Evaluation of a Real-Time Monitoring and Management System of Soybean Precision Seed Metering Devices

Abstract

:1. Introduction

2. Materials and Methods

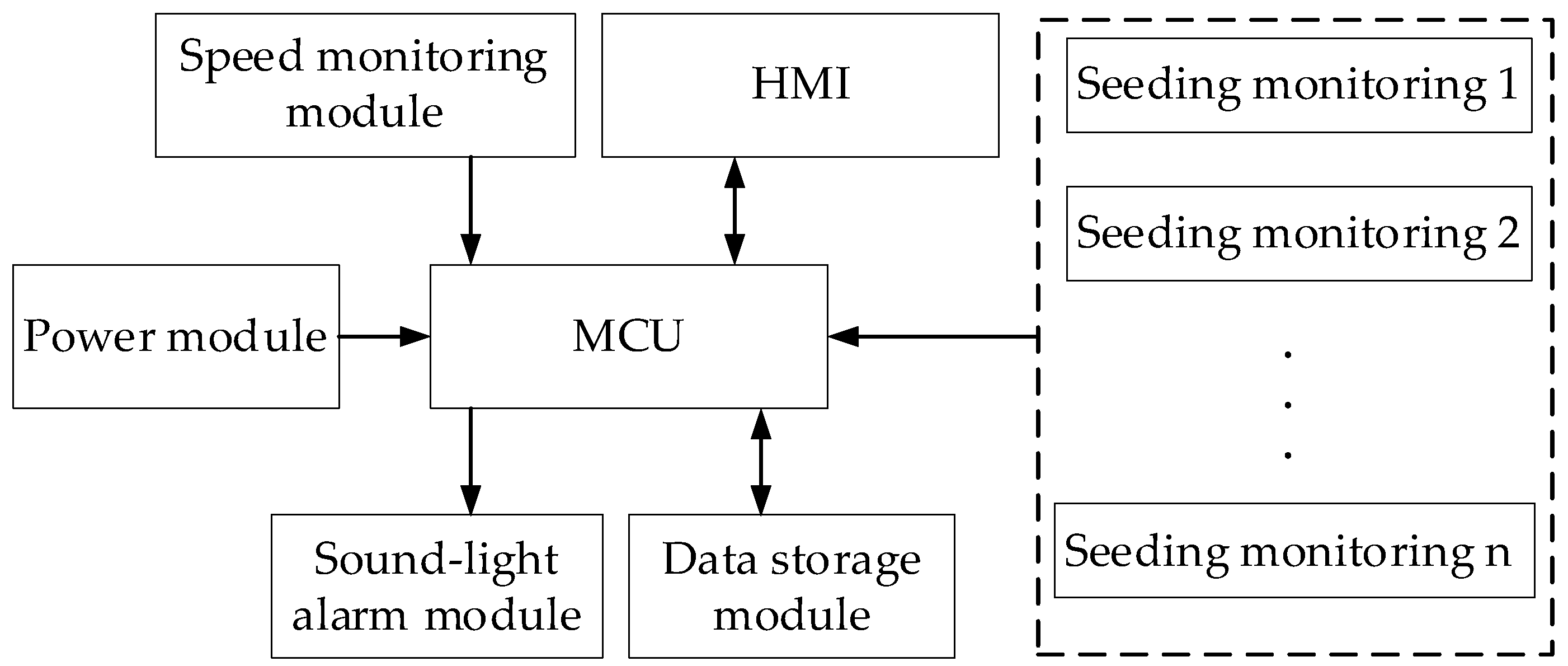

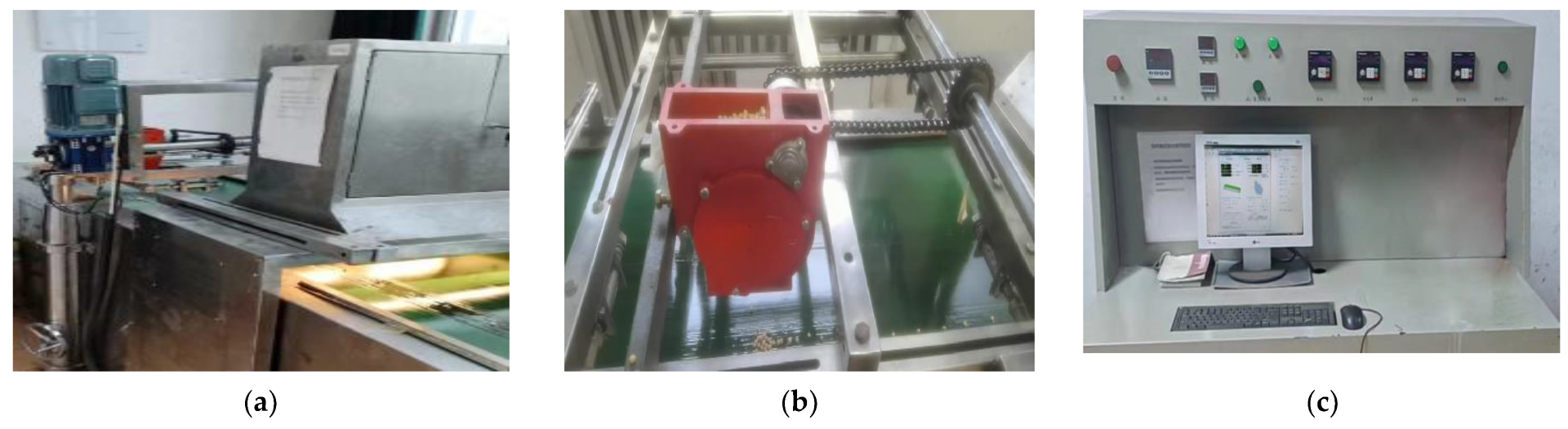

