Dynamic Optimization of Greenhouse Tomato Irrigation Schedule Based on Water, Fertilizer and Air Coupled Production Function

Abstract

:1. Introduction

2. Materials and Methods

2.1. Overview of the Study Area

2.2. Experimental Materials

2.3. Experimental Design

2.3.1. Field Management and Water, Fertilizer and Air Treatment

2.3.2. Calculation of Soil Moisture Content and Crop Water Consumption

Soil Moisture Content

Crop Water Consumption

Tomato Yield and Water and Nitrogen Use Efficiency

2.4. Research Methods

2.4.1. Production Function Model of Water, Fertilizer and Air

2.4.2. Optimization of Irrigation System by Dynamic Programming

2.4.3. Statistical Analysis Technique

3. Results and Analysis

3.1. Effect of ASDI on Water Consumption and Yield of Tomato

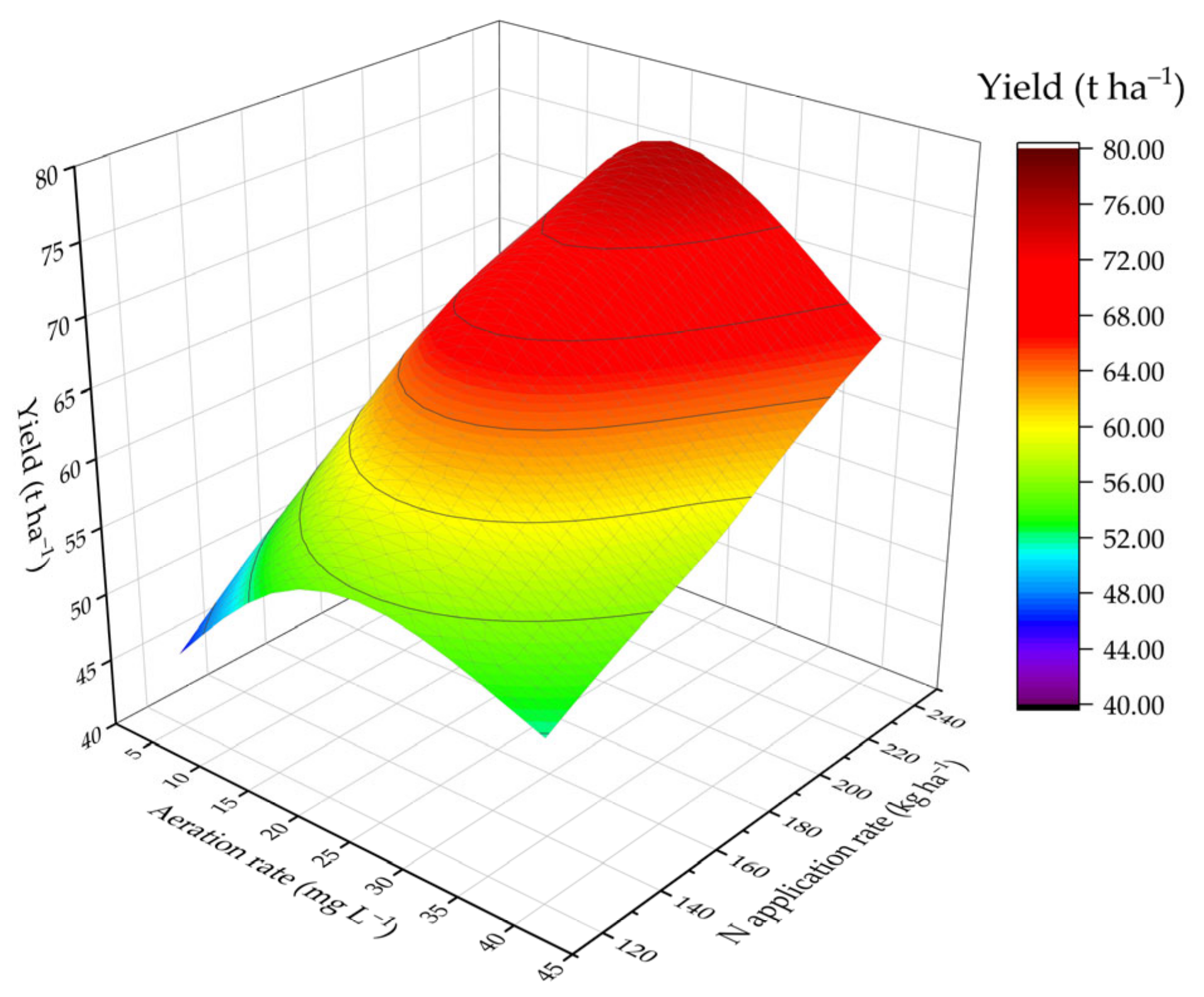

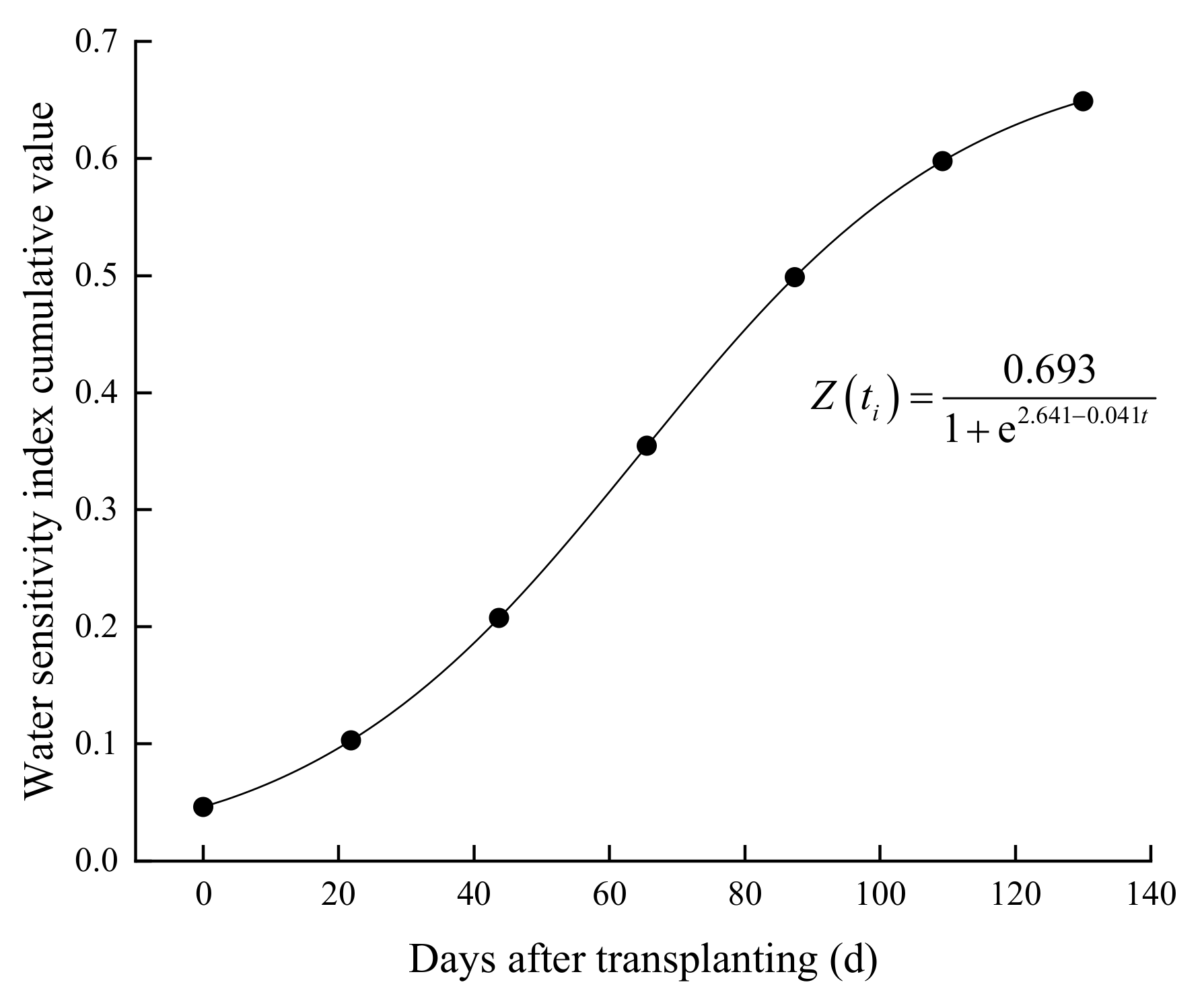

3.2. The Establishment of Water, Fertilizer and Air Coupled Production Function Based on the Jensen Model

