Performance Analysis and Testing of a Multi-Duct Orchard Sprayer

Abstract

1. Introduction

2. Materials and Methods

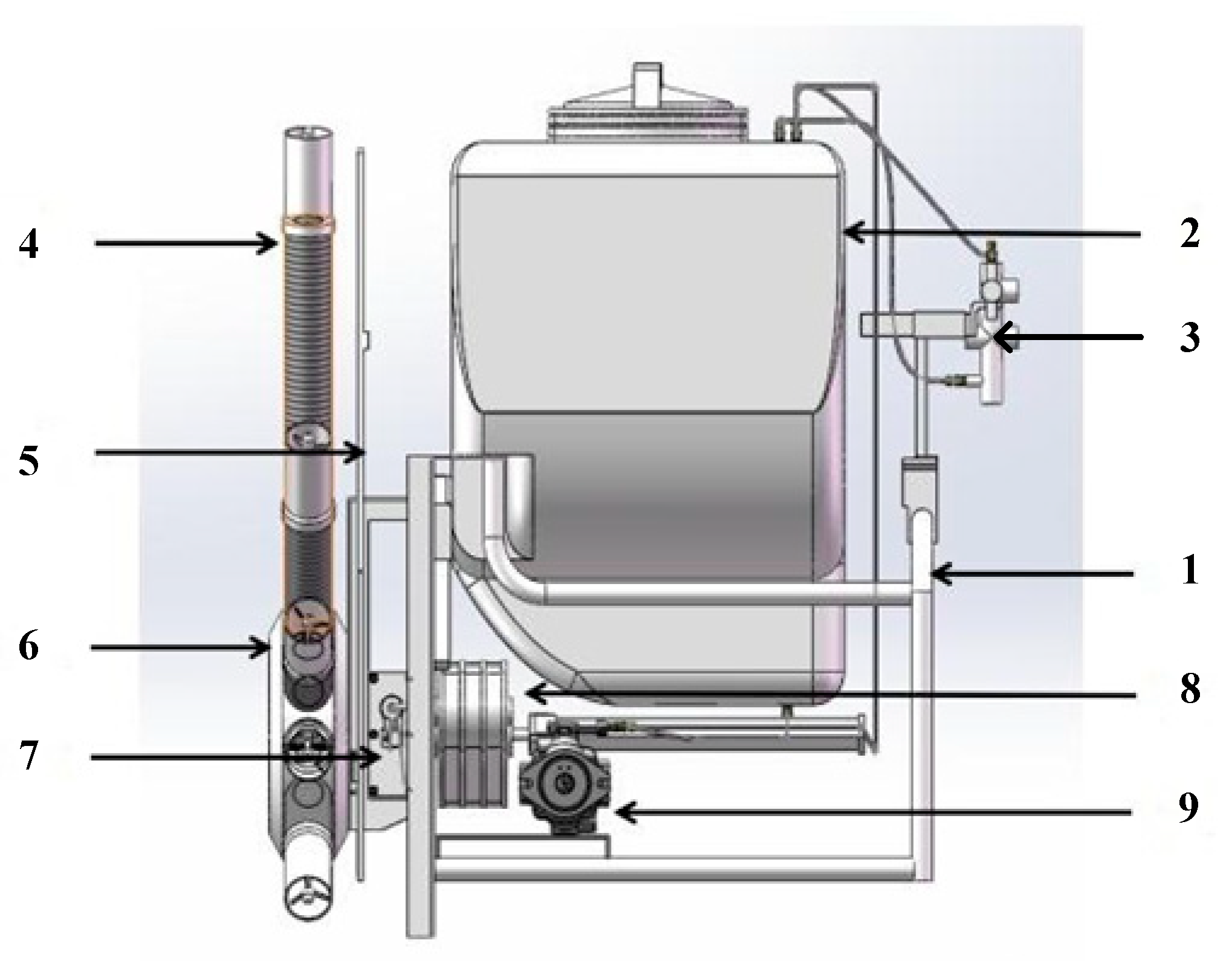

2.1. Overall Structure and Working Principle

2.2. Numerical Simulation of the Airflow Field out of the CFD Machine

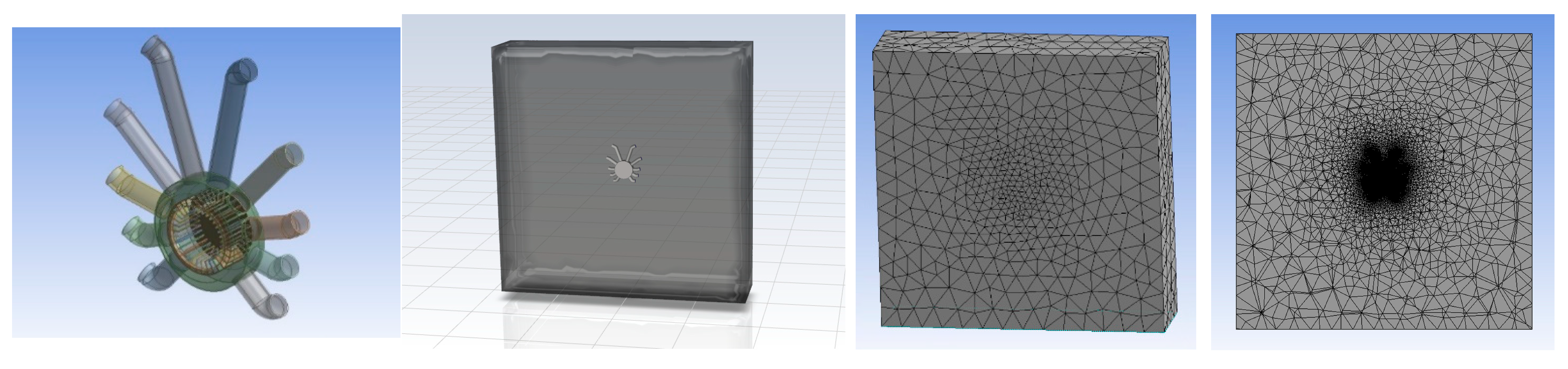

2.2.1. Modelling and Meshing of the Fluid Domain

2.2.2. Simulation Test Conditions and Assumptions

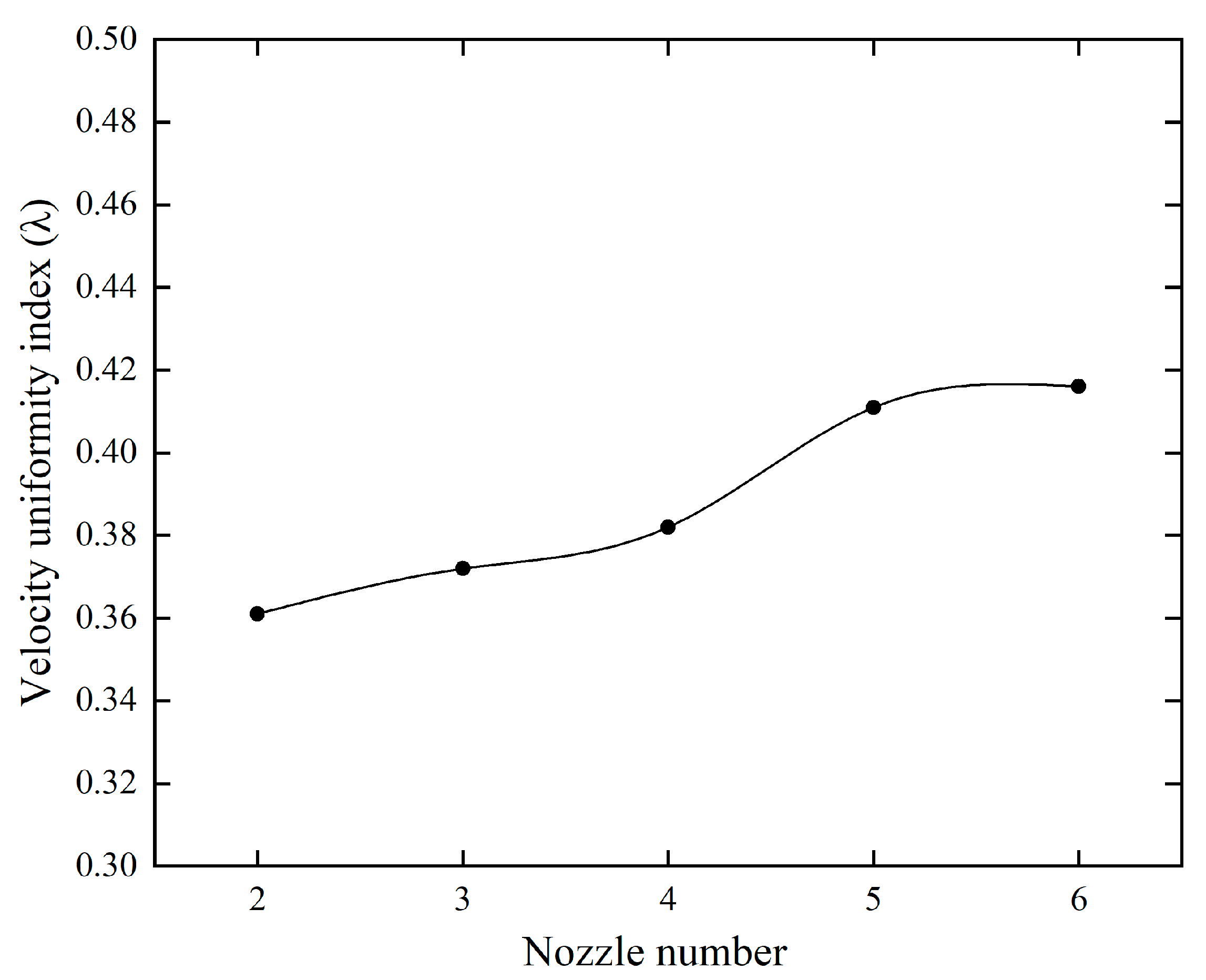

2.2.3. Parameter Calibration and Simulation Test

2.2.4. Fluent Simulation Results and Analysis

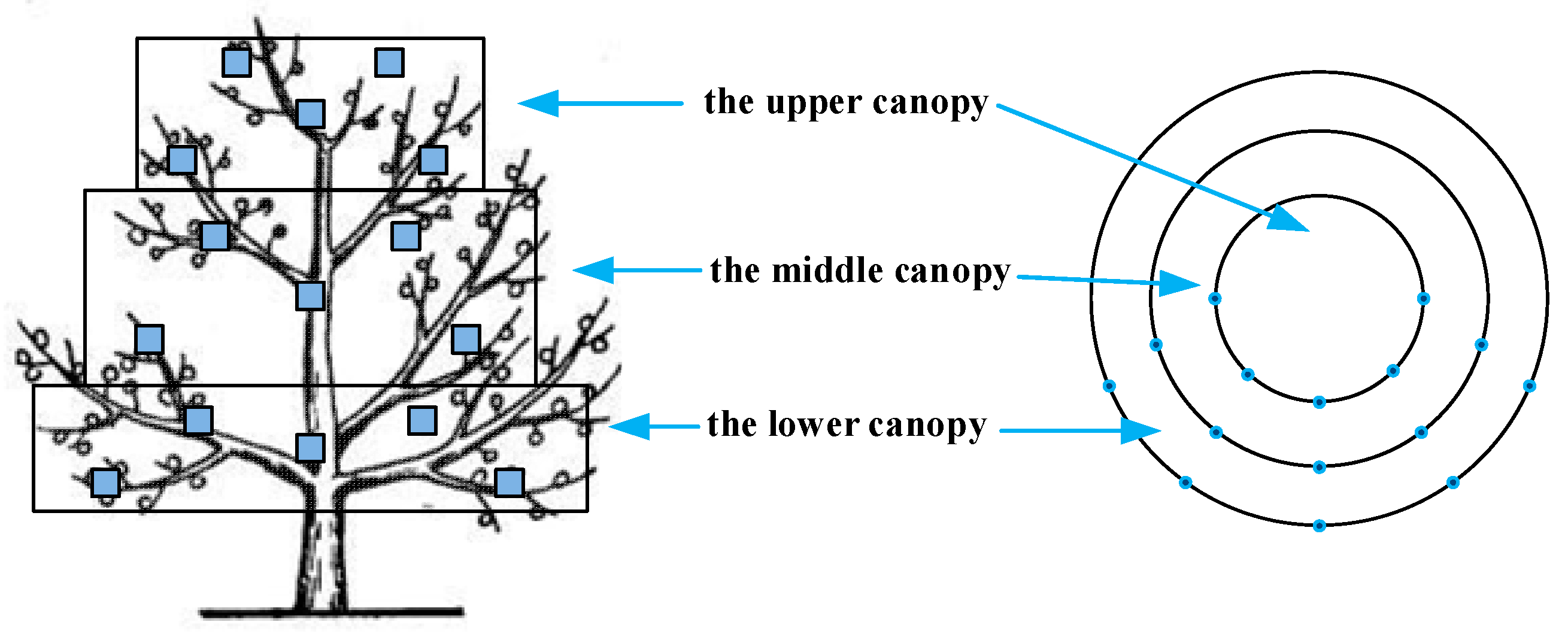

2.3. Spraying Performance Test and Processing Method

