Impact of Soil-Applied Humic Ameliorative Amendment on the Ligno-Cellulose Quality and Calorific Value of Switchgrass Panicum virgatum L.

Abstract

1. Introduction

2. Materials and Methods

2.1. Pilot Screening Trials during 2018–2022

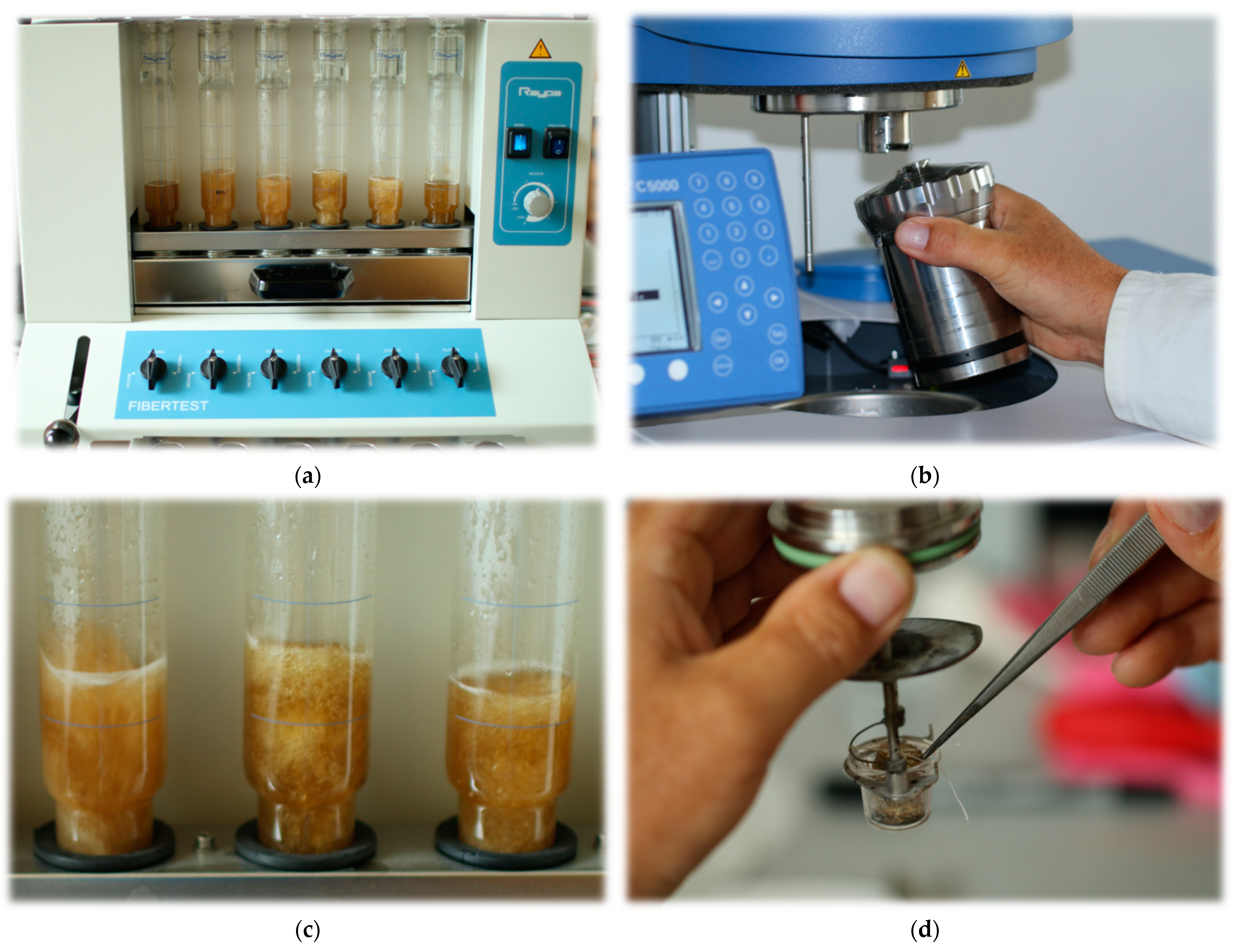

2.2. Laboratory Analyses

2.3. Statistical Methods

3. Results

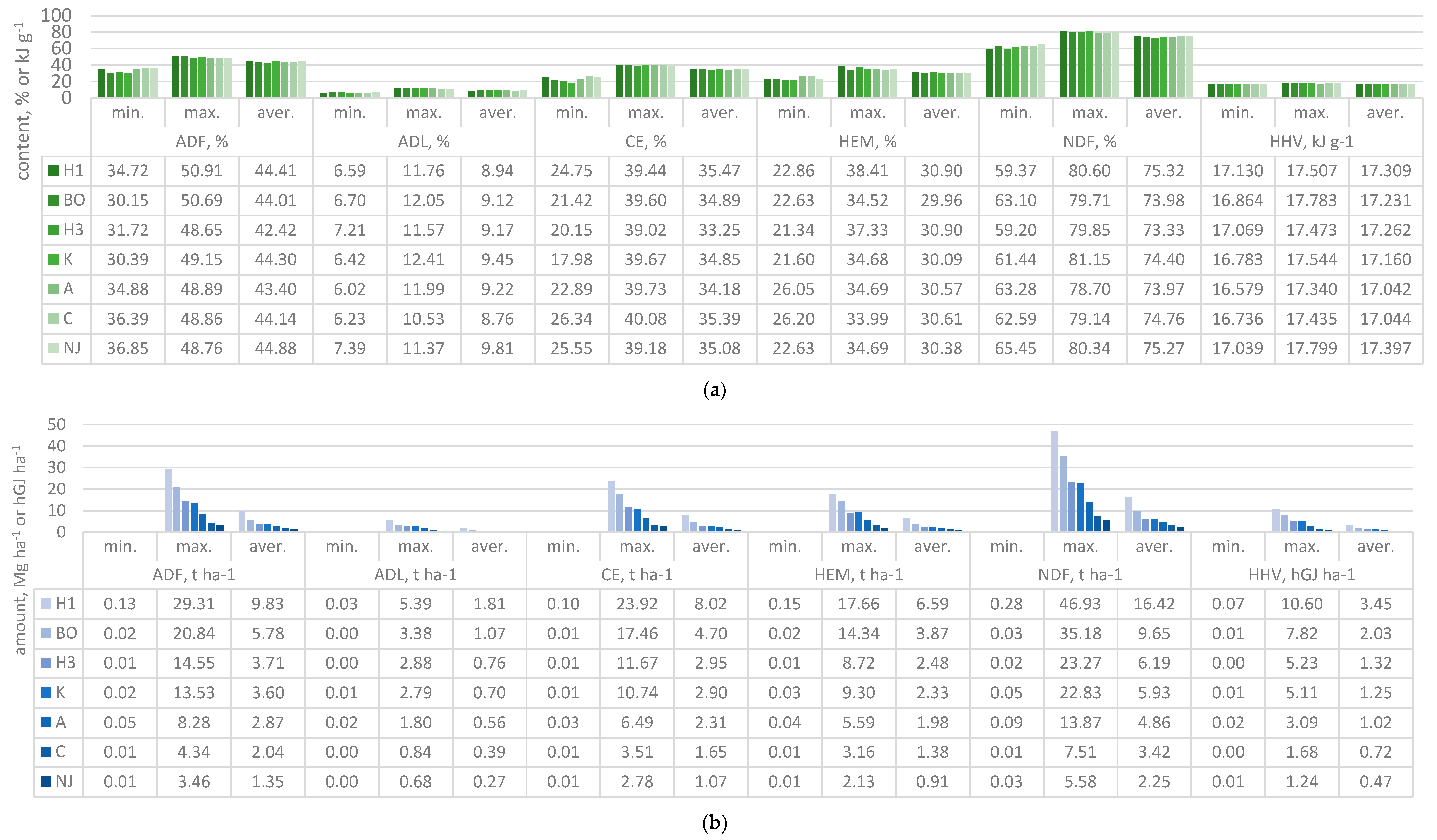

3.1. Mean Values and Main Effects

3.2. Levels of Main Effects

3.2.1. Quality Content

- the cultivars were accompanied by the highest proportion of differentiated homogeneous groups concerning calorific indicator HHV, while to a lesser extent concerning all ligno-cellulose indicators (ADF and NDF);

- the years were accompanied by a medium proportion of differentiated homogeneous groups, while to a lesser extent concerning HEM and NDF;

- the nutrition was accompanied by the smallest proportion of differentiated homogeneous groups.

3.2.2. Quality Yield

- cultivars were accompanied by a high proportion of differentiated groups, while

- ○

- the highest average values of each indicator always belonged to EG 1101 (the cultivar with the highest DM yield);

- ○

- the lowest average values of each indicators always belonged to NJ Ecotype (the cultivar with the lowest DM yield);

- ○