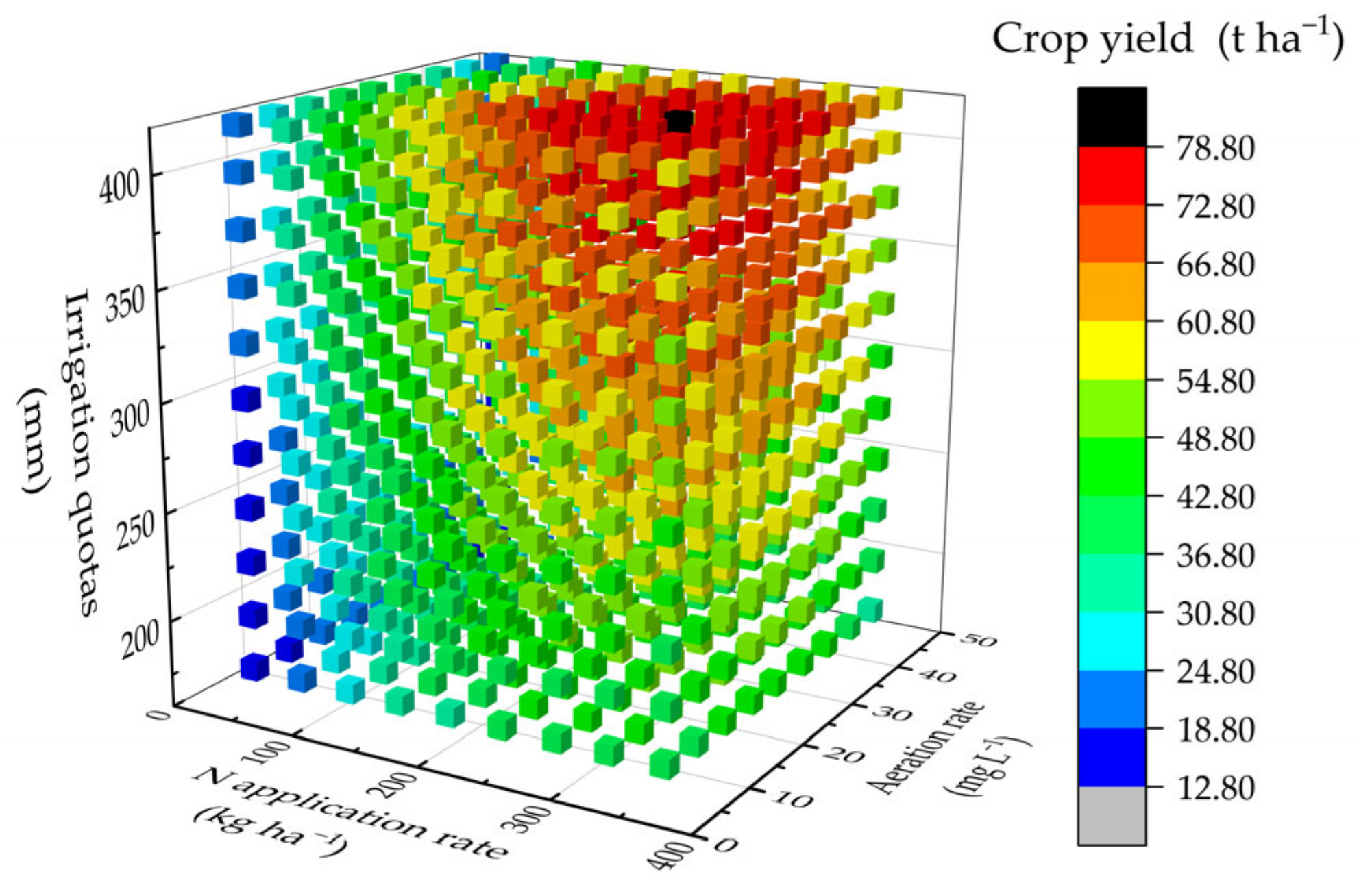

3.3. The Optimization of Water, Fertilizer and Air Coupled Irrigation Scheme

4. Discussion

5. Conclusions

- (i)

- The aeration rate of 24.55 mg L−1 DO in irrigation water and the nitrogen application rate of 281.43 kg ha−1 is the best combination scheme under ASDI.

- (ii)

- In areas where irrigation can be ensured, an irrigation quota of 420 mm was recommended to maximize the yield. When compared with non-aeration treatment, the net yield in ASDI increased by 11,012 USD ha−1 per crop season on average.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ministry of Water Resources of the People’s Republic of China. China Water Resources Bulletin. Available online: http://www.gov.cn/xinwen/2022-06/16/content_5695973.htm (accessed on 16 June 2022).

