Design and Parameter Optimization of a Combined Rotor and Lining Plate Crushing Organic Fertilizer Spreader

Abstract

1. Introduction

2. Materials and Methods

2.1. Overall Structure and Working Principle

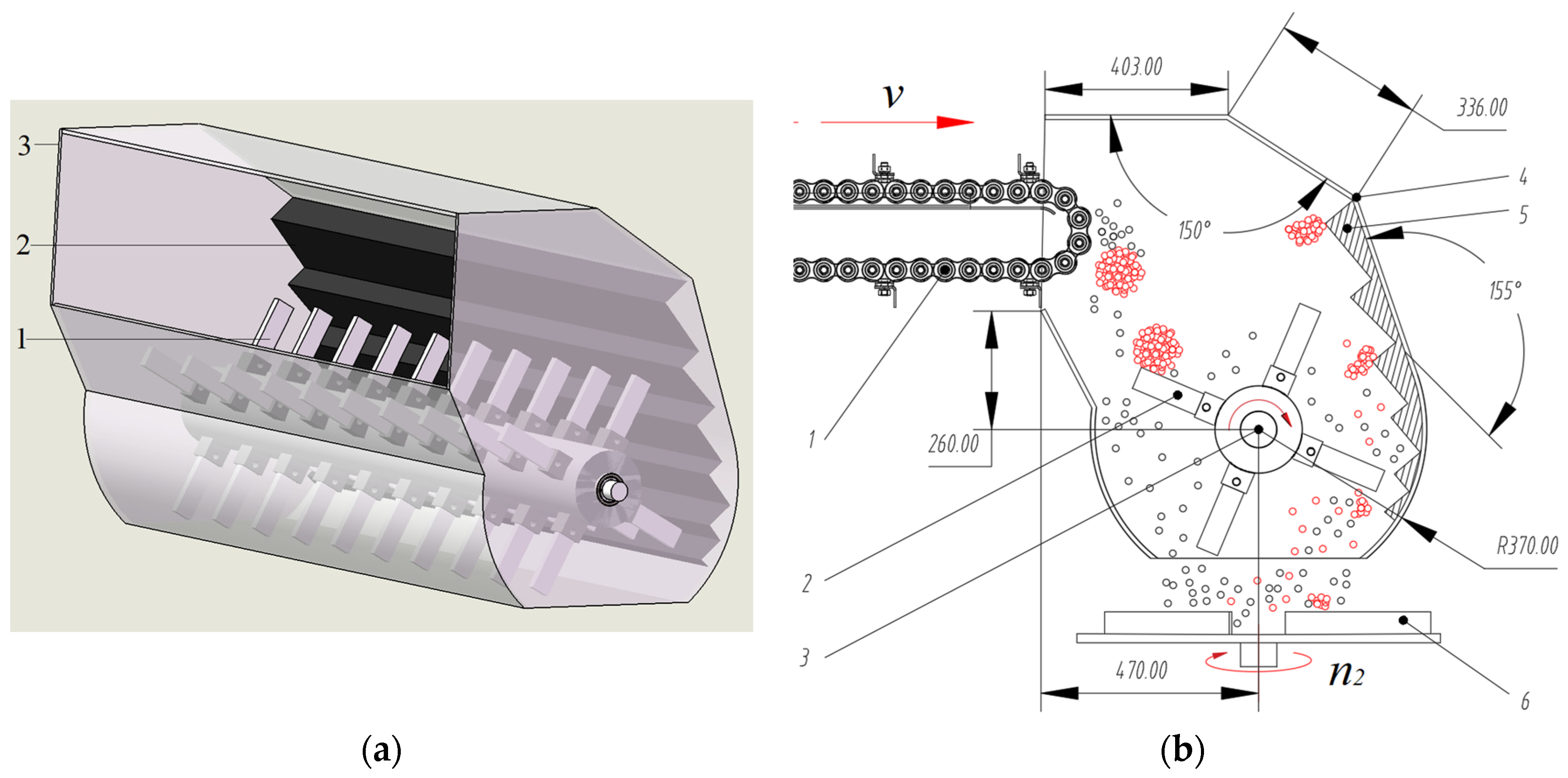

2.1.1. Overall Structure

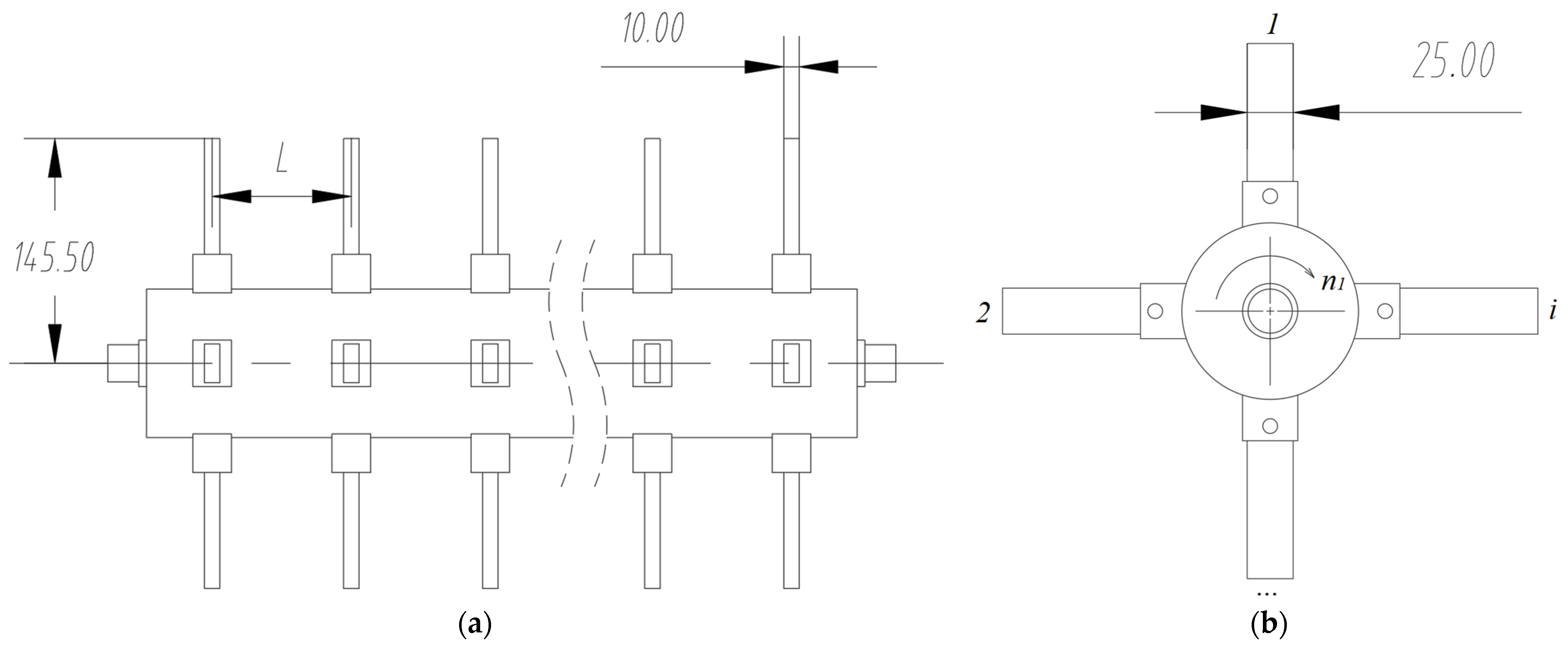

2.1.2. Structure and Working Principle of the Combined Rotor–Lining Plate Crushing Device

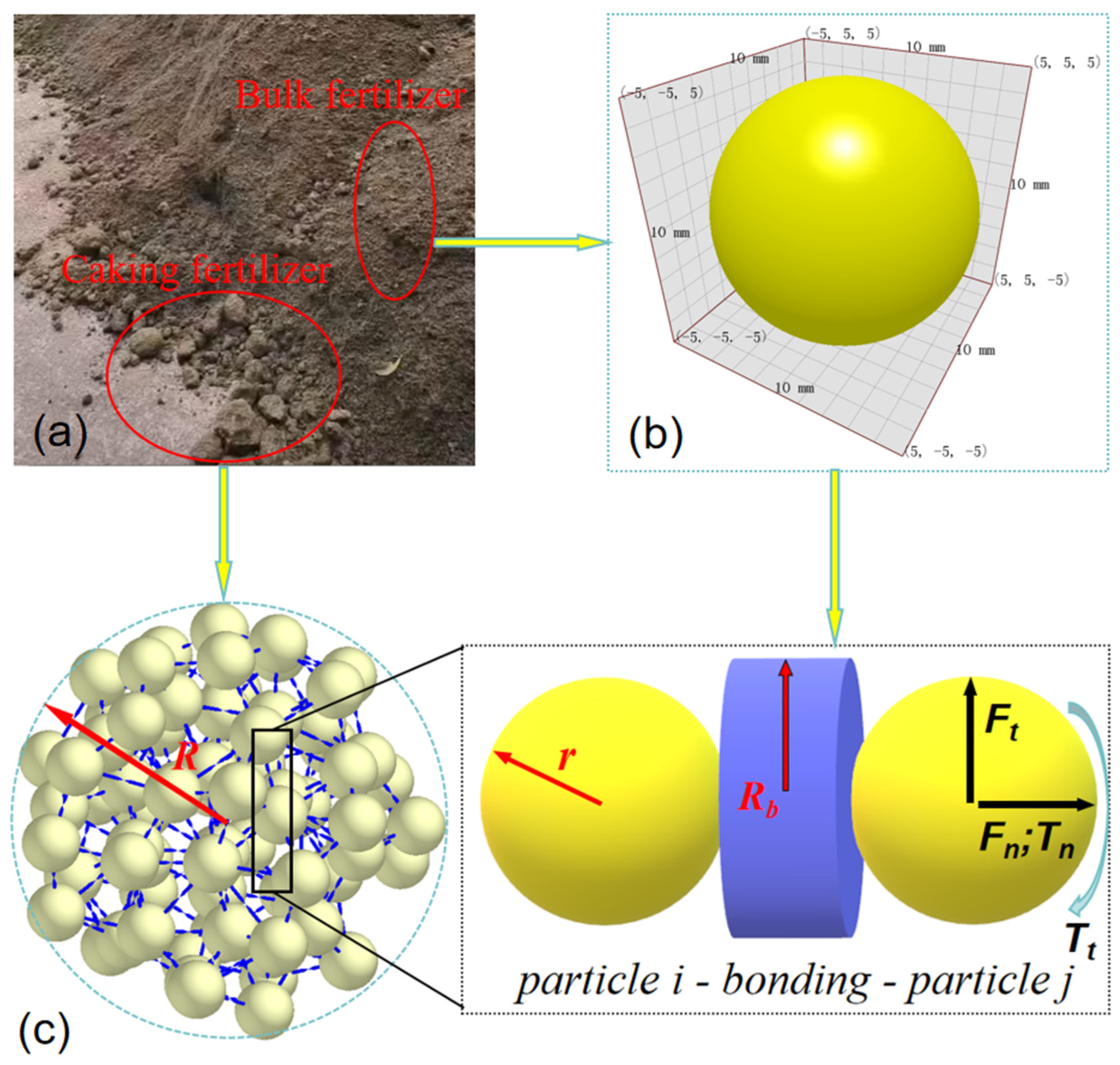

2.2. Construction of Discrete Element Model

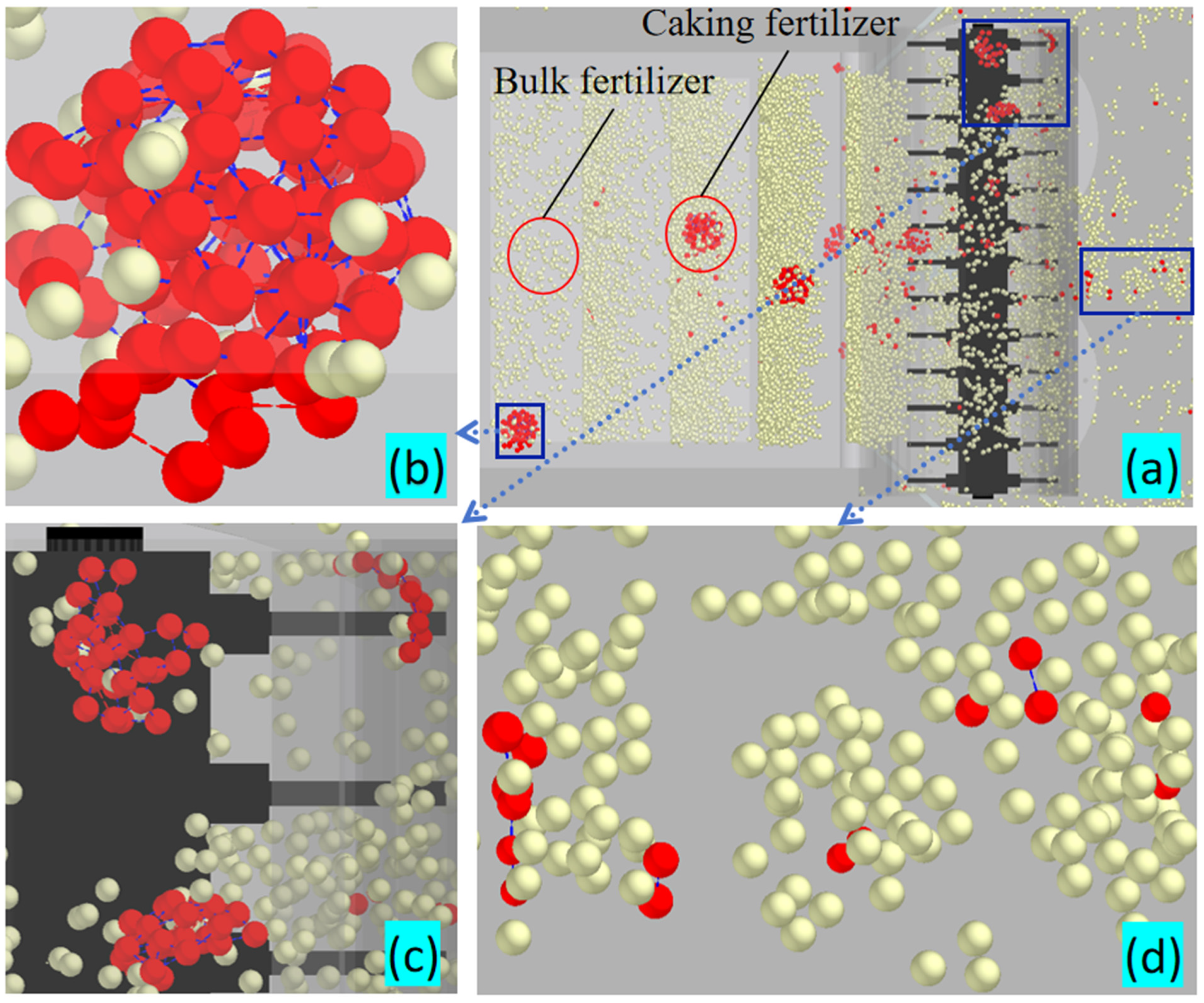

2.2.1. Construction of Discrete Element Model for Organic Fertilizer Particle Swarm

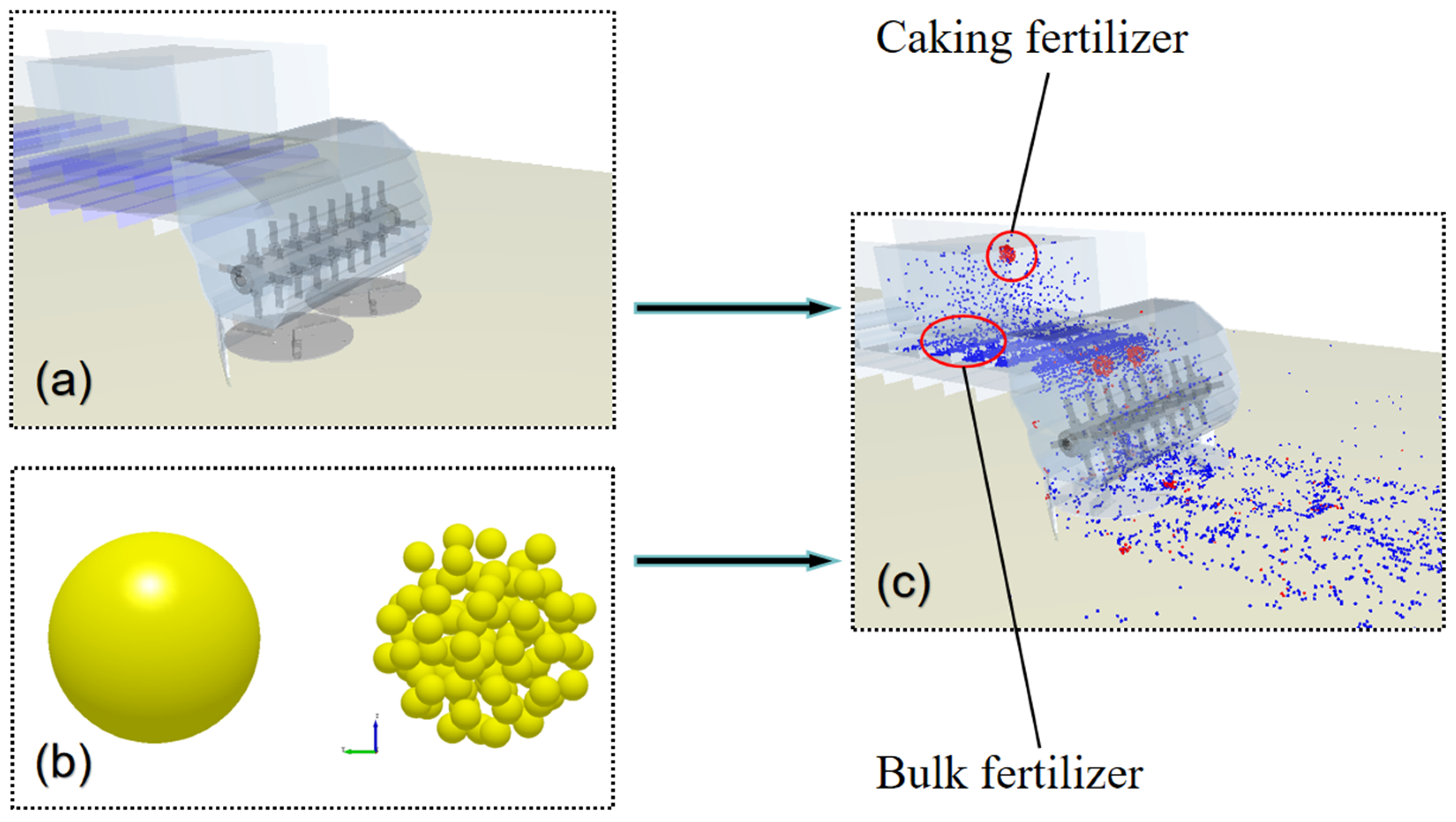

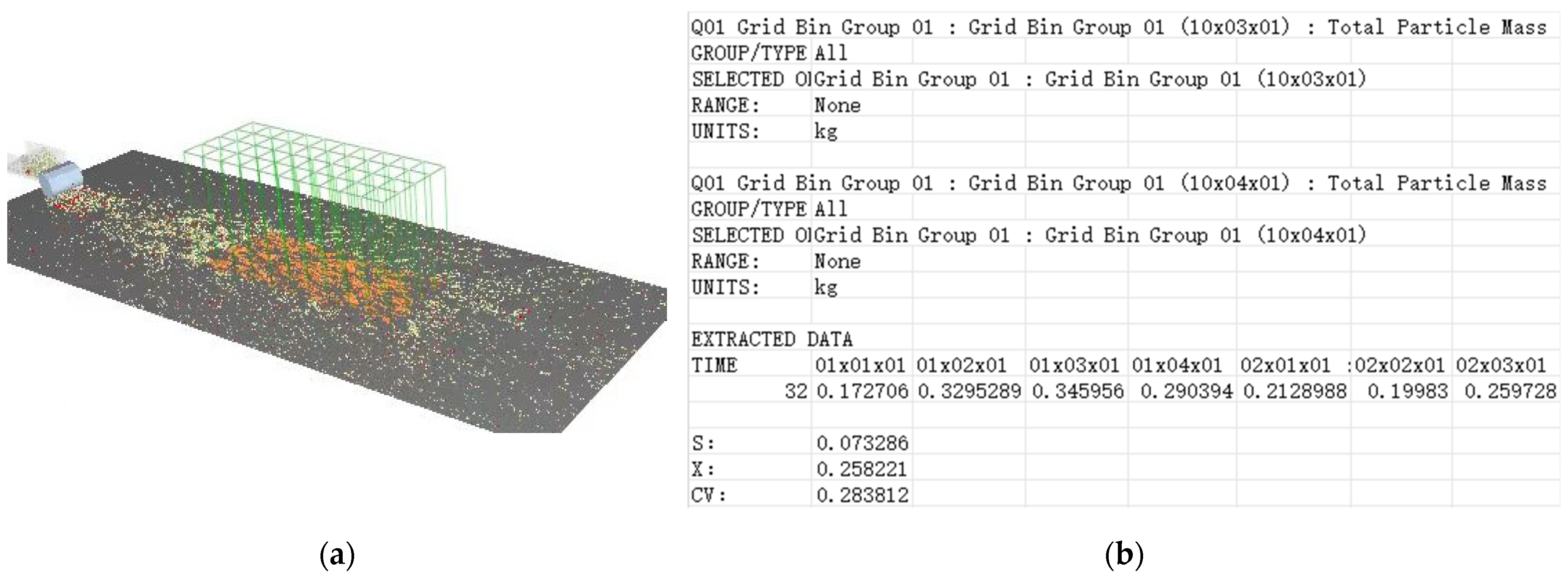

2.2.2. Construction of Discrete Element Model for Organic Fertilizer Crushing and Spreading

2.3. Simulation Test

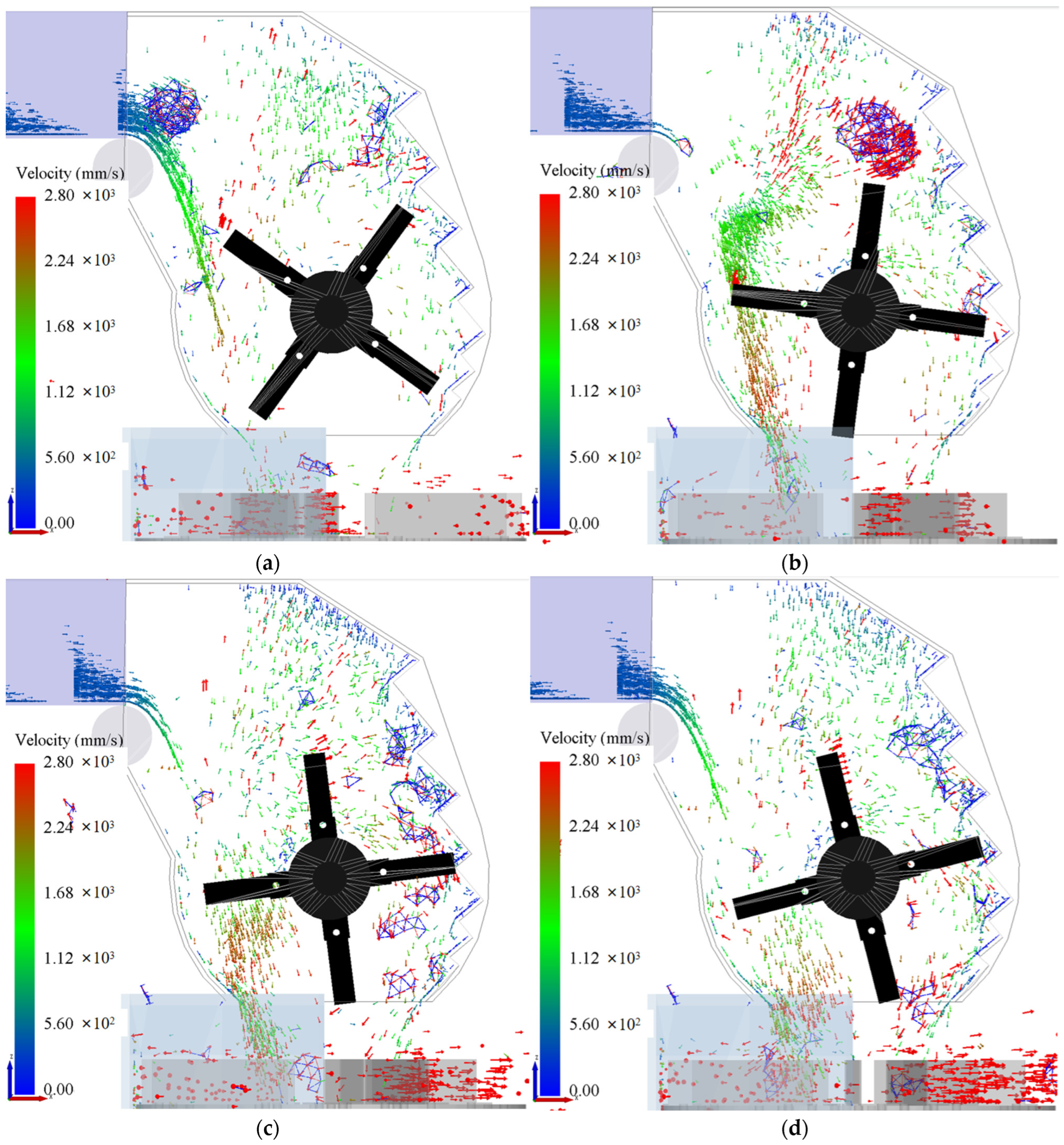

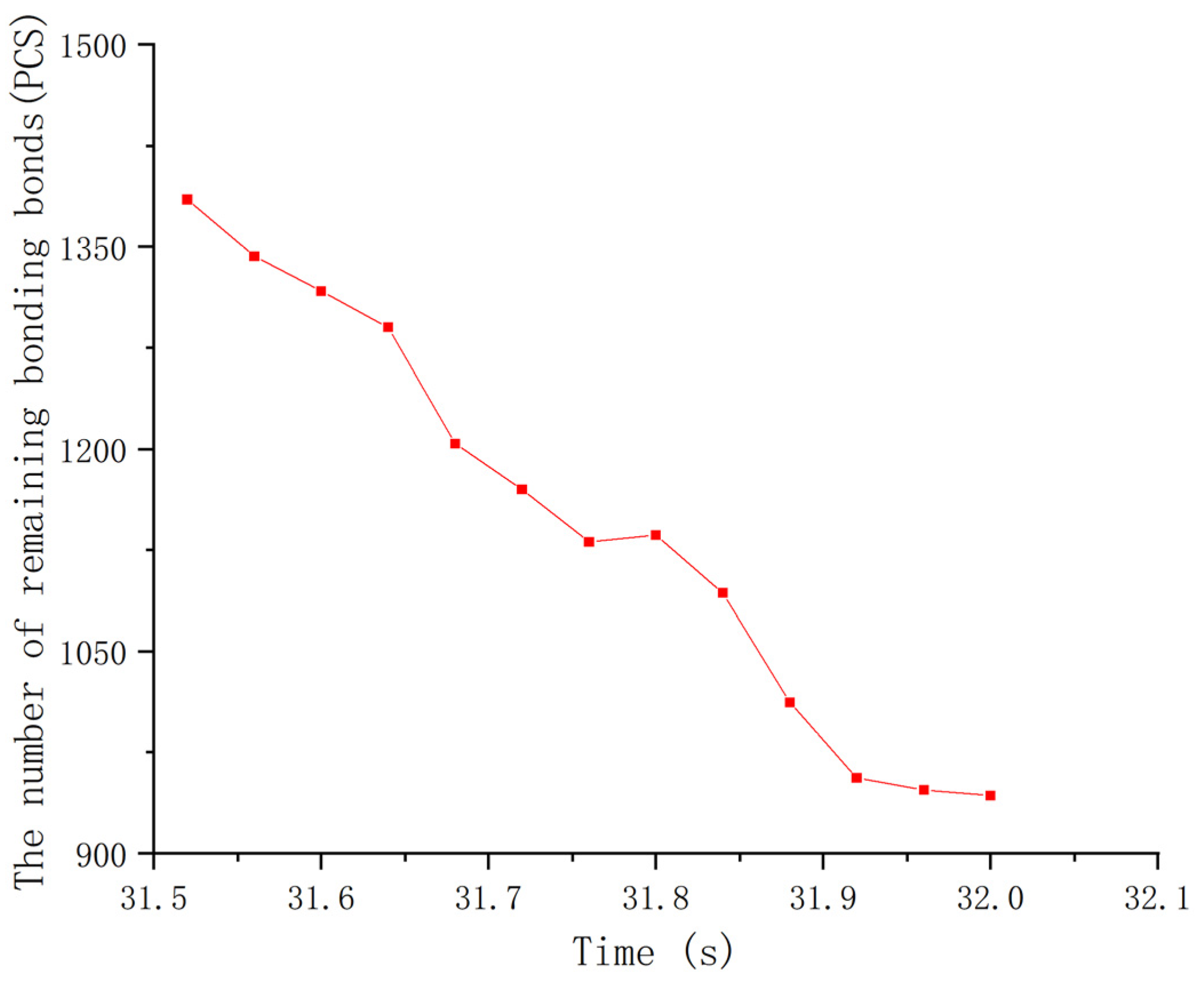

