Kenaf: Opportunities for an Ancient Fiber Crop

Abstract

:1. Introduction

2. History

3. Modern Production

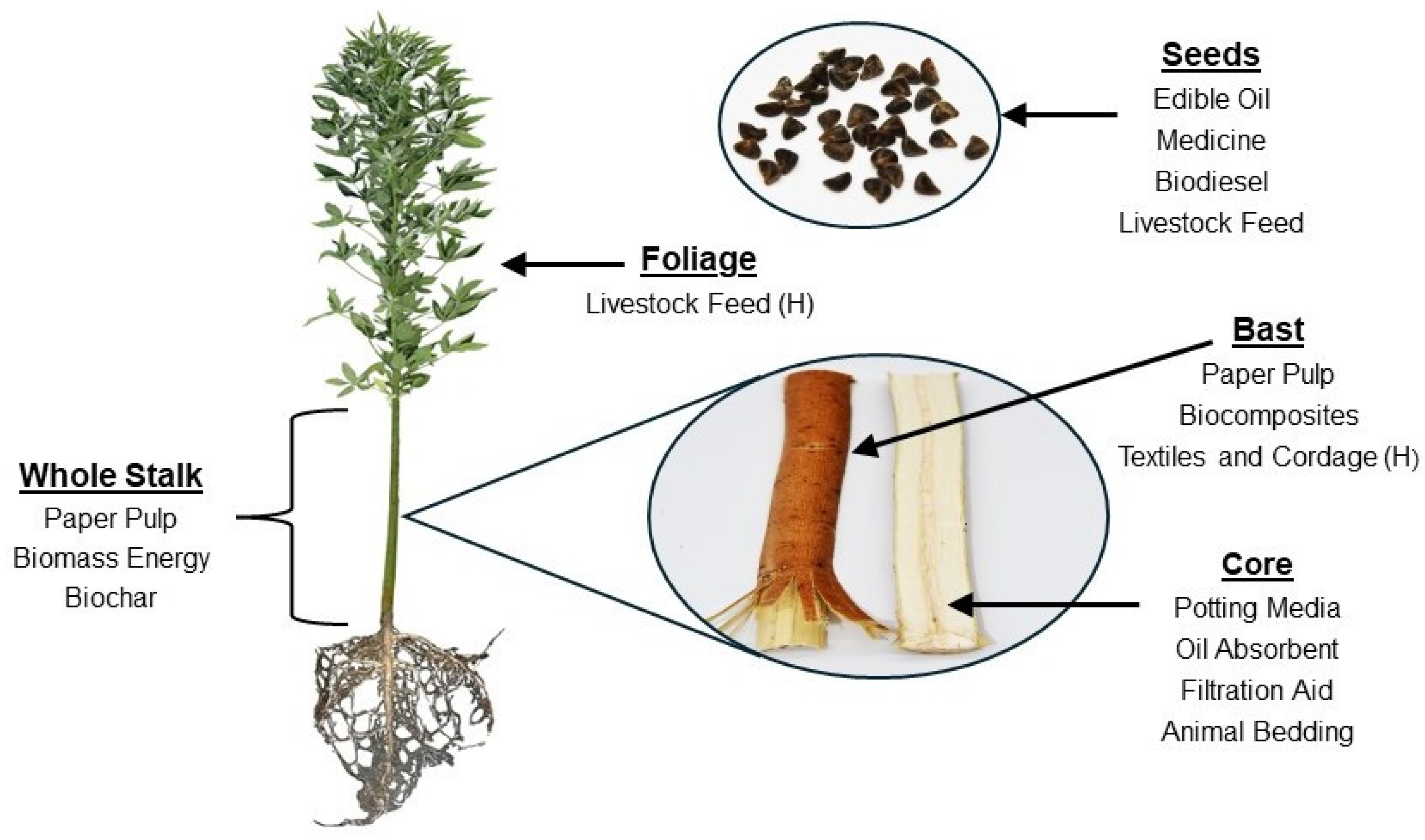

4. Kenaf Applications

4.1. Paper

4.2. Biocomposites

4.3. Oil Absorbent

4.4. Potting Medium

4.5. Livestock Feed

4.6. Biomass Energy

4.7. Additional Uses

5. Kenaf Compared to Other Fiber Crops

6. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Webber, C.L.; Bledsoe, V.K.; Bledsoe, R.E. Kenaf harvesting and processing. In Trends in New Crops and New Uses; Janick, J., Whipkey, A., Eds.; ASHS Press: Alexandria, VA, USA, 2002; pp. 340–347. [Google Scholar]

