Formulation of Matrine Oil-Based Suspension Concentrate for Improving the Wetting of Droplets and Spraying Performance

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials and Instruments

2.2. Preparation of Matrine OD

2.3. Stability Test

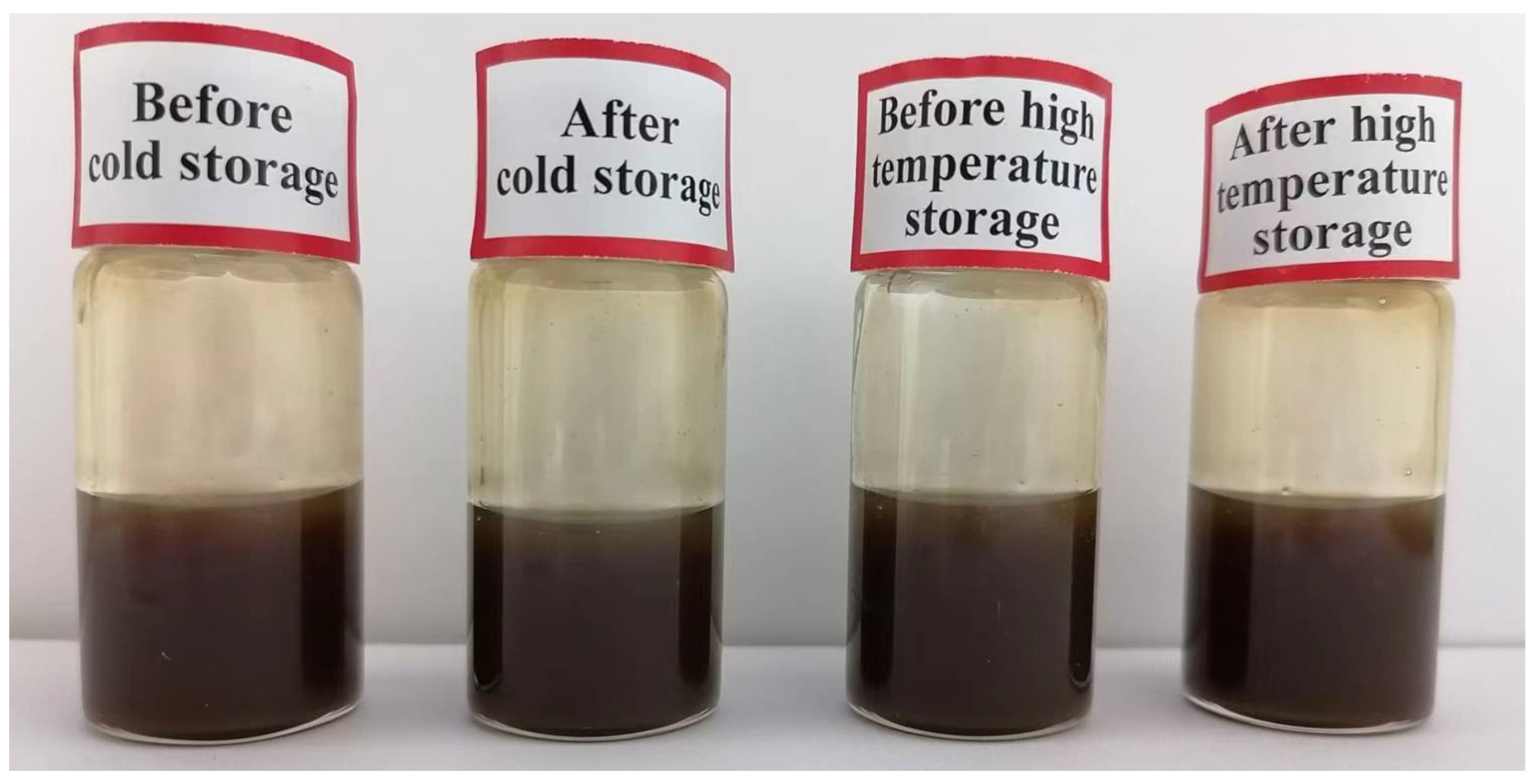

2.3.1. High-Temperature Stability

- a—Effective content before high-temperature storage%;

- b—Effective content after high-temperature storage%;

- c—Decomposition rate of active ingredient%.

