Multi-Objective Decision-Making Evaluation Method of Environmental Impact Associated with the Life Cycle of Agro-Friendly Biochar Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Construction of Assessment Methods

2.1.1. The Basic Idea of the Method Construction

- • The framework of the LCA for soil remediation materials

- • The ideas of the MCDM method construction

2.1.2. Construction Method

- (1)

- Constructing judgment matrix A = {aij}

- (2)

- Normalization

- (1)

- Constructing judgment Matrix

- (2)

- Matrix normalization

- (3)

- Weighting by Analytic Hierarchy Process (AHP)

- (4)

- The Euclidean distance calculation between each point and the reference point in TOPSIS

- (5)

- Calculation of relative proximity by TOPSIS

- (6)

- Sensitivity analysis

2.2. Applications

2.2.1. Determination of Research Objectives and Scope

2.2.2. Inventory Analysis

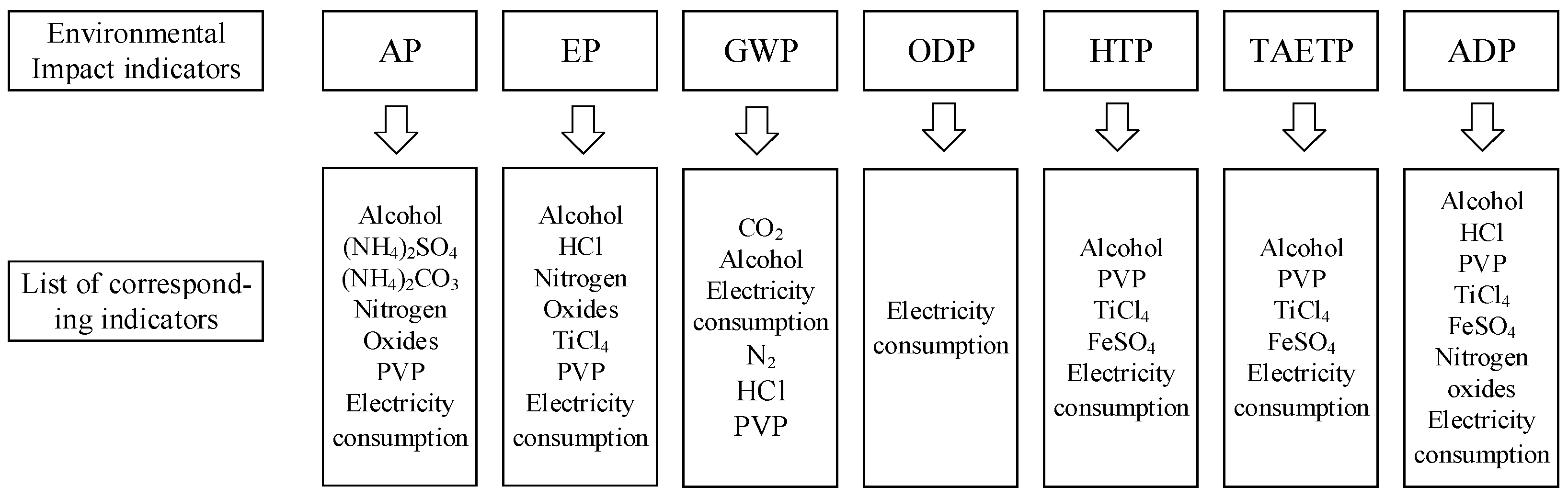

2.2.3. Index Selection

3. Results

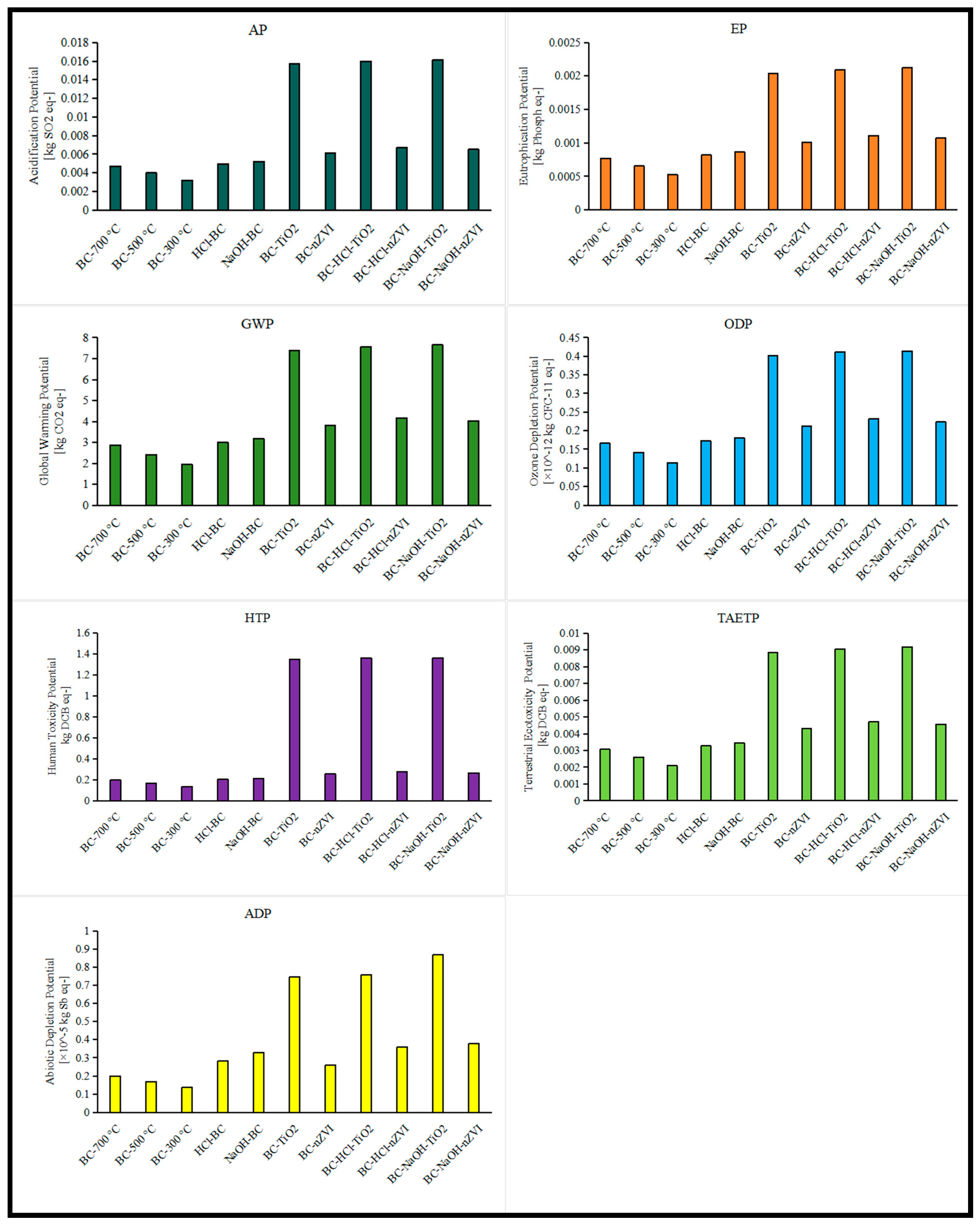

3.1. Impact Assessment

3.2. Sensitivity Analysis

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, C.C.; Zhang, Q.C.; Yan, C.A.; Tang, G.Y.; Zhang, M.Y.; Ma, L.Q.; Gu, R.H.; Xiang, P. Heavy metal(loid)s in agriculture soils, rice, and wheat across China: Status assessment and spatiotemporal analysis. Sci. Total Environ. 2023, 882, 163361. [Google Scholar] [CrossRef] [PubMed]