- Akil, H.M.; Omar, M.F.; Mazuki, A.A.M.; Safiee, S.; Ishak, Z.A.M.; Abu Bakar, A. Kenaf fiber reinforced composites: A review. Mater. Des. 2011, 32, 4107–4121. [Google Scholar] [CrossRef]

- Webber, C.L.; Bhardwaj, H.L.; Bledsoe, V.K. Kenaf production: Fiber, feed, and seed. In Trends in New Crops and New Uses; Janick, J., Whipkey, A., Eds.; ASHS Press: Alexandria, VA, USA, 2002; pp. 327–339. [Google Scholar]

- Webber, C.L. Yield components of five kenaf cultivars. Agron. J. 1993, 85, 533–535. [Google Scholar] [CrossRef]

- Webber, C.L.; Bledsoe, V.K. Kenaf yield components and plant composition. In Trends in New Crops and New Uses; Janick, J., Whipkey, A., Eds.; ASHS Press: Alexandria, VA, USA, 2002; pp. 348–357. [Google Scholar]

- Dempsey, J.M. Fiber Crops; The University Presses of Florida: Gainesville, FL, USA, 1975. [Google Scholar]

- Alexopoulou, E.; Papatheohari, Y.; Christou, M.; Monti, A. Origin, description, importance, and cultivation area of kenaf. In Kenaf: A Multi-Purpose Crop for Several Industrial Applications; Monti, A., Alexopoulou, E., Eds.; Green Energy and Technology; Springer: London, UK, 2013; pp. 1–15. [Google Scholar] [CrossRef]

- Li, D. Kenaf production, research, and development in China. In Proceedings of the International Kenaf Symposium, Beijing, China, 12–14 May 2003. [Google Scholar]

- Wilson, F.D.; Summers, T.E.; Joyner, J.F.; Fishler, D.W.; Seale, C.C. “Everglades 41” and “Everglades 71”, two new varieties of kenaf (Hibiscus cannabinus L.) for fiber and seed. Circ. Fla. Agric. Exp. Stn. 1965, S-158, 12. [Google Scholar]

- Nieschlag, H.J.; Nelson, G.H.; Wolff, I.A.; Perdue, R.E. A search for new fiber crops. TAPPI J. 1960, 43, 193–201. [Google Scholar]

- Alexopoulou, E.; Li, D.; Papatheohari, Y.; Siqi, H.; Scordia, D.; Testa, G. How kenaf (Hibiscus cannabinus L.) can achieve high yields in Europe and China. Ind. Crops Prod. 2015, 68, 131–140. [Google Scholar] [CrossRef]

- FAO. Jute, Kenaf, Sisal, Abaca, Coir and Allied Fibres Statistical Bulletin 2022; Food and Agriculture Organization of the United Nations: Rome, Italy, 2023; p. 6. [Google Scholar]

- Vayabari, D.A.G.; Ilham, Z.; Md Saad, N.; Usuldin, S.R.A.; Norhisham, D.A.; Abd Rahim, M.H.; Wan-Mohtar, W.A.A.Q.I. Cultivation strategies of kenaf (Hibiscus cannabinus L.) as a future approach in Malaysian agriculture industry. Horticulturae 2023, 9, 925. [Google Scholar] [CrossRef]

- LeMahieu, P.J.; Oplinger, E.S.; Puntnam, D.H. Kenaf. In Alternative Field Crops Manual; University of Wisconsin-Extension, Cooperative Extension University of Minnesota, Center for Alternative Plant and Animal Products and the Minnesota Extension Service: Alexandria, MN, USA, 1991; Available online: http://www.hort.purdue.edu/newcrop/afcm/Kenaf.html (accessed on 14 December 2023).