- the groups followed the cultivars in DM yield order: EG 1101 ˃ BO Master ˃ EG 1102 ˃ Kanlow ˃ Alamo ˃ Carthage ˃ NJ Ecotype (21.15, 12.48, 8.14, 7.70, 6.34, 4.47, and 2.89 Mg ha-1 DM, respectively, when ranking average yield);

- years were accompanied by the creation of four groups with a scheme identical to the crop increasing productivity in general, while

- ○

- the highest average values of each indicator were always achieved in 2021 (the year with the highest DM yield);

- ○

- the lowest average values of each indicators were always achieved in 2018 (the establishment year with the lowest DM yield);

- ○

- the groups followed the years by DM yield order: 2021 ˃ 2020 ˃ 2022 ˃ 2019 ˃ 2018 (19.13, 12.44, 7.73, 5.41, and 0.40 Mg ha−1 DM, respectively, when ranking average yield);

- nutrition treatments were accompanied by the creation of three groups with a scheme identical to the crop increasing productivity in general, while

- ○

- the highest average values of each indicators were always achieved with HA (the treatment with the highest DM yield);

- ○

- the lowest average values of each indicators were always achieved with UC (untreated control with the lowest DM yield);

- ○

- the groups followed the nutrition treatments by DM yield order HA ˃ NPK ˃ UC (13.69, 9.19, and 4.19 Mg ha−1 DM, respectively, when ranking average yield).

