Nitrogen and Potassium Application Effects on Grain-Filling and Rice Quality in Different Japonica Rice Cultivars

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Site Descriptions

2.2. Experimental Design and Crop Management

2.3. Data Collection

2.3.1. Sampling and Grain-Filling Parameters

2.3.2. Photosynthetic Gas Exchange Measurements and Related Enzyme Activities

2.3.3. Determination of Rice-Related Quality Indexes

2.3.4. Statistical Analysis

3. Results

3.1. Grain-Filling Characteristics

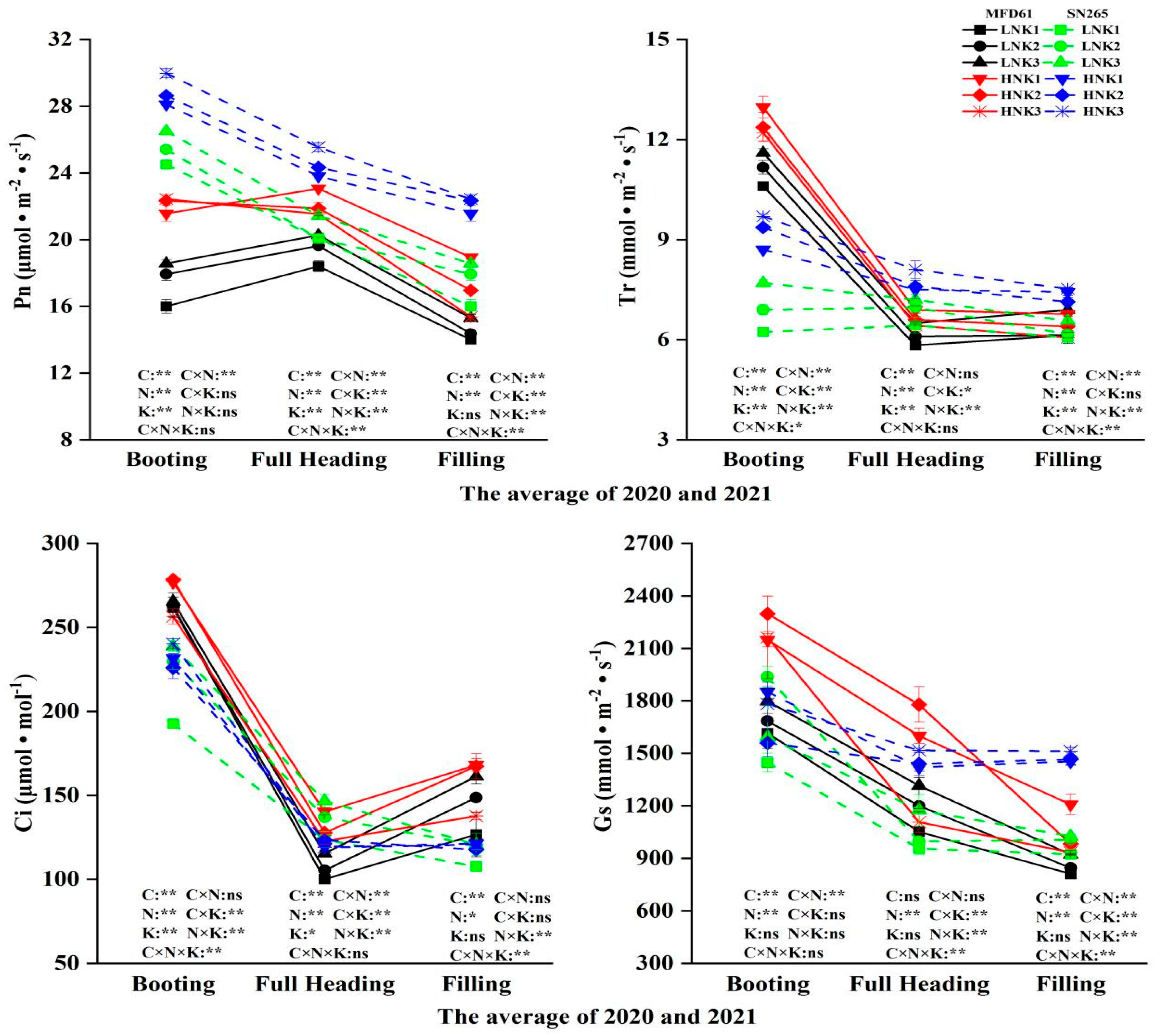

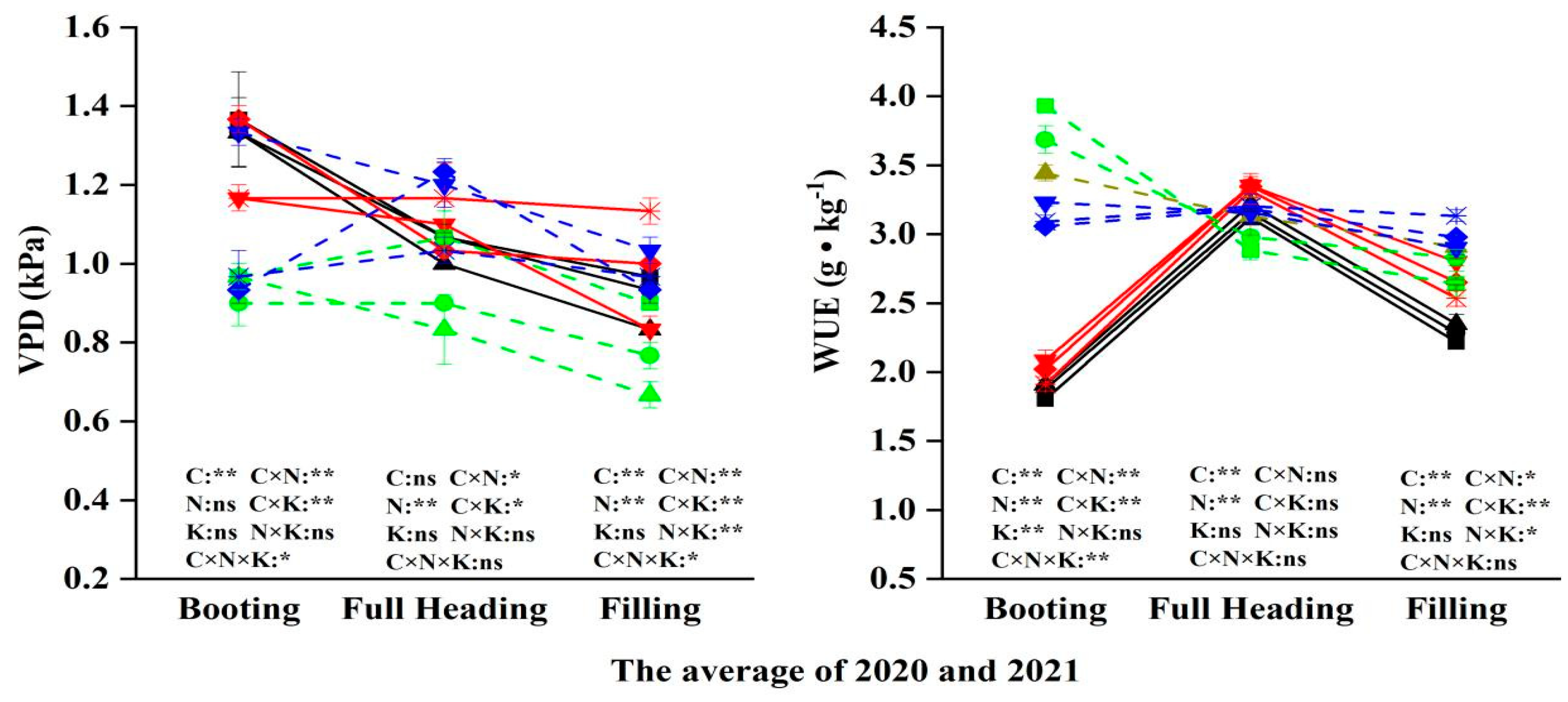

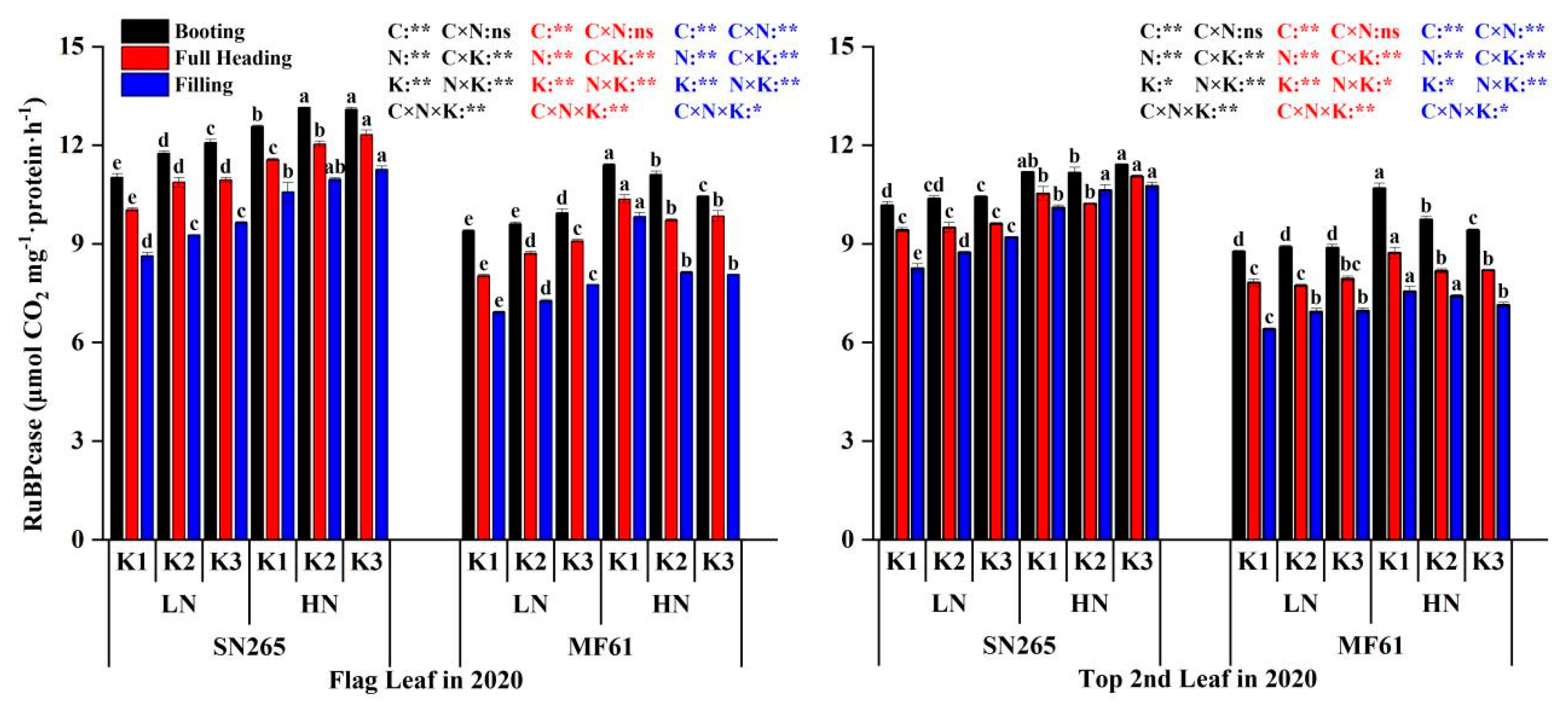

3.2. N- and K-Rationing Effects on Photosynthetic Characteristics and RuBPcase Activity of Different Cultivars

3.3. N- and K-Rationing Effects on the Processing Quality of Different Cultivars

3.4. N- and K-Application Effects on Cultivar Appearance and Nutritional Quality

3.5. N- and K-Rationing Effects on Different Cultivar Protein Components

3.6. N- and K-Rationing Effects on the Eigenvalues of Starch RVA Spectra of Different Cultivars

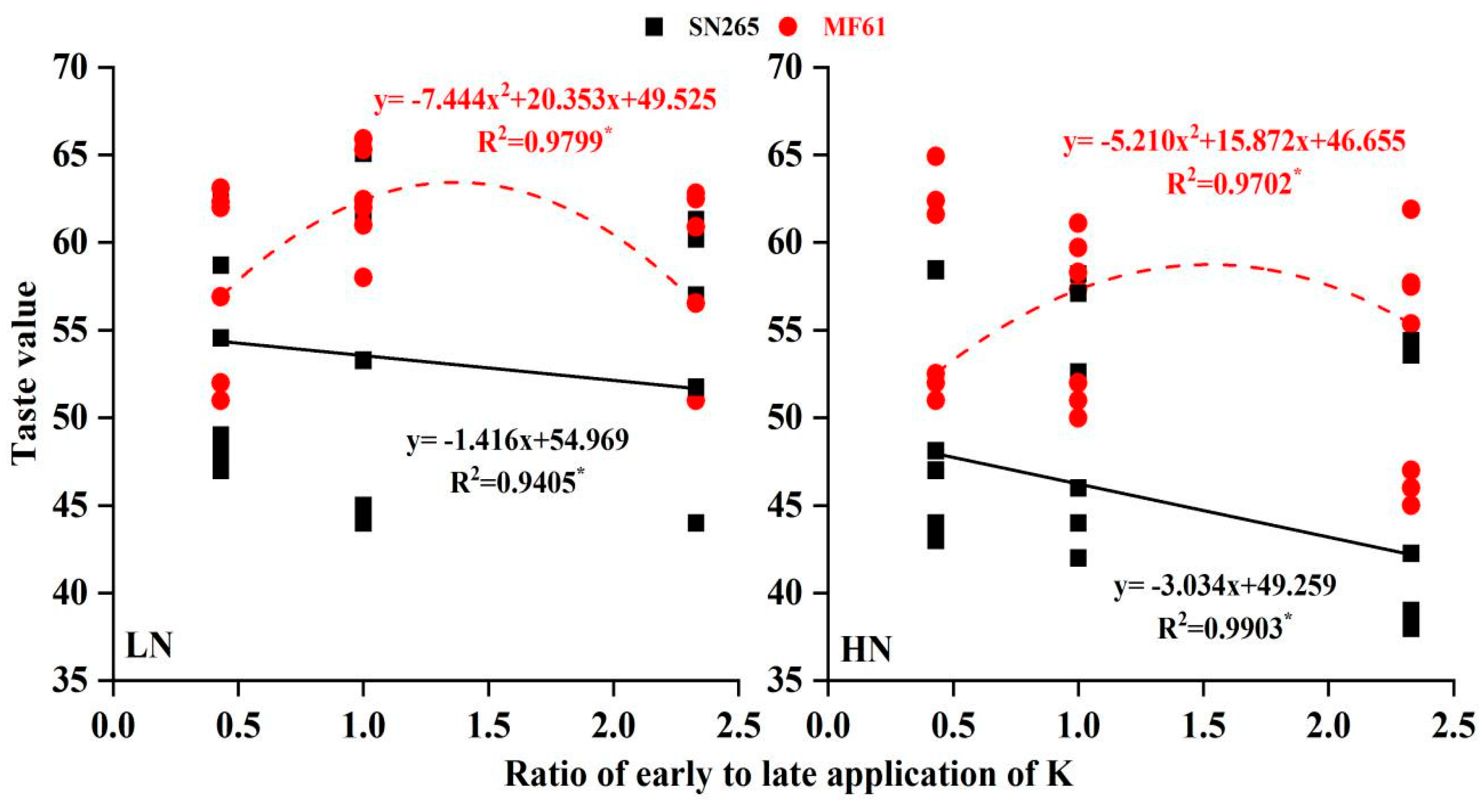

3.7. N- and K-Allocation Relationships and Taste Value of Different Cultivars

4. Discussion

4.1. N- and K-Application Effects on Photosynthetic Characteristics and Grain-Filling Rates of Different Cultivars

4.2. N- and K-Application Effects on the Quality of Different Cultivars

4.3. N- and K-Allocation Relationship on Grain-Filling Rates and Quality of Different Cultivars

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zeng, Y.; Tan, X.; Zeng, Y.; Zheng, Y.; Xie, X.; Pan, X.; Shi, Q.; Zhang, J. Changes in the rice grain quality of different high-quality rice varieties released in southern China from 2007 to 2017. J. Cereal Sci. 2019, 87, 111–116. [Google Scholar] [CrossRef]

- Jia, Y.; Liu, H.; Mei, Y.; Wang, H.; Zou, D.; Wang, J.; Zheng, H.; Wang, J.; Zhang, H.; Zhao, H. Analysis of Gaps Yield and Resource use Efficiency of Cold-Region Japonica Rice. Int. J. Plant Prod. 2022, 17, 17–33. [Google Scholar] [CrossRef]