- Zeng, S.Y.; Ma, J.; Yang, Y.J.; Zhang, S.L.; Liu, G.J.; Chen, F. Spatial assessment of farmland soil pollution and its potential human health risks in China. Sci. Total Environ. 2019, 687, 642–653. [Google Scholar] [CrossRef] [PubMed]

- Deng, M.H.; Zhu, Y.W.; Shao, K.; Zhang, Q.; Ye, G.H.; Shen, J. Metals source apportionment in farmland soil and the prediction of metal transfer in the soil-rice-human chain. J. Environ. Manag. 2020, 260, 110092. [Google Scholar] [CrossRef] [PubMed]

- Li, T.K.; Liu, Y.; Lin, S.J.; Liu, Y.Z.; Xie, Y.F. Soil Pollution Management in China: A Brief Introduction. Sustainability 2019, 11, 556. [Google Scholar] [CrossRef]

- Lin, H.; Wang, Z.W.; Liu, C.J.; Dong, Y.B. Technologies for removing heavy metal from contaminated soils on farmland: A review. Chemosphere 2022, 305, 135457. [Google Scholar] [CrossRef]

- Hu, Y.C.; Wang, J.B.; Yang, Y.S.; Li, S.; Wu, Q.H.; Nepovimova, E.; Zhang, X.J.; Kuca, K. Revolutionizing soil heavy metal remediation: Cutting-edge innovations in plant disposal technology. Sci. Total Environ. 2024, 918, 170577. [Google Scholar] [CrossRef]

- Yang, Z.S.; Wei, C.L.; Song, X.; Wan, J.Z.; Li, Y.L.; Tang, Z.W. Research on Sustainable Remediation of Contaminated Sites—Metrological Analysis Based on Web of Science Database. J. Soil Sci. 2022, 53, 221–233. [Google Scholar]

- Rashid, M.S.; Liu, G.J.; Yousaf, B.; Hamid, Y.; Rehman, A.; Arif, M.; Ahmed, R.; Ashraf, A.; Song, Y. A critical review on biochar-assisted free radicals mediated redox reactions influencing transformation of potentially toxic metals: Occurrence, formation, and environmental applications. Environ. Pollut. 2022, 315, 120335. [Google Scholar] [CrossRef]

- Yadav, R.; Ramakrishna, W. Biochar as an Environment-Friendly Alternative for Multiple Applications. Sustainability 2023, 15, 13421. [Google Scholar] [CrossRef]

- Xie, M.H.; Man, H.C.; Duan, H.B.; Li, X.Y.; Xue, J.; Sun, Q.H.; Liao, F.J.; Wu, C.H. Research progress on life cycle impact assessment methods and localization. J. Environ. Eng. Technol. 2022, 12, 2148–2156. [Google Scholar]

- Hu, X.T.; Zhu, J.X.; Ding, Q. Application of life cycle assessment (LCA) to remediation technologies selection for PCBs contaminated sites. Chin. Sci. Bull. 2012, 57, 129–137. [Google Scholar]

- Dong, J.Q. Assessment Methods and Case Studies on Contaminated Sites Green and Sustainable Remediation. Ph.D. Thesis, China University of Geosciences, Beijing, China, 2019. (In Chinese). [Google Scholar]

- Papageorgiou, A.; Azzi, E.S.; Enell, A.; Sundberg, C. Biochar produced from wood waste for soil remediation in Sweden: Carbon sequestration and other environmental impacts. Sci. Total Environ. 2021, 776, 145953. [Google Scholar] [CrossRef]