- Silberbush, M.; Gornat, B.; Goldberg, D. Effect of irrigation from a point source (trickling) on oxygen flux and on root extension in the soil. Plant Soil 1979, 52, 507–514. [Google Scholar] [CrossRef]

- Bhattarai, S.P.; Midmore, D.J.; Pendergast, L. Yield, water-use efficiencies and root distribution of soybean, chickpea and pumpkin under different subsurface drip irrigation depths and oxygation treatments in vertisols. Irrig. Sci. 2008, 26, 439–450. [Google Scholar] [CrossRef]

- Baram, S.; Weinstein, M.; Evans, J.F.; Berezkin, A.; Sade, Y.; Ben-Hur, M.; Bernstein, N.; Mamane, H. Drip irrigation with nanobubble oxygenated treated wastewater improves soil aeration. Sci. Hortic. 2022, 291, 110550. [Google Scholar] [CrossRef]

- Lei, H.J.; Xiao, Z.Y.; Zhang, Z.H.; Jin, C.C.; Pan, H.W.; Sun, K.P.; Xi, H.P. Effects of oxygen and nitrogen coupled irrigation on soil fertility and bacterial community under greenhouse pepper cropping system. Trans. Chin. Soc. Agric. Eng. 2021, 37, 158–166. (In Chinese) [Google Scholar]