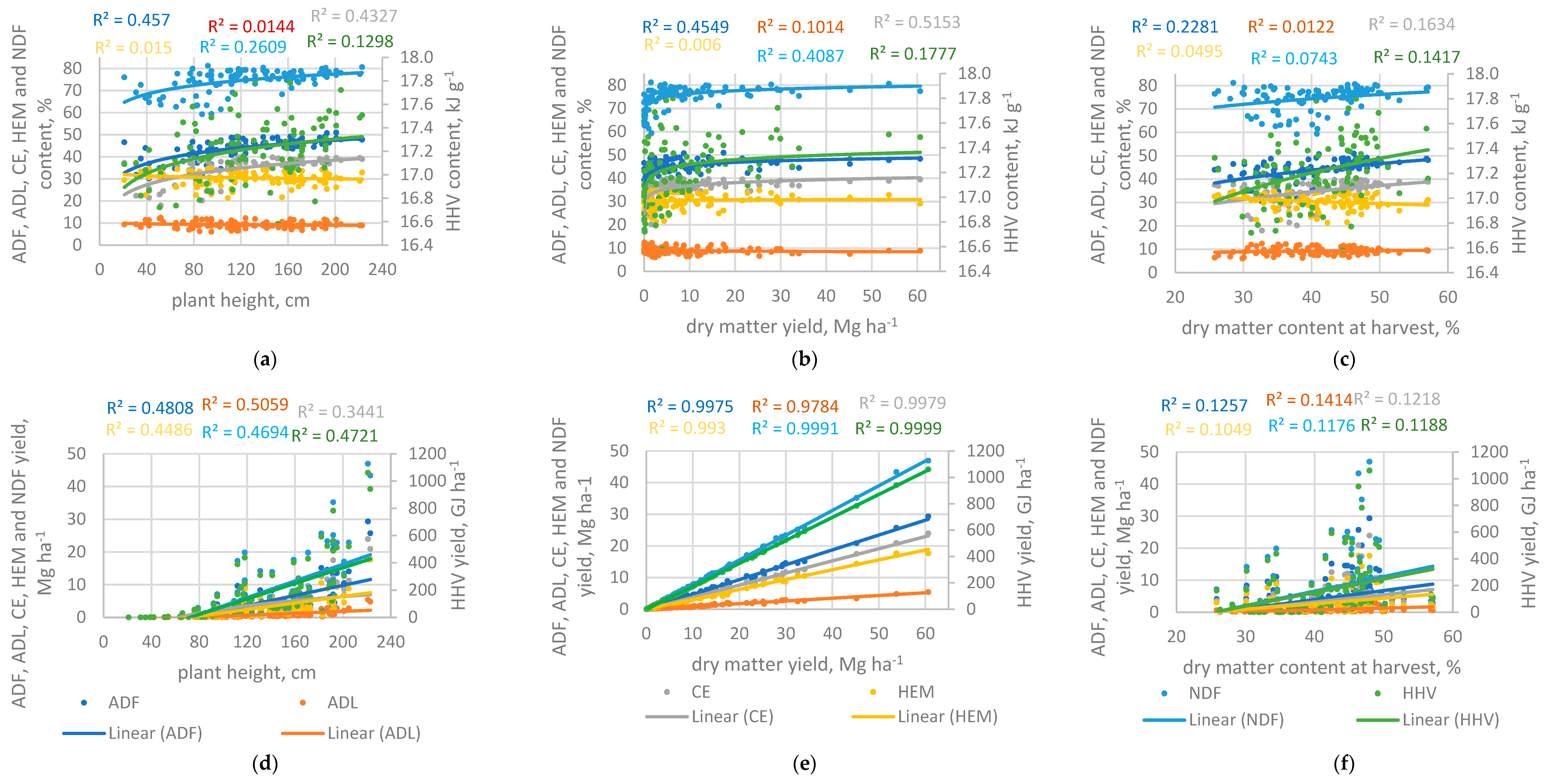

3.3. Impact of Plant Height, DM Yield and DM Content

- R2 ranged between 0.0150 and 0.2609 for the effect of ADL, HEM, NDF, and HHV on plant height;

- R2 ranged between 0.006 and 0.1777 for the effect of ADL, HEM and HHV on DM yield;

- R2 ranged between 0.0495 and 0.2281 for the effect of all the indicators on DM content at harvest;

- middle reliability within the indicators’ dependence on plant height, while

- ○

- R2 ranged from 0.3311 to 0.4721 under logarithmic courses and from 0.3441to 0.5059 under linear courses;

- ○

- the highest reliability was recorded for HHV (logarithmic 0.4721, linear 0.5059);

- strong reliability within the indicators’ dependence on DM yield with

- ○

- R2 ranging from 0.9784 to 0.9999 under linear courses, while

- ▪

- middle reliability was recorded with R2 of 0.3441–0.5059 under logarithmic courses, which was, therefore, less relevant for ligno-cellulose indicators (ADF and NDF)

- ▪

- there was strong reliability with R2 of 0.9999 for the calorific indicator HHV despite the logarithmic course being applied.

4. Discussion

4.1. Ligno-Cellulose Quality

4.2. Calorific Value

4.3. Impact of the Humic Amendment

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Scarlat, N.; Dallemand, J.; Taylor, N.; Banja, M. Brief on Biomass for Energy in the European Union; Publications Office of the European Union: Luxembourg, 2019; ISBN 978-92-79-77235-1. [Google Scholar] [CrossRef]

- Gordon, G.A.; Morris, C.; Lister, S.J.; Barraclough, T.; Yates, N.; Shield, I.; Donnison, I.S. Effect of nitrogen fertiliser application on cell wall composition in switchgrass and reed canary grass. Biomass Bioenergy 2012, 40, 19–26. [Google Scholar] [CrossRef]

- Owens, V.N.; Viands, D.R.; Mayton, H.S.; Fike, J.H.; Farris, R.; Heaton, E.; Bransby, D.I.; Hong, C.O. Nitrogen use in switchgrass grown for bioenergy across the USA. Biomass Bioenergy 2013, 58, 286–293. [Google Scholar] [CrossRef]

