Ammonia and Greenhouse Gas Emissions from Organic Manure Composting: The Effect of Membrane Cover

Abstract

1. Introduction

2. Materials and Methods

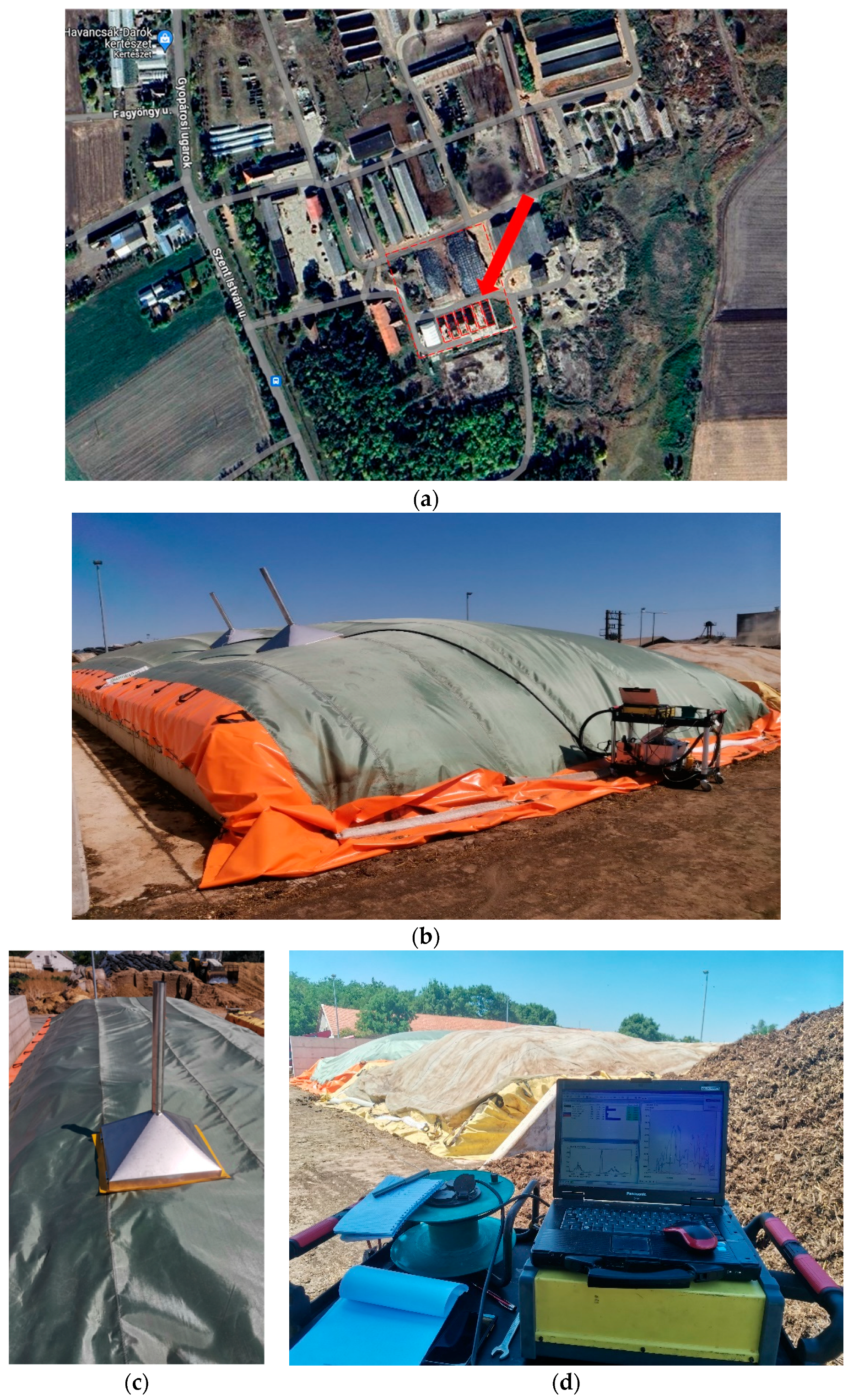

2.1. Composting Units under Study

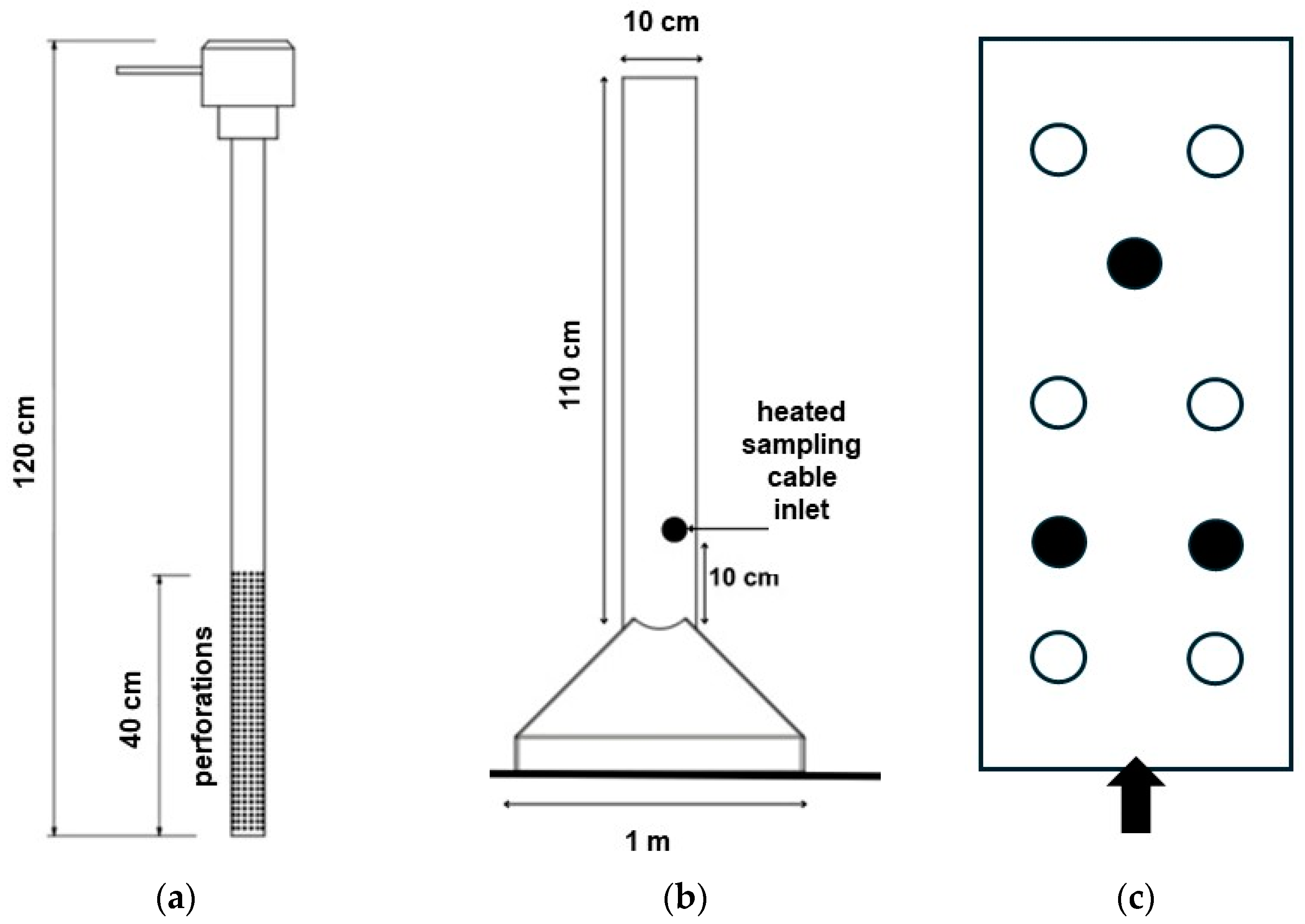

2.2. Sampling Procedures and Techniques

2.2.1. Gas Collection

2.2.2. Sampling Equipment

2.3. Measurement Protocols and Techniques

2.3.1. Ammonia Measurement

2.3.2. Greenhouse Gas Emissions Measurements

2.3.3. Volatile Organic Compound Measurements

2.4. Data and Statistical Analysis

3. Results

3.1. Analysis of Emissions: Inside vs. Outside of Compost Piles

3.1.1. Shapiro–Wilk Test Results on Data Distribution

3.1.2. Mann–Whitney U Test Results on Inside vs. Outside Emissions

3.2. Levene’s Test for Homoscedasticity

3.3. Comparative Analysis of Emissions from Covered and Uncovered Piles Using the Independent Sample T-Test

3.4. Emissions Reduction Analysis

3.5. Reduction from Inside to Outside

3.6. Reduction of Emissions Inside the Covered Piles Compared to Uncovered Piles

