Unattended Electric Weeder (UEW): A Novel Approach to Control Floor Weeds in Orchard Nurseries

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plant Species

2.2. Experimental Instruments Used to Expose the Plant Seedlings to an Electric Spark

2.2.1. The Charged Conductor Net and Determining the Spark Distance

2.2.2. Double-Net System for Exposing Plant Seedlings to an Electric Spark

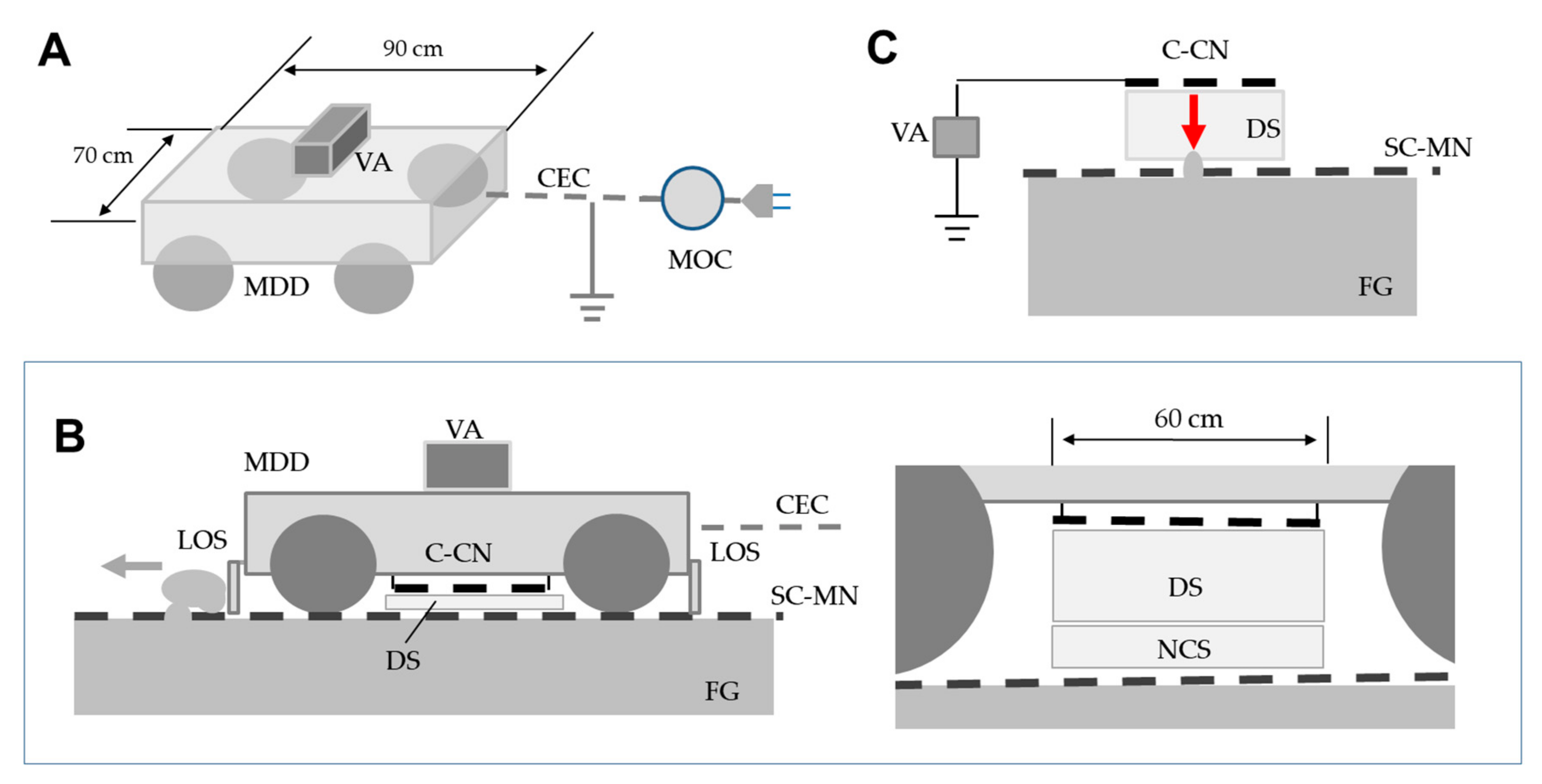

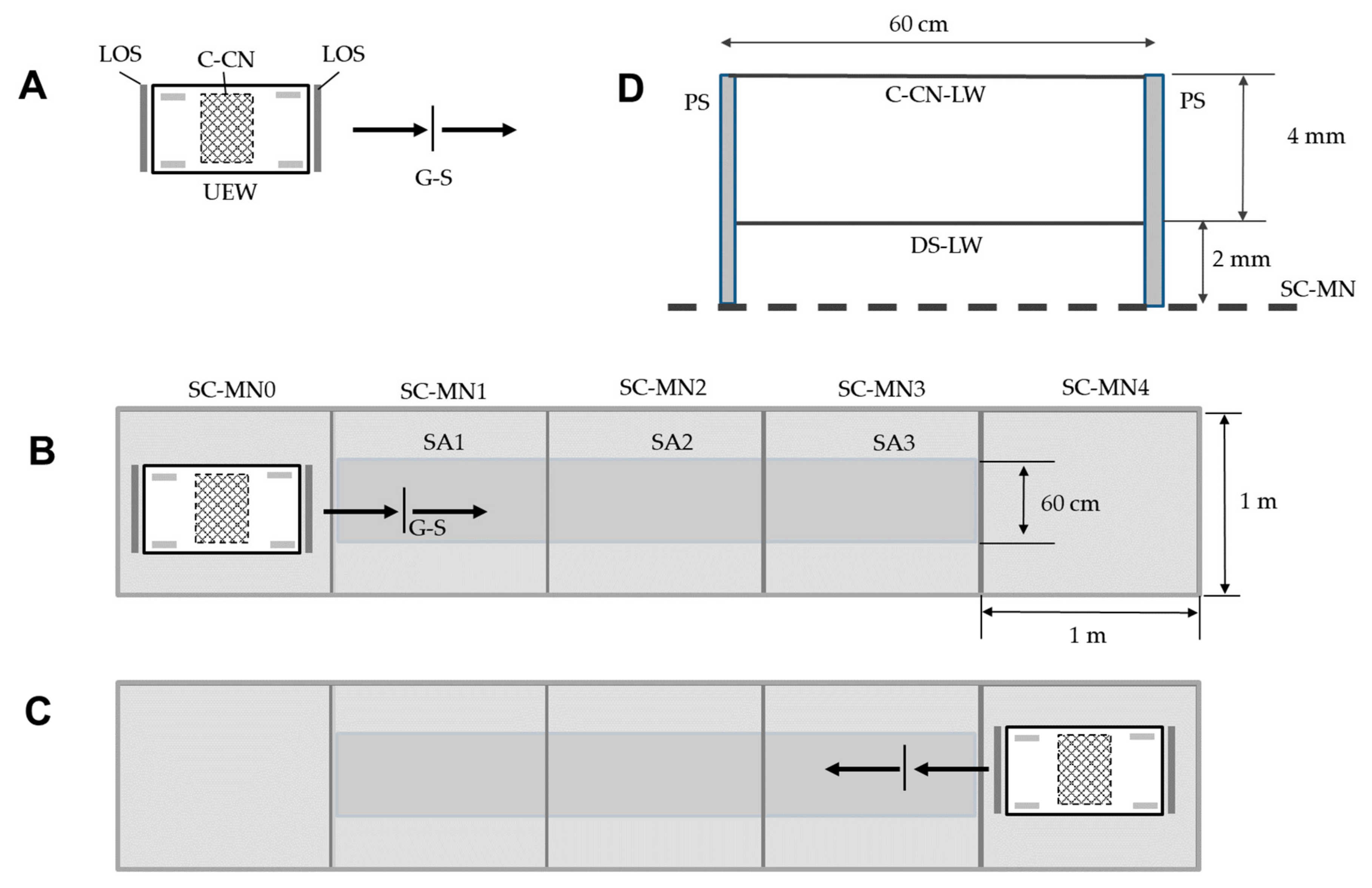

2.3. Construction of a Motor-Driven Dolly Carrying the C-CN and Its Application to Greenhouse Floor Weeding

2.3.1. Construction of the Unattended Electric Weeder