- Ameen, A.; Tang, C.; Liu, J.; Han, L.; Xie, G.H. Switchgrass as forage and biofuel feedstock: Effect of nitrogen fertilization rate on the quality of biomass harvested in late summer and early fall. Field Crops Res. 2019, 235, 154–162. [Google Scholar] [CrossRef]

- Nail, G.P.; Poonia, A.K.; Chaudhari, P.K. Pretreatment of lignocellulosic agricultural waste for delignification, rapid hydrolysis, and enhanced biogas production: A review. J. Ind. Chem. Soc. 2021, 98, 100147. [Google Scholar] [CrossRef]

- Bouton, J.H. Molecular breeding of switchgrass for use as a biofuel crop. Curr. Opin. Genet. Dev. 2007, 17, 553–558. [Google Scholar] [CrossRef]

- Song, Y.; Legeng, P.; Guanyi, C.; Mu, L.; Yan, B.; Li, H.; Zhou, T. Recent advancements in strategies to improve anaerobic digestion of perennial energy grasses for enhanced methane production. Sci. Total Environ. 2023, 861, 160552. [Google Scholar] [CrossRef]

- Vogel, J. Unique aspects of the grass cell wall. Curr. Opin. Plant Biol. 2008, 11, 301–307. [Google Scholar] [CrossRef]

- Butkuté, B.; Lemežiené, N.; Cesevičiené, J.; Liatukas, Ž.; Dabkevičiené, G. Carbohydrate and lignin partitioning in switchgrass (Panicum virgatum L.) biomass as a bioenergy feedstock. Zemdirb.-Agric. 2013, 100, 251–260. [Google Scholar] [CrossRef]

- Elbersen, H.W.; Christian, D.G.; El Bassem, N.; Bacher, W.; Sauerbeck, G.; Alexopoulou, E.; Sharma, N.; Piscioneri, I.; de Visser, P.; van der Berg, D. Switchgrass variety choice in Europe. Asp. Appl. Biol. 2001, 65, 21–28. [Google Scholar]

- Schmer, M.R.; Vogel, P.; Mitchell, R.B.; Perrin, R.K. Net energy of cellulosic ethanol from switchgrass. Proc. Natl. Acad. Sci. USA 2008, 105, 464–469. [Google Scholar] [CrossRef]

- Traversa, A.; Loffredo, E.; Gattullo, C.E.; Palazzo, A.J.; Bashore, T.L.; Senesi, N. Comparative evaluation of compost humic acids and their effects on the germination of switchgrass (Panicum vigatum L.). J. Soils Sedim. 2014, 14, 432–440. [Google Scholar] [CrossRef]

- Tóth, Š.; Dupľák, Š. Effect of a Soil-Applied Humic Ameliorative Amendment on the Yield Potential of Switchgrass Panicum virgatum L. Cultivated under Central European Continental Climate Conditions. Agronomy 2023, 13, 1095. [Google Scholar] [CrossRef]

- ISO 13906; Animal Feeding Stuffs–Determination of Acid Detergent Fibre (ADF) and Acid Detergent Lignin (ADL) Contents. 1st ed. International Organization for Standardization: Geneva, Switzerland, 2008; 17p.

- ISO 1928; Solid Mineral Fuels—Determination of Gross Calorific Value by the Bomb Calorimetric Method and Calculation of Net Calorific Value. International Organization for Standardization: Geneva, Switzerland, 2009; 62p.

- Lemus, R.; Brummer, E.C.; Moore, K.J.; Molstad, N.E.; Burras, C.L.; Barker, M.F. Biomass yield and quality of 20 switchgrass populations in southern Iowa, USA. Biomass Bioenergy 2002, 23, 433–442. [Google Scholar] [CrossRef]

- Pilon, G.; Lavoie, J.M. Biomass char production at low severity conditions under CO2 and N2 environments. Trans. Ecol. Environ. 2011, 143, 109–121. [Google Scholar] [CrossRef]

- Han, K.J.; Moon, Y.; Day, D.F.; Pitman, W.D. Feedstock analysis sensitivity for estimating ethanol production potential in switchgrass and energy cane biomass. Int. J. Energy Res. 2015, 40, 248–256. [Google Scholar] [CrossRef]

- Serapiglia, M.J.; Mullen, C.A.; Boateng, A.A.; Cortese, L.M.; Bonos, S.A.; Hoffman, L. Evaluation of the impact of compositional differences in switchgrass genotypes on pyrolysis product yield. Ind. Crops Prod. 2015, 74, 957–968. [Google Scholar] [CrossRef]

- Oginni, O.; Singh, K.; Zondlo, J.W. Pyrolysis of dedicated bioenergy crops grown on reclaimed mine land in West Virginia. J. Anal. Appl. Pyrol. 2017, 123, 319–329. [Google Scholar] [CrossRef]

- Oginni, O.; Singh, K. Pyrolysis characteristics of Arundo donax harvested from a reclaimed mine land. Ind. Crops Prod. 2019, 133, 44–53. [Google Scholar] [CrossRef]

- Kupryś-Caruk, M.; Podlaski, S.; Kotyrba, D. Influence of double-cut harvest system on biomass yield, quality and biogas production from C4 perennial grasses. Biomass Bioenergy 2019, 130, 105376. [Google Scholar] [CrossRef]