2.4. Box–Behnken Experiment Design

3. Results and Analysis

3.1. Experimental Results and Regression Models

3.2. Response Surface Analysis

3.3. Response Surface Optimisation

3.4. Verification Test

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zheng, W. Present situation and countermeasures of mechanisation development of forest and fruit industry in Xinjiang. Xinjiang Agric. Mech. 2019, 195, 7–9+13. [Google Scholar]

- Wegener, J.; Pelzer, T.; Ahrens, K. Assessment of Different Parameters Influencing the Quality of Spray Distribution on Orchard Sprayers. Gesunde. Pflanz. 2019, 71, 9–15. [Google Scholar] [CrossRef]

- Cross, J.V.; Walklate, P.J.; Murray, R.A.; Richardson, G.M. Spray deposits and losses in different sized apple trees from an axial fan orchard sprayer: 1. effects of spray liquid flow rate. Crop Prot. 2001, 20, 333–343. [Google Scholar] [CrossRef]

- Cross, J.V.; Walklate, P.J.; Murray, R.A.; Richardson, G.M. Spray deposits and losses in different sized apple trees from an axial fan orchard sprayer: 2. effects of spray quality. Crop Prot. 2001, 20, 333–343. [Google Scholar] [CrossRef]

- Cross, J.V.; Walklate, P.J.; Murray, R.A.; Richardson, G.M. Spray deposits and losses in different sized apple trees from an axial fan orchard sprayer: 3. Effects of air volumetric flow rate. Crop Prot. 2003, 22, 381–394. [Google Scholar] [CrossRef]

- Junior, S.S.; Balthazar, J.M.; Junior, B. Non-linear dynamics of a tower orchard sprayer based on an inverted pendulum model. Biosyst. Eng. 2009, 103, 417–426. [Google Scholar] [CrossRef]

- Li, J. Development of Directional Air-Fed Wolfberry Sprayer. Master’s Thesis, Ningxia University, Yinchuan, China, 2017. [Google Scholar]

- Cross, J.V.; Berrie, A.M. Field evaluation of a tunnel sprayer and effects of spray volume at constant drop size on spray deposits and efficacy of disease control on apple. Ann. Appl. Biol. 1995, 127, 521–532. [Google Scholar] [CrossRef]