- Kägi, T.; Dinkel, F.; Frischknecht, R.; Humbert, S.; Lindberg, J.; Mester, S.D.; Ponsioen, T.; Sala, S.; Schenker, U. Session “Midpoint, endpoint or single score for decision-making?”. SETAC Europe 25th Annual Meeting, Barcelona, Spain, May 5th, 2015. Int. J. Life Cycle Assess. 2016, 21, 129–132. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B. Life Cycle Assessment of construction materials: Methodologies, applications and future directions for sustainable decision-making. Case Stud. Constr. Mater. 2023, 19, e02326. [Google Scholar] [CrossRef]

- Ma, F.W.; Zhao, Y.; Pu, Y.F.; Li, J.H. A comprehensive MCDM model combining TOPSIS and IEM for sustainable material selection considering life cycle assessment method. IEEE Access 2018, 6, 58338–58354. [Google Scholar] [CrossRef]

- He, J.; Yuan, M.; Li, B.; Zhang, R. Research on the Optimization for Acidification Modification Scheme Considering Coal’s Wettability Based on the AHP-TOPSIS Method. ACS Omega 2023, 9, 15725. [Google Scholar] [CrossRef]

- Amirahmadi, E.; Ghorbani, M.; Krexner, T.; Hoertenhuber, S.J.; Bernas, J.; Neugschwandtner, R.W.; Konvalina, P.; Moudry, J. Life cycle assessment of biochar and cattle manure application in sugar beet cultivation—Insights into root yields, white sugar quality, environmental aspects in field and factory phases. J. Clean. Prod. 2024, 476, 143772. [Google Scholar] [CrossRef]

- Osman, A.I.; Farghali, M.; Rashwan, A.K. Life cycle assessment of biochar as a green sorbent for soil remediation. Curr. Opin. Green Sustain. Chem. 2024, 46, 100882. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy Proces; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Maccrimmon, K.R. Decision Making Among Multiple-Attribute Alternatives: A Survey and Consolidated Approach; The Rand Corporation: Santa Monica, CA, USA, 1968. [Google Scholar]

- Tzeng, G.H.; Huang, J.J. Multiple Attributes Decision Making—Methods and Applications; Chapman and Hall/CRC: Boca Raton, FL, USA, 2011; pp. 287–288. [Google Scholar]

- Rao, R.V. Decision Making in the Manufacturing Environment: Using Graph Theory and Fuzzy Multiple Attribute Decision Making Methods; Springer Series in Advanced Manufacturing; Springer: New York, NY, USA, 2007. [Google Scholar]

- Rao, R.V. A material selection model using grAHP theory and matrix approach. Mater. Sci. Eng. A 2006, 431, 248–255. [Google Scholar] [CrossRef]

- An, D.; Xi, B.D.; Ren, J.Z.; Wang, Y.; Jia, X.P.; He, C.; Li, Z.W. Sustainability assessment of groundwater remediation technologies based on multi-criteria decision making method. Resour. Conserv. Recycl. 2017, 119, 36–46. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, S.Q.; Ju, M.T.; Liu, L. Preparation and Modification of Biochar Materials and their Application in Soil Remediation. Appl. Sci. 2019, 9, 1365. [Google Scholar] [CrossRef]

- Belhachemi, M.; Jeguirim, M.; Limousy, L.; Addoun, F. Comparison of NO2 removal using date pits activated carbon and modified commercialized activated carbon via different preparation methods: Effect of porosity and surface chemistry. Chem. Eng. J. 2014, 253, 121–129. [Google Scholar] [CrossRef]

- ISO 14040; Environmental management—Life cycle assessment—Principles and framework. Technical Committee ISO/TC 207, Environmental management. ISO: Geneva, Switzerland, 2006.