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hao, X.; Chang, C.; Larney, F.; Travis, G. Greenhouse gas emissions during cattle feedlot manure composting. J. Environ. Qual. 2001, 30, 376–386. [Google Scholar] [CrossRef] [PubMed]

- Pagans, E.; Font, X.; Sánchez, A. Emission of volatile organic compounds from composting of different solid wastes: Abatement by biofiltration. J. Hazard. Mater. 2006, 131, 179–186. [Google Scholar] [CrossRef] [PubMed]

- Szántó, G.L.; Hamelers, H.V.M.; Rulkens, W.H.; Veeken, A.H.M. Turnover and losses of NH3 during manure composting: A critical review. In Ammonia Emissions in Agriculture; Monteny, G.J., Hartung, E., Eds.; Wageningen Academic Publishers: Wageningen, The Netherlands, 2007; pp. 215–218. ISBN 978-90-8686-029-6. [Google Scholar]

- Nordahl, S.L.; Preble, C.V.; Kirchstetter, T.W.; Scown, C.D. Greenhouse gas and air pollutant emissions from composting. Environ. Sci. Technol. 2023, 57, 2235–2247. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Li, S.; Chen, S.; Meng, Q.; Wang, Y.; Yang, W.; Shi, L.; Ding, F.; Zhu, J.; Ma, R.; et al. Measures for controlling gaseous emissions during composting: A review. Int. J. Environ. Res. Public Health 2023, 20, 3587. [Google Scholar] [CrossRef] [PubMed]

