An Explanatory Model of Red Lentil Seed Coat Colour to Manage Degradation in Quality during Storage

Abstract

1. Introduction

2. Materials and Methods

2.1. Measurement of Seed Coat Colour

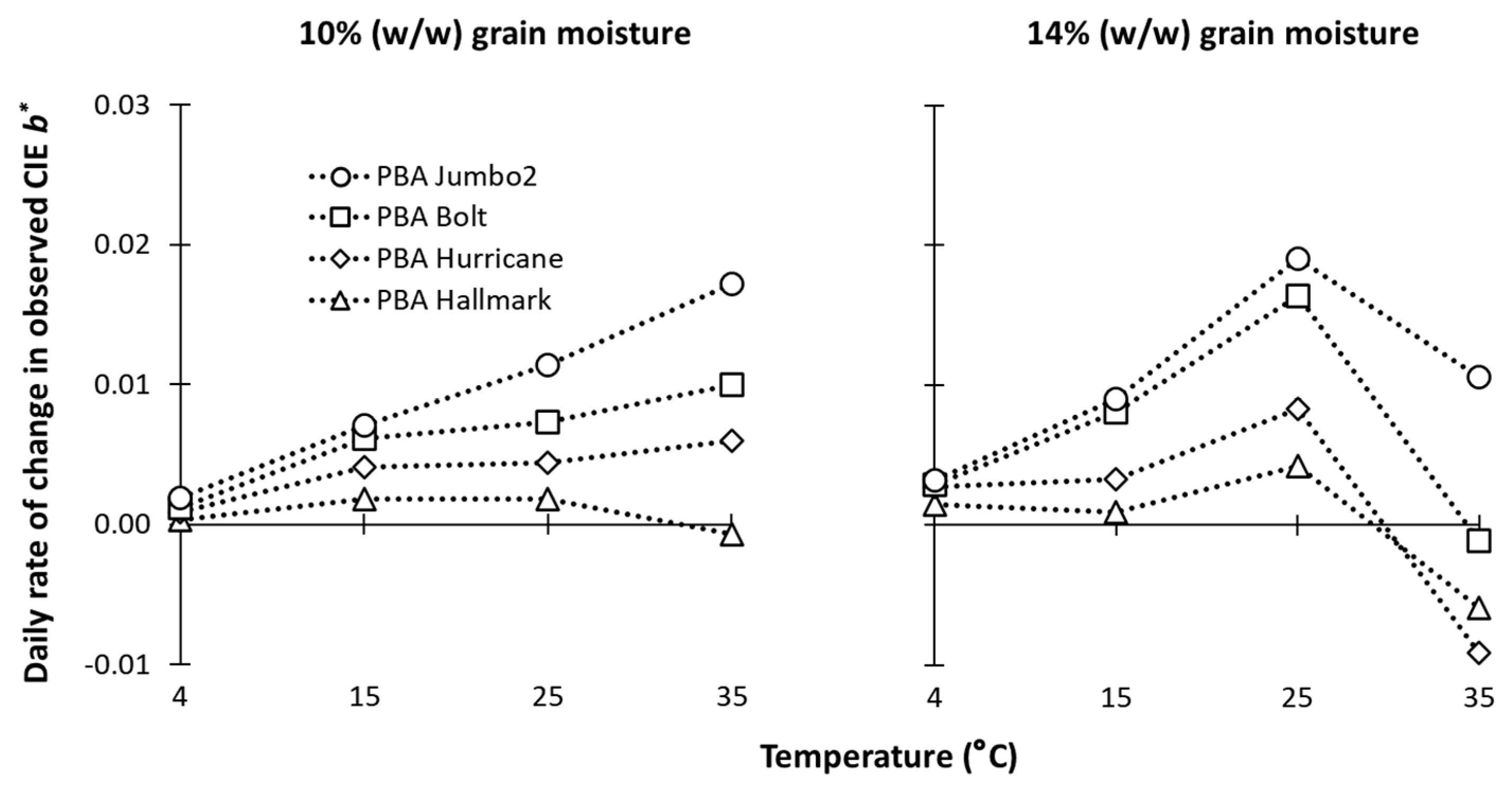

2.2. Development of Equations for the Model

