Research and Design of Hybrid Optimized Backpropagation (BP) Neural Network PID Algorithm for Integrated Water and Fertilizer Precision Fertilization Control System for Field Crops

Abstract

1. Introduction

2. Materials and Methods

2.1. Structural Components of Integrated Water and Fertilizer System for Field Crops

2.2. PID Controller Design Based on Hybrid Optimization BP Neural Network

2.2.1. Conventional PID Controller Design

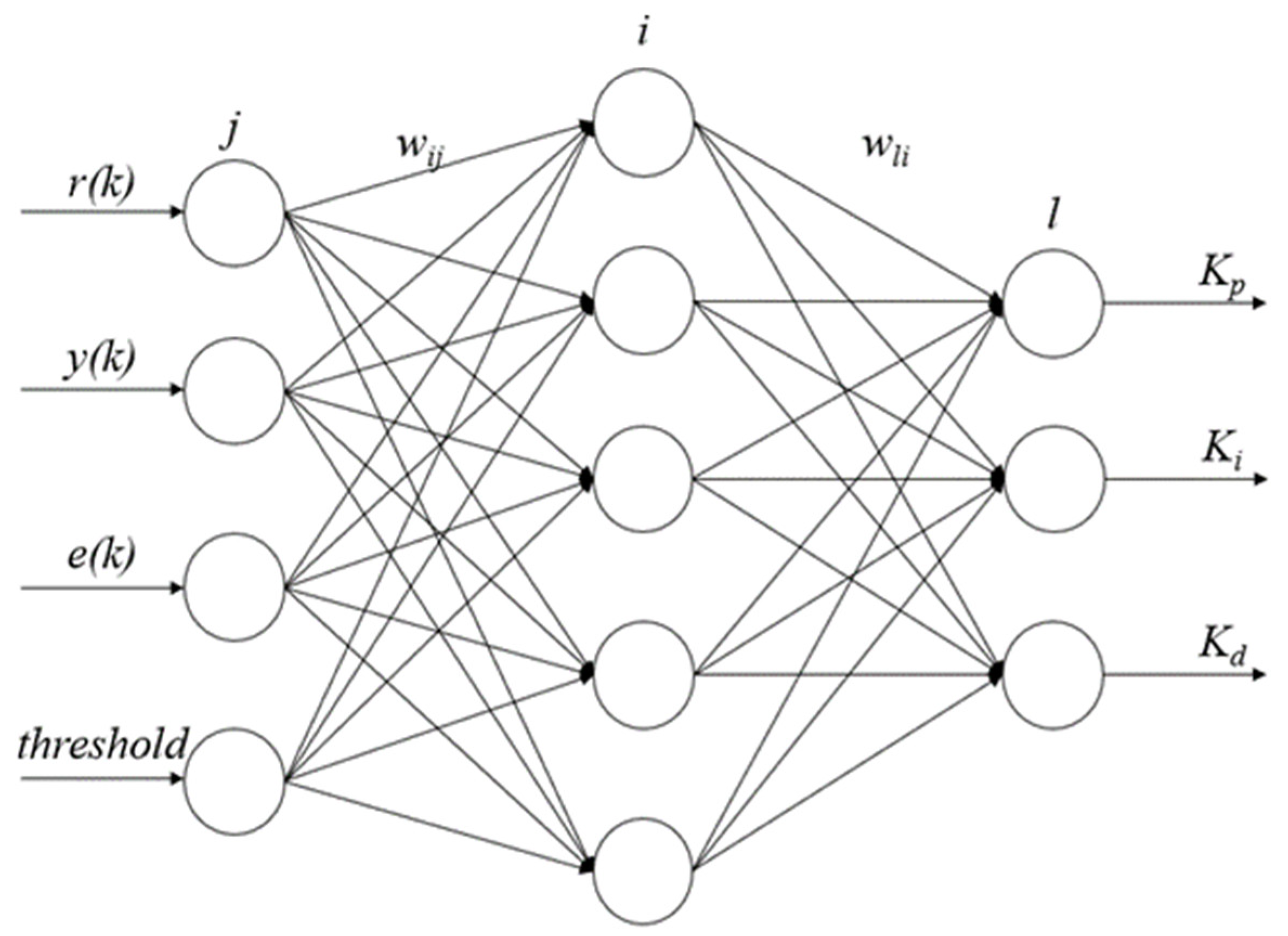

2.2.2. BP Neural Network-Based PID Controller Design

- (1)