- Alexander, J.R.; Spackman, J.A.; Wilson, M.L.; Fernández, F.G.; Venterea, R.T. Capture efficiency of four chamber designs for measuring ammonia emissions. Agrosyst. Geosci. Environ. 2021, 4, e20199. [Google Scholar] [CrossRef]

- Cattaneo, M.; Tayà, C.; Burgos, L.; Morey, L.; Noguerol, J.; Provolo, G.; Cerrillo, M.; Bonmatí, A. Assessing ammonia and greenhouse gas emissions from livestock manure storage: Comparison of measurements with dynamic and static chambers. Sustainability 2023, 15, 15987. [Google Scholar] [CrossRef]

- Mosier, A.; Halvorson, A.; Reule, C.; Liu, X. Net global warming potential and greenhouse gas intensity in irrigated cropping systems in Northeastern Colorado. J. Environ. Qual. 2006, 35, 1584–1598. [Google Scholar] [CrossRef] [PubMed]

- Smith, P.; Martino, D.; Cai, Z.; Gwary, D.; Janzen, H.; Kumar, P.; McCarl, B.; Ogle, S.; O’Mara, F.; Rice, C.; et al. Greenhouse gas mitigation in agriculture. Philos. Trans. R. Soc. B 2007, 363, 789–813. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Liu, D.; Qiao, Y.; Li, S.; Chen, Y.; Hu, C. Mitigation of carbon and nitrogen losses during pig manure composting: A meta-analysis. Sci. Total Environ. 2022, 783, 147103. [Google Scholar] [CrossRef]