2.3.2. Level-Off-Soil Operation to Avoid Undesired Sparking of the Ground Soil

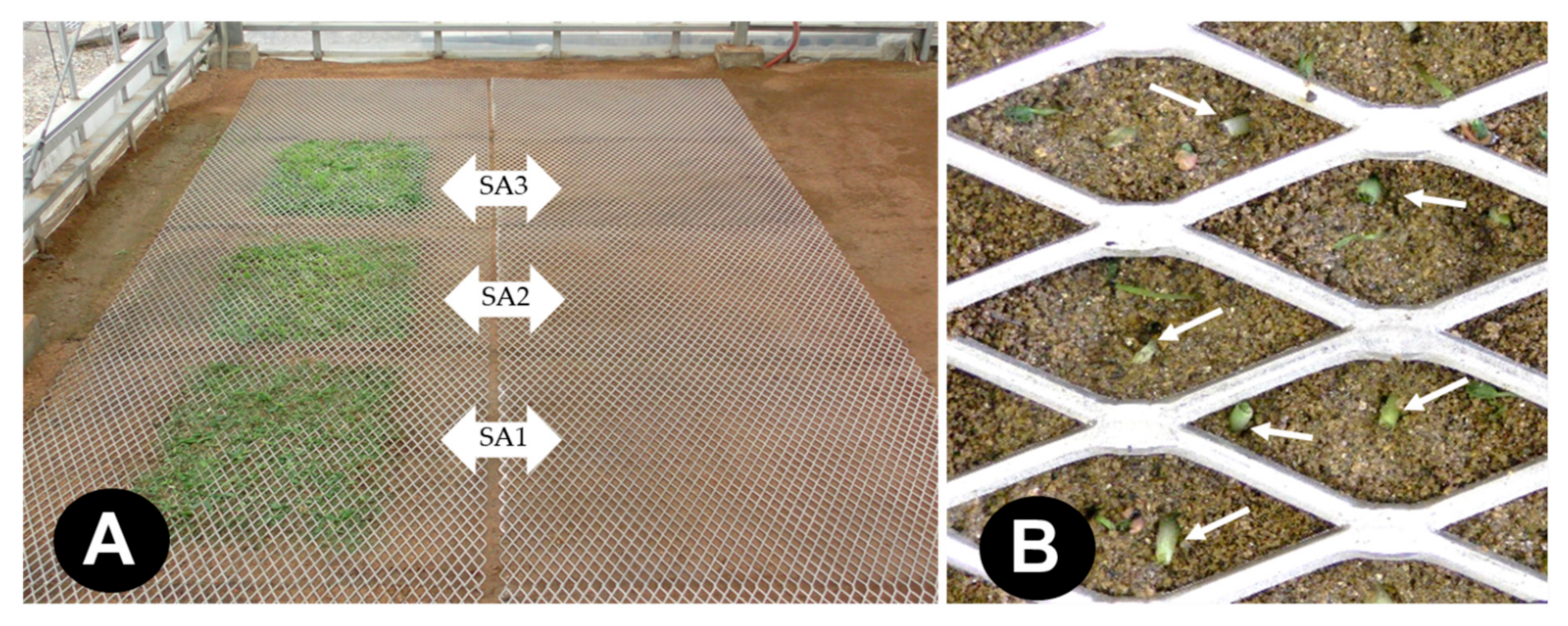

2.3.3. Application of the UEW to Control Floor Weeds in a Greenhouse

2.4. Statistical Analysis

3. Results

3.1. Sparking Distance of the C-CN

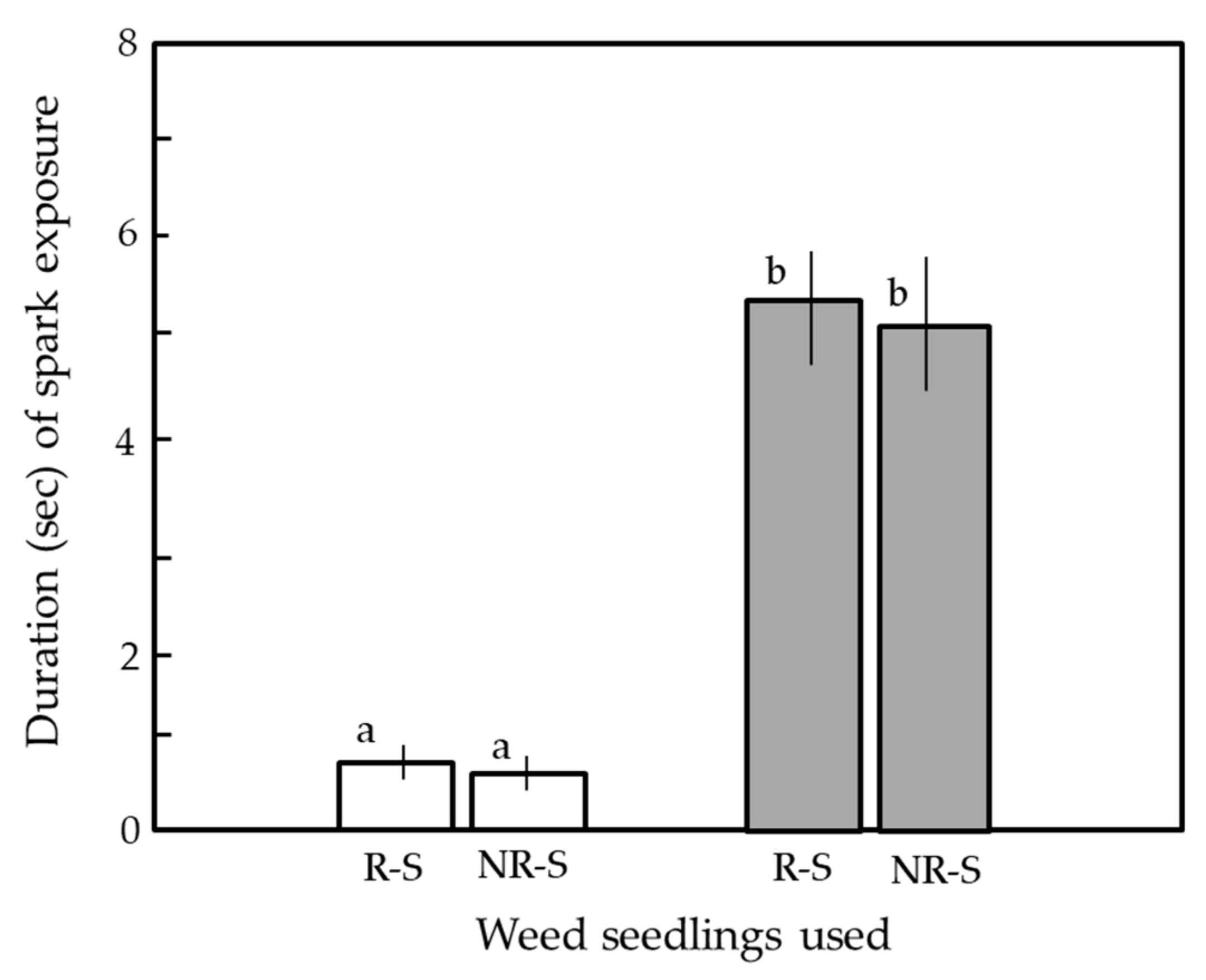

3.2. Exposure of Plant Seedlings to an Arc Discharge-Mediated Spark

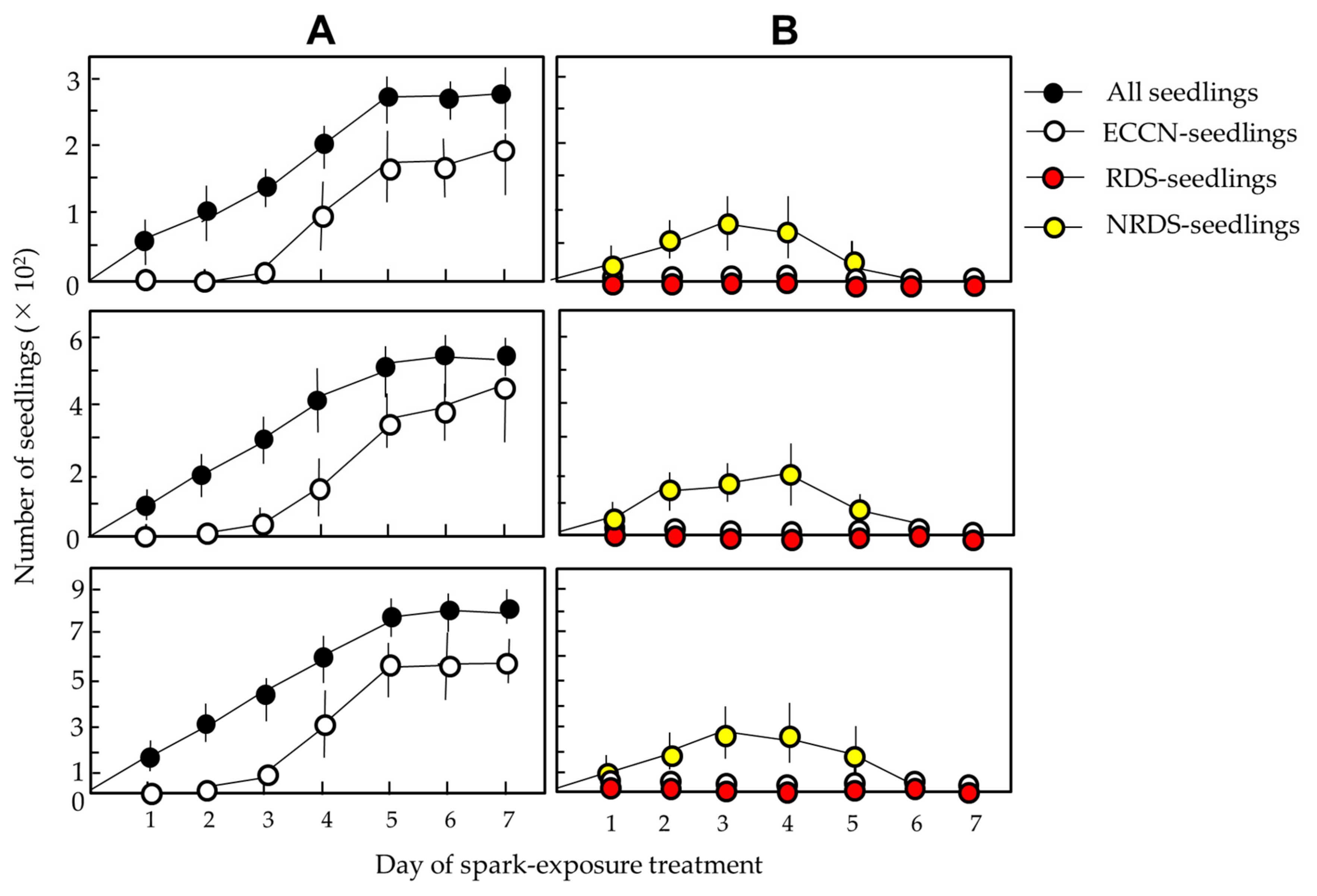

3.3. Application of the UEW to Control Floor Weeds in a Greenhouse

3.3.1. Prerequisite Operations before the Spark-Exposure Treatment

3.3.2. Greenhouse Assay for Controlling Floor Weeds by the UEW