- Wood, M.; Dunn, B.; Balindong, J.; Waters, D.; Blanchard, J.; Mawson, A.; Oli, P. Effect of agronomic management on rice grain quality Part II: Nitrogen rate and timing. Cereal Chem. 2021, 98, 234–248. [Google Scholar] [CrossRef]

- Zhou, C.; Huang, Y.; Jia, B.; Wang, Y.; Wang, Y.; Xu, Q.; Li, R.; Wang, S.; Dou, F. Effects of cultivar, nitrogen rate, and planting density on rice-grain quality. Agronomy 2018, 8, 246. [Google Scholar] [CrossRef]

- Atapattu, A.; Prasantha, R.; Amaratunga, K.; Marambe, B. Increased rate of potassium fertilizer at the time of heading enhances the quality of direct seeded rice. Chem. Biol. Technol. Agric. 2018, 5, 22. [Google Scholar] [CrossRef]

- Xue, J.; Chen, S.; Du, X.; Pan, G.; Wang, Y. Grain-filling Characteristics of Two Different panicle Type Rice Cultivars in Heilongjiang Province. Agric. Sci. Technol. 2016, 17, 301–308. [Google Scholar] [CrossRef]

- Chen, Y.; Teng, Z.; Yuan, Y.; Yi, Z.; Zheng, Q.; Yu, H.; LV, J.; Wang, Y.; Duan, M.; Zhang, J.; et al. Excessive nitrogen in field-grown rice suppresses grain filling of inferior spikelets by reducing the accumulation of cytokinin and auxin. Field Crops Res. 2022, 283, 108542. [Google Scholar] [CrossRef]

- Zhao, C.; Liu, G.; Chen, Y.; Jiang, Y.; Shi, Y.; Zhao, L.; Liao, P.; Wang, W.; Xu, K.; Dai, Q.; et al. Excessive nitrogen application leads to lower rice yield and grain quality by inhibiting the grain filling of inferior grains. Agriculture 2022, 12, 962. [Google Scholar] [CrossRef]

- Liu, Z.; Gao, J.; Gao, F.; Dong, S.; Liu, P.; Zhao, B.; Zhang, J. Integrated agronomic practices management improve yield and nitrogen balance in double cropping of winter wheat-summer maize. Field Crops Res. 2018, 221, 196–206. [Google Scholar] [CrossRef]

- Yu, N.; Ren, B.; Zhao, B.; Liu, P.; Zhang, J. Effects of nitrogen application rate on grain filling characteristics and nutritional quality of summer maize. J. Appl. Ecol. 2019, 30, 3771–3776. [Google Scholar] [CrossRef]