- Gao, L.L.; Li, J.; Huang, H.Y.; Xiang, B.; Li, S.F.; Li, S. Effects of aerated irrigation on soil habitat factors and yield of winter potato under drip irrigation in Yunnan. Agric. Res. Arid Areas 2022, 40, 108–115. (In Chinese) [Google Scholar]

- Wang, X.Y.; Wang, T.Z.; Zhou, Y.P.; Xiao, Y.; Liu, Y.X.; Li, Y.K. Effects of Oxygation with micro-nano air bubbles on yield, fruit quality and irrigation-water use efficiency of muskmelon. J. Irrig. Drain. 2021, 40, 38–46. (In Chinese) [Google Scholar]

- Xiao, Z.; Lei, H.; Jin, C.; Pan, H.; Lian, Y. Relationship between the dynamic characteristics of tomato plant height and leaf area index with yield, under aerated drip irrigation and nitrogen application in greenhouses. Agronomy 2023, 13, 116. [Google Scholar] [CrossRef]

- Cui, B.; Hu, C.; Fan, X.; Cui, E.; Li, Z.; Ma, H.; Gao, F. Changes of endophytic bacterial community and pathogens in pepper (Capsicum annuum) as affected by reclaimed water irrigation. Appl. Soil Ecol. 2020, 156, 103627. [Google Scholar] [CrossRef]

- Zhang, Q.; Du, Y.; Cui, B.; Sun, J.; Wang, J.; Wu, M.; Niu, W. Aerated irrigation offsets the negative effects of nitrogen reduction on crop growth and water-nitrogen utilization. J. Clean. Prod. 2021, 313, 127917. [Google Scholar] [CrossRef]

- Lu, J.; Shao, G.; Cui, J.; Wang, X.; Keabetswe, L. Yield, fruit quality and water use efficiency of tomato for processing under regulated deficit irrigation: A meta-analysis. Agric. Water Manag. 2019, 222, 301–312. [Google Scholar] [CrossRef]

- Li, H.; Liu, H.; Gong, X.; Li, S.; Pang, J.; Chen, Z.; Sun, J. Optimizing irrigation and nitrogen management strategy to trade off yield, crop water productivity, nitrogen use efficiency and fruit quality of greenhouse grown tomato. Agric. Water Manag. 2021, 245, 106570. [Google Scholar] [CrossRef]

- Du, Y.D.; Zhang, Q.; Cui, B.-J.; Sun, J.; Wang, Z.; Ma, L.-H.; Niu, W.Q. Aerated irrigation improves tomato yield and nitrogen use efficiency while reducing nitrogen application rate. Agric. Water Manag. 2020, 235, 106152. [Google Scholar] [CrossRef]

- Mukherjee, D. Optimizing Water production function and deficit irrigation scheduling during extreme dry periods. J. Irrig. Drain. Eng. 2021, 147, 04021060. [Google Scholar] [CrossRef]

- Li, Z.K.; Liu, H.; Zhao, W.Z. Revisiting crop water production functions in terms of cross-regional applications. Chin. J. Eco-Agric. 2018, 26, 1781–1794. (In Chinese) [Google Scholar]

- Ren, Q.S.; Sun, Z.J.; Wang, L.; Jiao, B.Z.; Han, L. An experimental research on water production function for potato in yellow river pumping irrigation area of ningxia. Water Sav. Irrig. 2019, 2, 43–46. (In Chinese) [Google Scholar]

- Wang, S.J.; Zhang, H.J.; Ba, Y.C.; Wang, Y.C.; Huang, C.X.; Xue, D.X.; Li, F.Q. The study of water regulated deficit on yield component and water production function of pepper with mulched drip irrigation. Acta Agric. Boreali-Sin. 2018, 33, 217–225. (In Chinese) [Google Scholar]

- Han, S.J.; Liu, Q.C.; Wang, S.L.; Hu, Y.Q. Improvement and verification of cumulative function of crop water sensitive index. Trans. Chin. Soc. Agric. Eng. 2010, 26, 83–88. (In Chinese) [Google Scholar]

- Wang, Y.R.; Lei, Z.D.; Yang, S.X. Study on accumulation function of water sensitive index of winter wheat. J. Hydraul. Eng. 1997, 5, 29–36. (In Chinese) [Google Scholar]

- Wu, X.; Xu, Y.Q.; Shi, J.C.; Zhang, T.; Wang, L.C.; Xue, X.Z.; Zuo, Q. Water production function of winter wheat based on root-weighted soil water availability. Trans. Chin. Soc. Agric. Eng. 2022, 38, 124–134. (In Chinese) [Google Scholar]

- Li, W.L.; Sun, X.H.; Zhang, J.H.; Ma, J.J.; Guo, X.H.; Lei, T.; Sun, R.F.; Song, T. The effect of water-nitrogen coupling on water-nitrogen production functions of greenhouse tomato under mulched drip irrigation. J. Irrig. Drain. 2021, 40, 47–54. (In Chinese) [Google Scholar]