- determine the BP neural network structure, and determine the initial values of connection weights and thresholds by the mathematical model of the controlled object, select the appropriate inertia factor and learning rate , and determine the initial values of the proportional, integral and differential coefficients of the PID;

- (2)

- the flowmeter collects the actual instantaneous flow value of liquid fertilizer at the current moment, inputs the desired instantaneous flow value of liquid fertilizer, and calculates and inputs the metering deviation value of liquid fertilizer;

- (3)

- according to Formula (8), u(k) is calculated and input to the controlled object to obtain the actual instantaneous flow rate value of liquid fertilizer at the moment k = 1;

- (4)

- The learning update of the BP neural network part is carried out, and the parameters of the modified PID control are obtained according to Formulas (10)–(17) to realize the adaptive adjustment of the PID parameters.

- (5)

- When k = k + 1, return to Formula (8).

2.2.3. Design of Hybrid Optimization BP Neural Network-Based PID Controller

3. Results

3.1. Analysis of Simulation Results

3.2. Flow Rate Adjustment Test of Water–fertilizer Integrated Precision Fertilizer Application Control System

3.2.1. Testing Device and System Design

3.2.2. Analysis of Test Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, M.; Li, Y.; Liu, J.; Wang, J.; Zhang, Z.; Xiao, N. Changes of soil water and heat transport and yield of tomato (Solanum lycopersicum) in greenhouses with Micro-Sprinkler irrigation under plastic film. Agronomy 2022, 12, 664. [Google Scholar] [CrossRef]

- Wang, H.; Li, J.; Cheng, M.; Zhang, F.; Wang, X.; Fan, J.; Wu, L.; Fang, D.; Zou, H.; Xiang, Y. Optimal drip fertigation management improves yield, quality, water and nitrogen use efficiency of greenhouse cucumber. Sci. Hortic. 2019, 243, 357–366. [Google Scholar] [CrossRef]

- Xiuyun, X.; Xufeng, X.; Zelong, Z.; Bin, Z.; Shuran, S.; Zhen, L.; Tiansheng, H.; Huixian, H. Variable Rate Liquid Fertilizer Applicator for Deep-fertilization in Precision Farming Based on ZigBee Technology. IFAC-PapersOnLine 2019, 52, 43–50. [Google Scholar] [CrossRef]

- Ren, P.; Huang, F.; Li, B. Spatiotemporal patterns of water consumption and irrigation requirements of wheat-maize in the Huang-Huai-Hai Plain, China and options of their reduction. Agric. Water Manag. 2022, 263, 107468. [Google Scholar] [CrossRef]

- Ying-Zi, Z.; Hai-Tao, C.; Shou-Yin, H.; Wen-Yi, J.; Bin-Lin, O.; Guo-Qiang, D.; Ji-Cheng, Z. Design and Experiment of Slave Computer Control System for Applying Variable-rate Liquid Fertilizer. J. Northeast Agric. Univ. 2015, 22, 73–79. [Google Scholar] [CrossRef]

- Zou, Z.; Yu, M.; Wang, Z.; Liu, X.; Guo, Y.; Zhang, F.; Guo, N. Nonlinear Model Algorithmic Control of a pH Neutralization Process. Chin. J. Chem. Eng. 2013, 21, 395–400. [Google Scholar] [CrossRef]

- Ben-Gal, A.; Beiersdorf, I.; Yermiyahu, U.; Soda, N.; Presnov, E.; Zipori, I.; Crisostomo, R.R.; Dag, A. Response of young bearing olive trees to irrigation-induced salinity. Irrig. Sci. 2017, 35, 99–109. [Google Scholar] [CrossRef]

- Bhite, B.R.; Pawar, P.S.; Bulbule, S.V. Standardization of Stage Wise Requirement of Nutrients in Sweet Orange. Trends Biosci. 2017, 10, 5644–5647. [Google Scholar]