- White, G.A.; Cummins, D.G.; Whiteley, E.L.; Fike, W.T.; Greig, J.K.; Martin, J.A.; Killinger, G.B.; Higgins, J.J.; Clark, T.F. Cultural and Harvesting Methods for Kenaf; USDA Production Research Report No. 113; United States Department of Agriculture: Washington, DC, USA, 1970.

- Kaldor, A.F.; Karlgren, C.; Verwest, H. Kenaf—A fast growing fiber source for papermaking. TAPPI J. 1990, 73, 205–209. [Google Scholar]

- Sabharwal, H.S.; Akhtar, M.; Blanchette, R.A.; Young, R.A. Biomechanical pulping of kenaf. TAPPI J. 1994, 77, 105–112. [Google Scholar]

- Kline, L.M.; Hayes, D.G.; Womac, A.R.; Labbé, N. Simplified determination of lignin content in hard and soft woods via uv-spectrophotometric analysis of biomass dissolved in ionic liquids. BioResources 2010, 5, 1366–1383. [Google Scholar] [CrossRef]

- Nishino, T.; Hirao, K.; Kotera, M.; Nakamae, K.; Inagaki, H. Kenaf reinforced biodegradable composite. Compos. Sci. Technol. 2003, 63, 1281–1286. [Google Scholar] [CrossRef]

- Wambua, P.; Ivens, J.; Verpoest, I. Natural fibres: Can they replace glass in fibre reinforced plastics? Compos. Sci. Technol. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

- Rowell, R.M.; Sanadi, A.; Jacobson, R.; Caulfield, D. Properties of kenaf/polypropylene composites. In Kenaf Properties, Processing and Products; Mississippi State University, Ag & Bio Engineering: Mississippi State, MS, USA, 1999; pp. 381–392. [Google Scholar]

- Shamsudin, R.; Abdullah, H.; Sinang, S.C. Properties of oil sorbent material produced from kenaf fiber. Int. J. Environ. Sci. Dev. 2015, 6, 551–554. [Google Scholar] [CrossRef]

- Senanurakwarkul, C.; Khongsricharoen, P.; Pejprom, D.; Tantayanon, S.; Khaodiar, S. Effects of the composition and the preparation methods on oil sorption capacity of recycled rayon wastekapok mixtures (RRWK) sorbent. Int. J. Environ. Sci. Dev. 2013, 4, 246–250. [Google Scholar] [CrossRef]

- Pelletier, É.; Siron, R. Silicone-based polymers as oil spill treatment agents. Environ. Toxicol. Chem. 1999, 18, 813–818. [Google Scholar] [CrossRef]

- Okeke, E.S.; Okoye, C.O.; Ezeorba, T.P.C.; Mao, G.; Chen, Y.; Xu, H.; Song, C.; Feng, W.; Wu, X. Emerging bio-dispersant and bioremediation technologies as environmentally friendly management responses toward marine oil spill: A comprehensive review. J. Environ. Manag. 2022, 322, 116123. [Google Scholar] [CrossRef] [PubMed]

- Karan, C.P.; Rengasamy, R.S.; Das, D. Oil spill cleanup by structured fibre assembly. Indian J. Fibre Text. Res. 2011, 36, 190–200. [Google Scholar]

- Goforth, C.E. The evaluation of kenaf as an oil sorbent. In A Summary of Kenaf Production and Product Development Research 1989–1993; Goforth, C.E., Fuller, M.J., Eds.; Mississippi Agricultural and Forestry Experiment Station Tech. Bulletin 1011; Mississippi State University: Mississippi State, MS, USA, 1994; p. 25. Available online: https://www.mafes.msstate.edu/publications/bulletins/b1011.pdf (accessed on 14 December 2023).