2.3.1. Verification Test of Crushing Mechanism

2.3.2. Box–Behnken Test

3. Results and Discussion

3.1. Verification Test Results of Crushing Mechanism

3.2. Box–Behnken Test Results and Analysis

3.2.1. The Influence of Various Factors on the Broken Bond Rate

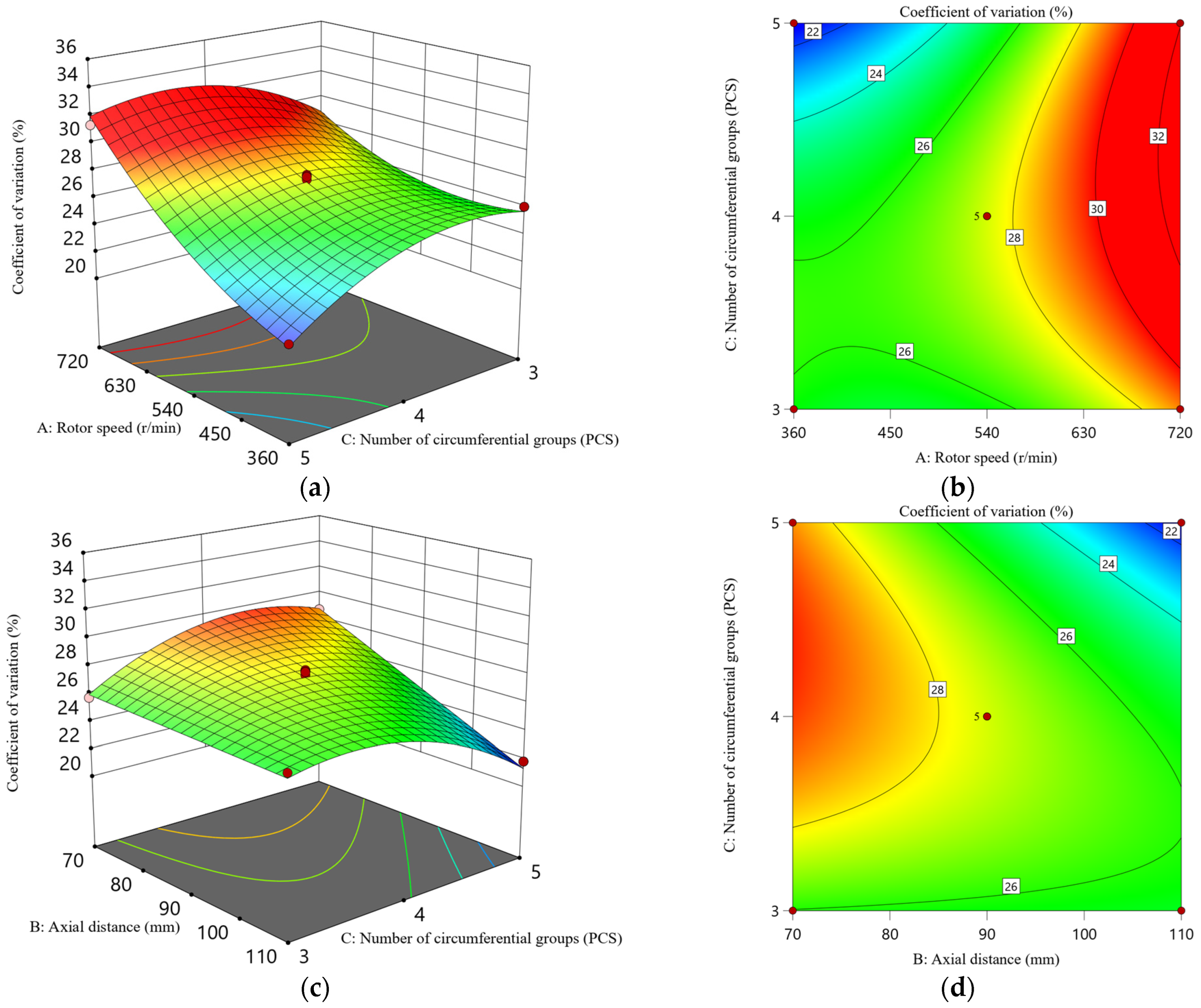

3.2.2. Response Surface Analysis

3.3. Optimal Parameter Design and Verification

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Burke, W.J.; Jayne, T.S.; Snapp, S.S. Nitrogen efficiency by soil quality and management regimes on Malawi farms: Can fertilizer use remain profitable? World Dev. 2022, 152, 105792. [Google Scholar] [CrossRef]

- Bai, Y.C.; Chang, Y.Y.; Hussain, M.; Lu, B.; Zhang, J.P.; Song, X.B.; Lei, X.S.; Pei, D. Soil chemical and microbiological properties are changed by long-term chemical fertilizers that limit ecosystem functioning. Microorganisms 2020, 8, 694. [Google Scholar] [CrossRef] [PubMed]