- Fang, C.; Su, Y.; He, X.; Han, L.; Qu, H.; Zhou, L.; Huang, G. Membrane-covered composting significantly decreases methane emissions and microbial pathogens: Insight into the succession of bacterial and fungal communities. Sci. Total Environ. 2022, 845, 157343. [Google Scholar] [CrossRef]

- Xiong, J.; Su, Y.; He, X.; Han, L.; Huang, G. Effects of functional membrane coverings on carbon and nitrogen evolution during aerobic composting: Insight into the succession of bacterial and fungal communities. Bioresour. Technol. 2023, 369, 128463. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Chen, W.; Liu, G.; Cui, B.; Zhang, L.; Wuyun, D.; Wang, D.; Wang, G.; Li, G.; Yuan, J. Effect of a semi-permeable membrane covered composting on greenhouse gas emissions and bacterial community succession: A comparative study with biomass materials covering. J. Clean. Prod. 2024, 434, 140146. [Google Scholar] [CrossRef]

- Hou, Y.; Velthof, G.; Oenema, O. Mitigation of ammonia, nitrous oxide and methane emissions from manure management chains: A meta-analysis and integrated assessment. Glob. Chang. Biol. 2014, 21, 1293–1312. [Google Scholar] [CrossRef]

- U.S. National Research Council; Committee on Toxicology; Committee on Acute Exposure Guideline Levels. Ammonia Acute Exposure Guideline Levels. In Acute Exposure Guideline Levels for Selected Airborne Chemicals; National Academies Press: Washington, DC, USA, 2008; Volume 6, pp. 58–114. Available online: https://nap.nationalacademies.org/catalog/12018/acute-exposure-guideline-levels-for-selected-airborne-chemicals-volume-6 (accessed on 3 July 2024).

- Wang, C.; Lu, H.; Dong, D.; Deng, H.; Strong, P.; Wang, H.; Wu, W. Insight into the effects of biochar on manure composting: Evidence supporting the relationship between n2o emission and denitrifying community. Environ. Sci. Technol. 2013, 47, 7341–7349. [Google Scholar] [CrossRef] [PubMed]

- Cardoso, F.; Malgaresi, G.; Mirre, R. A CO2 separation process of natural gas streams by membrane permeation: Technological and operational approach. J. Bioeng. Technol. Health 2023, 6, 87–90. [Google Scholar] [CrossRef]

- Makhloufi, C.; Lasseuguette, E.; Rémigy, J.; Belaissaoui, B.; Roizard, D.; Favre, É. mmonia based CO2 capture process using hollow fiber membrane contactors. J. Membr. Sci. 2014, 455, 236–246. [Google Scholar] [CrossRef]

- Lin, B.; Nowrin, F.; Rosenthal, J.; Bhown, A.; Malmali, M. Perspective on intensification of Haber−Bosch to enable ammonia production under milder conditions. ACS Sustain. Chem. Eng. 2023, 11, 9880–9899. [Google Scholar] [CrossRef]

- VDI (Verein Deutscher Ingenieure e.V.). VDI 3862 Blatt 8. Measurement of Gaseous Emissions—Measurement of Formaldehyde in the Exhaust Gas of Combustion Engines—FTIR Method; (June 2015) Engl.; VDI/DIN-Kommission Reinhaltung der Luft (KRdL)—Normenausschuss: Düsseldorf, Germany, 2015; pp. 1–27. Available online: https://www.vdi.de/en/home/vdi-standards/details/vdi-3862-blatt-8-measurement-of-gaseous-emissions-measurement-of-formaldehyde-in-the-exhaust-gas-of-combustion-engines-ftir-method (accessed on 3 July 2024).

