Effects of Superphosphate as an Additive on Nutrient Characteristics and NH3, CO2, CH4, and N2O Emissions during Pig Manure Composting

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Design

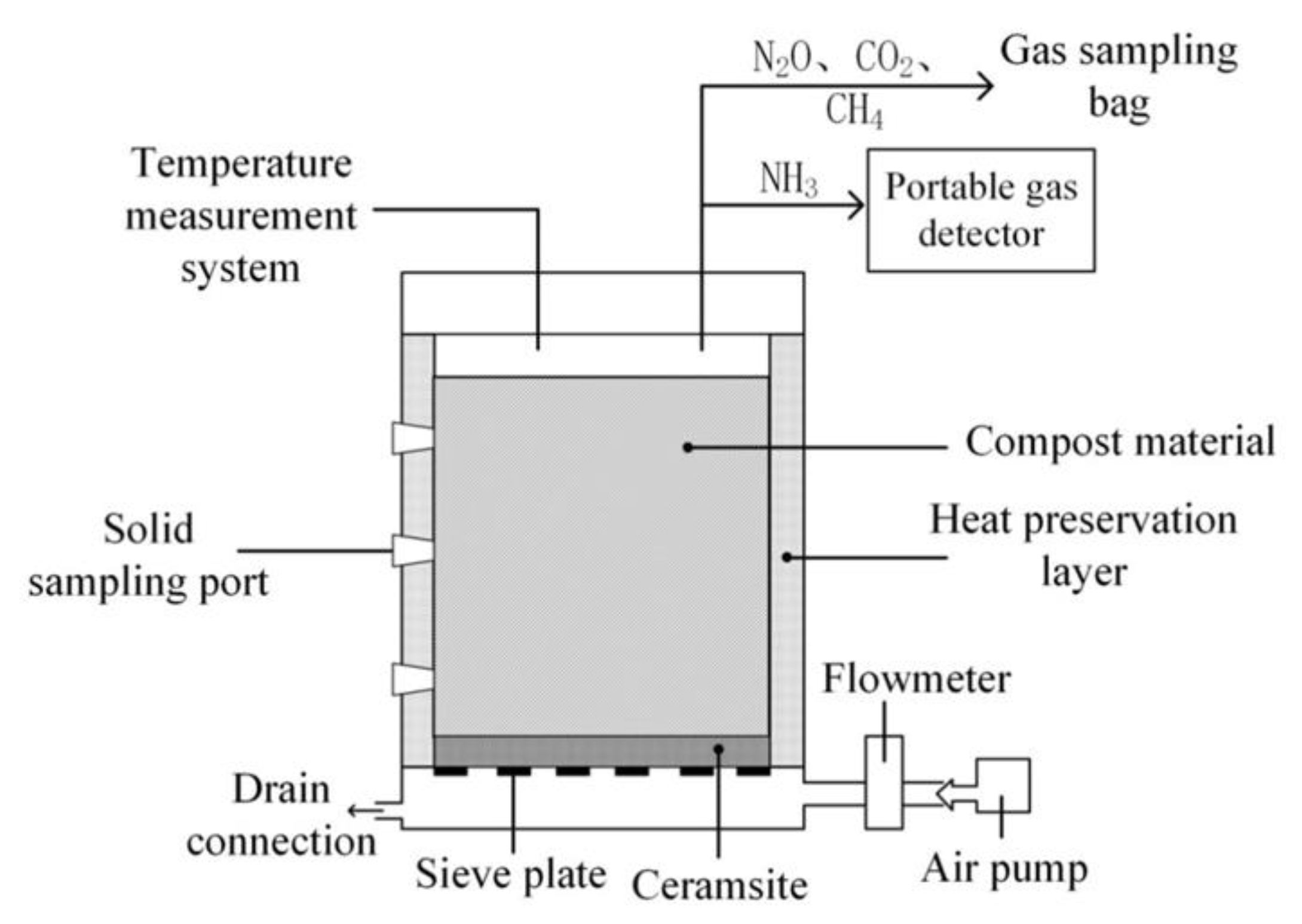

2.2. Composting Device and Implementation