- Feng, Y.; Fanghui, Y.; Li, C. Improved Entropy Weighting Model in Water Quality Evaluation. Water Resour. Manag. 2019, 33, 2049–2056. [Google Scholar] [CrossRef]

- Wang, P.; Zhu, Z.; Wang, Y. A novel hybrid MCDM model combining the SAW, TOPSIS and GRA methods based on experimental design. Inf. Sci. 2016, 345, 27–45. [Google Scholar] [CrossRef]

- Ishizaka, A.; Labib, A. Review of the main developments in the analytic hierarchy process. Expert Syst. Appl. 2011, 38, 14336–14345. [Google Scholar] [CrossRef]

- Dreyer, L.C.; Niemann, A.L.; Hauschild, M.Z. Comparison of three different LCIA methods: EDIP97, CML2001 and Eco-indicator 99—Does it matter which one you choose? Int. J. Life Cycle Assess. 2003, 8, 191–200. [Google Scholar] [CrossRef]

- Zhang, S.L.; Zhang, Y.F.; Yuan, H.X.; Ying, Y.L. Model for optimal selection of soft treatment schemes on considering uncertainty of evaluating indexes. J. Railw. Eng. Soc. 2010, 27, 19–23. (In Chinese) [Google Scholar]

- Nartey, O.D.; Zhao, B.W. Biochar Preparation, Characterization, and Adsorptive Capacity and Its Effect on Bioavailability of Contaminants: An Overview. Adv. Mater. Sci. Eng. 2014, 2014, 715398. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, Z.M.; Wang, Y.; Mu, G.T.; Wu, X.L.; Liu, Y.Y.; Luo, W.M.; Wen, X.M. Remediation of Soil Contaminated by Heavy Metals Using Biochar: Strategies and Future Prospects. Pol. J. Environ. Stud. 2023, 32, 27–40. [Google Scholar] [CrossRef]

- Mokete, R.; Eljamal, O.; Sugihara, Y. Exploration of the reactivity of nanoscale zero-valent iron (NZVI) associated nanoparticles in diverse experimental conditions. Chem. Eng. Process 2020, 150, 107879. [Google Scholar] [CrossRef]

- Agartan, L.; Kapusuz, D.; Park, J.; Ozturk, Z. Effect of initial water content and calcination temperature on photocatalytic properties of TiO2 nanopowders synthesized by the sol-gel process. Ceram. Int. 2015, 41, 12788–12797. [Google Scholar] [CrossRef]

- Tian, Y.Z.; Zheng, G. Approach to method of ascertaining weight in life cycle impact assessment. J. Chongqing Jianzhu Univ. 2003, 25, 61–64. [Google Scholar]

- Zhang, S.C.; Lu, X.J. Treatment of wastewater containing Reactive Brilliant Blue KN-R using TiO2/BC composite as heterogeneous photocatalyst and adsorbent. Chemosphere 2018, 206, 777–783. [Google Scholar] [CrossRef] [PubMed]

- Rajput, V.D.; Kumari, A.; Minkina, T.; Barakhov, A.; Singh, S.; Mandzhieva, S.S.; Sushkova, S.; Ranjan, A.; Rajput, P.; Garg, M.C. A practical evaluation on integrated role of biochar and nanomaterials in soil remediation processes. Environ. Geochem. Health 2023, 45, 9435–9449. [Google Scholar] [CrossRef]

- Zhu, Y.E.; Ning, Y.R.; Li, L.Z.; Chen, Z.Y.; Li, H.; Zhang, Y.X. Effective removal of hexavalent chromium from aqueous system by biochar-supported titanium dioxide (TiO2). Environ. Chem. 2022, 19, 432–445. [Google Scholar] [CrossRef]

- Zhang, D.J.; Yang, L.; Sun, A.W.; Tong, S.Q.; Su, G.Y.; Jiang, X.B.; Li, J.S.; Han, W.Q.; Sun, X.Y.; Wang, L.J. Enhanced nitrobenzene reduction by modified biochar supported sulfidated nano zerovalent iron: Comparison of surface modification methods. Sci. Total Environ. 2019, 694, 133701. [Google Scholar] [CrossRef]