- UK Environment Agency. Technical Guidance Note M22 (Monitoring). Measuring Stack Gas Emissions Using FTIR Instruments; Version 3 (March 2012); UK Environment Agency: Rotherham, UK, 2012; pp. 1–51. Available online: https://www.gov.uk/government/publications/m22-measuring-stack-gas-emissions-using-ftir-instruments (accessed on 3 July 2024).

- ASTM D6348-3; ASTM International Standard Test Method for Determination of Gaseous Compounds by Extractive Direct Interface Fourier Transform Infrared (FTIR) Spectroscopy. ASTM: West Conshohocken, PA, USA, 2019. Available online: https://www.astm.org/d6348-03.html (accessed on 3 July 2024).

- Gasmet (Gasmet Technologies Oy). Spectrum Library; Gasmet Technologies Oy: Vantaa, Finland, 2024; Available online: https://www.gasmet.com/products/tools/spectrum-library (accessed on 3 July 2024).

- Shapiro, S.S.; Wilk, M.B. An analysis of variance test for normality (complete samples). Biometrika 1965, 52, 591–611. [Google Scholar] [CrossRef]

- Mann, H.B.; Whitney, D.R. On a test of whether one of two random variables is stochastically larger than the other. Ann. Math. Stat. 1947, 18, 50–60. [Google Scholar] [CrossRef]

- le Cessie, S.; Goeman, J.J.; Dekkers, O.M. Who is afraid of non-normal data? Choosing between parametric and non-parametric tests. Eur. J. Endocrinol. 2020, 182, E1–E3. [Google Scholar] [CrossRef]

- Levene, H. Robust tests for equality of variances. In Contributions to Probability and Statistics: Essays in Honor of Harold Hotelling; Olkin, I., Ghurye, S.G., Hoeffding, W., Madow, W.G., Mann, H.B., Eds.; Stanford University Press: Palo Alto, CA, USA, 1960; pp. 278–292. ISBN 978-08-0470-596-7. Available online: https://books.google.hu/books/about/Contributions_to_Probability_and_Statist.html?id=ZUSsAAAAIAAJ (accessed on 3 July 2024).

- Song, Y.; Ruiyi, L.; Wang, Y.; Hou, Y.; Chen, G.; Yan, B.; Cheng, Z.; Mu, L. Co-composting of cattle manure and wheat straw covered with a semipermeable membrane: Organic matter humification and bacterial community succession. Environ. Sci. Pollut. Res. 2022, 30, 32776–32789. [Google Scholar] [CrossRef] [PubMed]

- Soto-Herranz, M.; Sánchez-Báscones, M.; Antolín-Rodríguez, J.; Martín-Ramos, P. Reduction of ammonia emissions from laying hen manure in a closed composting process using gas-permeable membrane technology. Agronomy 2021, 11, 2384. [Google Scholar] [CrossRef]

- Soto-Herranz, M.; Sánchez-Báscones, M.; García-González, M.C.; Martín-Ramos, P. Comparison of the ammonia trapping performance of different gas-permeable tubular membrane system configurations. Membranes 2022, 12, 1104. [Google Scholar] [CrossRef] [PubMed]

- Cao, J.; Li, R.; Qu, H.; Wang, P.; Fu, J.; Chen, M.; Chen, Y. Effects of the membrane-covered technology and superphosphate on the compost quality and nitrogen-containing gas emissions during aerobic composting. Bioresources 2022, 17, 1781–1793. [Google Scholar] [CrossRef]

- Dennehy, C.; Lawlor, P.; Jiang, Y.; Gardiner, G.; Xie, S.; Nghiem, L.; Zhan, X. Greenhouse gas emissions from different pig manure management techniques: A critical analysis. Front. Environ. Sci. Eng. 2017, 11, 11. [Google Scholar] [CrossRef]