- Zheng, E.; Zhang, C.; Qi, Z.; Zhang, Z. The effects of different water and nitrogen methods on fluorescence characteristic and growth of rice in black soil region on songnen plain, northeast China. Agric. Res. 2021, 10, 665–674. [Google Scholar] [CrossRef]

- Sun, Y.; Wu, Y.; Sun, Y.; Luo, Y.; Guo, C.; Li, B.; Li, F.; Xing, M.; Yang, Z.; Ma, J. Effects of Water and Nitrogen on Grain Filling Characteristics, Canopy Microclimate with Chalkiness of Directly Seeded Rice. Agriculture 2022, 12, 122. [Google Scholar] [CrossRef]

- Richards, F. A flexible growth function for empirical use. J. Exp. Bot. 1959, 10, 290–301. [Google Scholar] [CrossRef]

- Zhu, Q.; Cao, X.; Luo, Y. Growth analysis on the process of grain filling in rice. Acta Agron. Sin. 1988, 14, 182–193. [Google Scholar]

- Perdomo J, A.; Capó-Bauçà, S.; Carmo-Silva, E.; Galmés, J. Rubisco and rubisco activase play an important role in the biochemical limitations of photosynthesis in rice, wheat, and maize under high temperature and water deficit. Front. Plant Sci. 2017, 8, 490. [Google Scholar] [CrossRef]

- Pandey, V.; Shukla, A. Acclimation and tolerance strategies of rice under drought stress. Rice Sci. 2015, 22, 147–161. [Google Scholar] [CrossRef]

- Li, X.; Li, Z.; Xie, Y.; Wang, B.; Kuai, J.; Zhou, G. An improvement in oilseed rape Brassica napus L. productivity through optimization of rice-straw quantity and plant density. Field Crops Res. 2021, 273, 108290. [Google Scholar] [CrossRef]

- Nelson, D.; Sommers, L. Total nitrogen analysis of soil and plant tissues. J. Assoc. Off. Anal. Chem. 1980, 63, 770–778. [Google Scholar] [CrossRef]

- Fan, M.; Wang, X.; Sun, J.; Zhang, Q.; Xu, Z.; Xu, Q. Effect of indica pedigree on eating and cooking quality in rice backcross inbred lines of indica and japonica crosses. Breed. Sci. 2017, 67, 450–458. [Google Scholar] [CrossRef]