- Rezazadeh Baghal, S.; Khodashenas, S.R. Fuzzy number linear programming technique for design of rectangular canals. J. Irrig. Drain. Eng. 2022, 148, 04022027. [Google Scholar] [CrossRef]

- Yoo, D.I.; Chavas, J.P. Dynamic modeling of biotechnology adoption with individual versus social learning: An application to US corn farmers. Agribusiness 2023, 39, 148–166. [Google Scholar] [CrossRef]

- Tian, J.; He, G. Study on optimal design method of urban sewage collection network layout. Pol. J. Environ. Stud. 2022, 31, 1823–1836. [Google Scholar] [CrossRef] [PubMed]

- Epperson, J.E.; Hook, J.E.; Mustafa, Y.R. Dynamic programming for improving irrigation scheduling strategies of maize. Agric. Syst. 1993, 42, 85–101. [Google Scholar] [CrossRef]

- Yu, C.G.; He, Y.; Yue, H.Y.; Zhao, H.Z.; Zhao, L.J.; Li, Z.G.; Wei, X.D.; Zhang, L.L.; Li, B.S.; Sun, Z.P. Production status of fruit vegetables in solar greenhouse of northeast region and simplification pathway. China Veg. 2022, 4, 88–92. (In Chinese) [Google Scholar]

- Zhai, J.; Zhang, G.; Zhang, Y.; Xu, W.; Xie, R.; Ming, B.; Hou, P.; Wang, K.; Xue, J.; Li, S. Effect of the rate of nitrogen application on dry matter accumulation and yield formation of densely planted maize. Sustainability 2022, 14, 14940. [Google Scholar] [CrossRef]

- Bahrami, M.; Talebnejad, R.; Sepaskhah, A.R.; Bazile, D. Irrigation regimes and nitrogen rates as the contributing factors in quinoa yield to increase water and nitrogen efficiencies. Plants 2022, 11, 2048. [Google Scholar] [CrossRef] [PubMed]

- Lei, H.J.; Xiao, Z.Y.; Xiao, R.; Yang, H.G.; Pan, H.W. Effect of water-fertilizer-gas coupled drip irrigation on greenhouse tomato growth and fruit quality. Agric. Res. Arid Areas 2020, 38, 168–175. (In Chinese) [Google Scholar]

- Lei, H.J.; Jin, C.C.; Pan, H.W.; Xiao, Z.Y.; Sun, K.P. Integrative effects of irrigation and aeration on root morphology, yield and quality of pepper. Trans. Chin. Soc. Agric. Mach. 2022, 53, 344–352. (In Chinese) [Google Scholar]

- Zhu, Y.; Cai, H.J.; Song, L.B.; Shang, Z.H.; Chen, H. Comprehensive evaluation of different oxygation treatments based on fruit yield and quality of greenhouse tomato. Sci. Agric. Sin. 2020, 53, 2241–2252. (In Chinese) [Google Scholar]

- Wei, C.L.; Wang, Z.H.; Zhang, J.Z.; Zhu, Y.; Qin, C. Comprehensive evaluation of aerated irrigation treatment based on yield and quality of processing tomato. J. Arid Land Resour. Environ. 2022, 36, 122–127. (In Chinese) [Google Scholar]

- Zhu, Y.; Cai, H.J.; Song, L.B.; Chen, H. Oxygation improving soil aeration around tomato root zone in greenhouse. Trans. Chin. Soc. Agric. Eng. 2017, 33, 163–172. (In Chinese) [Google Scholar]

- Jin, C.; Pan, H.; Lei, H.; Xiao, Z.; Sun, K. Effects of aerated irrigation and nitrogen application on tomato yield and nitrogen absorption in greenhouse environment. Fresenius Environ. Bull. 2022, 31, 8150–8160. [Google Scholar]

- Cantore, V.; Lechkar, O.; Karabulut, E.; Sellami, M.H.; Albrizio, R.; Boari, F.; Stellacci, A.M.; Todorovic, M. Combined effect of deficit irrigation and strobilurin application on yield, fruit quality and water use efficiency of “cherry” tomato (Solanum lycopersicum). Agric. Water Manag. 2016, 167, 53–61. [Google Scholar] [CrossRef]

- Nangare, D.D.; Singh, Y.; Kumar, P.S.; Minhas, P.S. Growth, fruit yield and quality of tomato (Lycopersicon esculentum Mill.) as affected by deficit irrigation regulated on phenological basis. Agric. Water Manag. 2016, 171, 73–79. [Google Scholar] [CrossRef]

- Wang, D.; Kang, Y.; Wan, S. Effect of soil matric potential on tomato yield and water use under drip irrigation condition. Agric. Water Manag. 2007, 87, 180–186. [Google Scholar] [CrossRef]