2.3.2. Low-Temperature Stability

2.3.3. Suspensibility

2.3.4. Viscosity

2.4. Determination of Wettability

2.4.1. Static Surface Tension (SST)

2.4.2. Dynamic Contact Angle

2.4.3. Droplet Density and Coverage

2.4.4. Maximum Retention

2.5. Indoor Control Effect Test

2.6. Determination of Adhesion Work and Adhesion Tension

3. Results and Discussion

3.1. Influence of Emulsifiers on the Stability of Matrine OD

3.2. Suspensibility

3.3. Viscosity of Suspension

3.4. Wettability of Pesticide Droplets

3.5. Maximum Retention of Matrine OD Droplets

3.6. Pharmacodynamic Test

3.7. Wetting Mechanism of Matrine OD Droplets

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, N.J.; Sun, C.J.; Jiang, J.J.; Wang, A.; Wang, C.; Shen, Y.; Huang, B.; An, C.C.; Cui, B.; Zhao, X.; et al. Advances in controlled-release pesticide formulations with improved efficacy and targetability. J. Agric. Food Chem. 2021, 69, 12579–12597. [Google Scholar] [CrossRef]

- Guo, K.Y.; Deng, X.L.; Peng, Y.J.; Yang, N.; Qian, K.; Bai, L.Y. A MOF-based pH-responsive dual controlled release system for herbicide pretilachlor and safener AD-67 delivery that enhances the herbicidal efficacy and reduces side effects. Environ. Sci. Nano 2023, 10, 1016. [Google Scholar] [CrossRef]

- Deng, X.L.; Zhao, P.Y.; Xie, Y.; Bai, L.Y. Self-Assembled Sphere Covalent Organic Framework with Enhanced Herbicidal Activity by Loading Cyhalofop-butyl. J. Agric. Food Chem. 2023, 71, 1417–1425. [Google Scholar] [CrossRef] [PubMed]

- Deng, X.L.; Zhao, P.Y.; Zhou, X.M.; Bai, L.Y. Excellent sustained-release efficacy of herbicide quinclorac with cationic covalent organic frameworks. Chem. Eng. J. 2021, 405, 1269–1279. [Google Scholar] [CrossRef]

- Gontijo, P.C.; Abbade, D.N.; Oliveira, R.L.; Michaud, J.P.; Carvalho, G.A. Non-target impacts of soybean insecticidal seed treatments on the life history and behavior of podisus nigrispinus, a predator of fall armyworm. Chemosphere 2017, 191, 342–349. [Google Scholar] [CrossRef] [PubMed]

- Yu, A.; Wang, X.L.; Zuo, Z.H.; Cai, J.L.; Wang, C.G. Tributyltin exposure influences predatory behavior, neurotransmitter content and receptor expression in sebastiscus marmoratus. Aquat. Toxicol. 2013, 128, 158–162. [Google Scholar] [CrossRef]

- Pavela, R. Encapsulation—A convenient way to extend the persistence of the effect of eco-friendly mosquito larvicides. Curr. Org. Chem. 2016, 20, 2674–2680. [Google Scholar] [CrossRef] [Green Version]

- Benelli, G.; Pavela, R. Beyond mosquitoes—Essential oil toxicity and repellency against bloodsucking insects. Ind. Crops Prod. 2018, 117, 382–392. [Google Scholar] [CrossRef]

- Murunde, R.; Ringo, G.; Robinson-Boyer, L.; Xu, X. Effective Biocontrol of Rice Blast through Dipping Transplants and Foliar Applications. Agronomy 2022, 12, 592. [Google Scholar] [CrossRef]