- Hullet, J. Peat Supply Update: Why Communication Is Key. Greenhouse Product News. 2023. Available online: https://www.greenhousegrower.com/production/peat-supply-update-why-communication-is-key (accessed on 14 December 2023).

- Wang, Y.T. Using ground kenaf stem core as a major component of container media. J. Am. Soc. Hort. Sci. 1994, 119, 931–935. [Google Scholar] [CrossRef]

- Neumaier, D.; Meinken, E. Peat substitutes in growing media—Options and limitations. Acta Hortic. 2015, 1099, 159–166. [Google Scholar] [CrossRef]

- Reichert, N.A.; Baldwin, B.S. Growth of bedding plants in a kenaf-based potting medium. In Progress in New Crops: Proceedings of the Third National Symposium, Indianapolis, IN, USA, 22–25 October 1996; Janick, J., Ed.; ASHS Press: Alexandria, VA, USA, 1996; pp. 411–414. [Google Scholar]

- Webber, C.L.; Whitworth, J.; Dole, J. Kenaf (Hibiscus cannabinus L.) core as a containerized growth medium component. Ind. Crops Prod. 1999, 10, 97–105. [Google Scholar] [CrossRef]

- Webber, C.L. Crude protein and yield components of six kenaf cultivars as affected by crop maturity. Ind. Crops Prod. 1993, 2, 27–31. [Google Scholar] [CrossRef]

- Clark, T.F.; Wolff, I.A. A search for new fiber crops, XI. Compositional characteristics of Illinois kenaf at several population densities and maturities. TAPPI J. 1969, 52, 211–216. [Google Scholar]

- Killinger, G.B. Kenaf (Hibiscus cannabinus L.), a multi-use crop. Agron. J. 1969, 61, 734–736. [Google Scholar] [CrossRef]

- Suriyajantratong, W.; Tucker, R.E.; Sigafus, R.E.; Mitchell, G.E. Kenaf and rice straw for sheep. J. Anim. Sci. 1973, 37, 1251–1254. [Google Scholar] [CrossRef]

- Swingle, R.S.; Urias, A.R.; Doyle, J.C.; Voigt, R.L. Chemical composition of kenaf forage and its digestibility by lambs and in vitro. J. Anim. Sci. 1978, 46, 1346–1350. [Google Scholar] [CrossRef]

- Wing, J.M. Ensilability, acceptability and digestibility of kenaf. Feedstuffs 1967, 39, 26. [Google Scholar]

- Wildeus, S.; Bhardwaj, H.L.; Rangappa, M.; Webber, C.L. Consumption of chopped kenaf by Spanish goats. In Proceedings of the Kenaf Association International Conference; International Kenaf Association: Irving, TX, USA, 1995; Volume 7, pp. 161–164. [Google Scholar]

- Webber III, C.L.; Bledsoe, V.K. Plant maturity and kenaf yield components. Ind. Crops Prod. 2002, 16, 81–88. [Google Scholar] [CrossRef]

- Bera, T.; Inglett, K.S.; Wilkie, A.C. Biofuel: Concepts and Considerations: SL475/SS688, 9/2020. EDIS 2020, 2020, SL475. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Hakeem, K.R.; Paridah, M.T.; Khalina, A.; Alothman, O.Y. Potential of bioenergy production from industrial kenaf (Hibiscus cannabinus L.) based on Malaysian perspective. Renew. Sustain. Energy Rev. 2015, 42, 446–459. [Google Scholar] [CrossRef]

- Saba, N.; Paridah, M.T.; Jawaid, M.; Abdan, K.; Ibrahim, N.A. Potential utilization of kenaf biomass in different applications. In Agricultural Biomass Based Potential Materials; Hakeem, K.R., Jawaid, M., Alothman, O.Y., Eds.; Springer: Cham, Switzerland, 2015; pp. 1–34. [Google Scholar] [CrossRef]