2.1. System Components

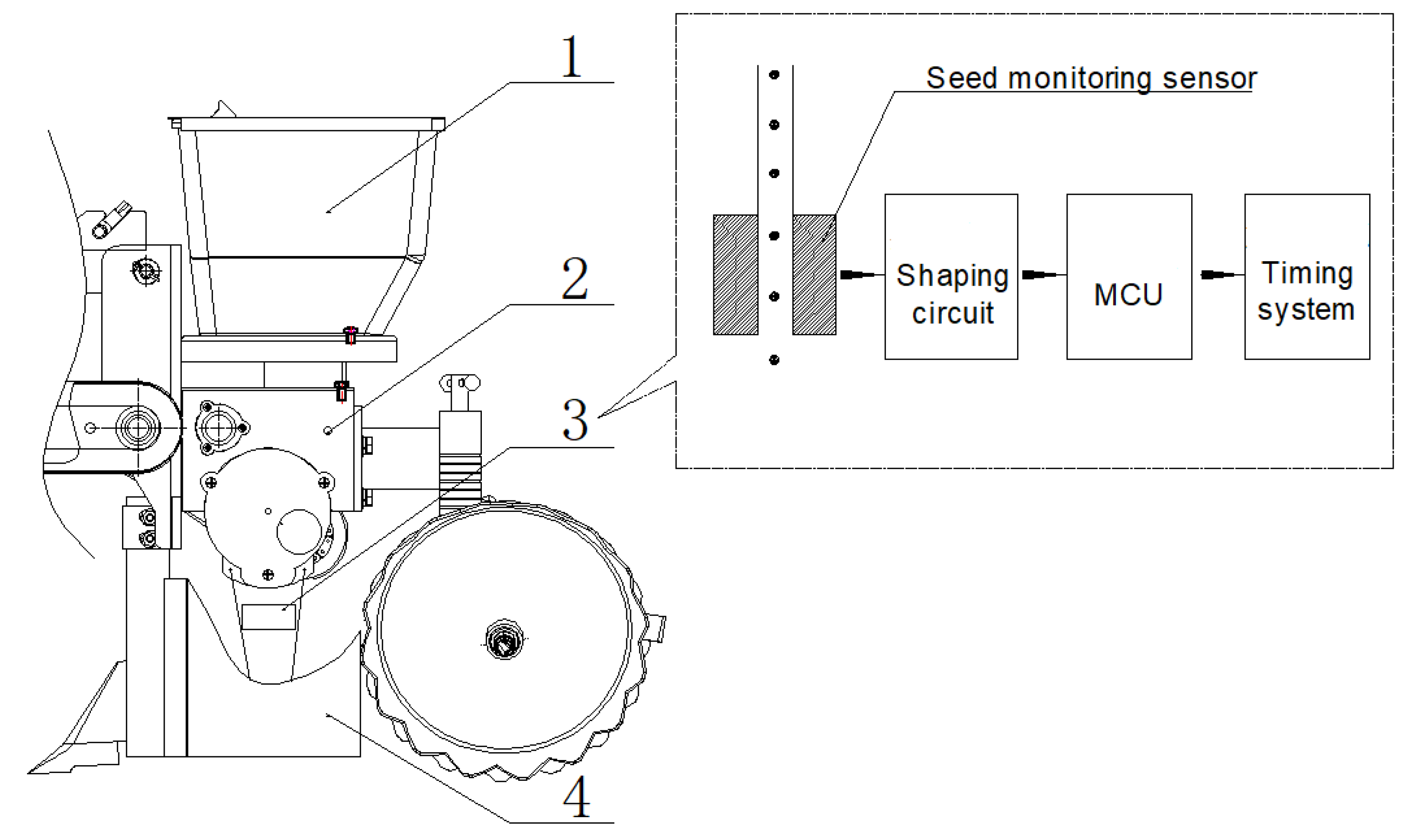

2.2. Working Principle

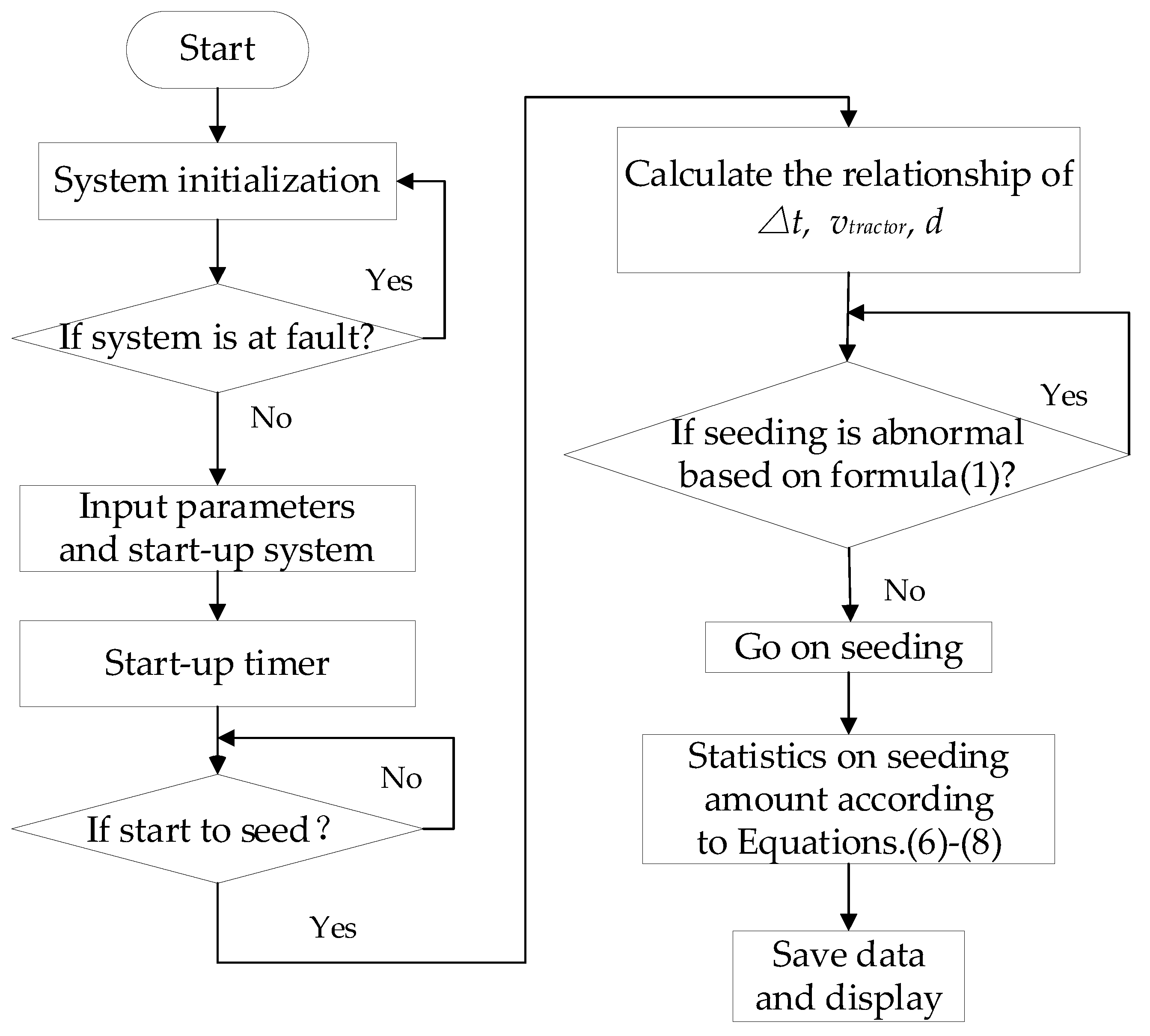

2.3. Software Working Flow Design

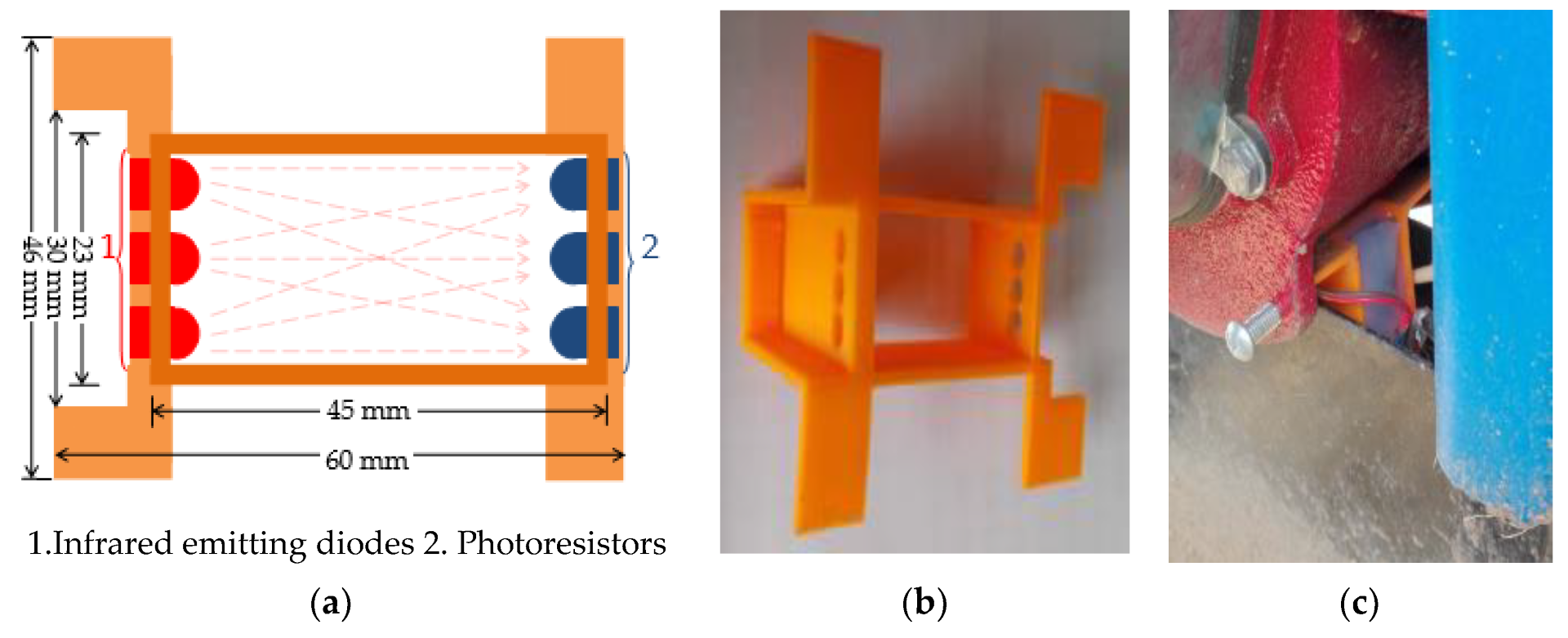

2.4. Seed Metering Monitoring Sensor

3. Results

3.1. Monitoring Test for Sensitivity

3.2. Static Monitoring Test

3.3. Field Dynamic Monitoring Test

4. Conclusions

- (1)

- The seed metering monitoring sensor used three pairs of infrared light-emitting diodes and phototransistors as the emitting and receiving ends of the photoelectric sensor, which could achieve the blind area free monitoring of the soybean seed metering tube. This sensor was simple, practical, and low-cost.