- Luthe, D. Storage protein accumulation in developing rice Oryza sativa L. seeds. Plant Sci. Lett. 1983, 32, 147–158. [Google Scholar] [CrossRef]

- Liu, Z.; Cheng, F.; Cheng, W.; Zhang, G. Positional variations in phytic acid and protein content within a panicle of japonica rice. J. Cereal Sci. 2005, 41, 297–303. [Google Scholar] [CrossRef]

- Champagne, E.; Bett, K.; Vinyard, B.; McClung, A.; Barton, F.; Moldenhauer, K.; Linscombe, S.; Mckenzie, K. Correlation between cooked rice texture and rapid visco analyser measurements. Cereal Chem. 1999, 76, 764–771. [Google Scholar] [CrossRef]

- Cao, X.; Sun, H.; Wang, C.; Wang, C.; Ren, X.; Liu, H.; Zhang, Z. Effects of late-stage nitrogen fertilizer application on the starch structure and cooking quality of rice. J. Sci. Food Agric. 2018, 98, 2332–2340. [Google Scholar] [CrossRef] [PubMed]

- Kato, T.; Takeda, K. Associations among characters related to yield sink capacity in space-planted rice. Crop Sci. 1996, 36, 1135–1139. [Google Scholar] [CrossRef]

- Ren, H.; Zhao, M.; Zhou, B.; Zhou, W.; Li, K.; Qi, H.; Jiang, Y.; Li, C. Understanding physiological mechanisms of variation in grain filling of maize under high planting density and varying nitrogen applicate rate. Front. Nutr. 2022, 9, 998946. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Zhang, Y.; Song, N.; Chen, Q.; Sun, H.; Peng, T.; Huang, S.; Zhao, Q. Response of grain-filling rate and grain quality of mid-season indica rice to nitrogen application. J. Integr. Agric. 2021, 6, 1465–1473. [Google Scholar] [CrossRef]

- Gong, Y.; Lei, Y.; Zhang, X.; Yan, B.; Ju, X.; Cheng, X. Nitrogen rate and plant density interaction enhances grain yield by regulating the grain distribution of secondary branches on the panicle axis and photosynthesis in japonica rice. Photosynthetica 2022, 60, 179–189. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, J. Grain-filling problem in ‘super’ rice. J. Exp. Bot. 2010, 61, 1–5. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, X.; Wu, L.; Wang, R.; Xiao, S. QTL mapping for grain filling rate and thousand-grain weight in different ecological environments in wheat. Acta Agron. Sin. 2008, 34, 1750–1756. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, Y.; He, P.; Huang, X.; Huang, K. Effect of different tillage methods on senescence and grain filling characteristics of tartary buckwheat. Zemdirb.-Agric. 2020, 4, 301–308. [Google Scholar] [CrossRef]

- Jiang, Q.; Du, Y.; Tian, X.; Wang, Q.; Xiong, R.; Xu, G.; Yan, C.; Ding, Y. Effect of panicle nitrogen on grain filling characteristics of high-yielding rice cultivars. Eur. J. Agron. 2016, 74, 185–192. [Google Scholar] [CrossRef]

- Liu, X.; Li, M.; Guo, P.; Zhang, Z. Optimization of water and fertilizer coupling system based on rice grain quality. Agric. Water Manag. 2019, 221, 34–46. [Google Scholar] [CrossRef]

- Bian, J.; Xu, F.; Han, C.; Qiu, S.; Ge, J.; Xu, J.; Zhang, H.; Wei, H. Effects of planting methods on yield and quality of different types of japonica rice in northern Jiangsu plain, China. J. Integr. Agric. 2018, 17, 2624–2635. [Google Scholar] [CrossRef]

- Yang, D.; Peng, S.; Zheng, C.; Xiang, H.; Huang, J.; Cui, K.; Wang, F. Effects of nitrogen fertilization for bud initiation and tiller growth on yield and quality of rice ratoon crop in central China. Field Crops Res. 2021, 272, 108286. [Google Scholar] [CrossRef]

- Xiong, F.; Wang, Z.; Gu, Y.; Chen, G.; Zhou, P. Effects of nitrogen application time on caryopsis development and grain quality of rice variety Yangdao 6. Rice Sci. 2008, 15, 57–62. [Google Scholar] [CrossRef]

- Zhang, J.; Tong, T.; Potcho, P.; Huang, S.; Ma, L.; Tang, X. Nitrogen effects on yield, quality and physiological characteristics of giant rice. Agronomy 2020, 10, 1816. [Google Scholar] [CrossRef]

- Hu, Y.; Cong, S.; Zhang, H. Comparison of the grain quality and starch physicochemical properties between japonica rice cultivars with different contents of amylose, as affected by nitrogen fertilization. Agriculture 2021, 11, 616. [Google Scholar] [CrossRef]

- Shi, S.; Zhang, G.; Chen, L.; Zhang, W.; Wang, X.; Pan, K.; Li, L.; Wang, J.; Liu, J.; Cao, C.; et al. Different nitrogen fertilizer application in the field affects the morphology and structure of protein and starch in rice during cooking. Food Res. Int. 2023, 163, 112193. [Google Scholar] [CrossRef] [PubMed]

- Lan, Y.; Sui, X.; Wang, J.; Duan, Q.; Wu, C.; Ding, C.; Li, T. Effects of nitrogen application rate on protein components and yield of low-gluten rice. Agriculture 2021, 11, 302. [Google Scholar] [CrossRef]

- Deng, N.; Ling, X.; Sun, Y.; Zhang, C.; Fahad, S.; Peng, S.; Cui, K.; Nie, L.; Huang, J. Influence of temperature and solar radiation on grain yield and quality in irrigated rice system. Eur. J. Agron. 2015, 64, 37–46. [Google Scholar] [CrossRef]

- Balindong, J.; Ward, R.; Liu, L.; Rose, T.; Pallas, L.; Ovenden, B.; Peter, J.; Snell, B.; Daniel, L. Rice grain protein composition influences instrumental measures of rice cooking and eating quality. J. Cereal Sci. 2018, 79, 35–42. [Google Scholar] [CrossRef]

- Chen, G.; Peng, L.; Li, C.; Tu, Y.; Lan, Y.; Wu, C.; Duan, Q.; Zhang, Q.; Yang, H.; Li, T. Effects of the potassium application rate on lipid synthesis and eating quality of two rice cultivars. J. Integr. Agric. 2023, 22, 2025–2040. [Google Scholar] [CrossRef]

- Huang, J.; Pan, Y.; Chen, H.; Zhang, Z.; Fang, C.; Shao, C.; Amjad, H.; Lin, W.; Lin, W. Physiochemical mechanisms involved in the improvement of grain-filling, rice quality mediated by related enzyme activities in the ratoon cultivation system. Field Crops Res. 2020, 258, 107962. [Google Scholar] [CrossRef]