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- WSU Tree Fruit: Comprehensive Tree Fruit Site. Weed Control. Available online: https://treefruit.wsu.edu/crop-protection/weed-control/ (accessed on 12 May 2023).

- Davis, A.S.; Frisvold, G.B. Are herbicides a once in a century method of weed control? Pest Manag. Sci. 2017, 73, 2209–2220. [Google Scholar] [CrossRef] [PubMed]

- Green, J.M. Current state of herbicides in herbicide-resistant crops. Pest Manag. Sci. 2014, 70, 1351–1357. [Google Scholar] [CrossRef] [PubMed]

- Heap, I. Global perspective of herbicide-resistant weeds. Pest Manag. Sci. 2014, 70, 1306–1315. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, F.P. Pesticides, environment, and food safety. Food Energy Secur. 2017, 6, 48–60. [Google Scholar] [CrossRef]

- Lewis, W.J.; van Lenteren, J.C.; Phatak, S.C.; Tumlinson, J.H., III. A total system approach to sustainable pest management. Proc. Natl. Acad. Sci. USA 1997, 94, 12243–12248. [Google Scholar] [CrossRef]

- Catton, H.A.; Lalonde, R.G.; De Clerck-Floate, R.A. Differential host-finding abilities by a weed biocontrol insect create within-patch spatial refuges for nontarget plants. Environ. Entomol. 2014, 43, 1333–1344. [Google Scholar] [CrossRef]

- Catton, H.A.; Lalonde, R.G.; De Clerck-Floate, R.A. Nontarget herbivory by a weed biocontrol insect is limited to spillover, reducing the chance of population-level impacts. Ecol. Appl. 2015, 25, 517–530. [Google Scholar] [CrossRef]