- (2)

- In laboratory tests, the monitoring of soybeans with big and small diameters was basically consistent, and the monitoring errors of seeder quantity was less than 2.0%. The errors of miss and multiples index between monitoring system and SIMP were less than 0.4% and 0.5%, respectively, at three rotation speeds. This demonstrates that this kind of sensors have a good monitoring performance.

- (3)

- This monitoring system can evaluate the precision of the performance of seed metering device in no-tillage machine seeding tests and verify that the big-diameter seeds can be detected more precisely than small ones.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xie, C.; Zhang, D.; Yang, L.; Cui, T.; He, X.; Du, Z. Precision seeding parameter monitoring system based on laser sensor and wireless serial port communication. Comput. Electron. Agric. 2021, 190, 106429. [Google Scholar] [CrossRef]

- Zhang, J.L.; Geng, Y.; Guo, F.; Li, X.G.; Wan, S.B. Research progress on the mechanism of improving peanut yield by single-seed precision sowing. J. Integr. Agric. 2020, 19, 1919–1927. [Google Scholar] [CrossRef]

- Nikolay, Z.; Nikolay, K.; Gao, X.; Li, Q.; Mi, G.; Huang, Y. Design and testing of novel seed miss prevention system for single seed precision metering devices. Comput. Electron. Agric. 2022, 198, 107048. [Google Scholar] [CrossRef]

- Xie, C.; Yang, L.; Zhang, D.; Cui, T.; He, X.; Du, Z.; Xiao, T. A signal output quantity (SOQ) judgment algorithm for improving seeding quantity accuracy. Comput. Electron. Agric. 2022, 201, 107321. [Google Scholar] [CrossRef]

- Kachman, S.D.; Smith, J.A. Alternative measures of mccuracy in plant spacing for planters using single seed metering. Trans. ASAE 1995, 38, 379–387. [Google Scholar] [CrossRef]

- Wang, G.; Sun, W.; Zhang, H.; Liu, X.; Li, H.; Yang, X.; Zhu, L. Research on a kind of seeding-monitoring and compensating control system for potato planter without additional seed-metering channel. Comput. Electron. Agric. 2020, 177, 105681. [Google Scholar] [CrossRef]

- Hou, S.; Zhu, Y.; Zhu, X.; Wang, Y.; Ji, W.; Chen, H. Design and experiment of a straw clearing mulching no-tillage planter. Biosys. Eng. 2022, 221, 69–80. [Google Scholar] [CrossRef]

- Kamgar, S.; Noei-Khodabadi, F.; Shafaei, S.M. Design, development and field assessment of a controlled seed metering unit to be used in grain drills for direct seeding of wheat. Inf. Process. Agric. 2015, 2, 169–176. [Google Scholar] [CrossRef]

- Sharipov, G.M.; Paraforos, D.S.; Pulatov, A.S.; Griepentrog, H.W. Dynamic performance of a no-till seeding assembly. Biosys. Eng. 2017, 158, 64–75. [Google Scholar] [CrossRef]

- Karimi, H.; Navid, H.; Besharati, B.; Behfar, H.; Eskandari, I. A practical approach to comparative design of non-contact sensing techniques for seed flow rate detection. Comput. Electron. Agric. 2017, 142, 165–172. [Google Scholar] [CrossRef]

- Bai, J.; Hao, F.; Cheng, G.; Li, C. Machine vision-based supplemental seeding device for plug seedling of sweet corn. Comput. Electron. Agric. 2021, 188, 106345. [Google Scholar] [CrossRef]

- Xie, C.; Yang, L.; Zhang, D.; Cui, T.; Zhang, K.; He, X.; Du, Z. Design of smart seed sensor based on microwave detection method and signal calculation model. Comput. Electron. Agric. 2022, 199, 107178. [Google Scholar] [CrossRef]

- Besharati, B.; Navid, H.; Karimi, H.; Behfar, H.; Eskandari, I. Development of an infrared seed-sensing system to estimate flow rates based on physical properties of seeds. Comput. Electron. Agric. 2019, 162, 874–881. [Google Scholar] [CrossRef]

- Bao, J.; Xie, Q. Artificial intelligence in animal farming: A systematic literature review. J. Clean. Prod. 2022, 331, 129956. [Google Scholar] [CrossRef]

- Hao, X.Z.; He, X.P.; Zhou, Y.; Li, X.; He, R.Y. Research on the sowing performance monitoring system for precision seeders based on photoelectric senso. J. South China Agric. Univ. 2017, 38, 120–124. (In Chinese) [Google Scholar]