- Klass, D.L. Biomass for Renewable Energy, Fuels, and Chemicals; Academic Press/Elsevier: San Diego, CA, USA, 1998. [Google Scholar]

- Huber, G.W.; Iborra, S.; Corma, A. Synthesis of transportation fuels from biomass: Chemistry, catalysts, and engineering. Chem. Rev. 2006, 106, 4044–4098. [Google Scholar] [CrossRef] [PubMed]

- Meryemoğlu, B.; Hasanoğlu, A.; Irmak, S.; Erbatur, O. Biofuel production by liquefaction of kenaf (Hibiscus cannabinus L.) biomass. Bioresour. Technol. 2014, 151, 278–283. [Google Scholar] [CrossRef]

- Demirbas, A. Potential applications of renewable energy sources, biomass combustion problems in boiler power systems and combustion related environmental issues. Prog. Energy Comb. Sci. 2005, 31, 171–192. [Google Scholar] [CrossRef]

- Khiari, B.; Ghouma, I.; Ferjani, A.I.; Azzaz, A.A.; Jellali, S.; Limousy, L.; Jeguirim, M. Kenaf stems: Thermal characterization and conversion for biofuel and biochar production. Fuel 2020, 262, 116654. [Google Scholar] [CrossRef]

- Norhisham, D.A.; Saad, N.M.; Ahmad Usuldin, S.R.; Vayabari, D.A.G.; Ilham, Z.; Ibrahim, M.F.; Wan-Mohtar, W.A.A.Q.I. Bioactivities of kenaf biomass extracts: A review. Processes 2023, 11, 1178. [Google Scholar] [CrossRef]

- Sim, Y.Y.; Nyam, K.L. Hibiscus cannabinus L. (kenaf) studies: Nutritional composition, phytochemistry, pharmacology, and potential applications. Food Chem. 2021, 344, 128582. [Google Scholar] [CrossRef]

- Ezzadin, N.A.; Salih, R.F.; Sultan, D.M. A comprehensive review on kenaf seeds and leaves for medicine. J. Med. Plants Stud. 2022, 10, 26–33. [Google Scholar] [CrossRef]

- Adnan, M.; Oh, K.K.; Azad, M.O.K.; Shin, M.H.; Wang, M.H.; Cho, D.H. Kenaf (Hibiscus cannabinus L.) leaves and seed as a potential source of the bioactive compounds: Effects of various extraction solvents on biological properties. Life 2020, 10, 223. [Google Scholar] [CrossRef] [PubMed]

- Yazan, L.S.; Foo, J.B.; Abd Ghafar, S.A.; Chan, K.W.; Tahir, P.M.; Ismail, M. Effect of kenaf seed oil from different ways of extraction towards ovarian cancer cells. Food Bioprod. Process. 2011, 89, 328–332. [Google Scholar] [CrossRef]

- Mohamed, A.; Bhardwaj, H.; Hamama, A.; Webber, C., III. Chemical composition of kenaf (Hibiscus cannabinus L.) seed oil. Ind. Crops Prod. 1995, 4, 157–165. [Google Scholar] [CrossRef]

- Cheng, W.Y.; Akanda, J.M.H.; Nyam, K.L. Kenaf seed oil: A potential new source of edible oil. Trends Food Sci. Tech. 2016, 52, 57–65. [Google Scholar] [CrossRef]

- Chew, S.C.; Nyam, K.L. Kenaf (Hibiscus cannabinus L.) seed oil. In Fruit Oils: Chemistry and Functionality; Ramadan, M., Ed.; Springer: Cham, Switzerland, 2019; pp. 451–494. [Google Scholar] [CrossRef]

- Chew, S.C.; Tan, C.P.; Long, K.; Nyam, K.L. Effect of chemical refining on the quality of kenaf (Hibiscus cannabinus) seed oil. Ind. Crops Prod. 2016, 89, 59–65. [Google Scholar] [CrossRef]