- Fontanier, C.H.; Aitkenhead-Peterson, J.A.; Wherley, B.G.; White, R.H.; Thomas, J.C. Effective rainfall estimates for St. Augustine grass lawns under varying irrigation programs. Agron. J. 2021, 113, 3720–3729. [Google Scholar] [CrossRef]

- Ahmad, U.; Nasirahmadi, A.; Hensel, O.; Marino, S. Technology and Data Fusion Methods to Enhance Site-Specific Crop Monitoring. Agronomy 2022, 12, 555. [Google Scholar] [CrossRef]

- Ahmad, U.; Begum, U. Enhancing production of Zea mays genotypes by K application in Peshawar, Pakistan. Indian J. Agric. Res. 2017, 51, 257–261. [Google Scholar] [CrossRef]

- Adeyemi, O.; Grove, I.; Peets, S.; Norton, T. Advanced monitoring and management systems for improving sustainability in precision irrigation. Sustainability 2017, 9, 353. [Google Scholar] [CrossRef]

- Chen, J.; Gao, Y.; Qian, H.; Jia, H.; Zhang, Q. Insights into water sustainability from a grey water footprint perspective in an irrigated region of the Yellow River Basin. J. Clean. Prod. 2021, 316, 128329. [Google Scholar] [CrossRef]

- Dong, Y.; Fu, Z.; Peng, Y.; Zheng, Y.; Yan, H.; Li, X. Precision fertilization method of field crops based on the Wavelet-BP neural network in China. J. Clean. Prod. 2020, 246, 118735. [Google Scholar] [CrossRef]

- Bai, J.; Tian, M.; Li, J. Control System of Liquid Fertilizer Variable-Rate Fertilization Based on Beetle Antennae Search Algorithm. Processes 2022, 10, 357. [Google Scholar] [CrossRef]

- Joseph, S.B.; Dada, E.G.; Abidemi, A.; Oyewola, D.O.; Khammas, B.M. Metaheuristic algorithms for PID controller parameters tuning: Review, approaches and open problems. Heliyon 2022, 8, e09399. [Google Scholar] [CrossRef]

- Yang, T.; Zheng, X.; Vidyarthi, S.K.; Xiao, H.; Yao, X.; Li, Y.; Zang, Y.; Zhang, J. Artificial Neural Network Modeling and Genetic Algorithm Multiobjective Optimization of Process of Drying-Assisted Walnut Breaking. Foods 2023, 12, 1897. [Google Scholar] [CrossRef]

- Tang, G.; Lei, J.; Du, H.; Yao, B.; Zhu, W.; Hu, X. Proportional-integral-derivative controller optimization by particle swarm optimization and back propagation neural network for a parallel stabilized platform in marine operations. J. Ocean Eng. Sci. 2017, 139, 116–126. [Google Scholar] [CrossRef]

- Huang, J.; He, L. Application of Improved PSO—BP Neural Network in Customer Churn Warning. Procedia Comput. Sci. 2018, 131, 1238–1246. [Google Scholar] [CrossRef]

- Ren, C.; An, N.; Wang, J.; Li, L.; Hu, B.; Shang, D. Optimal parameters selection for BP neural network based on particle swarm optimization: A case study of wind speed forecasting. Knowl. Based Syst. 2014, 56, 226–239. [Google Scholar] [CrossRef]

- Marino, S.; Aria, M.; Basso, B.; Leone, A.P.; Alvino, A. Use of soil and vegetation spectroradiometry to investigate crop water use efficiency of a drip irrigated tomato. Eur. J. Agron. 2014, 59, 67–77. [Google Scholar] [CrossRef]

- Wang, H.; Xiang, Y.; Zhang, F.; Tang, Z.; Guo, J.; Zhang, X.; Hou, X.; Wang, H.; Cheng, M.; Li, Z. Responses of yield, quality and water-nitrogen use efficiency of greenhouse sweet pepper to different drip fertigation regimes in Northwest China. Agric. Water Manag. 2022, 260, 107279. [Google Scholar] [CrossRef]

- Qi, W.; Zhang, Z.; Wang, C.; Huang, M. Prediction of infiltration behaviors and evaluation of irrigation efficiency in clay loam soil under Moistube® irrigation. Agric. Water Manag. 2021, 248, 106756. [Google Scholar] [CrossRef]

