance of sweet corn Zea mays and cowpea Vigna unguiculata. J. Am. Soc. Hortic. Sci. 1986, 111, 31–34. [Google Scholar] [CrossRef]

| Treatment | Component | Company and Location | |

|---|---|---|---|

| 1 | CONTROL | ||

| 2 | 0% * SAP | ||

| 3 | 2% SAP (Stockosorb-90AC) (PAL) | Cross-linked potassium polyacrylate | Evonik Corporation 2401 Doyle Street Greensboro, NC |

| 4 | 2% Soil Moist (PAM) | Cross-linked polyacrylamide-based polymer | JRM Chemical Inc. 4881 Neo Parkway, Cleveland, OH |

| 5 | 2% Soil Moist + Graphite (PAM+G) | Cross-linked polyacrylamide-based polymer | JRM Chemical Inc. 4881 Neo Parkway, Cleveland, OH |

| 6 | 2% K-BOOST STARCH (STR) | Starch-g-2-Propenoic acid, potassium salt, polymer | D2 Polymer Technologies Inc. 1539 N Wooster Road Scottsburg, IN |

| Stand Count % | ||||||

|---|---|---|---|---|---|---|

| Trial 1 | Trial 2 | Trial 3 | ||||

| Treatments | B | BR | B | BR | B | BR |

| Control | 6 c | 13 bc | 22 c | 40 c | 56 cd | 70 bc |

| 0% SAP | 7 c | 13 bc | 26 bc | 43 bc | 51 d | 70 bc |

| PAL | 9 bc | 15 B | 30 ab | 44 bc | 65 ab | 76 ab |

| PAM | 6 c | 13 bc | 24 bc | 45 ab | 58 cd | 73 abc |

| PAM+G | 10 ab | 13 bc | 34 a | 47 ab | 62 bc | 79 a |

| STR | 8 bc | 20 a | 24 bc | 52 a | 67 ab | 79 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amirkhani, M.; Mayton, H.; Loos, M.; Taylor, A. Development of Superabsorbent Polymer (SAP) Seed Coating Technology to Enhance Germination and Stand Establishment in Red Clover Cover Crop. Agronomy 2023, 13, 438. https://doi.org/10.3390/agronomy13020438

Amirkhani M, Mayton H, Loos M, Taylor A. Development of Superabsorbent Polymer (SAP) Seed Coating Technology to Enhance Germination and Stand Establishment in Red Clover Cover Crop. Agronomy. 2023; 13(2):438. https://doi.org/10.3390/agronomy13020438

Chicago/Turabian StyleAmirkhani, Masoume, Hilary Mayton, Michael Loos, and Alan Taylor. 2023. "Development of Superabsorbent Polymer (SAP) Seed Coating Technology to Enhance Germination and Stand Establishment in Red Clover Cover Crop" Agronomy 13, no. 2: 438. https://doi.org/10.3390/agronomy13020438

APA StyleAmirkhani, M., Mayton, H., Loos, M., & Taylor, A. (2023). Development of Superabsorbent Polymer (SAP) Seed Coating Technology to Enhance Germination and Stand Establishment in Red Clover Cover Crop. Agronomy, 13(2), 438. https://doi.org/10.3390/agronomy13020438