Detection of Localized Damage in Tomato Based on Bioelectrical Impedance Spectroscopy

Abstract

:1. Introduction

2. Materials and Methods

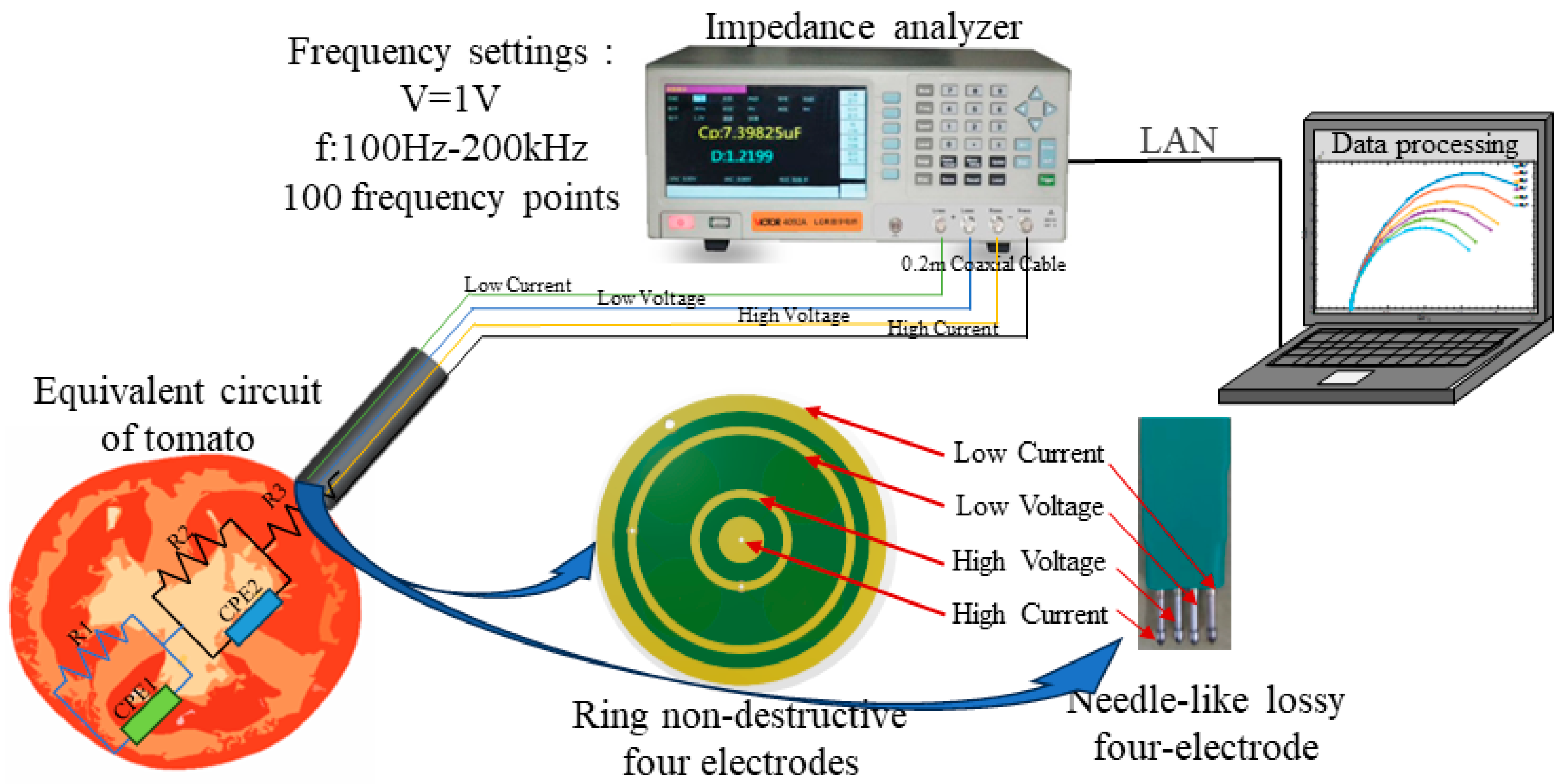

2.1. Impedance Measurement Experiments

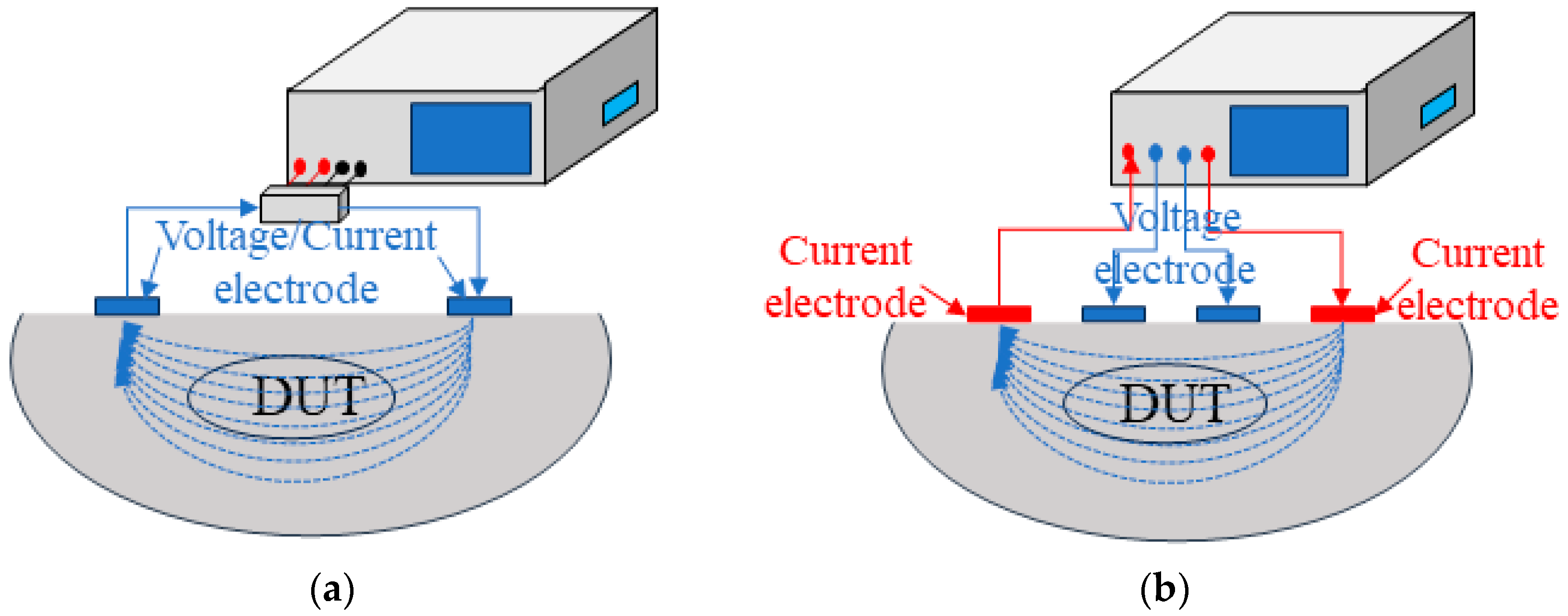

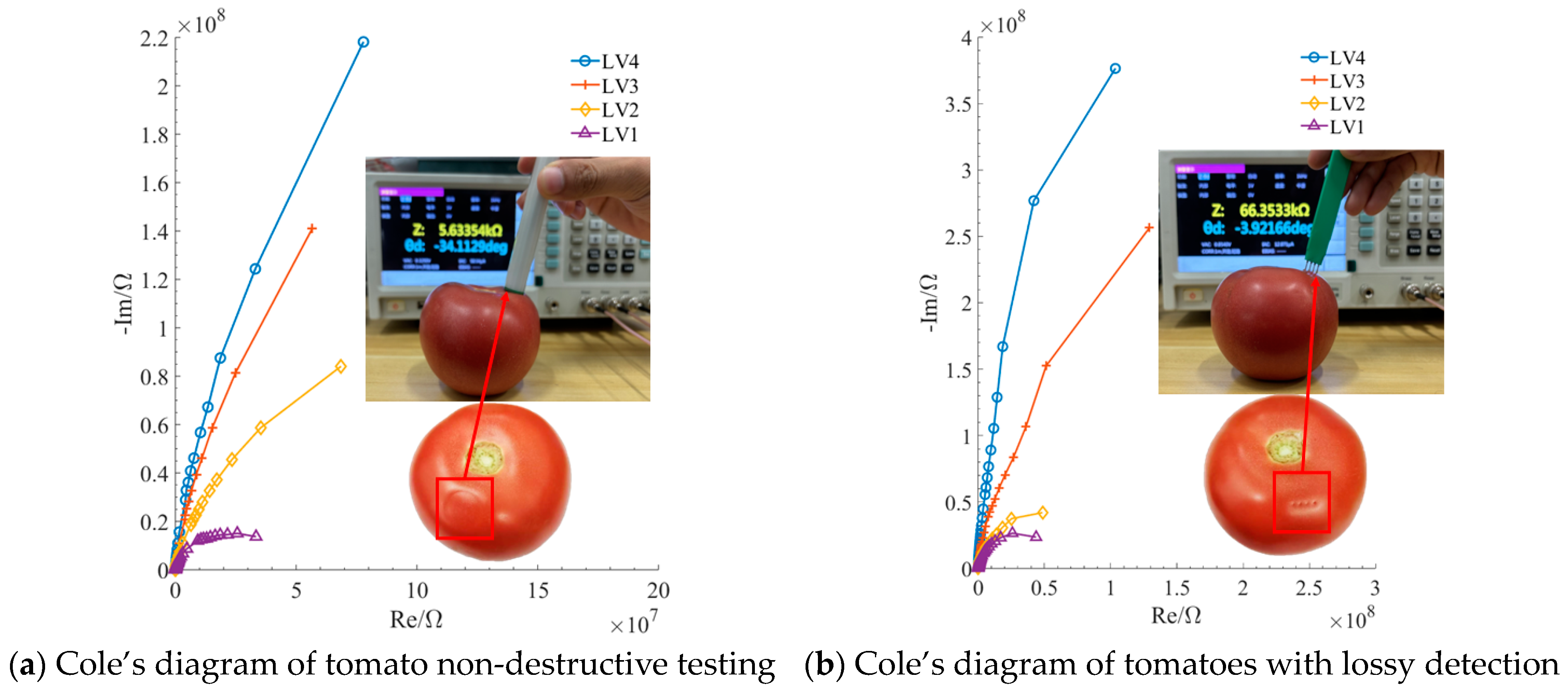

2.1.1. Principle of Tomato Four-Electrode Impedance Spectroscopy

2.1.2. Experimental Setup for Damage Measurement

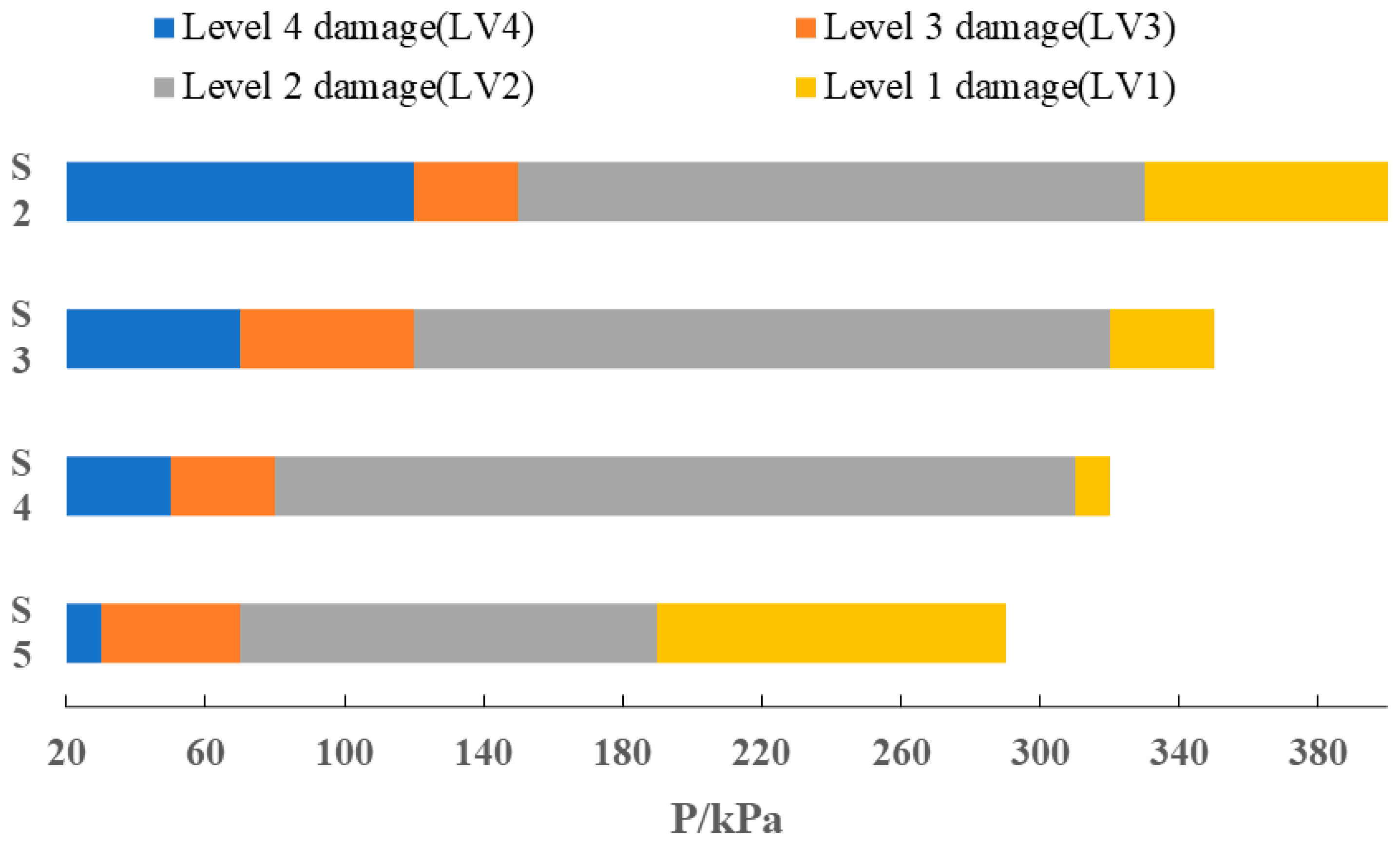

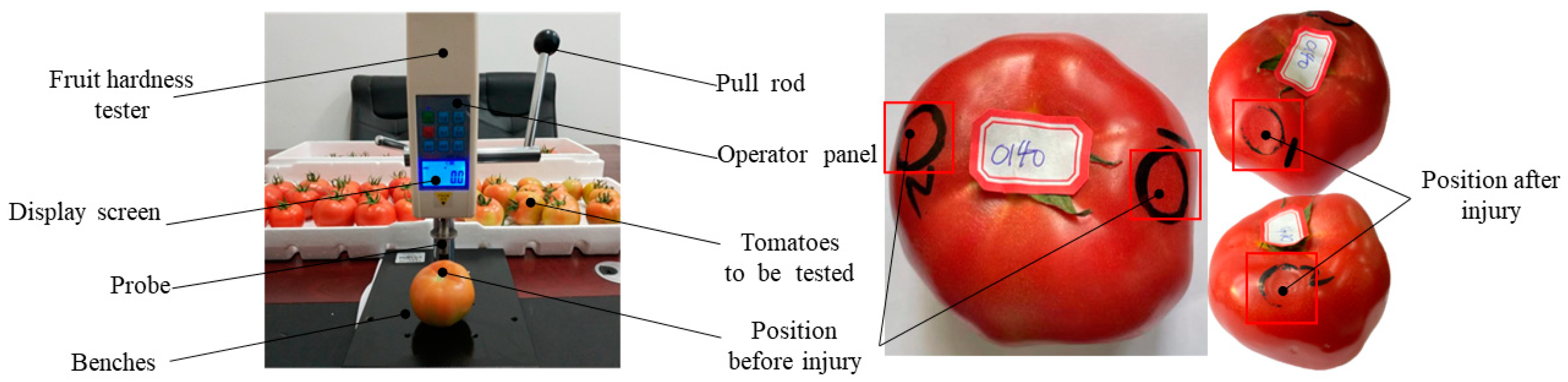

2.2. Pressing Test

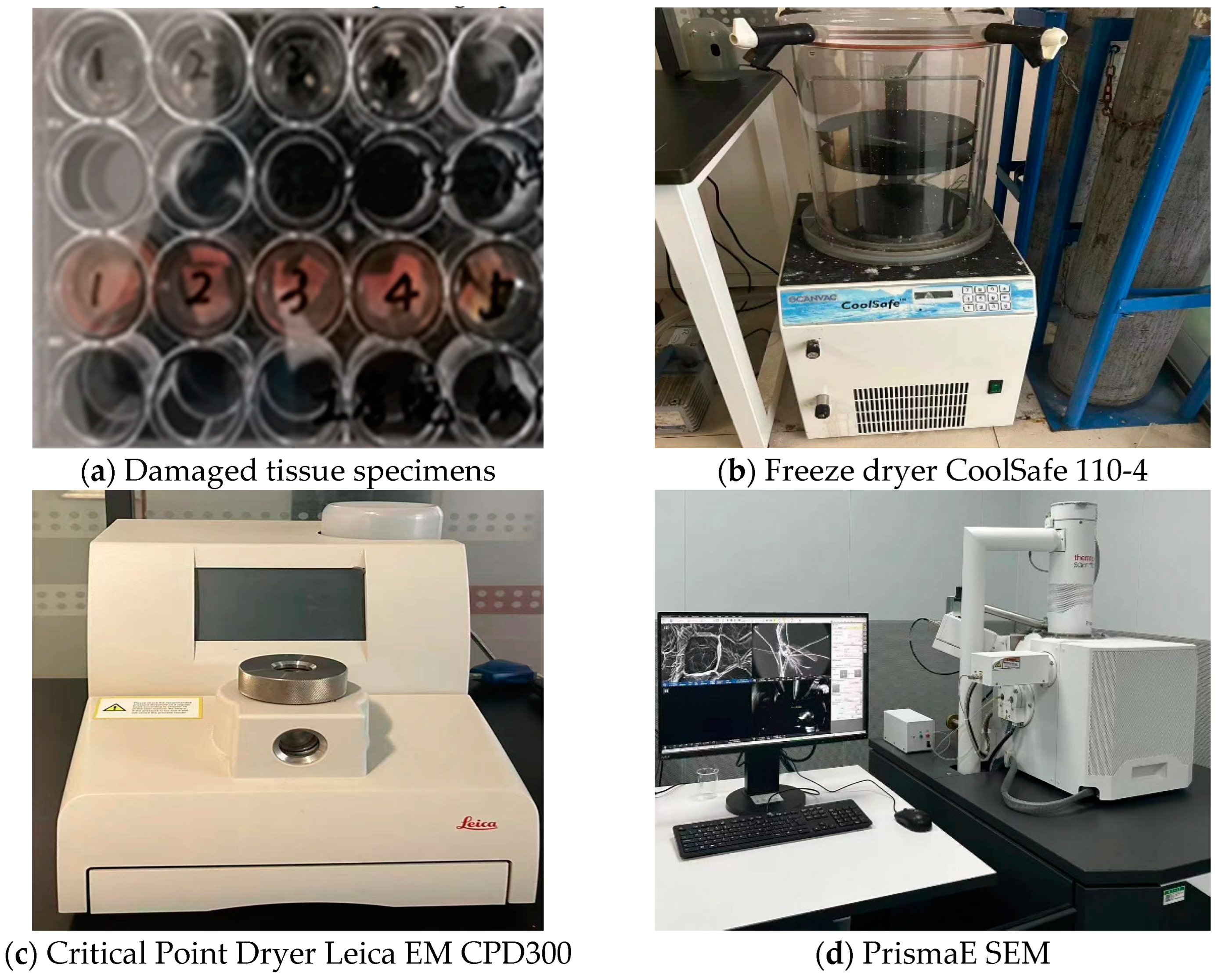

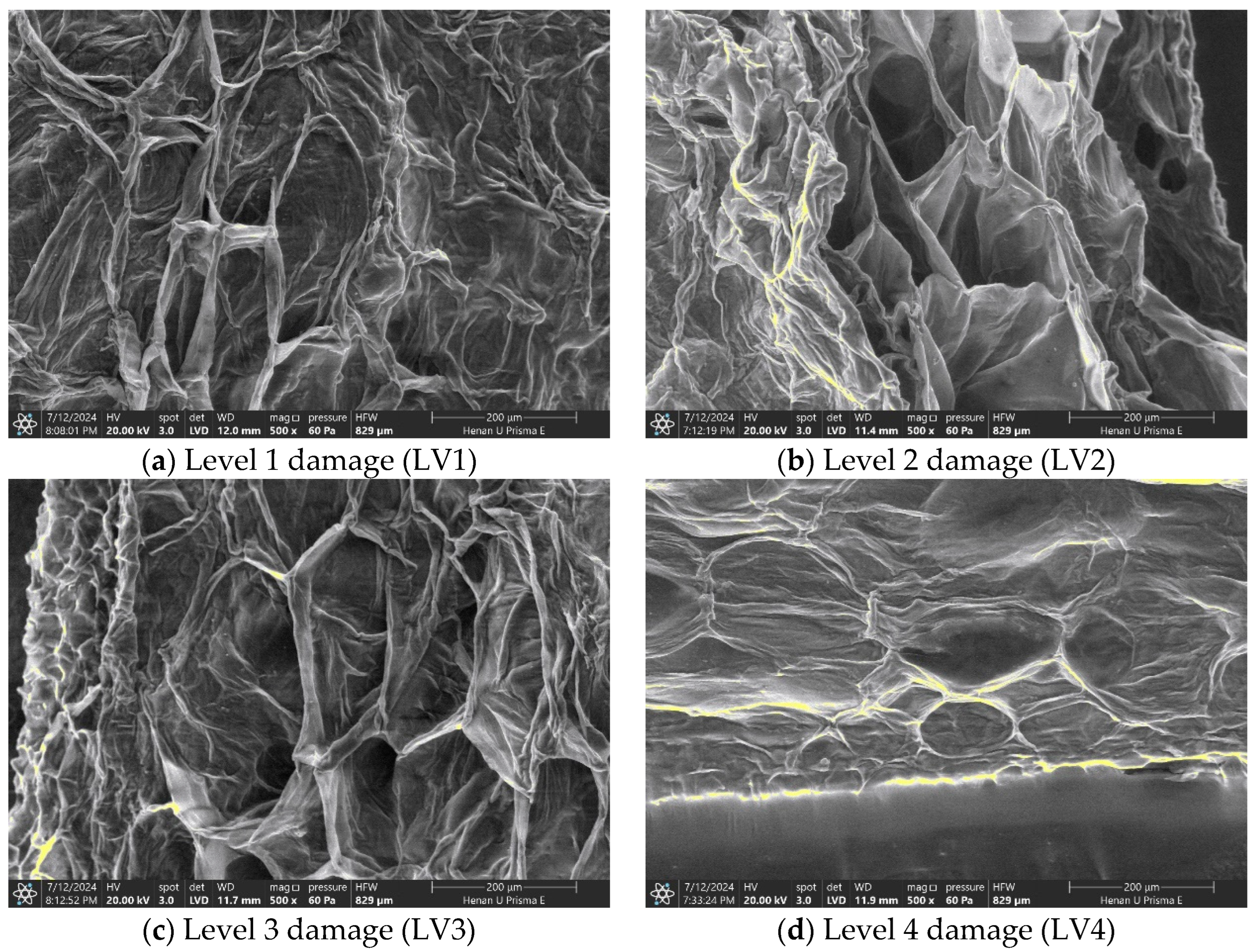

2.3. Scanning Electron Microscope Experiment

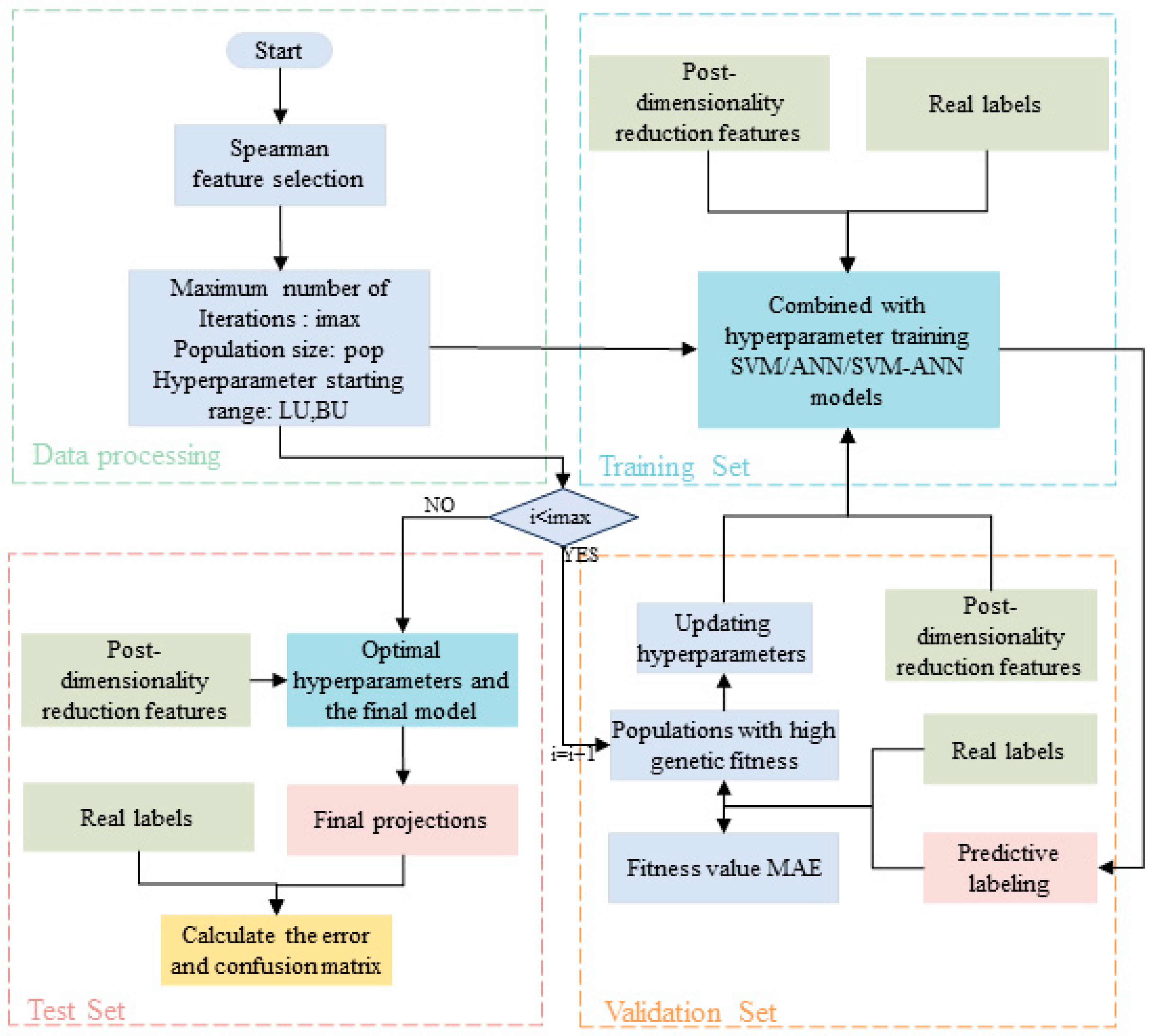

2.4. Modeling of Localized Injury Classification in Tomato

2.5. Evaluation Criteria for Localized Impairment Models

3. Results and Analysis

4. Summary and Outlook

4.1. Summary

- (1)