- Ning, C.C.; Wang, J.W.; Cai, K.Z. The effects of organic fertilizers on soil fertility and soil environmental quality: A review. Ecol. Environ. Sci. 2016, 25, 175–181, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Wang, H.X.; Xu, J.L.; Liu, X.J.; Zhang, D.; Li, L.W.; Li, W.; Sheng, L.X. Effects of long-term application of organic fertilizer on improving organic matter content and retarding acidity in red soil from China. Soil Tillage Res. 2019, 195, 104382. [Google Scholar] [CrossRef]

- Zhang, K.Q.; Du, L.Z.; Du, H.Y.; Shen, S.Z. Application of livestock and poultry waste to agricultural land: A review. J. Agro Environ. Sci. 2021, 40, 2472–2481, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Wan, L.J.; Tian, Y.; He, M.; Zheng, Y.Q.; Lyu, Q.; Xie, R.J.; Ma, Y.Y.; Deng, L.; Yi, S.L. Effects of Chemical Fertilizer Combined with Organic Fertilizer Application on Soil Properties, Citrus Growth Physiology, and Yield. Agriculture 2021, 11, 1207. [Google Scholar] [CrossRef]

- Dong, R.X.; Abdelkerim-Ouba, D.; Liu, D.Y.; Ma, X.F.; Wang, S. Impacts of Partial Substitution of Chemical Fertilizer with Organic Manure on the Kinetic and Thermodynamic Characteristics of Soil β-Glucosidase. Agronomy 2023, 13, 1065. [Google Scholar] [CrossRef]

- Xie, J.Y.; Zhang, H.F.; Luo, Y.Q.; Meng, H.S.; Zhang, J.; Hong, J.P.; Xu, M.G. Driving factors of improving fertility and maize yields in the reclaimed soils by seven years of applied organic manure and chemical fertilizer. Trans. Chin. Soc. Agric. Eng. 2024, 40, 142–152, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Du, W.Y.; Tang, S.; Wang, H. The status of organic fertilizer industry and organic fertilizer resources in China. Soil Fertil. Sci. China 2020, 3, 