- Zhou, L.; Jiang, L.; Zhai, H.; Wan, J. Current status and strategies for improvement of rice grain chalkiness. Hereditas 2009, 31, 563–572. [Google Scholar] [CrossRef] [PubMed]

| Cultivar | Treatment (N and K) | Grain Position | R0 | Tmax (d) | GRmax (mg grain−1 d−1) | Wmax (mg grain−1) | I (%) | GRmean (mg grain−1 d−1) | D (d) | T99 (d) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SN265 | LN | K1 | SG | 0.20 | 15.18 | 1.20 | 13.22 | 48.45 | 0.80 | 34.06 | 40.24 |

| K2 | 0.28 | 14.07 | 1.21 | 12.16 | 45.16 | 0.81 | 33.09 | 43.80 | |||

| K3 | 0.24 | 13.48 | 1.46 | 13.48 | 48.00 | 0.98 | 28.62 | 36.91 | |||

| K1 | IG | 0.27 | 14.21 | 1.25 | 11.74 | 46.12 | 0.84 | 30.37 | 40.68 | ||

| K2 | 0.30 | 14.02 | 1.29 | 11.39 | 45.83 | 0.87 | 28.53 | 39.07 | |||

| K3 | 0.30 | 13.99 | 1.30 | 11.37 | 45.96 | 0.87 | 28.34 | 33.51 | |||

| HN | K1 | SG | 0.07 | 34.07 | 1.21 | 18.57 | 73.91 | 0.72 | 34.71 | 40.12 | |

| K2 | 0.07 | 32.97 | 1.06 | 17.96 | 74.82 | 0.63 | 38.07 | 41.44 | |||

| K3 | 0.06 | 34.96 | 1.00 | 18.73 | 75.95 | 0.59 | 41.60 | 42.16 | |||

| K1 | IG | 0.07 | 34.96 | 1.04 | 17.70 | 75.02 | 0.62 | 38.14 | 41.52 | ||

| K2 | 0.07 | 34.03 | 1.11 | 17.61 | 74.35 | 0.66 | 35.84 | 39.71 | |||

| K3 | 0.07 | 34.12 | 1.15 | 17.76 | 73.95 | 0.69 | 34.92 | 40.52 | |||

| MF61 | LN | K1 | SG | 0.17 | 13.70 | 1.20 | 11.85 | 54.13 | 0.79 | 27.76 | 21.68 |

| K2 | 0.19 | 12.41 | 1.28 | 12.03 | 78.90 | 0.85 | 27.06 | 22.69 | |||

| K3 | 0.25 | 11.23 | 1.25 | 10.14 | 84.67 | 0.83 | 24.29 | 20.00 | |||

| K1 | IG | 0.19 | 12.70 | 1.28 | 11.62 | 83.33 | 0.85 | 25.93 | 21.93 | ||

| K2 | 0.16 | 12.66 | 1.24 | 12.37 | 84.88 | 0.81 | 27.04 | 21.77 | |||

| K3 | 0.16 | 13.74 | 1.21 | 11.71 | 81.33 | 0.79 | 26.37 | 20.61 | |||

| HN | K1 | SG | 0.08 | 30.81 | 0.98 | 13.96 | 78.93 | 0.59 | 32.15 | 18.45 | |

| K2 | 0.06 | 33.19 | 0.86 | 14.97 | 58.36 | 0.51 | 38.76 | 19.40 | |||

| K3 | 0.06 | 34.69 | 0.79 | 13.74 | 51.10 | 0.47 | 39.10 | 17.87 | |||

| K1 | IG | 0.07 | 31.50 | 0.92 | 14.49 | 46.76 | 0.56 | 35.44 | 19.75 | ||

| K2 | 0.07 | 33.53 | 0.89 | 14.92 | 55.55 | 0.53 | 37.76 | 19.90 | |||

| K3 | 0.06 | 35.58 | 0.82 | 15.52 | 53.41 | 0.48 | 42.24 | 19.88 | |||

| Cultivar | Treatment (N and K) | Grain Position | Early Stage | Middle Stage | Late Stage | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Days (d) | MGR (mg grain−1 d−1) | RGC (%) | Days (d) | MGR (mg grain−1 d−1) | RGC (%) | Days (d) | MGR (mg grain−1 d−1) | RGC (%) | ||||

| SN265 | LN | K1 | SG | 7.57 | 0.64 | 19.35 | 15.22 | 1.07 | 59.23 | 17.45 | 0.32 | 20.42 |

| K2 | 6.45 | 0.69 | 15.60 | 15.25 | 1.05 | 59.64 | 22.09 | 0.29 | 23.76 | |||

| K3 | 7.06 | 0.83 | 18.75 | 12.85 | 1.28 | 58.64 | 17.00 | 0.36 | 21.61 | |||

| K1 | IG | 29.59 | 0.45 | 53.19 | 8.97 | 1.16 | 43.10 | 1.56 | 0.36 | 2.71 | ||

| K2 | 28.21 | 0.45 | 54.89 | 9.51 | 0.96 | 38.83 | 3.71 | 0.34 | 5.28 | |||

| K3 | 29.98 | 0.43 | 56.36 | 9.95 | 0.94 | 39.45 | 2.23 | 0.35 | 3.19 | |||

| HN | K1 | SG | 7.27 | 0.67 | 16.60 | 13.88 | 1.08 | 59.35 | 19.52 | 0.29 | 23.06 | |

| K2 | 7.48 | 0.68 | 16.26 | 13.07 | 1.13 | 59.49 | 18.52 | 0.31 | 23.25 | |||

| K3 | 7.50 | 0.67 | 19.63 | 12.97 | 1.16 | 61.72 | 13.03 | 0.33 | 17.65 | |||

| K1 | IG | 30.24 | 0.41 | 59.89 | 9.46 | 0.99 | 35.73 | 1.82 | 0.36 | 3.38 | ||

| K2 | 29.48 | 0.43 | 52.05 | 9.11 | 1.08 | 43.35 | 1.13 | 0.38 | 3.59 | |||

| K3 | 29.62 | 0.43 | 53.60 | 9.01 | 1.10 | 42.83 | 1.89 | 0.39 | 2.57 | |||

| MF61 | LN | K1 | SG | 7.93 | 0.70 | 26.09 | 11.53 | 1.05 | 55.56 | 12.52 | 0.30 | 17.35 |

| K2 | 6.66 | 0.79 | 24.04 | 11.51 | 1.12 | 56.42 | 13.22 | 0.32 | 18.54 | |||

| K3 | 5.90 | 0.83 | 21.07 | 10.65 | 1.08 | 56.98 | 14.63 | 0.28 | 20.95 | |||

| K1 | IG | 7.21 | 0.82 | 24.90 | 10.98 | 1.07 | 53.47 | 16.11 | 0.29 | 20.63 | ||

| K2 | 7.22 | 0.78 | 28.71 | 10.87 | 1.10 | 54.20 | 11.05 | 0.32 | 16.09 | |||

| K3 | 8.44 | 0.70 | 28.81 | 10.60 | 1.07 | 54.16 | 10.70 | 0.31 | 16.03 | |||

| HN | K1 | SG | 26.74 | 0.38 | 53.71 | 8.16 | 0.93 | 40.71 | 2.02 | 0.36 | 4.58 | |

| K2 | 28.48 | 0.36 | 55.72 | 9.42 | 0.83 | 39.31 | 1.77 | 0.31 | 3.97 | |||

| K3 | 29.87 | 0.32 | 55.14 | 9.64 | 0.74 | 39.30 | 2.12 | 0.28 | 4.56 | |||

| K1 | IG | 31.49 | 0.28 | 42.15 | 9.25 | 0.70 | 32.90 | 7.28 | 0.67 | 23.95 | ||

| K2 | 30.55 | 0.36 | 53.51 | 9.74 | 0.85 | 39.40 | 4.07 | 0.38 | 6.09 | |||

| K3 | 32.40 | 0.35 | 56.67 | 10.06 | 0.77 | 38.08 | 1.95 | 0.28 | 4.25 | |||

| SN265 | MF61 | |||||||

|---|---|---|---|---|---|---|---|---|

| Year | Treatment (N and K) | Brown Rice Rate (%) | Milled Rice Rate (%) | Head Rice Rate (%) | Brown Rice Rate (%) | Milled Rice Rate (%) | Head Rice Rate (%) | |