2.3. Sampling and Analyses

2.4. Data Processing and Analysis

3. Results

3.1. Changes in Physicochemical Characteristics during Composting

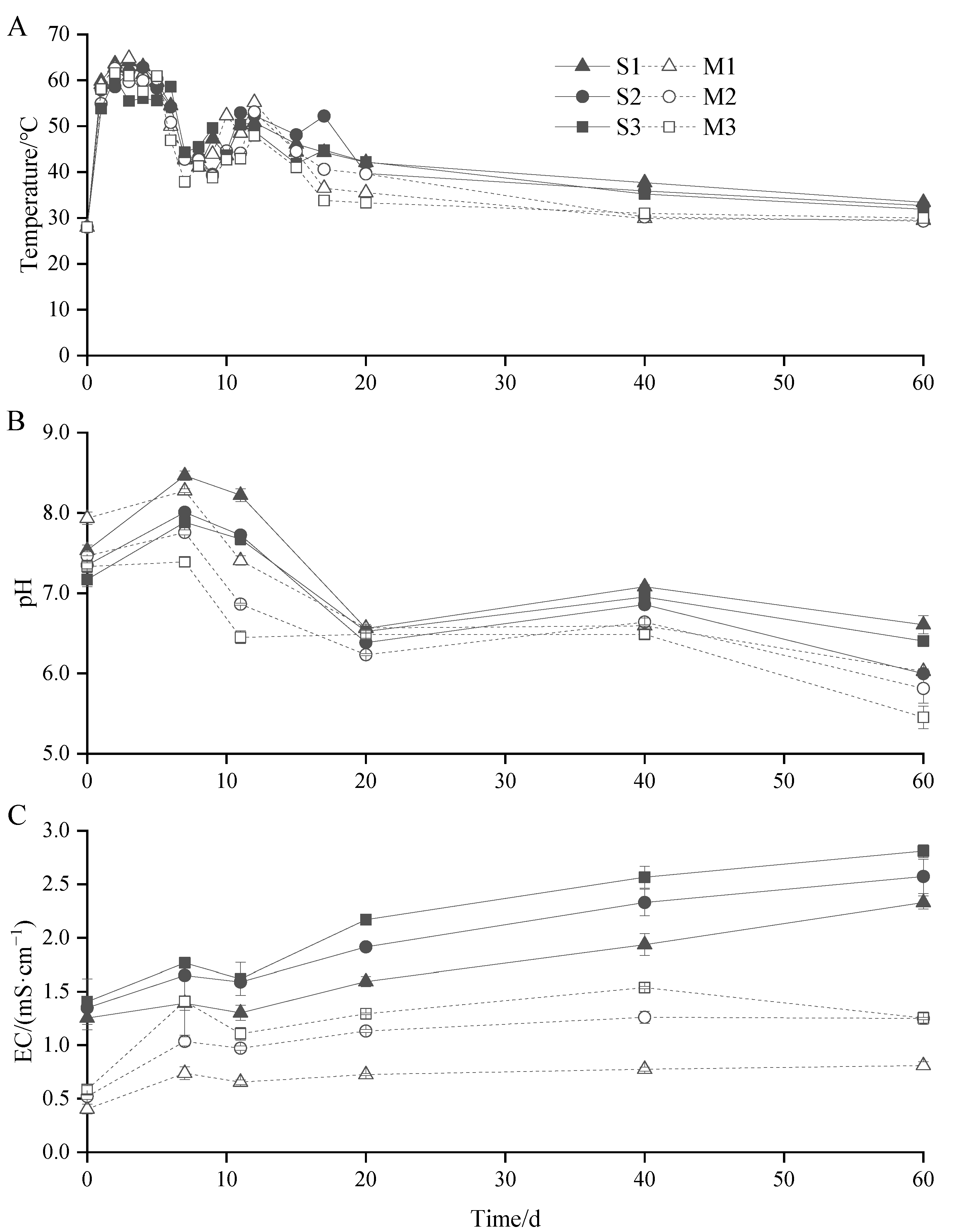

3.1.1. Changes in Temperature, pH, EC

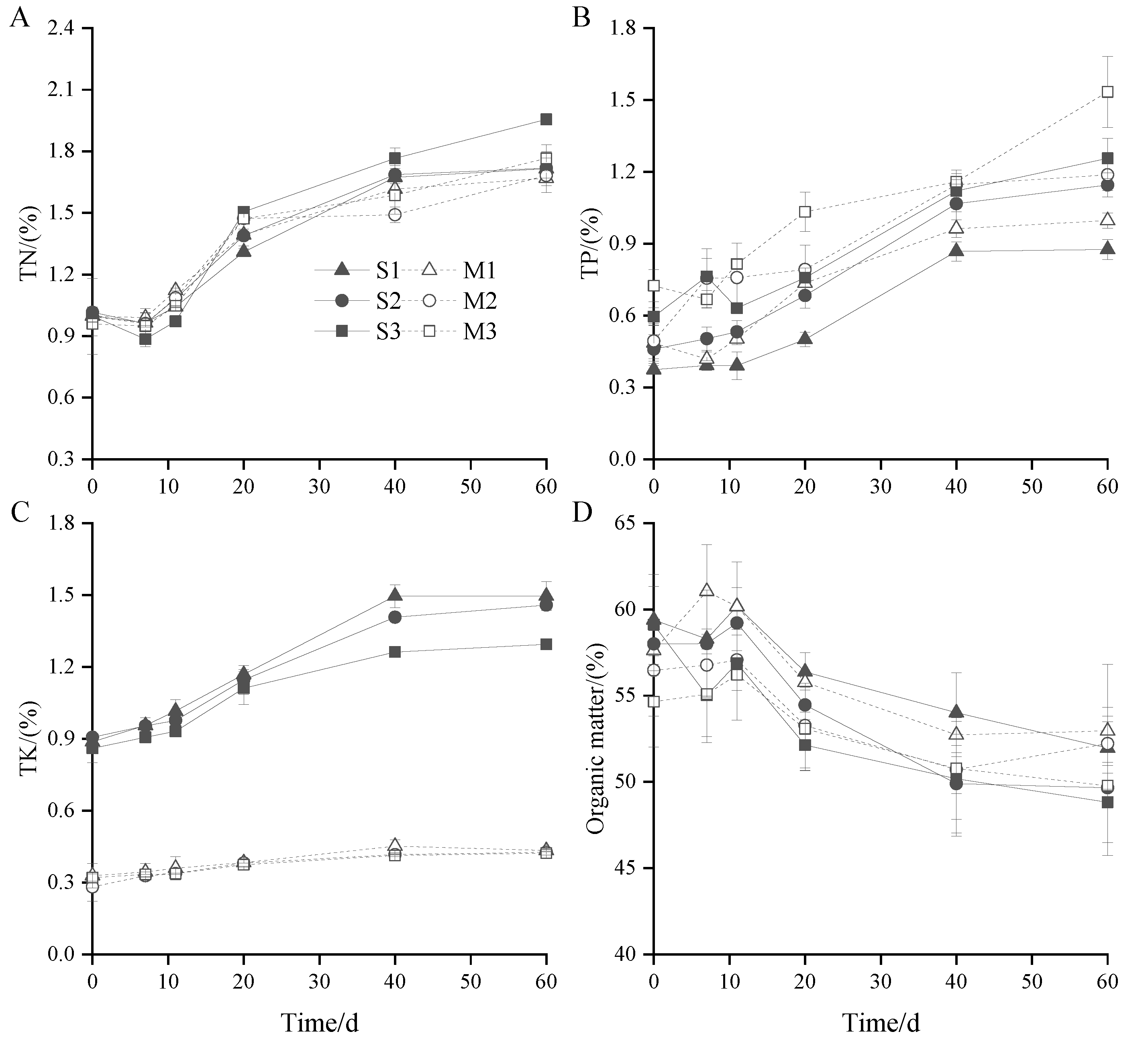