- Amaleviciute-Volunge, K.; Slepetiene, A.; Butkute, B. The suitability of perennial grasses for combustion as influenced by chemical composition and plant growth stage. Zemdirb.-Agric. 2020, 107, 317–322. [Google Scholar] [CrossRef]

- Razar, R.; Makaju, S.; Missaoui, A.M. QTL mapping of biomass and forage quality traits measured using near-infrared reflectance spectroscopy (NIRS) in switchgrass. Euphytica 2021, 217, 2021. [Google Scholar] [CrossRef]

- Sacristán, D.; Cifre, J.; Llompart, M.; Jaume, J.; Gulias, J. Lignocellulosic biomass production and persistence of perennial grass species grown in mediterranean marginal lands. Agronomy 2021, 11, 2060. [Google Scholar] [CrossRef]

- Brown, C.; Griggs, T.; Holaskova, I.; Skousen, J. Switchgrass biofuel production on reclaimed surface mines: II. Feedstock quality and theoretical ethanol production. BioEnergy Res. 2016, 9, 40–49. [Google Scholar] [CrossRef]

- Corleto, A.; Cazzato, E.; Ventricelli, P.; Cosentino, S.L.; Gresta, F.; Testa, G.; Maiorana, M.; Fornaro, F.; De Giorgio, D. Performance of perennial tropical grasses in different Mediterranean environments in southern Italy. Trop. Grassl. 2009, 43, 129–138. Available online: https://www.researchgate.net/publication/237052615_Performance_of_perennial_tropical_grasses_in_different_Mediterranean_environments_in_southern_Italy (accessed on 9 July 2023).

- Xu, Y.; Porter, N.; Foster, J.L.; Muir, J.P.; Schwab, P.; Burson, B.L.; Jessup, R.W. Silica production across candidate lignocellulosic biorefinery feedstocks. Agronomy 2020, 10, 82. [Google Scholar] [CrossRef]

- Madakadze, I.C.; Stewart, K.; Peterson, P.R.; Coulman, B.E.; Smith, D.L. Switchgrass biomass and chemical composition for biofuel in eastern Canada. Agron. J. 1999, 91, 696–701. [Google Scholar] [CrossRef]

- Sanderson, M.A.; Wolf, D.D. Switchgrass biomass composition during morphological development in diverse environments. Crop Sci. 1995, 35, 1432–1438. [Google Scholar] [CrossRef]

- Yan, J.; Hu, Z.; Pu, Y.; Brummer, E.C.; Ragauskas, A.J. Chemical compositions of four switchgrass populations. Biomass Bioenergy 2010, 34, 48–53. [Google Scholar] [CrossRef]

- Aurangzaib, M.; Moore, K.J.; Archontoulis, S.V.; Heaton, E.A.; Lenssen, A.W.; Fei, S. Compositional differences among upland and lowland switchgrass ecotypes grown as a bioenergy feedstock crop. Biomass Bioenergy 2016, 87, 169–177. [Google Scholar] [CrossRef]

- David, K.; Ragauskas, A.J. Switchgrass as an energy crop for biofuel production: A review of its ligno-cellulosic chemical properties. Energy Environ. Sci. 2010, 3, 1182–1190. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Q.; Liu, Y.; Cui, J.; Ma, X.; Gu, M.; Xia, M. Coupling effects of water availability and pH on switchgrass and the optimization of these variables for switchgrass productivity determined by response surface methodology. Biomass Bioenergy 2015, 83, 393–402. [Google Scholar] [CrossRef]

- Giannoulis, K.D.; Bartzialis, D.; Skoufogianni, E.; Charvalas, G.; Danalatos, N.G. Comparison of two perennial energy crops for biomass production at the end of their life cycle. Agron. Res. 2020, 18, 1267–1277. [Google Scholar] [CrossRef]

- Hoagland, K.C.; Ruark, M.D.; Renz, M.J.; Jackson, R.D. Agricultural management of switchgrass for fuel quality and thermal energy yield on highly erodible land in the driftless area of Southwest Wisconsin. Bioenergy Res. 2013, 6, 1012–1021. [Google Scholar] [CrossRef]

- Amabogha, O.; Garelick, H.; Jones, H.; Purchase, D. Combining phytoremediation with bioenergy production: Developing a multi-criteria decision matrix for plant species selection. Environ. Sci. Pollut. Res. 2023, 30, 40698–40711. [Google Scholar] [CrossRef] [PubMed]

- Florine, S.E.; Moore, K.J.; Fales, S.L.; White, T.A.; Burras, C.L. Yield and composition of herbaceous biomass harvested from naturalized grassland in southern Iowa. Biomass Bioenergy 2006, 30, 522–528. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Grinding performance and physical properties of wheat and barley straws, corn stover and switchgrass. Biomass Bioenergy 2004, 27, 339–352. [Google Scholar] [CrossRef]

- Iqbal, Y.; Gauder, M.; Claupein, W.; Graeff-Hönninger, S.; Lewandowski, I. Yield and quality development comparison between miscanthus and switchgrass over a period of 10 years. Energy 2015, 89, 268–276. [Google Scholar] [CrossRef]

- Mulkey, V.R.; Owens, V.N.; Lee, D.K. Management of switchgrass-dominated conservation reserve program lands for biomass production in South Dakota. Crop Sci. 2006, 46, 712–720. [Google Scholar] [CrossRef]

- Lemus, R.; Brummer, E.C.; Burras, C.L.; Moore, K.J.; Barker, M.F.; Molstad, N.E. Effects of nitrogen fertilization on biomass yield and quality in large fields of established switchgrass in southern Iowa, USA. Biomass Bioenergy 2008, 32, 1187–1194. [Google Scholar] [CrossRef]