- Sun, T.G.; Zhang, M.J.; Ma, T.Y.; Zhai, Y.; Li, X. Physiological and biochemical mechanism of exogenous spermidine improving drought resistance in melon seedlings under drought stress. North. Hortic. 2022, 12, 34–39. (In Chinese) [Google Scholar]

- Yang, S.; Song, Y.Q.; Li, J.; Chen, C.; Li, L.L. Regulated deficit irrigation technique and its application on fruit trees. North. Hortic. 2015, 11, 176–179. (In Chinese) [Google Scholar]

- Zhai, C.; Zhang, N.; Xiao, Y.; Zhou, H.P.; Xiao, C.H.; Meng, Y.C. Experiment on crop coefficient and water productivity of main grain crops under drip irrigation in Xinjiang. J. Arid Land Resour. Environ. 2021, 35, 162–167. (In Chinese) [Google Scholar]

- Zhang, H.J.; Zhang, J.D. Periodical water production function of processing tomato (Solanum lycopersicum) subjected to water deficit in an arid environment. Appl. Mech. Mater. 2014, 641–642, 196–200. [Google Scholar] [CrossRef]

- Mao, X.M.; Shang, S.H. Application of 0-1 programming model on optimization of crop deficit irrigation schedule. Trans. Chin. Soc. Agric. Mach. 2014, 45, 153–158. (In Chinese) [Google Scholar]

- Cui, Y.; Chen, S.; Chai, R.Y.; Jin, J.L.; Hu, T.T.; Qiu, Y. Responsive analysis of tomato yield to soil moisture during different growth stage. Agric. Res. Arid Areas 2015, 33, 14–21. (In Chinese) [Google Scholar]

- Zheng, J.; Zhu, C.Y.; Qi, X.Y.; Wei, J.F.; Yang, S.H.; Sun, Q. The effects of irrigation with diluted biogas slurry on growth, yield and fruit quality of tomato. J. Irrig. Drain. 2022, 41, 64–71. (In Chinese) [Google Scholar]

- Mitchell, J.P.; Shennan, C.; Grattan, S.R.; May, D.M. Tomato fruit yields and quality under water deficit and salinity. J. Am. Soc. Hortic. Sci. 1991, 116, 215–221. [Google Scholar] [CrossRef] [Green Version]

| Experimental Item | Tomato Growth Period | Start Date | End Date | Post–Transplant Period (d) | Days of Growth Period (d) |

|---|---|---|---|---|---|

| The first crop season in 2019 (Potential yield experiment) | Seeding stage | 9 March 2019 | 2 April 2019 | 1–25 | 25 |

| Flowering and fruit bearing stage | 3 April 2019 | 17 April 2019 | 26–40 | 15 | |

| Fruit expanding stage | 18 April 2019 | 21 May 2019 | 41–74 | 34 | |

| Maturity stage | 22 May 2019 | 10 July 2019 | 75–124 | 50 | |

| The second crop season in 2021 (Deficit irrigation experiment) | Seedling stage | 14 September 2021 | 15 October 2021 | 1–32 | 32 |

| Flowering and fruit bearing stage | 16 October 2021 | 4 December 2021 | 33–82 | 50 | |

| Maturity stage | 5 December 2021 | 13 January 2022 | 83–122 | 40 |

| Potential Yield Experimental | Deficit Irrigation Experimental | ||||||

|---|---|---|---|---|---|---|---|

| Treatment | Aeration Rate (mg·L−1) | N application Rate (kg·ha−1) | Treatment | Aeration Rate (mg·L−1) | Seedling Stage | Flowering and Fruit Bearing Stage | Maturity Stage |

| A1N3 | 5 | 240 | T1 | 5 | W1 | W1 | W3 |

| A2N3 | 15 | 240 | T2 | 5 | W1 | W3 | W1 |

| A3N3 | 40 | 240 | T3 | 5 | W2 | W2 | W3 |

| A1N2 | 5 | 180 | T4 | 5 | W3 | W3 | W3 |

| A2N2 | 15 | 180 | T5 | 5 | W3 | W1 | W2 |

| A3N2 | 40 | 180 | T6 | 5 | W3 | W2 | W1 |

| A1N1 | 5 | 120 | T7 | 25 | W1 | W2 | W2 |

| A2N1 | 15 | 120 | T8 | 25 | W1 | W1 | W3 |

| A3N1 | 40 | 120 | T9 | 25 | W2 | W3 | W2 |

| — | — | — | T10 | 25 | W2 | W1 | W1 |

| — | — | — | T11 | 25 | W3 | W3 | W3 |

| — | — | — | T12 | 25 | W3 | W2 | W1 |

| Treatment | Aeration Rate (mg L−1) | Soil Moisture Content at Seedling Stage | Soil Moisture Content during Flowering and Fruit Bearing Stage | Soil Moisture Content in Maturity Stage | Yield (t ha−1) |