- Morin, L. Progress in Biological Control of Weeds with Plant Pathogens. Annu. Rev. Phytopathol. 2020, 58, 201–223. [Google Scholar] [CrossRef]

- Sharma, S.; Pandey, L.M. Prospective of fungal pathogen-based bioherbicides for the control of water hyacinth: A review. J. Basic Microbiol. 2022, 62, 415–427. [Google Scholar] [CrossRef]

- Cimmino, A.; Masi, M.; Evidente, M.; Superchi, S.; Evidente, A. Fungal phytotoxins with potential herbicidal activity: Chemical and biological characterization. Nat. Prod. Rep. 2015, 32, 1629–1653. [Google Scholar] [CrossRef]

- Anese, S.; Rial, C.; Varela, R.M.; Torres, A.; Molinillo, J.M.G.; Macías, F.A. Search of new tools for weed control using Partocrat rotundifolia, a dominant species in the Cerrado. J. Agric. Food Chem. 2021, 69, 8684–8694. [Google Scholar] [CrossRef] [PubMed]

- Macías, F.A.; Mejías, F.J.; Molinillo, J.M. Recent advances in allelopathy for weed control: From knowledge to applications. Pest Manag. Sci. 2019, 75, 2413–2436. [Google Scholar] [CrossRef]

- Sportelli, M.; Frasconi, C.; Fontanelli, M.; Pirchio, M.; Gagliardi, L.; Raffaelli, M.; Peruzzi, A.; Antichi, D. Innovative living mulch management strategies for organic conservation field vegetables: Evaluation of continuous mowing, flaming, and tillage performances. Agronomy 2022, 12, 622. [Google Scholar] [CrossRef]