- Mohammed, Y.A.; Raun, W.; Kakani, G.; Zhang, H.; Taylor, R.; Desta, K.G.; Jared, C.; Mullock, J.; Bushong, J.; Sutradhar, A.; et al. Nutrient sources and harvesting frequency on quality biomass production of switchgrass (Panicum virgatum L.) for biofuel. Biomass Bioenergy 2015, 81, 242–248. [Google Scholar] [CrossRef]

- Seepaul, R.; Macoon, B.; Reddy, K.R.; Evans, W.B. First harvest timing and nitrogen application rate effects on chemical composition and ethanol yield of switchgrass. Crop Forage Turfgrass Manag. 2016, 2, 1–16. [Google Scholar] [CrossRef]

- Tang, C.C.; Han, L.P.; Xie, G.H. Response of switchgrass grown for forage and bioethanol to nitrogen, phosphorus, and potassium on semiarid marginal land. Agronomy 2020, 10, 1147. [Google Scholar] [CrossRef]

- Lee, M.S.; Urgun-Demirtas, M.; Shen, Y.; Zumpf, C.; Anderson, E.K.; Rayburn, A.L.; Lee, D.K. Effect of digestate and digestate supplemented with biochar on switchgrass growth and chemical composition. Biomass Bioenergy 2021, 144, 105928. [Google Scholar] [CrossRef]

- Saidur, R.; Atabani, A.E.; Mekhilef, S. A review on electrical and thermal energy for industries. Renew. Sustain. Energy Rev. 2011, 15, 2073–2086. [Google Scholar] [CrossRef]

- Saidur, R.; Abdelaziz, E.A.; Demirbas, A.; Hossain, M.S.; Mekhilef, S. A review on biomass as a fuel for boilers. Renew. Sustain. Energy Rev. 2011, 15, 2262–2289. [Google Scholar] [CrossRef]

- Amaleviciute, K.; Slepetiene, A.; Butkute, B. Methane yield of perennial grasses as affected by the chemical composition of their biomass. Zemdirbyste 2020, 107, 243–248. [Google Scholar] [CrossRef]

- Ayuso, M.; Hernández, T.; García, C.; Pascual, J.A. Stimulation of barley growth and nutrient absorption by humic substances originating from various organic materials. Bioresour. Technol. 1996, 5, 251–257. [Google Scholar] [CrossRef]

- Eyheraguibel, B.; Silvestre, J.; Morard, P. Effects of humic substances derived from organic waste enhancement on the growth and mineral nutrition of maize. Bioresour. Technol. 2008, 99, 4206–4212. [Google Scholar] [CrossRef]

- Loffredo, E.; Senesi, N. In vitro and in vivo assessment of the potential of compost and its humic acid fraction to protect ornamental plants from soil-borne pathogenic fungi. Sci. Hortic. 2009, 122, 432–439. [Google Scholar] [CrossRef]

- Tóth, Š.; Šoltysová, B.; Danilovič, M.; Kováč, L.; Hnát, A.; Kotorová, D.; Šariková, D.; Jakubová, J.; Balla, P.; Štyriak, I.; et al. The Meaning and Effect of Different Types of Soil Improvers in Conditions of Different Soil Management Practice, 1st ed.; Centrum Výskumu Rastlinnej Výroby Piešťany: Michalovce, Slovakia, 2013; p. 108. ISBN 978-80-89417-46-9. (In Slovak) [Google Scholar]

- Tóth, Š.; Rysak, W.; Šoltysová, B.; Karahuta, J. Effect of soil conditioner based on humic acids HUMAC Agro on soil and yield and sugar content of sugar beet in context of selected indicators of agriculture system sustainability. Listy Cukrov. Reparske 2015, 131, 53–58. [Google Scholar]

- Tóth, Š.; Szanyi, G.; Vančo, P.; Schubert, J.; Porvaz, P.; Bujňák, P.; Šoltysova, B.; Danielovič, I. The influence of mineral nutrition and humic acids on the intensity of photosynthesis, as well as the yield and quality of seeds, roots, and aboveground phytomass of milk thistle Silybum marianum (L.) Gaertn. in marginal growing conditions. Eur. Pharm. J. 2022, 69, 27–36. [Google Scholar] [CrossRef]

- Tóth, Š. Ligno-cellulose quality and calorific value of Elymus elongatus L. and the novel Secale cereanum tested under central european conditions. Agriculture 2022, 68, 155–175. [Google Scholar] [CrossRef]

| Main Source | ADF | ADL | CE | HEM | NDF | HHV | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IO | F-Ratio | p-Value | IO | F-Ratio | p-Value | IO | F-Ratio | p-Value | IO | F-Ratio | p-Value | IO | F-Ratio | p-Value | IO | F-Ratio | p-Value | |

| Cultivars | 1 | 49.63 | 0.0000 | 1 | 17.63 | 0.0000 | 1 | 70.54 | 0.0000 | 1 | 10.65 | 0.0000 | 3 | 0.98 | 0.4438 | 1 | 12.44 | 0.0000 |

| Years | 2 | 8.85 | 0.0003 | 2 | 2.54 | 0.0841 | 2 | 5.51 | 0.2080 | 2 | 3.70 | 0.0265 | 1 | 57.23 | 0.0000 | 2 | 8.34 | 0.0005 |