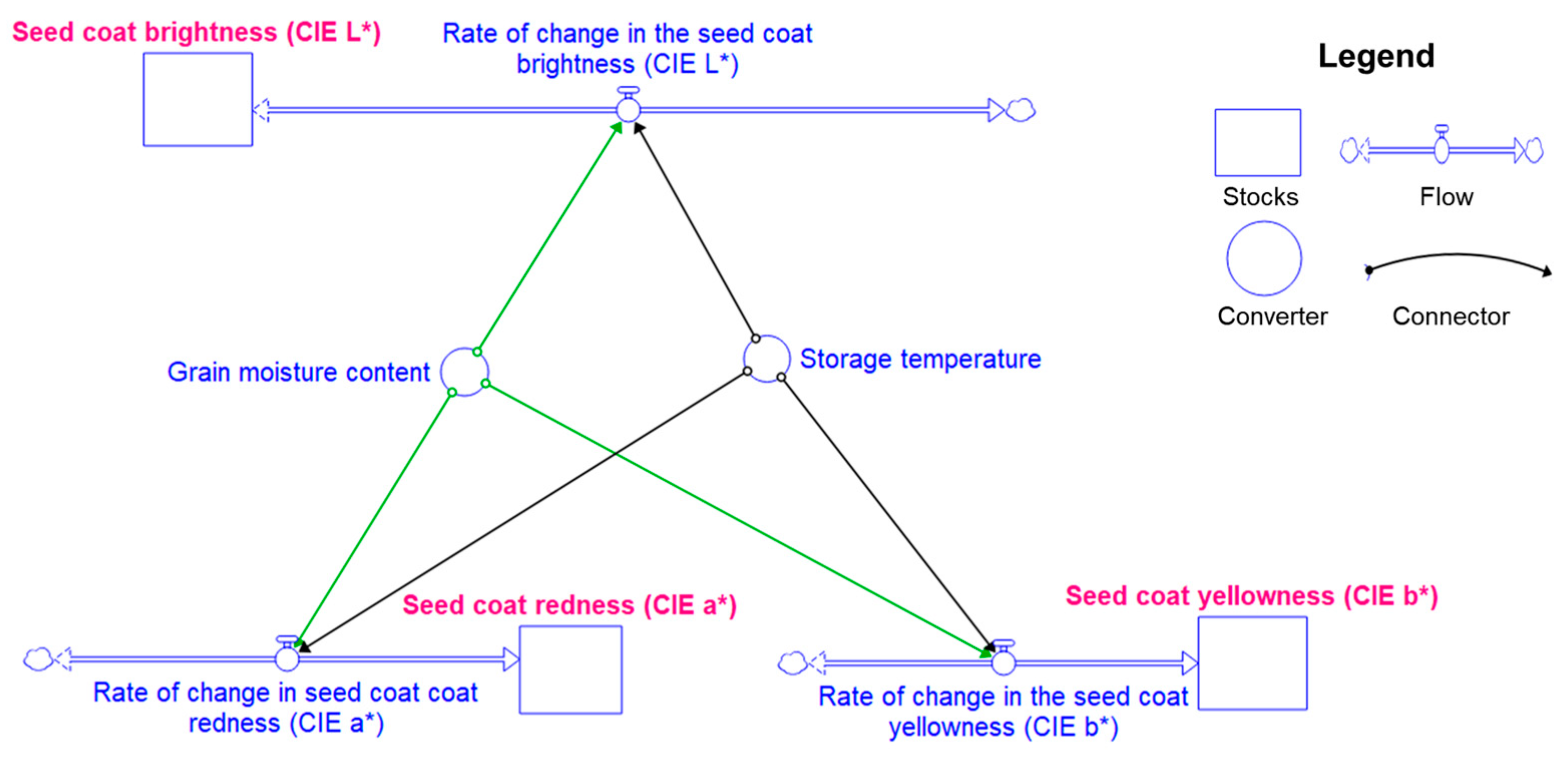

2.3. Development of the Model

2.4. Determination of Rate Constants

- ‘A’ represents a squared temperature coefficient.

- ‘B’ represents a linear temperature coefficient.

- ‘C’ represents the rate of change at 0 °C (which is assumed to be zero).