- Feng, H.; Ma, W.; Yin, C.; Cao, D. Trajectory control of electrohydraulic position servo system using improved PSO-PID controller. Automat. Construct. 2020, 127, 103722. [Google Scholar] [CrossRef]

- Yu, Y.; Xu, Y.; Wang, F.; Li, W.; Mai, X.; Wu, H. Adsorption control of a pipeline robot based on improved PSO algorithm. Complex Intell. Syst. 2020, 4, 964–977. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, Y.; Qi, R.; Zheng, X.; Li, W. Adaptive PID control of multi-DOF industrial robot based on neural network. J. Ambient Intell. Humaniz. Comput. 2020, 11, 95–102. [Google Scholar] [CrossRef]

- Meng, Z.; Zhang, L.; Wang, H.; Ma, X.; Li, H.; Zhu, F. Research and Design of Precision Fertilizer Application Control System Based on PSO-BP-PID Algorithm. Agriculture 2022, 12, 1395. [Google Scholar] [CrossRef]

| Controller Type | Rise Time (s) | Peak Time (s) | Regulation Time (s) | Maximum Overshoot |

|---|---|---|---|---|

| PID | 12.42 | 13.69 | 25.26 | 58.61% |

| BP–PID | 27.39 | 32.96 | 19.91 | 1.04% |

| GA–PSO-BP–PID | 11.95 | 12.50 | 11.77 | 3.6% |

| Controller Type | Rise Time (s) | Peak Time (s) | Regulation Time (s) | Maximum Overshoot |

|---|---|---|---|---|

| PID | 20.02 | 30.64 | 81.85 | 77.4% |

| BP–PID | 70.91 | 106.6 | 109.2 | 7.37% |

| GA–PSO-BP–PID | 32.02 | 74.69 | 122.3 | 6.83% |

| Controller Type | Rise Time (s) | Peak Time (s) | Regulation Time (s) | Maximum Overshoot |

|---|---|---|---|---|

| PID | 20.67 | 30.2 | 89.26 | 50.48% |

| BP–PID | 71.76 | 105.6 | 61.83 | 4.5% |

| GA–PSO-BP–PID | 33.45 | 51.89 | 28.65 | 3.16% |

| Controller Type | Rise Time (s) | Peak Time (s) | Regulation Time (s) | Maximum Overshoot |

|---|---|---|---|---|

| PID | 20.04 | 30.92 | 110.26 | 75.5% |

| BP–PID | 74.97 | 106.14 | 62.91 | 3.09% |

| GA–PSO-BP–PID | 33.39 | 53.48 | 56.02 | 5.31% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, F.; Zhang, L.; Hu, X.; Zhao, J.; Meng, Z.; Zheng, Y. Research and Design of Hybrid Optimized Backpropagation (BP) Neural Network PID Algorithm for Integrated Water and Fertilizer Precision Fertilization Control System for Field Crops. Agronomy 2023, 13, 1423. https://doi.org/10.3390/agronomy13051423

Zhu F, Zhang L, Hu X, Zhao J, Meng Z, Zheng Y. Research and Design of Hybrid Optimized Backpropagation (BP) Neural Network PID Algorithm for Integrated Water and Fertilizer Precision Fertilization Control System for Field Crops. Agronomy. 2023; 13(5):1423. https://doi.org/10.3390/agronomy13051423

Chicago/Turabian StyleZhu, Fenglei, Lixin Zhang, Xue Hu, Jiawei Zhao, Zihao Meng, and Yu Zheng. 2023. "Research and Design of Hybrid Optimized Backpropagation (BP) Neural Network PID Algorithm for Integrated Water and Fertilizer Precision Fertilization Control System for Field Crops" Agronomy 13, no. 5: 1423. https://doi.org/10.3390/agronomy13051423

APA StyleZhu, F., Zhang, L., Hu, X., Zhao, J., Meng, Z., & Zheng, Y. (2023). Research and Design of Hybrid Optimized Backpropagation (BP) Neural Network PID Algorithm for Integrated Water and Fertilizer Precision Fertilization Control System for Field Crops. Agronomy, 13(5), 1423. https://doi.org/10.3390/agronomy13051423