- Razon, L.F.; Bacani, F.T.; Evangelista, R.L.; Knothe, G. Fatty acid profile of kenaf seed oil. J. Am. Oil Chem. Soc. 2013, 90, 835–840. [Google Scholar] [CrossRef]

- Lewy, M. Kenaf seed oil. J. Am. Oil Chem. Soc. 1947, 24, 3–5. [Google Scholar] [CrossRef]

- Ng, S.K.; Jessie, L.Y.L.; Tan, C.P.; Long, K.; Nyam, K.L. Effect of accelerated storage on microencapsulated kenaf seed oil. J. Am. Oil Chem. Soc. 2013, 90, 1023–1029. [Google Scholar] [CrossRef]

- Chu, C.C.; Nyam, K.L. Kenaf (Hibiscus cannabinus L.) seed oil: Application as cosmetic product ingredients. Ind. Crops Prod. 2020, 156, 112871. [Google Scholar] [CrossRef]

- Giwa Ibrahim, S.A.; Karim, R.; Saari, N.; Wan Abdullah, W.Z.; Zawawi, N.; Ab Razak, A.F.; Hamim, N.A.; Umar, R.A. Kenaf (Hibiscus cannabinus L.) seed and its potential food applications: A review. J. Food Sci. 2019, 84, 2015–2023. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.A.; Eiteman, M.A. Ground kenaf core as a filtration aid. Ind. Crops Prod. 2001, 13, 155–161. [Google Scholar] [CrossRef]

- Rathana, Y.; Roces, S.A.; Bacani, F.T.; Tan, R.R.; Kubouchi, M.; Yimsiri, P. Microwave-enhanced alkali catalyzed transesterification of kenaf seed oil. Int. J. Chem. React. Eng. 2010, 8, S5. [Google Scholar] [CrossRef]

- Szulczyk, K.R.; Badeeb, R.A. Nontraditional sources for biodiesel production in Malaysia: The economic evaluation of hemp, jatropha, and kenaf biodiesel. Renew. Energy 2022, 192, 759–768. [Google Scholar] [CrossRef]

- Lips, S.J.J.; de Heredia, G.M.I.; Op den Kamp, R.G.M.; van Dam, J.E.G. Water absorption characteristics of kenaf core to use as animal bedding material. Ind. Crops Prod. 2009, 29, 73–79. [Google Scholar] [CrossRef]

- Hasfalina, C.M.; Maryam, R.Z.; Luqman, C.A.; Rashid, M. The potential use of kenaf as a bioadsorbent for the removal of copper and nickel from single and binary aqueous solution. J. Nat. Fibers 2010, 7, 267–275. [Google Scholar] [CrossRef]

- Frederick, W.J., Jr.; Lien, S.J.; Courchene, C.E.; DeMartini, N.A.; Ragauskas, A.J.; Iisa, K. Co-production of ethanol and cellulose fiber from southern pine: A technical and economic assessment. Biomass Bioenergy 2008, 32, 1293–1302. [Google Scholar] [CrossRef]

- Stanturf, J.A.; Kellison, R.C.; Broerman, F.S.; Jones, S.B. Productivity of southern pine plantations: Where are we and how did we get here? J. Forest. 2003, 101, 26–31. [Google Scholar] [CrossRef]

- Finnan, J.; Styles, D. Hemp: A more sustainable annual energy crop for climate and energy policy. Energy Policy 2014, 58, 152–162. [Google Scholar] [CrossRef]

- Islam, M.M. Varietal advances of jute, kenaf and mesta crops in Bangladesh: A review. Int. J. Bioorg. Chem. 2019, 4, 24–41. [Google Scholar] [CrossRef]

- Van der Werf, H.M.G.; van der Veen, J.E.H.; Bouma, A.T.M.; ten Cate, M. Quality of hemp (Cannabis sativa L.) stems as a raw material for paper. Ind. Crops Prod. 1994, 2, 219–227. [Google Scholar] [CrossRef]

- Dhali, K.; Daver, F.; Cass, P.; Adhikari, B. Isolation and characterization of cellulose nanomaterials from jute bast fibers. J. Environ. Chem. Eng. 2021, 9, 106447. [Google Scholar] [CrossRef]