210–219, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Wu, J.; Geng, Y.; Zhou, Y.J.; Lin, C.Y.; Deng, J.; Wang, P. Research Situation and Development Ideas of Organic Fertilizer Applicator. Agric. Eng. 2022, 12, 19–22, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Sun, D.X.; Li, M.J.; Wu, A.B.; Liang, Q.; Zhang, A. Research progress of organic fertilizer and its supporting mechanization technology. J. Chin. Agric. Mech. 2019, 40, 72–80, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Zeng, Z.W.; Ma, X.; Cao, X.L.; Li, Z.H.; Wang, X.C. Critical review of applications of discrete element method in agricultural engineering. Trans. Chin. Soc. Agric. Mach. 2021, 52, 1–20, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Yuan, Q.C.; Xu, L.M.; Xing, J.J.; Duan, Z.Z.; Ma, S.; Yu, C.C.; Chen, C. Parameter calibration of discrete element model of organic fertilizer particles for mechanical fertilization. Trans. Chin. Soc. Agric. Eng. 2018, 34, 21–27, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Peng, C.W.; Xu, D.J.; He, X.; Tang, Y.H.; Sun, S.L. Parameter calibration of discrete element simulation model for pig manure organic fertilizer treated with Hermetia illucen. Trans. Chin. Soc. Agric. Eng. 2020, 36, 212–218, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Chen, G.B.; Wang, Q.J.; Li, W.Y.; He, J.; Li, H.W.; Yu, C.C. Design and experiment of double roller differential speed crushing fertilizer device for block organic fertilizer. Trans. Chin. Soc. Agric. Mach. 2021, 52, 65–76, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Chen, G.B.; Wang, Q.J.; Li, H.W.; He, J.; Lu, C.Y.; Xu, D.J.; Sun, M.Y. Experimental research on a propeller blade fertilizer transport device based on a discrete element fertilizer block model. Comput. Electron. Agric. 2023, 208, 107781. [Google Scholar] [CrossRef]