- Li, R.; Cao, J.; Liang, C.; Wang, P.; Qu, H.; Chen, M.; Fu, J.; Chen, Y. Effects of combined membrane-covered systems on aerobic composting of strawberry vine and chicken manure. Bioresources 2022, 17, 1173–1186. [Google Scholar] [CrossRef]

- Sun, X.; Huang, G.; Huang, Y.; Chen, F.; He, X.; Zheng, Y. Large semi-membrane covered composting system improves the spatial homogeneity and efficiency of fermentation. Int. J. Environ. Res. Public Health 2022, 19, 15503. [Google Scholar] [CrossRef]

- Sun, X.; Ma, S.; Han, L.; Li, R.; Schlick, U.; Chen, P.; Huang, G. The effect of a semi-permeable membrane-covered composting system on greenhouse gas and ammonia emissions in the Tibetan plateau. J. Clean. Prod. 2018, 204, 778–787. [Google Scholar] [CrossRef]

- Fang, C.; Yin, H.; Han, L.; Ma, S.; He, X.; Huang, G. Effects of semi-permeable membrane covering coupled with intermittent aeration on gas emissions during aerobic composting from the solid fraction of dairy manure at industrial scale. Waste Manag. 2021, 131, 1–9. [Google Scholar] [CrossRef]

- Yuan, J.; Li, Y.; Chen, S.; Lia, D.; Tang, H.; Chadwick, D.; Lia, S.; Li, W.; Li, G. Effects of phosphogypsum, superphosphate, and dicyandiamide on gaseous emission and compost quality during sewage sludge composting. Bioresour. Technol. 2018, 270, 368–376. [Google Scholar] [CrossRef]

- Jiang, J.; Huang, Y.; Liu, X.; Huang, H. The effects of apple pomace, bentonite and calcium superphosphate on swine manure aerobic composting. Waste Manag. 2014, 34, 1595–1602. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Zhang, A.; Li, G.; Wei, Y.; He, S.; Lin, Z.; Shen, X.; Wang, Q. Effect of different components of single superphosphate on organic matter degradation and maturity during pig manure composting. Sci. Total Environ. 2019, 646, 587–594. [Google Scholar] [CrossRef] [PubMed]

- Voropaev, V.; Alfimova, N.; Nikulin, I.; Nikulicheva, T.; Titenko, A.; Nikulichev, V. Influence of gypsum-containing waste on ammonia binding in animal waste composting. Agriculture 2021, 11, 1153. [Google Scholar] [CrossRef]

- Pereira, J.L.S.; Perdigão, A.; Marques, F.; Wessel, D.F.; Trindade, H.; Fangueiro, D. Mitigating ammonia and greenhouse gas emissions from stored pig slurry using chemical additives and biochars. Agronomy 2022, 12, 2744. [Google Scholar] [CrossRef]

- Ma, S.; Xiong, J.; Wu, X.; Liu, H.; Han, L.; Huang, G. Effects of the functional membrane covering on the gas emissions and bacterial community during aerobic composting. Bioresour. Technol. 2021, 340, 125660. [Google Scholar] [CrossRef] [PubMed]

- Zuokaitė, E.; Zigmontienė, A. Application of a natural cover during sewage sludge composting to reduce gaseous emissions. Polish J. Environ. Stud. 2013, 22, 621–626. Available online: https://www.pjoes.com/Application-of-a-Natural-Cover-during-Sewage-r-nSludge-Composting-to-Reduce-Gaseous,89016,0,2.html (accessed on 3 July 2024).