- Wang, X.; Lin, H.; Ren, Z. The clinical efficacy and adverse effects of interferon combined with MATRINE in chronic hepatitis B: A systematrineic review and meta-analysis. Phytother. Res. 2017, 31, 849–857. [Google Scholar] [CrossRef]

- Yang, Y.; Dong, Q.; Li, R. Matrine induces the apoptosis of fibroblast-like synoviocytes derived from rats with collagen-induced arthritis by suppressing the activation of the jak/stat signaling pathway. Int. J. Mol. Med. 2017, 39, 307–316. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, Y.B.; Zhang, X.L.; Chen, N.H.; Wu, Z.N.; Ye, W.C.; Li, Y.L.; Wang, G.C. Four matrine-based alkaloids with antiviral activities against HBV from the seeds of Sophora alopecuroides. Org. Lett. 2017, 19, 424–427. [Google Scholar] [CrossRef] [PubMed]

- Zhou, B.G.; Wei, C.S.; Zhang, S.; Zhang, Z.; Gao, H.M. Matrine reversed multidrug resistance of breast cancer MCF-7/ADR cells through PI3K/AKT signal pathway. J. Cell. Biochem. 2017, 119, 3885–3891. [Google Scholar] [CrossRef]

- Dou, M.X.; Yao, M.; Wu, Z.F.; Zhang, W.; Ma, Z.Q.; Zhang, X. The environment behavior of matrine in the soil. Chin. J. Pestic. Sci. 2017, 19, 576–582. [Google Scholar]

- Ma, Z.Q.; Dou, M.X.; Yao, M.; Feng, J.T.; Zhang, X.; Wu, Z.F. Hydrolysis dynamic of matrine and its degradation properties in natural waters. Chin. J. Pestic. Sci. 2017, 19, 347–354. [Google Scholar]

- Dou, M.X.; Shi, X.L.; Ma, Z.Q.; Zhang, X.; Wu, Z.F. Toxicity evaluation of 4 matrine -based products on non-target organisms. Chin. J. Pestic. Sci. 2018, 20, 49–57. [Google Scholar]

- Ma, T.; Shi, X.L.; Ma, S.J.; Ma, Z.Q.; Zhang, X. Evaluation of physiological and biochemical effects of two Sophora alopecuroides alkaloids on pea aphids. Acyrthosiphon pisum. Pest Manag. Sci. 2020, 76, 4000–4008. [Google Scholar] [CrossRef]

- Day, R.; Abrahams, P.; Bateman, M.; Beale, T.; Clottey, V.; Cock, M.; Colmenarez, Y.; Corniani, N.; Early, R.; Godwin, J.; et al. Fall armyworm: Impacts and implications for Africa. Outlooks Pest Manag. 2017, 28, 196–201. [Google Scholar] [CrossRef] [Green Version]

- Goergen, G.; Kumar, P.L.; Sankung, S.B.; Togola, A.; Tamo, M. First report of outbreaks of the fall armyworm, Spodoptera frugiperda (JE Smith) (Lepidoptera, Noctuidae), a new alien invasive pest in west and central Africa. PLoS ONE 2016, 11, e0165632. [Google Scholar] [CrossRef] [Green Version]

- Montezano, D.G.; Specht, A.; Sosa-Gómez, D.R.; Roque-Specht, V.F.; Sousa-Silva, J.C.; Paula-Moraes, S.V.; Peterson, J.A.; Hunt, T.E. Host Plants of Spodoptera frugiperda (Lepidoptera: Noctuidae) in the Americas. Afr. Entomol. 2018, 26, 286–300. [Google Scholar] [CrossRef] [Green Version]

- Abbas, A.; Ullah, F.; Hafeez, M.; Han, X.; Dara, M.Z.N.; Gul, H.; Zhao, C.R. Biological Control of Fall Armyworm, Spodoptera frugiperda. Agronomy 2022, 12, 2704. [Google Scholar] [CrossRef]

- Pesticide Information. Available online: http://www.chinapesticide.org.cn (accessed on 30 June 2023).