|---|---|---|---|---|---|

| T1 | 1 | 1 | 1 | 3 | 44.54 ± 1.39 g |

| T2 | 1 | 1 | 3 | 1 | 53.51 ± 3.45 de |

| T3 | 1 | 2 | 2 | 3 | 55.31 ± 2.89 d |

| T4 | 1 | 3 | 3 | 3 | 62.38 ± 1.19 bc |

| T5 | 1 | 3 | 1 | 2 | 46.85 ± 1.53 efg |

| T6 | 1 | 3 | 2 | 1 | 45.5 ± 2.08 fg |

| T7 | 2 | 1 | 2 | 2 | 57.71 ± 2.43 cd |

| T8 | 2 | 1 | 1 | 3 | 51.78 ± 1.35 def |

| T9 | 2 | 2 | 3 | 2 | 68.41 ± 3.11 b |

| T10 | 2 | 2 | 1 | 1 | 48.06 ± 1.27 efg |

| T11 | 2 | 3 | 3 | 3 | 75.1 ± 1.7 a |

| T12 | 2 | 3 | 2 | 1 | 52.09 ± 1.34 def |

| 1 Mean value | 51.35 | 51.88 | 47.81 | 49.79 | |

| 2 Mean value | 58.86 | 57.26 | 52.65 | 57.65 | |

| 3 Mean value | — | 56.38 | 64.85 | 57.82 | |

| range | 7.51 | 5.37 | 17.04 | 8.03 | |

| Primary and secondary factors | 3 | 4 | 1 | 2 | |

| Optimal scheme | C3D3A2B2 | ||||

| Treatments | Seedling Stage ET (mm) | Flowering and Fruit Bearing Stage ET (mm) | Maturity Stage ET (mm) | ET during Whole Growth Period (mm) | WUE (kg m−3) | NPFP (kg kg−1) |

|---|---|---|---|---|---|---|

| T1 | 17.59 ± 0.42 bc | 112.97 ± 5.26 d | 147.56 ± 5.58 b | 278.11 ± 11.15 c | 16.03 ± 0.41 hi | 185.58 ± 5.8 g |

| T2 | 17.02 ± 0.42 bc | 213.44 ± 10.13 a | 137.24 ± 5.09 b | 367.7 ± 14.81 ab | 14.53 ± 0.34 j | 222.97 ± 14.37 de |

| T3 | 28.07 ± 1.72 a | 164.13 ± 7.58 b | 165.56 ± 6.46 a | 357.76 ± 15.45 b | 15.46 ± 0.37 i | 230.47 ± 12.06 d |

| T4 | 31.71 ± 2.26 a | 201.98 ± 9.53 a | 141.02 ± 5.27 b | 374.72 ± 12.9 ab | 16.67 ± 0.27 gh | 259.93 ± 4.94 bc |

| T5 | 31.1 ± 2.17 a | 139.2 ± 6.39 c | 91.22 ± 2.97 d | 261.52 ± 11.35 cd | 17.93 ± 0.2 ef | 195.21 ± 6.37 efg |

| T6 | 30.92 ± 2.15 a | 163.18 ± 7.53 b | 66.24 ± 1.99 e | 260.34 ± 10.85 cd | 17.48 ± 0.34 fg | 189.6 ± 8.68 fg |

| T7 | 14.9 ± 0.54 c | 158.27 ± 7.29 bc | 108.58 ± 3.44 c | 281.74 ± 10.31 c | 20.47 ± 0.13 d | 240.45 ± 10.12 cd |

| T8 | 15.66 ± 0.47 c | 103.91 ± 4.93 de | 109.57 ± 3.79 c | 229.14 ± 8.59 d | 22.62 ± 0.31 c | 215.75 ± 5.63 def |

| T9 | 27.51 ± 1.64 a | 193.97 ± 9.11 a | 116.27 ± 4.1 c | 337.75 ± 14.67 b | 20.25 ± 0.26 d | 285.02 ± 12.97 b |

| T10 | 21.7 ± 0.81 b | 88.05 ± 4.42 e | 53.78 ± 1.65 ef | 163.53 ± 3.84 e | 29.38 ± 0.12 a | 200.23 ± 5.29 efg |

| T11 | 29.43 ± 1.92 a | 200.45 ± 9.45 a | 172.08 ± 6.77 a | 401.97 ± 14.47 a | 18.7 ± 0.31 e | 312.93 ± 7.08 a |

| T12 | 28.23 ± 1.74 a | 112.56 ± 5.25 d | 51.71 ± 1.61 f | 192.5 ± 5.95 e | 27.07 ± 0.24 b | 217.02 ± 5.57 def |

| Treatments | Actual Yield (t ha−1) | Predicted Yield (t ha−1) | Treatments | Actual Yield (t ha−1) | Predicted Yield (t ha−1) |