3.1.2. Changes in TN, TP, TK, and Organic Matter

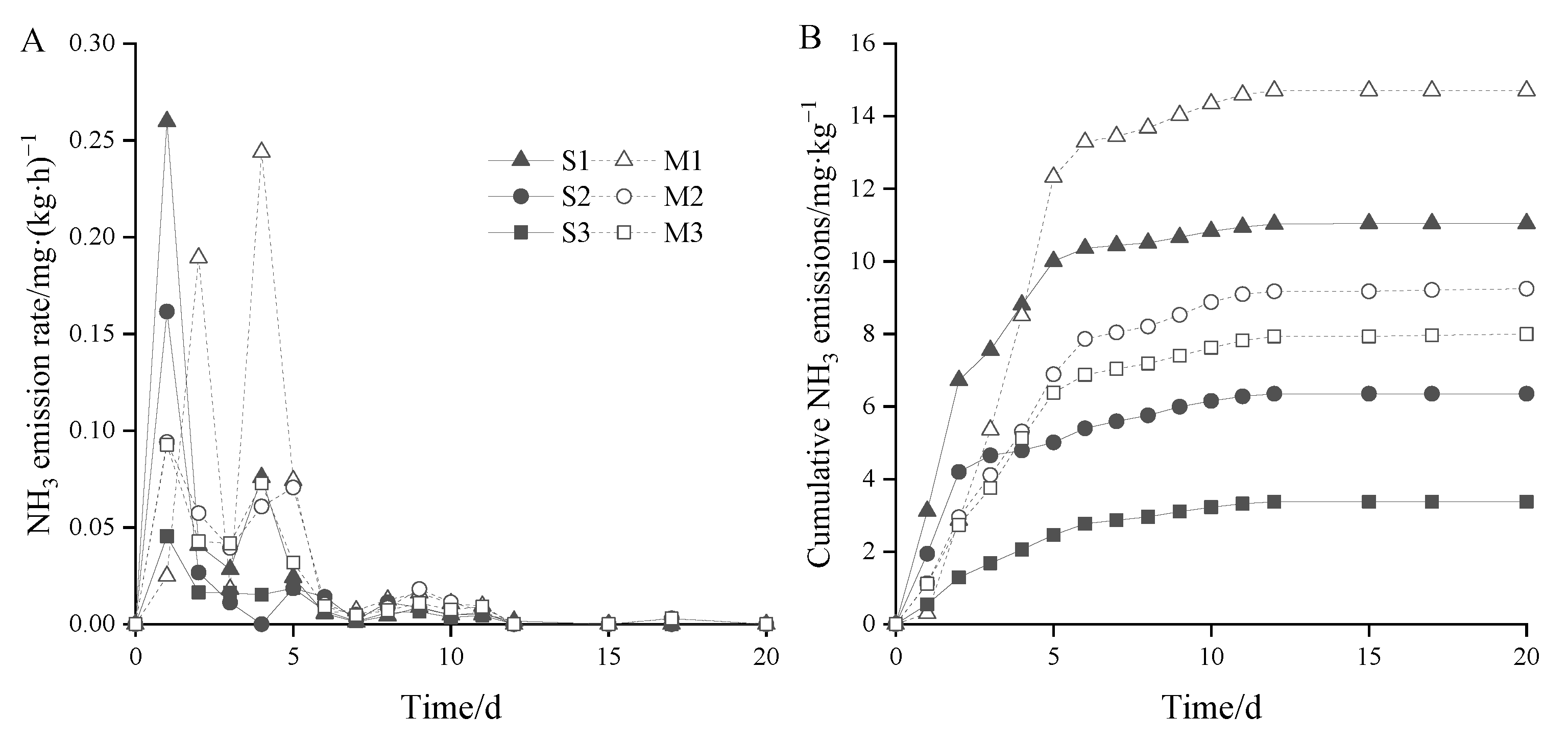

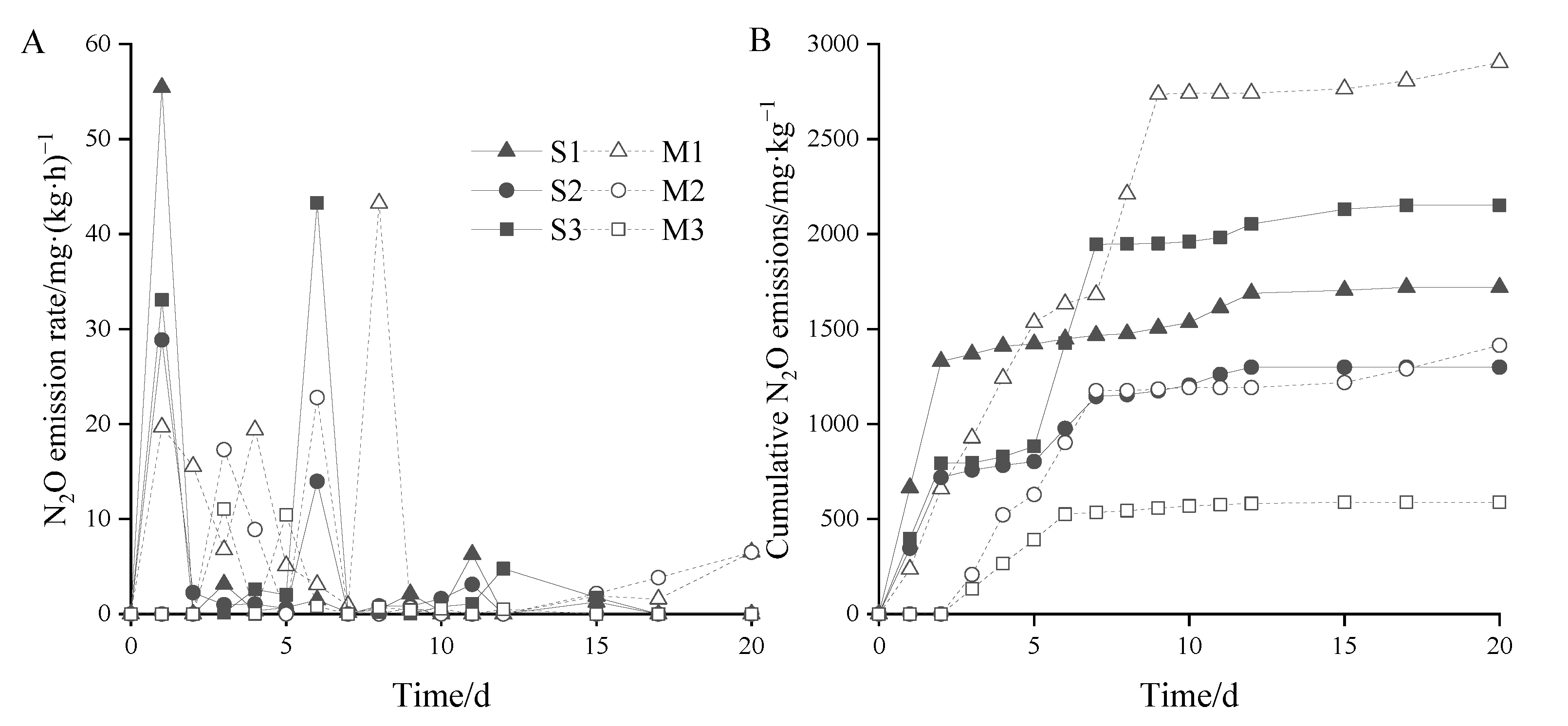

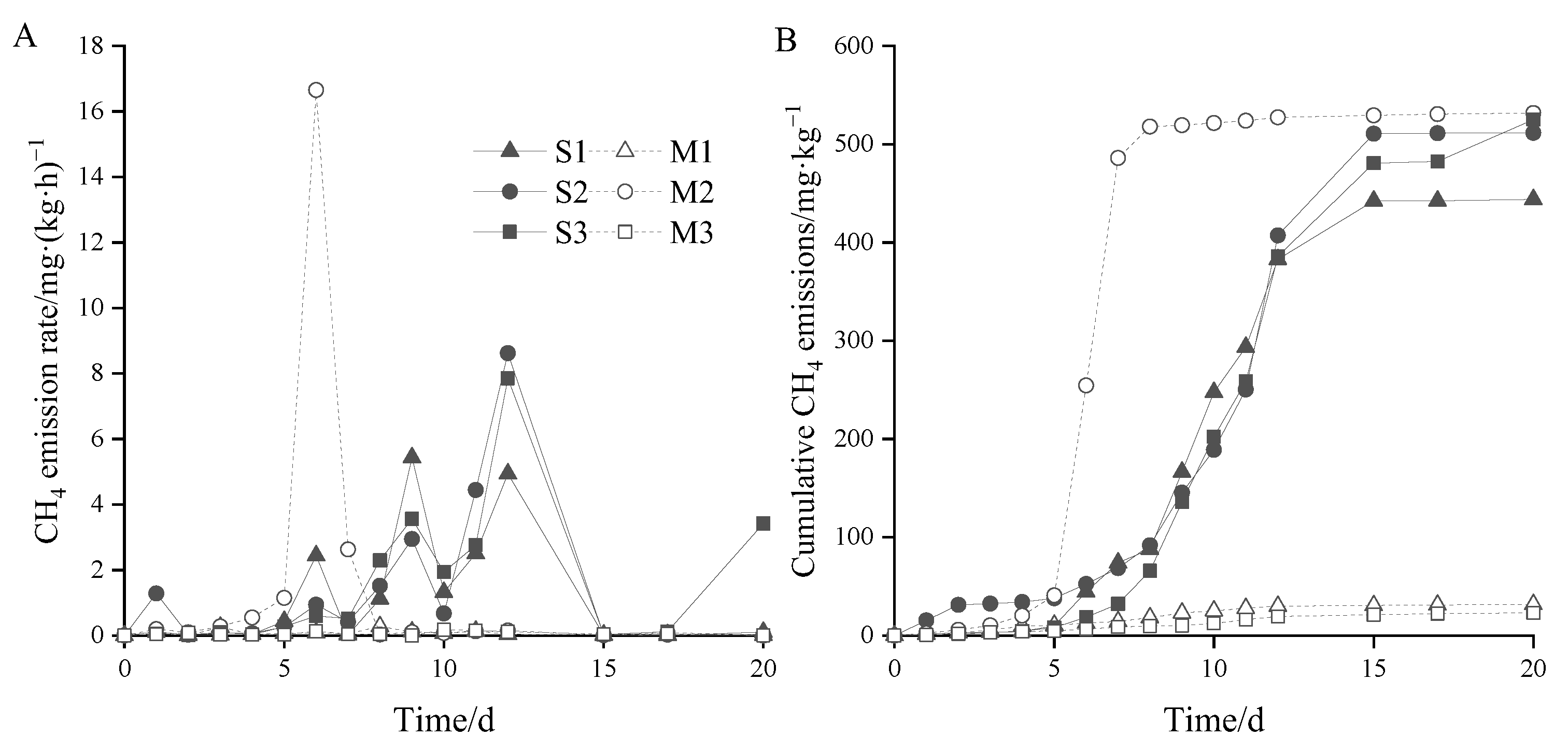

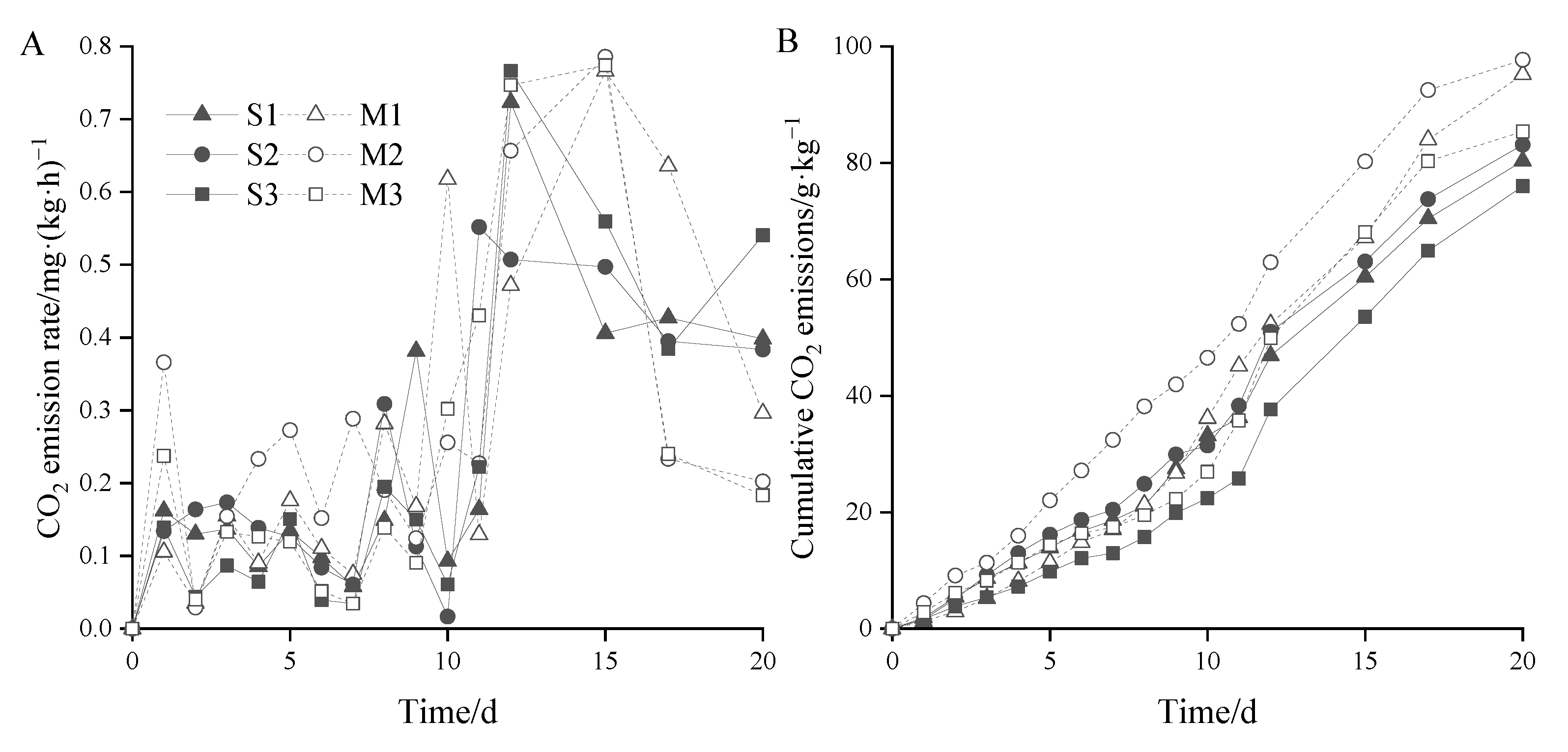

3.2. Characteristics of Gas Emissions during Composting

4. Discussion

4.1. Effects of Superphosphate on the Main Parameters of the Composting Process

4.2. Effects of Superphosphate on Compost Gas Emission

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hu, Z.Z.; Yu, F.W.; Zhao, Z.L. Review of research on utilization of livestock and poultry waste in China. Ecol. Econ. 2019, 35, 186–193. [Google Scholar]

- Rural Social and Economic Survey Division, National Bureau of Statistics. China Rural Statistical Yearbook; China Statistics Press: Beijing, China, 2019.