- Dou, Z.; Fang, Z.; Han, X.; Liu, Y.; Duan, L.; Zeeshan, M.; Arshad, M. Comparison of the Effects of Chemical Topping Agent Sprayed by a UAV and a Boom Sprayer on Cotton Growth. Agronomy 2022, 12, 1625. [Google Scholar] [CrossRef]

- Zhang, C.H.; Zhao, X.; Lei, J.M.; Ma, Y.; Du, F.P. The wetting behavior of aqueous surfactant solutions on wheat (Triticum aestivum) leaf surfaces. Soft Matter 2017, 13, 503–513. [Google Scholar] [CrossRef] [PubMed]

- Wagner, P.; Fürstner, R.; Barthlott, W.; Neinhuis, C. Quantitative assessment to the structural basis of water repellency in natural and technical surfaces. J. Exp. Bot. 2003, 54, 1295–1303. [Google Scholar] [CrossRef] [Green Version]

- Masato, Y.; Yoshito, T.; Keisuke, Y. Lattice Boltzmann simulation of dynamic behavior of liquid droplets on solid surfaces. Int. Conf. Comput. Exp. Eng. Sci. 2011, 18, 131–132. [Google Scholar]

- Xu, Z.Y.; He, Z.J.; Quan, X.B.; Sun, D.L.; Miao, Z.H.; Yu, H.; Yang, S.J.; Chen, Z.; Zeng, J.X.; Zhou, J. Molecular simulations of charged complex fluids: A review. Chin. J. Chem. Eng. 2021, 31, 206–226. [Google Scholar] [CrossRef]

- Cao, P.; Yang, D.J.; Zhu, J.H.; Liu, Z.P.; Jiang, D.G.; Xu, H.B. Estimatrineed assessment of cumulative dietary exposure to organophosphorus residues from tea infusion in China. Environ. Health Prev. Med. 2018, 23, 7. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mariana, M.; Mihaela, R.; Hlihor, R.M.; Cozma, P.; Gavrilescu, M. Modelling of health risk associated with the intake of pesticides from Romanian fruits and vegetables. Sustainability 2020, 12, 10035. [Google Scholar]

- Skanes, B.; Warriner, K.; Prosser, R.S. Hazard assessment using an in silico toxicity assessment of the transformatrineion products of boscalid, pyraclostrobin, fenbuconazole and glyphosate generated by exposure to an advanced oxidative process. Toxicology 2020, 70, 105049. [Google Scholar]

- Thibault, N.; Justus, O.; Zablon, E.; Nickson, M.; Inviolate, M.; Paula, F. Is vegetable cultivation under low tunnels a profitable alternative to pesticide use? The case of cabbage cultivation in northern Tanzania. Crop Prot. 2020, 134, 105169. [Google Scholar]

- Song, Y.; Huang, Q.; Huang, G.; Liu, M.; Cao, L.; Li, F.; Zhao, P.; Cao, C. The Effects of Adjuvants on the Wetting and Deposition of Insecticide Solutions on Hydrophobic Wheat Leaves. Agronomy 2022, 12, 2148. [Google Scholar] [CrossRef]

- Gong, W.; Zu, Y.Q.; Chen, S.; Yan, Y.Y. Wetting transition energy curves for a droplet on a square-post patterned surface. Sci. Bull. 2017, 62, 136–142. [Google Scholar] [CrossRef] [PubMed]

- Peng, R.F.; Pang, Y.X.; Qiu, X.Q.; Qian, Y.; Zhou, M.S. Synthesis of anti-photolysis lignin-based dispersant and its application in pesticide suspension concentrate. RSC Adv. 2020, 10, 13830–13837. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.X.; Wang, R.; Cao, H.C.; Luo, J.; Jing, T.F.; Li, B.X.; Mu, W.; Liu, F.; Hou, Y.M. Emamectin benzoate nanogel suspension constructed from poly(vinyl alcohol)-valine derivatives and lignosulfonate enhanced insecticidal efficacy. Colloids Surf. B Biointerfaces 2021, 209, 112166–112176. [Google Scholar] [CrossRef] [PubMed]