- Chen, G.B.; Wang, Q.J.; Wen, L.H.; He, J.; Lu, C.Y.; Zhang, X.Y. Design and experiment of solid organic fertilizer crushing and striping machines. Trans. Chin. Soc. Agric. Eng. 2023, 39, 13–24, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Xu, B.; Cui, Q.L.; Zheng, D.C. Improvement design and simulation analysis on centrifugal disc organic fertilizer spreader. INMATEH Agric. Eng. 2023, 70, 328–336. [Google Scholar] [CrossRef]

- Hwang, S.J.; Nam, J.S. DEM simulation model to optimise shutter hole position of a centrifugal fertiliser distributor for precise application. Biosyst. Eng. 2021, 204, 326–345. [Google Scholar] [CrossRef]

- Fan, C.S.; He, R.Y.; Shi, Y.Y.; He, L.N. Structure and operation mode of centrifugal side-throwing organic fertilizer spreader for greenhouses. Powder Technol. 2024, 438, 119457. [Google Scholar] [CrossRef]

- Zinkevičienė, R.; Jotautienė, E.; Juostas, A.; Comparetti, A.; Vaiciukevičius, E. Simulation of granular organic fertilizer application by centrifugal spreader. Agronomy 2021, 11, 247. [Google Scholar] [CrossRef]

- Balsari, P.; Dinuccio, E.; Gioelli, F.; Airoldi, G. Band spreader for the application of slurry solid fractions to orchards. Biosyst. Eng. 2015, 136, 69–76. [Google Scholar] [CrossRef]

- Hu, J.; He, J.C.; Wang, Y.; Wu, Y.P.; Chen, C.; Ren, Z.Y.; Li, X.X.; Shi, S.J.; Du, Y.P.; He, P.X. Design and study on lightweight organic fertilizer distributor. Comput. Electron. Agric. 2020, 169, 105149. [Google Scholar] [CrossRef]

- Liu, H.X.; Zhao, Y.J.; Xie, Y.T.; Zhang, Y.M.; Shang, J.J. Design and Experiment of Spiral Blades Auxiliary Roller of Organic Fertilizer Side Throwing Device. Trans. Chin. Soc. Agric. Mach. 2023, 54, 107–119, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Hao, Y.J.; Wang, C.; Wu, A.B.; Liu, K.K.; Fan, P.; Sun, D.X. Design and test of precise organic fertilizer applicator. J. Agric. Mech. Res. 2021, 43, 87–94, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Li, S.B.; Li, Q.H.; Sun, D.X. Design and test of self-propelled fertilizer applicator. J. Chin. Agric. Mech. 2023, 44, 202–209, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Smits, M.; Kronbergs, E. Determination centre of percussion for hammer mill hammers. In Proceedings of the International Conference Engineering for Rural Development, Jelgava, Latvia, 24–26 May 2017; pp. 364–368. [Google Scholar]

- Tanaś, W.; Szczepaniak, J.; Kromulski, J.; Szymanek, M.; Tanaś, J.; Sprawka, M. Modal analysis and acoustic noise characterization of a grain crusher. Ann. Agric. Environ. Med. 2018, 25, 433–436. [Google Scholar] [CrossRef] [PubMed]

- Li, C.D.; Liu, Y.; Cao, L.Y.; Bai, Y.Q.; Wang, F.; Zhang, S.W. Experimental research on optimization of working parameters of hammer mill. J. Chin. Agric. Mech. 2024, 45, 122–129, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Hu, L.; Zhu, H.; Hua, J. DEM simulation of energy transitions in a hammer mill: Effect of impeller configurations, agitation speed, and fill level. Powder Technol. 2021, 394, 1077–1093. [Google Scholar] [CrossRef]

- Xu, J. Optimization Study on Hammer Size and Arrangement of SWFP66X60A Hammer Mill. Master’s Thesis, Jiangnan University, Wuxi, China, 2009. [Google Scholar]

- Cotabarren, I.; Fernández, M.P.; Battista, A.D.; Pia, J. Modeling of maize breakage in hammer mills of different scales through a population balance approach. Powder Technol. 2020, 375, 433–444. [Google Scholar] [CrossRef]

- Wang, S.; Chu, P.; Tang, B.; Tian, X.; Wang, X.; Lin, Q. Enhancement of surface properties of 45# carbon steel using plasma immersion ion implantation. Thin Solid Film. 1997, 311, 190–195. [Google Scholar]

- Wu, J.; Tang, Q.; Mu, S.L.; Jiang, L.; Hu, Z.C. Test and optimization of oilseed rape (Brassica napus L.) threshing device based on DEM. Agriculture 2022, 12, 1580. [Google Scholar] [CrossRef]

- Wu, N. Research and Design of 2F50 Manure Spreader. Master Thesis, Chinese Academy of Agricultural Mechanization Sciences, Beijing, China, 2016. (In Chinese with English Abstract). [Google Scholar]

- Wu, T.; Huang, W.F.; Chen, X.S.; Ma, X.; Han, Z.Q.; Pan, T. Calibration of discrete element model parameters for cohesive soil considering the cohesion between particles. J. South China Agric. Univ. 2017, 38, 93–98, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Johnson, K.L.; Kendall, K.; Roberts, A.D. Surface Energy and the Contact of Elastic Solids. Proc. R. Soc. A Math. Phys. Eng. Sci. 1971, 324, 301–313. [Google Scholar] [CrossRef]

- Wang, L.M.; Fan, S.Y.; Cheng, H.S.; Meng, H.B.; Shen, Y.J.; Wang, J.; Zhou, H.B. Calibration of contact parameters for pig manure based on EDEM. Trans. Chin. Soc. Agric. Eng. 2020, 36, 95–102, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Li, L.; Cui, Q.L.; Zhang, Y.Q.; Hou, H.M.; Xi, P.; Hao, C. Experimental study on scattering performance of organic fertilizer spreader based on EDEM. Agric. Eng. 2022, 12, 88–94, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Liu, H.X.; Du, C.L.; Yin, L.W.; Zhang, G.F. Shooting flow shape and control of organic fertilizer side throwing on inclined opposite discs. Trans. Chin. Soc. Agric. Mach. 2022, 53, 168–177, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- GB/T 25401-2010; Agricultural Machinery—Manure Spreaders—Environmental Protection—Requirements and Test Methods. The Standardization Administration of China: Beijing, China, 2010. (In Chinese)