- Jahan, M.S.; Kanna, G.H.; Mun, S.P.; Chowdhury, D.A.N. Variations in chemical characteristics and pulpability within jute plant (Chorcorus capsularis). Ind. Crops Prod. 2008, 28, 199–205. [Google Scholar] [CrossRef]

- Basri, M.H.A.; Abdu, A.; Junejo, N.; Hamid, H.A.; Ahmed, K. Journey of kenaf in Malaysia: A review. Sci. Res. Essays 2014, 9, 458–470. [Google Scholar] [CrossRef]

| 2017/18 | 2018/19 | 2019/20 | 2020/21 | 2021/22 | |

|---|---|---|---|---|---|

| Developing countries | 202.6 | 198.6 | 204.6 | 200.3 | 195.7 |

| Far East | 155.3 | 151.3 | 157.7 | 150.2 | 146.7 |

| China | 50.0 | 45.97 | 52.37 | 45.03 | 41.43 |

| India | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 |

| Indonesia | 3.3 | 3.3 | 3.4 | 3.3 | 3.3 |

| Thailand | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 |

| Vietnam | 0.5 | 0.5 | 0.5 | 0.3 | 0.4 |

| Cambodia | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 |

| Pakistan | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Latin America and the Caribbean | 26.0 | 26.1 | 25.6 | 28.5 | 27.3 |

| Brazil | 2.8 | 2.9 | 2.6 | 5.5 | 4.4 |

| Cuba | 11.9 | 12.0 | 11.8 | 11.8 | 11.8 |

| Other | 11.3 | 11.2 | 11.2 | 11.2 | 11.1 |

| Africa | 15.5 | 15.4 | 15.5 | 15.6 | 15.7 |

| Near East | 5.7 | 5.7 | 5.8 | 6.0 | 6.0 |

| Developed countries | 6.8 | 6.8 | 6.9 | 6.8 | 6.8 |

| World | 209.4 | 205.4 | 211.5 | 207.1 | 202.5 |

| Crop | Dry-Stalk Yield (mt.ha−1.yr−1) | Cellulose (%) | Hemicellulose (%) | Lignin (%) | ||||

|---|---|---|---|---|---|---|---|---|

| Kenaf | 11–18 | [3] | 45–57 | [2] | 21.5 | [2] | 8–13 | [2] |

| Kenaf bast | 69.2 | [2] | 27.2 | [2] | 2.8 | [2] | ||

| Kenaf core | 32.1 | [2] | 41 | [2] | 25.2 | [2] | ||

| Hemp | 11–17 | [70] | 70–74 | [2] | 17.9–22.4 | [2] | 3.5–5.7 | [2] |

| Hemp bast | 64.8 | [72] | 7.7 | [72] | 4.3 | [72] | ||

| Hemp core | 34.5 | [72] | 17.8 | [72] | 20.8 | [72] | ||

| Jute | 4.3–7.6 | [71] | 61–71.5 | [2] | 13.6–20.4 | [2] | 12–13 | [2] |

| Jute bast | 62.1 | [73] | 21.8 | [73] | 14 | [73] | ||

| Jute core | 34–39.8 | [74] | 31.1–37.2 | [74] | 24–26 | [74] | ||

| Southern Pine | 17.9 | [69] | 43.6 | [68] | 21.2 | [68] | 26.8 | [68] |

| Plant Part | Application | Rationale | Reference |

|---|---|---|---|

| Whole Stalk | Paper Pulp | The whole stalk may be pulped, resulting in newsprint-quality paper. | Webber and Bledsoe [5] |

| Biomass Energy | Kenaf biomass can be used as a bioenergy feedstock for biofuel and biogas production, and as solid fuel for combustion, gasification, and pyrolysis. | Saba et al. [42] | |

| Biochar | Kenaf biochar can be used as a solid fuel, as a soil amendment, or for activated carbon production. | Khiari et al. [48] | |