- A circular four-electrode BIS sensor is designed for the nondestructive measurement of localized damage in tomato. A localized damage measurement platform for tomatoes is constructed by combining this sensor. A comparison of the impedance measurements obtained from the sensor with those obtained from the needle sensor proposed by previous scholars reveals a similar trend, with the impedance decreasing with the increasing damage degree. This validates the effectiveness of the circular four-electrode BIS sensor for tomato in characterizing damage.

- (2)

- Multiple features, including biological variables, fitted electrical parameters, and tomato ripeness, are subjected to Spearman feature selection, resulting in a downscaled feature set comprising 85% or more of the total features. This downscaled feature set is then inputted into the classification model. A total of 1616 sets of data obtained from the experiments are divided into three subsets: the training set, the validation set, and the test set. The ratio of the training set to the validation set and the validation set to the test set is 8:1:1, respectively. The classification accuracies of the tomato in each damage class are as follows, in descending order: the results demonstrate that 97.531%, 98.137%, and 98.765%, respectively, are the optimal classification algorithms, with Spearman-SVM-ANN being the most effective in detecting tomato damage.

4.2. Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bergougnoux, V. The history of tomato: From domestication to biopharming. Biotechnol. Adv. 2014, 32, 170–189. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.H.; Tan, D.H.; Zhong, X.S.; Jia, M.Q.; Ke, X.; Zhang, Y.M.; Cui, T.; Shi, L. Review on toxicology and activity of tomato glycoalkaloids in immature tomatoes. Food Chem. 2024, 447, 138937. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Miao, F.; Andrews, J. Mechanical Models of Compression and Impact on Fresh Fruits. Compr. Rev. Food Sci. Food Saf. 2017, 16, 1296–1312. [Google Scholar] [CrossRef] [PubMed]

- Milczarek, R.R.; Saltveit, M.E.; Garvey, T.C.; McCarthy, M.J. Assessment of tomato pericarp mechanical damage using multivariate analysis of magnetic resonance images. Postharvest Biol. Technol. 2009, 52, 189–195. [Google Scholar] [CrossRef]

- Watanabe, T.; Sekiyama, Y.; Kawamura, T.; Fukuda, Y.; Nagata, M. Tissue structural analysis for internal browning sweet potatoes using magnetic resonance imaging and bio-electrochemical impedance spectroscopy. J. Food Eng. 2023, 349, 111451. [Google Scholar] [CrossRef]

- Najjar, K.; Abu-Khalaf, N. Non-Destructive Quality Measurement for Three Varieties of Tomato Using VIS/NIR Spectroscopy. Sustainability 2021, 13, 10747. [Google Scholar] [CrossRef]

- Huang, Y.; Dong, W.; Chen, Y.; Wang, X.; Luo, W.; Zhan, B.; Liu, X.; Zhang, H. Online detection of soluble solids content and maturity of tomatoes using Vis/NIR full transmittance spectra. Chemom. Intell. Lab. Syst. 2021, 210, 104243. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Z.; Thomas, C. Viscoelastic-plastic behavior of single tomato mesocarp cells in high speed compression-holding tests. Innov. Food Sci. Emerg. Technol. 2016, 34, 44–50. [Google Scholar] [CrossRef]

- Yang, S.; Tang, Y.; Yang, T.; Xu, J.; Li, N.; Patiguli; Wang, B.; Gao, J.; Yu, Q. Fruit characteristic and flesh tissue feature of special firmness type processing tomato cultivar. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2017, 33, 285–290, (In Chinese with English Abstract). [Google Scholar]

- Peng, J.; Tang, J.; Jiao, Y.; Bohnet, S.G.; Barrett, D.M. Dielectric properties of tomatoes assisting in the development of microwave pasteurization and sterilization processes. LWT Food Sci. Technol. 2013, 54, 367–376. [Google Scholar] [CrossRef]

- Benavente, J.; Ramos-Barrado, J.R.; Heredia, A. A study of the electrical behaviour of isolated tomato cuticular membranes and cutin by impedance spectroscopy measurements. Colloids Surf. A Physicochem. Eng. Asp. 1998, 140, 333–338. [Google Scholar] [CrossRef]

- Zhang, B.; Dong, Z.; Sui, X.; Gao, J.; Feng, L. Detection of water content in tomato stems by electrical impedance spectroscopy: Preliminary study. Comput. Electron. Agric. 2024, 219, 108755. [Google Scholar] [CrossRef]

- Li, M.; Li, J.; Mao, H.; Wu, Y. Diagnosis and detection of phosphorus nutrition level for Solanum lycopersicum based on electrical impedance spectroscopy. Biosyst. Eng. 2016, 143, 108–118. [Google Scholar]