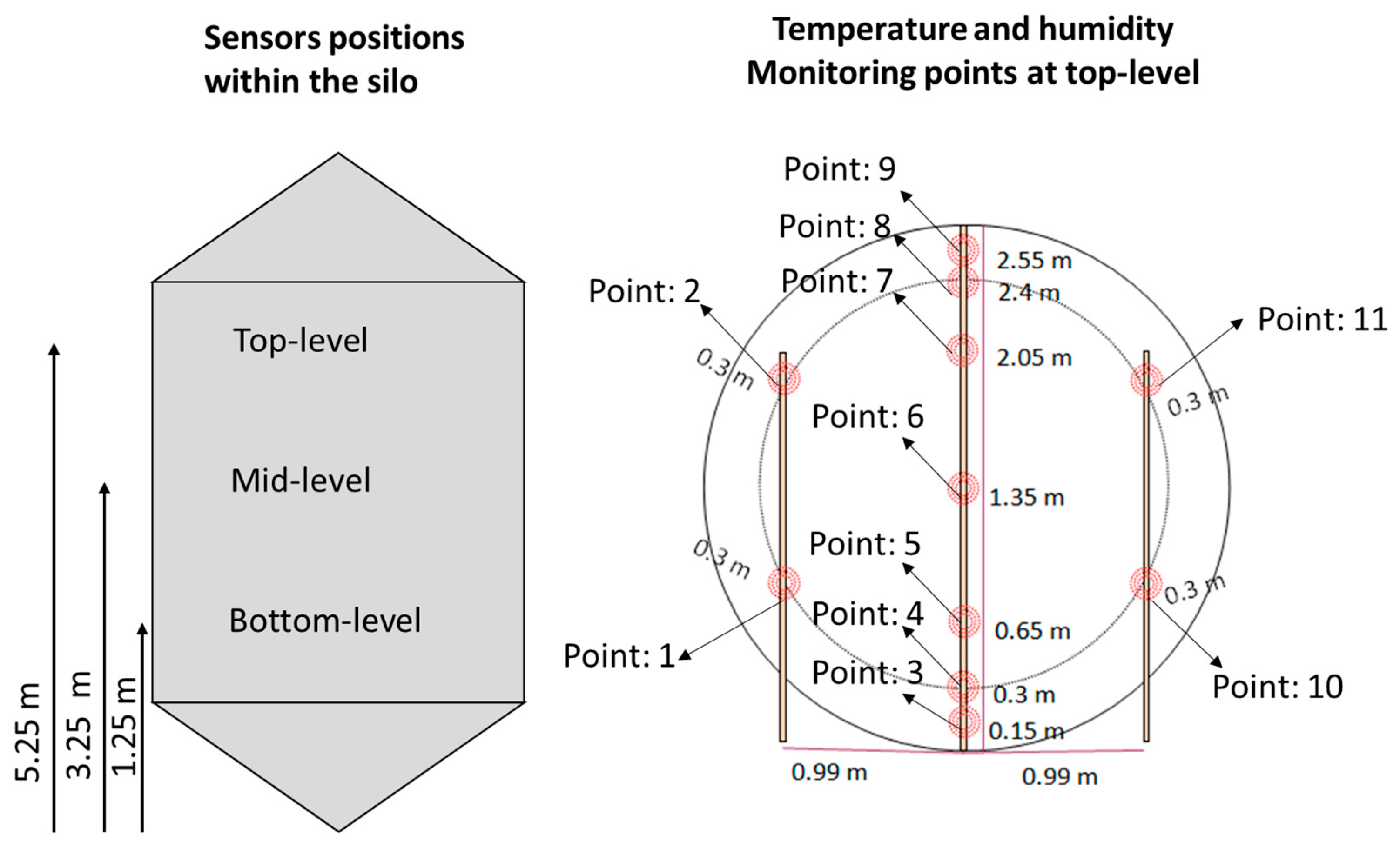

2.5. Model Verification and Validation

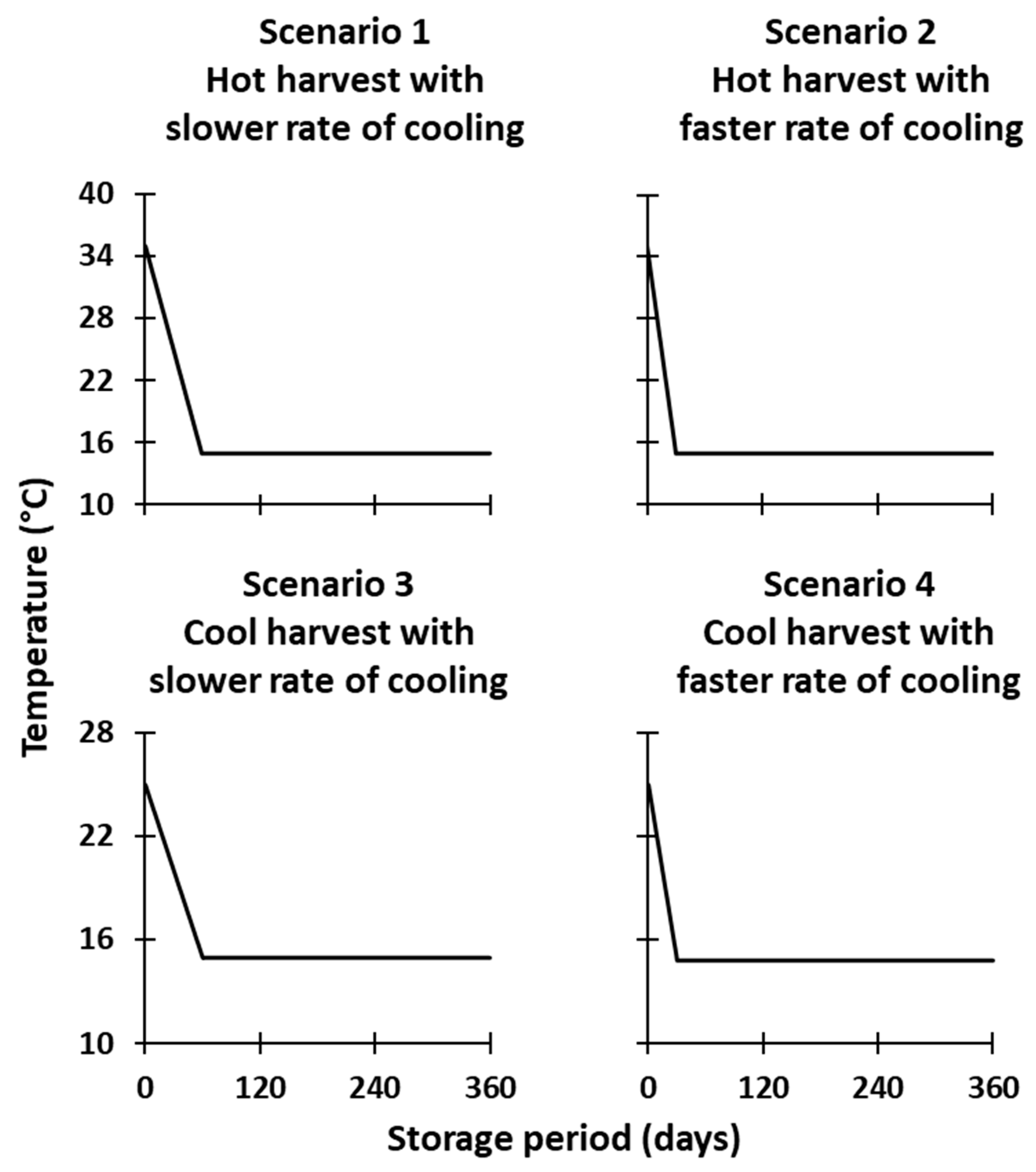

2.6. Simulation under Different Storage Scenarios

3. Results