- Ermolaev, E.; Sundberg, C.; Pell, M.; Jönsson, H. Greenhouse gas emissions from home composting in practice. Bioresour. Technol. 2014, 151, 174–182. [Google Scholar] [CrossRef]

- Szymula, A.; Wlazło, L.; Sasáková, N.; Wnuk, W.; Nowakowicz-Debek, B. The use of natural sorbents to reduce ammonia emissions from cattle faeces. Agronomy 2021, 11, 2543. [Google Scholar] [CrossRef]

- Wei, Y.; Li, J.; Shi, D.; Liu, G.; Zhao, Y.; Shimaoka, T. Environmental challenges impeding the composting of biodegradable municipal solid waste: A critical review. Resour. Conserv. Recycl. 2017, 122, 51–65. [Google Scholar] [CrossRef]

- Ma, S.; Sun, X.; Fang, C.; He, X.; Han, L.; Huang, G. Exploring the mechanisms of decreased methane during pig manure and wheat straw aerobic composting covered with a semi-permeable membrane. Waste Manag. 2018, 78, 393–400. [Google Scholar] [CrossRef]

- Ma, S.; Xiong, J.; Cui, R.; Sun, X.; Han, L.; Ya-Tong, X.; Xu, Y.; Kan, Z.; Gong, X.; Huang, G. Effects of intermittent aeration on greenhouse gas emissions and bacterial community succession during large-scale membrane-covered aerobic composting. J. Clean. Prod. 2020, 266, 121551. [Google Scholar] [CrossRef]

- Li, J.; Chen, Y.-T.; Xia, Z.-Y.; Gou, M.; Sun, Z.-Y.; Tang, Y.-Q. Changes in bacterial communities during a pilot-scale composting process of dairy manure. J. Environ. Eng. 2020, 146, 04020095. [Google Scholar] [CrossRef]

- Bernal, M.; Lopez-Real, J.; Scott, K. Application of natural zeolites for the reduction of ammonia emissions during the composting of organic wastes in a laboratory composting simulator. Bioresour. Technol. 1993, 43, 35–39. [Google Scholar] [CrossRef]

- Chadwick, D. Emissions of ammonia, nitrous oxide and methane from cattle manure heaps: Effect of compaction and covering. Atmos. Environ. 2005, 39, 787–799. [Google Scholar] [CrossRef]

- Berg, W.; Brunsch, R.; Pazsiczki, I. Greenhouse gas emissions from covered slurry compared with uncovered during storage. Agric. Ecosyst. Environ. 2006, 112, 129–134. [Google Scholar] [CrossRef]

- Cadena, E.; Colón, J.; Sánchez, A.; Font, X.; Artola, A. A methodology to determine gaseous emissions in a composting plant. Waste Manag. 2009, 29, 2799–2807. [Google Scholar] [CrossRef]

- Edjabou, M.E.; Scheutz, C. Quantification of—And determining factors affecting—Methane emissions from composting plants. Waste Manag. 2023, 170, 287–296. [Google Scholar] [CrossRef]

| Measurement | ePTE-TEXcomm | Mann–Whitney U Test p-Value | ProfiCover® | Mann–Whitney U Test p-Value | ||||

|---|---|---|---|---|---|---|---|---|

| In | Out | Difference | In | Out | Difference | |||

| Ammonia (NH3) [ppm] | 4259.8 ± 212.2 | 390.1 ± 77.2 | 3869.7 ± 289.4 | 0.0357 | 3343.8 ± 1400.7 | 225.8 ± 99.7 | 3118.0 ± 1500.4 | 0.0238 |

| Carbon dioxide (CO2) [v/v%] | 1.09 ± 0.25 | 0.44 ± 0.18 | 0.65 ± 0.43 | 0.0357 | 1.42 a | 0.20 ± 0.11 | 1.22 ± 0.11 | 0.0238 |

| Methane (CH4) [ppm] | 39.9 ± 23.8 | 81.2 | - | >0.05 | 69.3 | 30.8 ± 18.6 | 38.5 | >0.05 |

| Nitrous oxide (N2O) [ppm] | 1.30 ± 0.67 | 1.00 ± 0.20 | 0.30 ± 0.87 | 0.0357 | 1.50 | 0.65 ± 0.13 | 0.85 | 0.0256 |

| Propane equivalent [ppm] | 56.7 ± 13.9 | 31.3 | 25.4 | >0.05 | 79.2 | 12.3 ± 6.6 | 66.9 | 0.0238 |