- Naujokienė, V.; Bagdonienė, I.; Bleizgys, R.; Rubežius, M. A biotreatment effect on dynamics of cattle manure composition and reduction of ammonia emissions from agriculture. Agriculture 2021, 11, 11040303. [Google Scholar] [CrossRef]

- Jain, M.S.; Jambhulkar, R.; Kalamdhad, A.S. Biochar amendment for batch composting of nitrogen rich organic waste: Effect on degradation kinetics, composting physis and nutritional properties. Bioresour. Technol. 2018, 253, 204–213. [Google Scholar] [CrossRef] [PubMed]

- Wojcieszak, D.; Zaborowicz, M.; Przybył, J.; Boniecki, P.; Jedru´s, A. Assessment of the content of dry matter and dry organic matter in compost with neural modelling methods. Agriculture 2021, 11, 11040307. [Google Scholar] [CrossRef]

- Impraim, R.; Weatherley, A.; Coates, T.; Chen, D.L.; Suter, H. Lignite improved the quality of composted manure and mitigated emissions of ammonia and greenhouse gases during forced aeration composting. Sustainability 2020, 12, 10528. [Google Scholar] [CrossRef]

- Gabhane, J.; William, S.P.M.P.; Bidyadhar, R.; Bhilawe, P.; Anand, D.; Vaidya, A.N.; Wate, S.R. Additives aided composting of green waste: Effects on organic matter degradation, compost maturity, and quality of the finished compost. Bioresour. Technol. 2012, 114, 382–388. [Google Scholar] [CrossRef]

- Onwosi, C.O.; Igbokwe, V.C.; Odimba, J.N.; Eke, I.E.; Nwankwoala, M.O.; Iroh, I.N.; Ezeogu, L. Composting technology in waste stabilization: On the methods, challenges and future prospects. J. Environ. Manag. 2017, 190, 140–157. [Google Scholar] [CrossRef]

- Awasthi, M.K.; Duan, Y.; Awasthi, S.K.; Liu, T.; Zhang, Z.Q. Effect of biochar and bacterial inoculum additions on cow dung composting. Bioresour. Technol. 2020, 297, 122407. [Google Scholar] [CrossRef]

- Awasthi, M.K.; Wang, Q.; Huang, H.; Ren, X.N.; Lahori, A.H.; Mahar, A.; Ali, A.; Shen, F.; Li, R.H.; Zhang, Z.Q. Influence of zeolite and lime as additives on greenhouse gas emissions and maturity evolution during sewage sludge composting. Bioresour. Technol. 2016, 216, 172–181. [Google Scholar] [CrossRef]

- Li, Y.B.; Liu, T.T.; Song, J.L.; Lv, J.H.; Jiang, J.S. Effects of chemical additives on emissions of ammonia and greenhouse gas during sewage sludge composting. Process. Saf. Environ. Prot. 2020, 143, 129–137. [Google Scholar] [CrossRef]

- Fukumoto, Y.; Suzuki, K.; Kuroda, K.; Waki, M.; Yasuda, T. Effects of struvite formation and nitratation promotion on nitrogenous emissions such as NH3, N2O and NO during swine manure composting. Bioresour. Technol. 2011, 102, 1468–1474. [Google Scholar] [CrossRef]

- Jiang, T.; Ma, X.; Yang, J.; Tang, Q.; Yi, Z.; Chen, M.; Li, G. Effect of different struvite crystallization methods on gaseous emission and the comprehensive comparison during the composting. Bioresour. Technol. 2016, 217, 219–226. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Luo, W.; Yuan, J.; Li, G.; Luo, Y. Effects of woody peat and superphosphate on compost maturity and gaseous emissions during pig manure composting. Waste Manag. 2017, 68, 56–63. [Google Scholar] [CrossRef] [PubMed]

- Cao, J.; Li, R.; Qu, H.; Wang, P.; Fu, J.; Chen, M.; Chen, Y. Effects of the membrane-covered technology and superphosphate on the compost quality and nitrogencontaining gas emissions during aerobic composting. BioResources 2022, 17, 1781–1793. [Google Scholar] [CrossRef]

- Li, Y.; Qiu, H.Z.; Zang, J.B.; Su, Y.Q.; Wei, R.Y.; Cheng, Z.Y. Effects of superphosphate and furfural residue addition on NH3 emissions and nitrogen conversion during the aerobic composting. Chin. J. Environ. Eng. 2021, 15, 3992–4000. [Google Scholar]

- Wu, J.; He, S.Z.; Li, G.X.; Zhao, Z.H.; Wei, Y.Q.; Lin, Z.; Tao, D. Reducing ammonia and greenhouse gas emission with adding high levels of superphosphate fertilizer during composting. Environ. Sci. Pollut. Res. Int. 2019, 26, 30921–30929. [Google Scholar] [CrossRef]

- Jiang, T.; Schuchardt, F.; Li, G.X.; Guo, R.; Zhao, Y.Q. Effect of C/N ratio, aeration rate and moisture content on ammonia and greenhouse gas emission during the composting. J. Environ. Sci. 2011, 23, 1754–1760. [Google Scholar] [CrossRef] [PubMed]

- Luo, W.H.; Yuan, J.; Luo, Y.M.; Li, G.X.; Nghiem, L.D.; Price, W.E. Effects of mixing and covering with mature compost on gaseous emissions during composting. Chemosphere 2014, 117, 14–19. [Google Scholar] [CrossRef]

- Yuan, J.; Li, Y.; Zhang, H.; Zhang, D.; Chadwick, D.; Li, G.; Wang, G.; Chi, M.; Yang, F. Effects of adding bulking agents on the biodrying of kitchen waste and the odor emissions produced. J. Environ. Sci. 2018, 67, 344–355. [Google Scholar] [CrossRef]

- NY 525-2012; Organic Manure. The Ministry of Agriculture of the People’s Republic of China: Beijing, China, 2012.

- NY/T3442-2019; Technical Specification for Composting Livestock and Poultry Manure. Ministry of Agriculture and Rural Affairs of the People’s Republic of China: Beijing, China, 2019.