|---|---|---|---|---|---|

| T1 | 47.10 | 45.39 | T7 | 60.49 | 57.88 |

| T2 | 50.95 | 53.06 | T8 | 50.98 | 52.08 |

| T3 | 54.79 | 55.75 | T9 | 67.75 | 68.99 |

| T4 | 60.94 | 58.53 | T10 | 51.99 | 46.15 |

| T5 | 45.60 | 48.56 | T11 | 73.64 | 75.76 |

| T6 | 43.67 | 47.76 | T12 | 54.73 | 51.32 |

| R2 | 0.895 | ||||

| Root mean square error of crop yield (t ha−1) | 2.88 | ||||

| The average relative error (%) | 4.83 | ||||

| Stages | Days after Transplanting (d) | ET i (mm) | ETmi (mm) | λi |

|---|---|---|---|---|

| 1 | 1–20 | 3 | 5 | 0.0504 |

| 2 | 21–40 | 23 | 51 | 0.0897 |

| 3 | 41–60 | 35 | 82 | 0.1290 |

| 4 | 61–80 | 38 | 97 | 0.1384 |

| 5 | 81–100 | 34 | 96 | 0.1087 |

| 6 | 101–122 | 22 | 86 | 0.0710 |

| Irrigation Quotas (mm) | m1 (mm) | m2 (mm) | m3 (mm) | m4 (mm) | m5 (mm) | m6 (mm) | ASDI (O = 24.55 mg L−1) | Non-Aeration Drip Irrigation (O = 5 mg L−1) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Predicted Yield (t ha−1) | Relative Output (−) | Predicted Yield (t ha−1) | Relative Output (−) | |||||||

| 200 | 5 | 35 | 45 | 50 | 40 | 25 | 53.92 | 0.68 | 42.75 | 0.54 |

| 250 | 5 | 35 | 60 | 65 | 50 | 35 | 60.89 | 0.77 | 48.27 | 0.61 |

| 300 | 5 | 50 | 70 | 75 | 60 | 40 | 67.36 | 0.85 | 53.40 | 0.67 |

| 350 | 5 | 50 | 80 | 90 | 75 | 50 | 73.15 | 0.92 | 58.00 | 0.73 |

| 400 | 5 | 50 | 80 | 95 | 95 | 75 | 77.83 | 0.98 | 61.70 | 0.78 |

| 420 | 5 | 50 | 85 | 100 | 95 | 85 | 79.00 | 1.00 | 62.63 | 0.79 |

| Irrigation Quotas (mm) | Agricultural Input | Other Input | ASDI (DO at 24.55 mg L−1) | Non-Aeration Treatment (DO at 5 mg L−1) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Seedling Cost | Pesticides and Fertilizers | Irrigation Water | Labor Cost | Equipment Cost | Drip Belt Cost | Output Value | Total Input | Net Income | Output Value | Total Input | Net Income | |

| 200 | 3071 | 1815 | 177 | 11,718 | 1050 | 85 | 39,737 | 17,916 | 21,821 | 31,504 | 16,866 | 14,638 |

| 250 | 3071 | 1815 | 221 | 11,718 | 1050 | 85 | 44,872 | 17,960 | 26,912 | 35,576 | 16,910 | 18,666 |

| 300 | 3071 | 1815 | 265 | 11,718 | 1050 | 85 | 49,640 | 18,004 | 31,635 | 39,355 | 16,954 | 22,401 |

| 350 | 3071 | 1815 | 310 | 11,718 | 1050 | 85 | 53,911 | 18,048 | 35,863 | 42,742 | 16,998 | 25,743 |

| 400 | 3071 | 1815 | 354 | 11,718 | 1050 | 85 | 57,357 | 18,093 | 39,264 | 45,473 | 17,042 | 28,431 |

| 420 | 3071 | 1815 | 371 | 11,718 | 1050 | 85 | 58,221 | 18,110 | 40,111 | 46,158 | 17,060 | 29,098 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, H.; Lian, Y.; Du, J.; Pan, H.; Li, X.; Li, D.; Jin, C.; Xiao, Z.; Hou, Y. Dynamic Optimization of Greenhouse Tomato Irrigation Schedule Based on Water, Fertilizer and Air Coupled Production Function. Agronomy 2023, 13, 776. https://doi.org/10.3390/agronomy13030776

Lei H, Lian Y, Du J, Pan H, Li X, Li D, Jin C, Xiao Z, Hou Y. Dynamic Optimization of Greenhouse Tomato Irrigation Schedule Based on Water, Fertilizer and Air Coupled Production Function. Agronomy. 2023; 13(3):776. https://doi.org/10.3390/agronomy13030776

Chicago/Turabian StyleLei, Hongjun, Yingji Lian, Jun Du, Hongwei Pan, Xiaohong Li, Daoxi Li, Cuicui Jin, Zheyuan Xiao, and Yiran Hou. 2023. "Dynamic Optimization of Greenhouse Tomato Irrigation Schedule Based on Water, Fertilizer and Air Coupled Production Function" Agronomy 13, no. 3: 776. https://doi.org/10.3390/agronomy13030776