- Li, J.; Li, M.; Han, M.; Zhu, W. Diagnosis of potassium nutrition level in Solanum lycopersicum based on electrical impedance. Biosyst. Eng. 2016, 147, 130–138. [Google Scholar]

- Varlan, A.R.; Sansen, W. Nondestructive Electrical Impedance Analysis in Fruit: Normal Ripening and Injuries Characterization. Electromagn. Biol. Med. 1996, 15, 213–227. [Google Scholar] [CrossRef]

- Serrano-Pallicer, E.; Muñoz-Albero, M.; Pérez-Fuster, C.; Masot Peris, R.; Laguarda-Miró, N. Early Detection of Freeze Damage in Navelate Oranges with Electrochemical Impedance Spectroscopy. Sensors 2018, 18, 4503. [Google Scholar] [CrossRef]

- Aparisi, P.A.; Sánchez, E.F.; Rodrigo, L.C.; Peris, R.M.; Laguarda-Miro, N. A Rapid Electrochemical Impedance Spectroscopy and Sensor-Based Method for Monitoring Freeze-Damage in Tangerines. IEEE Sens. J. 2021, 21, 12009–12018. [Google Scholar] [CrossRef]

- Mohsen, M.; Said, L.A.; Madian, A.H.; Radwan, A.G.; Elwakil, A.S. Fractional-Order Bio-Impedance Modeling for Interdisciplinary Applications: A Review. IEEE Access 2021, 9, 33158–33168. [Google Scholar] [CrossRef]

- Jeon, E.; Choi, S.; Yeo, K.H.; Park, K.S.; Rathod, M.L.; Lee, J. Development of electrical conductivity measurement technology for key plant physiological information using microneedle sensor. J. Micromech. Microeng. 2017, 27, 85009. [Google Scholar] [CrossRef]

- Li, X.; Tsuta, M.; Hayakawa, F.; Nakano, Y.; Kazami, Y.; Ikehata, A. Estimating the sensory qualities of tomatoes using visible and near-infrared spectroscopy and interpretation based on gas chromatography–mass spectrometry metabolomics. Food Chem. 2021, 343, 128470. [Google Scholar] [CrossRef] [PubMed]

- Arazuri, S.; Arana, I.; Jaren, C. Evaluation of mechanical tomato harvesting using wireless sensors. Sensors 2010, 10, 11126–11143. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Chen, Y.; Song, Y.; Zhang, R.; Wang, X. Finding the lowest damage picking mode for tomatoes based on finite element analysis. Comput. Electron. Agric. 2023, 204, 107536. [Google Scholar] [CrossRef]

- Zhang, Y.N.; Zhang, R.F.; Sun, Y.; Zheng, E.L.; Sun, G.X.; Wang, X.S. Effects of local compression on the mechanical damage of tomato with different maturity. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2021, 37, 292–298, (In Chinese with English Abstract). [Google Scholar]

- Li, J.; Karkee, M.; Zhang, Q.; Xiao, K.; Feng, T. Characterizing apple picking patterns for robotic harvesting. Comput. Electron. Agric. 2016, 127, 633–640. [Google Scholar] [CrossRef]

- Peterson, K.S.; Chapman, A.B.; Widanagamaachchi, W.; Sutton, J.; Ochoa, B.; Jones, B.E.; Stevens, V.; Classen, D.C.; Jones, M.M. Automating detection of diagnostic error of infectious diseases using machine learning. PLoS Digit. Health 2024, 3, e0000528. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.D.; Esakkirajan, S.; Bama, S.; Keerthiveena, B. A microcontroller based machine vision approach for tomato grading and sorting using SVM classifier. Microprocess. Microsyst. 2020, 76, 103090. [Google Scholar] [CrossRef]

- Shomali, A.; Aliniaeifard, S.; Bakhtiarizadeh, M.R.; Lotfi, M.; Mohammadian, M.; Sadi, M.S.V.; Rastogi, A. Artificial neural network (ANN)-based algorithms for high light stress phenotyping of tomato genotypes using chlorophyll fluorescence features. Plant Physiol. Biochem. 2023, 201, 107893. [Google Scholar] [CrossRef]