| Measurement | Uncovered | ePTE-TEXcomm | ePTE-TEXcomm—Uncovered | Mann–Whitney U Test p-Value | ProfiCover® | ProfiCover®—Uncovered | Mann–Whitney U Test p-Value |

|---|---|---|---|---|---|---|---|

| In | In | Difference | In | Difference | |||

| Ammonia (NH3) [ppm] | 1584.8 ± 367.2 | 4259.8 ± 212.2 | 2675.0 ± 684.0 | 0.0357 | 3343.8 ± 1400.7 | 1759.0 | 0.0714 |

| Carbon dioxide (CO2) [v/v%] | 0.43 ± 0.16 | 1.09 ± 0.25 | 0.66 ± 0.50 | 0.0357 | 1.42 a | 1.0 | - |

| Methane (CH4) [ppm] | 3.45 ± 1.50 | 39.9 ± 23.8 | 36.5 ± 25.4 | 0.0357 | 69.3 | 65.9 | - |

| Nitrous oxide (N2O) [ppm] | 0.54 ± 0.39 | 1.30 ± 0.67 | 0.76 | >0.05 | 1.50 | 1.0 | - |

| Propane equivalent [ppm] | 13.9 ± 3.51 | 56.7 ± 13.9 | 42.8 ± 17.9 | 0.0357 | 79.2 | 65.3 | - |

| Measurement | Emission Reduction (%) | |||

|---|---|---|---|---|

| Between Inside and Outside of Membrane-Covered Compost Piles | Between Inside Membrane-Covered and Inside Uncovered Piles | |||

| ePTE-TEXcomm | ProfiCover® | ePTE-TEXcomm | ProfiCover® | |

| Ammonia (NH3) | 90.8 ± 1.9 | 93.3 ± 5.7 | 62.8a | 52.6 |

| Carbon dioxide (CO2) | 59.6 ± 18.8 | 85.9 ± 23.5 | 60.5 | 69.6 |

| Methane (CH4) | n.s.d. b | n.s.d. | 91.4 | 95.0 |

| Nitrous oxide (N2O) | 23.1 | 56.7 ± 49.3 | 58.3 | 63.9 |

| Propane equivalent | 44.8 | 84.5 ± 25.4 | 75.5 | 82.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Varga, Z.I.; Shahzad, S.; Ramay, M.W.; Damak, M.; Gulyás, M.; Béres, A.; Gyuricza, C.; Székács, A.; Aleksza, L. Ammonia and Greenhouse Gas Emissions from Organic Manure Composting: The Effect of Membrane Cover. Agronomy 2024, 14, 1471. https://doi.org/10.3390/agronomy14071471

Varga ZI, Shahzad S, Ramay MW, Damak M, Gulyás M, Béres A, Gyuricza C, Székács A, Aleksza L. Ammonia and Greenhouse Gas Emissions from Organic Manure Composting: The Effect of Membrane Cover. Agronomy. 2024; 14(7):1471. https://doi.org/10.3390/agronomy14071471

Chicago/Turabian StyleVarga, Zsolt István, Shaghil Shahzad, Muhammad Wajahat Ramay, Mariem Damak, Miklós Gulyás, András Béres, Csaba Gyuricza, András Székács, and László Aleksza. 2024. "Ammonia and Greenhouse Gas Emissions from Organic Manure Composting: The Effect of Membrane Cover" Agronomy 14, no. 7: 1471. https://doi.org/10.3390/agronomy14071471

APA StyleVarga, Z. I., Shahzad, S., Ramay, M. W., Damak, M., Gulyás, M., Béres, A., Gyuricza, C., Székács, A., & Aleksza, L. (2024). Ammonia and Greenhouse Gas Emissions from Organic Manure Composting: The Effect of Membrane Cover. Agronomy, 14(7), 1471. https://doi.org/10.3390/agronomy14071471