| Bast | Paper Pulp | Pulping the bast alone creates a higher quality paper than pulping the stalk as a whole. | Webber and Bledsoe [5] Kaldor et al. [16] |

| Biocomposites | Quality biocomposites can be generated using kenaf bast fibers, which offer increased durability and toughness, a high aspect ratio, and ecologic and economic benefits compared to their synthetic counterparts. | Akil et al. [2] Nishino et al. [19] Wambua et al. [20] Rowell et al. [21] | |

| Textiles And Cordage | One of the oldest uses of the crop, the bast of kenaf can be used to produce textiles and cordage. | Webber et al. [3] Dempsey [6] Alexopoulou et al. [7] Li [8] | |

| Core | Potting Media | Ground kenaf core may be effectively utilized as an environmentally and economically sustainable alternative to frequently used potting media components such as peat, depending on the fineness of its grind, its percentage in the growing media, and the growth requirements of a specific crop. | Wang [29] Reichert and Baldwin [31] Webber at al. [32] |

| Oil Absorbent | The kenaf plant’s core possesses exceptional absorbency and offers an ecologically friendly alternative to synthetic fibers as an oil absorbent. | Webber and Bledsoe [5] Shamsudin et al. [22] Goforth [27] | |

| Filtration Aid | Kenaf has been shown to be an effective replacement for diatomaceous earth in pool and spa filters. | Lee and Eiteman [63] | |

| Animal Bedding | Kenaf core particles were shown to have water retention levels and absorption capacity similar to other commercial bedding materials. | Lips et al. [66] | |

| Foliage | Livestock Feed | Kenaf plants, particularly their leaves, exhibit high protein levels, ensilage effectively, and have been shown to be a suitable forage for a variety of livestock. | Webber et al. [3] Alexopoulou et al. [7] Suriyajantratong et al. [36] Wing [38], Wildeus et al. [39] Webber and Bledsoe [40] |

| Seeds | Edible Oil | Due to their high oil content and unique fatty acid composition, the seeds of the kenaf plant may be used as a viable source of oil for human consumption or the production of cosmetics. | Webber and Bledsoe [5] Mohamed et al. [54] Cheng et al. [55] Chew and Nyam [56] Chu and Nyam [61] |

| Medicine | Kenaf seed oil has been found to possess anti-oxidant, anti-cancer, anti-ulcer, anti-inflammatory, anti-thrombotic, anti-tyrosinase, anti-hyperlipidemia, and hepatoprotective properties. | Norhisham et al. [49] Sim and Nyam [50] Ezzadin et al. [51] Adnan et al. [52] Yazan et al. [53] | |

| Biodiesel | Kenaf seed oil is a potential feedstock for biodiesel production through transesterification. | Rathana et al. [64] Szulczyk and Badeeb [65] | |

| Livestock Feed | After oil extraction, the concentrated seed cake can be used as livestock feed. | Szulczyk and Badeeb [65] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Austin, C.C.; Mondell, C.N.; Clark, D.G.; Wilkie, A.C. Kenaf: Opportunities for an Ancient Fiber Crop. Agronomy 2024, 14, 1542. https://doi.org/10.3390/agronomy14071542

Austin CC, Mondell CN, Clark DG, Wilkie AC. Kenaf: Opportunities for an Ancient Fiber Crop. Agronomy. 2024; 14(7):1542. https://doi.org/10.3390/agronomy14071542

Chicago/Turabian StyleAustin, Conner C., Colleen N. Mondell, David G. Clark, and Ann C. Wilkie. 2024. "Kenaf: Opportunities for an Ancient Fiber Crop" Agronomy 14, no. 7: 1542. https://doi.org/10.3390/agronomy14071542

APA StyleAustin, C. C., Mondell, C. N., Clark, D. G., & Wilkie, A. C. (2024). Kenaf: Opportunities for an Ancient Fiber Crop. Agronomy, 14(7), 1542. https://doi.org/10.3390/agronomy14071542