- Kornecki, T.S.; Price, A.J.; Raper, R.L.; Arriaga, F.J. New roller crimper concepts for mechanical termination of cover crops in conservation agriculture. Renew. Agric. Food Syst. 2009, 24, 165–173. [Google Scholar] [CrossRef] [Green Version]

- Petrikovszki, R.; Zalai, M.; Bogdányi, F.T.; Ferenc Tóth, F. The effect of organic mulching and irrigation on the weed species composition and the soil. Plants 2020, 9, 66. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.; Sun, X.; Long, B.; Li, F.; Yang, C.; Chen, J.; Ma, C.; Xie, D.; Wei, Y. Green production of biodegradable mulch films for effective weed control. ACS Omega 2021, 6, 32327–32333. [Google Scholar] [CrossRef] [PubMed]

- Mainardis, M.; Boscutti, F.; Cebolla, M.D.M.R.; Pergher, G. Comparison between flaming, mowing and tillage weed control in the vineyard: Effects on plant community, diversity and abundance. PLoS ONE 2020, 5, 0238396. [Google Scholar] [CrossRef]

- Bond, W.; Grundy, A.C. Non-chemical weed management in organic farming systems. Weed Res. 2001, 41, 383–405. [Google Scholar] [CrossRef]

- Martelloni, L.; Frasconi, C.; Sportelli, M.; Fontanelli, M.; Raffaelli, M.; Peruzzi, A. Hot foam and hot water for weed control: A comparison. J. Agric. Eng. 2021, 52, 1167. [Google Scholar] [CrossRef]

- Country Folks Grower: Orchard Insights: Weed Control Options in Tree Fruit. Available online: https://cfgrower.com/orchard-insights-weed-control-options-in-tree-fruit/ (accessed on 12 May 2023).

- Fennimore, S.A.; Cutulle, M. Robotic weeders can improve weed control options for specialty crops. Pest Manag. Sci. 2019, 75, 1767–1774. [Google Scholar] [CrossRef]

- Wilson, R.G.; Anderson, F.N. Control of three weed species in sugar beets (Betavulgaris) with an electrical discharge system. Weed Sci. 1981, 29, 93–97. [Google Scholar] [CrossRef]

- Diprose, M.F.; Benson, F.A. Electrical methods of killing plants. J. Agric. Eng. Res. 1984, 30, 197–209. [Google Scholar] [CrossRef]

- Nagura, A.; Tenma, T.; Sakaguchi, Y.; Yamano, N.; Mizuno, A. Destruction of weeds by pulsed high voltage discharges. J. Inst. Electrostat. Jpn. 1992, 16, 59–66. [Google Scholar]

- Mizuno, A. Destruction of weeds by high voltage discharge. J. Plasma Fusion Res. 1999, 75, 666–671. [Google Scholar] [CrossRef] [Green Version]

- Minoda, A. A basic study on weeding method by using high voltage. Jpn. J. Ind. Appl. Eng. 2021, 9, 21–24. [Google Scholar]

- Lati, R.N.; Rosenfeld, L.; David, I.B.; Bechar, A. Power on! Low-energy electrophysical treatment is an effective new weed control approach. Pest Manag. Sci. 2021, 77, 4138–4147. [Google Scholar] [CrossRef] [PubMed]

- Ekeleme, F.; Dixon, A.; Atser, G.; Hauser, S.; Chikoye, D.; Korie, S.; Olojede, A.; Agada, M.; Olorunmaiye, P.M. Increasing cassava root yield on farmers’ fields in Nigeria through appropriate weed management. Crop Prot. 2021, 150, 105810. [Google Scholar] [CrossRef]

- Research Association of Electric Field Screen Supporters. Major Projects. Available online: http://www.electric-field-screen.org (accessed on 12 May 2023).