- Ahmed, M.B.; Zhou, J.L.; Ngo, H.H.; Guo, W.S.; Chen, M.F. Progress in the preparation and application of modified biochar for improved contaminant removal from water and wastewater. Bioresour. Technol. 2016, 214, 836–851. [Google Scholar] [CrossRef]

- Lopes, R.P.; Astruc, D. Biochar as a support for nano catalysts and other reagents: Recent advances and applications. Coord. Chem. Rev. 2021, 426, 213585. [Google Scholar] [CrossRef]

- Mian, M.M.; Liu, G.J. Recent progress in biochar-supported photocatalysts: Synthesis, role of biochar, and application. RSC Adv. 2018, 8, 14237–14248. [Google Scholar] [CrossRef]

- Zhang, P.H.; Li, Y.C.; Hu, H.S.; Qi, H.L.; Hu, H.B. Preparation of biochar-based photocatalysts, properities and environmental applications: A review. Chem. Ind. Eng. Prog. 2021, 41, 1–16. [Google Scholar]

- Lu, L.L.; Shan, R.; Shi, Y.Y.; Wang, S.X.; Yuan, H.R. A novel TiO2/biochar composite catalyst for photocatalytic degradation of methyl orange. Chemosphere 2019, 222, 391–398. [Google Scholar] [CrossRef] [PubMed]

- Zheng, T.; Ouyang, S.H.; Zhou, Q.X. Synthesis, characterization, safety design, and application of NPs@BC for contaminated soil remediation and sustainable agriculture. Biochar 2023, 5, 5. [Google Scholar] [CrossRef]

- Mungkung, R.; Dangsiri, S.; Gheewala, S.H. Development of a low-carbon, healthy and innovative value-added riceberry rice product through life cycle design. Clean Technol. Environ. 2021, 23, 2037–2047. [Google Scholar] [CrossRef]

| AP | EP | GWP | ODP | HTP | TAETP | ADP | |

|---|---|---|---|---|---|---|---|

| BC-700 °C | 0.00471 | 0.00077 | 2.86 | 0.166 × 10−12 | 0.195 | 0.00307 | 0.199 × 10−5 |

| BC-500 °C | 0.00398 | 0.000652 | 2.42 | 0.141 × 10−12 | 0.165 | 0.0026 | 0.169 × 10−5 |

| BC-300 °C | 0.00319 | 0.000525 | 1.95 | 0.114 × 10−12 | 0.132 | 0.0021 | 0.137 × 10−5 |

| HCl-BC | 0.00496 | 0.000816 | 3 | 0.172 × 10−12 | 0.202 | 0.00327 | 0.283 × 10−5 |

| NaOH-BC | 0.00523 | 0.000862 | 3.17 | 0.181 × 10−12 | 0.212 | 0.00344 | 0.329 × 10−5 |

| BC-TiO2 | 0.0157 | 0.00204 | 7.39 | 0.401 × 10−12 | 1.35 | 0.00886 | 0.746 × 10−5 |

| BC-nZVI | 0.00615 | 0.00101 | 3.82 | 0.213 × 10−12 | 0.254 | 0.0043 | 0.259 × 10−5 |

| BC-HCl-TiO2 | 0.016 | 0.00209 | 7.55 | 0.411 × 10−12 | 1.36 | 0.00903 | 0.758 × 10−5 |

| BC-HCl-nZVI | 0.00672 | 0.00111 | 4.17 | 0.232 × 10−12 | 0.276 | 0.00472 | 0.359 × 10−5 |

| BC-NaOH-TiO2 | 0.0161 | 0.00212 | 7.65 | 0.414 × 10−12 | 1.36 | 0.00917 | 0.868 × 10−5 |

| BC-NaOH-nZVI | 0.00651 | 0.00107 | 4.03 | 0.223 × 10−12 | 0.265 | 0.00456 | 0.378 × 10−5 |