- Pergher, G.; Petris, R. A novel, air-assisted tunnel sprayer for vineyards: Optimisation of operational parameters and first assessment in the field. J. Agric. Eng-Italy 2009, 40, 358–367. [Google Scholar] [CrossRef]

- Ramón, S.; Elena, S.; Heping, Z.; Xavier, F.; Francisco, G.; Emilio, G. Evaluation of an electrostatic spray charge system implemented in three conventional orchard sprayers used on a commercial apple trees plantation. Crop Prot. 2023, 167, 106212. [Google Scholar]

- Mamidi, V.R.; Ghanshyam, C.; Kumar, P.M.; Kapur, P. Electrostatic hand pressure knapsack spray system with enhanced performance for small scale farms. J. Electrostat. 2013, 71, 785–790. [Google Scholar] [CrossRef]

- Llorens, J.; Gil, E.; Llop, J.; Escolà, A. Variable rate dosing in precision viticulture: Use of electronic devices to improve application efficiency. Crop Prot. 2009, 29, 239–248. [Google Scholar] [CrossRef]

- Wei, J.; Salyani, M. Development of a laser scanner for measuring tree canopy characteristics: Phase 1. prototype development. Trans. ASAE 2004, 47, 2101–2107. [Google Scholar] [CrossRef]

- Wei, J.; Salyani, M. Development of a laser scanner for measuring tree canopy characteristics: Phase 2. foliage density measurement. Trans. ASAE 2005, 48, 1595–1601. [Google Scholar] [CrossRef]

- Landers, A.; Muise, B. The development of an automatic precision canopy sprayer for fruit crops. Asp. Appl. Biol. 2010, 2010, 29–34. [Google Scholar]

- Cao, L. Experimental Study on Droplet Deposition Characteristics and Optimal Air Delivery System of Three Typical Orchards Air-Fed Sprayers. Master’s Thesis, Shandong Agricultural University, Tai’an, China, 2014. [Google Scholar]

- Chao, X.; Chen, S.; Qiu, W.; Lv, X.; Ahmad, F. Simulation and validation of the air flow generated by a multi-channel air assisted sprayer. IEEE Access 2019, 7, 94848–94857. [Google Scholar] [CrossRef]

- Duga, A.; Dekeyser, D.; Ruysen, K.; Bylemans, D.; Nuyttens, D.; Nicolai, B.; Pieter, V. Numerical Analysis of the Effects of Wind and Sprayer Type on Spray Distribution in Different Orchard Training Systems. Bound-Lay. Meteorol. 2015, 157, 517–535. [Google Scholar] [CrossRef]

- Hu, Y.; Yang, H.; Hou, B.; Xi, Z.; Yang, Z. Influence of Spray Control Parameters on the Performance of an Air-Blast Sprayer. Agriculture 2022, 12, 1260. [Google Scholar] [CrossRef]

- Jensen, P.; Olesen, M. Spray mass balance in pesticide application: A review. Crop Prot. 2014, 61, 23–31. [Google Scholar] [CrossRef]

- Baetens, K.; Nuyttens, D.; Verboven, P.; De Schampheleire, M.; Nicolaï, B.; Ramon, H. Predicting drift from field spraying by means of a 3D computational fluid dynamics model. Comput. Electron. Agric. 2007, 56, 161–173. [Google Scholar] [CrossRef]

- Qi, L.; Zhao, Y.; Wang, J.; Ji, R.; Mang, L. Analysis of droplet distribution characteristics of orchard air-driven sprayer based on CFD. Trans. Chin. Soc. Agric. Mach. 2010, 41, 62–67. [Google Scholar]

- GB/T 32250.3-2022; China National Standard. Standardization Administration of China: Beijing, China, 2022. Available online: https://kns.cnki.net/kcms2/article/abstract?v=Rda1fYUAxTnkltrBFY9fab5YRqm6klGT80idp919kvKhcBuEopBtUa0F9npU3QUyOKWFlMZcbAF0UXmydJX6gO6Bna01gG_27VcjPZivLr8Wg0ee0afpUd0iv23rAbzn&uniplatform=NZKPT&language=CHS (accessed on 17 May 2023).