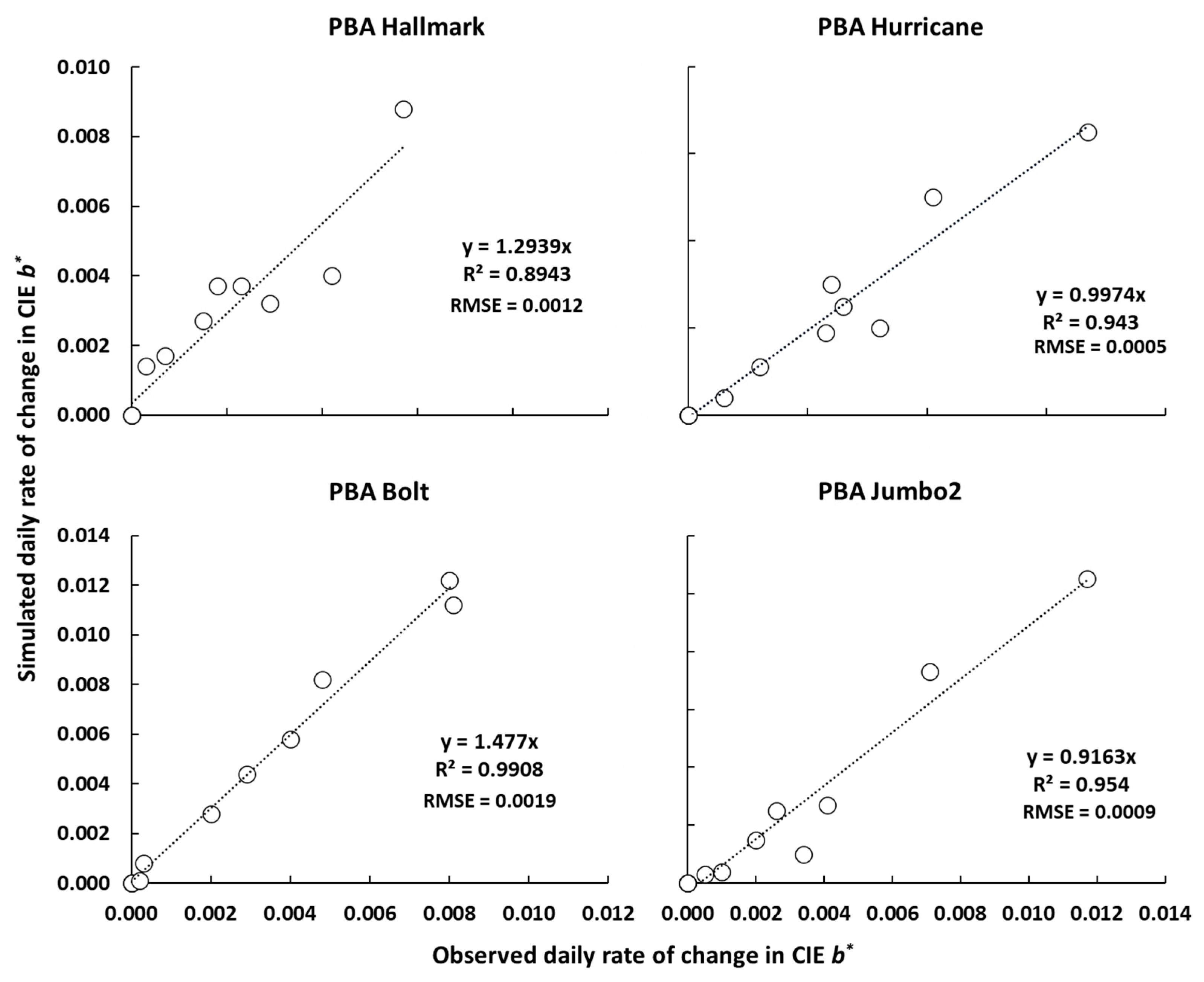

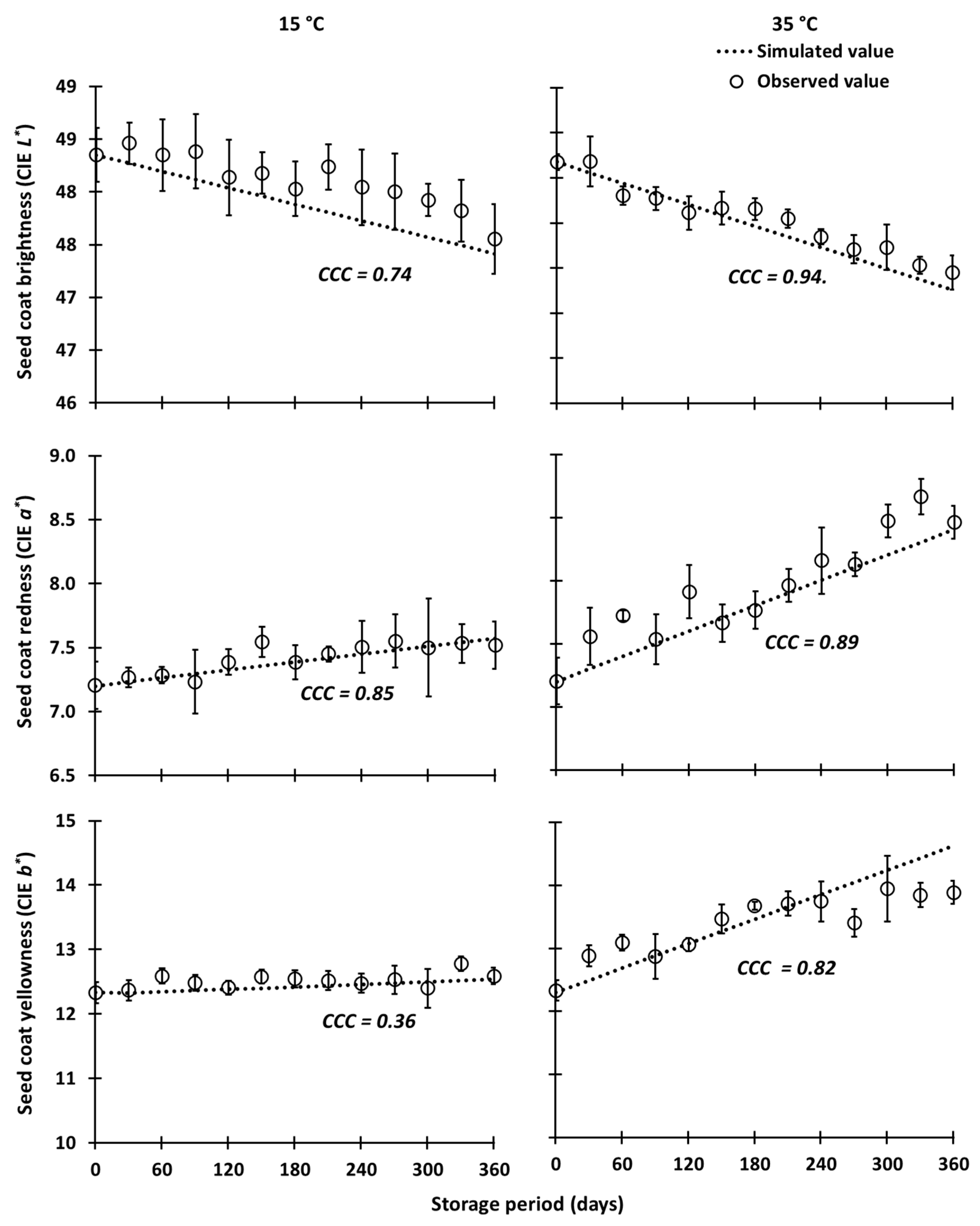

3.1. Performance of the Model

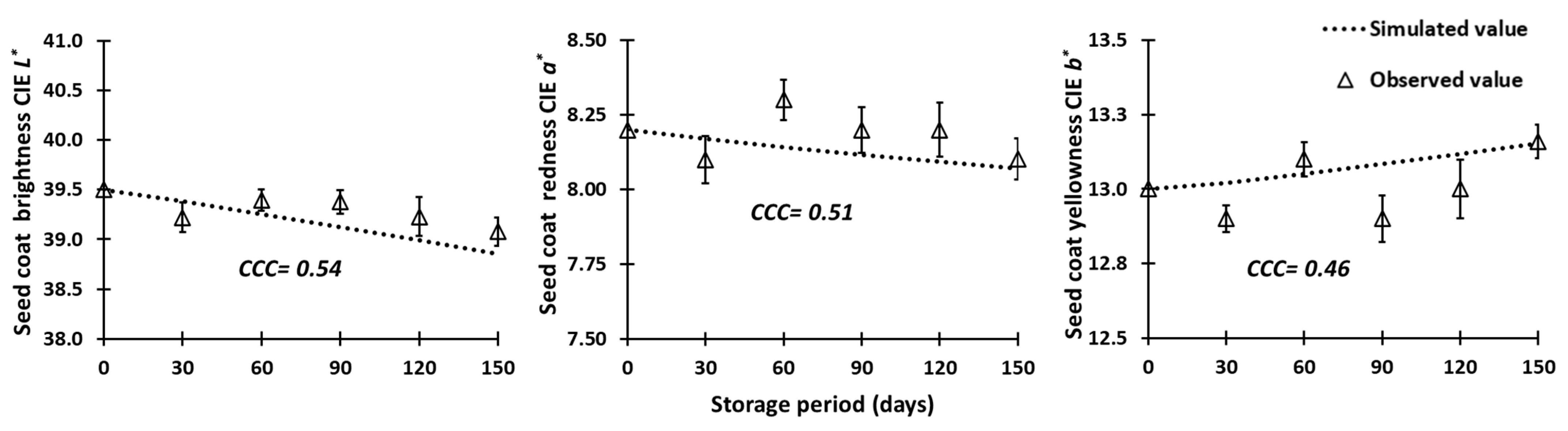

3.2. Model Validation