| Nutrition | 3 | 1.48 | 0.1945 | 3 | 1.30 | 0.2672 | 3 | 1.44 | 0.0000 | 3 | 0.25 | 0.9572 | 2 | 2.55 | 0.0839 | 3 | 10.09 | 0.0000 |

| Main Source | ADF | ADL | CE | HEM | NDF | HHV | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IO | F-Ratio | p-Value | IO | F-Ratio | p-Value | IO | F-Ratio | p-Value | IO | F-Ratio | p-Value | IO | F-Ratio | p-Value | IO | F-Ratio | p-Value | |

| Cultivars | 1 | 23.39 | 0.0000 | 1 | 22.18 | 0.0000 | 1 | 23.46 | 0.0000 | 1 | 24.48 | 0.0000 | 3 | 12.62 | 0.0000 | 3 | 12.86 | 0.0000 |

| Years | 2 | 17.05 | 0.0000 | 2 | 18.32 | 0.0000 | 2 | 16.59 | 0.0000 | 2 | 17.24 | 0.0000 | 1 | 24.01 | 0.0000 | 2 | 17.68 | 0.0000 |

| Nutrition | 3 | 12.32 | 0.0000 | 3 | 11.50 | 0.0000 | 3 | 12.38 | 0.0000 | 3 | 12.80 | 0.0000 | 2 | 17.28 | 0.0000 | 1 | 24.13 | 0.0000 |

| Main Source | ADF | ADL | CE | HEM | NDF | HHV | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H | LS Mean | LS Sigma | H | LS Mean | LS Sigma | H | LS Mean | LS Sigma | H | LS Mean | LS Sigma | H | LS Mean | LS Sigma | H | LS Mean | LS Sigma | |

| cultivars | ||||||||||||||||||

| EG 1101 | a | 44.411 | 0.6617 | b | 8.941 | 0.3000 | a | 35.469 | 0.6467 | a | 30.903 | 0.7313 | a | 75.315 | 0.7406 | ab | 17,309 | 41.88 |

| BO Master | ab | 44.015 | 0.6617 | ab | 9.123 | 0.3000 | ab | 34.891 | 0.6467 | a | 29.964 | 0.7313 | a | 73.978 | 0.7406 | bc | 17,231 | 41.88 |

| EG 1102 | b | 42.424 | 0.6617 | ab | 9.169 | 0.3000 | c | 32.255 | 0.6467 | a | 30.903 | 0.7313 | a | 73.327 | 0.7406 | b | 17,262 | 41.88 |

| Kanlow | a | 44.303 | 0.6617 | ab | 9.453 | 0.3000 | ab | 34.850 | 0.6467 | a | 30.092 | 0.7313 | a | 74.396 | 0.7406 | cd | 17,160 | 41.88 |

| Alamo | ab | 43.401 | 0.6617 | ab | 9.217 | 0.3000 | ab | 34.184 | 0.6467 | a | 30.571 | 0.7313 | a | 73.971 | 0.7406 | d | 17,042 | 41.88 |

| Carthage | ab | 44.144 | 0.6617 | b | 8.759 | 0.3000 | a | 35.385 | 0.6467 | a | 30.611 | 0.7313 | a | 74.755 | 0.7406 | d | 17,044 | 41.88 |

| NJ Ecotype | a | 44.885 | 0.6617 | a | 9.806 | 0.3000 | a | 35.079 | 0.6467 | a | 30.384 | 0.7313 | a | 75.268 | 0.7406 | a | 17,398 | 41.88 |

| years | ||||||||||||||||||

| 2018 | c | 37.036 | 0.5759 | a | 10.423 | 0.2535 | c | 26.512 | 0.5466 | b | 29.329 | 0.6181 | c | 66.365 | 0.6259 | c | 17,043 | 35.40 |

| 2019 | a | 46.052 | 0.5759 | a | 10.194 | 0.2535 | b | 35.858 | 0.5466 | b | 29.126 | 0.6181 | b | 75.178 | 0.6259 | b | 17,244 | 35.40 |

| 2020 | a | 46.151 | 0.5759 | b | 8.923 | 0.2535 | ab | 37.228 | 0.5466 | b | 28.720 | 0.6181 | b | 74.871 | 0.6259 | b | 17,186 | 35.40 |

| 2021 | a | 46.162 | 0.5759 | bc | 8.559 | 0.2535 | a | 37.603 | 0.5466 | a | 32.045 | 0.6181 | a | 78.207 | 0.6259 | a | 17,387 | 35.40 |

| 2022 | b | 44.301 | 0.5759 | c | 7.95 | 0.2535 | ab | 36.351 | 0.5466 | a | 33.231 | 0.6181 | a | 77.531 | 0.6259 | b | 17,172 | 35.40 |

| nutrition | ||||||||||||||||||

| HA | a | 44.390 | 0.4332 | a | 9.417 | 0.1964 | a | 34.974 | 0.4234 | b | 29.619 | 0.4788 | ab | 74.010 | 0.4848 | b | 17,182 | 27.42 |

| NPK | a | 44.944 | 0.4332 | ab | 9.363 | 0.1964 | a | 35.580 | 0.4234 | ab | 30.379 | 0.4788 | a | 75.323 | 0.4848 | a | 17,295 | 27.42 |

| UC | b | 42.487 | 0.4332 | b | 8.849 | 0.1964 | b | 33.637 | 0.4234 | a | 31.471 | 0.4788 | b | 73.958 | 0.4848 | b | 17,143 | 27.42 |