| 2020 | LN | K1 | 78.42 ± 0.14 a | 69.74 ± 0.19 a | 59.07 ± 0.33 a | 75.07 ± 0.96 a | 68.14 ± 0.88 a | 66.38 ± 0.51 a |

| K2 | 78.44 ± 0.06 a | 69.91 ± 0.32 a | 60.04 ± 0.46 a | 75.74 ± 0.09 a | 68.62 ± 0.14 a | 66.35 ± 0.92 a | ||

| K3 | 78.59 ± 0.11 a | 70.07 ± 0.42 a | 60.09 ± 0.57 a | 74.80 ± 0.41 a | 67.87 ± 0.43 a | 65.66 ± 0.20 a | ||

| HN | K1 | 79.24 ± 0.16 b | 70.17 ± 1.01 b | 59.27 ± 0.20 c | 78.03 ± 0.26 a | 70.06 ± 0.35 a | 66.98 ± 0.41 a | |

| K2 | 79.61 ± 0.98 b | 72.51 ± 0.21 a | 60.36 ± 0.10 b | 77.03 ± 0.15 ab | 69.77 ± 0.22 a | 66.82 ± 0.58 a | ||

| K3 | 80.95 ± 0.27 a | 70.73 ± 0.20 b | 62.83 ± 0.50 a | 76.16 ± 0.06 b | 69.07 ± 0.12 a | 66.40 ± 0.07 a | ||

| 2021 | LN | K1 | 78.66 ± 0.26 a | 70.31 ± 0.39 b | 62.67 ± 0.51 b | 74.14 ± 0.65 b | 63.74 ± 0.31 b | 60.22 ± 0.38 b |

| K2 | 78.99 ± 0.19 a | 70.33 ± 0.38 b | 62.69 ± 0.92 b | 74.70 ± 0.14 b | 65.52 ± 0.44 a | 60.36 ± 0.59 b | ||

| K3 | 79.12 ± 0.01 a | 71.05 ± 0.19 a | 65.94 ± 0.20 a | 76.55 ± 0.90 a | 66.71 ± 0.13 a | 62.24 ± 0.20 a | ||

| HN | K1 | 79.71 ± 0.15 a | 71.82 ± 0.01 a | 66.14 ± 0.41 b | 77.36 ± 0.44 a | 69.76 ± 0.37 a | 65.54 ± 0.22 a | |

| K2 | 79.79 ± 0.45 a | 71.99 ± 0.23 a | 67.23 ± 0.58 ab | 76.81 ± 0.54 a | 68.96 ± 0.10 a | 64.01 ± 0.56 b | ||

| K3 | 79.91 ± 0.02 a | 72.05 ± 0.10 a | 67.83 ± 0.07 a | 76.28 ± 0.43 a | 68.86 ± 0.34 a | 63.62 ± 0.11 b | ||

| FY | ns | ** | ** | ns | ** | ** | ||

| FN | ** | ** | ** | ** | ** | ** | ||

| FK | * | * | ** | ns | ns | ns | ||

| FY×N | ns | ns | ** | ns | ** | ** | ||

| FY×K | ns | * | ns | * | ** | ns | ||

| FN×K | ns | * | ns | ** | ** | * | ||

| FN×K×Y | ns | ns | ** | ns | ns | * | ||

| SN265 | MF61 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Year | Treatment (N and K) | Amylose Content (%) | Protein Contents (%) | Chalkiness Degree (%) | Chalkiness Percentage (%) | Amylose Content (%) | Protein Contents (%) | Chalkiness Degree (%) | Chalkiness Percentage (%) | |

| 2020 | LN | K1 | 19.00 ± 0.01 a | 7.47 ± 0.01 b | 6.90 ± 0.30 c | 23.03 ± 0.37 b | 18.90 ± 0.09 a | 7.40 ± 0.01 ab | 3.50 ± 0.25 c | 15.50 ± 0.36 c |

| K2 | 18.90 ± 0.06 a | 7.40 ± 0.03 c | 8.33 ± 0.19 b | 23.97 ± 0.09 ab | 18.83 ± 0.03 a | 7.30 ± 0.06 b | 5.67 ± 0.17 b | 18.70 ± 0.90 b | ||

| K3 | 19.07 ± 0.03 a | 7.60 ± 0.01 a | 9.40 ± 0.12 a | 24.70 ± 0.09 a | 18.90 ± 0.03 a | 7.47 ± 0.03 a | 6.77 ± 0.18 a | 21.30 ± 0.21 a | ||

| HN | K1 | 18.87 ± 0.06 a | 7.73 ± 0.01 b | 11.17 ± 0.03 c | 30.57 ± 0.46 c | 18.83 ± 0.03 a | 7.87 ± 0.03 a | 8.00 ± 0.07 a | 25.63 ± 0.48 a | |

| K2 | 18.83 ± 0.03 a | 7.70 ± 0.03 b | 12.27 ± 0.28 b | 32.67 ± 0.33 b | 18.80 ± 0.07 a | 7.53 ± 0.03 b | 8.23 ± 0.15 a | 23.57 ± 0.87 b | ||

| K3 | 19.00 ± 0.03 a | 7.90 ± 0.01 a | 13.47 ± 0.17 a | 34.30 ± 0.56 a | 18.40 ± 0.12 b | 7.77 ± 0.03 a | 7.20 ± 0.31 b | 18.47 ± 0.33 c | ||

| 2021 | LN | K1 | 18.47 ± 0.09 b | 7.40 ± 0.01 b | 4.93 ± 0.03 c | 17.57 ± 0.15 b | 18.23 ± 0.03 a | 7.07 ± 0.06 b | 4.93 ± 0.12 c | 12.70 ± 0.12 b |

| K2 | 18.60 ± 0.09 b | 7.70 ± 0.01 a | 6.50 ± 0.12 b | 18.37 ± 0.18 a | 18.30 ± 0.12 a | 7.20 ± 0.01 ab | 6.50 ± 0.15 b | 13.77 ± 0.12 a | ||

| K3 | 18.87 ± 0.01 a | 7.73 ± 0.03 a | 8.03 ± 0.06 a | 17.43 ± 0.09 b | 18.40 ± 0.06 a | 7.37 ± 0.03 a | 8.03 ± 0.07 a | 14.60 ± 0.09 a | ||

| HN | K1 | 18.47 ± 0.03 b | 7.80 ± 0.03 b | 10.27 ± 0.04 c | 16.70 ± 0.07 c | 18.50 ± 0.03 a | 7.73 ± 0.03 a | 10.27 ± 0.08 c | 15.67 ± 0.12 a | |

| K2 | 18.50 ± 0.06 b | 8.00 ± 0.03 a | 11.14 ± 0.07 b | 17.73 ± 0.15 b | 18.30 ± 0.01 ab | 7.67 ± 0.09 a | 11.14 ± 0.03 b | 13.67 ± 0.09 b | ||