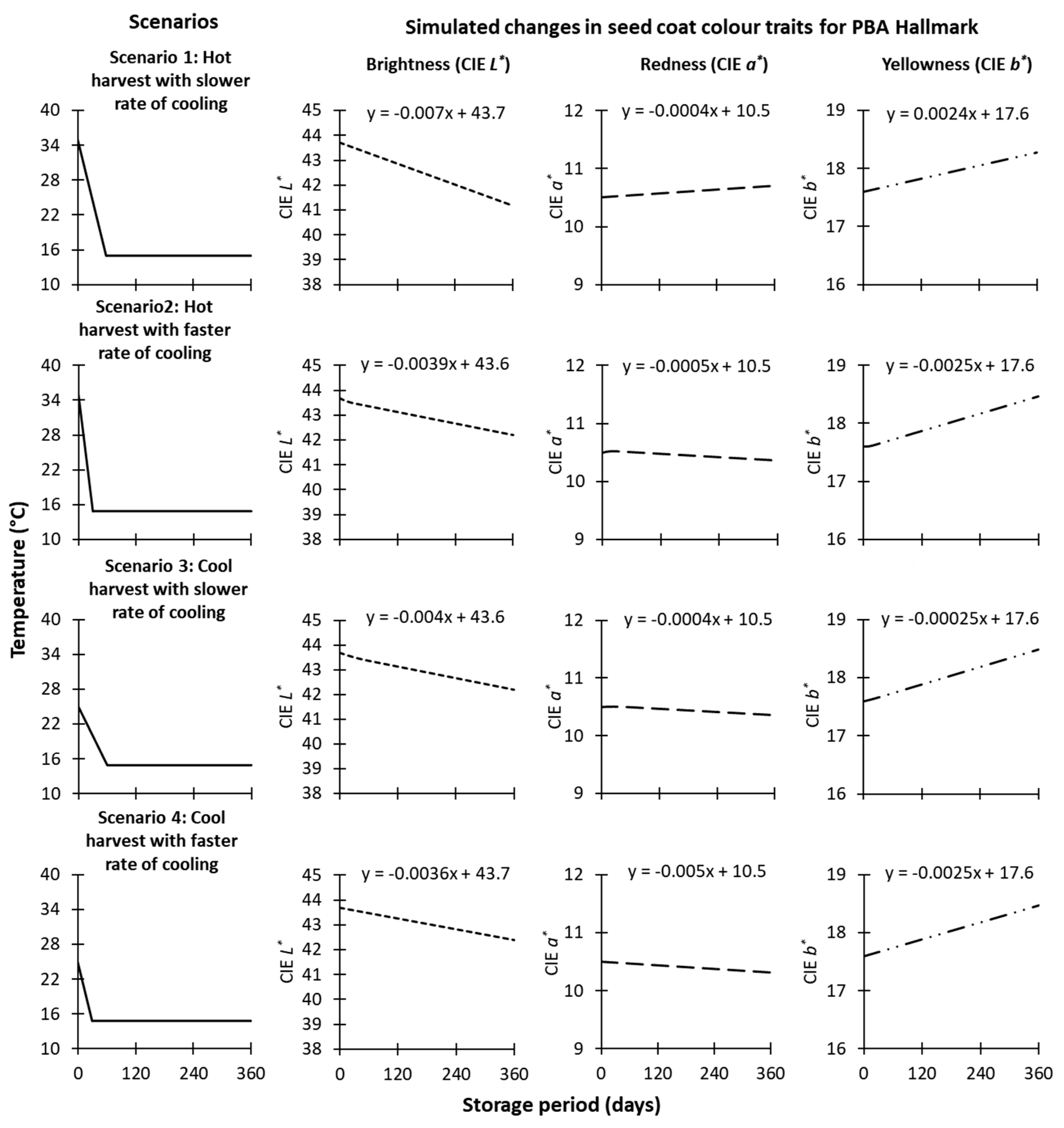

3.3. Simulation of Storage Scenarios

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bhattarai, B.; Walker, C.K.; Wallace, A.J.; Nuttall, J.G.; Hepworth, G.; Panozzo, J.F.; Partington, D.L.; Fitzgerald, G.J. Storage Temperature and grain moisture effects on market and end use properties of red lentil. Agronomy 2023, 13, 2261. [Google Scholar] [CrossRef]