- Zhang, J.C.; Chen, H.T.; Ouyang, B.L.; Ji, W.Y. Monitoring system for precision seeders based on a photosensitive sensor. J. Tsinghua Univ. (Sci. Technol.) 2013, 53, 265–268. (In Chinese) [Google Scholar]

- Wu, C.; Li, D.; Zhang, X.; Pan, J.; Quan, L.; Yang, L.; Yang, W.; Ma, Q.; Su, C.; Zhai, W. China’s agricultural machinery operation big data system. Comput. Electron. Agric. 2023, 205, 107594. [Google Scholar] [CrossRef]

- Du, R.C.; Gong, B.C.; Liu, N.N.; Wang, C.; Yang, Z.; Ma, M. Design and experiment on intelligent fuzzy monitoring system for corn planters. Int. J. Agric. Biol. Eng. 2013, 6, 11–18. [Google Scholar]

- Zhao, B.; Kuang, L.H.; Zhang, W. Seed and fertilizer intelligent gauging and monitoring system of suction precision seeder. Trans. CSAE 2010, 26, 147–153. (In Chinese) [Google Scholar]

- Karimi, H.; Navid, H.; Besharati, B.; Eskandari, I. Assessing an infrared-based seed drill monitoring system under field operating conditions. Comput. Electron. Agric. 2019, 162, 543–551. [Google Scholar] [CrossRef]

- Yu, H.; Ding, Y.; Fu, X.; Liu, H.; Jin, M.; Yang, C.; Liu, Z.; Sun, G.; Dou, X. A solid fertilizer and seed application rate measuring system for a seed-fertilizer drill machine. Comput. Electron. Agric. 2019, 162, 836–844. [Google Scholar] [CrossRef]

- Yazgi, A.; Degirmencioglu, A. Measurement of seed spacing uniformity performance of a precision metering unit as function of the number of holes on vacuum plate. Measurement 2014, 56, 128–135. [Google Scholar] [CrossRef]

- Mellet, D.S.; du Plessis, M.D. A novel CMOS Hall effect sensor. Sens. Actuators A Phys. 2014, 211, 60–66. [Google Scholar] [CrossRef]

- Banjevic, M.; Furrer, B.; Blagojevic, M.; Popovic, R.S. High-speed CMOS magnetic angle sensor based on miniaturized circular vertical Hall devices. Sens. Actuators A Phys. 2012, 178, 64–75. [Google Scholar] [CrossRef]

- Zhai, J.B.; Xia, J.F.; Zhou, Y.; Zhang, S. Design and experimental study of the control system for precision seed-metering device. Int. J. Agric. Biol. Eng. 2014, 7, 13–18. [Google Scholar]

- Qi, J.T.; Jia, H.L.; Yang, L.; Yu, H.B.; Liu, X.H.; Lan, Y.B.; Feng, X.Z.; Yang, Y.X. Design and test of fault monitoring system for corn precision planter. Int. J. Agric. Biol. Eng. 2015, 8, 13–19. [Google Scholar]

- Sun, X.; Li, H.; Qi, X.; Nyambura, S.M.; Yin, J.; Ma, Y.; Wang, J. Performance parameters optimization of a three-row pneumatic precision metering device for brassica chinensis. Agronomy 2022, 12, 1011. [Google Scholar] [CrossRef]

- St. Jack, D.; Hesterman, D.C.; Guzzomi, A.L. Precision metering of Santalum spicatum (Australian Sandalwood) seeds. Biosys. Eng. 2013, 115, 171–183. [Google Scholar] [CrossRef]

- Jin, M.F.; Ding, Y.Q.; Yu, H.F.; Liu, H.T.; Jiang, Y.Z.; Fu, X.Q. Optimal structure design and performance tests of seed metering device with fluted rollers for precision wheat seeding machine. IFAC-PapersOnLine 2018, 51, 509–514. [Google Scholar]

- Siponen, M.; Seilonen, I.; Brodie, S.; Oksanen, T. Next generation task controller for agricultural machinery using OPC unified architecture. Comput. Electron. Agric. 2022, 203, 107475. [Google Scholar] [CrossRef]