| Main Source | ADF | ADL | CE | HEM | NDF | HHV | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H | LS Mean | LS Sigma | H | LS Mean | LS Sigma | H | LS Mean | LS Sigma | H | LS Mean | LS Sigma | H | LS Mean | LS Sigma | H | LS Mean | LS Sigma | |

| cultivars | ||||||||||||||||||

| EG 1101 | a | 9.828 | 0.8171 | a | 1.812 | 0.1503 | a | 8.016 | 0.6676 | a | 6.594 | 0.5366 | a | 16.422 | 1.3474 | a | 367.89 | 29.891 |

| BO Master | b | 5.775 | 0.8171 | b | 1.073 | 0.1503 | b | 4.702 | 0.6676 | b | 3.872 | 0.5366 | b | 9.647 | 1.3474 | b | 216.18 | 29.891 |

| EG 1102 | bc | 3.707 | 0.8171 | bc | 0.757 | 0.1503 | bc | 2.950 | 0.6676 | bc | 2.485 | 0.5366 | bc | 6.191 | 1.3474 | bc | 141.05 | 29.891 |

| Kanlow | bcd | 3.598 | 0.8171 | bcd | 0.695 | 0.1503 | bcd | 2.903 | 0.6676 | cd | 2.335 | 0.5366 | bcd | 5.933 | 1.3474 | bcd | 133.42 | 29.891 |

| Alamo | cd | 2.872 | 0.8171 | cd | 0.561 | 0.1503 | cd | 2.312 | 0.6676 | cd | 1.983 | 0.5366 | cd | 4.856 | 1.3474 | cd | 108.67 | 29.891 |

| Carthage | cd | 2.036 | 0.8171 | cd | 0.389 | 0.1503 | cd | 1.647 | 0.6676 | cd | 1.383 | 0.5366 | cd | 3.419 | 1.3474 | cd | 76.62 | 29.891 |

| NJ Ecotype | d | 1.346 | 0.8171 | d | 0.272 | 0.1503 | d | 1.074 | 0.6676 | d | 0.907 | 0.5366 | d | 2.253 | 1.3474 | d | 50.42 | 29.891 |

| years | ||||||||||||||||||

| 2018 | d | 0.145 | 0.6906 | d | 0.043 | 0.1293 | d | 0.101 | 0.5642 | d | 0.109 | 0.4535 | d | 0.254 | 1.1388 | d | 6.84 | 25.262 |

| 2019 | c | 2.590 | 0.6906 | c | 0.570 | 0.1293 | d | 0.202 | 0.5642 | c | 1.541 | 0.4535 | c | 4.132 | 1.1388 | c | 93.52 | 25.262 |

| 2020 | b | 5.706 | 0.6906 | b | 1.088 | 0.1293 | b | 4.618 | 0.5642 | b | 3.722 | 0.4535 | b | 9.428 | 1.1388 | b | 214.71 | 25.262 |

| 2021 | a | 8.967 | 0.6906 | a | 1.660 | 0.1293 | a | 7.307 | 0.5642 | a | 6.027 | 0.4535 | a | 14.994 | 1.1388 | a | 333.42 | 25.262 |

| 2022 | c | 3.422 | 0.6906 | c | 0.609 | 0.1293 | c | 2.813 | 0.5642 | bc | 2.571 | 0.4535 | c | 5.993 | 1.1388 | c | 133.13 | 25.262 |

| nutrition | ||||||||||||||||||

| HA | a | 6.314 | 0.5349 | a | 1.208 | 0.1002 | a | 5.106 | 0.4370 | a | 4.209 | 0.3513 | a | 10.524 | 0.8821 | a | 236.82 | 19.568 |

| NPK | b | 4.284 | 0.5349 | b | 0.823 | 0.1002 | b | 3.460 | 0.4370 | b | 2.878 | 0.3513 | b | 7.161 | 0.8821 | b | 159.78 | 19.568 |

| UC | c | 1.901 | 0.5349 | c | 0.352 | 0.1002 | c | 1.549 | 0.4370 | c | 1.295 | 0.3513 | c | 3.196 | 0.8821 | c | 72.37 | 19.568 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tóth, Š.; Šoltysová, B.; Dupľák, Š.; Porvaz, P. Impact of Soil-Applied Humic Ameliorative Amendment on the Ligno-Cellulose Quality and Calorific Value of Switchgrass Panicum virgatum L. Agronomy 2023, 13, 1854. https://doi.org/10.3390/agronomy13071854

Tóth Š, Šoltysová B, Dupľák Š, Porvaz P. Impact of Soil-Applied Humic Ameliorative Amendment on the Ligno-Cellulose Quality and Calorific Value of Switchgrass Panicum virgatum L. Agronomy. 2023; 13(7):1854. https://doi.org/10.3390/agronomy13071854

Chicago/Turabian StyleTóth, Štefan, Božena Šoltysová, Štefan Dupľák, and Pavol Porvaz. 2023. "Impact of Soil-Applied Humic Ameliorative Amendment on the Ligno-Cellulose Quality and Calorific Value of Switchgrass Panicum virgatum L." Agronomy 13, no. 7: 1854. https://doi.org/10.3390/agronomy13071854

APA StyleTóth, Š., Šoltysová, B., Dupľák, Š., & Porvaz, P. (2023). Impact of Soil-Applied Humic Ameliorative Amendment on the Ligno-Cellulose Quality and Calorific Value of Switchgrass Panicum virgatum L. Agronomy, 13(7), 1854. https://doi.org/10.3390/agronomy13071854