- Kampf, N.; Wachtel, E.J.; Zilman, A.; Ben, S.N.; Klein, J. Anomalous viscosity-time behavior of polysaccharide dispersions. J. Chem. Phys. 2018, 149, 163320. [Google Scholar] [CrossRef]

- Liu, J.; Guo, X.; Xu, Y.; Wu, X. Spreading of Oil Droplets Containing Surfactants and Pesticides on Water Surface Based on the Marangoni Effect. Molecules 2021, 26, 1408. [Google Scholar] [CrossRef]

- Mohammad, A.T.; Mohammad, H.G.; Abolfazl, D.M. On the size-dependent behavior of drop contact angle in wettability alteration of reservoir rocks to preferentially gas wetting using nanofluid. J. Pet. Sci. Eng. 2019, 178, 1143–1154. [Google Scholar]

- Elif, C.C. The effect of drop size on contact angle measurements of superhydrophobic surfaces. RSC Adv. 2014, 4, 1197–1203. [Google Scholar]

- Song, R.; Shen, G.Q.; Liu, Y.X.; Tang, F.L.; Chen, Q.C.; Sun, P. Preparation and characterization of an oil-in-water microemulsion of thiamethoxam and acetamiprid without organic solvent for unmanned aerial vehicle spraying. Colloids Surf. A Physicochem. Eng. Asp. 2020, 607, 125485–125493. [Google Scholar] [CrossRef]

- Zhu, F.; Cao, C.; Cao, L.; Li, F.M.; Du, F.P.; Huang, Q.L. Wetting Behavior and Maximum Retention of Aqueous Surfactant Solutions on Tea Leaves. Molecules 2019, 24, 2094. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Wang, Z.; Meng, H.W.; Dong, B.Z.; Zhou, H.Y. Formulation and Wetting and Spraying Properties of 1.0% Matrine Soluble Agent. Chin. J. Biol. Control 2022, 6, 1410–1417. [Google Scholar]

- Long, Y.J.; Zhang, H.Y.; Liao, G.H.; Chen, M.G.I.; Chen, X.Y.; Qin, L.X.; Chen, C.J.; Chen, Z.; Wu, X.M.; Zhu, F. Distribution of Emamectin Benzoate Granules in Maize Plants by Broadcasting into Maize Leaf Whorls. ACS Omega 2023, 8, 4209–4219. [Google Scholar] [CrossRef] [PubMed]

- He, L.F.; Li, X.X.; Gao, Y.Y.; Li, B.X.; Mu, W.; Liu, F. Oil Adjuvants Enhance the Efficacy of Pyraclostrobin in Managing Cucumber Powdery Mildew (Podosphaera xanthii) by Modifying the Affinity of Fungicide Droplets on Diseased Leaves. Plant Dis. 2019, 103, 1657–1664. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Mei, Y.; Quan, J.X.; Xiao, X.; Zhang, L.; Tian, D.M.; Li, H.B. The macroscopic wettable surface: Fabricated by calix [4] arene-based host-guest interaction and chiral discrimination of glucose. Chem. Commun. 2016, 52, 14416–14418. [Google Scholar] [CrossRef]

- Yan, X.Y.; Zhai, Z.L.; Song, Z.Q.; Shang, S.B.; Rao, X.P. Synthesis of comb-like polymeric surfactants with a tricyclic rigid core and their use as dispersants in pymetrozine water suspension concentrates. RSC Adv. 2017, 7, 55741–55747. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.P.; Wang, J.; Yang, X.X.; Zhang, B.; Ren, T.R. Impact of EO chain length of dodecanol ethoxylates (C12En) on the rheological properties and physical stability of pesticide suspension concentrate. Colloids Surf. A Physicochem. Eng. Asp. 2021, 627, 127163–127171. [Google Scholar] [CrossRef]