- Belasco, R.; Edwards, T.; Munoz, A.J.; Rayo, V.; Buono, M.J. The effect of hydration on urine color objectively evaluated in CIE L*a*b* color space. Front. Nutr. 2020, 7, 576974. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.-K.; Kim, S.-H. Effect of the number of coloring liquid applications on the optical properties of monolithic zirconia. Dent. Mater. 2014, 30, e229–e237. [Google Scholar] [CrossRef] [PubMed]

- Karim, A.; Hassan, A.; Akanda, M.; Mallik, A. Monitoring food storage humidity and temperature data using IoT. MOJ Food Process Technol. 2018, 6, 400–404. [Google Scholar]

- Junxiang, G.; Jingtao, X. Fruit cold storage environment monitoring system based on wireless sensor network. Procedia Eng. 2011, 15, 3466–3470. [Google Scholar] [CrossRef]

- Lutz, É.; Coradi, P.C.; Jaques, L.B.A.; de Oliveira Carneiro, L.; Teodoro, L.P.R.; Teodoro, P.E.; Meneghetti, V.L.; de Souza, G.A.C. Real-time equilibrium moisture content monitoring to predict grain quality of corn stored in silo and raffia bags. J. Food Process Eng. 2022, 45, e14076. [Google Scholar] [CrossRef]

- Coradi, P.C.; Lutz, É.; dos Santos Bilhalva, N.; Jaques, L.B.A.; Leal, M.M.; Teodoro, L.P.R. Prototype wireless sensor network and internet of things platform for real-time monitoring of intergranular equilibrium moisture content and predict the quality corn stored in silos bags. Expert Syst. Appl. 2022, 208, 118242. [Google Scholar] [CrossRef]

- Zhao, L.; Wang, J.; Li, Z.; Hou, M.; Dong, G.; Liu, T.; Sun, T.; Grattan, K.T.V. Quasi-distributed fiber optic temperature and humidity sensor system for monitoring of grain storage in granaries. IEEE Sens. J. 2020, 20, 9226–9233. [Google Scholar] [CrossRef]

- Faree, A.; Wang, Y.; Li, G. Modeling Grain Storage Quality with Linear Regression. In Proceedings of the 2017 3rd IEEE International Conference on Computer and Communications (ICCC), Chengdu, China, 13–16 December 2017; pp. 2904–2909. [Google Scholar]

- Zhang, Q.; Li, Z.; Dong, W.; Wei, S.; Liu, Y.; Zuo, M. A model for predicting and grading the quality of grain storage processes affected by microorganisms under different environments. Int. J. Environ. Res. Public Health 2023, 20, 4120. [Google Scholar] [CrossRef] [PubMed]

- Szwedziak, K. The Use of Vision Techniques for the Evaluation of Selected Quality Parameters of Maize Grain during Storage. In Proceedings of the XXII International Scientific Conference POLSITA 2019 “Progress of Mechanical Engineering Supported by Information Technology, E3S Web of Conferences, Milan, Italy, 22 November 2019; p. 01026. [Google Scholar]

- Wawrzyniak, J. Prediction of fungal infestation in stored barley ecosystems using artificial neural networks. Lebensm.-Wiss. Technol. 2021, 137, 110367. [Google Scholar] [CrossRef]

- Wrolstad, R.E.; Smith, D.E. Color Analysis. In Food Analysis; Nielsen, S.S., Ed.; Springer International Publishing: Cham, Switzerland, 2017; pp. 545–555. [Google Scholar]

- ISSE_Systems. Technical Document for iTHINK and STELLA Software. Available online: https://www.iseesystems.com (accessed on 1 December 2023).

- Ouyang, Y.; Zhang, J.E.; Lin, D.; Liu, G.D. A STELLA model for the estimation of atrazine runoff, leaching, adsorption, and degradation from an agricultural land. J. Soils Sediments 2010, 10, 263–271. [Google Scholar] [CrossRef]

- Aassine, S.; El Jai, M.C. Vegetation dynamics modelling: A method for coupling local and space dynamics. Ecol. Model. 2002, 154, 237–249. [Google Scholar] [CrossRef]

- Costanza, R.; Voinov, A.; Boumans, R.; Maxwell, T.; Villa, F.; Wainger, L.; Voinov, H. Integrated ecological economic modeling of the patuxent river watershed, maryland. Ecol. Monogr. 2002, 72, 203–231. [Google Scholar] [CrossRef]

- Bhattarai, B.; Walker, C.K.; Wallace, A.J.; Nuttall, J.G.; Hepworth, G.; Panozzo, J.F.; Partington, D.L.; Fitzgerald, G.J. Modified storage atmosphere prevents the degradation of key grain quality traits in lentil. Agronomy 2023, 13, 2160. [Google Scholar] [CrossRef]

- Panozzo, J.F.; Walker, C.K.; Partington, D.L.; Neumann, N.C.; Tausz, M.; Seneweera, S.; Fitzgerald, G.J. Elevated carbon dioxide changes grain protein concentration and composition and compromises baking quality. A FACE study. J. Cereal Sci. 2014, 60, 461–470. [Google Scholar] [CrossRef]

- Telesense. Information Sheet for Telesense Spear. Available online: https://telesense.com (accessed on 1 December 2023).