- Abdolahzare, Z.; Mehdizadeh, S.A. Real time laboratory and field monitoring of the effect of the operational parameters on seed falling speed and trajectory of pneumatic planter. Comput. Electron. Agric. 2018, 145, 187–198. [Google Scholar] [CrossRef]

| Items | Small Seeds | Big Seeds | ||||

|---|---|---|---|---|---|---|

| Sensor 1 | Sensor 2 | Sensor 3 | Sensor 4 | Sensor 5 | Sensor 6 | |

| Seeds quantity monitored/grain | 11,473 | 11,553 | 11,472 | 11,432 | 11,519 | 11,000 |

| Seeds weight/g | 2540.00 | 2560.12 | 2539.24 | 2536.13 | 2561.63 | 3062.85 |

| Seeds quantity calculated/grain | 11,660 | 11,753 | 11,657 | 11,642 | 11,760 | 10,829 |

| Error/% | 1.6 | 1.7 | 1.6 | 1.8 | 2.0 | 1.6 |

| Speed/m·s−1 | Disk Rotation Rate/r·min−1 | Miss Index/% | Multiples Index/% | Flow Rate/Grain·s−1 | Application Rate/Grain·m−2 | ||||

|---|---|---|---|---|---|---|---|---|---|

| SIMP | Monitor System | Error | SIMP | Monitor System | Error | ||||

| 0.50 | 9.00 | 1.20 | 1.10 | 0.10 | 2.30 | 2.10 | 0.20 | 28.31 ± 2.40 | 16.18 |

| 1.00 | 18.00 | 1.80 | 1.60 | 0.20 | 3.10 | 2.80 | 0.30 | 56.26 ± 5.52 | 16.07 |

| 1.50 | 27.00 | 2.50 | 2.10 | 0.40 | 4.40 | 3.90 | 0.50 | 85.17 ± 6.82 | 16.22 |

| Gear No. | Planting Space/cm | Small Diameter (2016) | Big Diameter (2019) | ||

|---|---|---|---|---|---|

| Sowing Rate/Grain·s−1 | Application Rate/Grain·m−2 | Sowing Rate/Grain·s−1 | Application Rate/Grain·m−2 | ||

| I | 5.0 | 160.43 | 32.29 | 172.2 | 32.84 |

| II | 8.0 | 100.58 | 20.24 | 109.18 | 20.82 |

| III | 10.0 | 80.73 | 16.25 | 85.48 | 16.30 |

| Gear No. | Small Diameter (2016) | Big Diameter (2019) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Miss | Multi Ples | Blockage | Quantity/Grain | Miss Index/% | Multiples Index/% | Miss | Multi Ples | Blockage | Quantity/Grain | Miss Index/% | Multiples Index/% | |

| I | 1986 | 2134 | 5 | 63,650 | 3.12 | 3.36 | 1590 | 1794 | 4 | 52,360 | 3.04 | 3.42 |

| II | 1846 | 1952 | 5 | 63,210 | 2.92 | 3.09 | 1443 | 1726 | 2 | 53,009 | 2.72 | 3.26 |

| III | 1583 | 1722 | 6 | 63,300 | 2.50 | 2.72 | 1237 | 1546 | 3 | 54,132 | 2.29 | 2.86 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Hou, Y.; Ji, W.; Zheng, P.; Yan, S.; Hou, S.; Cai, C. Evaluation of a Real-Time Monitoring and Management System of Soybean Precision Seed Metering Devices. Agronomy 2023, 13, 541. https://doi.org/10.3390/agronomy13020541

Zhang J, Hou Y, Ji W, Zheng P, Yan S, Hou S, Cai C. Evaluation of a Real-Time Monitoring and Management System of Soybean Precision Seed Metering Devices. Agronomy. 2023; 13(2):541. https://doi.org/10.3390/agronomy13020541

Chicago/Turabian StyleZhang, Jicheng, Yinghui Hou, Wenyi Ji, Ping Zheng, Shichao Yan, Shouyin Hou, and Changqing Cai. 2023. "Evaluation of a Real-Time Monitoring and Management System of Soybean Precision Seed Metering Devices" Agronomy 13, no. 2: 541. https://doi.org/10.3390/agronomy13020541

APA StyleZhang, J., Hou, Y., Ji, W., Zheng, P., Yan, S., Hou, S., & Cai, C. (2023). Evaluation of a Real-Time Monitoring and Management System of Soybean Precision Seed Metering Devices. Agronomy, 13(2), 541. https://doi.org/10.3390/agronomy13020541