- Zhang, S.P.; Yang, X.D.; Tu, Z.B.; Hua, W.D.; He, P.H.; Li, H.H.; Zhang, B.; Ren, T.R. Influence of the hydrophilic moiety of polymeric surfactant on their surface activity and physical stability of pesticide suspension concentrate. J. Mol. Liq. 2020, 317, 114136. [Google Scholar] [CrossRef]

- Kang, Y.S.; Wang, H.J.; Sun, Z.L. Structural and thermodynamic properties of inhomogeneous fluids in rectangular corrugated nano-pores. Chin. Phys. B 2022, 5, 578–589. [Google Scholar] [CrossRef]

- Wang, P.; Li, C.Y.; Zhang, D. Recent advances in chemical durability and mechanical stability of superhydrophobic materials: Multi-strategy design and strengthening. J. Mater. Sci. Technol. 2022, 34, 40–69. [Google Scholar] [CrossRef]

- Zdziennicka, A.; Krawczyk, J.; Jańczuk, B. Wettability and adhesion work prediction in the polymer–aqueous solution of surface active agent systems. Colloids Interfaces 2018, 2, 21. [Google Scholar] [CrossRef]

- Xun, L.; García Ruiz, F.; Fàbregas, X.; Gil, E. Pesticide dose based on canopy characteristics in apple trees: Reducing environmental risk by reducing the amount of pesticide while maintaining pest and disease control efficacy. Sci. Total Environ. 2022, 826, 154204. [Google Scholar] [CrossRef] [PubMed]

- Zhao, R.; Yu, M.; Sun, Z.; Li, L.J.; Shang, H.Y.; Xi, W.J.; Li, B.; Li, Y.Y.; Xu, Y.; Wu, X.M. Using tank-mix adjuvant improves the physicochemical properties and dosage delivery to reduce the use of pesticides in wheat unmanned aerial vehicles plant protection. Pest Manag. Sci. 2022, 6, 2512–2522. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.J.; Li, Y.; Feng, Y.T.; Li, G.Y.; Cui, Y.J.; Zhang, R.X. Effects of spray adjuvants on the wetting and retention of sulfoxaflor on the surface of Fuji apple leaves. Chin. J. Pestic. Sci. 2023, 25, 150–157. [Google Scholar]

- Mansha, M.; Ullah, N.; Kalgaonkar, R.A.; Baqader, N. Synthesis, Characterization, and Viscosification of Amidosulfobutaine and Zwitterionic Gemini Surfactants. J. Surfactants Deterg. 2020, 24, 697–706. [Google Scholar] [CrossRef]

- Wong, T.S.; Kang, S.H.; Tang, S.K.Y.; Smythe, E.J.; Hatton, B.D.; Grinthal, A.; Aizenberg, J. Bioinspired self-repairing slippery surfaces with pressure-stable omniphobicity. Nature 2011, 477, 443–447. [Google Scholar] [CrossRef]

- Anish, T.W.C.; Joseph, M.M.; Gareth, H.M.; McKinley, G.H.; Cohen, R.E. Robust omniphobic surfaces. Proc. Natl. Acad. Sci. USA 2008, 105, 18200–18205. [Google Scholar]

- Liu, T.L.; Kim, C.J. Turning a surface superrepellent even to completely wetting liquids. Science 2014, 346, 1096–1100. [Google Scholar] [CrossRef] [Green Version]

- Malvadkar, N.A.; Hancock, M.J.; Sekeroglu, K.; Dressick, W.J.; Demirel, M.C. An engineered anisotropic nanofilm with unidirectional wetting properties. Nat. Mater. 2010, 9, 1023–1028. [Google Scholar] [CrossRef]

- Kota, A.K.; Li, Y.; Mabry, J.M.; Tuteja, A. Hierarchically structured superoleophobic surfaces with ultralow contact angle hysteresis. Adv. Mater. 2012, 24, 5838–5843. [Google Scholar] [CrossRef]