- Tao, H.; Chen, H.; Xie, J.; Hu, Y. An alternative approach to quantifying fluid flow uniformity based on area-weighted average velocity and mass-weighted average velocity. Energy Build. 2012, 45, 116–123. [Google Scholar] [CrossRef]

- Tao, H.; Chen, H.; Xie, J.; Shu, C.; Hu, Y.; Lu, H. Fluid flow uniformity index based on area weighted average velocity and mass weighted average velocity. CIESC J. 2010, 61, 116–120. [Google Scholar]

- Wang, S.; Wang, W.; Lei, X.; Wang, S.; Li, X.; Norton, T. Canopy Segmentation Method for Determining the Spray Deposition Rate in Orchards. Agronomy 2022, 12, 1195. [Google Scholar] [CrossRef]

- Li, J.; Cui, H.; Ma, Y.; Xun, L.; Li, Z.; Yang, Z.; Lu, H. Orchard Spray Study: A Prediction Model of Droplet Deposition States on Leaf Surfaces. Agronomy 2020, 10, 747. [Google Scholar] [CrossRef]

- Chen, Y. Study on the Relationship between the Properties of Spray Liquid and the Utilisation Rate of Pesticide Deposition. Master’s Thesis, Chinese Academy of Agricultural Sciences, Beijing, China, 2021. [Google Scholar]

- Shi, R.; Sun, H.; Qiu, W.; Lv, X.; Ahmad, F.; Gu, J.; Yu, H.; Zhang, Z. Analysing Airflow Velocity in the Canopy to Improve Droplet Deposition for Air-Assisted Spraying: A Case Study on Pears. Agronomy 2022, 12, 2424. [Google Scholar] [CrossRef]

- GB/T 17997-2008; China National Standard. Standardization Administration of China: Beijing, China, 2008. Available online: https://kns.cnki.net/kcms2/article/abstract?v=Rda1fYUAxTkmTIqStvKu31rUxilqSlTOZEXUxQtQtMlV8KuMni31mrTDi3-cRrpyTN6py5DSjKya5ZHfqzg2RUmgpJPwaul_c4mIQHgtmXnh1hg_gonOijFh9v26Eo8v&uniplatform=NZKPT&language=CHS (accessed on 17 May 2023).

| Level | Factor | ||

|---|---|---|---|

| A (m/s) | B (°) | C (mm) | |

| −1 | 0.36 | 60 | 0.6 |

| 0 | 0.68 | 70 | 0.8 |

| 1 | 1 | 80 | 1 |

| Test Number | A (m/s) | B (°) | C (mm) | The Droplet Coverage of the Upper Canopy (%) | The Droplet Coverage of the Middle Canopy (%) | The Droplet Coverage of the Lower Canopy (%) |