- Akdeniz, N. A systematic review of biochar use in animal waste composting. Waste Manag. 2019, 88, 291–300. [Google Scholar] [CrossRef]

- Szanto, G.L.; Hamelers, H.V.; Rulkens, W.H.; Veeken, A.H.M. NH3, N2O and CH4 emissions during passively aerated composting of straw-rich pig manure. Bioresour. Technol. 2007, 98, 2659–2670. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Yin, Z.M.; Li, L.Q.; Li, Y.; Liu, Y.; Luo, Y.M.; Li, G.X.; Yuan, J. Effects of dicyandiamide, phosphogypsum and superphosphate on greenhouse gas emissions during pig manure composting. Sci. Total Environ. 2022, 846, 157487. [Google Scholar] [CrossRef] [PubMed]

- Bernal, M.P.; Sommer, S.G.; Chadwick, D.; Chen, Q.; Li, G.X.; Michel, F.C. Current approaches and future trends in compost quality criteria for agronomic, environmental, and human health benefits. Adv. Agron. 2017, 144, 143–233. [Google Scholar]

- Lei, L.S.; Gu, J.; Wang, X.J.; Song, Z.L.; Wang, J.; Yu, J.; Hu, T.; Dai, X.X.; Xie, J.; Zhao, W.Y. Microbial succession and molecular ecological networks response to the addition of superphosphate and phosphogypsum during swine manure composting. J. Environ. Manag. 2021, 279, 111560. [Google Scholar] [CrossRef]

- Voropaev, V.; Alfimova, N.; Nikulin, I.; Nikulicheva, T.; Titenko, A.; Nikulichev, V. Influence of gypsum-containing waste on ammonia binding in animal waste composting. Agriculture 2021, 11, 1153. [Google Scholar] [CrossRef]

- Mei, J.; Li, B.; Su, L.H.; Zhou, X.J.; Duan, E.S. Effects of potassium persulfate on nitrogen loss and microbial community during cow manure and corn straw composting. Bioresour. Technol. 2022, 363, 127919. [Google Scholar] [CrossRef] [PubMed]

- Bernal, M.P.; Alburquerque, J.A.; Moral, R. Composting of animal manures and chemical criteria for compost maturity assessment. A review. Bioresour. Technol. 2009, 100, 5444–5453. [Google Scholar] [CrossRef] [PubMed]

- Kammoun, M.; Ghorbel, I.; Charfeddine, S.; Kamoun, L.; Gargouri-Bouzid, R.; Nouri-Ellouz, O. The positive effect of phosphogypsum-supplemented composts on potato plant growth in the field and tuber yield. J. Environ. Manag. 2017, 200, 475–483. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, D.H.; Qiao, Y.; Li, S.L.; Chen, Y.F.; Hu, C. Mitigation of carbon and nitrogen losses during pig manure composting: A meta-analysis. Sci. Total Environ. 2021, 783, 147103. [Google Scholar] [CrossRef]

- Predotova, M.; Schlecht, E.; Buerkert, A. Nitrogen and carbon losses from dung storage in urban gardens of Niamey, Niger. Nutr. Cycl. Agroecosyst. 2010, 87, 103–114. [Google Scholar] [CrossRef]

- Hu, Y.T.; Shi, L.H.; Liu, D.M.; Tong, S.W.; Wei, M.Y.; Sun, J. Effects of adding sulphuric acid on composting process of cattle manure and changes of main nutrients. J. Plant Nutr. 2014, 20, 718–725. [Google Scholar]

- Bustamante, M.A.; Ceglie, F.G.; Aly, A.; Mihreteab, H.T.; Ciaccia, C.; Tittarelli, F. Phosphorus availability from rock phosphate: Combined effect of green waste composting and sulfur addition. J. Environ. Manag. 2016, 182, 557–563. [Google Scholar] [CrossRef] [PubMed]

- Li, G.X.; Zhang, F.S. Solid Waste Composting and Organic Compound Fertilizer Production; Chemical Industry Press: Beijing, China, 2000. [Google Scholar]

- Walling, E.; Trémier, A.; Vaneeckhaute, C. A review of mathematical models for composting. Waste Manag. 2020, 113, 379–394. [Google Scholar] [CrossRef] [PubMed]

- El-Rahim, M.G.M.A.; Dou, S.; Xin, L.; Xie, S.; Sharaf, A.; Alio Moussa, A.; Eissa, M.A.; Mustafa, A.A.; Ali, G.A.M.; Hamed, M.H. Effect of biochar addition method on ammonia volatilization and quality of chicken manure compost. Zemdirb. Agric. 2021, 108, 331–338. [Google Scholar] [CrossRef]

- Barthod, J.; Rumpel, C.; Dignac, M. Composting with additives to improve organic amendments. A review. Agron. Sustain. Dev. 2018, 38, 1–23. [Google Scholar] [CrossRef]

- Yuan, J.; Li, Y.; Chen, S.L.; Li, D.Y.; Tang, H.; Chadwick, D.; Li, S.Y.; Li, W.W.; Li, G.X. Effects of phosphogypsum, superphosphate, and dicyandiamide on gaseous emission and compost quality during sewage sludge composting. Bioresour. Technol. 2018, 270, 368–376. [Google Scholar] [CrossRef]

- Sarda, L.G.; Higarashi, M.M.; Nicoloso, R.S.; Falkoski, C.; Ribeiro, S.M.S.; Silveira, C.A.P.; Soares, H.M. Effects of dicyandiamide and Mg/P on the global warming potential of swine slurry and sawdust cocomposting. Environ. Sci. Pollut. Res. 2020, 27, 30405–30418. [Google Scholar] [CrossRef]

- Cáceres, R.; Maliãska, K.; Marfà, O. Nitrification within composting: A review. Waste Manag. 2018, 72, 119–137. [Google Scholar] [CrossRef]