| K3 | 18.67 ± 0.03 a | 8.07 ± 0.03 a | 12.28 ± 0.20 a | 20.63 ± 0.44 a | 18.27 ± 0.06 b | 7.50 ± 0.06 a | 12.28 ± 0.03 a | 13.63 ± 0.06 b | ||

| FY | ** | ** | ** | ** | ** | ** | ** | ** | ||

| FN | ** | ** | ** | ** | ** | ns | ** | ** | ||

| FK | ** | ** | ** | ** | ns | ns | ** | ns | ||

| FY×N | * | ns | ** | ** | ns | * | ** | ** | ||

| FY×K | ** | * | ns | ns | * | ns | ** | * | ||

| FN×K | ns | ns | * | ** | ** | ** | ** | ** | ||

| FN×K×Y | ns | ns | ns | ns | ns | ns | ** | ** | ||

| SN265 | MF61 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Year | Treatment (N and K) | Albumin (%) | Globlulin (%) | Prolamin (%) | Glutelin (%) | Albumin (%) | Globlulin (%) | Prolamin (%) | Glutelin (%) | |

| 2020 | LN | K1 | 0.31 ± 0.01 a | 0.61 ± 0.04 c | 0.57 ± 0.05 b | 8.04 ± 0.16 b | 0.18 ± 0.01 a | 0.35 ± 0.05 b | 0.51 ± 0.05 c | 7.53 ± 0.47 b |

| K2 | 0.33 ± 0.01 a | 0.76 ± 0.07 b | 0.80 ± 0.08 a | 7.40 ± 0.31 ab | 0.29 ± 0.03 b | 0.50 ± 0.02 a | 0.78 ± 0.01 b | 7.49 ± 0.34 b | ||

| K3 | 0.38 ± 0.01 b | 0.82 ± 0.04 a | 0.98 ± 0.03 a | 6.39 ± 0.08 a | 0.32 ± 0.01 c | 0.63 ± 0.11 a | 1.29 ± 0.16 a | 6.18 ± 0.05 a | ||

| HN | K1 | 0.38 ± 0.01 b | 0.71 ± 0.02 c | 0.83 ± 0.31 b | 6.87 ± 0.13 c | 0.37 ± 0.02 a | 0.70 ± 0.07 a | 1.23 ± 0.12 a | 7.12 ± 0.09 a | |

| K2 | 0.45 ± 0.01 b | 0.75 ± 0.10 b | 1.10 ± 0.13 b | 5.99 ± 0.18 b | 0.37 ± 0.01 b | 0.62 ± 0.06 a | 1.20 ± 0.21 a | 7.13 ± 0.22 a | ||

| K3 | 0.49 ± 0.01 a | 1.19 ± 0.03 a | 1.97 ± 0.18 a | 5.87 ± 0.20 a | 0.28 ± 0.01 b | 0.62 ± 0.07 b | 1.13 ± 0.17 a | 7.47 ± 0.45 a | ||

| 2021 | LN | K1 | 0.25 ± 0.01 a | 0.46 ± 0.04 c | 0.59 ± 0.07 c | 6.96 ± 0.05 c | 0.13 ± 0.01 a | 0.24 ± 0.03 c | 0.67 ± 0.08 c | 6.49 ± 0.09 b |

| K2 | 0.28 ± 0.01 b | 0.60 ± 0.01 b | 0.70 ± 0.07 b | 6.51 ± 0.08 b | 0.19 ± 0.01 ab | 0.30 ± 0.01 b | 0.59 ± 0.06 b | 6.12 ± 0.04 b | ||

| K3 | 0.31 ± 0.01 b | 0.70 ± 0.02 a | 0.88 ± 0.01 a | 5.39 ± 0.13 a | 0.24 ± 0.01 b | 0.42 ± 0.02 a | 1.06 ± 0.04 a | 6.09 ± 0.01 a | ||

| HN | K1 | 0.35 ± 0.01 b | 0.61 ± 0.02 b | 0.68 ± 0.03 c | 5.78 ± 0.29 c | 0.32 ± 0.01 a | 0.63 ± 0.03 a | 1.11 ± 0.02 a | 5.99 ± 0.05 a | |

| K2 | 0.37 ± 0.01 a | 0.68 ± 0.03 b | 0.85 ± 0.02 b | 5.43 ± 0.14 b | 0.26 ± 0.02 a | 0.59 ± 0.01 b | 1.06 ± 0.02 a | 6.25 ± 0.08 a | ||

| K3 | 0.42 ± 0.01 a | 0.90 ± 0.04 a | 1.31 ± 0.07 a | 5.22 ± 0.13 a | 0.22 ± 0.02 a | 0.59 ± 0.02 c | 1.06 ± 0.03 a | 6.40 ± 0.04 a | ||

| FY | ** | ** | ** | * | ** | ** | * | ** | ||

| FN | ** | ** | ** | ** | ** | ** | ** | ns | ||

| FK | ** | ** | ** | ** | ** | ** | ** | * | ||

| FY×N | ns | ns | ** | ns | ns | ** | ns | ns | ||

| FY×K | ** | ** | ** | ns | ** | ns | ns | * | ||

| FN×K | ns | ** | ** | ns | ** | ** | ** | ** | ||

| FN×K×Y | * | ** | ns | ns | ns | ns | ns | ** | ||

| Year | Treatment (N and K) | Peak Viscosity (cP) | Hot Paste Viscosity (cP) | Cool Paste Viscosity (cP) | Breakdown Viscosity (cP) | Setback Viscosity (cP) | Peak Time (s) | Pasting Temp. (°C) | |

|---|---|---|---|---|---|---|---|---|---|

| 2020 | LN | K1 | 2371.00 ± 11.36 a | 1622.67 ± 11.78 a | 2510.33 ± 14.08 b | 748.33 ± 0.88 b | 139.33 ± 17.61 c | 6.18 ± 0.02 a | 72.72 ± 0.33 a |

| K2 | 2269.33 ± 8.09 b | 1562.67 ± 8.29 b | 2551.67 ± 24.97 ab | 706.67 ± 3.18 b | 282.33 ± 16.9 b | 6.29 ± 0.02 a | 72.40 ± 0.26 a | ||

| K3 | 2165.67 ± 7.26 c | 1352.67 ± 25.71 c | 2555.00 ± 19.86 a | 813.00 ± 9.61 a | 389.33 ± 14.45 a | 6.25 ± 0.09 a | 72.35 ± 0.04 a | ||

| HN | K1 | 2143.33 ± 2.40 a | 1500.00 ± 5.69 a | 2628.33 ± 11.79 c | 643.33 ± 3.84 b | 485.00 ± 11.02 c | 6.15 ± 0.02 a | 72.93 ± 0.02 a | |

| K2 | 2101.33 ± 2.73 b | 1373.33 ± 9.94 b | 2703.33 ± 16.60 b | 728.00 ± 8.02 a | 602.00 ± 14.18 b | 6.20 ± 0.01 a | 72.68 ± 0.03 a | ||

| K3 | 2022.33 ± 3.53 c | 1368.00 ± 43.5 b | 2838.33 ± 8.35 a | 654.33 ± 14.29 b | 816.00 ± 5.03 a | 6.22 ± 0.02 a | 72.65 ± 0.28 a | ||