|---|---|---|---|---|---|---|

| 1 | 0.36 | 80 | 0.8 | 75.325 | 89.426 | 62.822 |

| 2 | 0.68 | 70 | 0.8 | 70.386 | 92.554 | 69.971 |

| 3 | 1 | 70 | 1 | 49.285 | 65.872 | 63.288 |

| 4 | 1 | 80 | 0.8 | 73.462 | 70.812 | 61.657 |

| 5 | 0.68 | 80 | 0.6 | 73.192 | 82.084 | 57.054 |

| 6 | 0.68 | 70 | 0.8 | 72.064 | 88.955 | 70.189 |

| 7 | 0.36 | 70 | 1 | 72.826 | 77.308 | 68.216 |

| 8 | 0.36 | 60 | 0.8 | 62.95 | 76.658 | 73.92 |

| 9 | 0.68 | 70 | 0.8 | 72.547 | 90.169 | 69.437 |

| 10 | 1 | 60 | 0.8 | 52.206 | 70.344 | 66.126 |

| 11 | 0.36 | 70 | 0.6 | 78.852 | 71.028 | 62.27 |

| 12 | 0.68 | 60 | 1 | 47.676 | 70.843 | 71.892 |

| 13 | 0.68 | 60 | 0.6 | 56.068 | 77.624 | 70.971 |

| 14 | 0.68 | 80 | 1 | 50.265 | 82.023 | 66.773 |

| 15 | 1 | 70 | 0.6 | 73.074 | 73.092 | 60.68 |

| 16 | 0.68 | 70 | 0.8 | 70.92 | 88.33 | 71.596 |

| 17 | 0.68 | 70 | 0.8 | 71.231 | 90.275 | 67.937 |

| Source | R1 The Droplet Coverage of the Upper Canopy | R2 The Droplet Coverage of the Middle Canopy | R3 The Droplet Coverage of the Lower Canopy | |||

|---|---|---|---|---|---|---|

| F-Value | p-Value | F-Value | p-Value | F-Value | p-Value | |

| Model | 90.10 | 0.0001 | 20.04 | 0.0003 | 27.54 | 0.0001 |

| A | 148.52 | 0.0001 | 22.47 | 0.0021 | 21.39 | 0.0024 |

| B | 127.98 | 0.0001 | 15.92 | 0.0053 | 106.93 | 0.0001 |

| C | 230.04 | 0.0001 | 1.16 | 0.3178 | 32.90 | 0.0007 |

| AB | 0.0017 | 0.9684 | 5.78 | 0.0472 | 7.85 | 0.0265 |

| AC | 33.49 | 0.0007 | 6.96 | 0.0335 | 1.99 | 0.2012 |

| BC | 25.18 | 0.0015 | 1.72 | 0.2305 | 13.82 | 0.0075 |

| A2 | 9.13 | 0.0194 | 61.56 | 0.0001 | 34.30 | 0.0006 |

| B2 | 174.58 | 0.0001 | 7.72 | 0.0274 | 0.3039 | 0.5986 |

| C2 | 56.44 | 0.0001 | 45.92 | 0.0003 | 24.19 | 0.0017 |

| Lack of Fit | 5.11 | 0.0745 | 4.49 | 0.0905 | 0.5316 | 0.6846 |

| The Droplet Coverage of the Upper Canopy | The Droplet Coverage of the Middle Canopy | The Droplet Coverage of the Lower Canopy | |

|---|---|---|---|

| Optimal value | 74.92% | 90.01% | 69.9% |

| Test value | 76.59% | 87.11% | 71.75% |

| Error | 2.23% | 3.22% | 2.65% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Wang, X.; Li, C.; Lan, H.; He, Y.; Tang, Z.; Tang, Y. Performance Analysis and Testing of a Multi-Duct Orchard Sprayer. Agronomy 2023, 13, 1815. https://doi.org/10.3390/agronomy13071815

Li Z, Wang X, Li C, Lan H, He Y, Tang Z, Tang Y. Performance Analysis and Testing of a Multi-Duct Orchard Sprayer. Agronomy. 2023; 13(7):1815. https://doi.org/10.3390/agronomy13071815

Chicago/Turabian StyleLi, Zhanbiao, Xingyu Wang, Cui Li, Haipeng Lan, Yichuan He, Zhihui Tang, and Yurong Tang. 2023. "Performance Analysis and Testing of a Multi-Duct Orchard Sprayer" Agronomy 13, no. 7: 1815. https://doi.org/10.3390/agronomy13071815

APA StyleLi, Z., Wang, X., Li, C., Lan, H., He, Y., Tang, Z., & Tang, Y. (2023). Performance Analysis and Testing of a Multi-Duct Orchard Sprayer. Agronomy, 13(7), 1815. https://doi.org/10.3390/agronomy13071815