| Parameters | Values |

|---|---|

| Normal Stiffness per unit area | 1 × 108 N/m−3 |

| Shear Stiffness per unit area | 5 × 107 N/m−3 |

| Critical Normal Stress | 0.55 MPa |

| Critical Shear Stress | 0.55 MPa |

| Bonded Disc Radius | 5 mm |

| Project | Parameters | Values |

|---|---|---|

| Organic Fertilizer | Poisson’s ratio | 0.315 |

| Shear modulus/Pa | 5.5 × 106 | |

| Density/(kg·m−3) | 1.25 × 103 | |

| Steel | Poisson’s ratio | 0.30 |

| Shear modulus/Pa | 7.90 × 1010 | |

| Density/(kg·m−3) | 7.90 × 103 | |

| Soil | Poisson’s ratio | 0.30 |

| Shear modulus/Pa | 5 × 107 | |

| Density/(kg·m−3) | 2.60 × 103 | |

| Organic Fertilizer–Organic Fertilizer | Coefficient of restitution | 0.01 |

| Static friction coefficient | 1.2 | |

| Rolling friction coefficient | 1 | |

| Organic Fertilizer–Steel | Coefficient of restitution | 0.6 |

| Static friction coefficient | 0.75 | |

| Rolling friction coefficient | 0.75 | |

| Organic Fertilizer–Soil | Coefficient of restitution | 0.4 |

| Static friction coefficient | 0.66 | |

| Rolling friction coefficient | 0.18 |

| Factors | Code Level | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| Rotor speed (r/min) | 360 | 540 | 720 |

| Axial distance (mm) | 70 | 90 | 110 |

| Number of circumferential groups | 3 | 4 | 5 |

| Number | Factors | The Broken Bond Rate (%) | Coefficient of Variation (%) | ||

|---|---|---|---|---|---|

| Rotor Speed A | Axial Distance B | Number of Circumferential Groups C | |||

| 1 | −1 | 1 | 0 | 86.33 | 21.94 |

| 2 | 0 | 1 | 1 | 86.93 | 21.81 |

| 3 | 0 | −1 | −1 | 92.91 | 25.74 |

| 4 | −1 | −1 | 0 | 88.21 | 28.73 |

| 5 | 0 | 0 | 0 | 90.11 | 25.41 |

| 6 | 1 | 0 | 1 | 91.29 | 31.31 |

| 7 | 1 | −1 | 0 | 93.80 | 34.23 |

| 8 | 1 | 0 | −1 | 93.63 | 28.40 |

| 9 | 0 | 0 | 0 | 89.85 | 27.95 |

| 10 | −1 | 0 | 1 | 90.42 | 21.45 |

| 11 | 0 | 1 | −1 | 85.64 | 25.84 |

| 12 | 0 | 0 | 0 | 91.07 | 28.04 |

| 13 | −1 | 0 | −1 | 89.52 | 26.05 |

| 14 | 0 | 0 | 0 | 91.28 | 27.68 |

| 15 | 1 | 1 | 0 | 84.85 | 31.93 |

| 16 | 0 | −1 | 1 | 92.14 | 28.70 |

| 17 | 0 | 0 | 0 | 89.80 | 27.89 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | Significance |

|---|---|---|---|---|---|---|

| Model | 114.05 | 9 | 12.67 | 30.77 | <0.0001 | ** |

| A | 10.33 | 1 | 10.33 | 25.08 | 0.0016 | ** |

| B | 67.92 | 1 | 67.92 | 164.93 | <0.0001 | ** |

| C | 0.1058 | 1 | 0.1058 | 0.2569 | 0.6278 | |

| AB | 12.50 | 1 | 12.50 | 30.35 | 0.0009 | ** |

| AC | 2.62 | 1 | 2.62 | 6.37 | 0.0396 | * |

| BC | 1.06 | 1 | 1.06 | 2.58 | 0.1525 | |

| A2 | 0.1041 | 1 | 0.1041 | 0.2528 | 0.6305 | |

| B2 | 16.30 | 1 | 16.30 | 39.57 | 0.0004 | ** |

| C2 | 3.80 | 1 | 3.80 | 9.23 | 0.0189 | * |

| Residual | 2.88 | 7 | 0.4118 | |||

| Lack of Fit | 0.9151 | 3 | 0.3050 | 0.6202 | 0.6380 | |

| Pure Error | 1.97 | 4 | 0.4919 | |||

| Cor Total | 116.93 | 16 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | Significance |

|---|---|---|---|---|---|---|

| Model | 187.91 | 9 | 20.88 | 20.75 | 0.0003 | ** |

| A | 95.91 | 1 | 95.91 | 95.30 | <0.0001 | ** |

| B | 31.52 | 1 | 31.52 | 31.32 | 0.0008 | ** |

| C | 0.9522 | 1 | 0.9522 | 0.9462 | 0.3631 | |

| AB | 5.04 | 1 | 5.04 | 5.01 | 0.0603 | |

| AC | 14.10 | 1 | 14.10 | 14.01 | 0.0072 | ** |

| BC | 12.22 | 1 | 12.22 | 12.14 | 0.0102 | * |

| A2 | 10.07 | 1 | 10.07 | 10.01 | 0.0158 | * |

| B2 | 0.2996 | 1 | 0.2996 | 0.2977 | 0.6023 | |

| C2 | 19.25 | 1 | 19.25 | 19.13 | 0.0033 | ** |

| Residual | 7.04 | 7 | 1.01 | |||

| Lack of Fit | 2.05 | 3 | 0.6847 | 0.5488 | 0.6752 | |

| Pure Error | 4.99 | 4 | 1.25 | |||

| Cor Total | 194.95 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, B.; Cui, Q.; Guo, L.; Hao, L. Design and Parameter Optimization of a Combined Rotor and Lining Plate Crushing Organic Fertilizer Spreader. Agronomy 2024, 14, 1732. https://doi.org/10.3390/agronomy14081732

Xu B, Cui Q, Guo L, Hao L. Design and Parameter Optimization of a Combined Rotor and Lining Plate Crushing Organic Fertilizer Spreader. Agronomy. 2024; 14(8):1732. https://doi.org/10.3390/agronomy14081732

Chicago/Turabian StyleXu, Bing, Qingliang Cui, Lina Guo, and Lirong Hao. 2024. "Design and Parameter Optimization of a Combined Rotor and Lining Plate Crushing Organic Fertilizer Spreader" Agronomy 14, no. 8: 1732. https://doi.org/10.3390/agronomy14081732

APA StyleXu, B., Cui, Q., Guo, L., & Hao, L. (2024). Design and Parameter Optimization of a Combined Rotor and Lining Plate Crushing Organic Fertilizer Spreader. Agronomy, 14(8), 1732. https://doi.org/10.3390/agronomy14081732