- Takikawa, Y.; Matsuda, Y.; Nonomura, T.; Kakutani, K.; Okada, K.; Shibao, M.; Kusakari, S.; Miyama, K.; Toyoda, H. Exclusion of whiteflies from a plastic hoop greenhouse by a bamboo blind-type electric field screen. J. Agric. Sci. 2020, 12, 50–60. [Google Scholar]

- Takikawa, Y.; Nonomura, T.; Sonoda, T.; Matsuda, Y. Developing a phototactic electrostatic insect trap targeting whiteflies, leafminers, and thrips in greenhouses. Insects 2021, 12, 960. [Google Scholar] [CrossRef]

- Kakutani, K.; Matsuda, Y.; Nonomura, T.; Takikawa, Y.; Osamura, K.; Toyoda, H. Remote-controlled monitoring of flying pests with an electrostatic insect capturing apparatus carried by an unmanned aerial vehicle. Agriculture 2021, 11, 176. [Google Scholar] [CrossRef]

- Matsuda, Y.; Shimizu, K.; Sonoda, T.; Takikawa, Y. Use of electric discharge for simultaneous control of weeds and houseflies emerging from soil. Insects 2020, 11, 861. [Google Scholar] [CrossRef] [PubMed]

- Matsuda, M.; Takikawa, Y.; Shimizu, K.; Kusakari, S.; Toyoda, H. Use of a pair of pulse-charged grounded metal nets as an electrostatic soil-cover for eradicating weed seedlings. Agronomy 2023, 13, 1115. [Google Scholar] [CrossRef]

- Kaiser, K.L. Air breakdown. In Electrostatic Discharge; Kaiser, K.L., Ed.; Taylor & Francis: New York, NY, USA, 2006; pp. 1–93. [Google Scholar]

- Matsuda, Y.; Takikawa, Y.; Kakutani, K.; Nonomura, T.; Okada, K.; Kusakari, S.; Toyoda, H. Use of pulsed arc discharge exposure to impede expansion of the invasive vine Pueraria montana. Agriculture 2020, 10, 600. [Google Scholar] [CrossRef]

- Jones, E.; Childers, R. Electric charge and electric field. In Physics, 3rd ed.; McGraw-Hill: Boston, MA, USA, 2002; pp. 495–525. [Google Scholar]

- Free Statistical Software EZR Version 1.61. Available online: https://www.jichi.ac.jp/saitama-sct/SaitamaHP.files/statmedEN.html (accessed on 12 May 2023).

- Jones, E.; Childers, R. Electric current and resistance. In Physics, 3rd ed.; McGraw-Hill: Boston, MA, USA, 2002; pp. 557–593. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matsuda, Y.; Kakutani, K.; Toyoda, H. Unattended Electric Weeder (UEW): A Novel Approach to Control Floor Weeds in Orchard Nurseries. Agronomy 2023, 13, 1954. https://doi.org/10.3390/agronomy13071954

Matsuda Y, Kakutani K, Toyoda H. Unattended Electric Weeder (UEW): A Novel Approach to Control Floor Weeds in Orchard Nurseries. Agronomy. 2023; 13(7):1954. https://doi.org/10.3390/agronomy13071954

Chicago/Turabian StyleMatsuda, Yoshinori, Koji Kakutani, and Hideyoshi Toyoda. 2023. "Unattended Electric Weeder (UEW): A Novel Approach to Control Floor Weeds in Orchard Nurseries" Agronomy 13, no. 7: 1954. https://doi.org/10.3390/agronomy13071954

APA StyleMatsuda, Y., Kakutani, K., & Toyoda, H. (2023). Unattended Electric Weeder (UEW): A Novel Approach to Control Floor Weeds in Orchard Nurseries. Agronomy, 13(7), 1954. https://doi.org/10.3390/agronomy13071954