- Elitech. RC-51H PDF Temperature & Humidity Data Logger. Available online: https://www.elitechus.com (accessed on 1 December 2023).

- Steichen, T.J.; Cox, N.J. A note on the concordance correlation coefficient. Stata J. 2002, 2, 183–189. [Google Scholar] [CrossRef]

- CGC. Official Grain Grading Guide. Available online: https://www.grainscanada.gc.ca/en/grain-quality/official-grain-grading-guide (accessed on 1 December 2023).

- GTA. Australian Pulse Standards. Available online: https://www.graintrade.org.au/commodity_standards (accessed on 1 December 2023).

- Jayas, D.; Alagusundaram, K.; Shunmugam, G.; Muir, W.; White, N. Simulated temperatures of stored grain bulks. Can. Agric. Eng. 1994, 36, 239–246. [Google Scholar]

- Sathya, G.; Jayasl, D.S.; White, N.D.G. Safe storage guidelines for rye. Can. Biosyst. Eng. J. 2008, 50, 3.1–3.8. [Google Scholar]

- Plumier, B.; Maier, D. Effect of temperature sensor numbers and placement on aeration cooling of a stored grain mass using a 3d finite element model. Agriculture 2021, 11, 231. [Google Scholar] [CrossRef]

| Colour Traits | Cultivars | Initial Colour | a1 | a2 | b1 | b2 | n | R2 | RMSE |

|---|---|---|---|---|---|---|---|---|---|

| CIE L* | PBA Hallmark | 43.7 (0.86) 1 | −0.00857 | 0.00084 | 0.17724 | −0.02005 | 3 | 0.98 | 0.0013 |

| PBA Hurricane | 44.7 (0.15) | −0.00170 | 0.00005 | −0.01529 | −0.00071 | 3 | 0.99 | 0.0004 | |

| PBA Bolt | 46.5 (0.13) | −0.00571 | 0.00050 | 0.09067 | −0.00960 | 3 | 0.99 | 0.0010 | |

| PBA Jumbo2 | 48.3 (0.09) | −0.00272 | 0.00025 | 0.00641 | −0.00199 | 3 | 1.00 | 0.0005 | |

| CIE a* | PBA Hallmark | 10.5 (0.13) | 0.00273 | −0.00023 | −0.03932 | 0.00313 | 3 | 0.98 | 0.0005 |

| PBA Hurricane | 10.1 (0.15) | 0.00069 | 0.00007 | 0.00666 | −0.00367 | 3 | 0.99 | 0.0001 | |

| PBA Bolt | 9.50 (0.12) | 0.00160 | −0.00006 | −0.00181 | −0.00228 | 3 | 0.99 | 0.0005 | |

| PBA Jumbo2 | 8.00 (0.13) | 0.00114 | −0.00009 | −0.01528 | 0.00161 | 3 | 0.99 | 0.0002 | |

| CIE b* | PBA Hallmark | 17.6 (0.14) | −0.00132 | 0.000421 | 0.05000 | −0.00200 | 3 | 0.89 | 0.0012 |

| PBA Hurricane | 18.5 (0.18) | −0.00507 | 0.00057 | 0.13750 | −0.01425 | 3 | 0.94 | 0.0005 | |

| PBA Bolt | 16.4 (0.18) | −0.00154 | 0.00014 | 0.07500 | −0.00550 | 3 | 0.99 | 0.0019 | |

| PBA Jumbo2 | 14.2 (0.86) | 0.00182 | −0.00011 | −0.05643 | 0.00504 | 3 | 0.95 | 0.0009 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bhattarai, B.; Nuttall, J.G.; Walker, C.K.; Wallace, A.J.; Fitzgerald, G.J.; O’Leary, G.J. An Explanatory Model of Red Lentil Seed Coat Colour to Manage Degradation in Quality during Storage. Agronomy 2024, 14, 373. https://doi.org/10.3390/agronomy14020373

Bhattarai B, Nuttall JG, Walker CK, Wallace AJ, Fitzgerald GJ, O’Leary GJ. An Explanatory Model of Red Lentil Seed Coat Colour to Manage Degradation in Quality during Storage. Agronomy. 2024; 14(2):373. https://doi.org/10.3390/agronomy14020373

Chicago/Turabian StyleBhattarai, Bhawana, James G. Nuttall, Cassandra K. Walker, Ashley J. Wallace, Glenn J. Fitzgerald, and Garry J. O’Leary. 2024. "An Explanatory Model of Red Lentil Seed Coat Colour to Manage Degradation in Quality during Storage" Agronomy 14, no. 2: 373. https://doi.org/10.3390/agronomy14020373

APA StyleBhattarai, B., Nuttall, J. G., Walker, C. K., Wallace, A. J., Fitzgerald, G. J., & O’Leary, G. J. (2024). An Explanatory Model of Red Lentil Seed Coat Colour to Manage Degradation in Quality during Storage. Agronomy, 14(2), 373. https://doi.org/10.3390/agronomy14020373