- Wang, Q.; Awasthi, M.K.; Ren, X.N.; Zhao, J.C.; Li, R.H.; Wang, Z.; Wang, M.J.; Chen, H.Y.; Zhang, Z.Q. Combining biochar, zeolite and wood vinegar for composting of pig manure: The effect on greenhouse gas emission and nitrogen conservation. Waste Manag. 2018, 74, 221–230. [Google Scholar] [CrossRef]

- Luo, Y.M.; Li, G.X.; Frank, S.; Wang, K.; Jiang, T.; Luo, W.H. Effects of additive superphosphate on NH3, N2O and CH4 emissions during pig manure composting. Trans. Chin. Soc. Agric. Eng. 2012, 28, 235–242. [Google Scholar]

- Yang, Y.; Sun, Q.P.; Li, N.; Liu, C.S.; Li, J.J.; Liu, B.S.; Zou, G.Y. Effects of superphosphate addition on NH3 and greenhouse gas emissions during vegetable waste composting. Agric. Sci. Technol. 2016, 17, 900–905. [Google Scholar]

- Yamulki, S. Effect of straw addition on nitrous oxide and methane emissions from stored farmyard manures. Agric. Ecosyst. Environ. 2006, 112, 140–145. [Google Scholar] [CrossRef]

- Maeda, K.; Toyoda, S.; Philippot, L.; Hattori, S.; Nakajima, K.; Ito, Y.; Yoshida, N. Relative contribution of nirKand nirS-bacterial denitrifiers as well as fungal denitrifiers to nitrous oxide production from dairy manure compost. Environ. Sci. Technol. 2017, 51, 14083–14091. [Google Scholar] [CrossRef] [PubMed]

- Santos, A.; Bustamante, M.A.; Tortosa, G.; Moral, R.; Bernal, M.P. Gaseous emissions and process development during composting of pig slurry: The influence of the proportion of cotton gin waste. J. Clean. Prod. 2016, 112, 81–90. [Google Scholar] [CrossRef]

- Philippe, F.X.; Laitat, M.; Nicks, B.; Cabaraux, J.F. Ammonia and greenhouse gas emissions during the fattening of pigs kept on two types of straw floor. Agric. Ecosyst. Environ. 2012, 150, 45–53. [Google Scholar] [CrossRef]

- Awasthi, M.K.; Wang, M.; Chen, H.; Wang, Q.; Zhao, J.; Ren, X.; Li, D.; Awasthi, S.K.; Shen, F.; Li, R.; et al. Heterogeneity of biochar amendment to improve the carbon and nitrogen sequestration through reduce the greenhouse gases emissions during sewage sludge composting. Bioresour. Technol. 2017, 224, 428–438. [Google Scholar] [CrossRef]

- Caricasole, P.; Provenzano, M.R.; Hatcher, P.G.; Senesi, N. Chemical characteristics of dissolved organic matter during composting of different organic wastes assessed by C-13 CPMAS NMR spectroscopy. Bioresour. Technol. 2010, 101, 8232–8236. [Google Scholar] [CrossRef]

- Zhao, C.Y.; Li, H.M.; Wei, Y.S.; Zhong, J.; Zheng, J.X.; Han, S.H.; Wan, H.F. Effects of turning frequency on emission of greenhouse gas and ammonia during swine manure windrow composting. Environmental 2014, 35, 533–540. [Google Scholar]

- Jiang, J.S.; Huang, Y.M.; Liu, X.L.; Huang, H. The effects of apple pomace, bentonite and calcium superphosphate on swine manure aerobic composting. Waste Manag. 2014, 34, 1595–1602. [Google Scholar] [CrossRef]

| Materials | pH | TN/(%) | TP/(%) | TK/(%) | TOC/(%) |

|---|---|---|---|---|---|

| Pig manure | 7.93 ± 0.08 | 1.00 ± 0.00 | 0.49 ± 0.08 | 0.33 ± 0.05 | 57.61 ± 1.17 |

| Straw | 6.71 ± 0.07 | 0.83 ± 0.05 | 0.39 ± 0.06 | 1.00 ± 0.04 | 61.03 ± 2.17 |

| Treatment | N2O | CH4 | CO2 | Total |

|---|---|---|---|---|

| S1 | 512.19 | 11.10 | 80.34 | 603.63 |

| M1 | 865.00 | 0.80 | 95.19 | 960.98 |

| S2 | 387.02 | 12.79 | 83.12 | 482.93 |

| M2 | 421.35 | 13.29 | 97.71 | 532.35 |

| S3 | 641.06 | 13.13 | 76.01 | 730.20 |

| M3 | 175.17 | 0.58 | 85.39 | 261.14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, Y.; Chang, H.; Song, P. Effects of Superphosphate as an Additive on Nutrient Characteristics and NH3, CO2, CH4, and N2O Emissions during Pig Manure Composting. Agronomy 2023, 13, 560. https://doi.org/10.3390/agronomy13020560

Pan Y, Chang H, Song P. Effects of Superphosphate as an Additive on Nutrient Characteristics and NH3, CO2, CH4, and N2O Emissions during Pig Manure Composting. Agronomy. 2023; 13(2):560. https://doi.org/10.3390/agronomy13020560

Chicago/Turabian StylePan, Yajie, Huiqing Chang, and Panpan Song. 2023. "Effects of Superphosphate as an Additive on Nutrient Characteristics and NH3, CO2, CH4, and N2O Emissions during Pig Manure Composting" Agronomy 13, no. 2: 560. https://doi.org/10.3390/agronomy13020560

APA StylePan, Y., Chang, H., & Song, P. (2023). Effects of Superphosphate as an Additive on Nutrient Characteristics and NH3, CO2, CH4, and N2O Emissions during Pig Manure Composting. Agronomy, 13(2), 560. https://doi.org/10.3390/agronomy13020560