- Mohan Kumar, K.; Velmurugan, V. Wetting behavior of textured silicon surfaces-an experimental study. Mater. Res. Express 2020, 7, 054001. [Google Scholar]

- Herminghaus, S.; Brinkmann, M.; Seemann, R. Wetting and dewetting of complex surface geometries. Annu. Rev. Mater. Res. 2008, 38, 101–121. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.F.; Wang, Y.N.; Wu, X.L.; Tang, C.; Liu, Z.H.; Zhou, G.Y.; Yu, J.X. Combined effects of pinning and adhesion force on solid\liquid interfacial friction behaviors under applied voltage. Tribol. Int. 2019, 134, 102–108. [Google Scholar] [CrossRef]

| Emulsifier | Usage of an Emulsifier | pH | Active Ingredient Content (%) | |||

|---|---|---|---|---|---|---|

| Before High-Temperature Storage | After High-Temperature Storage | Before High-Temperature Storage | After High-Temperature Storage | Decomposition Rate (%) | ||

| VO/02N | 8% | 6.69 | 6.76 | 7.24 | 7.10 | 1.84 |

| VO/03 | 8% | 6.48 | 6.50 | 7.89 | 7.67 | 2.79 |

| VO/01 | 8% | 7.84 | 7.79 | 7.62 | 7.48 | 1.84 |

| Name of an Emulsifier | Use Level (%) | Suspensibility (%) | |

|---|---|---|---|

| Before High-Temperature Storage | After High-Temperature Storage | ||

| VO/02N | 8% | 99.09 | 98.25 |

| VO/03 | 8% | 99.33 | 98.89 |

| VO/01 | 8% | 99.17 | 98.64 |

| Treatment | Active Ingredient Rate (mL/hm2) | Days after Treatment | |||

|---|---|---|---|---|---|

| 7 d | 10 d | ||||

| Population Decline Rate (%) | Efficacy (%) | Population Decline Rate (%) | Efficacy (%) | ||

| CK | - | 15.63 | - | 18.75 | - |

| SL | 50 | 71.88 | (66.66 ± 2.48) a | 68.75 | (61.54 ± 0.61) b |

| OD VO/02N | 50 | 75.00 | (70.37 ± 12.10) a | 72.39 | (65.50 ± 7.66) ab |

| OD VO/03 | 50 | 84.38 | (77.78 ± 8.55) a | 78.13 | (73.08 ± 7.69) a |

| OD VO/01 | 50 | 70.83 | (65.43 ± 8.56) a | 66.67 | (58.97 ± 2.18) b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Wang, Z.; Meng, H.; Dong, B.; Deng, X.; Zhou, H. Formulation of Matrine Oil-Based Suspension Concentrate for Improving the Wetting of Droplets and Spraying Performance. Agronomy 2023, 13, 1895. https://doi.org/10.3390/agronomy13071895

Li M, Wang Z, Meng H, Dong B, Deng X, Zhou H. Formulation of Matrine Oil-Based Suspension Concentrate for Improving the Wetting of Droplets and Spraying Performance. Agronomy. 2023; 13(7):1895. https://doi.org/10.3390/agronomy13071895

Chicago/Turabian StyleLi, Meng, Zhen Wang, Huanwen Meng, Baozhu Dong, Xile Deng, and Hongyou Zhou. 2023. "Formulation of Matrine Oil-Based Suspension Concentrate for Improving the Wetting of Droplets and Spraying Performance" Agronomy 13, no. 7: 1895. https://doi.org/10.3390/agronomy13071895

APA StyleLi, M., Wang, Z., Meng, H., Dong, B., Deng, X., & Zhou, H. (2023). Formulation of Matrine Oil-Based Suspension Concentrate for Improving the Wetting of Droplets and Spraying Performance. Agronomy, 13(7), 1895. https://doi.org/10.3390/agronomy13071895