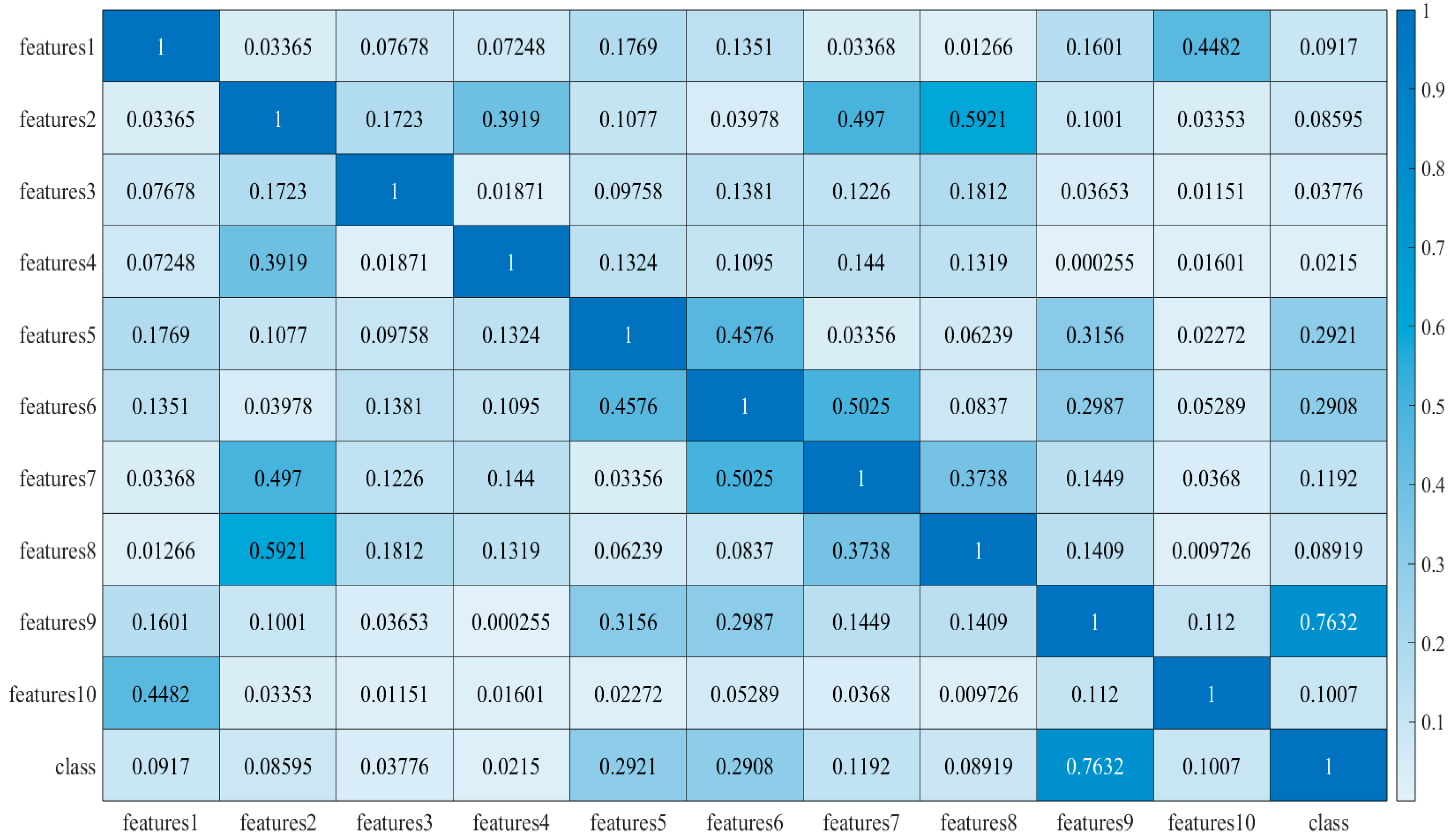

| Features | Eigenvalue | Cumulative Percentage (%) | Relevance |

|---|---|---|---|

| Features 9 | 0.7632 | 40.338 | 40.338 |

| Features 5 | 0.2921 | 55.777 | 15.439 |

| Features 6 | 0.2908 | 71.146 | 15.369 |

| Features 7 | 0.1007 | 77.444 | 6.297 |

| Features 1 | 0.0917 | 82.764 | 5.320 |

| Features 10 | 0.0891 | 87.611 | 4.847 |

| Classification Algorithms | Training Time (s) | Training Set ACC | Validation Set ACC | Test Set ACC |

|---|---|---|---|---|

| Spearman-SVM | 5.262 | 99.065% | 98.137% | 97.531% |

| Spearman-ANN | 5.748 | 99.056% | 98.758% | 98.137% |

| Spearman-SVM-ANN | 3.294 | 99.381% | 98.758% | 98.765% |

| Forecasting Team Member Information | ||||||

|---|---|---|---|---|---|---|

| LV1 | LV2 | LV3 | LV4 | Total | ||

| count | LV1 | 48 | 6 | 0 | 0 | 54 |

| LV2 | 3 | 490 | 1 | 0 | 494 | |

| LV3 | 0 | 1 | 264 | 0 | 265 | |

| LV4 | 0 | 0 | 1 | 802 | 803 | |

| % | LV1 | 88.9% | 11.1% | 0% | 0% | 100% |

| LV2 | 0.6% | 99.2% | 0.2% | 0% | 100% | |

| LV3 | 0% | 0.4% | 99.6% | 0% | 100% | |

| LV4 | 0% | 0% | 0.1% | 99.9% | 100% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Chen, Y.; Chang, Z.; Zhao, J.; Wang, X.; Xian, J. Detection of Localized Damage in Tomato Based on Bioelectrical Impedance Spectroscopy. Agronomy 2024, 14, 1822. https://doi.org/10.3390/agronomy14081822

Zhang Y, Chen Y, Chang Z, Zhao J, Wang X, Xian J. Detection of Localized Damage in Tomato Based on Bioelectrical Impedance Spectroscopy. Agronomy. 2024; 14(8):1822. https://doi.org/10.3390/agronomy14081822

Chicago/Turabian StyleZhang, Yongnian, Yinhe Chen, Zhenwei Chang, Jie Zhao, Xiaochan Wang, and Jieyu Xian. 2024. "Detection of Localized Damage in Tomato Based on Bioelectrical Impedance Spectroscopy" Agronomy 14, no. 8: 1822. https://doi.org/10.3390/agronomy14081822

APA StyleZhang, Y., Chen, Y., Chang, Z., Zhao, J., Wang, X., & Xian, J. (2024). Detection of Localized Damage in Tomato Based on Bioelectrical Impedance Spectroscopy. Agronomy, 14(8), 1822. https://doi.org/10.3390/agronomy14081822