| AP | EP | GWP | ODP | HTP | TAETP | ADP | |

|---|---|---|---|---|---|---|---|

| AP | 1 | 1 | 1/5 | 1/4 | 1/6 | 1/5 | 3 |

| EP | 1 | 1 | ¼ | 1/4 | 1/6 | 1/5 | 4 |

| GWP | 5 | 4 | 1 | 2 | 1/3 | 1/2 | 5 |

| ODP | 4 | 4 | ½ | 1 | 1/4 | 1/3 | 4 |

| HTP | 6 | 6 | 3 | 4 | 1 | 2 | 8 |

| TAETP | 5 | 5 | 2 | 3 | 1/2 | 1 | 7 |

| ADP | 1/3 | 1/4 | 1/5 | 1/4 | 1/8 | 1/7 | 1 |

| Remediation Materials | di+ | di− | ∆i | rank | Ui | ∆Ui | Sensitivity |

|---|---|---|---|---|---|---|---|

| BC-700 °C | 0.2253 | 0.0209 | 0.0849 | 9 | 0.146 | 0.065 | 0.445 |

| BC-500 °C | 0.2343 | 0.0100 | 0.0410 | 10 | 0.121 | 0.055 | 0.455 |

| BC-300 °C | 0.2434 | 0 | 0 | 11 | 0.099 | 0.044 | 0.444 |

| HCl-BC | 0.2231 | 0.0240 | 0.0970 | 8 | 0.153 | 0.068 | 0.444 |

| NaOH-BC | 0.2199 | 0.0277 | 0.1119 | 7 | 0.162 | 0.072 | 0.444 |

| BC-TiO2 | 0.0117 | 0.2389 | 0.9533 | 3 | 0.535 | 0.278 | 0.520 |

| BC-nZVI | 0.2081 | 0.0426 | 0.1699 | 6 | 0.192 | 0.087 | 0.455 |

| BC-HCl-TiO2 | 0.003 | 0.2423 | 0.9878 | 2 | 0.545 | 0.282 | 0.517 |

| BC-HCl-nZVI | 0.2017 | 0.0483 | 0.1932 | 5 | 0.211 | 0.096 | 0.453 |

| BC-NaOH-TiO2 | 0 | 0.2434 | 1.0000 | 1 | 0.550 | 0.283 | 0.515 |

| BC-NaOH-nZVI | 0.1993 | 0.0481 | 0.1944 | 4 | 0.205 | 0.092 | 0.449 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Wei, J.; Li, H.; Ding, D.; Zhang, Y.; Zhu, Y.; Deng, S.; Luo, Y. Multi-Objective Decision-Making Evaluation Method of Environmental Impact Associated with the Life Cycle of Agro-Friendly Biochar Materials. Agronomy 2024, 14, 2583. https://doi.org/10.3390/agronomy14112583

Wang S, Wei J, Li H, Ding D, Zhang Y, Zhu Y, Deng S, Luo Y. Multi-Objective Decision-Making Evaluation Method of Environmental Impact Associated with the Life Cycle of Agro-Friendly Biochar Materials. Agronomy. 2024; 14(11):2583. https://doi.org/10.3390/agronomy14112583

Chicago/Turabian StyleWang, Shunyang, Jing Wei, Hua Li, Da Ding, Yaxin Zhang, Yuen Zhu, Shaopo Deng, and Yongming Luo. 2024. "Multi-Objective Decision-Making Evaluation Method of Environmental Impact Associated with the Life Cycle of Agro-Friendly Biochar Materials" Agronomy 14, no. 11: 2583. https://doi.org/10.3390/agronomy14112583

APA StyleWang, S., Wei, J., Li, H., Ding, D., Zhang, Y., Zhu, Y., Deng, S., & Luo, Y. (2024). Multi-Objective Decision-Making Evaluation Method of Environmental Impact Associated with the Life Cycle of Agro-Friendly Biochar Materials. Agronomy, 14(11), 2583. https://doi.org/10.3390/agronomy14112583