| 2021 | LN | K1 | 2285.67 ± 16.13 a | 1921.67 ± 13.35 a | 2451.00 ± 4.91 c | 364.00 ± 7.54 a | 165.33 ± 11.35 b | 5.76 ± 0.12 b | 79.14 ± 0.20 a |

| K2 | 2047.67 ± 9.17 b | 1828.67 ± 16.29 b | 2565.33 ± 29.58 b | 219.00 ± 2.91 b | 517.67 ± 35.93 a | 5.98 ± 0.02 a | 78.92 ± 0.06 ab | ||

| K3 | 2050.00 ± 28.01 b | 1806.00 ± 24.58 b | 2637.67 ± 41.68 a | 244.00 ± 5.36 b | 587.67 ± 20.01 a | 5.40 ± 0.04 c | 78.57 ± 0.06 b | ||

| HN | K1 | 2148.00 ± 5.57 a | 1773.67 ± 10.84 a | 2368.67 ± 6.57 b | 374.33 ± 2.40 a | 220.67 ± 8.17 b | 5.95 ± 0.02 b | 79.33 ± 0.04 a | |

| K2 | 2075.00 ± 11.37 b | 1759.67 ± 3.38 ab | 2363.33 ± 25.62 b | 315.33 ± 5.13 a | 288.33 ± 10.48 b | 6.15 ± 0.08 a | 78.72 ± 0.21 b | ||

| K3 | 1904.00 ± 31.79 c | 1709.00 ± 12.17 b | 2544.67 ± 18.25 a | 195.00 ± 4.06 b | 640.67 ± 9.94 a | 5.98 ± 0.02 b | 78.16 ± 0.24 c | ||

| FY | ** | ** | ** | ** | ** | ** | ** | ||

| FN | ** | ** | * | * | ** | ** | ns | ||

| FK | ** | ** | ** | * | ** | ** | ns | ||

| FY×N | ** | ns | ** | ** | ** | ** | ns | ||

| FY×K | ** | ** | ns | ** | ** | ** | ** | ||

| FN×K | ** | ** | ** | ** | ** | * | ns | ||

| FN×K×Y | ** | ** | ** | ns | ** | ns | ns | ||

| Year | Treatment (N and K) | Peak Viscosity (cP) | Hot Paste Viscosity (cP) | Cool Paste Viscosity (cP) | Breakdown Viscosity (cP) | Setback Viscosity (cP) | Peak Time (s) | Pasting Temp. (°C) | |

|---|---|---|---|---|---|---|---|---|---|

| 2020 | LN | K1 | 2372.67 ± 26.77 a | 1691.00 ± 37.47 a | 2459.33 ± 35.15 b | 681.67 ± 17.4 a | 86.67 ± 4.26 c | 6.49 ± 0.02 a | 73.55 ± 0.02 a |

| K2 | 2356.67 ± 43.17 a | 1631.67 ± 11.79 b | 2568.33 ± 7.31 a | 725.00 ± 31.58 a | 211.67 ± 15.62 b | 6.51 ± 0.06 a | 73.57 ± 0.04 a | ||

| K3 | 2101.67 ± 70.05 b | 1472.00 ± 4.36 c | 2545.33 ± 18.89 a | 629.67 ± 65.79 a | 443.67 ± 56.84 a | 6.31 ± 0.02 b | 73.02 ± 0.29 a | ||

| HN | K1 | 2266.33 ± 51.91 a | 1343.00 ± 25.16 b | 2579.67 ± 19.36 a | 923.33 ± 3.84 a | 313.33 ± 42.4 b | 6.25 ± 0.02 a | 73.48 ± 0.03 a | |

| K2 | 2103.33 ± 2.40 b | 1408.33 ± 13.87 a | 2519.33 ± 13.86 b | 695.00 ± 11.62 b | 416.00 ± 11.59 a | 6.29 ± 0.02 a | 73.25 ± 0.28 a | ||

| K3 | 2127.33 ± 2.91 b | 1362.67 ± 21.06 b | 2489.33 ± 2.19 b | 764.67 ± 18.18 b | 362.00 ± 1.00 ab | 6.22 ± 0.02 a | 73.30 ± 0.30 a | ||

| 2021 | LN | K1 | 2408.67 ± 28.79 a | 1608.00 ± 12.13 a | 2498.33 ± 12.10 b | 800.67 ± 5.69 c | 89.67 ± 3.71 c | 6.34 ± 0.01 a | 76.17 ± 0.24 b |

| K2 | 2342.33 ± 19.2 b | 1347.67 ± 23.95 b | 2696.67 ± 9.64 a | 994.67 ± 11.46 a | 354.33 ± 15.17 b | 6.32 ± 0.01 ab | 76.63 ± 0.18 ab | ||

| K3 | 2276.33 ± 11.57 c | 1349.00 ± 3.48 b | 2715.67 ± 18.85 a | 927.33 ± 4.93 b | 439.33 ± 16.92 a | 6.28 ± 0.01 b | 76.93 ± 0.20 a | ||

| HN | K1 | 2149.67 ± 28.34 b | 1272.67 ± 17.48 b | 2406.67 ± 46.26 a | 877.00 ± 16.92 a | 257.00 ± 17.93 a | 6.24 ± 0.03 b | 77.78 ± 0.07 a | |

| K2 | 2285.33 ± 19.17 a | 1433.67 ± 9.87 a | 2340.67 ± 7.22 b | 851.67 ± 11.68 a | 55.33 ± 12.78 b | 6.31 ± 0.02 a | 77.33 ± 0.07 a | ||

| K3 | 2283.67 ± 13.96 a | 1391.33 ± 9.17 a | 2381.67 ± 7.02 ab | 892.33 ± 5.24 a | 98.00 ± 9.17 b | 6.33 ± 0.01 a | 76.22 ± 0.13 b | ||

| FY | ** | ** | ns | ** | ** | ** | ** | ||

| FN | ** | ** | ** | * | ns | ** | ns | ||

| FK | ** | ** | ** | ns | ** | ** | ns | ||

| FY×N | ns | ** | ** | ** | ** | ** | * | ||

| FY×K | ** | ** | ** | ** | * | ** | ns | ||

| FN×K | ** | ** | ** | ** | ** | ** | * | ||

| FN×K×Y | ** | ** | ns | ns | ** | ns | ** | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, L.; Gao, J.; Zhang, W.; Jiang, H.; Liu, Y.; Yan, B.; Wan, X. Nitrogen and Potassium Application Effects on Grain-Filling and Rice Quality in Different Japonica Rice Cultivars. Agronomy 2024, 14, 1629. https://doi.org/10.3390/agronomy14081629

Chen L, Gao J, Zhang W, Jiang H, Liu Y, Yan B, Wan X. Nitrogen and Potassium Application Effects on Grain-Filling and Rice Quality in Different Japonica Rice Cultivars. Agronomy. 2024; 14(8):1629. https://doi.org/10.3390/agronomy14081629

Chicago/Turabian StyleChen, Liqiang, Jiping Gao, Wenzhong Zhang, Hongfang Jiang, Ya Liu, Bingchun Yan, and Xue Wan. 2024. "Nitrogen and Potassium Application Effects on Grain-Filling and Rice Quality in Different Japonica Rice Cultivars" Agronomy 14, no. 8: 1629. https://doi.org/10.3390/agronomy14081629